Non-Destructive Testing of Steel Corrosion Fluctuation Parameters Based on Spontaneous Magnetic Flux Leakage and Its Relationship with Steel Bar Diameter

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Preparation

2.2. Experimental Procedure

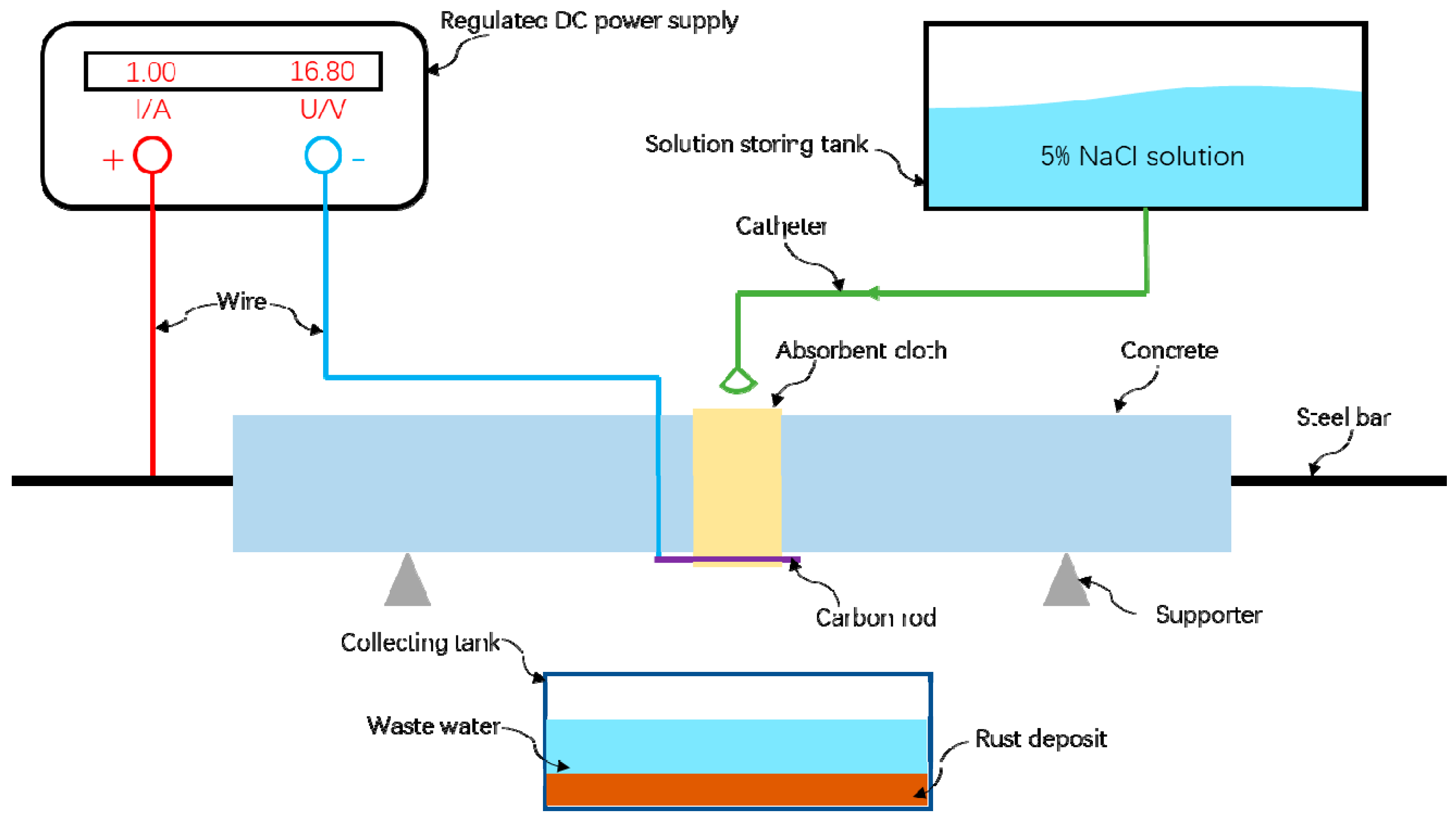

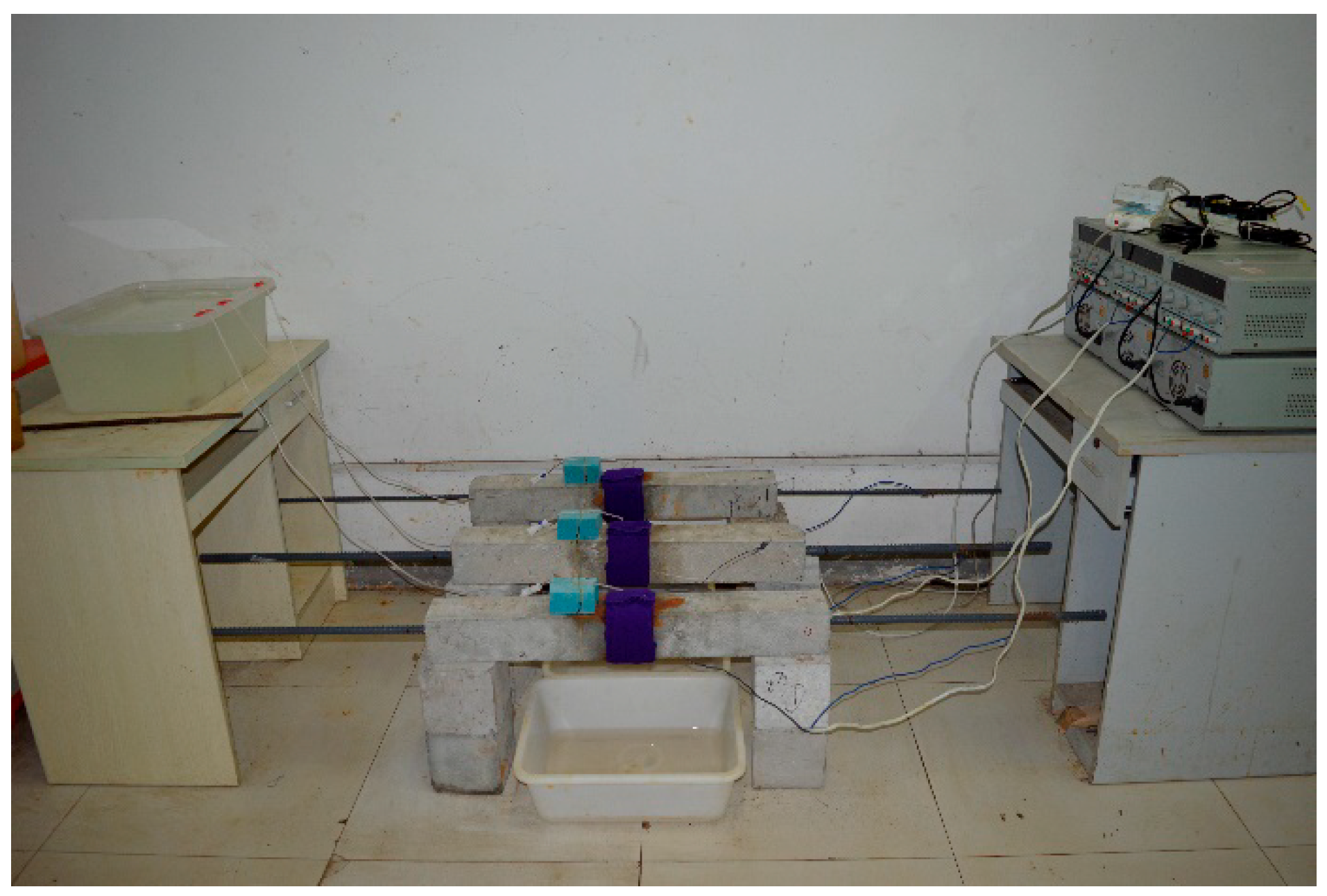

2.2.1. Electrochemical Acceleration of Corrosion

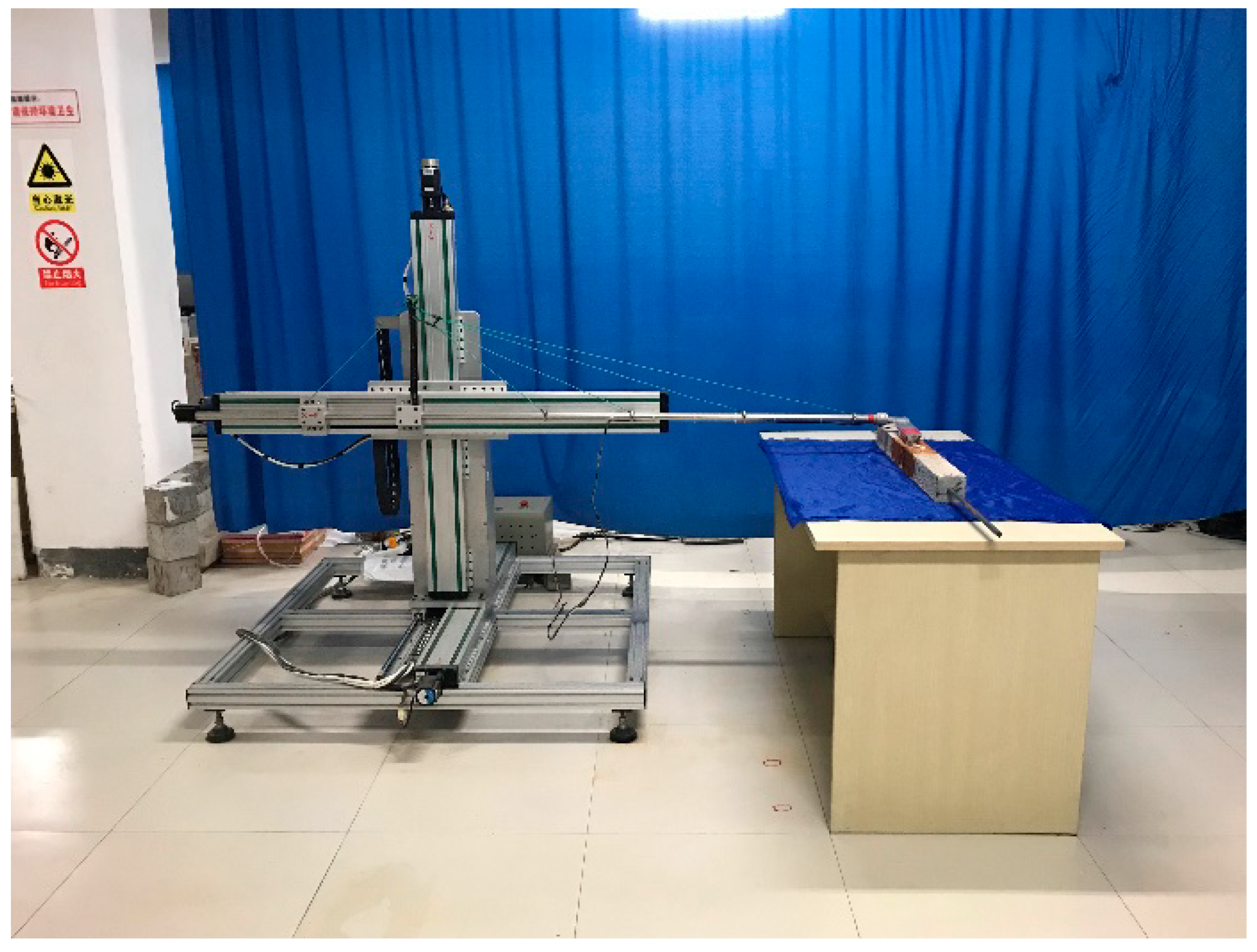

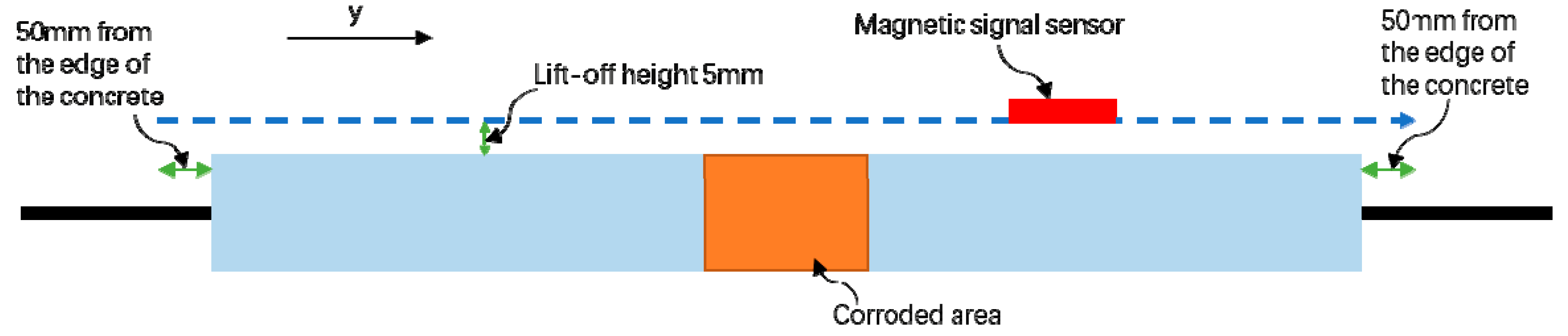

2.2.2. Magnetic Flux Leakage Signal Acquisition

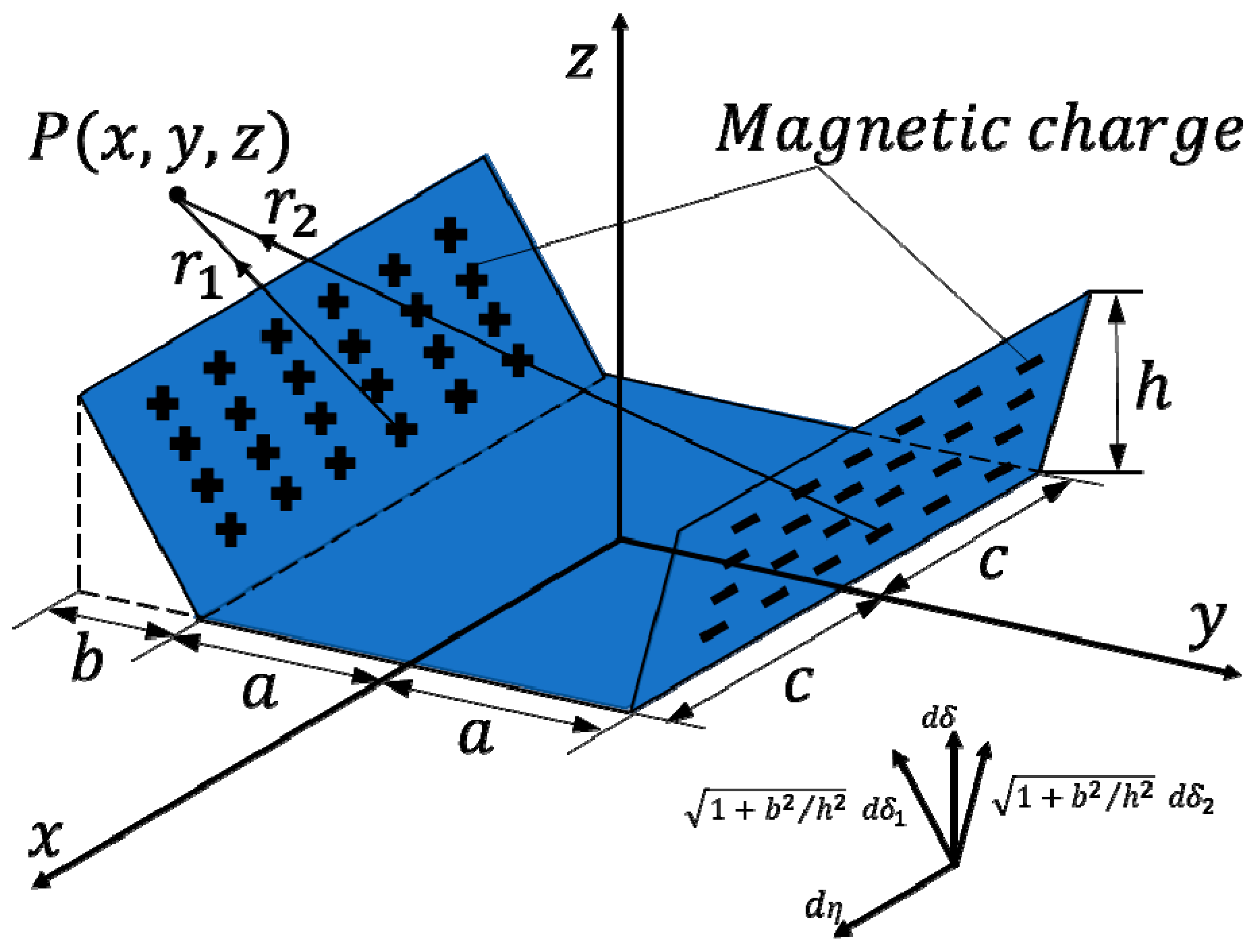

2.3. Magnetic Dipole Model

3. Test Conclusions and Discussion

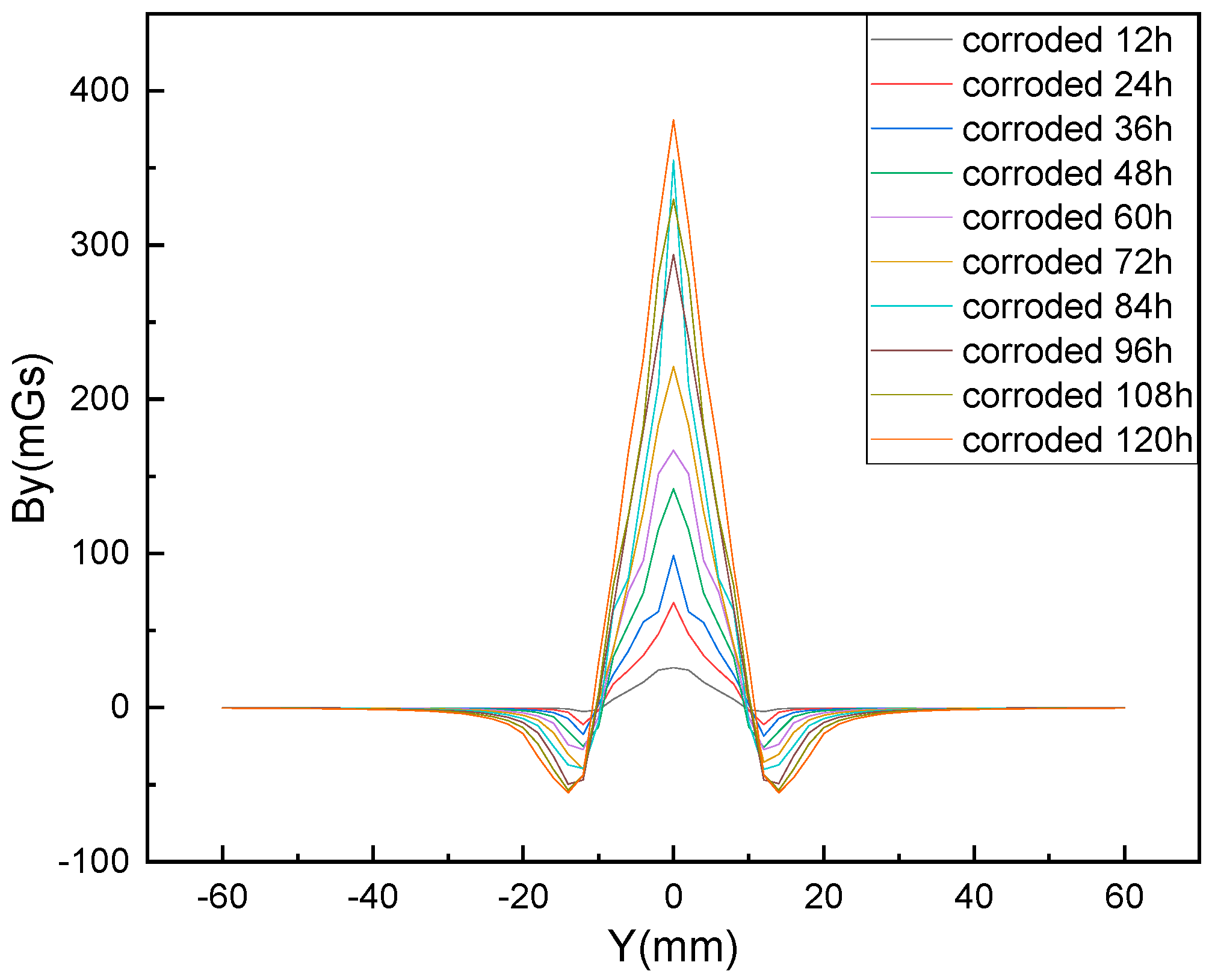

3.1. Magnetic Leakage Signal of Concrete Specimen

3.2. The Relationship between the Change of Magnetic Flux Leakage Signal and the Diameter of the Steel Bar of Steel-Reinforced Concrete Specimens

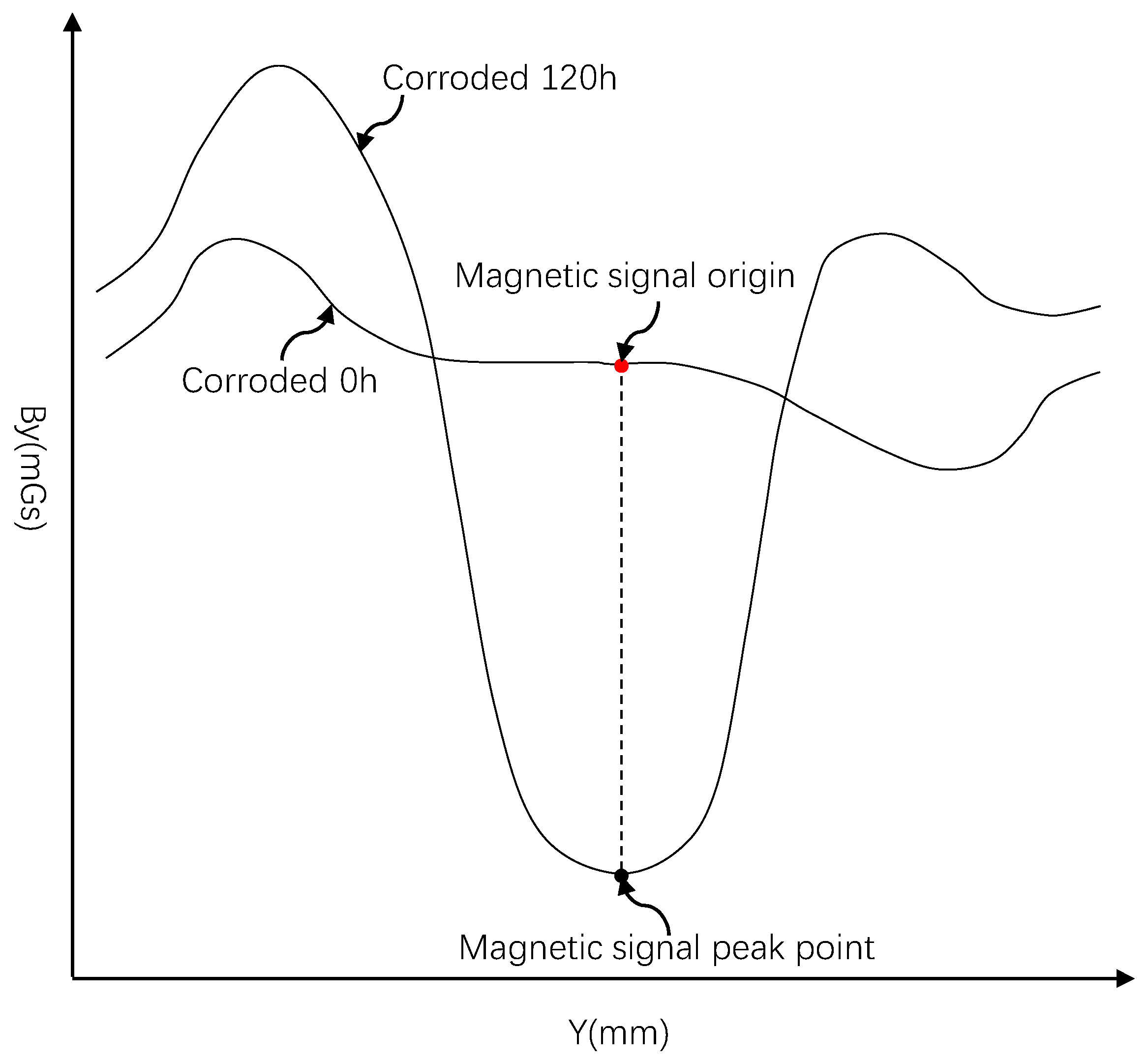

3.2.1. Selection of Origin of the Magnetic Flux Leakage Signal

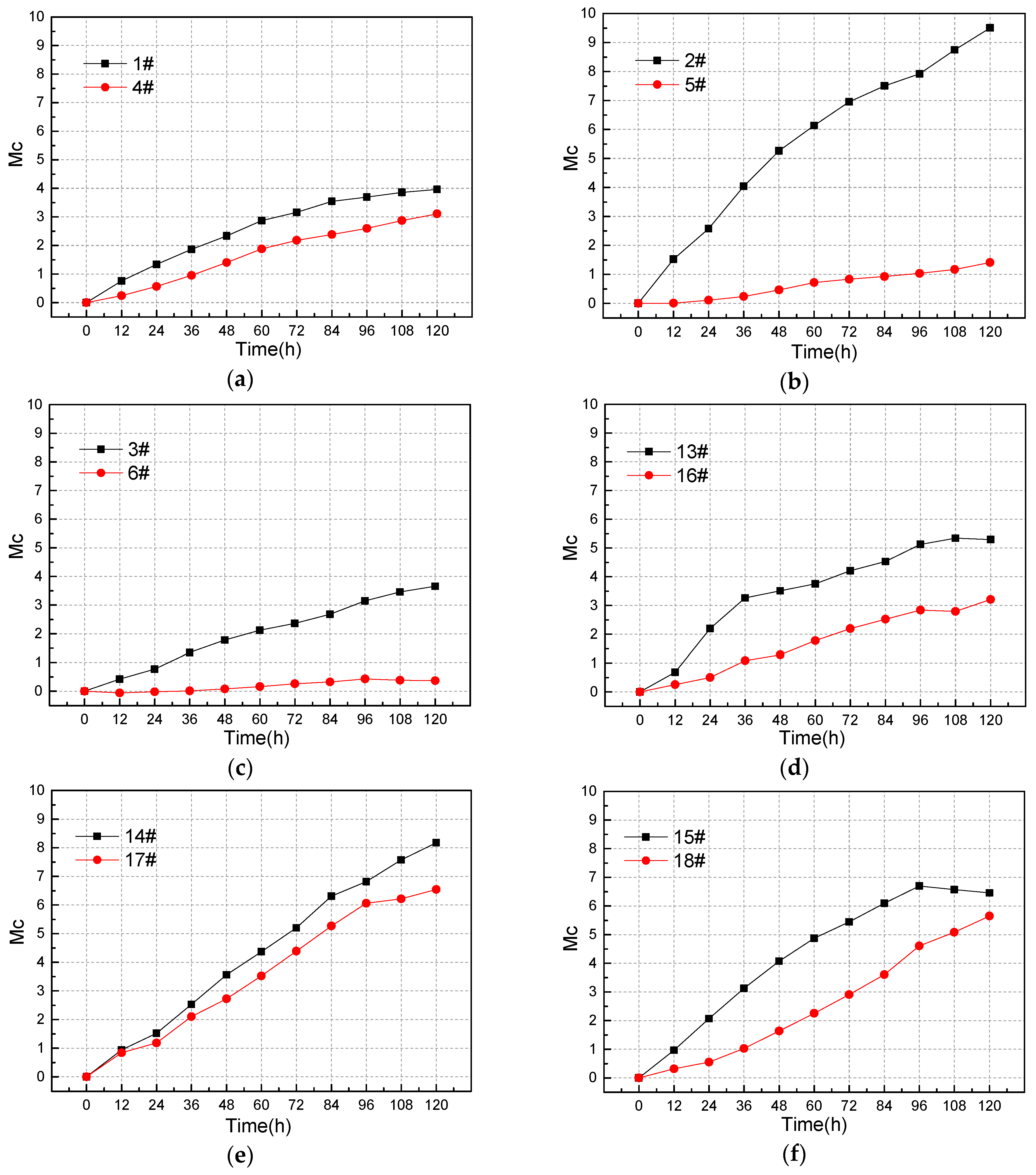

3.2.2. Proposal of Rust-Magnetic Fluctuation Parameter Mc

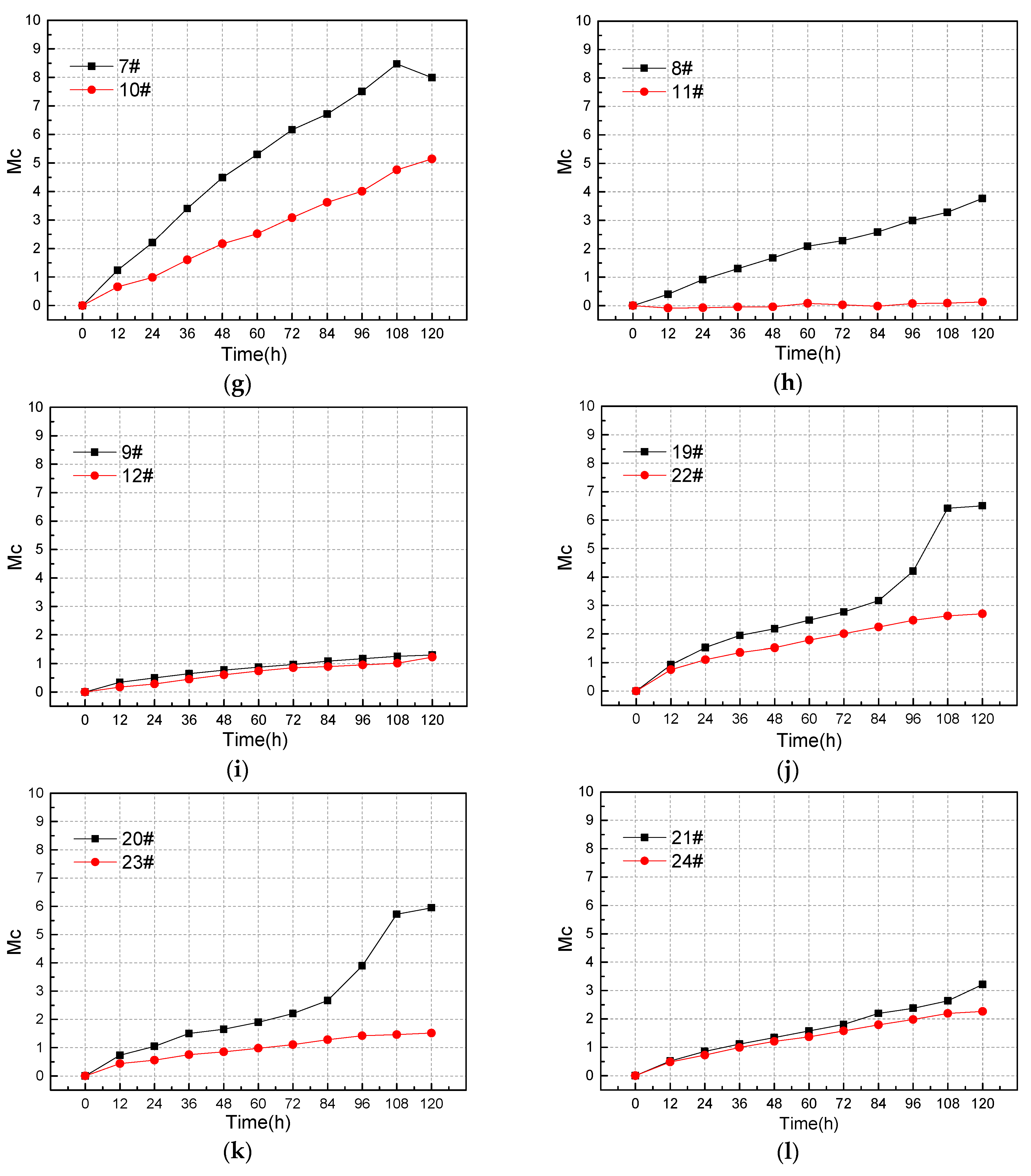

3.2.3. Correlation between Rust-Magnetic Fluctuation Parameter Mc and Steel Bar Diameter

4. Conclusions

- (1)

- In the steel bar corrosion test of the steel-reinforced concrete test piece, the tangential component By of the magnetic flux leakage signal on the surface of the test piece is deepened as the degree of corrosion increases; the extreme value in the rusted area becomes larger and larger. The width of the rusted area becomes wider as the degree of rust increases due to the diffusion of the electrolyte in the concrete. The “origin of magnetic flux leakage signal” By0 is defined as a reference point in the data analysis in order to carry out data comparison more finely; it can more effectively add the magnetic signal curve under each rust condition to the comparison.

- (2)

- Besides, the “rust magnetic fluctuation parameter” Mc is also proposed in this paper. Let the area sandwiched between the magnetic signal curve and the straight line By = By0 formed by the magnetic signal origin extending in the direction of the reinforcing bar under each corrosion condition be Sqmax. Let the area sandwiched by the magnetic signal curve and By = By0 under the non-corrosive condition be Sqmin. (Sqmax − Sqmin)/Sqmin is the fluctuation parameter Mc.

- (3)

- The sudden change of the leakage magnetic field caused by the rust of the steel bar can be accurately reflected by the Mc parameter as well as the rate of change of the tangential component By of the magnetic flux leakage signal with the deepening of the rust depth. Moreover, it can be connected to various influencing factors. In this paper, the coefficient is related to the diameter of the steel bar. It is verified that under the same rust condition, the smaller the diameter of the steel bar, the larger the valley extreme value of the magnetic flux leakage signal, that is, the greater the fluctuation.

- (4)

- Based on the spontaneous magnetic leakage theory, a new idea and data processing method for the non-destructive detection of steel corrosion is provided by metal spontaneous magnetic leakage is this study. We were able to effectively remove the effect of the diameter of the reinforcing bar on the magnetic flux leakage signal. Furthermore, the accuracy of non-destructive detection of steel bar corrosion by the spontaneous magnetic leakage technology is effectively improved. The method has low cost, simple equipment, and safe and convenient operation, as well as good application prospects.

Author Contributions

Funding

Conflicts of Interest

References

- Li, L. Corrosion Monitoring of Reinforced Concrete Structure Based on Electrochemical Theory. J. Nanoelectron. Optoelectron. 2018, 13, 572–577. [Google Scholar] [CrossRef]

- Jung, J.S.; Lee, B.Y.; Lee, K.S. Experimental Study on the Structural Performance Degradation of Corrosion-Damaged Reinforced Concrete Beams. Adv. Civ. Eng. 2019, 2019, 14. [Google Scholar] [CrossRef]

- James, A.; Bazarchi, E.; Chiniforush, A.A.; Aghdam, P.P.; Hosseini, M.R.; Akbarnezhad, A.; Martek, I.; Ghodoosi, F. Rebar Corrosion Detection, Protection, and Rehabilitation of Reinforced Concrete Structures in Coastal Environments: A Review. Constr. Build. Mater. 2019, 224, 1026–1039. [Google Scholar] [CrossRef]

- Zhang, H.; Liao, L.; Zhao, R.; Zhou, J.; Yang, M.; Xia, R. The Non-Destructive Test of Steel Corrosion in Reinforced Concrete Bridges Using a Micro-Magnetic Sensor. Sensors 2016, 16, 1439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, H.; Zhou, J.; Zhao, R.; Liao, L.; Yang, M.; Xia, R. Experimental Study On Detection of Rebar Corrosion in Concrete Based On Metal Magnetic Memory. Int. J. Robot. Autom. 2017, 32, 530–537. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.M.; Zhu, J.S. Study on characteristics of local stress concentration of corroded reinforcing bars in concrete. In Proceedings of the 20th National Bridge Conference, Wuhan, China, 15–17 May 2012. [Google Scholar]

- Sassine, E.; Laurens, S.; Francois, R.; Ringot, E. A Critical Discussion on Rebar Electrical Continuity and Usual Interpretation Thresholds in the Field of Half-Cell Potential Measurements in Steel Reinforced Concrete. Mater. Struct. 2018, 51, 93. [Google Scholar] [CrossRef]

- Scully, J.R. Polarization Resistance Method for Determination of Instantaneous Corrosion Rates. Corrosion 2000, 56, 199–204. [Google Scholar] [CrossRef]

- Angst, U.; Buechler, M. On the Applicability of the Stern-Geary Relationship to Determine Instantaneous Corrosion Rates in Macro-Cell Corrosion. Mater. Corros. 2015, 66, 1017–1028. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Cobo, A.; Gonzalez, M.N.; Feliu, S. On-Site Determination of Corrosion Rate in Reinforced Concrete Structures by Use of Galvanostatic Pulses. Corros. Sci. 2001, 43, 611–625. [Google Scholar] [CrossRef]

- Macdonald, D.D.; Mckubre, M.; Urquidimacdonald, M. Theoretical Assessment of Ac Impedance Spectroscopy for Detecting Corrosion of Rebar in Reinforced-Concrete. Corrosion 1988, 44, 2–7. [Google Scholar] [CrossRef]

- Bellezze, T.; Giuliani, G.; Roventi, G. Study of Stainless Steels Corrosion in a Strong Acid Mixture. Part 1: Cyclic Potentiodynamic Polarization Curves Examined by Means of an Analytical Method. Corros. Sci. 2018, 130, 113–125. [Google Scholar] [CrossRef]

- Zou, X.; Schmitt, T.; Perloff, D.; Wu, N.; Yu, T.; Wang, X. Nondestructive Corrosion Detection Using Fiber Optic Photoacoustic Ultrasound Generator. Measurement 2015, 62, 74–80. [Google Scholar] [CrossRef]

- Du, C.; Twumasi, J.O.; Tang, Q.; Guo, X.; Zhou, J.; Yu, T.; Wang, X. All-Optical Photoacoustic Sensors for Steel Rebar Corrosion Monitoring. Sensors 2018, 18, 1353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cho, H.M.; Cho, H.S.; Kim, K.S.; Lim, H.W.; Park, S.Y.; Lee, S.R.; Kim, K.C.; Je, U.K.; Park, Y.O.; Hong, D.K.; et al. Experimental Study On the Application of a Compressed-Sensing (CS)-based Deblurring Method in X-Ray Nondestructive Testing and its Image Performance. NDT&E Int. 2015, 75, 1–7. [Google Scholar]

- Hanke, R.; Fuchs, T.; Uhlmann, N. X-Ray Based Methods for Non-Destructive Testing and Material Characterization. Nucl. Instrum. Methods A 2008, 591, 14–18. [Google Scholar] [CrossRef]

- Shim, H.; Choi, M.S.; Lee, D.H.; Hur, D.H. A Prediction Method for the General Corrosion Behavior of Alloy 690 Steam Generator Tube Using Eddy Current Testing. Nucl. Eng. Des. 2016, 297, 26–31. [Google Scholar] [CrossRef]

- Xu, C.; Zhou, N.; Xie, J.; Gong, X.; Chen, G.; Song, G. Investigation On Eddy Current Pulsed Thermography to Detect Hidden Cracks On Corroded Metal Surface. NDT&E Int. 2016, 84, 27–35. [Google Scholar]

- Wicker, M.; Alduse, B.P.; Jung, S. Detection of Hidden Corrosion in Metal Roofing Shingles Utilizing Infrared Thermography. J. Build. Eng. 2018, 20, 201–207. [Google Scholar] [CrossRef]

- Ruiko, W.; Toshiaki, M. Study On Evaluation of Corrosion Condition of Reinforcing Bar Embedded Concrete Using Infrared Thermal Imaging Camera. Int. Soc. Opt. Photonics 2017, 10170, 101702N. [Google Scholar]

- Li, D.; Tan, M.; Zhang, S.; Ou, J. Stress Corrosion Damage Evolution Analysis and Mechanism Identification for Prestressed Steel Strands Using Acoustic Emission Technique. Struct. Control Health Monit. 2018, 25, e2189. [Google Scholar] [CrossRef]

- Mangual, J.; ElBatanouny, M.K.; Velez, W.; Ziehl, P.; Matta, F.; Gonzalez, M. Characterization of Corrosion Damage in Prestressed Concrete Using Acoustic Emission. Int. Soc. Opt. Photonics 2012, 8345, 834543. [Google Scholar]

- Qu, Y.H.; Zhang, H.; Zhao, R.Q.; Liao, L.; Zhou, Y. Research On the Method of Predicting Corrosion Width of Cables Based On the Spontaneous Magnetic Flux Leakage. Materials 2019, 12, 2154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, B.; Fu, Y.; Xu, B. Study on Metal Magnetic Memory Testing Mechanism. Res. Nondestruct. Eval. 2015, 26, 1–12. [Google Scholar] [CrossRef]

- Guo, P.J.; Guan, W.H.; Yan, C.Z.; Qin, Z.C.; Chen, X.D. Characteristics of Spontaneous Magnetic Field of Artificial Crack Induced by Complex Stress in Large Components. Amsterdam 2015, 130, 1642–1648. [Google Scholar] [CrossRef] [Green Version]

- Xia, R.; Zhou, J.; Zhang, H.; Zhou, D.; Zhang, Z. Experimental Study On Corrosion of Unstressed Steel Strand Based On Metal Magnetic Memory. KSCE J. Civ. Eng. 2019, 23, 1320–1329. [Google Scholar] [CrossRef]

| Type of Steel | Chemical Composition | ||||

|---|---|---|---|---|---|

| C | Si | Mn | P | S | |

| HRB400 | 0.2 | 0.4 | 1.3 | 0.03 | 0.02 |

| Number | Name | Number | Name |

|---|---|---|---|

| 1# | 2000-120-30-a | 13# | 2000-120-30-b |

| 2# | 2000-120-40-a | 14# | 2000-120-40-b |

| 3# | 2000-120-50-a | 15# | 2000-120-50-b |

| 4# | 2000-160-30-a | 16# | 2000-160-30-b |

| 5# | 2000-160-40-a | 17# | 2000-160-40-b |

| 6# | 2000-160-50-a | 18# | 2000-160-50-b |

| 7# | 1500-120-30-a | 19# | 1500-120-30-b |

| 8# | 1500-120-40-a | 20# | 1500-120-40-b |

| 9# | 1500-120-50-a | 21# | 1500-120-50-b |

| 10# | 1500-160-30-a | 22# | 1500-160-30-b |

| 11# | 1500-160-40-a | 23# | 1500-160-40-b |

| 12# | 1500-160-50-a | 24# | 1500-160-50-b |

| Rebar Diameter | 12 h | 24 h | 36 h | 48 h | 60 h | 72 h | 84 h | 96 h | 108 h | 120 h |

|---|---|---|---|---|---|---|---|---|---|---|

| d = 12 mm | 14.2% | 28.4% | 42.5% | 56.7% | 70.9% | 85.1% | 99.3% | 113.4% | 127.6% | 141.8% |

| d = 16 mm | 8.0% | 16.0% | 23.9% | 31.9% | 39.9% | 47.9% | 55.8% | 63.8% | 71.8% | 79.8% |

| Rebar Diameter | 12 h | 24 h | 36 h | 48 h | 60 h | 72 h | 84 h | 96 h | 108 h | 120 h |

|---|---|---|---|---|---|---|---|---|---|---|

| d = 12 mm | 9.5% | 18.9% | 28.4% | 37.8% | 47.3% | 56.7% | 66.2% | 75.6% | 85.1% | 94.5% |

| d = 16 mm | 5.3% | 10.6% | 16.0% | 21.3% | 26.6% | 31.9% | 37.2% | 42.5% | 47.9% | 53.2% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Zhou, J.; Xia, Q.; Zhang, S.; Zhang, H. Non-Destructive Testing of Steel Corrosion Fluctuation Parameters Based on Spontaneous Magnetic Flux Leakage and Its Relationship with Steel Bar Diameter. Materials 2019, 12, 4116. https://doi.org/10.3390/ma12244116

Zhao Q, Zhou J, Xia Q, Zhang S, Zhang H. Non-Destructive Testing of Steel Corrosion Fluctuation Parameters Based on Spontaneous Magnetic Flux Leakage and Its Relationship with Steel Bar Diameter. Materials. 2019; 12(24):4116. https://doi.org/10.3390/ma12244116

Chicago/Turabian StyleZhao, Qingyuan, Jianting Zhou, Qianwen Xia, Senhua Zhang, and Hong Zhang. 2019. "Non-Destructive Testing of Steel Corrosion Fluctuation Parameters Based on Spontaneous Magnetic Flux Leakage and Its Relationship with Steel Bar Diameter" Materials 12, no. 24: 4116. https://doi.org/10.3390/ma12244116