Extraordinary Room-Temperature Tensile Ductility of Pure Magnesium

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Characterization of Macrostructure after MAF

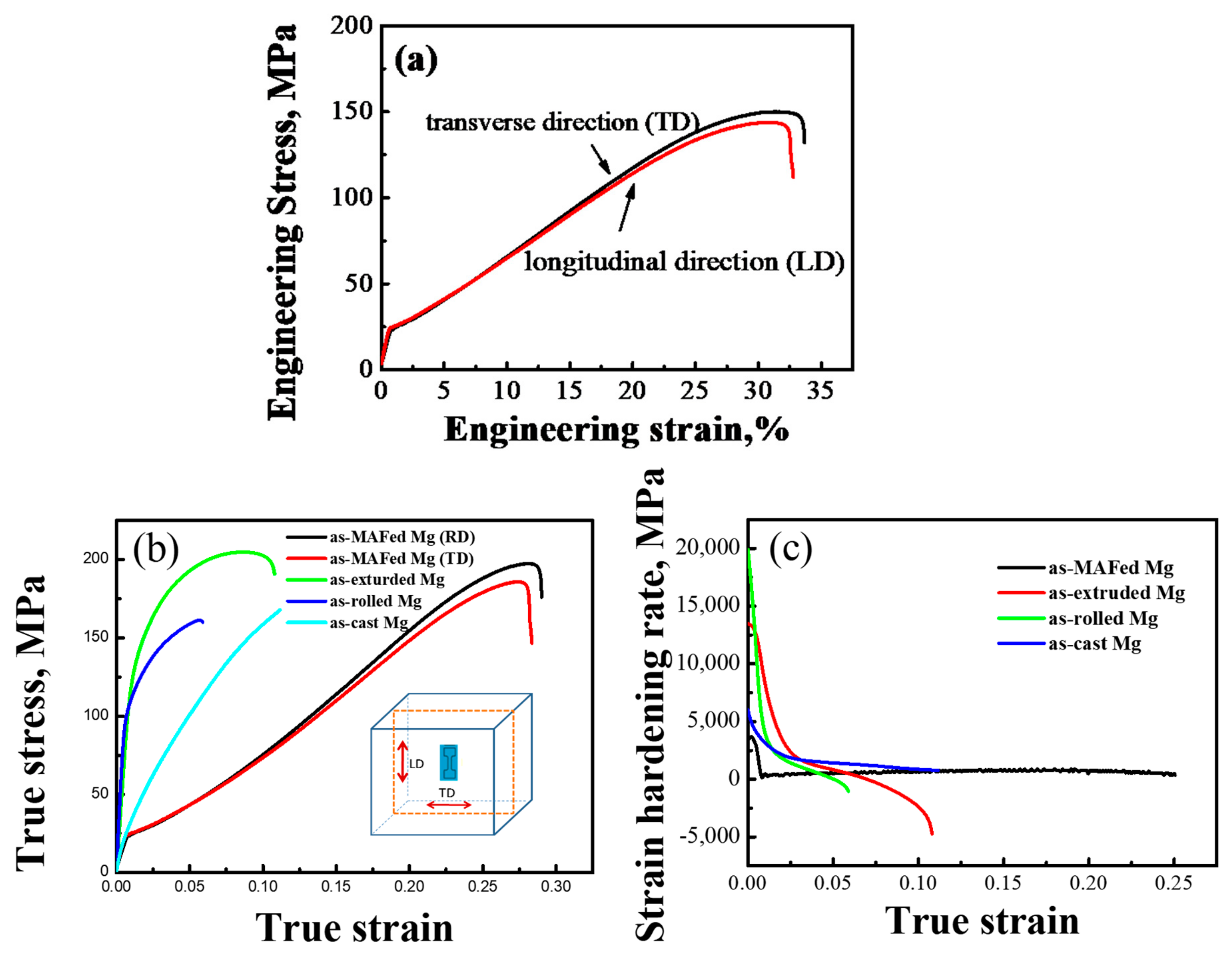

3.2. Tensile Behavior of as-MAFed Mg Samples at Room Temperature

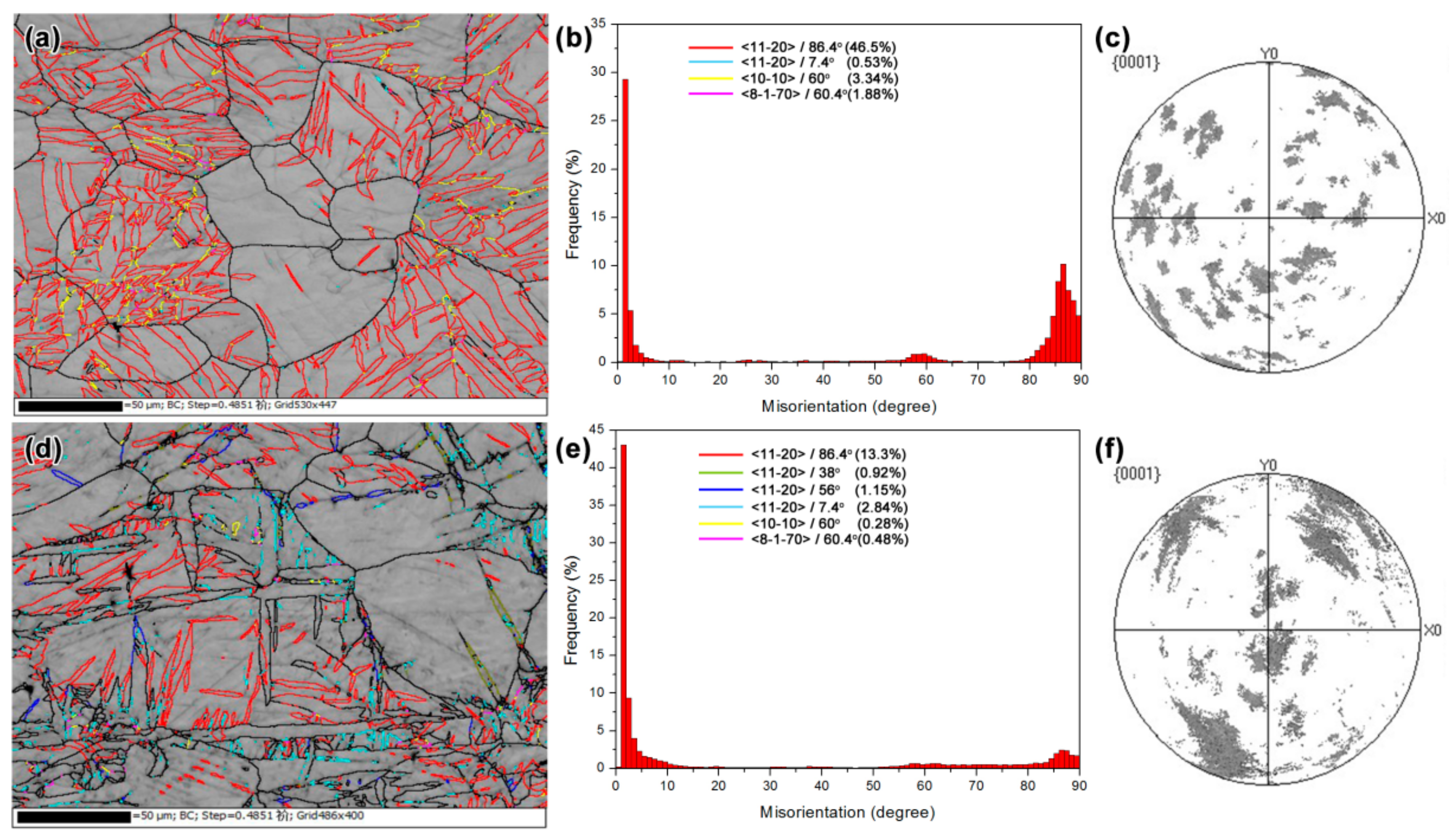

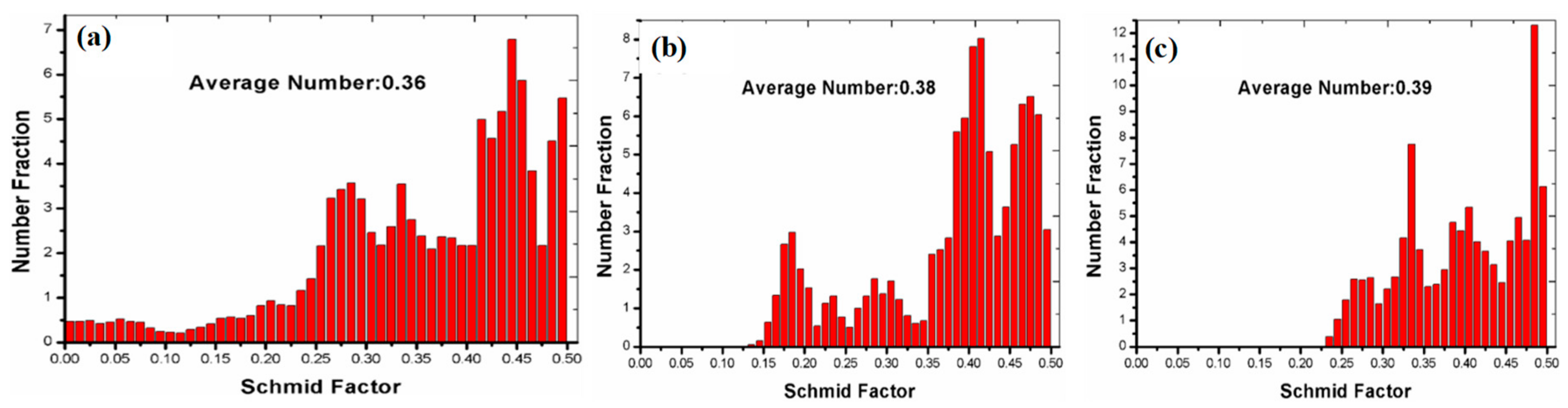

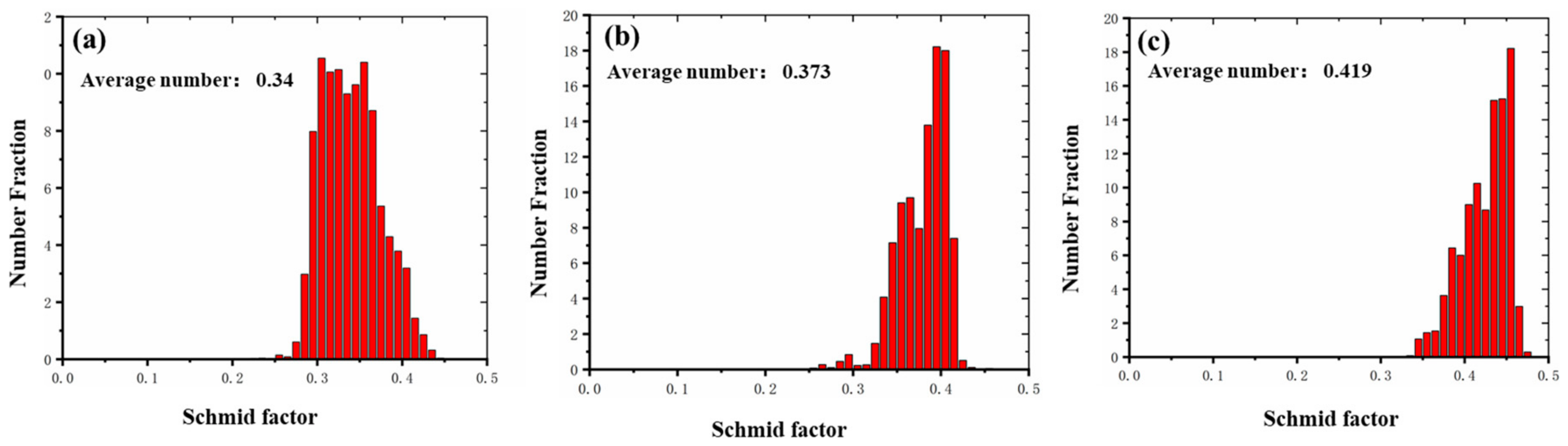

3.3. Characterization of Microstructural Evolution during Tension Process by EBSD

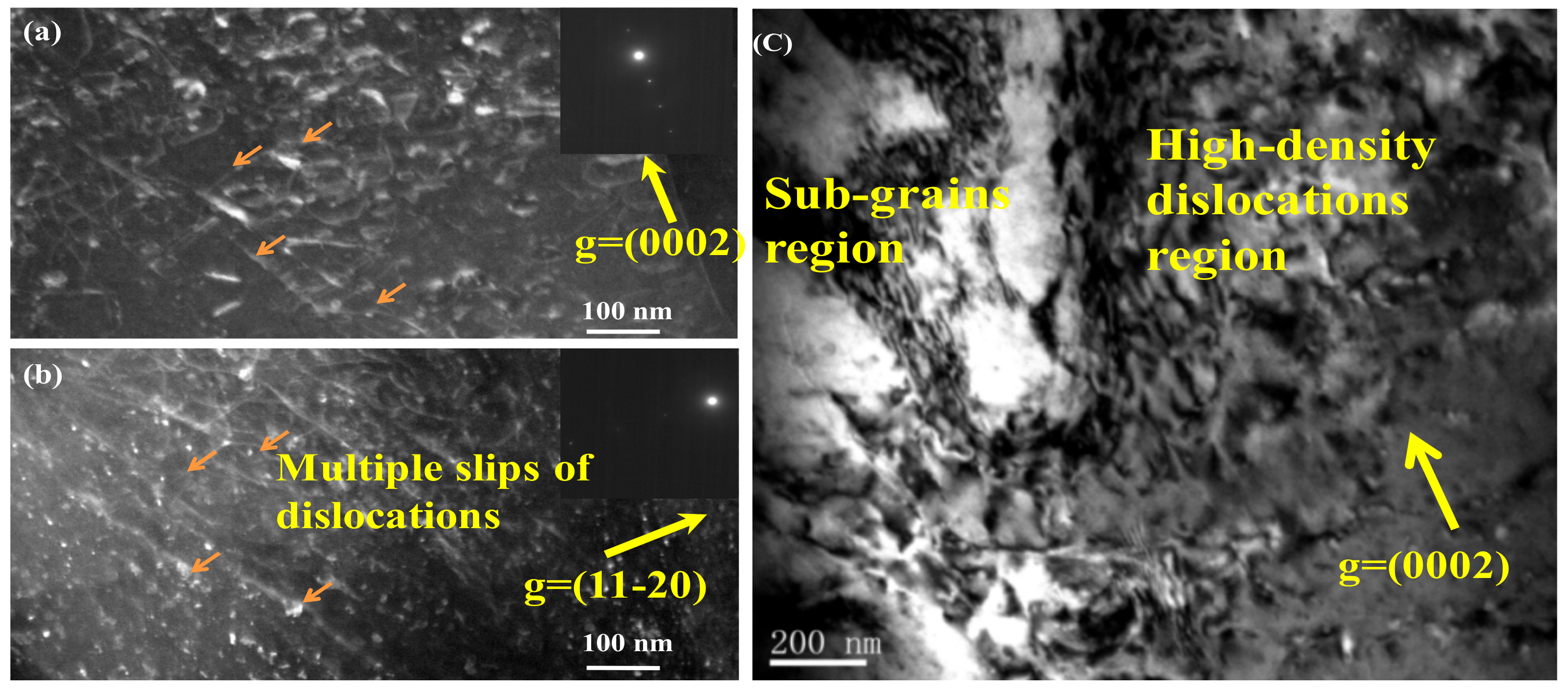

3.4. Characterization of Microstructural Evolution during Tension Process by TEM

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yu, Q.; Qi, L.; Mishra, R.K. Reducing deformation anisotropy to achieve ultrahigh strength and ductility in Mg at the nanoscale. Proc. Natl. Acad. Sci. USA 2013, 110, 13289–13293. [Google Scholar] [CrossRef] [PubMed]

- Luo, A.A. Recent magnesium alloy development for automotive powertrain applications. In Magnesium Alloys; Kojima, Y., Aizawa, T., Higashi, K., Kamado, S., Eds.; Pts 1 and 2; Trans Tech Publications Ltd.: Zurich-Uetikon, Switzerland, 2003; Volume 57. [Google Scholar]

- Groves, G.; Kelly, A. Independent slip systems in crystals. Philos. Mag. 1963, 8, 877–887. [Google Scholar] [CrossRef]

- Wonsiewicz, B.C.; Backofen, W.A. Plasticity of magnesium crystals. Trans. TMS AIME 1967, 239, 1422–1431. [Google Scholar]

- Nave, M.D.; Barnett, M.R. Microstructures and textures of pure magnesium deformed in plane-strain compression. Scr. Mater. 2004, 51, 881–885. [Google Scholar] [CrossRef]

- Yoo, M.H. Slip, twinning, and fracture in hexagonal close-packed metals. Metall. Trans. A 1981, 12, 409–418. [Google Scholar] [CrossRef]

- Yoo, M.H.; Morris, J.R.; Ho, K.M.; Agnew, S.R. Nonbasal deformation modes of HCP metals and alloys: Role of dislocation source and mobility. Metall. Mater. Trans. A 2002, 33, 813–822. [Google Scholar] [CrossRef]

- Price, P.B. Nonbasal Glide in Dislocation-Free Cadmium Crystals. II. The (112) [23] System. J. Appl. Phys. 1961, 32, 1750–1757. [Google Scholar] [CrossRef]

- Feaugas, X.; Clavel, M. Cyclic deformation behaviour of an α/β titanium alloy—I. Micromechanisms of plasticity under various loading paths. Acta Mater. 1997, 45, 2685–2701. [Google Scholar] [CrossRef]

- Agnew, S.R.; Yoo, M.H.; Tome’, C.N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta Mater. 2001, 49, 4277–4289. [Google Scholar] [CrossRef]

- Chino, Y.; Kado, M.; Mabuchi, M. Compressive deformation behavior at room temperature −773 K in Mg–0.2 mass% (0.035 at. %) Ce alloy. Acta Mater. 2008, 56, 387–394. [Google Scholar] [CrossRef]

- Chino, Y.; Kado, M.; Mabuchi, M. Enhancement of tensile ductility and stretch formability of magnesium by addition of 0.2 wt% (0.035 at%) Ce. Mater. Sci. Eng. A 2008, 284, 343–349. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Friák, S.M.; Zaefferer, S.; Dick, A.; Yi, S.; Letzig, D.; Pei, Z.; Zhu, L.F.; Neugebauer, J.; Raabe, D. The relation between ductility and stacking fault energies in Mg and Mg–Y alloys. Acta Mater. 2012, 60, 3011–3021. [Google Scholar] [CrossRef]

- Sandlobes, S.; Zaefferer, S.; Schestakow, I.; Yi, S.; Gonzalez-Martinez, R. On the role of non-basal deformation mechanisms for the ductility of Mg and Mg–Y alloys. Acta Mater. 2011, 59, 429–439. [Google Scholar] [CrossRef]

- Fan, G.D.; Zheng, M.Y.; Hu, X.S.; Xu, C.; Wu, K.; Golovin, I.S. Improved mechanical property and internal friction of pure Mg processed by ECAP. Mater. Sci. Eng. A 2012, 556, 588–594. [Google Scholar] [CrossRef]

- Obara, T.; Yoshiga, H.; Morozumi, S. {112} <1123> Slip system in magnesium. Acta Metall. 1973, 21, 845–853. [Google Scholar] [CrossRef]

- Koike, J.; Fujiyama, N.; Ando, D.; Sutou, Y. Roles of deformation twinning and dislocation slip in the fatigue failure mechanism of AZ31 Mg alloys. Scr. Mater. 2010, 63, 747–750. [Google Scholar] [CrossRef]

- Song, B.; Guo, N.; Liu, T.T.; Yang, Q.S. Improvement of formability and mechanical properties of magnesium alloys via pre-twinning: A review. Mater. Des. 2014, 62, 352–360. [Google Scholar] [CrossRef]

- Song, B. Study on the plastic deformation behavior and anisotropy of precipitation and twinning strengthening magnesium alloys. In Materials Science and Engineering; Chongqing University: Chongqing, China, 2013. [Google Scholar]

- Xin, Y.; Wang, M.; Zeng, Z.; Huang, G.; Liu, Q. Tailoring the texture of magnesium alloy by twinning deformation to improve the rolling capacity. Scr. Mater. 2011, 64, 986–989. [Google Scholar] [CrossRef]

- Dixit, N.; Xie, K.Y.; Hemker, K.J.; Ramesh, K.T. Microstructural evolution of pure magnesium under high strain rate loading. Acta Mater. 2015, 87, 56–67. [Google Scholar] [CrossRef]

- Miura, H.; Maruok, T.; Yang, X.; Jonas, J.J. Microstructure and mechanical properties of multi-directionally forged Mg–Al–Zn alloy. Scr. Mater. 2012, 66, 49–51. [Google Scholar] [CrossRef]

- Jiang, M.G.; Yan, H.; Chen, R.S. Enhanced mechanical properties due to grain refinement and texture modification in an AZ61 Mg alloy processed by small strain impact forging. Mater. Sci. Eng. A 2015, 621, 204–211. [Google Scholar] [CrossRef]

- Sarker, D.; Chen, D.L. Detwinning and strain hardening of an extruded magnesium alloy during compression. Scr. Mater. 2012, 67, 165–168. [Google Scholar] [CrossRef]

- Stanford, N.; Barnett, M.R. The origin of “rare earth” texture development in extruded Mg-based alloys and its effect on tensile ductility. Mater. Sci. Eng. A 2008, 496, 399–408. [Google Scholar] [CrossRef]

- Stanford, N.; Sha, G.; Xia, J.H.; Ringer, S.P.; Barnett, M.R. Solute segregation and texture modification in an extruded magnesium alloy containing gadolinium. Scr. Mater. 2011, 65, 919–921. [Google Scholar] [CrossRef]

- C´aceres, C.H.; Blake, A.H. On the strain hardening behavior of magnesium at room temperature. Mater. Sci. Eng. A 2007, 462, 193–196. [Google Scholar] [CrossRef]

- Yang, X.; Miura, H.; Sakai, T. Structural development at severely high strain in AZ31 magnesium alloy processed by cold forging and subsequent annealing. Mater. Des. 2013, 44, 573–579. [Google Scholar] [CrossRef]

- Kioke, J.; Koboyashi, T.; Mukai, T.; Watanabe, H.; Suzuki, M.; Muruyama, K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys. Acta Mater. 2003, 51, 2055–2065. [Google Scholar] [CrossRef]

- Valle, J.; Carren, F.; Ruano, O.A. Influence of texture and grain size on work hardening and ductility in magnesium-based alloys processed by ECAP and rolling. Acta Mater. 2006, 54, 4247–4259. [Google Scholar] [CrossRef]

- Agnew, S.R.; Duygulu, O. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Huchinson, W.B.; Barnett, M.R. Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other hcp metals. Scr. Mater. 2010, 63, 737–740. [Google Scholar] [CrossRef]

- Buey, D.; Ghazisaeidi, M. Atomistic simulation of < c + a > screw dislocation cross-slip in Mg. Scr. Mater. 2016, 17, 51–54. [Google Scholar] [CrossRef]

- Rohatgi, A.; Vecchio, K.S.; Gray, G.T., III. The influence of stacking fault energy on the mechanical behavior of Cu and Cu-Al alloys: Deformation twinning, work hardening, and dynamic recovery. Metall. Mater. Trans. A 2001, 32, 135–145. [Google Scholar] [CrossRef]

- Huang, H.L.; Wu, Y.; He, J.Y.; Wang, H.; Liu, X.J.; An, K.; Wu, W.; Lu, Z.P. Phase-Transformation ductilization of brittle high-entropy alloys via metastability engineering. Adv. Mater. 2017, 29, 1701678. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.J.; Kula, A.; Mishra, R.K.; Niewczas, M. Mechanical properties of Mg-Sc binary alloys under compression. Mater. Sci. Eng. A 2017, 692, 199–213. [Google Scholar] [CrossRef]

- Men, S.J.; Yua, H.; Zhang, H.X.; Cui, H.W.; Park, S.K.H.; Zhao, W.M.; You, B.S. Microstructure and mechanical properties of an extruded Mg-8Bi-1Al-1Zn (wt%) alloy. Mater. Sci. Eng. A 2017, 690, 80–87. [Google Scholar]

- Ma, R.; Zhao, Y.Q.; Wang, Y.N. Grain refinement and mechanical properties improvement of AZ31 Mg alloy sheet obtained by two-stage rolling. Mater. Sci. Eng. A 2017, 691, 81–87. [Google Scholar] [CrossRef]

- Wang, Q.H.; Jiang, B.; Tanga, A.; Ma, S.X.; Jiang, Z.T.; Chai, Y.F.; Liu, B.; Pan, F.S. Ameliorating the mechanical properties of magnesium alloy: Role of texture. Mater. Sci. Eng. A 2017, 689, 395–403. [Google Scholar] [CrossRef]

- Kula, A.; Jia, X.; Mishra, R.K.; Niewczas, M. Flow stress and work hardening of Mg-Y alloys. Int. J. Plast. 2017, 92, 96–121. [Google Scholar] [CrossRef]

- Bhattacharya, B.; Niewczas, M. Work-hardening behaviour of Mg single crystals oriented for basal slip. Philos. Mag. 2011, 91, 2227–2247. [Google Scholar] [CrossRef]

- Cácees, C.H.; Lukáč, P. Strain hardening behaviour and the Taylor factor of pure magnesium. Philos. Mag. 2008, 88, 977–989. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Sitdikov, O. Dynamic recrystallization of magnesium at ambient temperature. Z. Metallkd. 1994, 85, 738–743. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Chang, H.; Chen, C.; Huo, X.; Li, W.; Huang, J.C.; Duan, G.; Wu, B. Extraordinary Room-Temperature Tensile Ductility of Pure Magnesium. Materials 2019, 12, 3813. https://doi.org/10.3390/ma12233813

Du X, Chang H, Chen C, Huo X, Li W, Huang JC, Duan G, Wu B. Extraordinary Room-Temperature Tensile Ductility of Pure Magnesium. Materials. 2019; 12(23):3813. https://doi.org/10.3390/ma12233813

Chicago/Turabian StyleDu, Xinghao, Haitao Chang, Cai Chen, Xiaofeng Huo, Wanpeng Li, Jacob C. Huang, Guosheng Duan, and Baolin Wu. 2019. "Extraordinary Room-Temperature Tensile Ductility of Pure Magnesium" Materials 12, no. 23: 3813. https://doi.org/10.3390/ma12233813

APA StyleDu, X., Chang, H., Chen, C., Huo, X., Li, W., Huang, J. C., Duan, G., & Wu, B. (2019). Extraordinary Room-Temperature Tensile Ductility of Pure Magnesium. Materials, 12(23), 3813. https://doi.org/10.3390/ma12233813