The Effect of Withdrawal Rate on Crystal Structure Perfection, Microstructure and Creep Resistance of Single Crystal Castings Made of CMSX-4 Nickel-Based Superalloy

Abstract

:1. Introduction

- -

- Strengthening of γ solid solution–Co, Cr, Mo, Re, Ru and W,

- -

- Forming precipitations of the strengthening phase γ’-Al, Ta and Ti.

2. Experimental

3. Results and Discussion

4. Conclusions

- Porosity has the greatest impact on the creep resistance of single crystal castings. Increased pore content leads to reduced creep resistance. Castings containing a large number of pores are broken after a shorter time.

- The withdrawal rate of castings in the employed range (1–7 mm/min) does not affect the crystal orientation. For each adopted withdrawal rate, the casting was obtained in the [001] crystal orientation (αz < 15°).

- There was no influence of withdrawal rate on the volume fraction of the γ’ phase. The volume fraction of this phase in “as-cast” CMSX-4 superalloy is close to approximately 60%.

- The value of the lattice parameter a0γ’ decreases with the increase in the withdrawal rate.

Author Contributions

Funding

Conflicts of Interest

References

- Reed, R.C. The Superalloys, Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Durand-Charre, M. The Microstructure of Superalloys; Gordon and Breach Science Publishers: London, UK, 2003. [Google Scholar]

- Szeliga, D.; Gancarczyk, K.; Ziaja, W. The Control of Solidification of Ni-Based Superalloy Single-Crystal Blade by Mold Design Modification using Inner Radiation Baffle. Adv. Eng. Mater. 2018, 20, 1700973. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Nowak, W.J.; Ochał, K.; Wierzba, P.; Gancarczyk, K.; Wierzba, B. Effect of Substrate Roughness on Oxidation Resistance of an Aluminized Ni-Base Superalloy. Metals 2019, 9, 782. [Google Scholar] [CrossRef]

- Zhu, Q.; Chen, G.; Wang, C.; Qin, H.; Zhang, P. Tensile Deformation and Fracture Behaviors of a Nickel-Based Superalloy via In Situ Digital Image Correlation and Synchrotron Radiation X-ray Tomography. Materials 2019, 12, 2461. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhu, Q.; Chen, G.; Qin, H.; Wang, C. Effect of Heat Treatment Process on Microstructure and Fatigue Behavior of a Nickel-Base Superalloy. Materials 2015, 8, 6179–6194. [Google Scholar] [CrossRef] [Green Version]

- Papadaki, C.; Li, W.; Korsunsky, A.M. On the Dependence of γ′ Precipitate Size in a Nickel-Based Superalloy on the Cooling Rate from Super-Solvus Temperature Heat Treatment. Materials 2018, 11, 1528. [Google Scholar] [CrossRef]

- Dai, H.J.; Dong, H.B.; D’Souza, N.; Gebelin, J.-C.; Reed, R.C.; Dong, H. Grain Selection in Spiral Selectors During Investment Casting of Single-Crystal Components: Part II. Numerical Modeling. Met. Mater. Trans. A 2011, 42, 3439–3446. [Google Scholar] [CrossRef]

- Dai, H.J.; Gebelin, J.-C.; D’Souza, N.; Brown, P.D.; Dong, H. Effect of spiral shape on grain selection during casting of single crystal turbine blades. Int. J. Cast Met. Res. 2009, 22, 54–57. [Google Scholar] [CrossRef]

- Brundidge, C.L.; van Drasek, D.; Wang, B.; Pollock, T.M. Structure refinement by a liquid metal cooling solidification process for single–crystal nickel-base superalloys. Metall. Mater. Trans. 2012, 43, 965–976. [Google Scholar] [CrossRef]

- Szeliga, D.; Ziaja, W.; Motyka, M.; Kubiak, K.; Sieniawski, J. Application of Inner Radiation Baffles in the Bridgman Process for Flattening the Temperature Profile and Controlling the Columnar Grain Structure of Directionally Solidified Ni-Based Superalloys. Materials 2019, 12, 935. [Google Scholar] [CrossRef]

- Ma, D.; Wang, F.; Wu, Q.; Bogner, S.; Bührig-Polaczek, A. Innovations in Casting Techniques for Single Crystal Turbine Blades of Superalloys. In Superalloys 2016; Wiley: Hoboken, NJ, USA, 2016; pp. 237–246. [Google Scholar]

- Epishin, A.I.; Link, T.; Noltze, G.; Svetlov, I.L.; Bokshtein, B.S.; Rodin, A.O.; Salivan-Neumann, R.; Öder, G. Diffusion processes in multicomponent nickel-base superalloy-nickel system. Phys. Met. Met. 2014, 115, 21–29. [Google Scholar] [CrossRef]

- Schulze, C.; Feller-Kniepmeier, M. Transmisson electron microscopy of phase composition and lattice misfit in the Re-containing nickel-base superalloy CMSX-10. Mater. Sci. Eng. A 2000, 281, 204–212. [Google Scholar] [CrossRef]

- Rappaz, M.; Gandin, C.-A.; Gandin, C.-A. Probabilistic modelling of microstructure formation in solidification processes. Acta Met. Mater. 1993, 41, 345–360. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Mackay, D. Estimation of the γ and γ’ lattice parameters in Nickel-base superalloys using neural network analysis. ISIJ Int. 1998, 38, 495–502. [Google Scholar]

- Vehn, M.; Dedecke, D.; Paul, U.; Sahm, P. Undercooling Related Casting Defects in Single Crystal Turbine Blades. Superalloys 1996, 471–479. [Google Scholar]

- Kermanpur, A.; Rappaz, M.; Varahram, N.; Davami, P. Thermal and grain-structure simulation in a land-based turbine blade directionally solidified with the liquid metal cooling process. Met. Mater. Trans. A 2000, 31, 1293–1304. [Google Scholar] [CrossRef]

- Caron, P.; Khan, T. Evolution of Ni-based superalloys for single crystal gas turbine blade applications. Aerosp. Sci. Technol. 1999, 3, 513–523. [Google Scholar] [CrossRef]

- Szeliga, D.; Kubiak, K.; Burbelko, A.; Motyka, M.; Sieniawski, J. Modeling of directional solidification of columnar grain structure in CMSX-4 nickel-based superalloy castings. J. Mater. Eng. Perform. 2014, 23, 1088–1095. [Google Scholar] [CrossRef]

- Reed, R.; Matan, N.; Cox, D.; Rist, M.; Rae, C. Creep of CMSX-4 superalloy single crystals: Effects of rafting at high temperature. Acta Mater. 1999, 47, 3367–3381. [Google Scholar] [CrossRef]

- Albrecht, R.; Rak, J.; Bogdanowicz, W.; Gancarczyk, K.; Sieniawski, J.; Kubiak, K.; Lelątko, J. Effect of Creep on Crystallographic Orientation in Single Crystal Superalloy. Acta Phys. Pol. A 2016, 130, 1094–1096. [Google Scholar] [CrossRef]

- Le Graverend, J.-B.; Jacques, A.; Cormier, J.; Ferry, O.; Schenk, T.; Mendez, J. Creep of a nickel-based single-crystal superalloy during very high-temperature jumps followed by synchrotron X-ray diffraction. Acta Mater. 2015, 84, 65–79. [Google Scholar] [CrossRef]

- Völkl, R.; Glatzel, U.; Feller-Kniepmeier, M. Measurement of the lattice misfit in the single crystal nickel based superalloys CMSX-4, SRR99 and SC16 by convergent beam electron diffraction. Acta Mater. 1998, 46, 4395–4404. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Q. Simulation and Experimental Studies on Grain Selection and Structure Design of the Spiral Selector for Casting Single Crystal Ni-Based Superalloy. Materials 2017, 10, 1236. [Google Scholar] [CrossRef] [PubMed]

- Callister, W.; Rethwisch, D. Materials Science and Engineering an Introduction; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Okazaki, M.; Take, K.; Kakehi, K.; Yamazaki, Y.; Sakane, M.; Arai, M.; Sakurai, S.; Kaneko, H.; Harada, Y.; Itoh, A.; et al. Collaborative research on thermo-mechanical and isothermal low-cycle fatigue strength of ni-base superalloys and protective coatings at elevated temperatures in The Society of Materials Science, Japan (JSMS). In Thermomechanical Fatigue Behavior of Materials; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Ying, S.; Ma, L.; Sui, T.; Papadaki, C.; Salvati, E.; Brandt, L.R.; Zhang, H.; Korsunsky, A.M. Nanoscale Origins of the Size Effect in the Compression Response of Single Crystal Ni-Base Superalloy Micro-Pillars. Materials 2018, 11, 561. [Google Scholar] [CrossRef]

- Kang, M.; Gao, H.; Wang, J.; Ling, L.; Sun, B. Prediction of Microporosity in Complex Thin-Wall Castings with the Dimensionless Niyama Criterion. Materials 2013, 6, 1789–1802. [Google Scholar] [CrossRef] [Green Version]

- Szczotok, A.; Rzychoń, T.; Cwajna, J. Quantitative evaluation of y’phase in CMSX-4 superalloy. Inz. Mater. 2010, 31, 686–690. [Google Scholar]

- Łągiewka, E. Fundamentals of X-ray, Electron and Neutron Diffraction; Silesian University Press: Katowice, Poland, 2015. [Google Scholar]

- Yang, W.; Xu, M.; Bai, H.; Meng, Y.; Wang, L.; Shi, L.; Pei, Y.; Zhang, J.; Zheng, L. Concentration depth distribution of grain boundary segregation measured by wavelength dispersive X-ray spectroscopy. Ultramicroscopy 2015, 159, 432–437. [Google Scholar] [CrossRef]

- Frackowiak, J.E. Studies of B2 and DO3 Type Superstructures Using the Mössbauer Effect Method; Silesia University Press: Katowice, Poland, 1993. [Google Scholar]

- Gancarczyk, K.; Albrecht, R.; Berger, H.; Szeliga, D.; Gradzik, A.; Sieniawski, J. Determination of crystal orientation by Ω-scan method in nickel-based single crystal turbine blades. Metall. Mater. Trans. 2017, 48, 5200–5205. [Google Scholar] [CrossRef]

- Lamm, M.; Singer, R. The Effect of Casting Conditions on the High-Cycle Fatigue Properties of the Single-Crystal Nickel-Base Superalloy PWA 1483. Metall. Mater. Trans. 2007, 38, 1177–1183. [Google Scholar] [CrossRef]

- Guo, X.; Fu, H.; Sun, J. Influence of solid/liquid interfaces on the microstructure and stress-rupture life of the single-crystal nickel-base superalloy NASAIR 100. Metall. Mater. Trans. 1997, 28, 997–1009. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, G.; Wang, D.; Dong, J.; Wang, L.; Lou, L. Microstructure and Stress-Rupture Property of Large-Scale Complex Nickel-Based Single Crystal Casting. Acta Metall. Sin. 2018, 31, 887–896. [Google Scholar] [CrossRef] [Green Version]

| Element Content, % wt. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cr | Co | Mo | W | Ta | Al | Ti | Hf | Re | Ni |

| 6.5 | 9 | 0.6 | 6 | 6.5 | 5.6 | 1 | 0.1 | 3 | bal. |

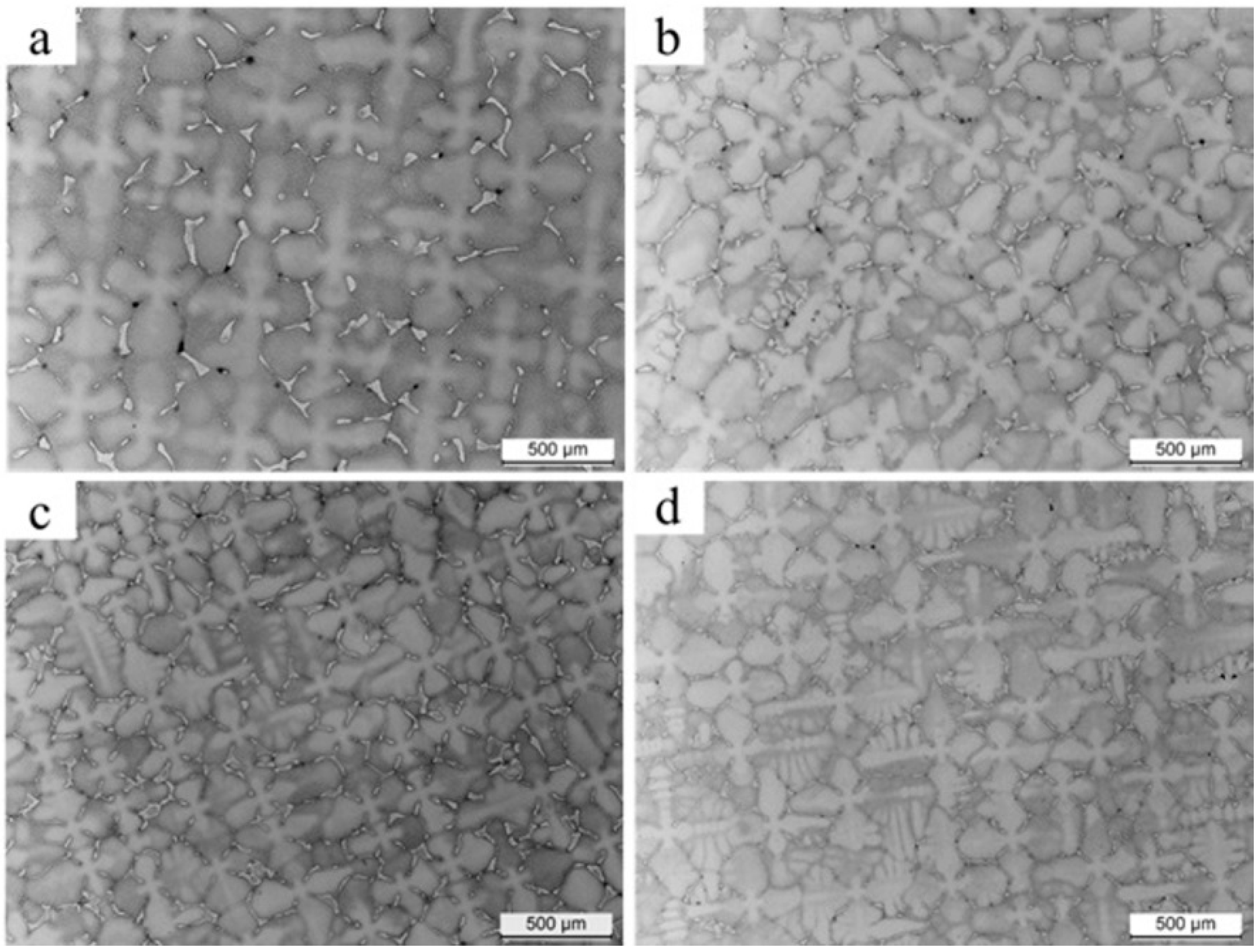

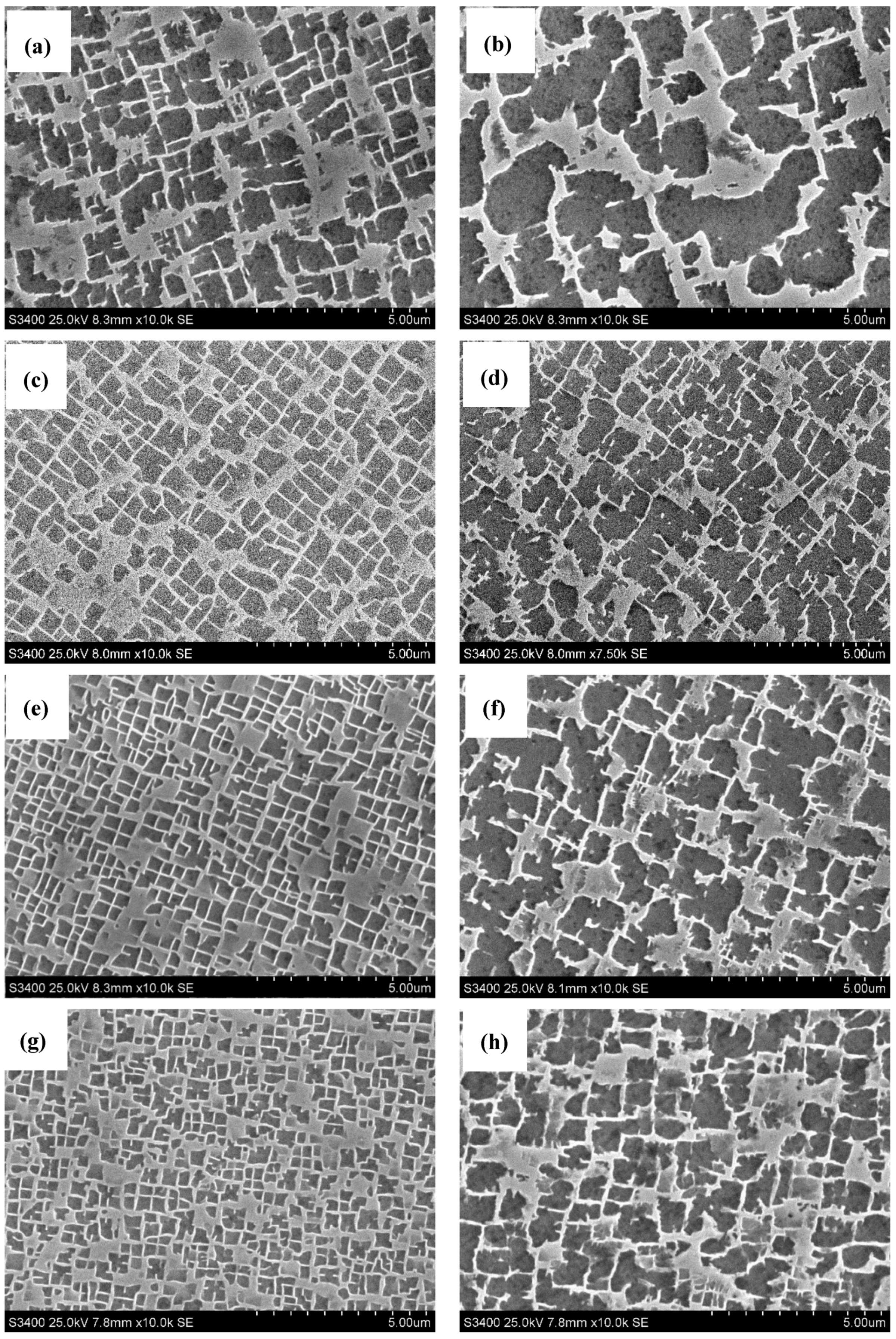

| Withdrawal Rate vw, mm/min | Relative Volume of γ’ Phases VVγ’, % | Surface Area of γ’ Phase Sγ’, μm2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Average | Dendritic | Interdendritic Region | Dendritic | Interdendritic Region | |||||

| Min | Max | Ave | Min | Max | Ave | ||||

| 1 | 61.1 (0.6) | 55.1 | 69.2 | 0.05 | 2.08 | 0.64 | 0.08 | 6.2 | 1.13 |

| 3 | 59.9 (2.0) | 54.8 | 65.8 | 0.09 | 1.0 | 0.31 | 0.09 | 4.1 | 0.55 |

| 5 | 64.6 (3.7) | 58.7 | 68.7 | 0.07 | 0.35 | 0.16 | 0.05 | 3.7 | 0.53 |

| 7 | 59.9 (11.1) | 60.1 | 65.2 | 0.02 | 0.38 | 0.09 | 0.05 | 3.4 | 0.46 |

| Withdrawal Rate vw, mm/min | |||||

|---|---|---|---|---|---|

| 1 | 3 | 5 | 7 | ||

| Elements content in γ’ phase, % at. (standard deviation) | Cr | 2.5 (0.5) | 2.3 (0.7) | 5.4 (2.8) | 3.2 (1.1) |

| Co | 7.3 (0.4) | 8.2 (0.5) | 10.09 (2.3) | 8.2 (0.8) | |

| Mo | 0.3 (0.2) | 0.3 (0.1) | 0.5 (0.2) | 0,1 (0.1) | |

| W | 0.9 (0.1) | 1.1 (0.1) | 3.5 (1.0) | 2,2 (0.4) | |

| Ta | 1.7 (0.2) | 1.5 (0.3) | 4.0 (1.3) | 5.4(0.5) | |

| Re | 0.3(0.1) | 0.2 (0.1) | 1.9(0.9) | 0.4 (0.1) | |

| Al | 10.6 (0.5) | 8.5 (1.4) | 3.7 (0.9) | 4.5(0.3) | |

| Ti | 1.1 (0.2) | 1.1 (0.15) | 0.7 (0.3) | 1.1 (0.2) | |

| Ni | 75.3 (1.0) | 76.2 (1.4) | 70.2 (4.9) | 75.1 (0.6) | |

| Al+Ta+Ti | 13.4 | 11.1 | 10.4 | 12.7 | |

| Withdrawal Rate vw, mm/min | Lattice Parameter a, nm (Standard Deviation) | |

|---|---|---|

| aγ | aγ’ | |

| 1 | 0.3563 (0.0005) | 0.3604 (0.0006) |

| 3 | 0.3571 (0.0012) | 0.3604 (0.0008) |

| 5 | 0.3568 (0.0004) | 0.3594 (0.0011) |

| 7 | 0.3564 (0.0008) | 0.3589 (0.0008) |

| Withdrawal Rate vw, mm/min | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 5 | 7 | ||||||||

| αz min | αz max | Δ αz | αz min | αz max | Δ αz | αz min | αz max | Δ αz | αz min | αz max | Δ αz |

| 5.7 | 9.6 | 3.9 | 7.0 | 8.3 | 1.3 | 4.9 | 6.3 | 1.4 | 5.1 | 7.6 | 2.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gancarczyk, K.; Zubko, M.; Hanc-Kuczkowska, A.; Kościelniak, B.; Albrecht, R.; Szeliga, D.; Motyka, M.; Ziaja, W.; Sieniawski, J. The Effect of Withdrawal Rate on Crystal Structure Perfection, Microstructure and Creep Resistance of Single Crystal Castings Made of CMSX-4 Nickel-Based Superalloy. Materials 2019, 12, 3422. https://doi.org/10.3390/ma12203422

Gancarczyk K, Zubko M, Hanc-Kuczkowska A, Kościelniak B, Albrecht R, Szeliga D, Motyka M, Ziaja W, Sieniawski J. The Effect of Withdrawal Rate on Crystal Structure Perfection, Microstructure and Creep Resistance of Single Crystal Castings Made of CMSX-4 Nickel-Based Superalloy. Materials. 2019; 12(20):3422. https://doi.org/10.3390/ma12203422

Chicago/Turabian StyleGancarczyk, Kamil, Maciej Zubko, Aneta Hanc-Kuczkowska, Barbara Kościelniak, Robert Albrecht, Dariusz Szeliga, Maciej Motyka, Waldemar Ziaja, and Jan Sieniawski. 2019. "The Effect of Withdrawal Rate on Crystal Structure Perfection, Microstructure and Creep Resistance of Single Crystal Castings Made of CMSX-4 Nickel-Based Superalloy" Materials 12, no. 20: 3422. https://doi.org/10.3390/ma12203422

APA StyleGancarczyk, K., Zubko, M., Hanc-Kuczkowska, A., Kościelniak, B., Albrecht, R., Szeliga, D., Motyka, M., Ziaja, W., & Sieniawski, J. (2019). The Effect of Withdrawal Rate on Crystal Structure Perfection, Microstructure and Creep Resistance of Single Crystal Castings Made of CMSX-4 Nickel-Based Superalloy. Materials, 12(20), 3422. https://doi.org/10.3390/ma12203422