Friction and Wear between Polymer and Metal in the Mixing Process

Abstract

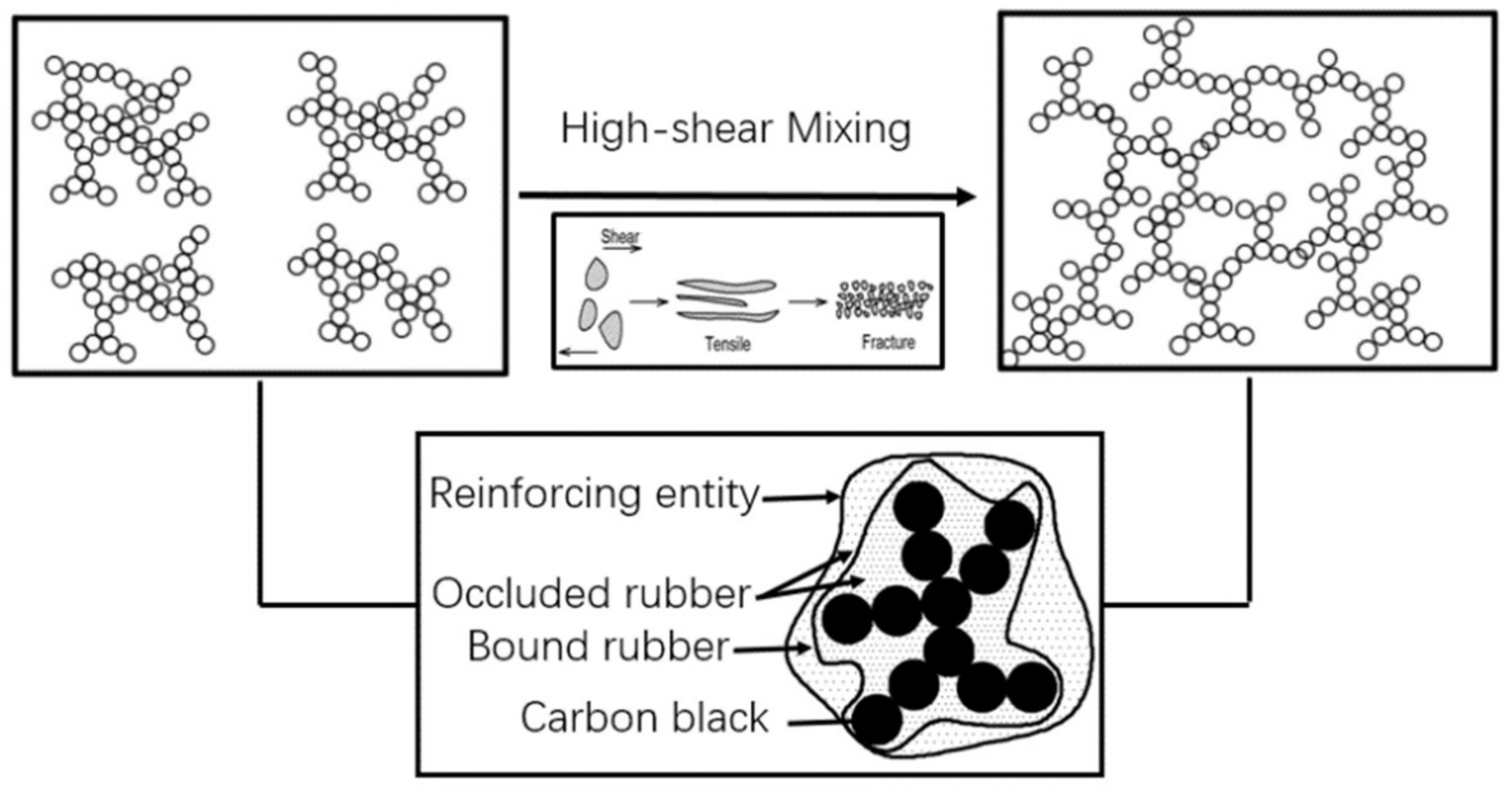

:1. Introduction

2. Materials and Methods

2.1. EDEM Simulation Parameters

2.1.1. Simulation Parameters

2.1.2. Simulation Mathematical Model

2.2. Materials

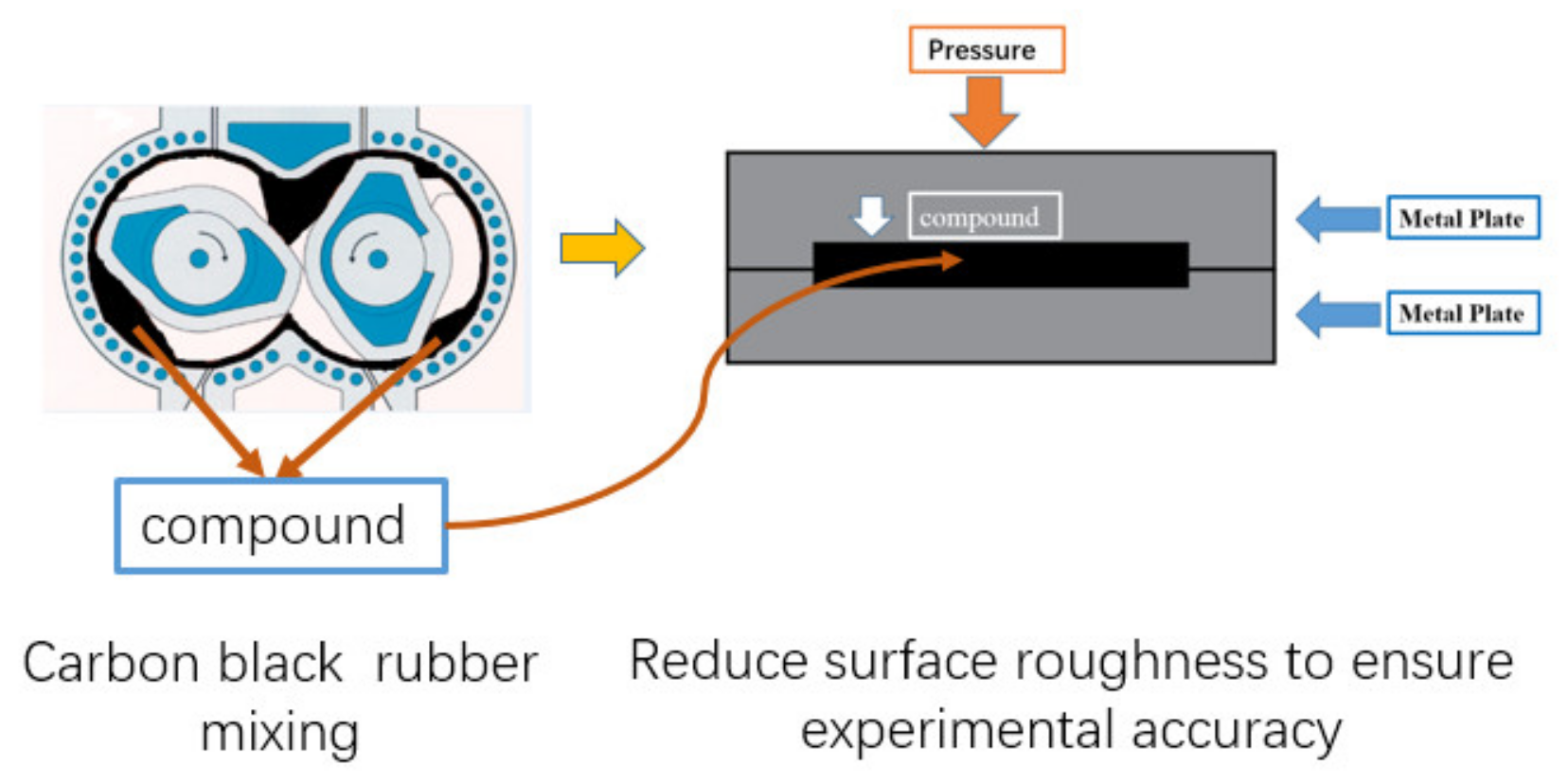

2.3. Preparation and Testing of Rubber Compounds

2.3.1. Experimental Formulation

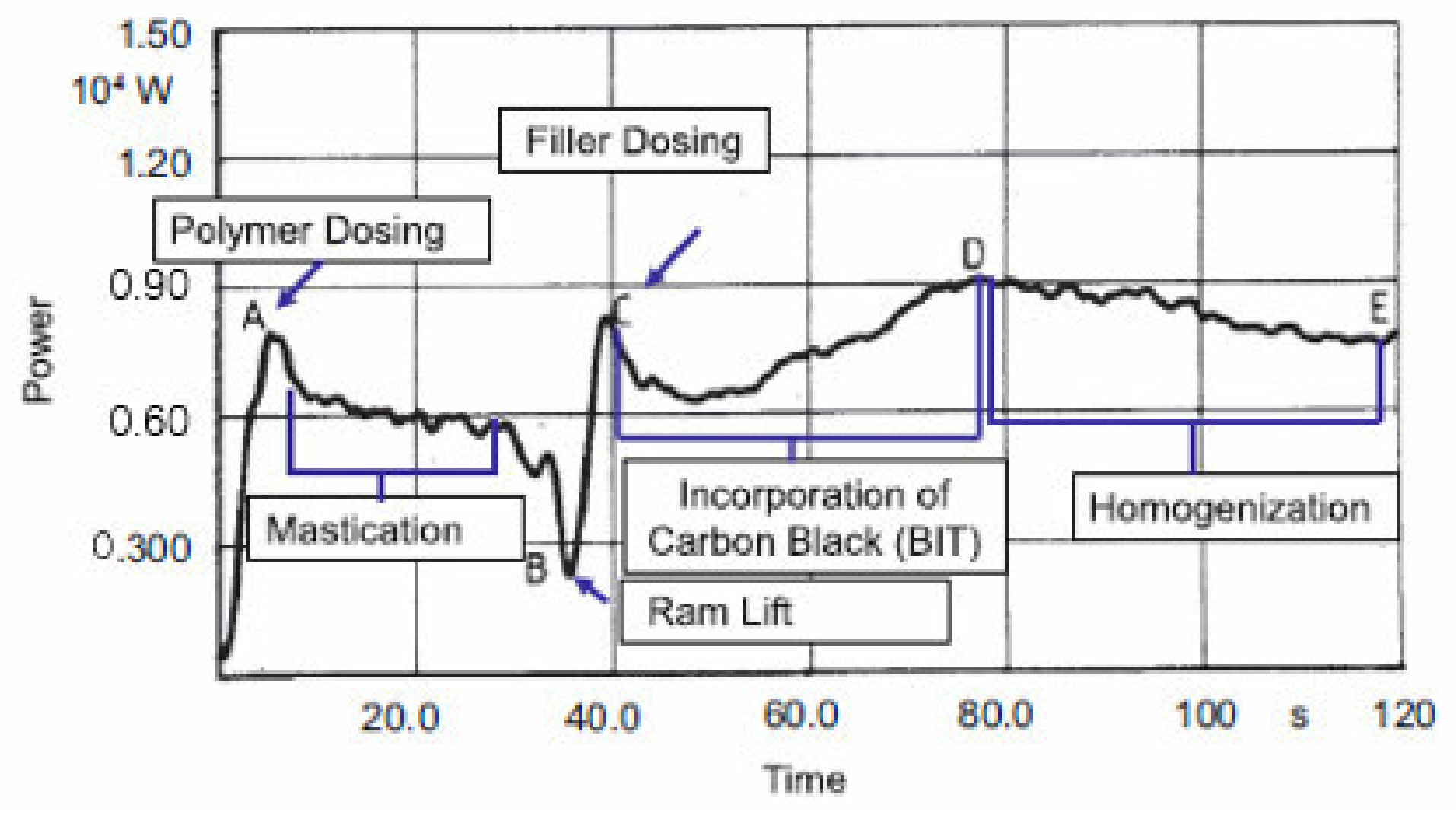

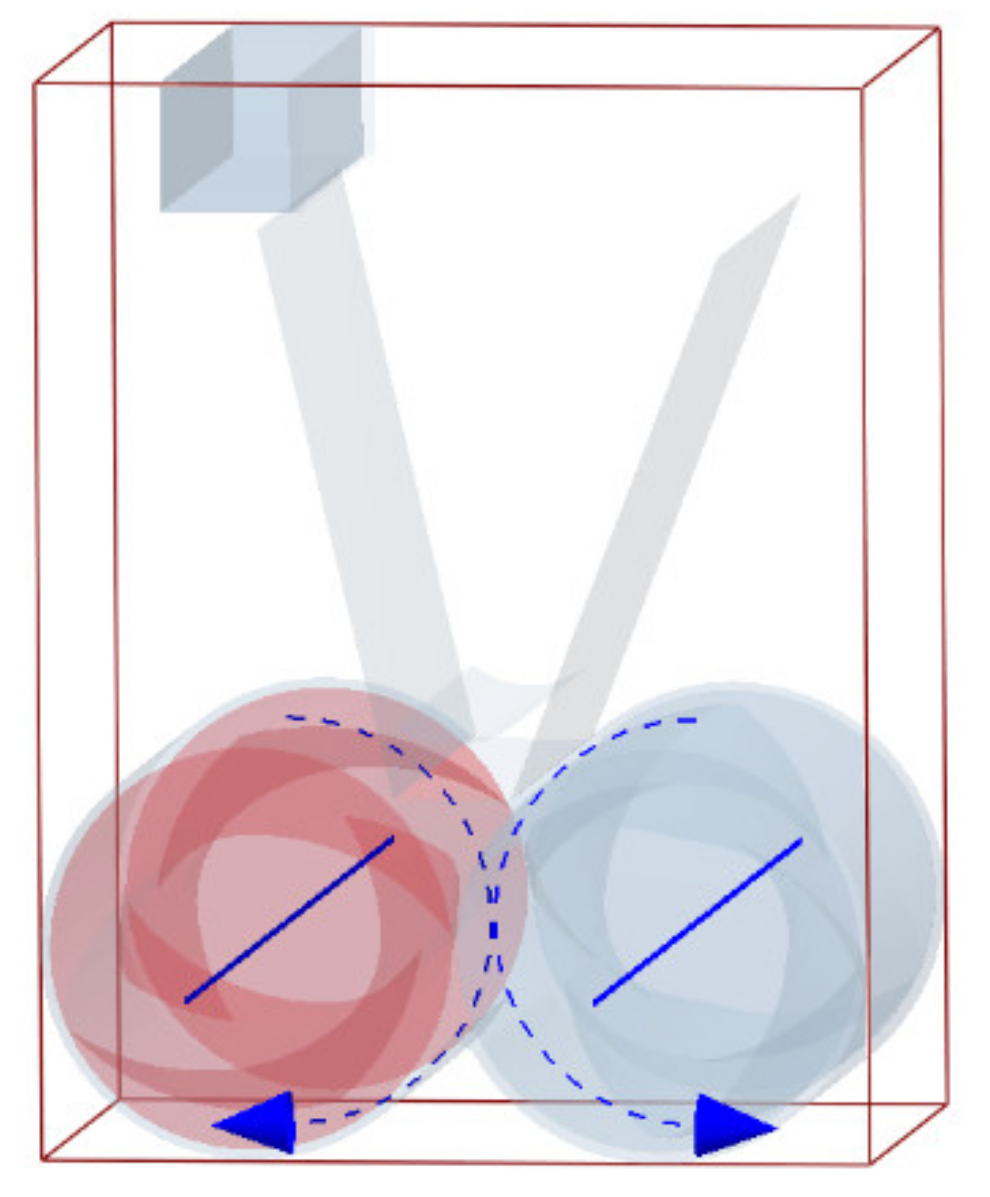

2.3.2. Experimental Process

3. Results and Discussion

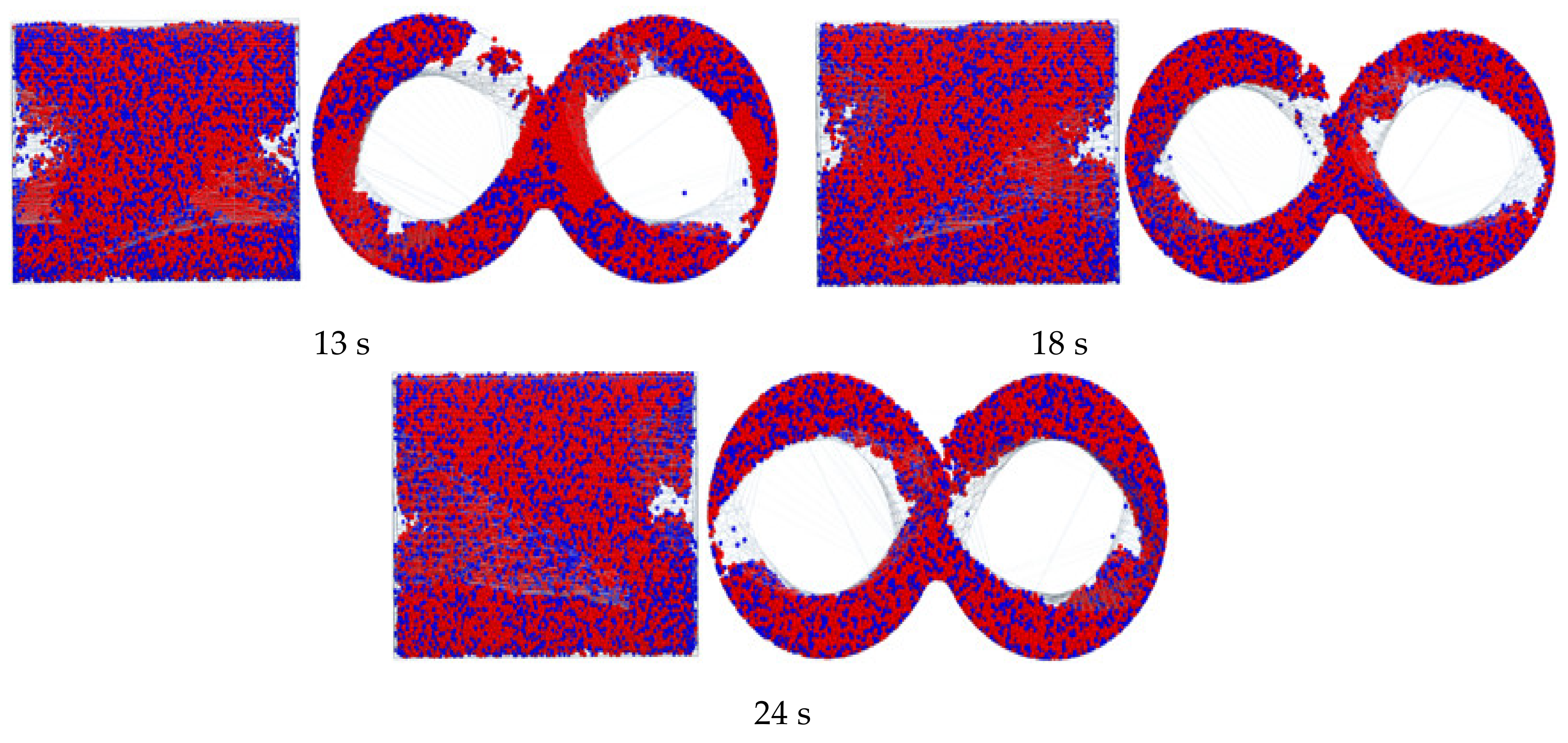

3.1. EDEM Simulation and Experimental Results of the Mixing Process

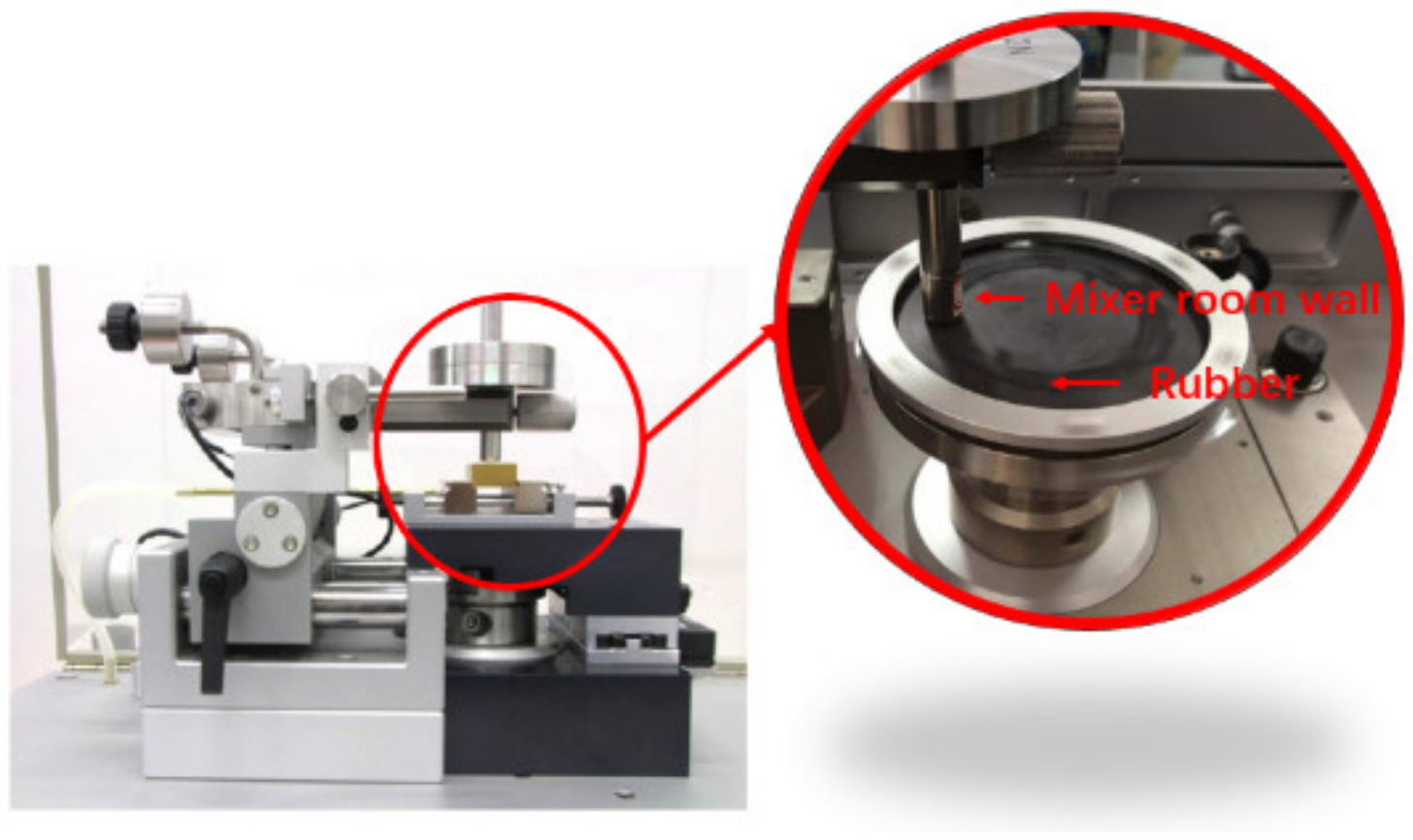

3.2. Test Results

4. Conclusios

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, Q.Z. Modern Rubber Technology; Chemical Industry Press: Beijing, China, 2001; pp. 154–244. [Google Scholar]

- Wang, C.S.; Li, Z.; Kan, L.L. The effect of carbon black dispersion on physical and mechanical properties of rubber compound. China Rubber/Plast. Technol. Equip. 2010, 36, 1–5. [Google Scholar]

- Zhang, H.X.; Liu, Y.D. Effects of carbon combined with rubber on properties of natural rubber. Appl. Chem. 1985, 2, 47–51. [Google Scholar]

- Wang, M.J. Effect of Polymer-Filler and Filler-Filler Interactions. Rubber Chem. Technol. 1998, 71, 527–528. [Google Scholar] [CrossRef]

- Kim, M.H.; White, J.L. Simulation of Flow in a Farrel Continuous Mixer. Int. Polym. Process. 1992, 7, 15–19. [Google Scholar] [CrossRef]

- Inoue, T.; Soen, T.; Hashimoto, T.; Kawai, H. Studies on Domain Formation of the A-B-Type Block Copolymer from Its Solutions. Ternary Polymer Blend of the Styrene-Isoprene Block Colopymer with Polystyrene and Polyisoprene. Macromolecules 1970, 3, 87–92. [Google Scholar] [CrossRef]

- White, J.L. Rubber Processing Technology Materials Principles; Hanser Publishers: New York, NY, USA, 1995; Chapter 9. [Google Scholar]

- Nicholasp, C. Polymer Mixing and Extrusion Technology; CRC Press: New York, NY, USA; Marcel Dekker: Basel, Switzerland, 1987; Chapter 3. [Google Scholar]

- Stein, R.S.; Khambatta, F.B.; Warner, F.P.; Russell, T.; Escala, A.; Balizer, E. X-ray and optical studies of the morphology of polymer blends. Polym. Sci. Polym. Symp. 1978, 63, 313–328. [Google Scholar] [CrossRef]

- Payne, A.R. The Dynamic Properties of Carbon Black Loaded Natural Rubber Vulcanizates. Part I. J. Appl. Polym. Sci. 1962, 6, 57–63. [Google Scholar] [CrossRef]

- Hongxiang, T.; Rui, S.; Yan, D.; Xiaoyu, S. Measurement of Restitution and Friction Coefficients for Granular Particles and Discrete Element Simulation for the Tests of Glass Beads. Materials 2019, 10, 19. [Google Scholar]

- Zhang, H.Q. Analysis and improvement of main assembly and wear clearance in mixing chamber of F 370 mixer. Guangxi J. Light Ind. 2009, 133, 45–46. [Google Scholar]

- Nakajima, N. Elongational Flow in Mixing Elastomer with Carbon Black. Rubber Chem. Tech. 1980, 3, 088. [Google Scholar] [CrossRef]

- Min, K.; Suh, K.G. Experiments and Modeling of Flow of Elastomers in an Internal Mixerwith Intermeshing Rotors. Polym. Eng. Sci. 1991, 31, 779. [Google Scholar] [CrossRef]

- Chen, G.; Schott, D.L.; Lodewijks, G. Sensitivity analysis of DEM prediction for sliding wear by single iron ore particle. Eng. Comput. 2017, 34, 2031–2053. [Google Scholar] [CrossRef] [Green Version]

- Dhakal, P.; Das, S.R.; Poudyal, H.; Chandy, A.J. Numerical simulations of partially-filled rubber mixing in a 2-wing rotor-equipped chamber. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

| Test List | Indicators Project |

|---|---|

| Iodine Adsorption Number (g/kg) | 90 ± 6 |

| DBP (10−5 m3/kg) | 114 ± 6 |

| CATB (103 m2/kg) | 90–102 |

| Ash %≤ | 0.7 |

| List | Phr |

|---|---|

| TSR20 | 50 |

| BR9000 | 50 |

| N375 | 58 |

| Sum | 158 |

| 1.6 L hake mixer, 80 rpm, 75% FF | ||

|---|---|---|

| Time | T (°C) | Ingredients |

| Master batch | ||

| 0:00 | 70 | Polymers |

| 0:40 | - | Half carbon |

| 1:20 | - | Another half carbon, take sample |

| 1:40 | 110 | Take sample |

| 2:10 | 120 | Take sample |

| 2:40 | 130 | Take sample |

| 3:10 | 140 | Take sample |

| 3:40 | 140 | Take sample |

| 4:00 | 140 | Take sample |

| Test List | Volume (mm3) | Superficial Area (mm2) | Surface Roughness (μm) |

|---|---|---|---|

| 0 | 0.75 | 37.95 | 1.738 |

| 2 | 0.743 | 38.09 | 1.697 |

| 3 | 0.672 | 35.73 | 1.684 |

| 4 | 0.525 | 26.52 | 1.672 |

| 5 | 0.477 | 26.44 | 1.721 |

| 6 | 0.490 | 23.08 | 1.703 |

| 7 | 0.456 | 22.69 | 1.694 |

| 8 | 0.529 | 28.60 | 1.70 |

| 9 | 0.536 | 28.64 | 1.704 |

| Sample | Determination of Light Transmittance of Toluene % |

|---|---|

| N375 | 87% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Zhu, L.; Liu, H.; Zhang, M.; Han, W.; Wang, C.; Bian, H. Friction and Wear between Polymer and Metal in the Mixing Process. Materials 2019, 12, 4029. https://doi.org/10.3390/ma12244029

Pan Y, Zhu L, Liu H, Zhang M, Han W, Wang C, Bian H. Friction and Wear between Polymer and Metal in the Mixing Process. Materials. 2019; 12(24):4029. https://doi.org/10.3390/ma12244029

Chicago/Turabian StylePan, Yiren, Lin Zhu, Huaqiao Liu, Meng Zhang, Wenwen Han, Chuansheng Wang, and Huiguang Bian. 2019. "Friction and Wear between Polymer and Metal in the Mixing Process" Materials 12, no. 24: 4029. https://doi.org/10.3390/ma12244029

APA StylePan, Y., Zhu, L., Liu, H., Zhang, M., Han, W., Wang, C., & Bian, H. (2019). Friction and Wear between Polymer and Metal in the Mixing Process. Materials, 12(24), 4029. https://doi.org/10.3390/ma12244029