Mechanical High-Temperature Properties and Damage Behavior of Coarse-Grained Alumina Refractory Metal Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation

2.2. Mechanical Testing

2.3. Microstructural Investigations

3. Results and Discussion

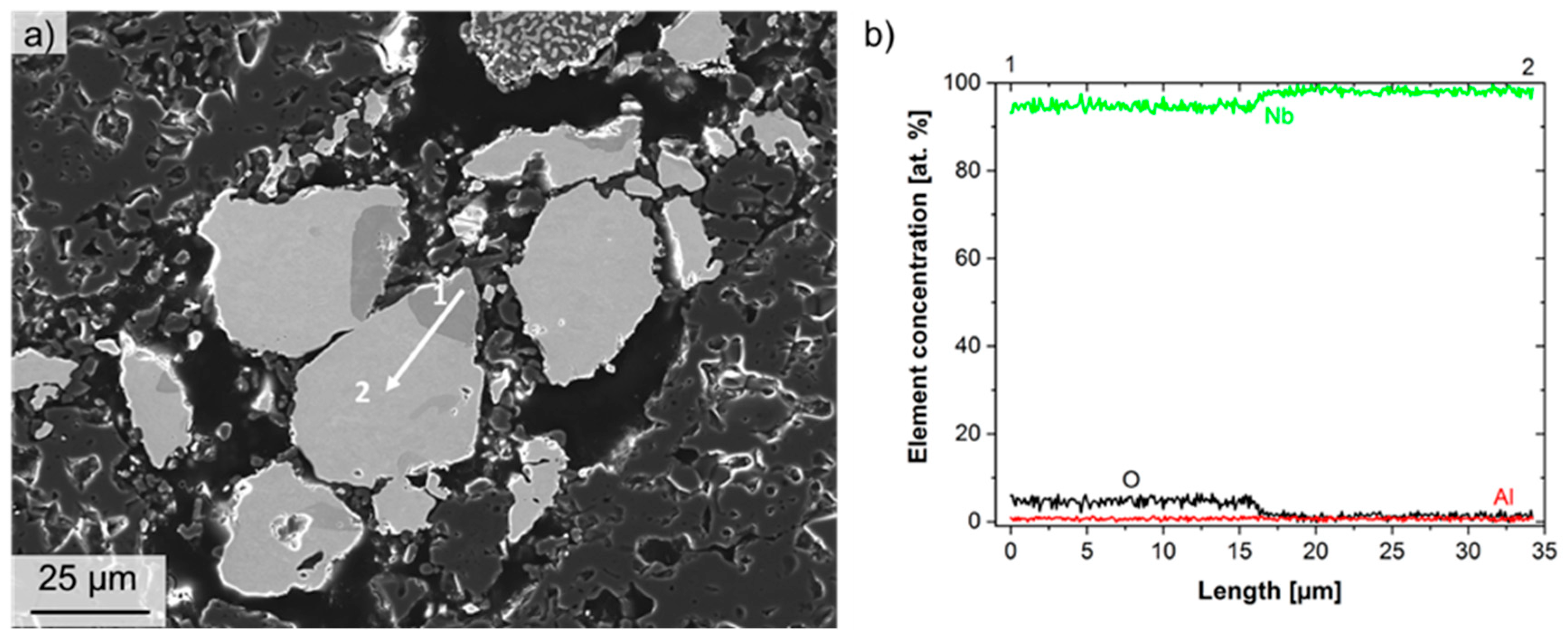

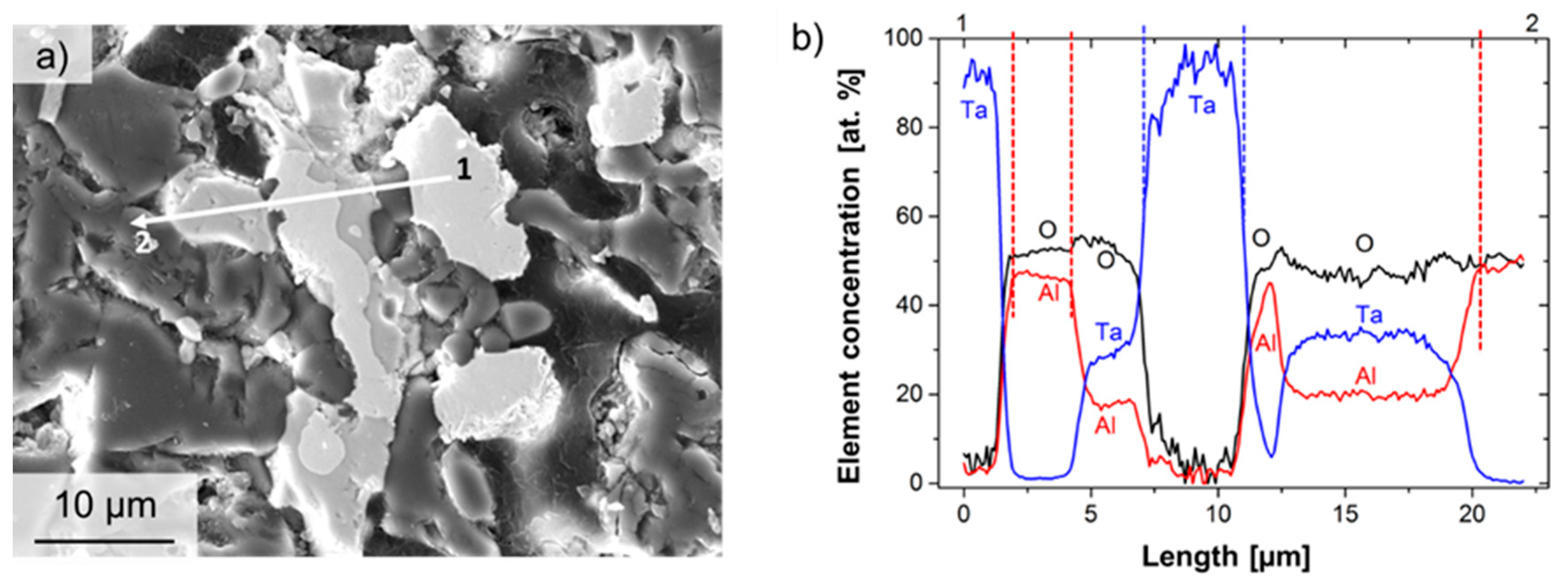

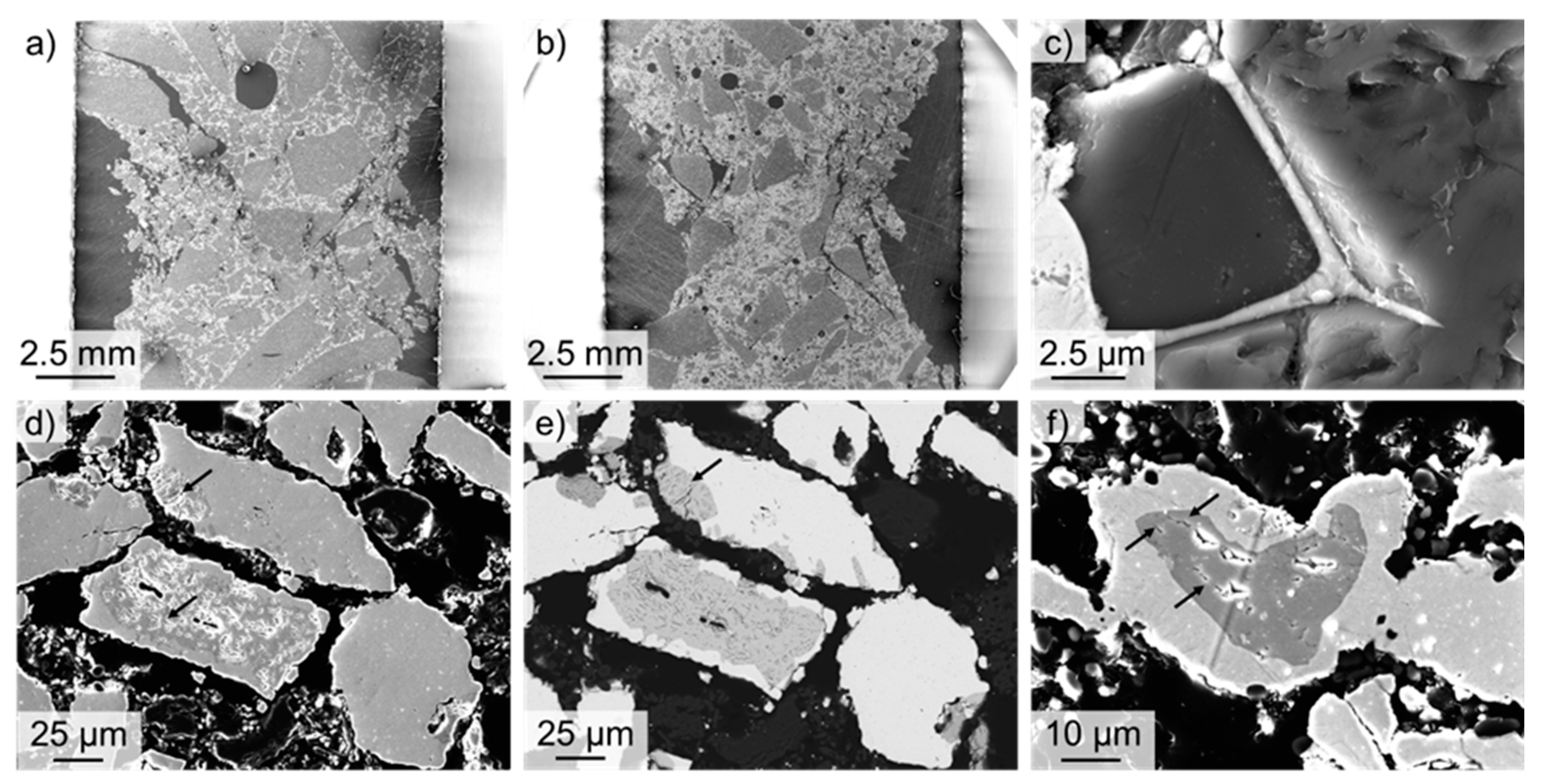

3.1. Initial Microstructure of Refractory Metal-Alumina Composites

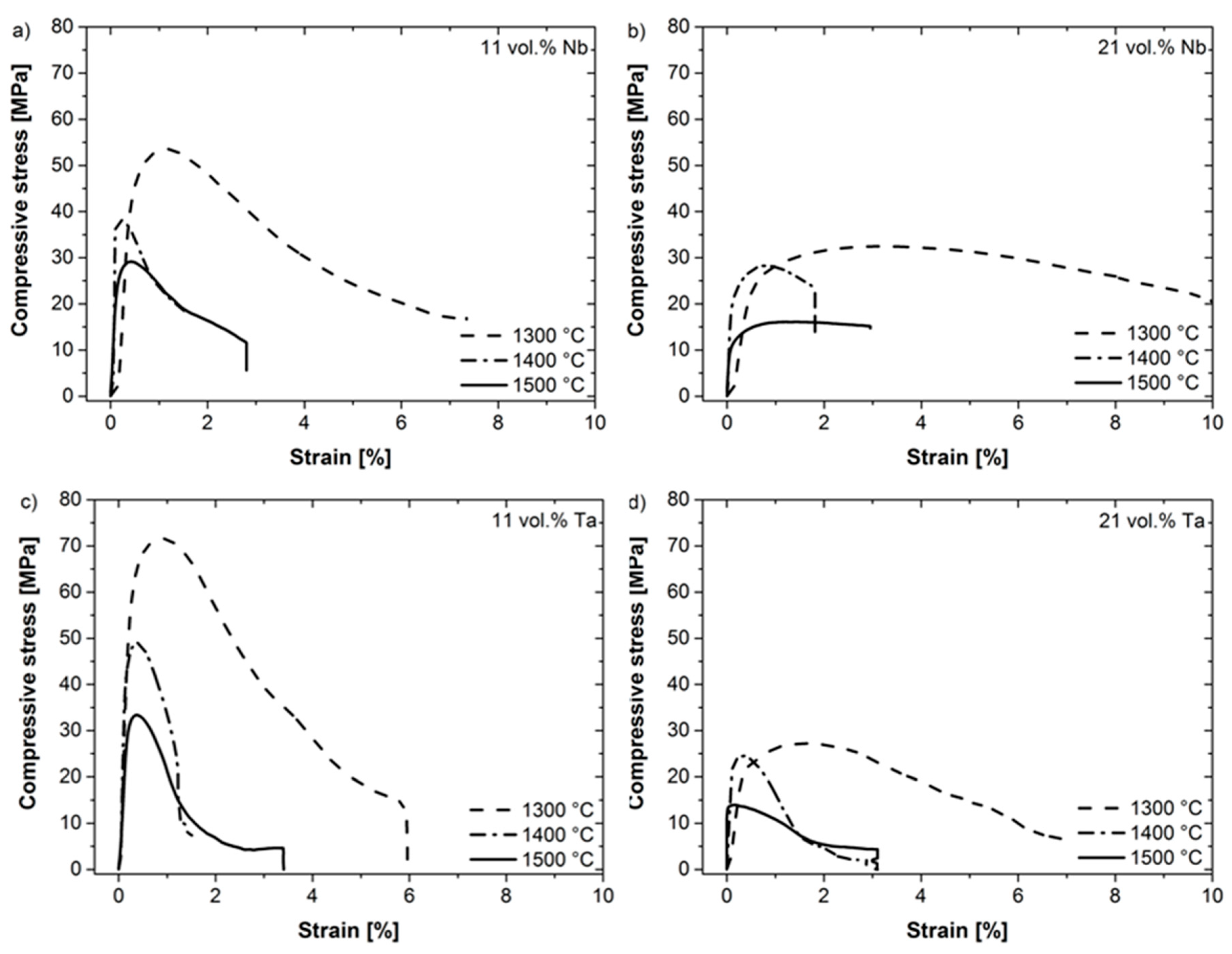

3.2. High-Temperature Compression Behavior

3.3. Stress-Relaxation Tests

4. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aneziris, C.G.; Homola, F.; Borzov, D. Material and Process development of Advanced Refractories for Innovative Metal Processing. Adv. Eng. Mater. 2004, 6, 562–568. [Google Scholar] [CrossRef]

- Davis, J.R. Heat-Resistant Materials, 1st ed.; ASM International: Metals Park, OH, USA, 1997. [Google Scholar]

- Schider, S. Hochschmelzende Metalle: Pulvermetallurgische Werkstoffe für High-Tech-Anwendungen; Verlag Moderne Industrie: Landsberg-Am Lech, Germany, 1990. [Google Scholar]

- Kirby, R.K.; Hahn, T.A.; Rothrock, B.D. American Institute of Physics Handbook-4f. Thermal Expansion, 3rd ed.; McGraw-Hill Book Company: New York, NY, USA, 1972. [Google Scholar]

- Kramer, C. Thermal Shock Resistance of Al2O3 and Al2O3/Nb Cermets; Sandia Labs.: Livermore, CA, USA, 1975; pp. 11–34.

- Beals, J.; Nardone, V. Tensile behaviour of a niobium/alumina composite laminate. J. Mater. Sci. 1994, 29, 2526–2530. [Google Scholar] [CrossRef]

- Shaw, L.; Miracle, D.; Abbaschian, R. Microstructure and mechanical properties of metal/oxide and metal/silicide interfaces. Acta Metall. Mater. 1995, 43, 4267–4279. [Google Scholar] [CrossRef]

- García, D.; Schicker, S.; Janssen, R.; Claussen, N. Nb- and Cr-Al2O3 composites with interpenetrating networks. J. Eur. Ceram. Soc. 1998, 18, 601–605. [Google Scholar] [CrossRef]

- García, D.; Schicker, S.; Bruhn, J.; Janssen, R.; Claussen, N. Processing and Mechanical Properties of Pressureless-Sintered Niobium-Alumina-Matrix Composites. J. Am. Ceram. Soc. 1998, 81, 429–432. [Google Scholar] [CrossRef]

- Korn, D.; Elssner, G.; Cannon, R.; Rühle, M. Fracture properties of interfacially doped Nb-Al2O3 bicrystals: I, fracture characteristics. Acta Mater. 2002, 50, 3881–3901. [Google Scholar] [CrossRef]

- Thomson, K.; Jiang, D.; Yao, W.; Ritchie, R.; Mukherjee, A. Characterization and mechanical testing of alumina-based nanocomposites reinforced with niobium and/or carbon nanotubes fabricated by spark plasma sintering. Acta Mater. 2012, 60, 622–632. [Google Scholar] [CrossRef]

- Morozumi, S.; Kikuchi, M.; Nishino, T. Bonding mechanism between alumina and niobium. J. Mater. Sci. 1981, 16, 2137–2144. [Google Scholar] [CrossRef]

- Burger, K.; Mader, W.; Rühle, M. Structure, chemistry and diffusion bonding of metal/ceramic interfaces. Ultramicroscopy 1987, 22, 1–13. [Google Scholar] [CrossRef]

- Mader, W.; Rühle, M. Electron microscopy studies of defects at diffusion-bonded Nb/Al2O3 interfaces. Acta Metall. 1989, 37, 853–866. [Google Scholar] [CrossRef]

- Rühle, M.; Evans, A. Structure and chemistry of metal/ceramic interfaces. Mater. Sci. Eng. A 1989, 107, 187–197. [Google Scholar] [CrossRef]

- Bruley, J.; Brydson, R.; Müllejans, H.; Mayer, J.; Gutekunst, G.; Mader, W.; Knauss, D.; Rühle, M. Investigations of the chemistry and bonding at niobium-sapphire interfaces. J. Mater. Res. 1994, 9, 2574–2583. [Google Scholar] [CrossRef]

- Kapsa, R.; Matolín, M.; Gruzza, B. The AES and EELS study of thin alumina films deposited on niobium. Vacuum 1998, 50, 233–235. [Google Scholar] [CrossRef]

- Sichinava, M.; Kobyakov, V. Interfacial reactions in layered composites of Nb-Al2O3 and Nb (1% Zr)-Al2O3 in high-temperature annealing. Refract. Ind. Ceram. 1999, 40, 203–207. [Google Scholar] [CrossRef]

- Scheu, C.; Dehm, G.; Kaplan, W.D.; García, D.E.; Claussen, N. Microstructure of Alumina Composites Containing Niobium and Niobium Aluminides. J. Am. Ceram. Soc. 2000, 83, 397–402. [Google Scholar] [CrossRef]

- McKeown, J.T.; Sugar, J.D.; Gronsky, R.; Glaeser, A.M. Effects of impurities on alumina-niobium interfacial microstructures. Mater. Charac. 2006, 57, 50–57. [Google Scholar] [CrossRef]

- Portu, G.d.; Guicciardi, S.; Melandri, C.; Monteverde, F. Wear behaviour of Al2O3-Mo and Al2O3-Nb composites. Wear 2007, 262, 1346–1352. [Google Scholar] [CrossRef]

- Grossman, L. Niobium-Al2O3 Reactions Yielding Condensed and Volatile Products. J. Chem. Phys. 1966, 44, 4127–4131. [Google Scholar] [CrossRef]

- Santos, W.N.D.; Filho, P.I.P.; Taylor, R. Effect of addition of niobium oxide on the thermal conductivity of alumina. J. Eur. Ceram. Soc. 1998, 18, 807–811. [Google Scholar] [CrossRef]

- Huang, T.; Rahaman, M.; Bal, B. Alumina–tantalum composite for femoral head applications in total hip arthroplasty. Mater. Sci. Eng. C 2009, 29, 1935–1941. [Google Scholar] [CrossRef]

- Ferber, M.K.; Jenkins, M.G.; Tennery, V.J. Comparison of tension, compression, and flexure creep for alumina and silicon nitride ceramics. Ceram. Eng. Sci. Proc. 1990, 11, 1028–1045. [Google Scholar]

- Robertson, A.G.; Wilkinson, D.S.; Cacerest, C.H. Creep and creep fracture in hot- pressed alumina. J. Am. Ceram. Soc. 1991, 74, 915–921. [Google Scholar] [CrossRef]

- Scheu, C.; Dehm, G.; Kaplan, W.D.; Wagner, F.; Claussen, N. Microstructure and phase evolution of niobium-aluminide-alumina composites prepared by melt-infiltration. Phys. Stat. Sol. A 1998, 166, 241–255. [Google Scholar] [CrossRef]

- Thomson, K.E.; Jiang, D.; Lemberg, J.A.; Koester, K.J.; Ritchie, R.O.; Mukherjee, A.K. In situ bend testing of niobium-reinforced alumina nanocomposites with and without single-walled carbon nanotubes. Mater. Sci. Eng. A 2008, 493, 256–260. [Google Scholar] [CrossRef]

- Moya, J.S.; Diaz, M.; Gutiérrez-González, C.F.; Diaz, L.A.; Torrecillas, R.; Bartolomé, J.F. Mullite-refractory metal (Mo, Nb) composites. J. Eur. Ceram. Soc. 2008, 28, 479–491. [Google Scholar] [CrossRef]

- Bartolomé, J.F.; Gutiérrez-González, C.F.; Pecharroman, C.; Moya, J.S. Synergistic toughening mechanism in 3Y–TZP/Nb composites. Acta Mater. 2007, 55, 5924–5933. [Google Scholar] [CrossRef]

- Bartolomé, J.F.; Gutiérrez-González, C.F.; Torrecillas, R. Mechanical properties of alumina-zirconia-Nb micro-nano hybrid composites. Compos. Sci. Technol. 2008, 68, 1392–1398. [Google Scholar] [CrossRef]

- Smirnov, A.; Bartolomé, J.F.; Kurland, H.D.; Grabow, J.; Müller, F.A. Design of a new zirconia–alumina–Ta micro-nanocomposite with unique mechanical properties. J. Am. Ceram. Soc. 2016, 99, 3205–3209. [Google Scholar] [CrossRef]

- Smirnov, A.; Beltrán, J.I.; Rodriguez-Suarez, T.; Pecharromán, C.; Muñoz, M.C.; Moya, J.S.; Bartolomé, J.F. Unprecedented simultaneous enhancement in damage tolerance and fatigue resistance of zirconia/Ta composites. Sci. Rep. 2017, 7, 44922. [Google Scholar] [CrossRef]

- Mocellin, A.; Kingery, W. Creep Deformation in MgO-Saturated Large-Grain-Size Al2O3. J. Am. Ceram. Soc. 1971, 54, 339–341. [Google Scholar] [CrossRef]

- Cannon, W.R.; Sherby, O.D. Creep Behavior and Grain-Boundary Sliding in Polycrystalline Al2O3. J. Am. Ceram. Soc. 1977, 60, 44–47. [Google Scholar] [CrossRef]

- Rice, R. Review—Ceramic tensile strength-grain size relations: Grain sizes, slopes, and branch intersections. J. Mater. Sci. 1997, 32, 1673–1692. [Google Scholar] [CrossRef]

- Schafföner, S.; Aneziris, C.G. Pressure slip casting of coarse grain oxide ceramics. Ceram. Int. 2012, 38, 417–422. [Google Scholar] [CrossRef]

- Fruhstorfer, J.; Demuth, C.; Goetze, P.; Aneziris, C.G.; Ray, S.; Gross, U.; Trimis, D. How the coarse fraction influences the microstructure and the effective thermal conductivity of alumina castables—An experimental and numerical study. J. Eur. Ceram. Soc. 2018, 38, 303–312. [Google Scholar] [CrossRef]

- Zienert, T.; Farhani, M.; Dudczig, S.; Aneziris, C.G. Coarse-grained refractory composites based on Nb-Al2O3 and Ta-Al2O3 castables. Ceram. Int. 2018, 44, 16809–16818. [Google Scholar] [CrossRef]

- Jasper-Tönnies, B.; Müller-Buschbaum, H.K. Synthese und Struktur yon AITaO4. Z. Anorg. Allg. Chem. 1983, 504, 113–116. [Google Scholar] [CrossRef]

- Harneit, O.; Müller-Buschbaum, H.K. AITaO4 mit AINbO4-Struktur. Z. Anorg. Allg. Chem. 1991, 596, 107–110. [Google Scholar] [CrossRef]

- Vermilyea, D.A. The oxidation of tantalum at 50–300°C. Acta Metall. 1958, 6, 166–171. [Google Scholar] [CrossRef]

- Voitovich, V.B.; Lavrenko, V.A.; Adejev, V.M.; Golovko, E.J. High-temperature oxidation of tantalum of different purity. Oxid. Met. 1995, 43, 509–526. [Google Scholar] [CrossRef]

- Sych, A.M.; Golub, A.M. Niobates and Tantalates of tervalent elements. Russ. Chem. Rev. 1977, 46, 210–225. [Google Scholar] [CrossRef]

- King, B.W.; Schultz, J.; Durbin, E.A.; Duckworth, W.H. Some Properties of Tantala Systems; BMI-1106; United States Atomic Energy Commission: Germantown, MD, USA, 1956; Volume 13, pp. 1–39. [Google Scholar]

- Roth, R.S.; Waring, J.L. Effect of oxide additions on the polymorphism of tantalum pentoxide III. Stabilization of the low temperature structure. J. Res. Natl. Bur. Stand. A 1970, 74, 485–493. [Google Scholar] [CrossRef]

- Yamaguchi, O.; Tomihisa, D.; Uegaki, T.; Shimizu, K. Formation and transformation of δ-Ta2O5 solid solution in the system Ta2O5-Al2O3. J. Am. Ceram. Soc. 1987, 70, C335–C338. [Google Scholar] [CrossRef]

- Massih, A.R.; Pérez, R.J. Thermodynamic Evaluation of the Nb-O System; Technical Report. PM 05-002 v2; Quantum Technologies AB: Uppsala, Sweden, 2006. [Google Scholar]

- Solarek, J.; Himcinschi, C.; Klemm, Y.; Aneziris, C.G.; Biermann, H. Ductile behaviour of fine-grained, carbon-bonded materials at elevated temperature. Carbon 2017, 122, 141–149. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weidner, A.; Ranglack-Klemm, Y.; Zienert, T.; Aneziris, C.G.; Biermann, H. Mechanical High-Temperature Properties and Damage Behavior of Coarse-Grained Alumina Refractory Metal Composites. Materials 2019, 12, 3927. https://doi.org/10.3390/ma12233927

Weidner A, Ranglack-Klemm Y, Zienert T, Aneziris CG, Biermann H. Mechanical High-Temperature Properties and Damage Behavior of Coarse-Grained Alumina Refractory Metal Composites. Materials. 2019; 12(23):3927. https://doi.org/10.3390/ma12233927

Chicago/Turabian StyleWeidner, Anja, Yvonne Ranglack-Klemm, Tilo Zienert, Christos G. Aneziris, and Horst Biermann. 2019. "Mechanical High-Temperature Properties and Damage Behavior of Coarse-Grained Alumina Refractory Metal Composites" Materials 12, no. 23: 3927. https://doi.org/10.3390/ma12233927