Prediction of Electrical Conductivity of Fiber-Reinforced Cement-Based Composites by Deep Neural Networks

Abstract

:1. Introduction

2. Sample Preparation and Property Measurement

2.1. Preparation of CFRCs

2.1.1. Raw Materials

2.1.2. Specimen Preparation

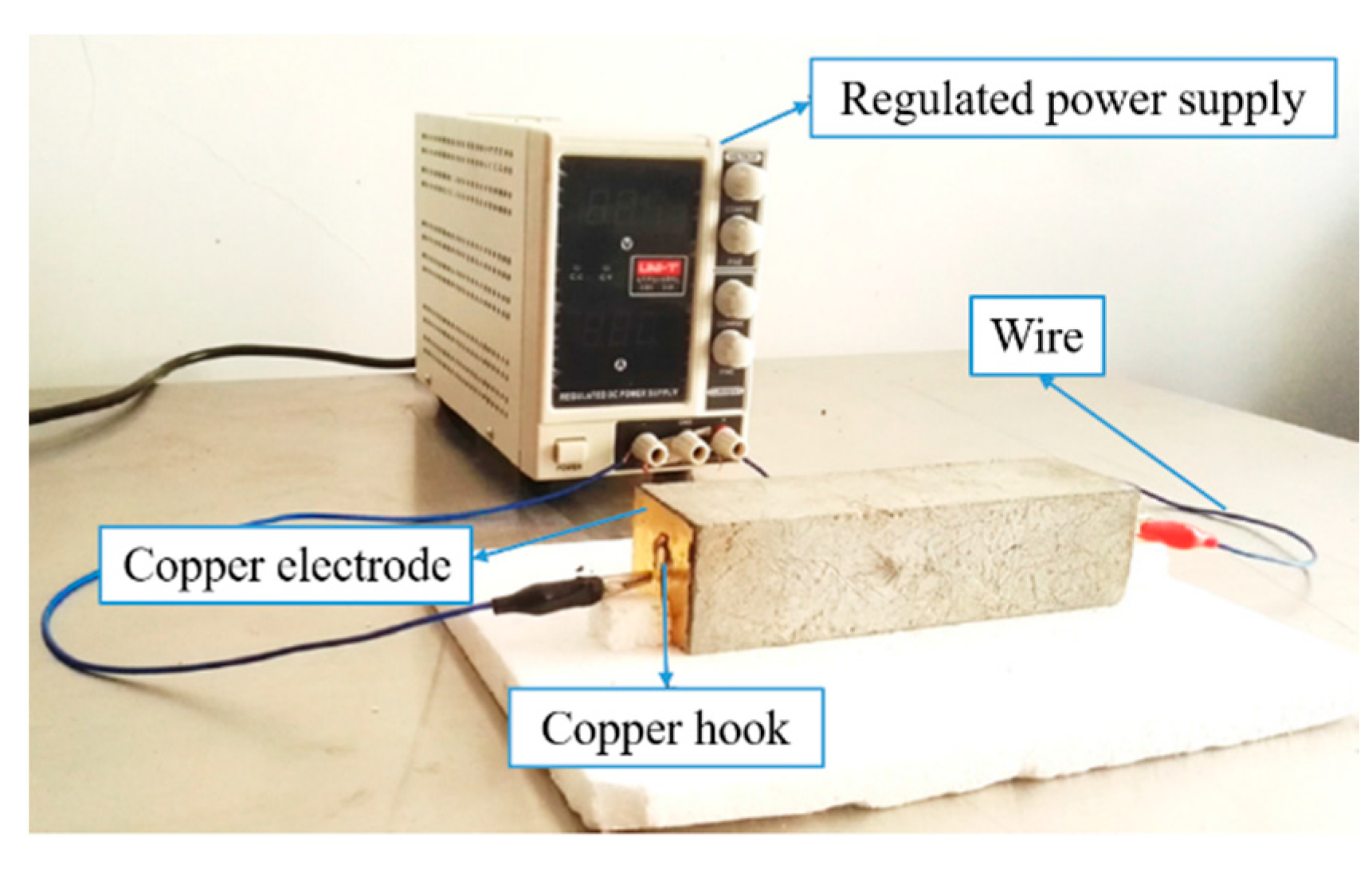

2.2. Electrical Conductivity Measurement

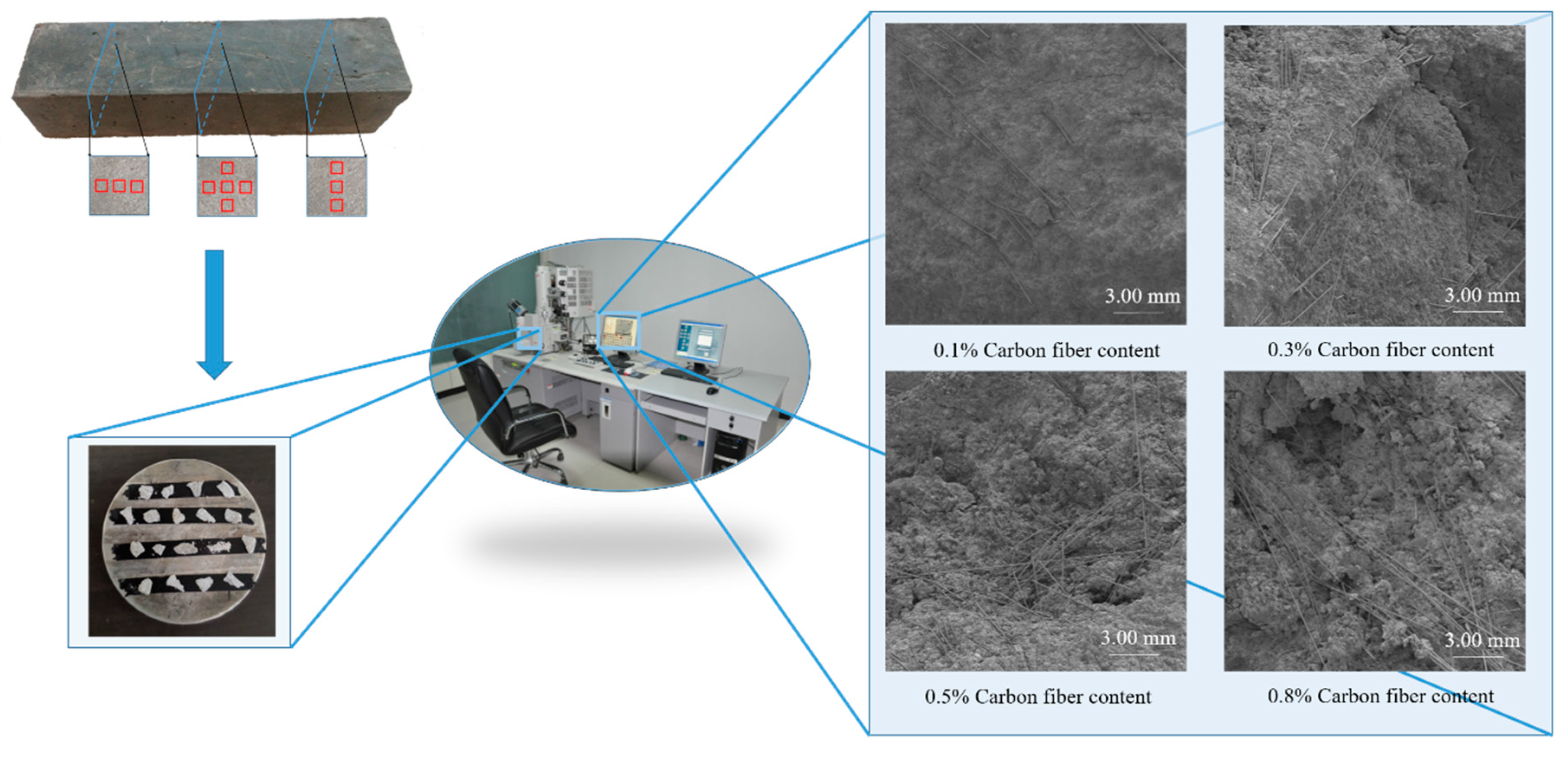

2.3. SEM Image Acquisition

3. Evaluation and Prediction Method Based on Deep Learning

3.1. Evaluation Method for CF Distribution

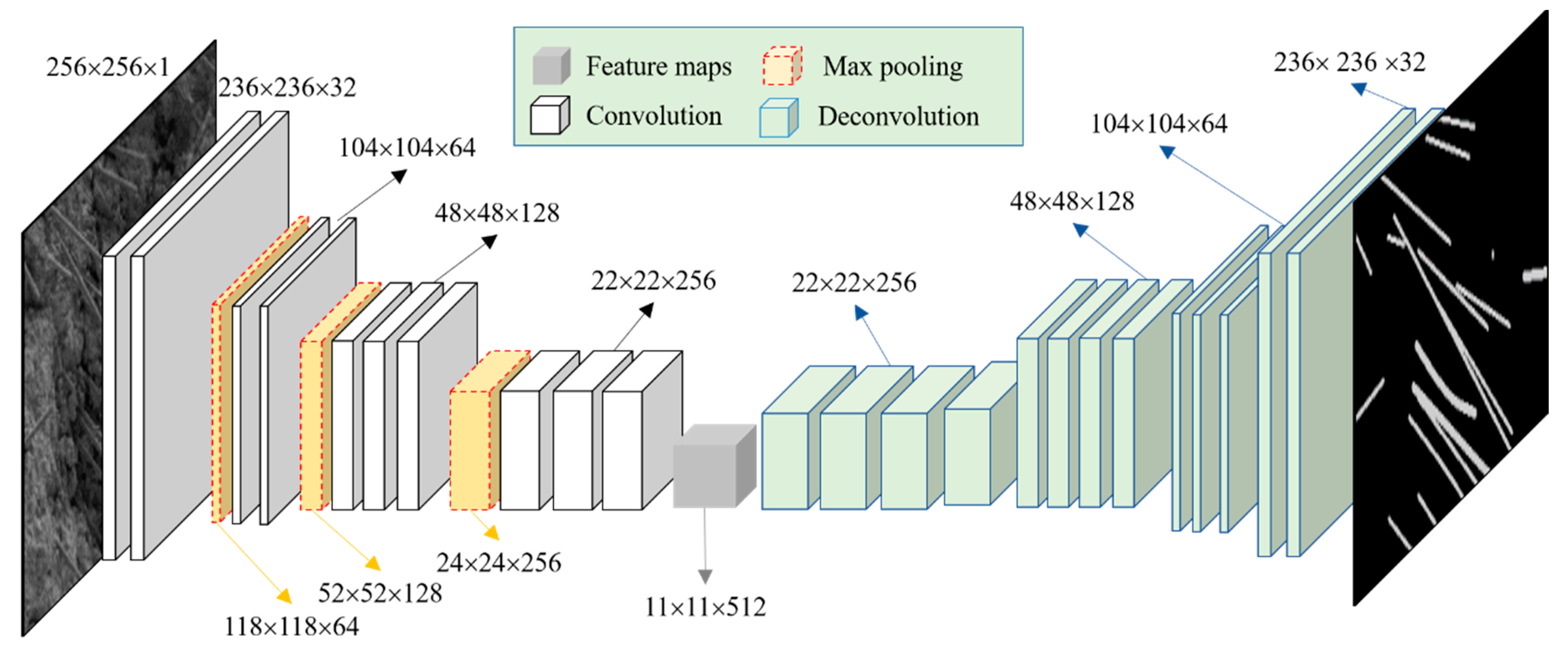

3.1.1. CF Segmentation

3.1.2. Evaluation of CF Distribution

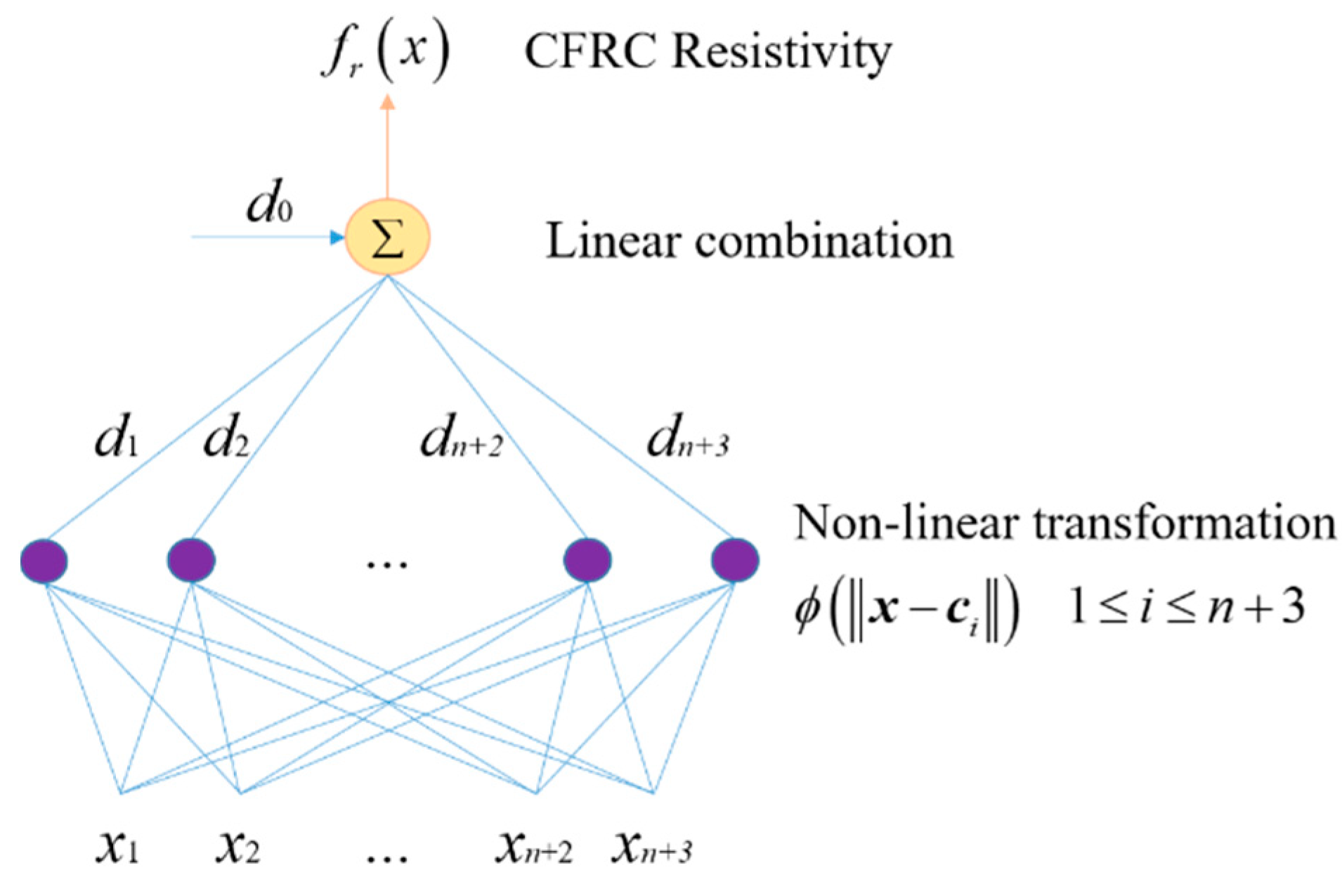

3.2. Electrical Conductivity Prediction Method

4. Results and Discussion

4.1. Performance of Evaluating CF Distribution

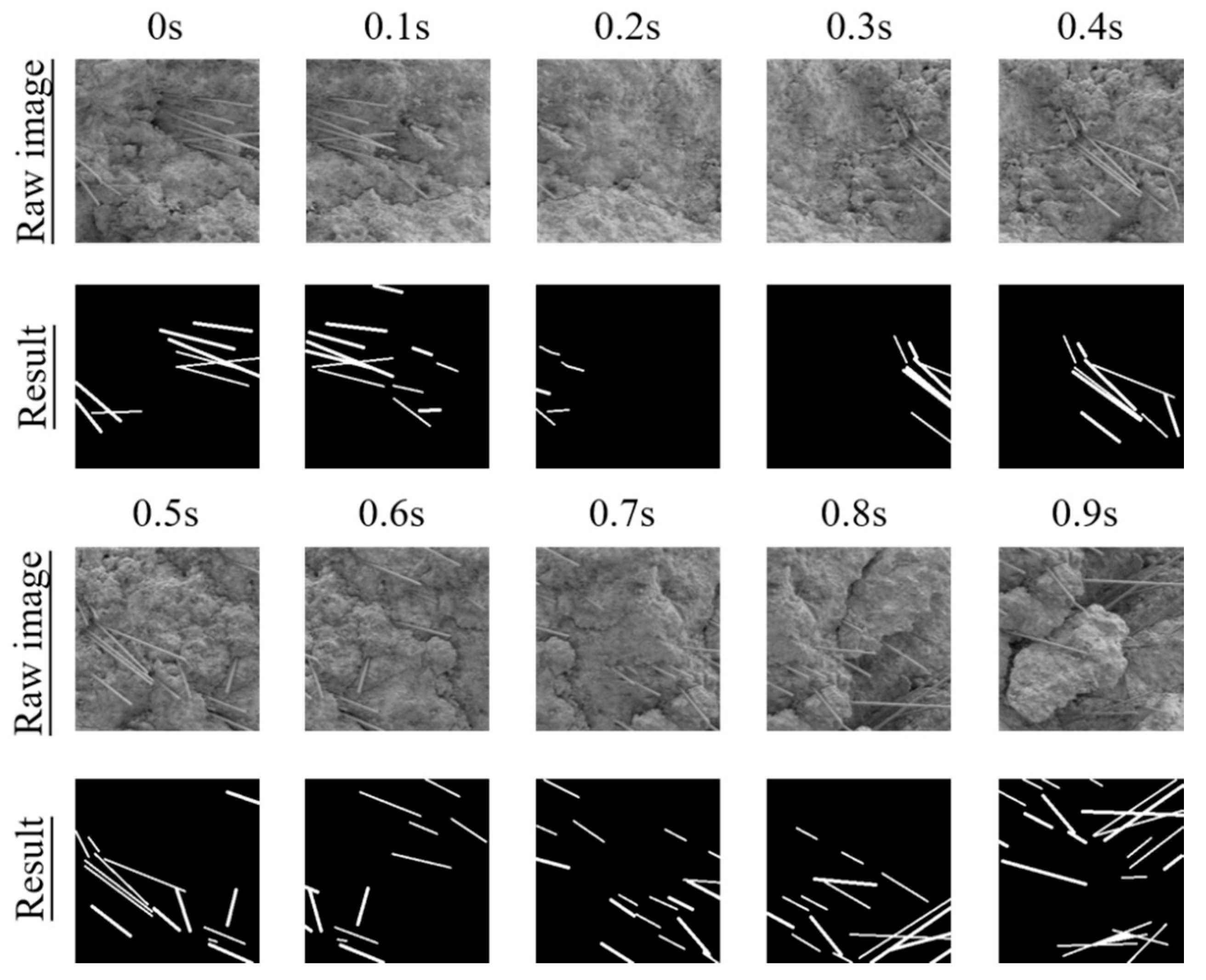

4.1.1. CF Segmentation Results

4.1.2. Distribution Evaluation Results

4.2. Analysis of Electrical Conductivity Prediction Results

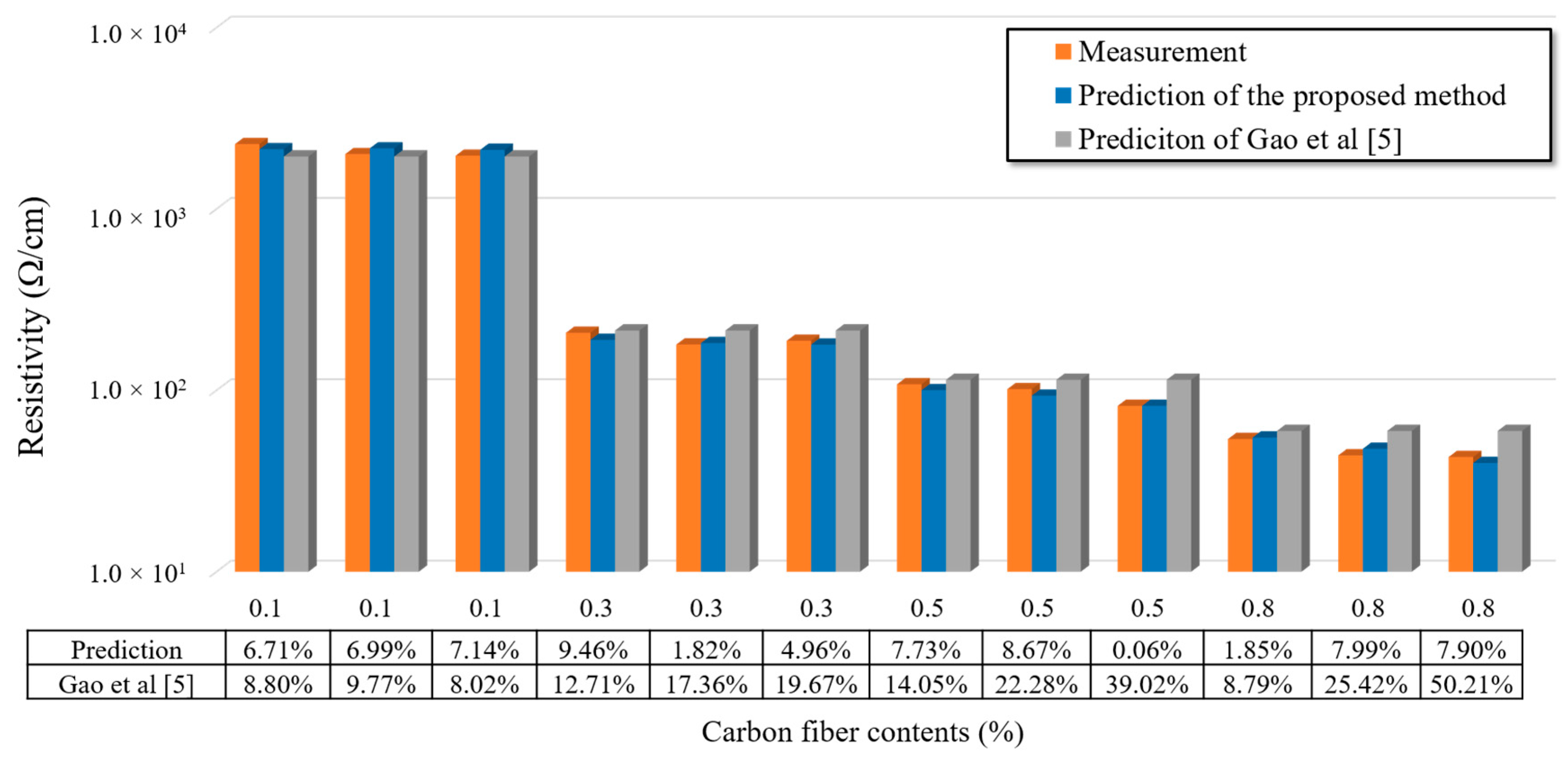

4.2.1. Electrical Conductivity Prediction

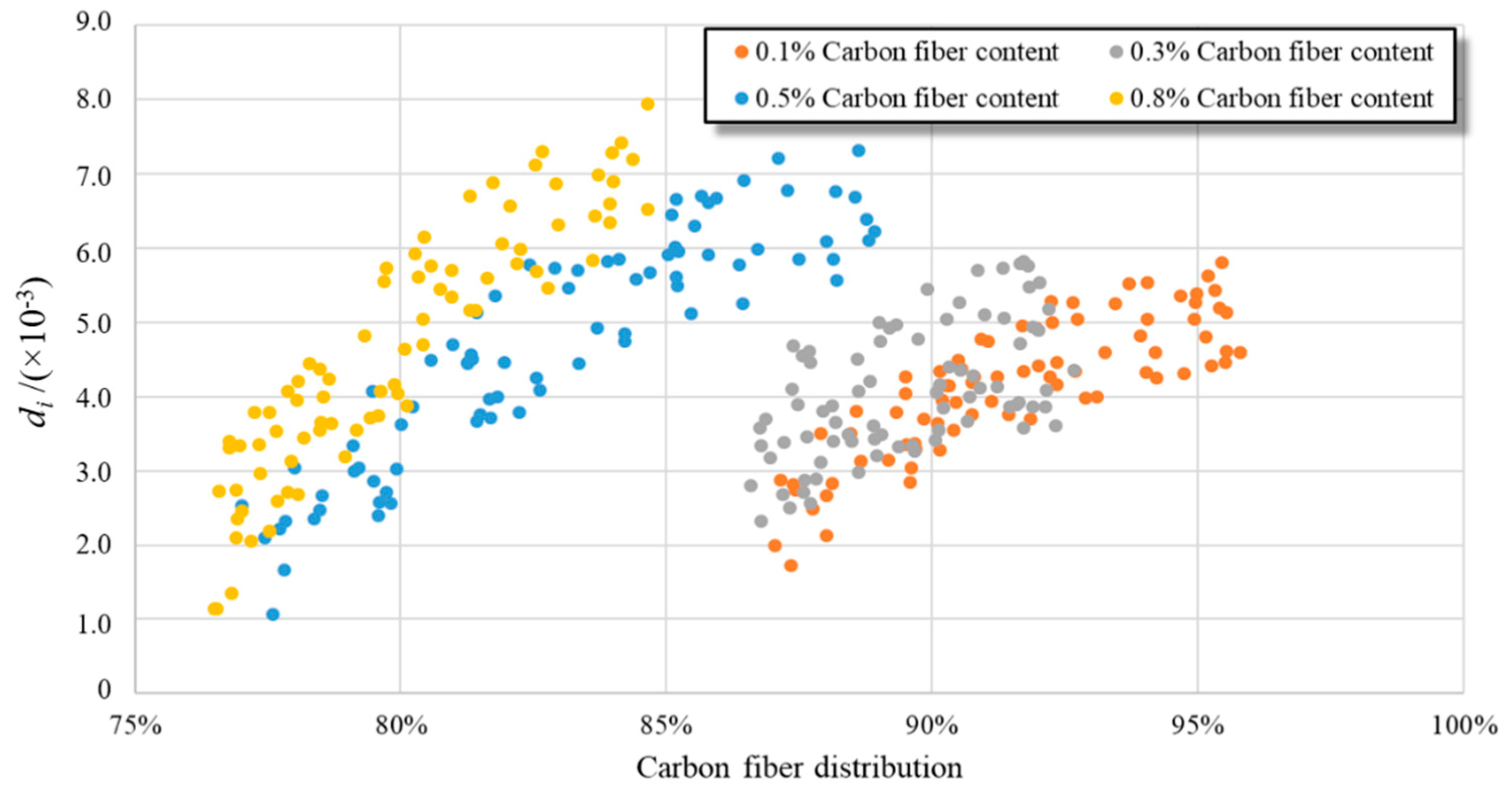

4.2.2. Distribution Impact Assessment

5. Conclusions

- (1)

- The proposed FCN was able to be utilized for real-time CF segmentation in SEM images with Precision, Recall, and F-Measure values of 0.956, 0.927, and 0.938, respectively. The outputs of the FCN can be used to evaluate the CF distribution in the local regions.

- (2)

- The proposed index DSample can be used for characterizing the real CF distribution in CFRC based on the outputs of the FCN. The DSample results became stable with increasing number of SEM images. It is desirable to utilize DSample with 80 SEM images for evaluating the overall distribution under 100× magnification. The values of other magnification levels for DSample can also be determined by the same method. The CF distribution decreased sharply with increasing CF content. Thus, the increase in the CF content has a negative effect on the performance of CFRC specimens if the preparation method is not suitable.

- (3)

- The average error between the predicted results of the RBNN and measured results was 6.58%, indicating that the RBNN was able to accurately predict the electrical conductivities of the CFRC specimens. It fully considered the influence of CF distribution (CF number, CF shapes, and space distribution) on the predicted results. The predicted results also showed that, with increasing CF content, the CF distribution had significant effects on the electrical conductivity of CFRC specimens. Therefore, to guarantee the electrical conductivity of CFRC specimens, a proper mixing method is required to ensure satisfactory CF distribution in CFRC specimens. In addition, this study only presents an example to predict the electrical conductivities of CFRCs based on their real microstructure. A generalized method should be developed in the future for predicting all other properties of CFRC.

- (4)

- The relationship between di and DSEM indicates that the contribution of a small CF distribution is less than the contribution of a large one. An increase in the local CF distribution of a CFRC specimen is useful in the improvement of CFRC conductivity. Additionally, di values were able to quantitatively represent the influence weights of the local distributions on CFRC conductivity. This indicates that it is necessary to control the CF distribution in CFRCs to guarantee their electrical conductivity, rather than only controlling CF mass.

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- Tuan, C.Y. Conductive Concrete for Bridge Deck Deicing and Anti-Icing (Technical Report); Department of Civil Engineering, University of Nebraska-Lincoln: Lincoln, NE, USA, 2004. [Google Scholar]

- Chiarello, M.; Zinno, R. Electrical conductivity of self-monitoring CFRC. Cem. Concr. Compos. 2005, 27, 463–469. [Google Scholar] [CrossRef]

- Wang, C.; Li, K.; Li, H.; Guo, L.; Jiao, G. Influence of CVI treatment of carbon fibers on the electromagnetic interference of CFRC composites. Cem. Concr. Compos. 2008, 30, 478–485. [Google Scholar] [CrossRef]

- Xu, J.; Zhong, W.; Yao, W. Modeling of conductivity in carbon fiber-reinforced cement-based composite. J. Mater. Sci. 2010, 45, 3538–3546. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Z.; Zhang, T.; Zhou, L. Dispersion of carbon fibers in cement-based composites with different mixing methods. Constr. Build. Mater. 2017, 134, 220–227. [Google Scholar] [CrossRef]

- CECS38:2004, Technical Specification for Fiber Reinforced Concrete Structures; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2004.

- ASTM C1229-94, Standard Test Method for Determination of Glass Fiber Content in Glass Fiber Reinforced Concrete (GFRC) (Wash-Out Test); ASTM International: West Conshohocken, PA, USA, 2015.

- Berrocal, C.G.; Karla, H.; Mette, R.G.; Ingemar, L.; Karin, L.; Dimitrios, G.B. Electrical electrical conductivity measurements in steel fibre reinforced cementitious materials. Cem. Concr. Compos. 2018, 89, 216–229. [Google Scholar] [CrossRef]

- Gao, J.; Guo, H.; Wang, X.; Wang, P.; Wei, Y.; Wang, Z.; Huang, Y.; Yang, B. Microwave deicing for asphalt mixture containing steel wool fibers. J. Clean. Prod. 2019, 206, 1110–1122. [Google Scholar] [CrossRef]

- Gao, J.; Sha, A.; Wang, Z.; Hu, L.; Yun, D.; Liu, Z.; Huang, Y. Characterization of carbon fiber distribution in cement-based composites by Computed Tomography. Constr. Build. Mater. 2018, 177, 134–147. [Google Scholar] [CrossRef]

- Bordelon, A.C.; Roesler, J.R. Spatial distribution of synthetic fibers in concrete with X-ray computed tomography. Cem. Concr. Compos. 2014, 53, 35–43. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Zhang, C.; Wang, Y.; Yu, X.; Ou, J. Reinforcement effect and mechanism of carbon fibers to mechanical and electrically conductive properties of cement-based materials. Constr. Build. Mater. 2016, 125, 479–489. [Google Scholar] [CrossRef]

- Wang, C.; Li, K.Z.; Li, H.J.; Zhai, Y.Q.; Liu, H. Dispersion of carbon fibers and conductivity of carbon-fiber-reinforced cement-based composites. J. Funct. Mater. 2007, 38, 1641–1644. [Google Scholar]

- Safiuddin, M.; Yakhlaf, M.; Soudki, K.A. Key mechanical properties and microstructure of carbon fibre reinforced self-consolidating concrete. Constr. Build. Mater. 2018, 164, 477–488. [Google Scholar] [CrossRef]

- Jiang, Z.; Ouyang, T.; Yang, Y.; Chen, L.; Fan, X.; Chen, Y.; Li, W.; Fei, Y. Thermal conductivity enhancement of phase change materials with form-stable carbon bonded carbon fiber network. Mater. Des. 2018, 143, 177–184. [Google Scholar] [CrossRef]

- Liu, Y.; He, D.; Hamon, A.L.; Fan, B.; Paul, H.A.; Thomas, R.; Bai, J. Comparison of different surface treatments of carbon fibers used as reinforcements in epoxy composites: Interfacial strength measurements by in-situ scanning electron microscope tensile tests. Compos. Sci. Technol. 2018, 167, 331–338. [Google Scholar] [CrossRef]

- Nili, M.; Ehsani, A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater. Des. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Ueda, M.; Saito, W.; Imahori, R.; Kanazawa, D.; Jeong, T.K. Longitudinal direct compression test of a single carbon fiber in a scanning electron microscope. Compos. A Appl. Sci. Manuf. 2014, 67, 96–101. [Google Scholar] [CrossRef]

- Newcomb, B.A. Processing, structure, and properties of carbon fibers. Compos. A Appl. Sc. Manuf. 2016, 91, 262–282. [Google Scholar] [CrossRef]

- Wang, K.; Shriver, D.; Banu, M.; Hu, S.J.; Xiao, G.; Arinez, J.; Fan, H.T. Performance prediction for ultrasonic spot welds of short carbon fiber-reinforced composites under shear loading. J. Manuf. Sci. Eng. 2017, 139, 111001. [Google Scholar] [CrossRef]

- Sun, F.; Fan, H.; Zhou, C.; Fang, D. Equivalent analysis and failure prediction of quasi-isotropic composite sandwich cylinder with lattice core under uniaxial compression. Compos. Struct. 2013, 101, 180–190. [Google Scholar] [CrossRef]

- Naseri, F.; Faezeh, J.; Ehsan, M.; Tang, W.; Abdosattar, F.; Mohsen, K. Experimental observations and SVM-based prediction of properties of polypropylene fibres reinforced self-compacting composites incorporating nano-CuO. Constr. Build. Mater. 2017, 143, 589–598. [Google Scholar] [CrossRef]

- Shi, L.; Lin, S.T.K.; Lu, Y.; Ye, L.; Zhang, Y.X. Artificial neural network based mechanical and electrical property prediction of engineered cementitious composites. Constr. Build. Mater. 2018, 174, 667–674. [Google Scholar] [CrossRef]

- Tong, Z.; Gao, J.; Zhang, H. Innovation for evaluating aggregate angularity based upon 3D convolutional neural network. Constr. Build. Mater. 2017, 155, 919–929. [Google Scholar] [CrossRef]

- Liu, H.; Sha, A.; Tong, Z.; Gao, J. Autonomous microscopic bunch inspection using region-based deep learning for evaluating graphite powder distribution. Constr. Build. Mater. 2018, 173, 525–539. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, J.; Zhao, P.; Dai, N.; Zhai, Z.; Ai, T. Improving cracking resistance of cement mortar by thermo-sensitive poly N-isopropyl acrylamide (PNIPAM) gels. J. Clean. Prod. 2017, 176, 1292–1303. [Google Scholar] [CrossRef]

- Ming, Y.; Jixiang, G.; Weidong, T.; Zhang, Y. Symmetric convolutional neural network for mandible segmentation. Knowl. Based Syst. 2018, 159, 63–71. [Google Scholar]

- Ang, L.L.; Hacer, Y.K. Foreground segmentation using convolutional neural networks for multiscale feature encoding. Pattern Recognit. Lett. 2018, 112, 256–262. [Google Scholar]

- Tong, Z.; Guo, H.; Gao, J.; Wang, Z. A Novel Method for Multi-scale Carbon Fiber Distribution Characterization in Cement-based Composites. Constr. Build. Mater. 2019, 218, 40–52. [Google Scholar] [CrossRef]

- Yang, Y. Methods study on dispersion of fibers in CFRC. Cem. Concr. Res. 2002, 32, 747–750. [Google Scholar] [CrossRef]

- Zeiler, M.D.; Graham, W.T.; Rob, F. Adaptive deconvolutional networks for mid and high level feature learning. In Proceedings of the IEEE International Conference on Computer Vision (ICCV), Barcelona, Spain, 6–13 November 2011; Volume 1, p. 6. [Google Scholar]

- Chen, B. Conductivity of carbon fiber reinforced cement-based composites. Cem. Concr. Compos. 2004, 26, 291–297. [Google Scholar] [CrossRef]

- Lu, L.; Xing, D.; Xie, Y.; Teh, K.S.; Zhang, B.; Chen, S.; Tang, Y. Electrical conductivity investigation of a nonwoven fabric composed of carbon fibers and polypropylene/polyethylene core/sheath bicomponent fibers. Mater. Des. 2016, 112, 383–391. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Chen, S.; Cowan, C.F.; Grant, P.M. Orthogonal least squares learning algorithm for radial basis function networks. IEEE Trans. Neural Netw. 1991, 2, 302–309. [Google Scholar] [CrossRef]

- Chung, D.D. Distribution of short fibers in cement. J. Mater. Civ. Eng. 2005, 17, 379–383. [Google Scholar] [CrossRef]

- Jia, Y.; Shelhamer, E.; Donahue, J.; Karayev, S.; Long, J.; Girshick, R.; Guadarrama, S.; Darrell, T. Caffe: Convolutional architecture for fast feature embedding. In Proceedings of the 22nd ACM International Conference on Multimedia (ACM), Orlando, FL, USA, 3–7 November 2014; pp. 675–678. [Google Scholar]

| Fineness (m2/kg) | Density (kg/m3) | Electrical Conductivity (Ω⋅m) | Flexural/Compressive Strength (MPa) | |

|---|---|---|---|---|

| 3 d | 28 d | |||

| 320 | 3114 | 0.72 | 5.9/19.5 | 7.2/54.1 |

| Radius (μm) | Lengths (mm) | Carbon Content (%) | Elasticity Modulus (GPa) | Ultimate Tensile Strength (MPa) | Electrical Conductivity (10−3 Ω·cm) |

|---|---|---|---|---|---|

| 4.0 | 2–5 | 95.3 | 241 | 3880 | 0.784 |

| Category | 50× | 100× | 200× | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Recall | Precision | F-Measure | Recall | Precision | F-Measure | Recall | Precision | F-Measure | |

| CF | 0.947 | 0.981 | 0.962 | 0.934 | 0.978 | 0.957 | 0.966 | 0.952 | 0.956 |

| CF clusters | 0.908 | 0.976 | 0.934 | 0.892 | 0.971 | 0.938 | 0.834 | 0.977 | 0.902 |

| Overall | 0.925 | 0.976 | 0.950 | 0.914 | 0.975 | 0.943 | 0.902 | 0.961 | 0.929 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, D.; Jiang, W.; Tong, Z.; Gao, J.; Xiao, J.; Ye, W. Prediction of Electrical Conductivity of Fiber-Reinforced Cement-Based Composites by Deep Neural Networks. Materials 2019, 12, 3868. https://doi.org/10.3390/ma12233868

Yuan D, Jiang W, Tong Z, Gao J, Xiao J, Ye W. Prediction of Electrical Conductivity of Fiber-Reinforced Cement-Based Composites by Deep Neural Networks. Materials. 2019; 12(23):3868. https://doi.org/10.3390/ma12233868

Chicago/Turabian StyleYuan, Dongdong, Wei Jiang, Zheng Tong, Jie Gao, Jingjing Xiao, and Wanli Ye. 2019. "Prediction of Electrical Conductivity of Fiber-Reinforced Cement-Based Composites by Deep Neural Networks" Materials 12, no. 23: 3868. https://doi.org/10.3390/ma12233868

APA StyleYuan, D., Jiang, W., Tong, Z., Gao, J., Xiao, J., & Ye, W. (2019). Prediction of Electrical Conductivity of Fiber-Reinforced Cement-Based Composites by Deep Neural Networks. Materials, 12(23), 3868. https://doi.org/10.3390/ma12233868