Bi-Material Negative Thermal Expansion Inverted Trapezoid Lattice based on A Composite Rod

Abstract

:1. Introduction

2. The Composite Rod and the ITL

2.1. Composite Rod

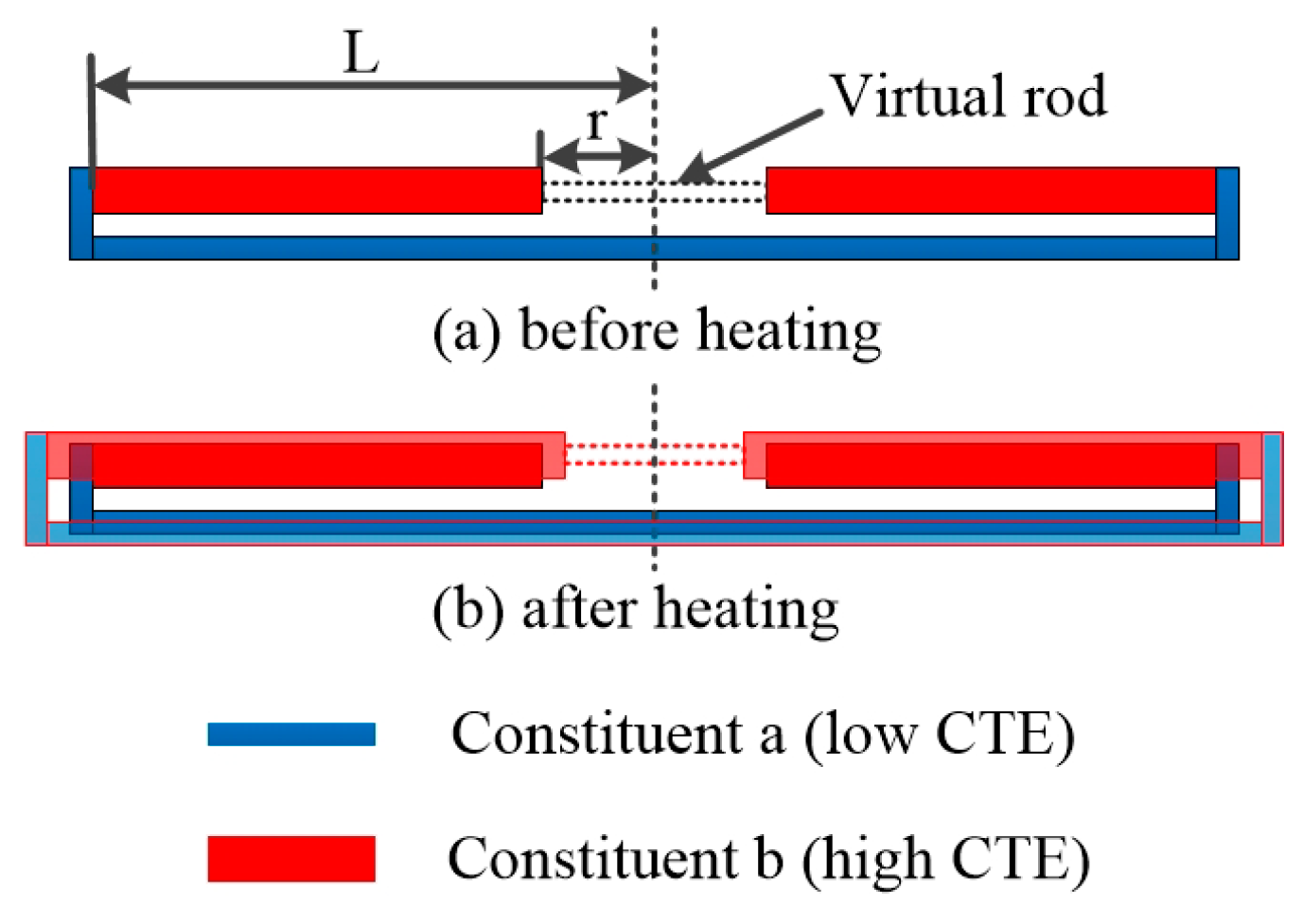

2.1.1. Structure of The Composite Rod

2.1.2. Thermal Expansion of the ‘Virtual Rod’

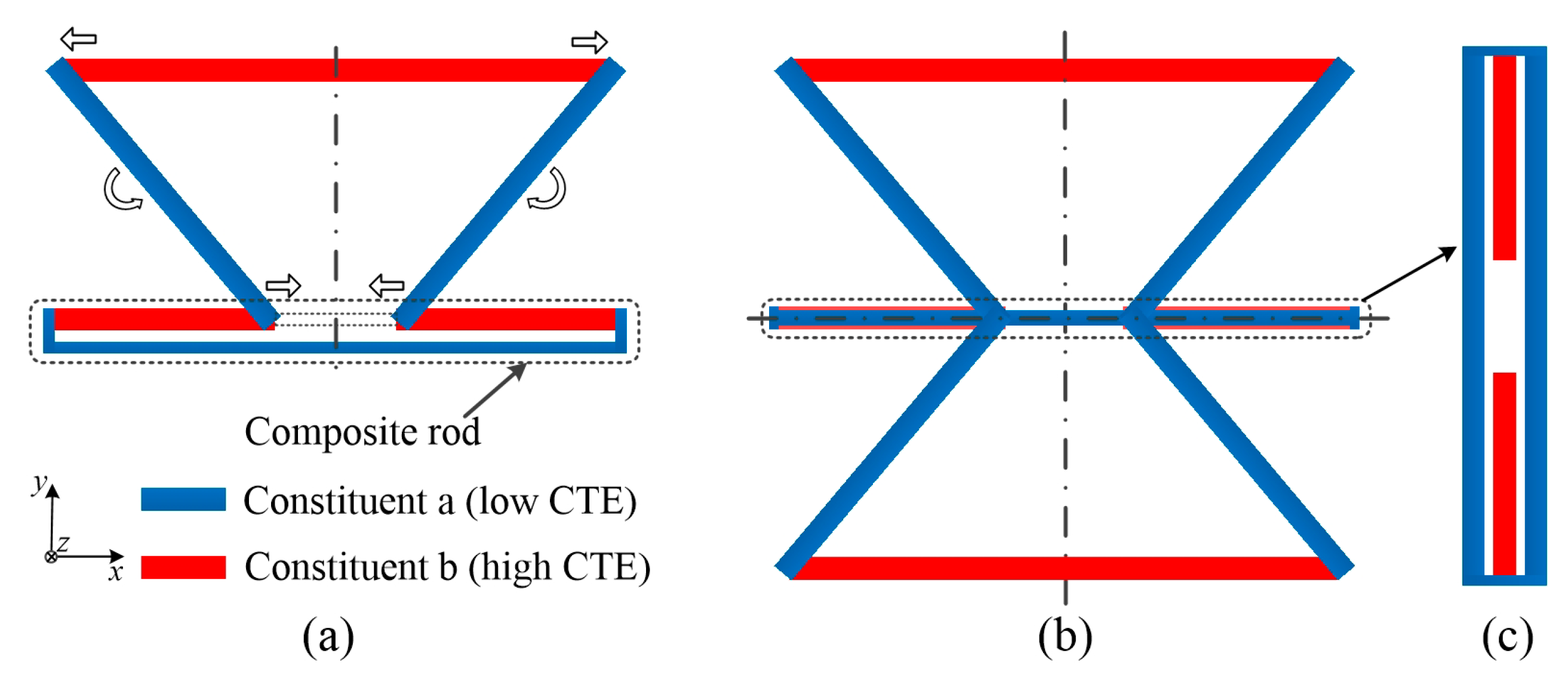

2.2. ITL

2.2.1. Structure of the ITL

2.2.2. NTE Mechanism of the ITL

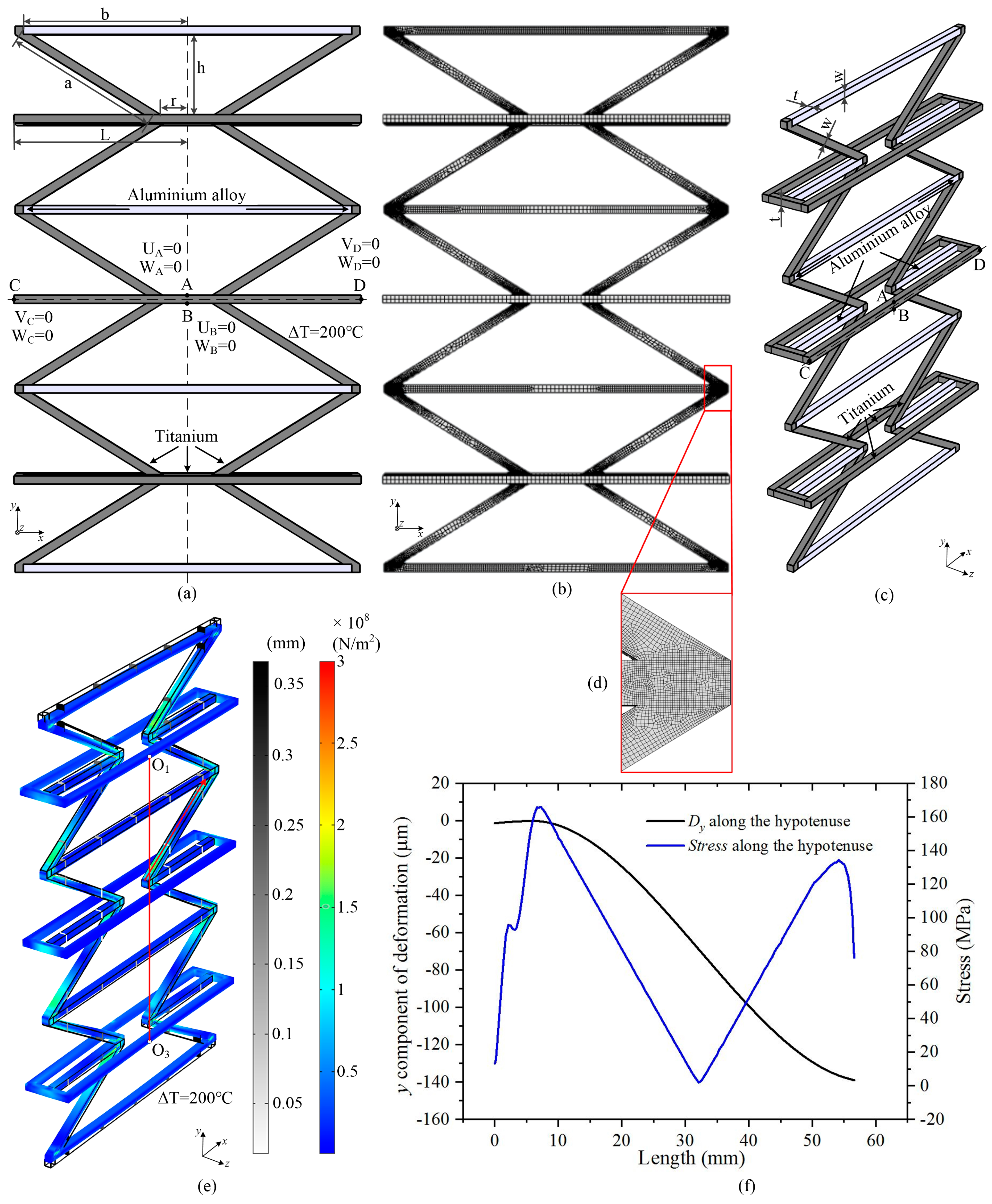

3. Effects of The Basic Structure Parameters

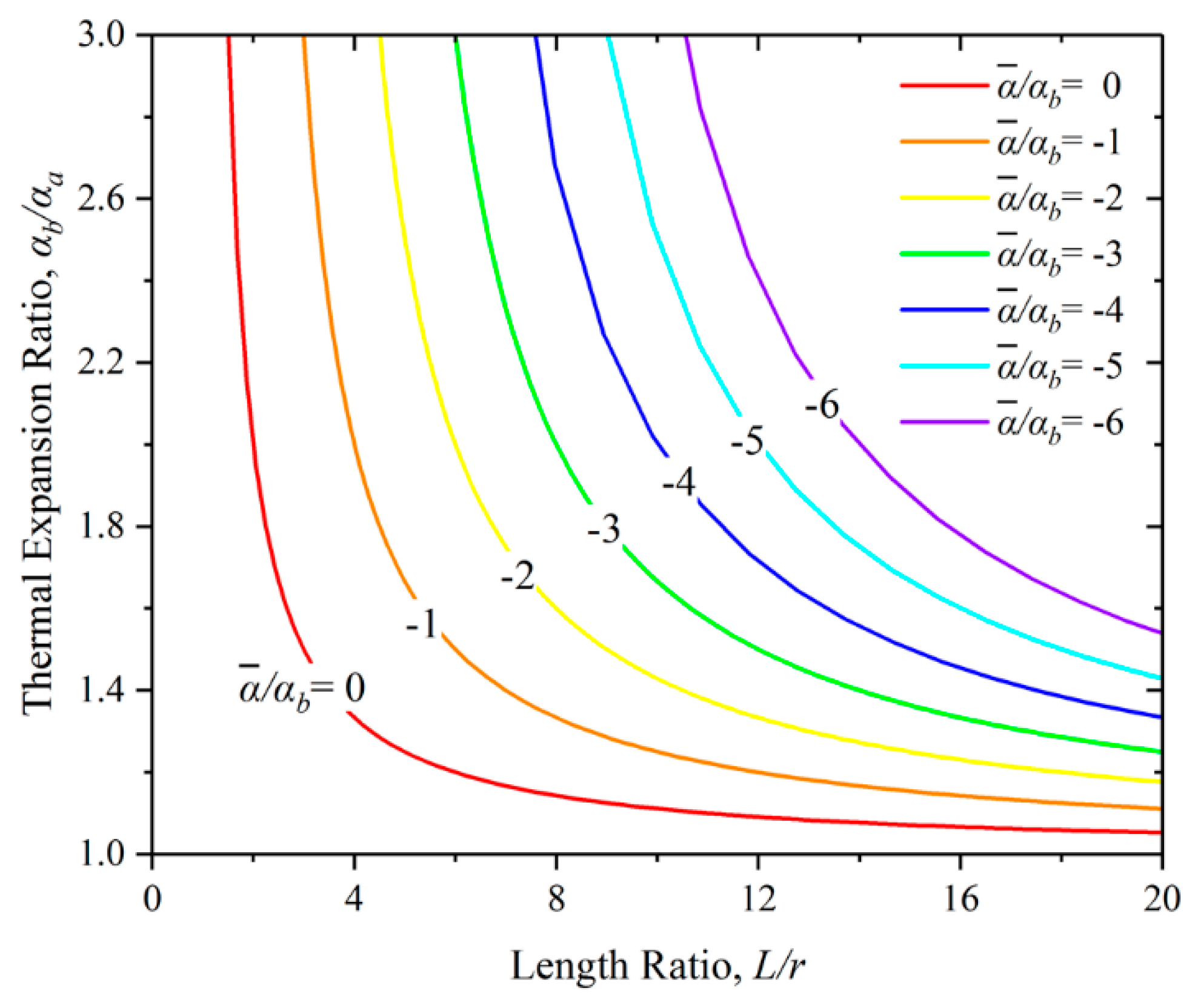

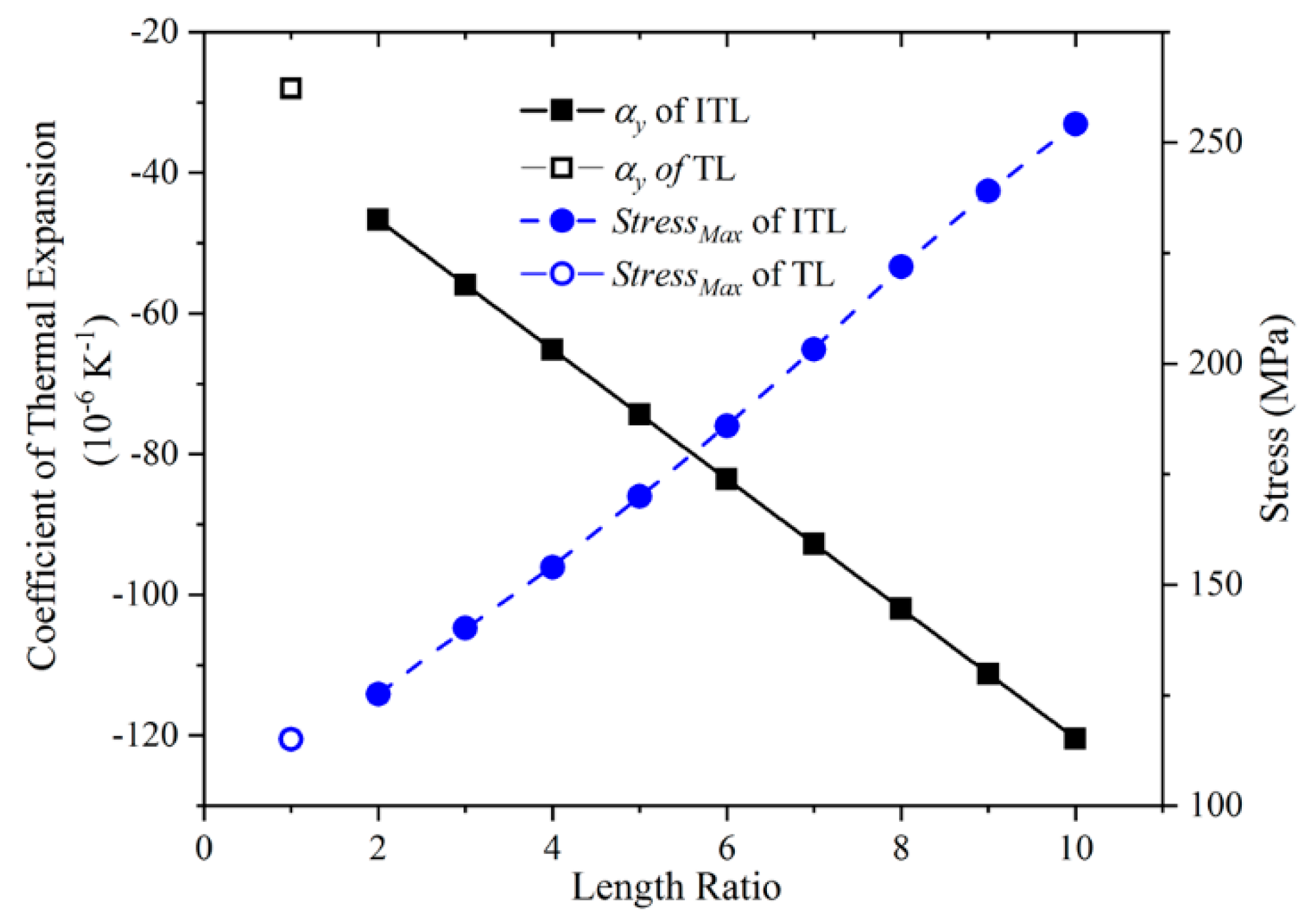

3.1. The Length Ratio of The Long Rod and The Virtual Rod, L/r

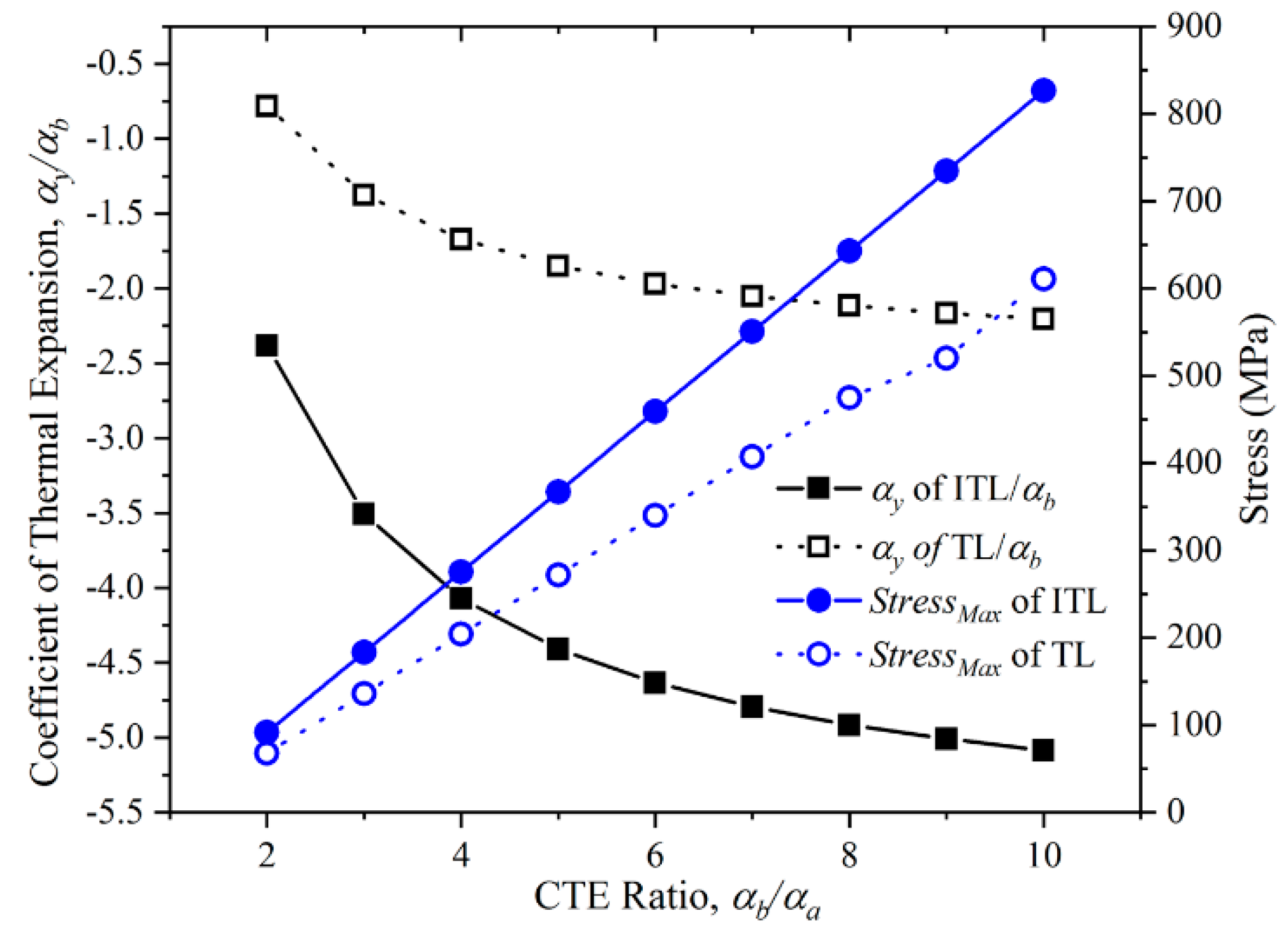

3.2. The CTE Ratio of The Two Constituents

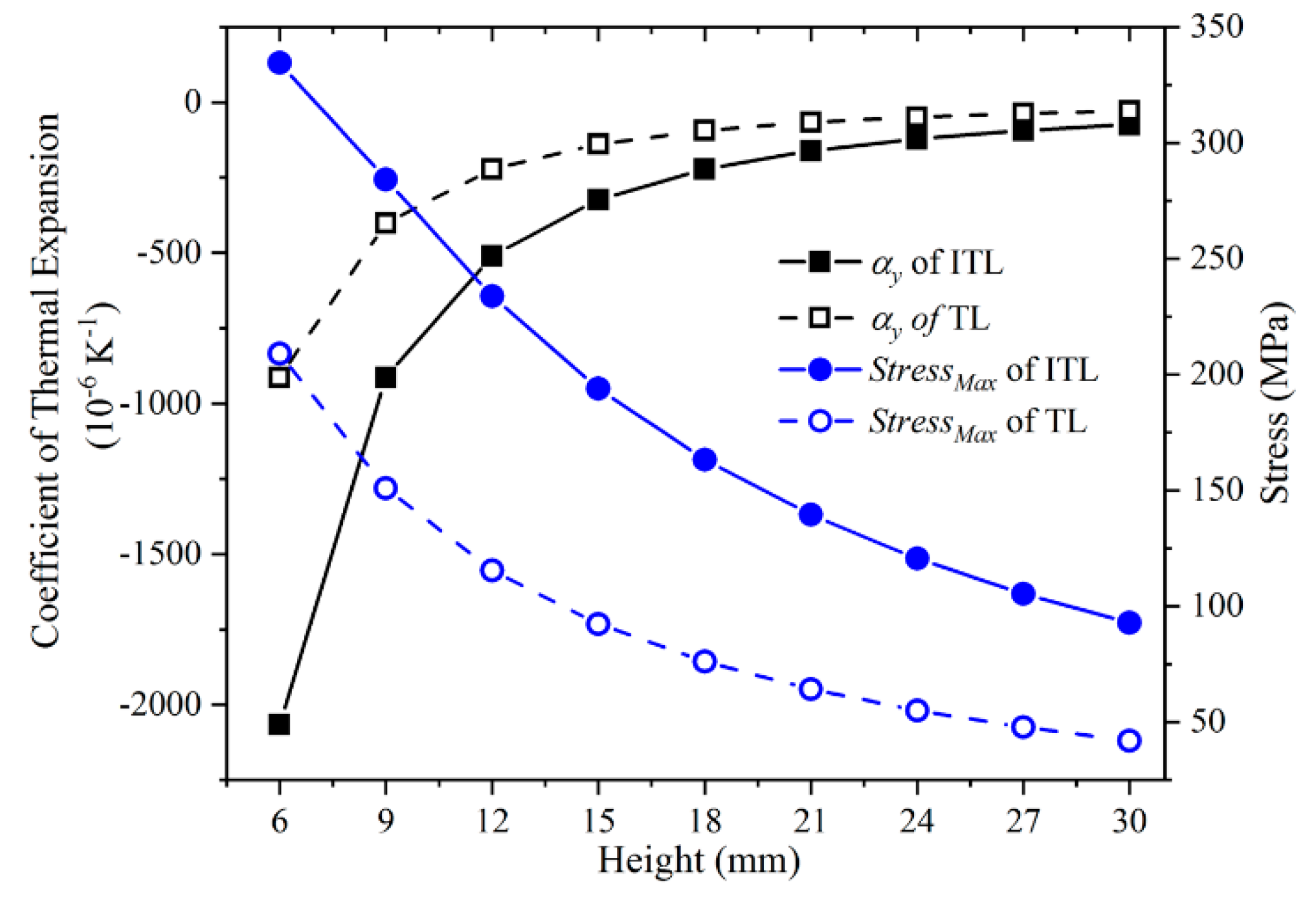

3.3. Height of The Lattice

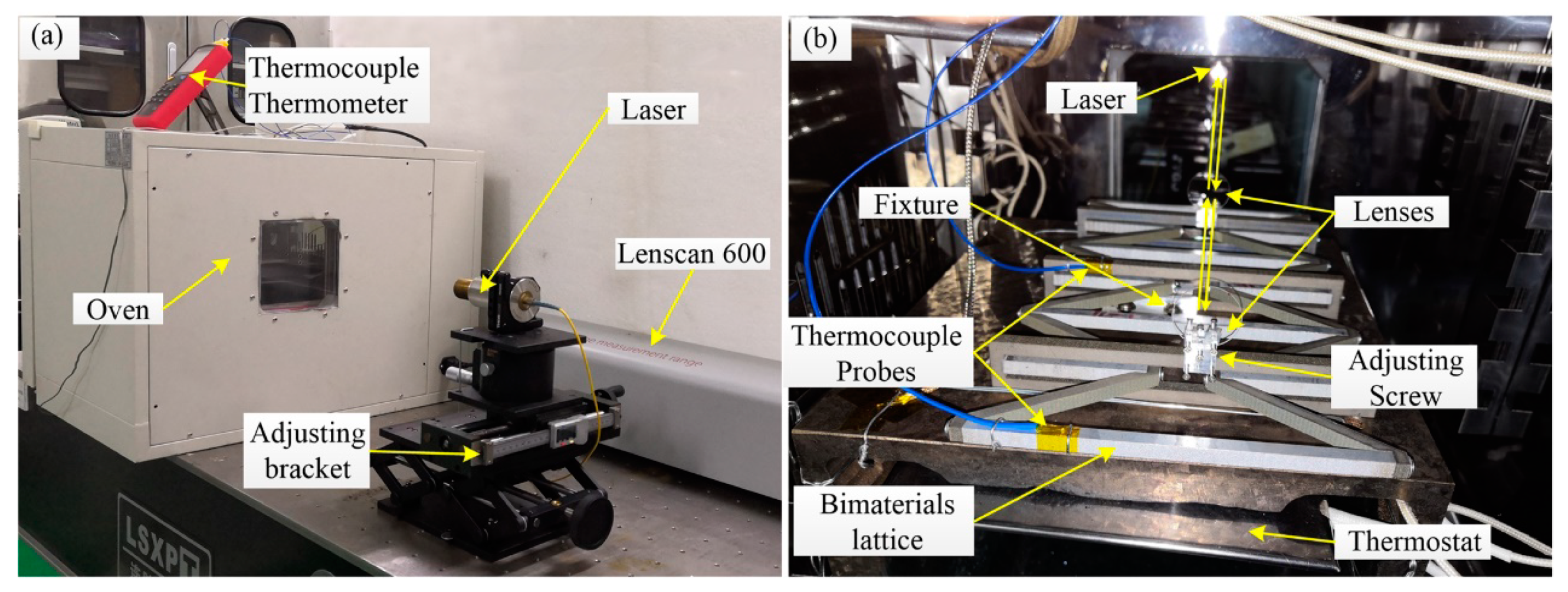

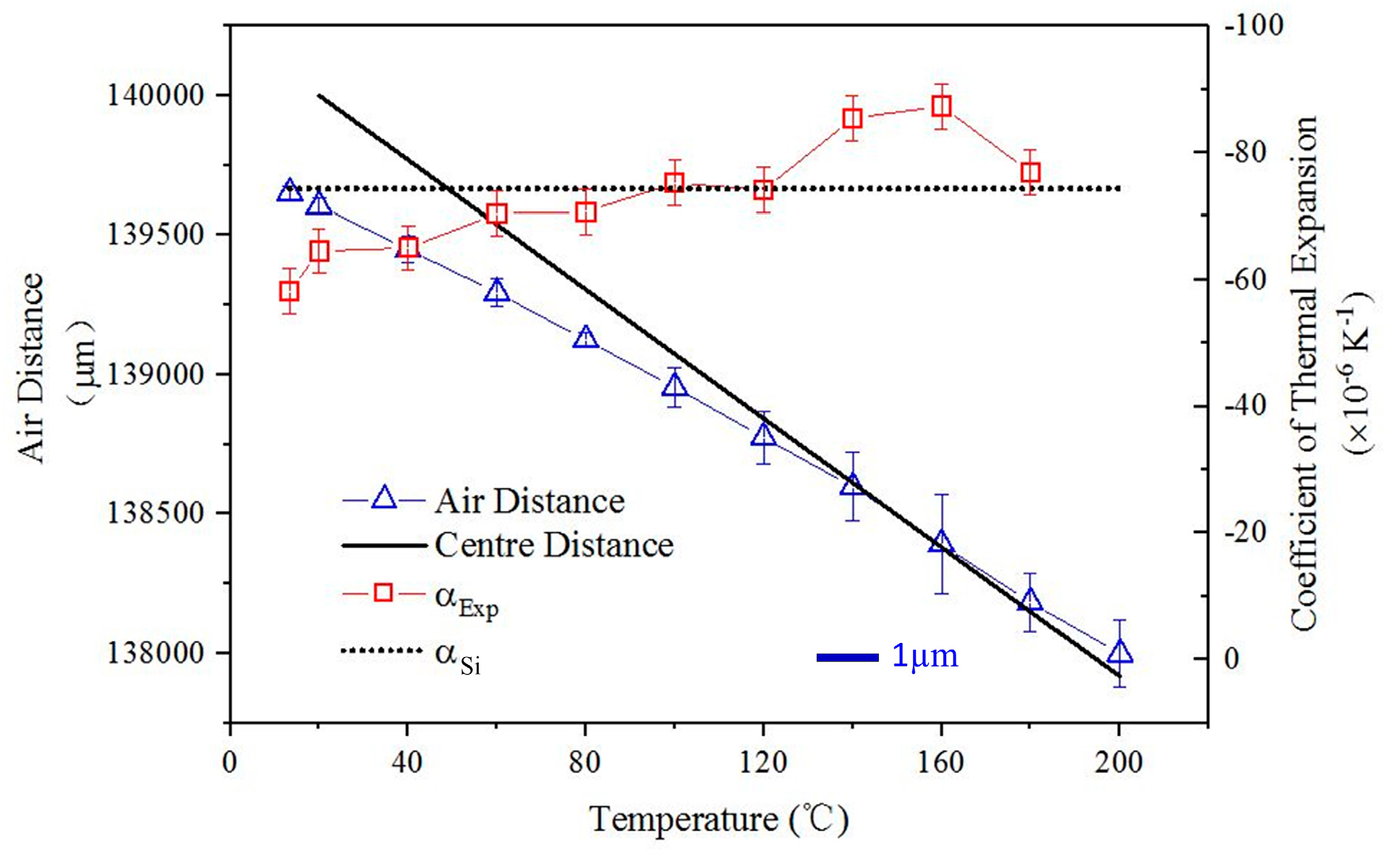

4. Experiment and Results

5. Discussion

- The residual stress of the sample has an important effect on the deformation measurement. During the machining process, we find that the remaining part of the plate after machining having a buckling deformation. The buckling deformation of the residual part of the plate indicates that there is residual stress on the sample. When the sample is heated, the residual stress on the specimen will redistribute. This will generate extra deformation and influence the measurement results. Heat treatment could obviously decrease the residual stress. Hence, we decrease the measurement error thought heat treatment.

- The temperature homogeneity is another factor which influent the thermal deformation of the sample. When the sample is heated, the temperature of the part, which is close to the heat source, is higher compared with the other part. In the experiment, to obtain an approximate homogeneous temperature, we used the thermocouple probes to monitor the temperature of the sample in different positions. It can only provide the temperature of the measurement point. This is not consistent with the homogeneous temperature hypothesis. It will generate a large measurement error. In our future work, we will use the thermal imager to monitor the temperature of the sample. It will provide a global temperature distribution of the sample. This will decrease the temperature differences of the different part of the sample, and improve the accuracy of the measuring results.

- The air refractive index also affects the measurement results. It needs the air refractive index to calculate the optical distance of the two parallel lenses. During the measurement, the air refractive index is set as a constant, but it changes when the temperature increases actually. It should be considered in order to obtain a more accurate results in our future work.

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dong, K.; Peng, X.; Zhang, J.; Gu, B.; Sun, B. Temperature-dependent thermal expansion behaviors of carbon fiber/epoxy plain woven composites: Experimental and numerical studies. Compos. Struct. 2017, 176, 329–341. [Google Scholar] [CrossRef]

- Sigmund, O.; Torquato, S. Design of materials with extreme thermal expansion using a three-phase topology optimization method. J. Mech. Phys. Solids 1997, 45, 1037–1067. [Google Scholar] [CrossRef]

- Zhu, H.; Fan, T.; Peng, Q.; Zhang, D. Giant thermal expansion in 2D and 3D cellular materials. Adv. Mater. 2018, 30, 1705048. [Google Scholar] [CrossRef] [PubMed]

- Takenaka, K. Progress of research in negative thermal expansion materials: Paradigm shift in the control of thermal expansion. Front. Chem. 2018, 6, 267. [Google Scholar] [CrossRef]

- Takenaka, K. Negative thermal expansion materials: Technological key for control of thermal expansion. Sci. Technol. Adv. Mater. 2012, 13, 013001. [Google Scholar] [CrossRef]

- Wei, K.; Pei, Y.M. Development of designing lightweight composites and structures for tailorable thermal expansion. Chin. Sci. Bull. 2017, 62, 53–66. (In Chinese) [Google Scholar] [CrossRef]

- Mary, T.A.; Evans, J.S.O.; Vogt, T.; Sleight, A.W. Negative thermal expansion from 0.3 to 1050 K in ZrW2O8. Science 1996, 272, 90–92. [Google Scholar] [CrossRef]

- Evans, J.S.O.; Mary, T.A.; Sleight, A.W. Negative thermal expansion in Sc2(WO4)3. J. Solid State Chem. 1998, 137, 148–160. [Google Scholar] [CrossRef]

- Charles, M.; Hummel, F.A. Linear thermal expansion of three tungstates. J. Am. Ceram. Soc. 2010, 51, 227–228. [Google Scholar]

- Long, Y.W.; Hayashi, N.; Saito, T.; Azuma, M.; Muranaka, S.; Shimakawa, Y. ChemInform Abstract: Temperature-induced A—B intersite charge transfer in an A-site-ordered LaCu3Fe4O12 perovskite. Nature 2009, 40, 60–63. [Google Scholar] [CrossRef]

- Yamada, I.; Tsuchida, K.; Ohgushi, K.; Hayashi, N.; Kim, J.; Tsuji, N.; Takahashi, R.; Matsushita, M.; Nishiyama, N.; Irifune, T.; et al. Giant negative thermal expansion in the iron perovskite SrCu3Fe4O12. Angew. Chem. Int. Ed. 2011, 50, 6579–6582. [Google Scholar] [CrossRef] [PubMed]

- Azuma, M.; Chen, W.T.; Seki, H.; Czapski, M.; Olga, S.; Oka, K.; Mizumaki, M.; Watanuki, T.; Ishimatsu, N.; Kawamura, N.; et al. Colossal negative thermal expansion in BiNiO3 induced by intermetallic charge transfer. Nat. Commun. 2011, 2, 347. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.G.; Kubozono, H.; Yamada, H.; Kato, K.; Ishiwata, Y.; Xu, C.N. Giant negative thermal expansion in magnetic nanocrystals. Nat. Nanotechnol. 2008, 3, 724–726. [Google Scholar] [CrossRef] [PubMed]

- Goodwin, A.L.; Kepert, C.J. Negative thermal expansion and low-frequency modes in cyanide-bridged framework materials. Phys. Rev. B 2005, 71, 140301. [Google Scholar] [CrossRef]

- Arvanitidis, J.; Papagelis, K.; Margadonna, S.; Prassides, K.; Fitch, A.N. Temperature-induced valence transition and associated lattice collapse in samarium fulleride. Nature 2003, 425, 599–602. [Google Scholar] [CrossRef]

- Sigmund, O.; Torquato, S. Composites with extremal thermal expansion coefficients. Appl. Phys. Lett. 1996, 69, 3203–3205. [Google Scholar] [CrossRef]

- Oruganti, R.K.; Ghosh, A.K.; Mazumder, J. Thermal expansion behavior in fabricated cellular structures. Mater. Sci. Eng. A 2004, 371, 24–34. [Google Scholar] [CrossRef]

- Aboudi, J.; Gilat, R. Micromechanical analysis of lattice blocks. Int. J. Solids Struct. 2005, 42, 4372–4392. [Google Scholar] [CrossRef]

- Lim, T.C. Anisotropic and negative thermal expansion behavior in a cellular microstructure. J. Mater. Sci. 2005, 40, 3275–3277. [Google Scholar] [CrossRef]

- Miller, W.; Mackenzie, D.S.; Smith, C.W.; Evans, K.E. A generalised scale-independent mechanism for tailoring of thermal expansivity: Positive and negative. Mech. Mater. 2008, 40, 351–361. [Google Scholar] [CrossRef]

- Steeves, C.A.; Lucato, S.L.D.S.; He, M.; Antinucci, E.; Hutchinson, J.W.; Evans, A.G. Concepts for structurally robust materials that combine low thermal expansion with high stiffness. J. Mech. Phys. Solids 2007, 55, 1803–1822. [Google Scholar] [CrossRef] [Green Version]

- Steeves, C.A.; Mercer, C.; Antinucci, E.; He, M.Y.; Evans, A.G. Experimental investigation of the thermal properties of tailored expansion lattices. Int. J. Mech. Mater. Des. 2009, 5, 195–202. [Google Scholar] [CrossRef] [Green Version]

- Wei, K.; Chen, H.; Pei, Y.; Fang, D. Planar lattices with tailorable coefficient of thermal expansion and high stiffness based on dual-material triangle unit. J. Mech. Phys. Solids 2016, 86, 173–191. [Google Scholar] [CrossRef]

- Wei, K.; Peng, Y.; Qu, Z.; Pei, Y.; Fang, D. A cellular metastructure incorporating coupled negative thermal expansion and negative Poisson’s ratio. Int. J. Solids Struct. 2018, 150, 255–267. [Google Scholar] [CrossRef]

- Timoshenko, S. Analysis of bi-metal thermostats. J. Opt. Soc. Am. Rev. Sci. Instrum. 1925, 11, 233–255. [Google Scholar] [CrossRef]

- Lehman, J.; Lakes, R. Stiff lattices with zero thermal expansion. J. Intell. Mater. Syst. Struct. 2012, 23, 1263–1268. [Google Scholar] [CrossRef]

- Lehman, J.; Lakes, R. Stiff lattices with zero thermal expansion and enhanced stiffness via rib cross section optimization. Int. J. Mech. Mater. Des. 2013, 9, 213–225. [Google Scholar] [CrossRef]

- Lakes, R. Cellular solids with tunable positive or negative thermal expansion of unbounded magnitud. Appl. Phys. Lett. 2007, 90, 221905. [Google Scholar] [CrossRef]

- Lakes, R. Cellular solid structures with unbounded thermal expansion. J. Mater. Sci. Lett. 1996, 15, 475–477. [Google Scholar] [CrossRef]

- Jefferson, G.; Parthasarathy, T.A.; Kerans, R.J. Tailorable thermal expansion hybrid structures. Int. J. Solid Struct. 2009, 46, 2372–2387. [Google Scholar] [CrossRef]

- Kelly, A.; McCartney, L.N.; Clegg, W.J.; Stearn, R.J. Controlling thermal expansion to obtain negative expansivity using laminated composites. Compos. Sci. Technol. 2005, 65, 47–59. [Google Scholar] [CrossRef]

- Wei, K.; Peng, Y.; Wang, K.; Duan, S.; Yang, X.; Wen, W. Three dimensional lightweight lattice structures with large positive, zero and negative thermal expansion. Compos. Struct. 2018, 188, 287–296. [Google Scholar] [CrossRef]

- Rhein, R.K.; Novak, M.D.; Levi, C.G.; Pollock, T.M. Bimetallic low thermal-expansion panels of Co-base and silicide-coated Nb-base alloys for high-temperature structural applications. Mater. Sci. Eng. A 2011, 528, 3973–3980. [Google Scholar] [CrossRef]

- Ng, C.K.; Saxena, K.K.; Das, R.; Flores, E.S. On the anisotropic and negative thermal expansion from dual-material re-entrant-type cellular metamaterials. J. Mater. Sci. 2016, 52, 899–912. [Google Scholar] [CrossRef]

- Ai, L.; Gao, X.L. Metamaterials with negative Poisson’s ratio and non-positive thermal expansion. Compos. Struct. 2017, 162, 70–84. [Google Scholar] [CrossRef]

- Wei, K.; Peng, Y.; Qu, Z.; Zhou, H.; Pei, Y.; Fang, D. Lightweight composite lattice cylindrical shells with novel character of tailorable thermal expansion. Int. J. Mech. Sci. 2018, 137, 77–85. [Google Scholar] [CrossRef]

- Lim, T.C. Negative thermal expansion structures constructed from positive thermal expansion trusses. J. Mater. Sci. 2011, 47, 368–373. [Google Scholar] [CrossRef]

- Lehman, J.; Lakes, R. Stiff, strong, zero thermal expansion lattices via material hierarchy. Compos. Struct. 2014, 107, 654–663. [Google Scholar] [CrossRef]

- Wang, Q.; Jackson, J.A.; Ge, Q.; Hopkins, J.B.; Spadaccini, C.M.; Fang, N.X. Lightweight mechanical metamaterials with tunable negative thermal expansion. Phys. Rev. Lett. 2016, 117, 175901. [Google Scholar] [CrossRef]

- Parsons, E.M. Lightweight cellular metal composites with zero and tunable thermal expansion enabled by ultrasonic additive manufacturing: Modeling, manufacturing, and testing. Compos. Struct. 2019, 223, 110656. [Google Scholar] [CrossRef]

- Wei, K.; Peng, Y.; Wen, W.; Pei, Y.; Fang, D. Tailorable thermal expansion of lightweight and robust dual-constituent triangular lattice material. J. Appl. Mech. 2017, 84, 101006. [Google Scholar] [CrossRef]

- Xu, H.; Farag, A.; Pasini, D. Multilevel hierarchy in bi-material lattices with high specific stiffness and unbounded thermal expansion. Acta Mater. 2017, 134, 155–166. [Google Scholar] [CrossRef]

- Yan, M.G. Aluminium alloy. In China Aeronautical Materials Handbook, 2nd ed.; China Standard Press: Beijing, China, 2001; Volume 3, pp. 308–318. [Google Scholar]

- Yan, M.G. Titanium alloy. In China Aeronautical Materials Handbook, 2nd ed.; China Standard Press: Beijing, China, 2001; Volume 4, pp. 8–18. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, W.; Xue, S.; Zhang, M.; Zhao, C.; Li, G. Bi-Material Negative Thermal Expansion Inverted Trapezoid Lattice based on A Composite Rod. Materials 2019, 12, 3379. https://doi.org/10.3390/ma12203379

Luo W, Xue S, Zhang M, Zhao C, Li G. Bi-Material Negative Thermal Expansion Inverted Trapezoid Lattice based on A Composite Rod. Materials. 2019; 12(20):3379. https://doi.org/10.3390/ma12203379

Chicago/Turabian StyleLuo, Weipeng, Shuai Xue, Meng Zhang, Cun Zhao, and Guoxi Li. 2019. "Bi-Material Negative Thermal Expansion Inverted Trapezoid Lattice based on A Composite Rod" Materials 12, no. 20: 3379. https://doi.org/10.3390/ma12203379

APA StyleLuo, W., Xue, S., Zhang, M., Zhao, C., & Li, G. (2019). Bi-Material Negative Thermal Expansion Inverted Trapezoid Lattice based on A Composite Rod. Materials, 12(20), 3379. https://doi.org/10.3390/ma12203379