Analysis of Cryogenic Impact Properties for a Glass-Fiber-Reinforced Dicyclopentadiene with a Different Amount of Decelerator Solution

Abstract

:1. Introduction

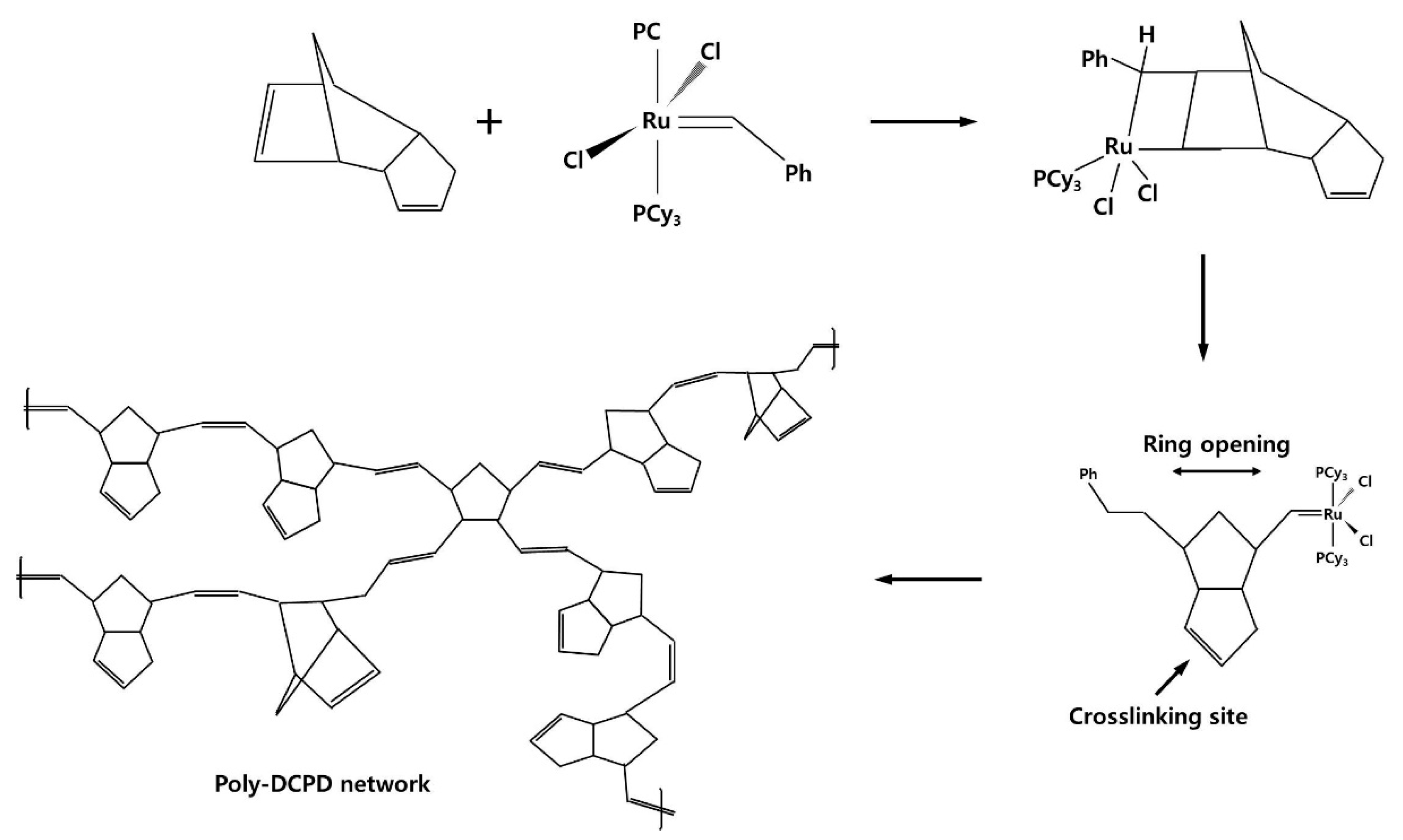

2. Experimental

2.1. Materials

2.2. Test Specimen

2.3. Charpy Impact Test

2.4. Experimental Conditions

3. Results and Discussion

3.1. Observation of Glass Temperature

3.2. DBTT for the Neat DCPD and DCPD with Decelerators

3.3. DBTT for the GF/DCPD Composite with Different Weight Fractions

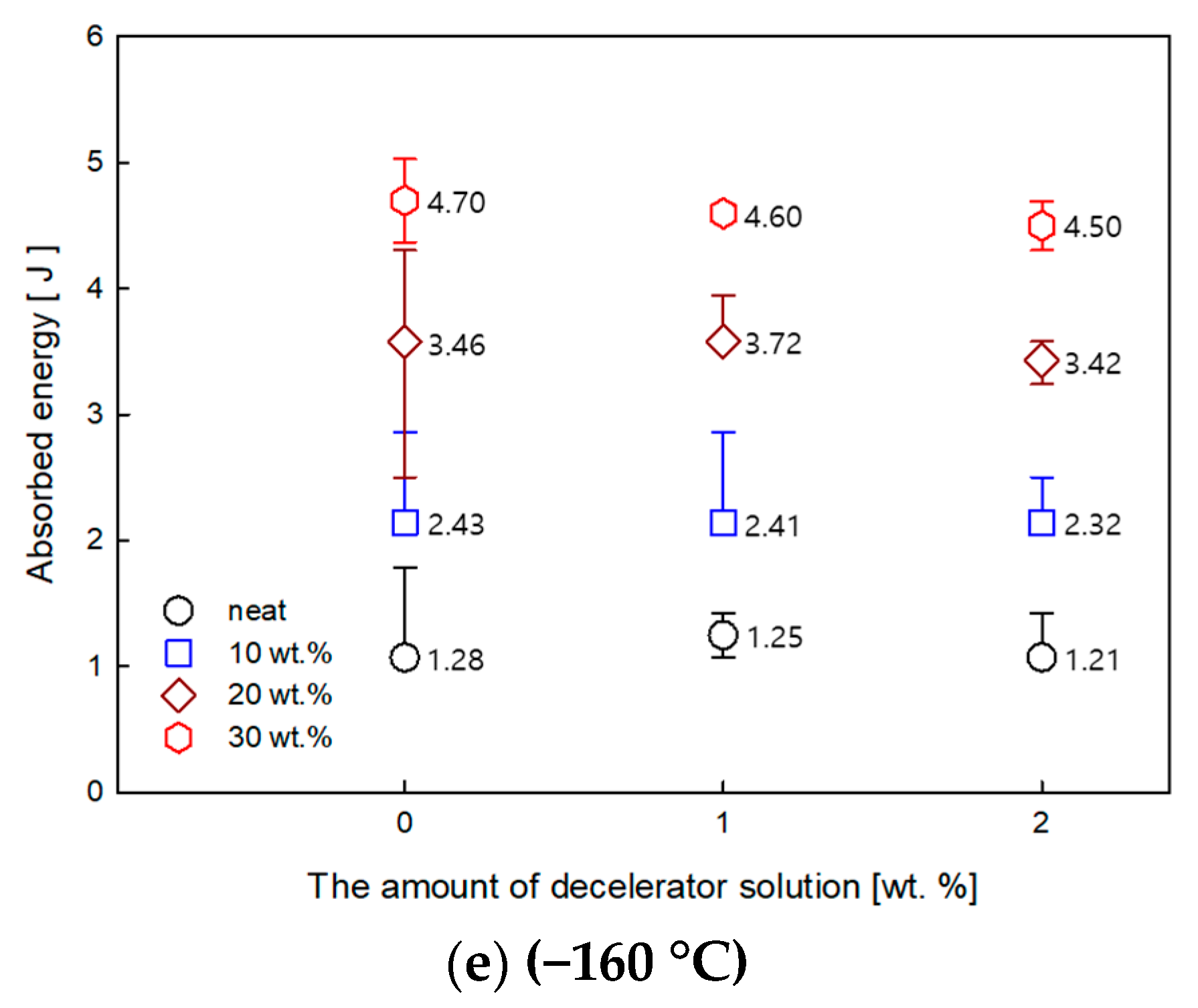

3.4. Decelerator Effect with Different Weight Fractions

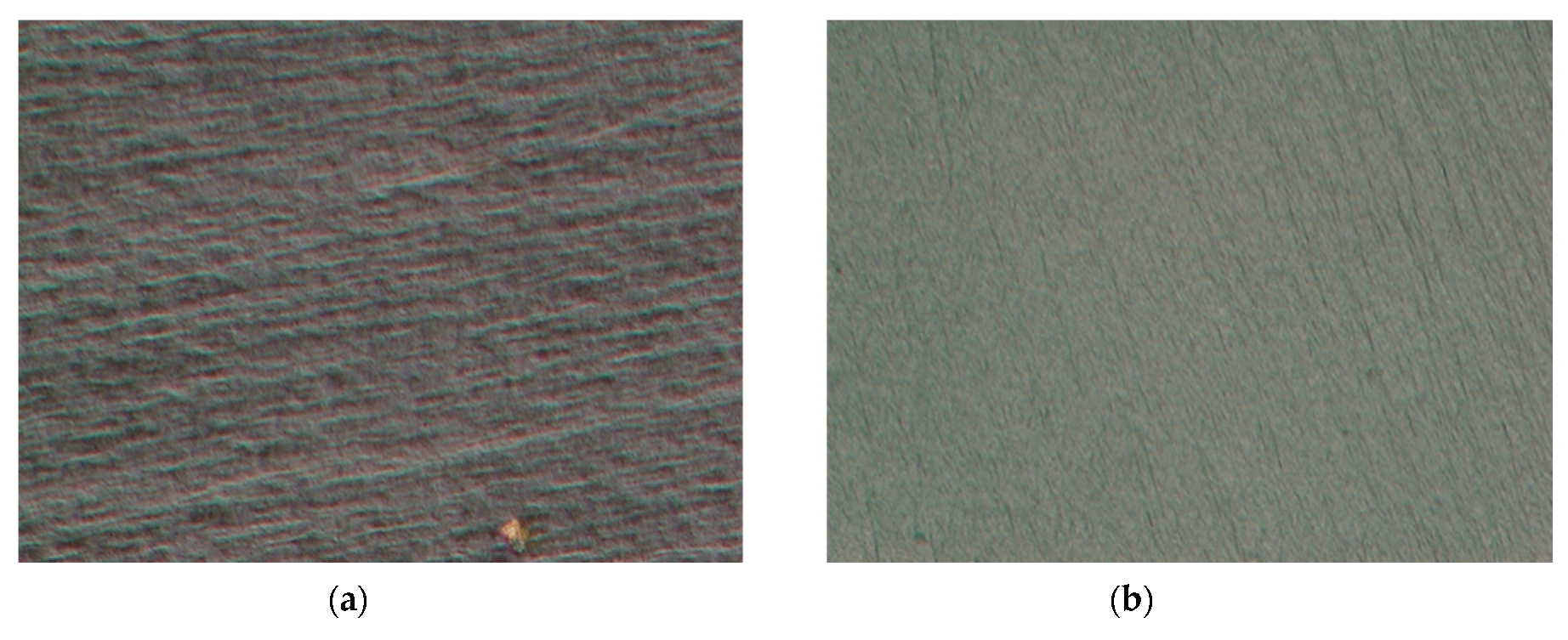

3.5. Fractograph Analysis

4. Concluding Remarks

- Thermal properties of neat DCPD and those with a decelerator were measured using DSC. The Tg of DCPD decreased by 11% with the addition of 2 wt.% decelerator, owing to the reduction in the crosslinking density in the polymer chain with increasing decelerator, leading to a decreased curing reaction.

- The temperature dependence of the impact absorbed energy for neat DCPD from RT to CT was observed. The impact absorbed energy decreased from RT to CT by 19%. With the decelerator, the impact behavior of 1 wt.% and 2 wt.% decreased by 16% and 9%, respectively, under CT compared to RT.

- With the variations in the fiber weight fractions of the GF/DCPD composite, the effect of the DBTT significantly decreased for GF/DCPD composites. The decreasing rate was retarded, however, as the weight fraction of the GF increased. The absorbed energy decreased gradually as the experimental temperature decreased, indicating the DBTT.

- The decrease in DBTT with the additions of GF for the GF/DCPD can be explained with differences in the thermal expansion ratio and interfacial force between neat DCPD and the fiber.

- The effect of the weight percent of the decelerator on the DBTT of GF/DCPD composites as a function of temperature was clearly observed. The decreasing rate of the impact absorbed energy under decreasing temperature declined as the amount of the decelerator was increased, owing to the different thermal property of DCPD and Tg with different amounts of decelerator.

- The micrographs of the fracture surfaces of neat DCPD after the Charpy impact tests were observed. It demonstrated that the neat DCPD specimens had typical characteristics of brittle fracture, indicating a greater brittle fractured surface at CT than at RT. The fracture surface of neat DCPD with the addition of a decelerator provides the reason for the lower impact of absorbed energy when 2 wt.% of the decelerator was added to DCPD.

- In our future research, we evaluate the tensile properties dependent on temperature, particularly near the cryogenic temperature.

Author Contributions

Funding

Conflicts of Interest

References

- Mazumdar, S. Composites Manufacturing: Materials, Product, and Process Engineering; CrC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Ho, M.P.; Wang, H.; Lee, J.H.; Ho, C.K.; Lau, K.T.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Yang, G.; Lee, J.K. Curing kinetics and mechanical properties of endo-dicyclopentadiene synthesized using different Grubbs’ catalysts. Ind. Eng. Chem. Res. 2014, 53, 3001–3011. [Google Scholar] [CrossRef]

- Schutz, J.B. Properties of composite materials for cryogenic applications. Cryogenics 1998, 38, 3–12. [Google Scholar] [CrossRef]

- Toplosky, V.J.; Walsh, R.P. Thermal and Mechanical Properties of Poly-Dicyclopentadiene (DCPD) at Cryogenic Temperatures. AIP Conf. Proc. 2006, 824, 219. [Google Scholar]

- Laura, D.M.; Keskkula, H.; Barlow, J.W.; Paul, D.R. Effect of glass fiber and maleated ethylene–propylene rubber content on tensile and impact properties of nylon 6. Polymer 2000, 41, 7165–7174. [Google Scholar] [CrossRef]

- Tjong, S.C.; Xu, S.A.; Mai, Y.W. Impact fracture toughness of short glass fiber-reinforced polyamide 6, 6 hybrid composites containing elastomer particles using essential work of fracture concept. Mater. Sci. Eng. A 2003, 347, 338–345. [Google Scholar] [CrossRef]

- Daiyan, H.; Andreassen, E.; Grytten, F.; Lyngstad, O.V.; Luksepp, T.; Osnes, H. Low-velocity impact response of injection-moulded polypropylene plates–Part 1: Effects of plate thickness, impact velocity and temperature. Polym. Test. 2010, 29, 648–657. [Google Scholar] [CrossRef]

- Daiyan, H.; Andreassen, E.; Grytten, F.; Lyngstad, O.V.; Luksepp, T.; Osnes, H. Low-velocity impact response of injection-moulded polypropylene plates–Part 2: Effects of moulding conditions, striker geometry, clamping, surface texture, weld line and paint. Polym. Test. 2010, 29, 894–901. [Google Scholar] [CrossRef]

- Yoo, Y.; Spencer, M.W.; Paul, D.R. Morphology and mechanical properties of glass fiber reinforced Nylon 6 nanocomposites. Polymer 2011, 52, 180–190. [Google Scholar] [CrossRef]

- Fu, S.Y.; Pan, Q.Y.; Huang, C.J.; Yang, G.; Liu, X.H.; Ye, L.; Mai, Y.W. A preliminary study on cryogenic mechanical properties of epoxy blend matrices and SiO2/epoxy nanocomposites. In Key Engineering Materials; Trans Tech Publications Ltd.: Zürich, Switzerland, 2006; Volume 312. [Google Scholar]

- Yang, G.; Zheng, B.; Yang, J.P.; Xu, G.S.; Fu, S.Y. Preparation and cryogenic mechanical properties of epoxy resins modified by poly (ethersulfone). J. Polym. Sci. Part A Polym. Chem. 2008, 46, 612–624. [Google Scholar] [CrossRef]

- Yang, J.P.; Chen, Z.K.; Yang, G.; Fu, S.Y.; Ye, L. Simultaneous improvements in the cryogenic tensile strength, ductility and impact strength of epoxy resins by a hyperbranched polymer. Polymer 2008, 49, 3168–3175. [Google Scholar] [CrossRef]

- Kaiser, M.R.; Anuar, H.; Razak, S.B.A. Ductile–brittle transition temperature of polylactic acid-based biocomposite. J. Thermoplast. Compos. Mater. 2013, 26, 216–226. [Google Scholar] [CrossRef]

- Flexman, E.A., Jr. Impact behavior of nylon-66 compositions: Ductile-brittle transitions. Polym. Eng. Sci. 1979, 19, 564–571. [Google Scholar] [CrossRef]

- Yoo, H.M.; Jeon, J.H.; Li, M.X.; Lee, W.I.; Choi, S.W. Analysis of curing behavior of endo-dicyclopentadiene using different amounts of decelerator solution. Compos. Part B Eng. 2019, 161, 439–454. [Google Scholar] [CrossRef]

- Davidson, T.A.; Wagener, K.B. The polymerization of dicyclopentadiene: An investigation of mechanism. J. Mol. Catal. A Chem. 1998, 133, 67–74. [Google Scholar] [CrossRef]

- Yoo, H.M.; Kwon, D.J.; Park, J.M.; Yum, S.H.; Lee, W.I. Mechanical properties of norbornene-based silane treated glass fiber reinforced polydicyclopentadiene composites manufactured by the S-RIM process. e-Polymers 2017, 17, 159–166. [Google Scholar] [CrossRef]

- Plastics—Determination of Charpy Impact Properties; BS EN ISO 179-1; BSI: London, UK, 2010.

- Chen, Z.K.; Yang, G.; Yang, J.P.; Fu, S.Y.; Ye, L.; Huang, Y.G. Simultaneously increasing cryogenic strength, ductility and impact resistance of epoxy resins modified by n-butyl glycidyl ether. Polymer 2009, 50, 1316–1323. [Google Scholar] [CrossRef]

- Ma, H.L.; Jia, Z.; Lau, K.T.; Leng, J.; Hui, D. Impact properties of glass fiber/epoxy composites at cryogenic environment. Compos. Part B Eng. 2016, 92, 210–217. [Google Scholar] [CrossRef]

| Decelerator Content (wt.%) | Neat | 1 | 2 |

|---|---|---|---|

| Tg | 105.49 | 98.56 | 93.43 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, J.H.; Lee, W.I.; Choi, J.M.; Choi, S.W. Analysis of Cryogenic Impact Properties for a Glass-Fiber-Reinforced Dicyclopentadiene with a Different Amount of Decelerator Solution. Materials 2019, 12, 3246. https://doi.org/10.3390/ma12193246

Jeon JH, Lee WI, Choi JM, Choi SW. Analysis of Cryogenic Impact Properties for a Glass-Fiber-Reinforced Dicyclopentadiene with a Different Amount of Decelerator Solution. Materials. 2019; 12(19):3246. https://doi.org/10.3390/ma12193246

Chicago/Turabian StyleJeon, Ji Ho, Woo Il Lee, Jong Min Choi, and Sung Woong Choi. 2019. "Analysis of Cryogenic Impact Properties for a Glass-Fiber-Reinforced Dicyclopentadiene with a Different Amount of Decelerator Solution" Materials 12, no. 19: 3246. https://doi.org/10.3390/ma12193246

APA StyleJeon, J. H., Lee, W. I., Choi, J. M., & Choi, S. W. (2019). Analysis of Cryogenic Impact Properties for a Glass-Fiber-Reinforced Dicyclopentadiene with a Different Amount of Decelerator Solution. Materials, 12(19), 3246. https://doi.org/10.3390/ma12193246