Effect of Scanning and Support Strategies on Relative Density of SLM-ed H13 Steel in Relation to Specimen Size

Abstract

1. Introduction

2. Materials and Methods

- stage I—effect of scanning strategy depending on cross-section (x × y) dimensions of specimens (4 mm × 5 mm; 8 mm × 10 mm and 16 mm × 20 mm ) and height of 5 mm (z),

- stage II—effect of support structures,

- stage III—effect of intermediate layers (connecting supports with standard layers) built with lower laser power.

- Strategy (1) consisted of alternating scanning of stripes, where subsequent stripes are scanned from the edge of that scanning after the previous strip was finished (Figure 4a).

- Strategy (2) consisted of scanning strips in the same direction, where starting points of scanning individual stripes were located on the same edge (Figure 4b).

- Strategy (3) consisted of longitudinal scanning of stripes, similar to standard scanning, while scanning of individual stripes took place in a strictly determined order (Figure 5a).

- Strategy (4), so-called chessboard, consisted of scanning individual square fields relative to those for which the specimen surface was divided. The scanning sequence of the fields is marked in Figure 5b.

3. Results

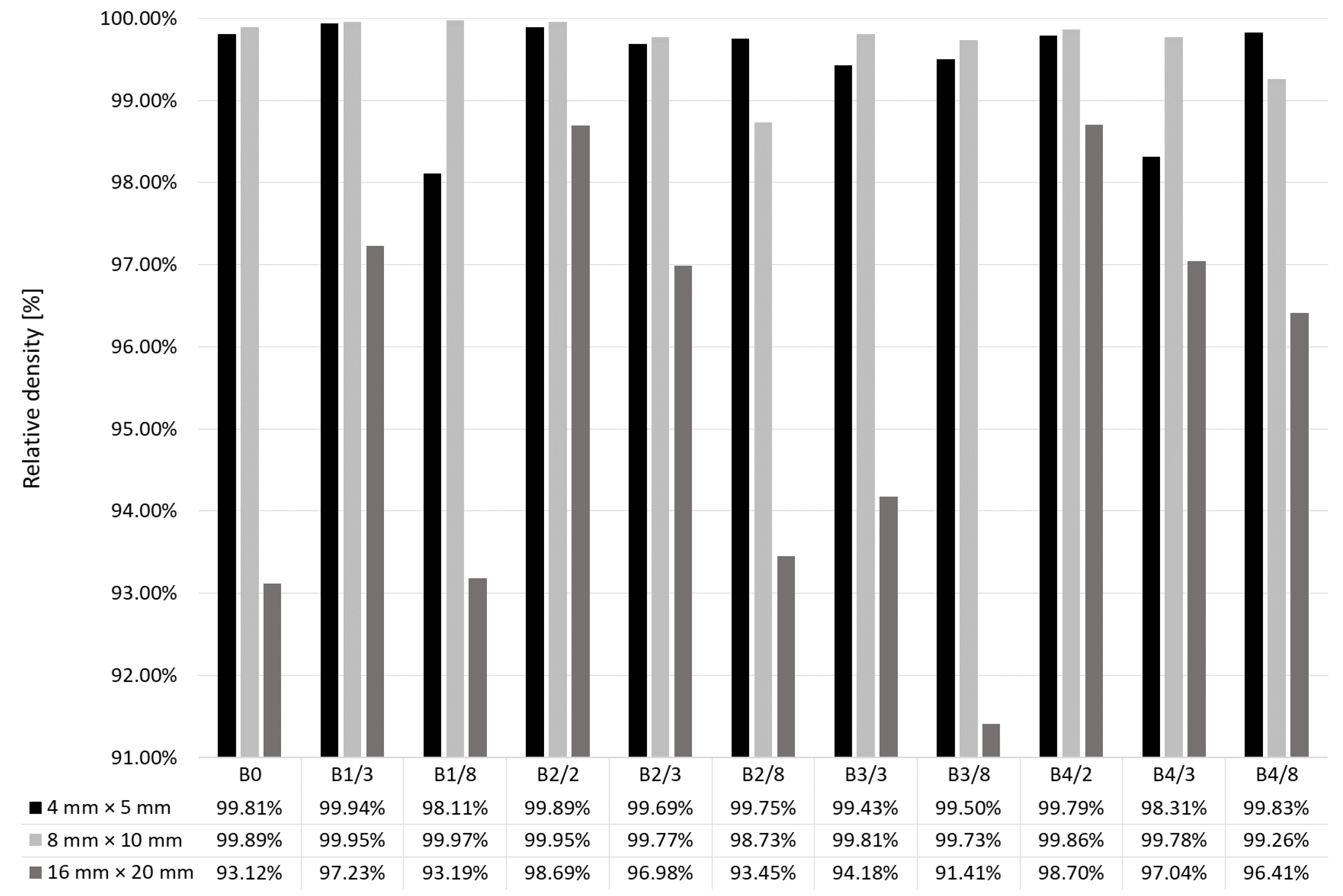

3.1. Effect of Scanning Strategy on Relative Denisty Depending on Specimen Dimensions

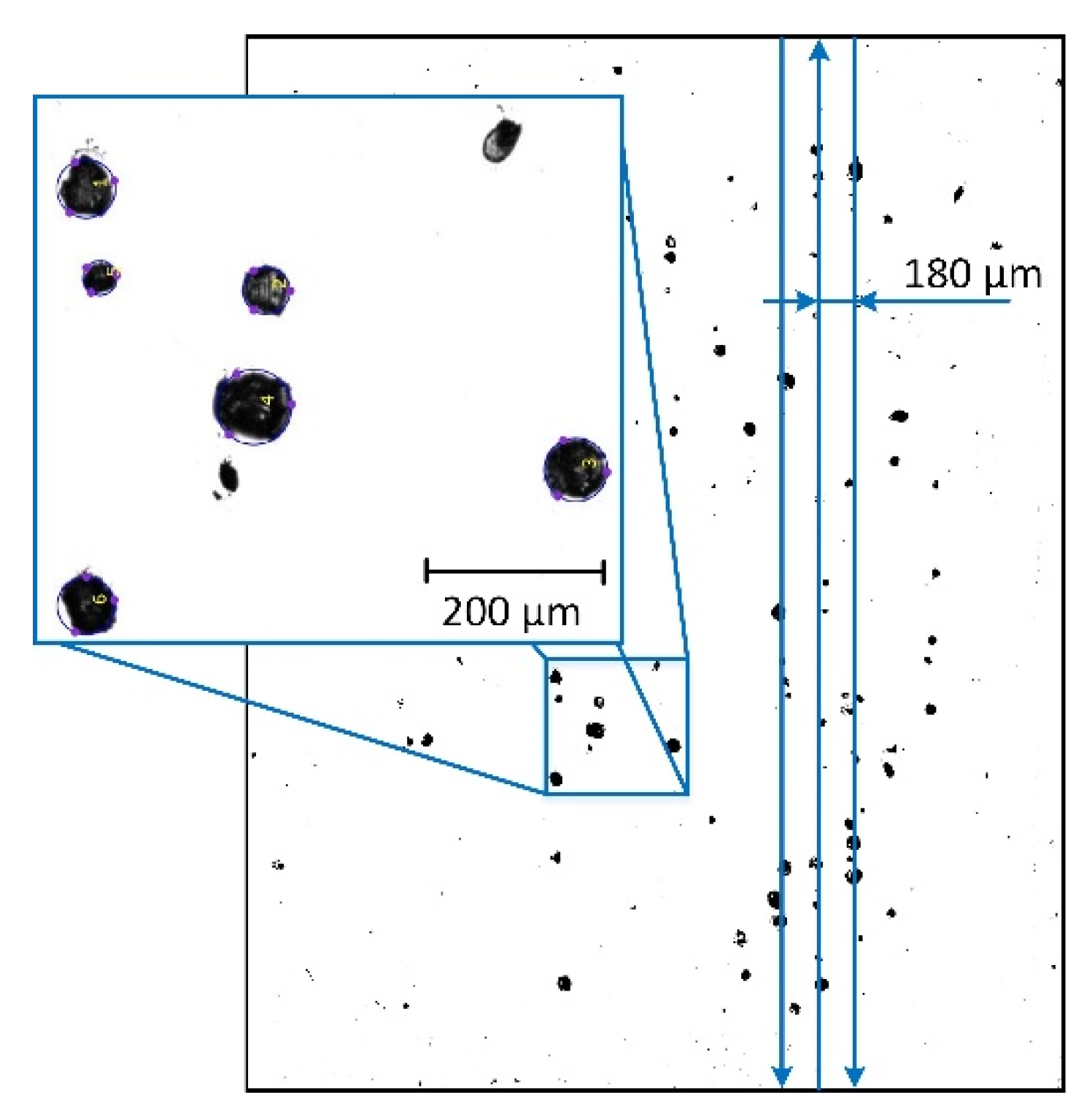

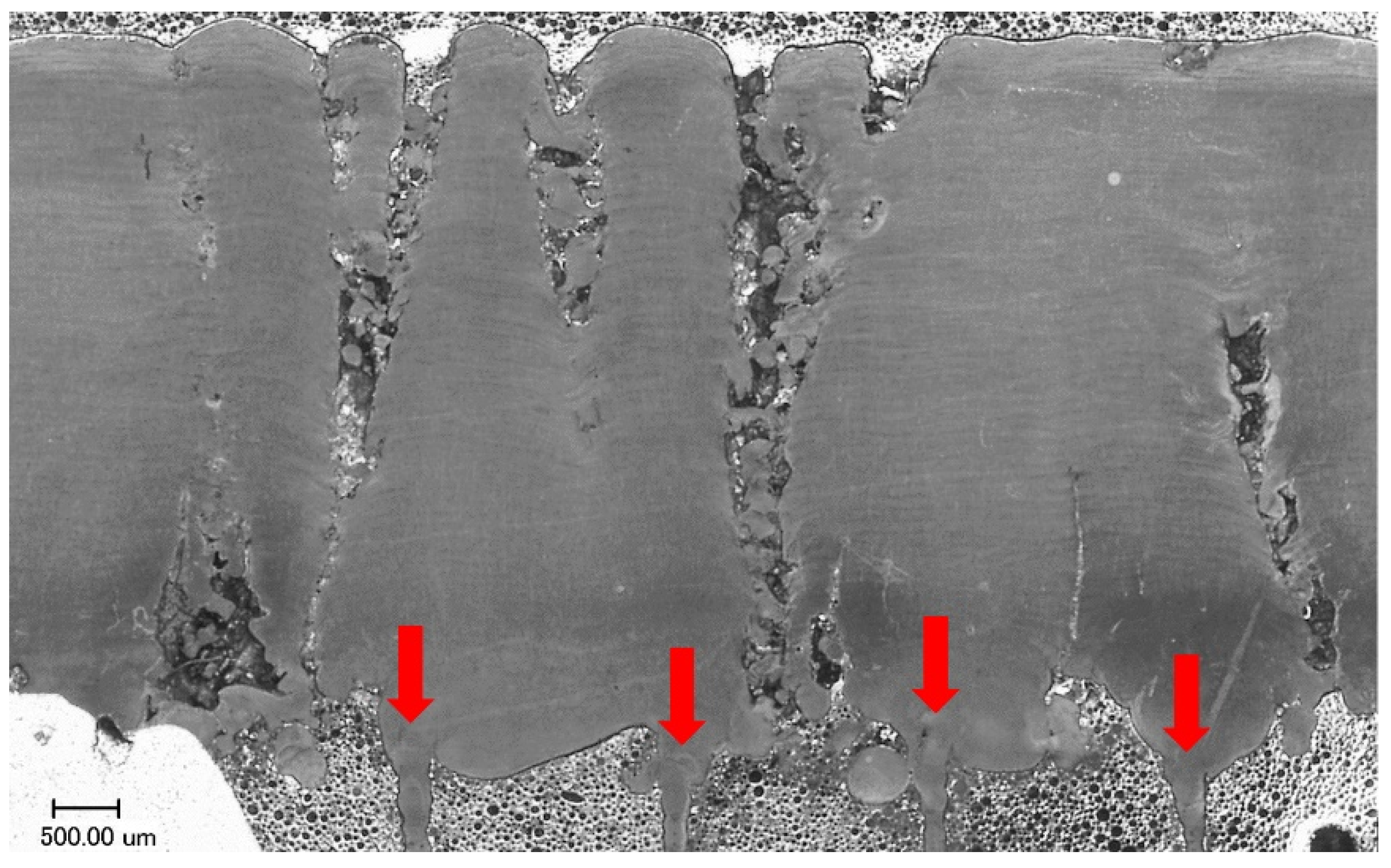

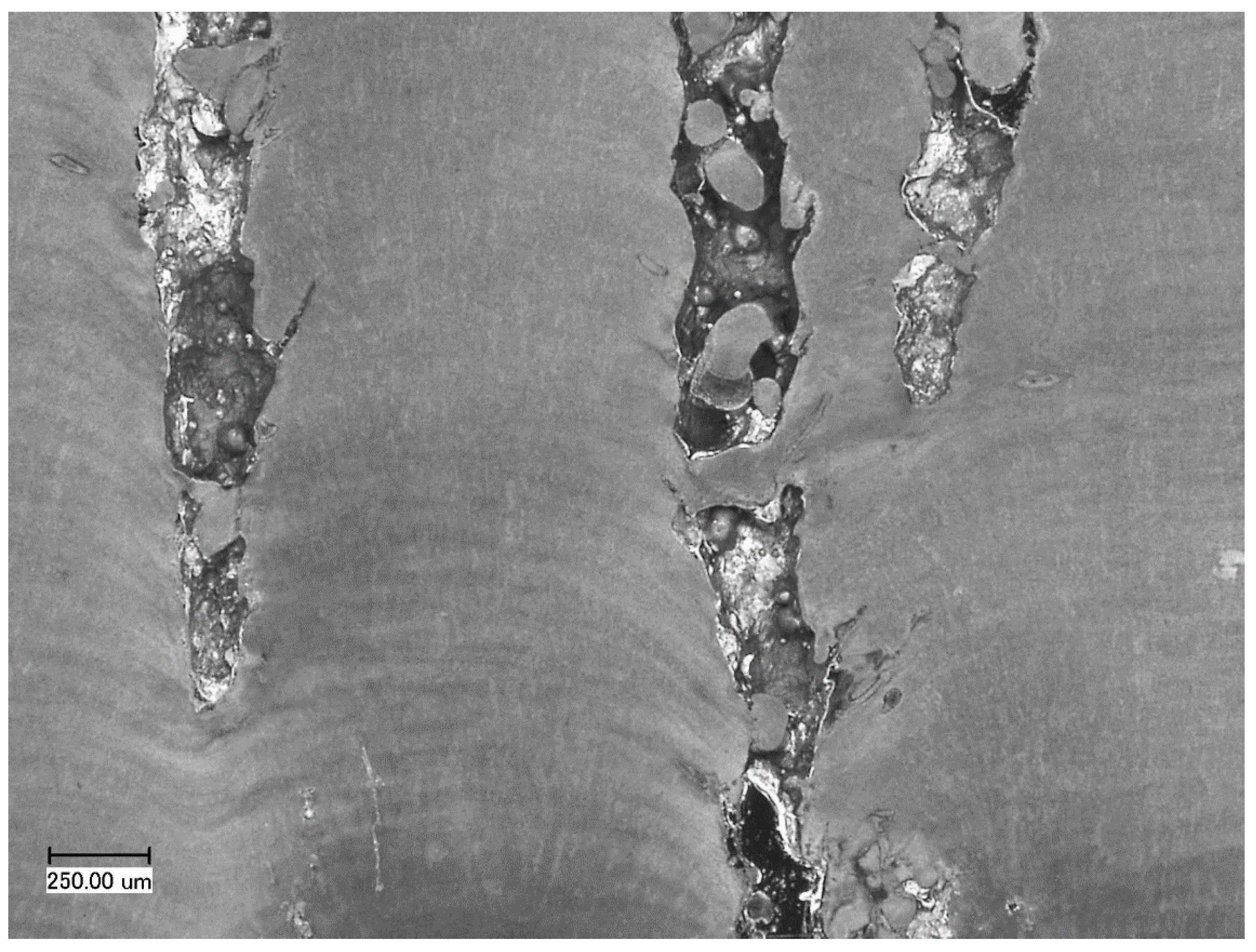

3.2. Effect of Support Structures

3.3. Effect of Intermediate Layers

- at laser power reduced from 200 W to 150 W in order to decrease the tendency of the first solidifying metal layers to overhang,

- at the same laser power of 200 W but with introduced an intermediate layer, i.e., the first five layers built at lower laser power of 125 W (to decrease volume energy density in order to obtain a stable pool of liquid metal).

4. Discussion

- laser power (W)—P,

- layer thickness (µm)—L,

- hatch spacing (µm)—H,

- scanning speed (mm/s)—V,

- focused beam diameter (µm)—f.

5. Conclusions

- Application of the same process parameters in the manufacture of specimens with various scanning surface areas results in a decrease of relative density for larger sizes to the degree dependent on the applied scanning strategy.

- Scanning strategy significantly influences quantity, sizes and arrangement of pores. Proper selection of strategy (e.g., chessboard with small dimensions of individual fields) makes it possible to suppress influence of size of the scanning section on relative density of the manufactured parts.

- Double scanning does not significantly reduce porosity of specimens, but reduces the influence of the scanning strategy.

- Distances between supports and their inclination angle to the X axis influence the occurrence of columnar pores. Density of supports and their proper inclination make it possible to reduce the number of columnar pores.

- Application of intermediate layers (first layers from sides of supports, made at properly selected process parameters) makes it possible to reduce the quantity of columnar pores and to maximize density in the entire specimen volume.

Author Contributions

Funding

Conflicts of Interest

References

- Gausemeier, J.; Echterhoff, N.; Wall, M. Thinking ahead the Future of Additive Manufacturing—Innovation Roadmapping of Required Advancements. Available online: https://dmrc.unipaderborn.de/fileadmin/dmrc/Download/data/DMRC_Studien/DMRC_Study_Part_3.pdf (accessed on 20 December 2018).

- Gausemeier, J.; Echterhoff, N.; Kokoschka, M.; Wall, M. Thinking ahead the Future of Additive Manufacturing—Analysis of Promising Industries. Available online: https://dmrc.uni-paderborn.de/fileadmin/dmrc/06_Downloads/01_Studies/DMRC_Study_Part_1.pdf (accessed on 20 December 2018).

- 3D Metals. Available online: https://slm-solutions.com/sites/default/files/downloads/201en171023-01-001-powder_web.pdf (accessed on 20 December 2018).

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Measurement Sci. Tech. 2017, 28, 1–25. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Xia, M.; Gu, D.; Yu, G.; Dai, D.; Chen, H.; Shi, Q. Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2017, 116, 96–106. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; Physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Taheri, H.; Shoaib, M.R.B.M.; Koester, L.; Bigelow, T.; Collins, P.C.; Bond, L.J. Powder-based additive manufacturing—A review of types of defects, generation mechanisms, detection, property evaluation and metrology. Int. J. Addit. Subtractive Mater. Manuf. 2017, 2, 172–209. [Google Scholar] [CrossRef]

- Panwisawas, C.; Perumal, B.; Ward, R.M.; Turner, N.; Turner, R.P.; Brooks, J.W.; Basolto, H.C. Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: Experimental and modelling. Acta Materialia 2017, 126, 251–263. [Google Scholar] [CrossRef]

- Xiao, R.; Zhang, X. Problems and issues in laser beam welding of aluminum-lithium alloys. J. Manuf. Processes 2014, 16, 166–175. [Google Scholar] [CrossRef]

- Panwisawas, C.; Qiu, C.L.; Sovani, Y.; Brooks, J.W.; Attallah, M.M.; Basoalto, H.C. On the role of thermal fluid dynamics into the evolution of porosity during selective laser melting. Scr. Materialia 2015, 105, 14–17. [Google Scholar] [CrossRef]

- Koester, L.W.; Taheri, H.; Bigelow, T.A.; Collins, P.C.; Bond, L.J. Nondestructive testing for metal parts fabricated using powder-based additive manufacturing. Mater. Eval. 2018, 76, 514–524. Available online: https://www.researchgate.net/publication/324209458_Nondestructive_Testing_for_Metal_Parts_Fabricated_Using_Powder-Based_Additive_Manufacturing (accessed on 7 January 2019).

- Bauereiß, A.; Scharowsky, T.; Körner, C. Defect generation and propagation mechanism during additive manufacturing by selective beam melting. J. Mater. Process. Technol. 2014, 214, 2497–2504. [Google Scholar] [CrossRef]

- Gustmann, T.; Neves, A.; Kühn, U.; Gargarella, P.; Kiminami, C.S.; Bolfarini, C.; Eckert, J.; Pauly, S. Influence of processing parameters on the fabrication of a Cu-Al-Ni-Mn shape-memory alloy by selective laser melting. Addit. Manuf. 2016, 11, 23–31. [Google Scholar] [CrossRef]

- Beal, V.E.; Erasenthiran, P.; Hopkinson, N.; Dickens, P.; Ahrens, C.H. Scanning strategies and spacing effect on laser fusion of H13 tool steel powder using high power Nd:YAG pulsed laser. Int. J. Prod. Res. 2008, 46, 217–232. [Google Scholar] [CrossRef]

- Gan, M.X.; Wong, C.H. Practical support structures for selective laser melting. J. Mater. Process. Technol. 2016, 238, 474–484. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Cloots, M.; Spierings, A.B.; Wegener, K. Assessing new support minimizing strategies for the additive manufacturing technology SLM. In Proceedings of the Annual International Solid Freeform. Fabrication Symposium an Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2013; pp. 631–643. Available online: http://sffsymposium.engr.utexas.edu/Manuscripts/2013/2013-50-Cloots.pdf (accessed on 20 December 2018).

- Prashanth, K.G.; Scudino, S.; Maity, T.; Das, J.; Eckert, J. Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef]

- Scipioni Bertoli, U.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.P.R.; Schoenung, J.M. On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- Laakso, P.; Riipinen, T.; Laukkanen, A.; Andersson, T.; Jokinen, A.; Revuelta, A.; Ruusuvuori, K. Optimization and simulation of SLM process for high density H13 tool steel parts. Phys. Procedia 2016, 83, 26–35. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; McMillan, M.; Elambasseril, J.; Brandt, M. SLM additive manufacture of H13 tool steel with conformal cooling and structural lattices. Rapid Prototyp. J. 2016, 22, 504–518. [Google Scholar] [CrossRef]

- Lee, J.H.; Jang, J.H.; Joo, B.D.; Yim, H.S.; Moon, Y.H. Application of direct laser metal tooling for AISI H13 tool steel. Trans. Nonferrous Met. Soc. China 2009, 19, 284–287. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Körner, C.; Attar, E.; Heinl, P. Mesoscopic simulation of selective beam melting processes. J. Mater. Process. Technol. 2011, 211, 978–987. [Google Scholar] [CrossRef]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef]

| Concentration (wt %) | Fe | Cr | Mo | Si | V | Mn | C | P | S |

|---|---|---|---|---|---|---|---|---|---|

| AISI H13 | Reminder | 4.75–5.50 | 1.10–1.75 | 0.8–1.25 | 0.8–1.20 | 0.2–0.6 | 0.32–0.45 | 0.03 | 0.03 |

| Used powder | Reminder | 5.07 | 1.72 | 0.88 | 1.02 | 0.44 | 0.41 | 0.008 | 0.009 |

| Laser Power (W) | Exposure Time (µs) | Distance between Scanning Points (µm) | Hatch Distance (µm) | Layer Thickness (µm) | Scanning Speed (mm/s) |

|---|---|---|---|---|---|

| 200 | 800 | 80 | 180 | 50 | 100 |

| Item | Designation | Definition | Unit | Reference |

|---|---|---|---|---|

| 1 | Surface power density | - | ||

| 2 | Surface energy density | [13] | ||

| 3 | Surface energy density | - | ||

| 4 | Volume energy density | [13] | ||

| 5 | Volume energy density | - |

| Parameter | This Work A0 | This Work A4/3 | This Work A4/2, 1.5 mm, 30°, 150 W | Laakso [23] | Mazur VED 80 [24] | Mazur VED 120 [24] |

|---|---|---|---|---|---|---|

| Laser power (W) | 200 | 200 | 150 | 251 | 225 | 375 |

| Layer thickness (µm) | 50 | 50 | 50 | 30 | 30 | 30 |

| Scanning speed (mm/s) | 100 | 100 | 100 | 994 | 781 | 868 |

| Hatch spacing (µm) | 180 | 180 | 180 | 100 | 120 | 120 |

| Focused beam diameter (µm) | 200 | 200 | 200 | 80 | 80 | 80 |

| Ps (W/mm2) | 6369 | 6369 | 4777 | 49863 | 44785 | 74642 |

| El (J/mm2) | 40 | 40 | 30 | 8 | 10 | 14 |

| Ef (J/mm2) | 10 | 10 | 7.5 | 3.15 | 3.6 | 5.4 |

| VEDH (J/mm3) | 222 | 222 | 167 | 84 | 80 | 120 |

| VEDf (J/mm3) | 200 | 200 | 150 | 105,04 | 120 | 180 |

| Strategy | A0 | A4/3 | A4/2 | Rotated 67° | N/A | N/A |

| Specimen dimensions (mm3) | 8 × 10 × 5 | 8 × 10 × 5 | 8 × 10 × 5 | 10 × 10 × 10 | 4 × 4 × 4 | 4 × 4 × 4 |

| Method of relative density measurement | Image analysis without boundary | Image analysis without boundary | Image analysis without boundary | Image analysis without boundary | CT | CT |

| Relative density (%) | 99.83 | 99.97 | 99.98 | 99.91 | 99.91 | 99.99 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurzynowski, T.; Stopyra, W.; Gruber, K.; Ziółkowski, G.; Kuźnicka, B.; Chlebus, E. Effect of Scanning and Support Strategies on Relative Density of SLM-ed H13 Steel in Relation to Specimen Size. Materials 2019, 12, 239. https://doi.org/10.3390/ma12020239

Kurzynowski T, Stopyra W, Gruber K, Ziółkowski G, Kuźnicka B, Chlebus E. Effect of Scanning and Support Strategies on Relative Density of SLM-ed H13 Steel in Relation to Specimen Size. Materials. 2019; 12(2):239. https://doi.org/10.3390/ma12020239

Chicago/Turabian StyleKurzynowski, Tomasz, Wojciech Stopyra, Konrad Gruber, Grzegorz Ziółkowski, Bogumiła Kuźnicka, and Edward Chlebus. 2019. "Effect of Scanning and Support Strategies on Relative Density of SLM-ed H13 Steel in Relation to Specimen Size" Materials 12, no. 2: 239. https://doi.org/10.3390/ma12020239

APA StyleKurzynowski, T., Stopyra, W., Gruber, K., Ziółkowski, G., Kuźnicka, B., & Chlebus, E. (2019). Effect of Scanning and Support Strategies on Relative Density of SLM-ed H13 Steel in Relation to Specimen Size. Materials, 12(2), 239. https://doi.org/10.3390/ma12020239