Liquid Penetration Depth and Strength of Concretes Modified with Polymer Admixtures Under the Action of Crude-Oil Products

Abstract

1. Introduction

2. Materials and Methods

- Control concrete (CC);

- Concrete modified with a polymer dispersion of vinyl-benzene and acrylic (PC1); and

- Concrete modified with styrene–butadiene dispersion (PC2).

- Consistency measurements for the concrete mix determined with the cone fall method, according to PN-EN 12350-2;

- Determination of the concrete mix density, according to PN-EN 12350-6;

- Determination of the compressive strength of concrete cubic samples, according to PN-EN 12390-3, tested after 28 days of hydration;

- Water absorption measurements in compliance with PN-B 06250:1988, tested after 28 days of hydration;

- Determination of the water permeability for concrete, according to PN-B 06250:1988, tested after 28 days of hydration;

- Determination of the compressive strength after storing the samples in crude-oil products, according to PN-EN 858-1 and PN-EN 12390-3, tested after 28 days of hydration plus 1000 hours of storing samples in crude-oil products; and

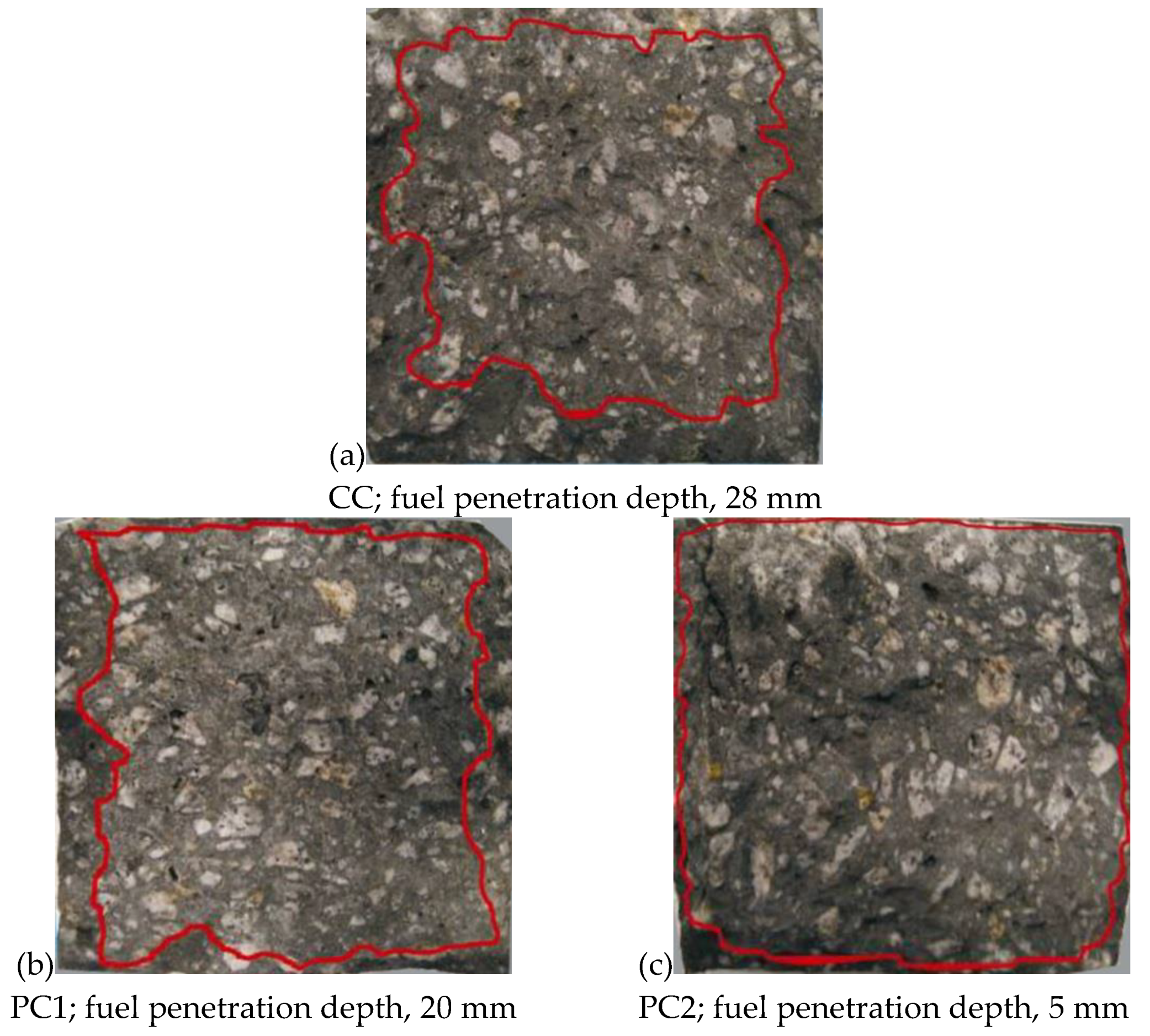

- Measurements of the penetration depth of non-ethylated fuel into concrete samples after a specified time, conducted by splitting the samples and measuring the depth of fuel penetration and tested after 28 days of hydration plus 1000 h of storing samples in crude-oil products.

3. Test Results and Analysis

3.1. Fresh Concrete Tests

3.2. Tests of Hardened Concrete After 28 Days of Hydration

3.3. Tests of Hardened Concrete After 1000 Hours of Storage in Light Liquids

- 90% (m/m) de-mineralized water;

- 0.75% (m/m) sodium hydroxide;

- 3.75% (m/m) sodium orthophosphate;

- 0.50% (m/m) (meta) sodium silicate;

- 3.25% (m/m) sodium carbonate; and

- 1.75% (m/m) sodium metaphosphate.

4. Conclusions

- Tests for 28-day strength indicated that concretes modified with polymer dispersions are characterized with a lower compressive strength than a control concrete (CC). For the PC1 modified concrete, the difference was almost 14%, while for PC2 it was 11%;

- Concretes modified with polymer dispersions, especially with the styrene–butadiene dispersion (PC2), indicated a smaller degree of liquid penetration into the samples. The penetration depth for non-ethylated fuel for PC2 concrete, after 1000 h of storage, was only 5 mm, while for the control concrete (CC) it was 28 mm. The water penetration depth determined after 28 days of concrete maturation was 60 mm for the control concrete and 15 mm for the PC2 concrete. There was a consistent general trend for the penetration depths for both liquids in the concrete, but the water penetration depths were greater, because pressure was applied on these samples;

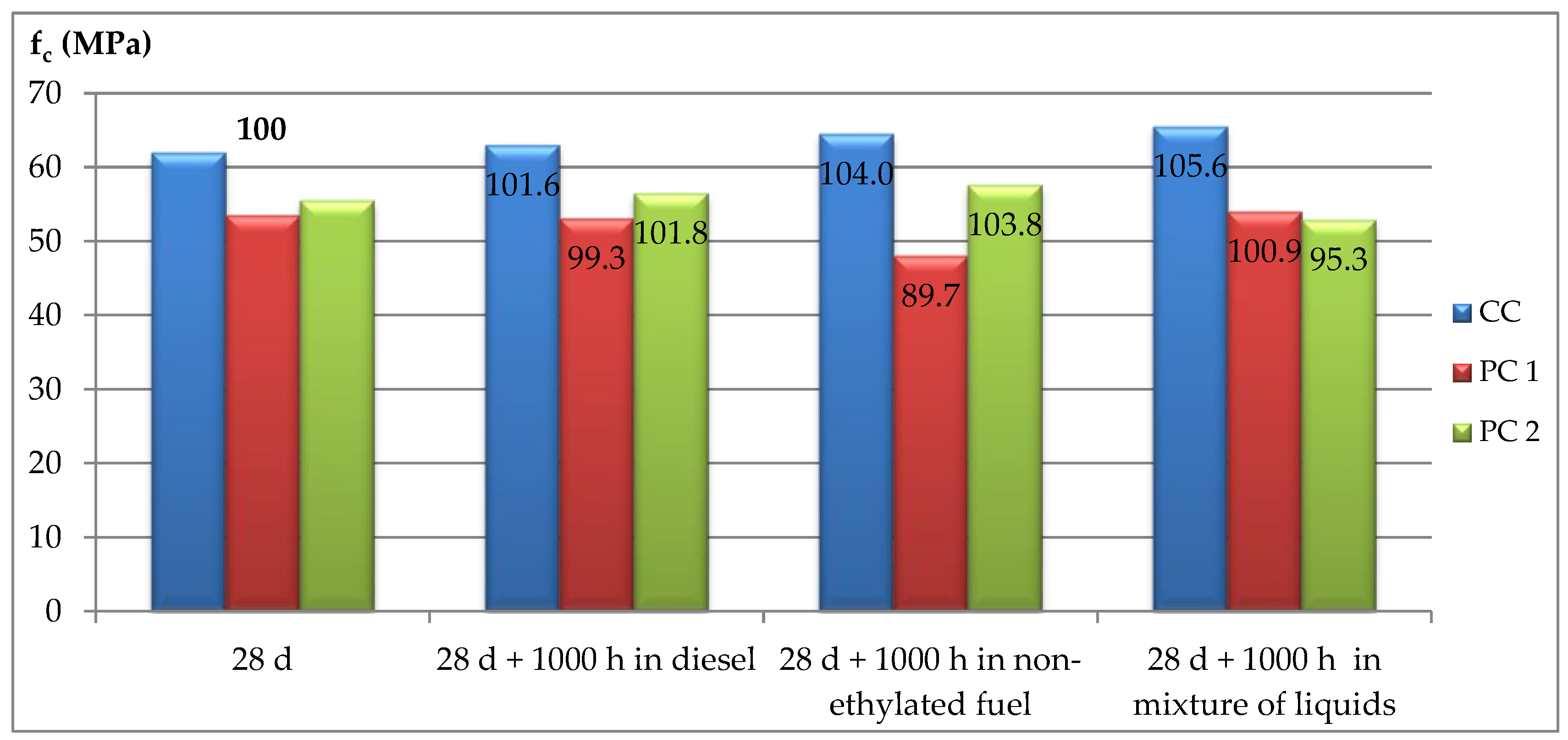

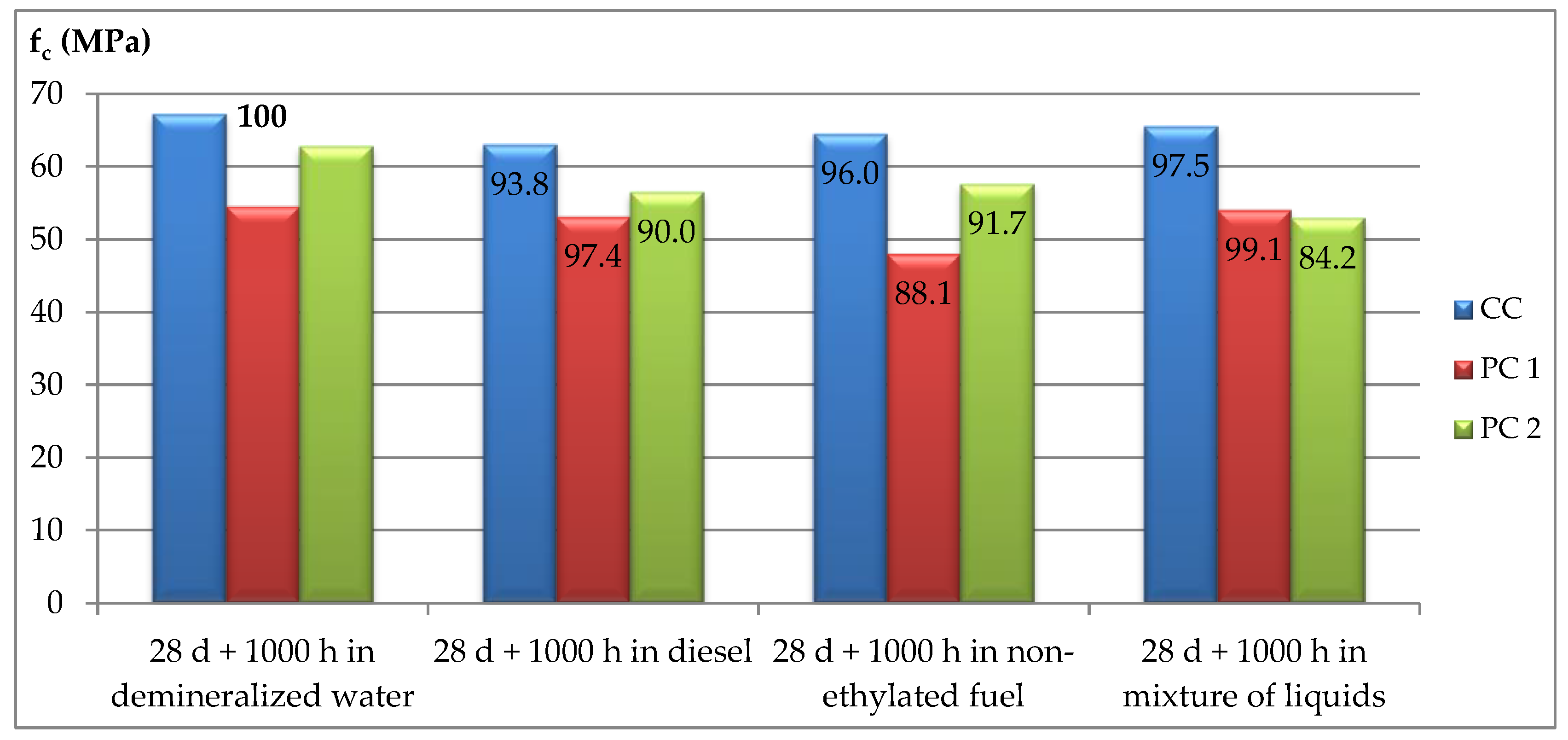

- The compressive strength for the tested concretes determined after 1000 h of storage in crude-oil products was close to the 28-day strength. However, compared to the strength of the samples stored in de-mineralized water, there was a significant decrease in results, with the maximum difference equal to 12% for PC2 concrete.

Author Contributions

Funding

Conflicts of Interest

References

- Shahrabadi, H.; Sayareh, S.; Sarkardeh, H. Effect of silica fume on compressive strength of oil-polluted concrete in different marine environments. China Ocean Eng. 2017, 31, 716–723. [Google Scholar] [CrossRef]

- Anikiev, V.V.; Mishukov, V.F.; Moiseevsky, G.N.; Tkalin, A.V. The Effect of Oil Films on Water Evaporation and Oxygen Content in Sea Water. GeoJournal 1988, 16, 19–24. [Google Scholar] [CrossRef]

- Majewski, T.; Niedostatkiewicz, M. Repair of heavily oily concrete floor. Build. Rev. 2016, 5, 38–40. (In Polish) [Google Scholar]

- Pukhov, I.E. Effect of Mineral Oil on the Reinforced-Concrete Floors of the Uglich and Rybinsk Hydroelectric Power Plants. Hydrotech. Constr. 2001, 35, 370–372. [Google Scholar] [CrossRef]

- Ksit, B. Changes in the mass and strength of oiled road concretes. Build. Mater. 2004, 12, 62–63. (In Polish) [Google Scholar]

- Linek, M.; Żebrowski, W.; Wolka, P. Change of physical parameters and compressive strength of airport concrete under the influence of hydraulic mineral oil. Build. Mater. 2016, 11, 144–147. (In Polish) [Google Scholar]

- Pużak, T. Concrete resistant to the influence of petroleum fuels and light liquids. BTA 2007, 3, 60–62. (In Polish) [Google Scholar]

- Runkiewicz, L.; Konieczny, K.; Brzęk, R. Changes in strength and deformability of oily concrete in the structure. Build. Rev. 2002, 2, 26–29. (In Polish) [Google Scholar]

- Błaszczyński, T. Corrosion of concrete as a result of the interaction of hydrocarbon substances. Part 1. Mechanisms of concrete destruction by petroleum products. Corros. Prot. 2003, 4, 91–96. (In Polish) [Google Scholar]

- Błaszczyński, T. Corrosion of concrete as a result of the interaction of hydrocarbon substances. Part 2. The method of assessing the degree of corrosion as a result of the interaction of hydrocarbon substances. Corros. Prot. 2003, 6, 162–164. (In Polish) [Google Scholar]

- Yurtdas, I.; Xie, S.Y.; Burlion, N.; Shao, J.F.; Saint-Marc, J.; Garnier, A. Influence of chemical degradation on mechanical behavior of a petroleum cement paste. Cem. Concr. Res. 2011, 41, 412–421. [Google Scholar] [CrossRef]

- Osuji, S.; Nwankwo, E. Effect of Crude Oil Contamination on the Compressive Strength of Concrete. Niger. J. Technol. 2015, 34, 259. [Google Scholar] [CrossRef]

- Błaszczyński, T. Assessment of RC structures influenced by crude oil products. Arch. Civ. Mech. Eng. 2011, 11, 5–17. [Google Scholar] [CrossRef]

- Salman, A.A.A.; Alghazali, J.J.H.; Alwash, N.O.S. The effect of fibers on the properties of self-compacting concrete subjected to petroleum products. Int. J. Civ. Eng. Technol. 2018, 9, 993–1005. [Google Scholar]

- Talib, A. Influence of Oil Products on Strength and Durability of High Strength Latex Modified Concrete Coated by Epoxy. Kufa J. Eng. 2018, 09, 13–30. [Google Scholar] [CrossRef][Green Version]

- Abbas, Z. Effect of Kerosene and Gas Oil Products on Different Types of Concrete. Int. J. Sci. Res. 2017, 6, 1718–1722. [Google Scholar]

- Jasim, A.T.; Faris, A.J. Effect of Oil on Strength of Normal and High Performance Concrete. Al Qadisiya J. Eng. Sci. 2017, 3, 24–32. [Google Scholar]

- Svinstov, A.P.; Shambina, S.L. Influence of viscosity of vegetable and mineral oil on deformation properties of concrete and cement-sand mortar. Constr. Build. Mater. 2018, 190, 964–974. [Google Scholar]

- Svinstov, A.P.; Nikolenko, Y.V.; Kharun, M.; Kazakov, A.S. Effect of viscosity of petroleum products on deformation properties of concrete. Mag. Civ. Eng. 2014, 51, 16–22. [Google Scholar]

- Diab, H. Effect of mineral oil on reinforced concrete structures. Part I. Deterioration of compressive strength. J. Eng. Sci. 2011, 39, 1321–1333. [Google Scholar]

- Diab, H. Compressive strength performance of low- and high-strength concrete soaked in mineral oil. Constr. Build. Mater. 2012, 33, 25–31. [Google Scholar] [CrossRef]

- Gruszczyński, M. Resistance of Polymer Dispersion Additive Modified Concrete to Light Liquids Action. Adv. Mater. Res. 2014, 941–944, 730–733. [Google Scholar] [CrossRef]

- Kameche, Z.A.; Ghomari, F.; Choinska, M.; Khelidj, A. Assessment of liquid water and gas permeability of partially saturated ordinary concrete. Constr. Build. Mater. 2014, 65, 551–565. [Google Scholar] [CrossRef]

- Abousnina, R.M.; Manalo, A.; Lokuge, W. Physical and mechanical properties of cement mortar containing fine sand contaminated with light crude oil. Procedia Eng. 2016, 145, 250–258. [Google Scholar] [CrossRef]

- Abousnina, R.M.; Manalo, A.; Lokuge, W.; Al-Jabri, K.S. Properties and structural behaviour of concrete containing fine sand contaminated with light crude oil. Constr. Build. Mater. 2018, 189, 1214–1231. [Google Scholar] [CrossRef]

- Wolicka, D. Microorganisms found in crude oil and in reservoir waters. Oil Gas 2010, 4, 267–273. [Google Scholar]

- Błaszczyński, T. The influence of crude oil products on RC structure destruction. J. Civ. Eng. Manag. 2011, 17, 146–156. [Google Scholar] [CrossRef]

- Lenart, M. Influence of the composition of cement mortars modified by lime or polymers on the mechanical properties and microstructure of mortars. Key Eng. Mater. 2014, 592–593, 647–650. [Google Scholar] [CrossRef]

- Łukowski, P. Role of Polymers in Forming of Properties of Polymer-Cement Binders and Composites; Publishing House of the Warsaw University of Technology: Warsaw, Poland, 2008. [Google Scholar]

| Properties | Mean Value |

|---|---|

| Chemical Properties | |

| Loss on Ignition (%) | 0.58 |

| Insoluble Residue (%) | 0.19 |

| SO3 Content (%) | 2.56 |

| Cl− Content (%) | 0.007 |

| Na2Oeq Content (%) | 0.44 |

| Al2O3 Content (%) | 4.14 |

| C3A Content (%) | 1.42 |

| C3S Content (%) | 57.3 |

| C4AF + 2C3A Content (%) | 19.9 |

| Physical Properties | |

| Initial Setting Time (min) | 215 |

| Final Setting Time (min) | 270 |

| 2-day Compressive Strength (MPa) | 16.8 |

| 28-day Compressive Strength (MPa) | 49.7 |

| Soundness (mm) | 1.0 |

| Specific Gravity (g/cm3) | 3.2 |

| Specific Surface Area According to Blaine (cm2/g) | 3350 |

| Component | Composition (kg/m3) | ||

|---|---|---|---|

| CC | PC1 | PC2 | |

| Cement | 380 | 380 | 380 |

| Water | 133 | 133 | 133 |

| Fine aggregate 0/2 | 720 | 720 | 720 |

| Coarse aggregate 2/8 | 500 | 500 | 500 |

| Coarse aggregate 8/16 | 700 | 700 | 700 |

| Super-plasticizer | 2.1 | - | 1.1 |

| P1 (10% cem. mass) | - | 38 | - |

| P2 (10% cem. mass) | - | - | 38 |

| Type of Concrete Mix | Cone Fall (mm) | Consistency Class | Density (kg/m3) |

|---|---|---|---|

| CC | 150 | S3 | 2405 |

| PC1 | 170 | S4 | 2440 |

| PC2 | 165 | S4 | 2425 |

| Type of Concrete | 28-Day Compressive Strength (MPa) | |

|---|---|---|

| fci | fcm | |

| CC | 64.3 | |

| 61.1 | 62.0 | |

| 60.6 | ||

| PC1 | 52.4 | |

| 53.8 | 53.5 | |

| 54.3 | ||

| PC2 | 55.6 | |

| 55.5 | 55.5 | |

| 55.4 | ||

| Type of Concrete | Water Absorption (%) | Water-Tightness Degree | Average Depth of Water Penetration (mm) | |

|---|---|---|---|---|

| WAi | WAm | |||

| CC | 4.0 | 4.0 | W8 | 60 |

| 4.1 | ||||

| 3.9 | ||||

| PC1 | 3.5 | 3.3 | W8 | 30 |

| 3.3 | ||||

| 3.1 | ||||

| PC2 | 2.5 | 2.5 | W8 | 15 |

| 2.4 | ||||

| 2.6 | ||||

| Type of Concrete Mix | Mean Compressive Strength Determined after 1000 h of Storage in Liquids: fc (MPa) | |||

|---|---|---|---|---|

| De-Mineralized Water | Diesel | Non-Ethylated Fuel | Mixture of Liquids | |

| CC | 67.2 | 63.0 | 64.5 | 65.5 |

| PC1 | 54.5 | 53.1 | 48.0 | 54.0 |

| PC2 | 62.8 | 56.5 | 57.6 | 52.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gruszczyński, M.; Lenart, M. Liquid Penetration Depth and Strength of Concretes Modified with Polymer Admixtures Under the Action of Crude-Oil Products. Materials 2019, 12, 3900. https://doi.org/10.3390/ma12233900

Gruszczyński M, Lenart M. Liquid Penetration Depth and Strength of Concretes Modified with Polymer Admixtures Under the Action of Crude-Oil Products. Materials. 2019; 12(23):3900. https://doi.org/10.3390/ma12233900

Chicago/Turabian StyleGruszczyński, Maciej, and Małgorzata Lenart. 2019. "Liquid Penetration Depth and Strength of Concretes Modified with Polymer Admixtures Under the Action of Crude-Oil Products" Materials 12, no. 23: 3900. https://doi.org/10.3390/ma12233900

APA StyleGruszczyński, M., & Lenart, M. (2019). Liquid Penetration Depth and Strength of Concretes Modified with Polymer Admixtures Under the Action of Crude-Oil Products. Materials, 12(23), 3900. https://doi.org/10.3390/ma12233900