Photocatalytic Activity and Mechanical Properties of Cements Modified with TiO2/N

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.3. Compressive and Flexural Strength Measurements

2.4. Setting Time (Vicat Needle Test)

2.5. Hydration Heat Measurements

2.6. Zeta Potential Measurements

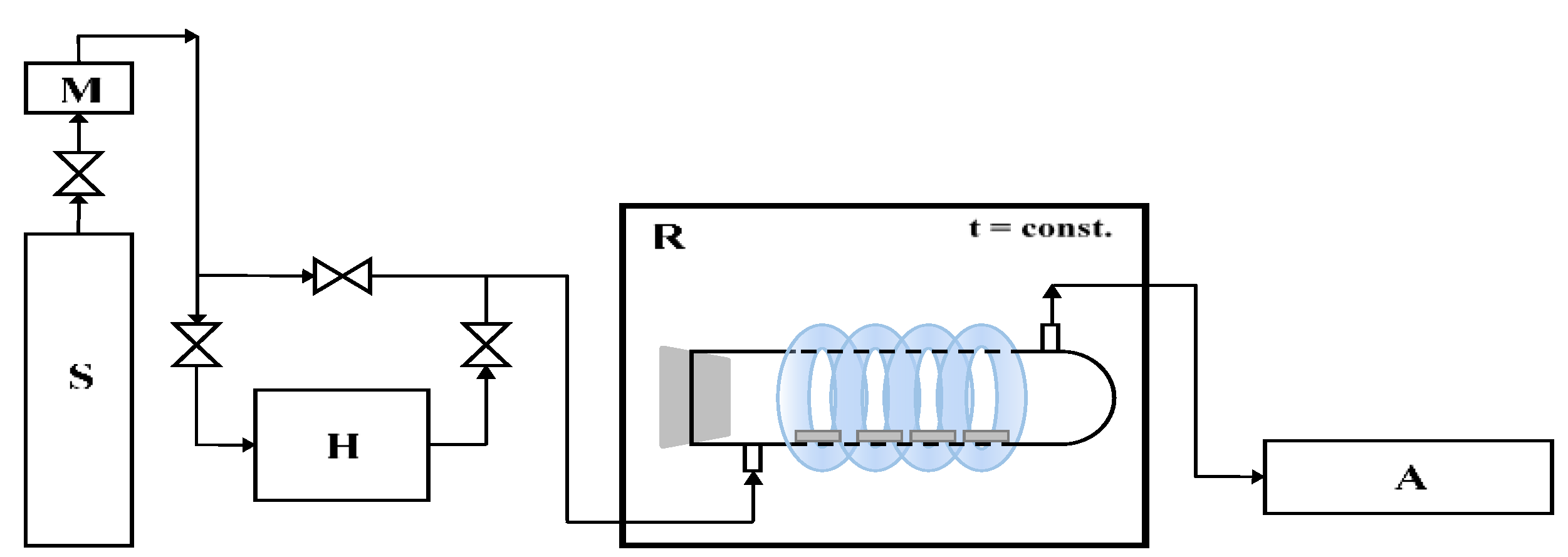

2.7. NOx Decomposition

3. Results

3.1. Compressive and Flexural Strength

3.2. Setting Time

3.3. Hydration Heat

3.4. Zeta Potential Measurements

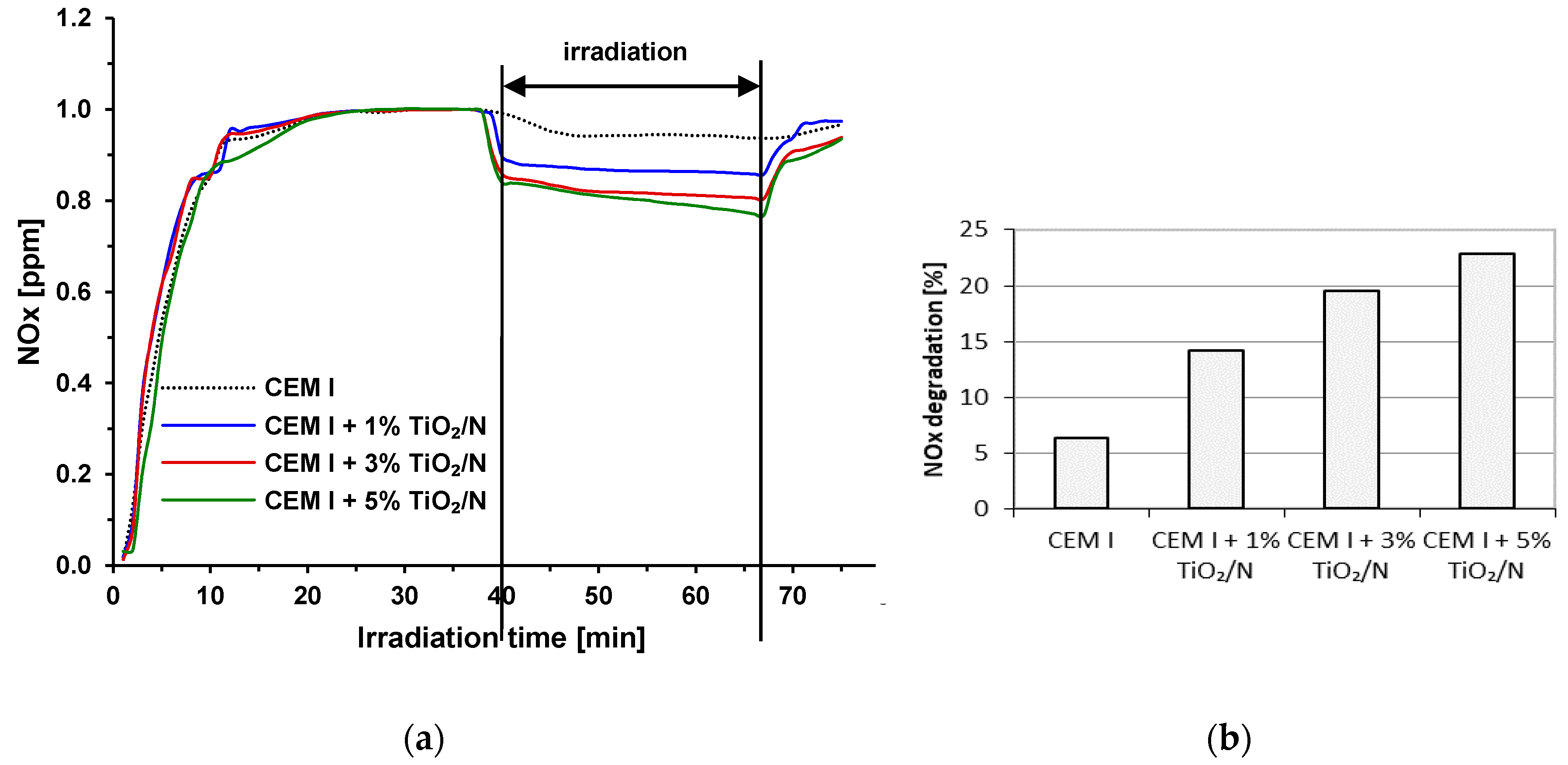

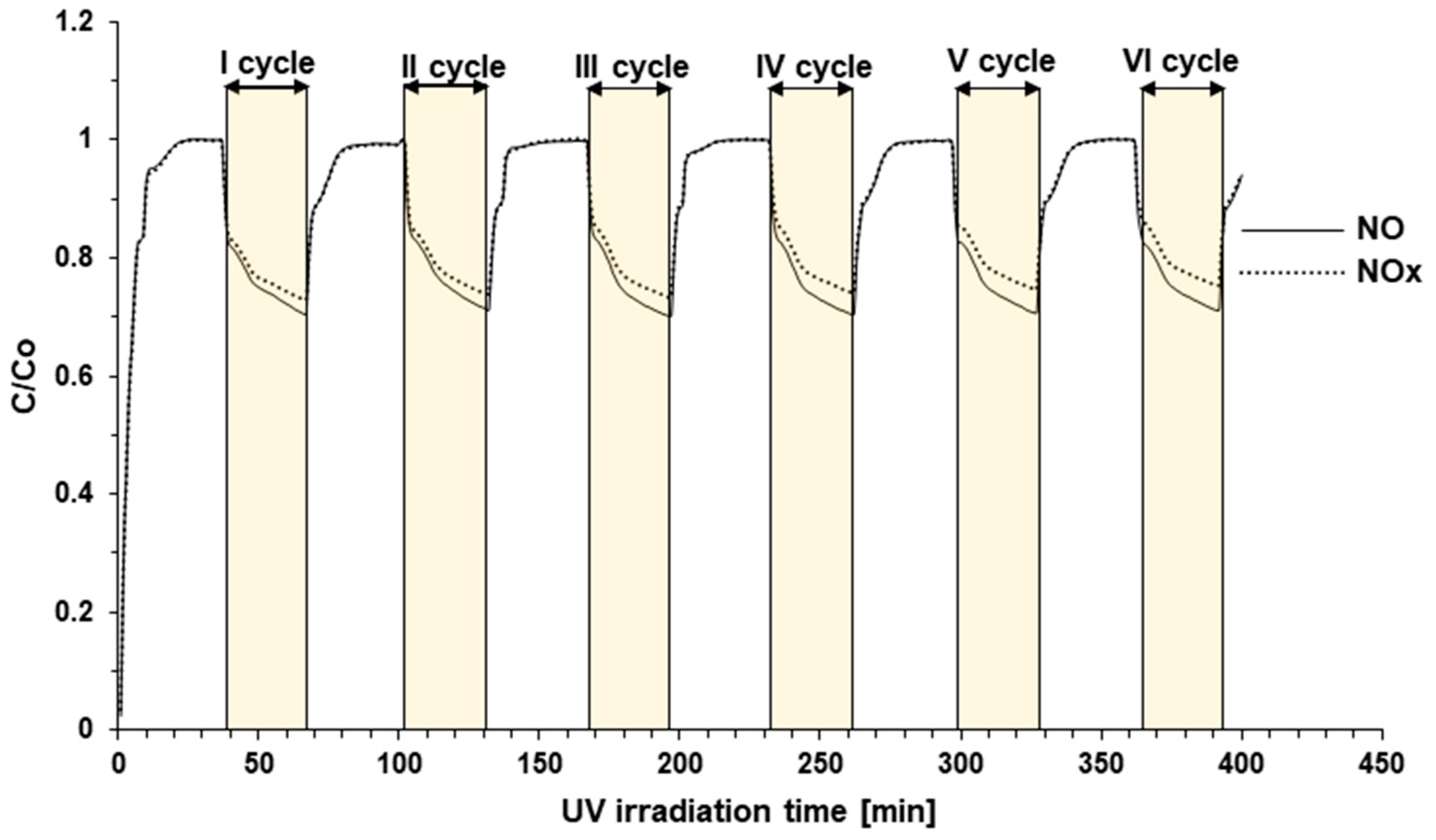

3.5. NOx Decomposition

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar] [CrossRef]

- Stein, H.; Stevels, J. Influence of silica on the hydration of 3 CaO, SiO2. J. Appl. Chem. 1964, 14, 338–346. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Ou, J.-P. A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.-G.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. Controlling cement hydration with nanoparticles. Cem. Concr. Compos. 2015, 57, 64–67. [Google Scholar] [CrossRef]

- Karapati, S.; Giannakopoulou, T.; Todorova, N.; Boukos, N.; Antiohos, S.; Papageorgiou, D.; Chaniotakis, E.; Dimotikali, D.; Trapalis, C. TiO2 functionalization for efficient NOx removal in photoactive cement. Appl. Surf. Sci. 2014, 319, 29–36. [Google Scholar] [CrossRef]

- Macphee, D.E.; Folli, A. Photocatalytic concretes—The interface between photocatalysis and cement chemistry. Cem. Concr. Res. 2016, 85, 48–54. [Google Scholar] [CrossRef]

- Lucas, S.S.; Ferreira, V.M.; de Aguiar, J.B. Incorporation of titanium dioxide nanoparticles in mortars—Influence of microstructure in the hardened state properties and photocatalytic activity. Cem. Concr. Res. 2013, 43, 112–120. [Google Scholar] [CrossRef]

- Cárdenas, C.; Tobón, J.I.; García, C.; Vila, J. Functionalized building materials: Photocatalytic abatement of NOx by cement pastes blended with TiO2 nanoparticles. Constr. Build. Mater. 2012, 36, 820–825. [Google Scholar] [CrossRef]

- Seo, D.; Yun, T.S. NOx removal rate of photocatalytic cementitious materials with TiO2 in wet condition. Build. Environ. 2017, 112, 233–240. [Google Scholar] [CrossRef]

- Yang, L.; Hakki, A.; Wang, F.; Macphee, D.E. Photocatalyst efficiencies in concrete technology: The effect of photocatalyst placement. Appl. Catal. B Environ. 2018, 222, 200–208. [Google Scholar] [CrossRef]

- Guo, M.-Z.; Chen, J.; Xia, M.; Wang, T.; Poon, C.S. Pathways of conversion of nitrogen oxides by nano TiO2 incorporated in cement-based materials. Build. Environ. 2018, 144, 412–418. [Google Scholar] [CrossRef]

- Lee, B.Y.; Jayapalan, A.R.; Bergin, M.H.; Kurtis, K.E. Photocatalytic cement exposed to nitrogen oxides: Effect of oxidation and binding. Cem. Concr. Res. 2014, 60, 30–36. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, F.; Xu, W.; Cao, S.; Zhu, H. Recent progress in enhancing photocatalytic efficiency of TiO2-based materials. Appl. Catal. A Gen. 2015, 495, 131–140. [Google Scholar] [CrossRef]

- Agbe, H.; Nyankson, E.; Raza, N.; Dodoo-Arhin, D.; Chauhan, A.; Osei, G.; Kumar, V.; Kim, K.-H. Recent advances in photoinduced catalysis for water splitting and environmental applications. J. Ind. Eng. Chem. 2019, 72, 31–49. [Google Scholar] [CrossRef]

- Rimoldi, L.; Pargoletti, E.; Meroni, D.; Falletta, E.; Cerrato, G.; Turco, F.; Cappelletti, G. Concurrent role of metal (Sn, Zn) and N species in enhancing the photocatalytic activity of TiO2 under solar light. Catal. Today 2018, 313, 40–46. [Google Scholar] [CrossRef]

- Li, Z.; Ding, S.; Yu, X.; Han, B.; Ou, J. Multifunctional cementitious composites modified with nano titanium dioxide: A review. Compos. Part A Appl. Sci. Manuf. 2018, 111, 115–137. [Google Scholar] [CrossRef]

- Rahim, A.; Nair, S.R. Influence of nano-materials in high strength concrete. J. Chem. Pharm. Sci. 2016, 974, 15–21. [Google Scholar]

- Han, B.; Li, Z.; Zhang, L.; Zeng, S.; Yu, X.; Han, B.; Ou, J. Reactive powder concrete reinforced with nano SiO2-coated TiO2. Constr. Build. Mater. 2017, 148, 104–112. [Google Scholar] [CrossRef]

- Yang, L.Y.; Jia, Z.J.; Zhang, Y.M.; Dai, J.G. Effects of nano-TiO2 on strength, shrinkage and microstructure of alkali activated slag pastes. Cem. Concr. Comp. 2015, 57, 1–7. [Google Scholar] [CrossRef]

- Jimenez-Relinque, E.; Rodriguez-Garcia, J.R.; Castillo, A.; Castellote, M. Characteristics and efficiency of photocatalytic cementitious materials: Type of binder, roughness and microstructure. Cem. Concr. Res. 2015, 71, 124–131. [Google Scholar] [CrossRef]

- Zhao, A.; Yang, J.; Yang, E.-H. Self-cleaning engineered cementitious composites. Cem. Concr. Comp. 2015, 64, 74–83. [Google Scholar] [CrossRef]

- Yousefi, A.; Allahverdi, A.; Hejazi, P. Effective dispersion of nano-TiO2 powder for enhancement of photocatalytic properties in cement mixes. Constr. Build. Mater. 2013, 41, 224–230. [Google Scholar] [CrossRef]

- Lowke, D.; Gehlen, C. The zeta potential of cement and additions in cementitious suspensions with high solid fraction. Cem. Concr. Res. 2017, 95, 195–204. [Google Scholar] [CrossRef]

- Plank, J.; Hirsch, C. Impact of zeta potential of early cement hydration phases on superplasticizer adsorption. Cem. Concr. Res. 2007, 37, 537–542. [Google Scholar] [CrossRef]

- Jennings, H.M. Refinements to colloid model of C-S-H in cement: CM-II. Cem. Concr. Res. 2008, 38, 275–289. [Google Scholar] [CrossRef]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Chen, J.; Kou, S.C.; Poon, C.S. Hydration and properties of nano-TiO2 blended cement composites. Cem. Concr. Comp. 2012, 34, 642–649. [Google Scholar] [CrossRef]

- Zhang, R.; Cheng, X.; Hou, P.; Ye, Z. Influences of nano-TiO2 on the properties of cement-based materials: Hydration and drying shrinkage. Constr. Build. Mater. 2015, 81, 35–41. [Google Scholar] [CrossRef]

- Bubacz, K.; Choina, J.; Dolat, D.; Borowiak-Paleń, E.; Moszyński, D.; Morawski, A.W. Studies on nitrogen modified TiO2 photocatalyst prepared in different conditions. Mater. Res. Bull. 2010, 45, 1085–1091. [Google Scholar] [CrossRef]

- Zając, K.; Janus, M.; Kuźmiński, K.; Morawski, A.W. Preparation of gypsum building materials with photocatalytic properties. A strong emphasis on waste gypsum from flue gas desulfurization. Przemysł Chem. 2016, 95, 2222–2226. [Google Scholar]

- Janus, M.; Zając, K.; Ehm, C.; Stephan, D. Fast Method for Testing the Photocatalytic Performance of Modified Gypsum. Catalysts 2019, 9, 693–701. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H.; Gao, Y. Effect of TiO2 Nanoparticles on Physical and Mechanical Properties of Cement at Low Temperatures. Adv. Mater. Sci. Eng. 2018. [Google Scholar] [CrossRef] [Green Version]

- Praveenkumar, T.R.; Vijayalakshim, M.M.; Meddah, M.S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 2019, 217, 343–351. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The effect of TiO2 nanoparticles on water permeability and thermal and mechanical properties of high strength self-compacting concrete. Mater. Sci. Eng. A 2010, 528, 756–763. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The effects of TiO2 nanoparticles on physical, thermal and mechanical properties of concrete using ground granulated blast furnace slag as binder. Mater. Sci. Eng. A 2011, 528, 2085–2092. [Google Scholar] [CrossRef]

- Hernández-Rodríguez, M.J.; Santana Rodríguez, R.; Darias, R.; González Díaz, O.; Pérez Luzardo, J.M.; Doña Rodríguez, J.M.; Pulido Melián, E. Effect of TiO2 Addition on Mortars: Characterisation and Photoactivity. Appl. Sci. 2019, 9, 2598–2611. [Google Scholar] [CrossRef] [Green Version]

- Taylor, P.C.; Kosmatka, G.F.; Voigt, G.F. Integrated Materials and Constructions Practices for Concrete Pavement: A State-of-the-Practice Manual. 2006. Available online: https://intrans.iastate.edu/app/uploads/2018/03/imcp_manual_october2007.pdf (accessed on 15 June 2019).

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Mozia, S.; Bubacz, K.; Janus, M.; Morawski, A.W. Decomposition of 3-chlorophenol on nitrogen modified TiO2 photocatalysts. J. Hazard. Mater. 2012, 203, 128–136. [Google Scholar] [CrossRef]

- Zingg, A.; Winnefeld, F.; Holzer, L.; Pakusch, J.; Becker, S.; Gauckler, L.J. Adsorption of polyelectrolytes and its influence on the rheology, zeta potential, and microstructure of various cement and hydrate phases. Colloid Interface Sci. 2008, 323, 301–312. [Google Scholar] [CrossRef]

- Ballari, M.M.; Yu, Q.L.; Brouwers, H.J.H. Experimental study of the NO and NO2 degradation by photocatalytically active concrete. Catal. Today 2011, 161, 175–180. [Google Scholar] [CrossRef]

- Xu, M.; Bao, Y.; Wu, T.; Xia, T.; Clark, H.L.; Shi, H.; Li, V.C. Influence of TiO2 incorporation methods on NOx abatement in Engineered Cementitious Composites. Const. Build. Mater. 2019, 221, 375–383. [Google Scholar] [CrossRef]

| Photocatalyst | Local Mean Crystallite Size According to TEM [nm] | Global Mean Crystallite Size According to XRD [nm] | Mean Particle Size According to DLS (Dynamic Light Scattering) [nm] | SBET [m2/g] |

|---|---|---|---|---|

| TiO2/N | 6.1 | 10.8 | 167.6 | 235 |

| Materials | Mass of Used Materials [g] | ||

|---|---|---|---|

| 1% | 3% | 5% | |

| CEM I 42.5 N | 444.5 | 436.5 | 427.5 |

| TiO2/N | 4.5 | 13.5 | 22.5 |

| Standard sand | 1350 | 1350 | 1350 |

| Water | 180 | 180 | 180 |

| Samples | The Initial Setting Time [min] | The Final Setting Time [min] |

|---|---|---|

| CEM I 42.5N | 218 | 305 |

| CEM + 1 wt %TiO2/N | 217 | 310 |

| CEM + 3 wt %TiO2/N | 207 | 275 |

| CEM + 5 wt %TiO2/N | 178 | 248 |

| Sample | NO Removal [ppm] | NO2 Formation [ppm] | NOx Removal [ppm] |

|---|---|---|---|

| Photolysis | 0.023 | 0.013 | 0.010 |

| CEM I | 0.057 | 0.009 | 0.048 |

| CEM I + 1% TiO2/N | 0.141 | 0.030 | 0.111 |

| CEM I + 3% TiO2/N | 0.179 | 0.025 | 0.154 |

| CEM I + 5% TiO2/N | 0.211 | 0.032 | 0.179 |

| Sample | NO Removal [µg/cm2/h] | NO2 Formation [µg/cm2/h] | NOx Total Removal [µg/cm2/h] |

|---|---|---|---|

| Photolysis | 0.289 | 0.038 | 0.251 |

| CEM I | 0.315 | 0.091 | 0.224 |

| CEM I + 1% TiO2/N | 2.530 | 0.622 | 1.908 |

| CEM I + 3% TiO2/N | 3.145 | 0.496 | 2.649 |

| CEM I + 5% TiO2/N | 3.403 | 0.651 | 2.752 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janus, M.; Mądraszewski, S.; Zając, K.; Kusiak-Nejman, E.; Morawski, A.W.; Stephan, D. Photocatalytic Activity and Mechanical Properties of Cements Modified with TiO2/N. Materials 2019, 12, 3756. https://doi.org/10.3390/ma12223756

Janus M, Mądraszewski S, Zając K, Kusiak-Nejman E, Morawski AW, Stephan D. Photocatalytic Activity and Mechanical Properties of Cements Modified with TiO2/N. Materials. 2019; 12(22):3756. https://doi.org/10.3390/ma12223756

Chicago/Turabian StyleJanus, Magdalena, Szymon Mądraszewski, Kamila Zając, Ewelina Kusiak-Nejman, Antoni W. Morawski, and Dietmar Stephan. 2019. "Photocatalytic Activity and Mechanical Properties of Cements Modified with TiO2/N" Materials 12, no. 22: 3756. https://doi.org/10.3390/ma12223756

APA StyleJanus, M., Mądraszewski, S., Zając, K., Kusiak-Nejman, E., Morawski, A. W., & Stephan, D. (2019). Photocatalytic Activity and Mechanical Properties of Cements Modified with TiO2/N. Materials, 12(22), 3756. https://doi.org/10.3390/ma12223756