Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process

Abstract

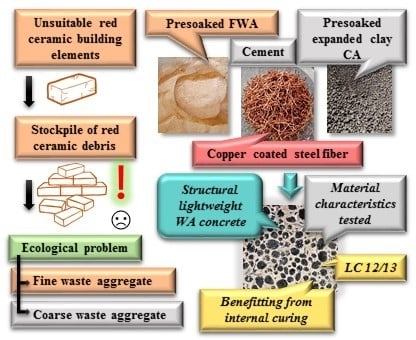

:1. Introduction

2. Used Materials

3. Design of the Concrete Mix

4. Conducted Tests and Results

4.1. Compressive Strength

4.2. Splitting Tensile Strength

4.3. Static Modulus of Elasticity

4.4. Dynamic Modulus of Elasticity

4.5. Flexural Characteristics

4.6. Shear Strength

5. Discussion

6. Conclusions

- -

- It is feasible to create concrete using only pre-soaked porous aggregates and no extra water;

- -

- The proposed method of the creation of lightweight concretes with no extra water is easy to execute both in laboratory and in situ;

- -

- Achieved density and basic compressive strength enable created concretes to be classified using strength classes according to EN 206-01;

- -

- Achieved flexural characteristics enabled using fib Model Code 2010 [36] strength classes of SFRC;

- -

- All cast SFRC are enabled for reinforcement substitution;

- -

- The mechanical properties of cast SFRC enable using them for the chosen structural applications;

- -

- Additional tests associated with the durability and thermal conductivity of concretes in question should be conducted.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and Applications of Foamed Concrete; A Review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Neville, A.; Brooks, J. Concrete Technology, 2nd ed.; Pearson Canada Inc.: Newmarket, ON, Canada, 2010. [Google Scholar] [CrossRef]

- Katzer, J.; Kobaka, J. Harnessing Waste Fine Aggregate for Sustainable Production of Concrete Precast Elements. Rocznik Ochr. Srodowiska 2010, 12, 33–45. [Google Scholar]

- Suzuki, M.; Seddik Meddah, M.; Sato, R. Use of Porous Ceramic Waste Aggregates for Internal Curing of High-Performance Concrete. Cem. Concr. Res. 2009, 39, 373–381. [Google Scholar] [CrossRef]

- Cichocki, K.; Domski, J.; Katzer, J.; Ruchwa, M. Mechanical Properties and Numerical Approach to Fibre Reinforced Wca Concrete Slabs. In Brittle Matrix Composites 11; Andrzej, B., Jan, O., Michał, G., Christopher, L., Jerzy, L., Eds.; Institute of Fundamental Technological Research Polish Academy of Sciences: Warsaw, Poland, 2015; pp. 309–318. [Google Scholar]

- Rahhal, V.F.; Trezza, M.A.; Tironi, A.; Castellano, C.C.; Pavlíková, M.; Pokorný, J.; Irassar, E.F.; Jankovský, O.; Pavlík, Z. Complex Characterization and Behavior of Waste Fired Brick Powder-Portland Cement System. Materials 2019, 12, 1650. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seitl, S.; Viszlay, V.; Domski, J.; Katzer, J. Fracture Mechanical Properties of Cement Based Composites with Various Amount of Waste Aggregates. Procedia Eng. 2017, 190, 345–351. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of Selected Waste Materials in Concrete Mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef] [PubMed]

- Ogrodnik, P.; Szulej, J.; Franus, W. The Wastes of Sanitary Ceramics as Recycling Aggregate to Special Concretes. Materials 2018, 11, 1275. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Katzer, J.; Kuźmińska, E. Optimal Composition of Blended Waste Ceramic Aggregate. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies SCMT4, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Cichocki, K.; Domski, J.; Katzer, J.; Ruchwa, M. Static and Dynamic Characteristics of Waste Ceramic Aggregate Fibre Reinforced Concrete. Trans. VŠB–Tech. Univ. Ostrava, Civ. Eng. Ser. 2016, 15. [Google Scholar] [CrossRef] [Green Version]

- Spratt, B.H. Lightweight Aggregate Concrete; Civil Engineering: London, UK, 1984. [Google Scholar]

- EN 933-2. Tests for Geometrical Properties of Aggregates-Part 2: Determination of Particle Size Distribution-Test Sieves, Nominal Size of Apertures; BSI-British Standard Institution: London, UK, 1996. [Google Scholar]

- Katzer, J. Median Diameter as a Grading Characteristic for Fine Aggregate Cement Composite Designing. Constr. Build. Mater. 2012, 35, 884–887. [Google Scholar] [CrossRef]

- EN 1097-6. Tests for Mechanical and Physical Properties of Aggregates-Part 6: Determination of Particle Density and Water Absorption; BSI-British Standard Institution: London, UK, 2013. [Google Scholar]

- EN 1097-3. Tests for Mechanical and Physical Properties of Aggregates-Part 3: Determination of Loose Bulk Density and Voids; BSI-British Standard Institution: London, UK, 1998. [Google Scholar]

- EN 197-1. Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements; BSI-British Standard Institution: London, UK, 2011. [Google Scholar]

- EN 1008. Mixing Water for Concrete-Specification for Sampling, Testing and Assessing the Suitability of Water, Including Water Recovered from Processes in the Concrete Industry, as Mixing Water for Concrete; BSI-British Standard Institution: London, UK, 2002. [Google Scholar]

- Katzer, J.; Domski, J. Quality and Mechanical Properties of Engineered Steel Fibres Used as Reinforcement for Concrete. Constr. Build. Mater. 2012, 34, 243–248. [Google Scholar] [CrossRef]

- Naaman, A.E. Engineered Steel Fibers with Optimal Properties for Reinforcement of Cement Composites. J. Adv. Concr. Technol. 2003, 1, 241–525. [Google Scholar] [CrossRef] [Green Version]

- American Society for Testing and Materials. Standard Test Method for Tensile Strength and Young’s Modulus of Fibers; ASTM C1557-14; ASTM international: West Conshohocken, PA, USA, 2014; pp. 1–10. [Google Scholar] [CrossRef]

- ACI 211.2-98. Standard Practice for Selecting Proportions for Structural Lightweight Concrete; ACI Committee 211: Farmington Hills, MI, USA, 1998. [Google Scholar]

- ACI 213R-03. Guide for Structural Lightweight Aggregate Concrete; ACI Committee 213: Farmington Hills, MI, USA, 2014. [Google Scholar]

- EN 12350-2. Testing Fresh Concrete-Part 2: Slump Test; British Standard Institution: London, UK, 2009. [Google Scholar]

- Di Prisco, M.; Plizzari, G.; Vandewalle, L. Fibre Reinforced Concrete: New Design Perspectives. Mater. Struct. 2009, 42, 1261–1281. [Google Scholar] [CrossRef]

- EN 206-1. Performance-Based Specifications and Control of Concrete Durability. Concrete-Part 1: Specification, Performance, Production and Conformity; BSI-British Standard Institution: London, UK, 2006. [Google Scholar]

- ImageJ. Available online: https://imagej.nih.gov/ (accessed on 10 December 2019).

- EN 12390-3. Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens; BSI-British Standard Institution: London, UK, 2009. [Google Scholar]

- Kobaka, J.; Katzer, J.; Ponikiewski, T. A Combined Electromagnetic Induction and Radar-Based Test for Quality Control of Steel Fibre Reinforced Concrete. Materials 2019, 12, 3507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- EN 12390-6. Testing Hardened Concrete-Part 6: Tensile Splitting Strength of Test Specimens; BSI-British Standard Institution: London, UK, 2009. [Google Scholar]

- EN 12390-13. Testing Hardened Concrete-Part 13: Determination of Secant Modulus of Elasticity in Compression; BSI-British Standard Institution: London, UK, 2013. [Google Scholar]

- ČSN 73 1371. Non-Destructive Testing of Concrete–Method of Ultrasonic Pulse Testing of Concrete; TNK-Technical normalization commission: Prague, Czech Republic, 2011. [Google Scholar]

- EN 14651. Test Method for Metallic Fibred Concrete—Measuring the Flexural Tensile Strength; BSI-British Standard Institution: London, UK, 2005. [Google Scholar]

- Domski, J.; Katzer, J. Validation of Aramis Digital Image Correlation System for Tests of Fibre Concrete Based on Waste Aggregate. Key Eng. Mater. 2018, 761, 106–110. [Google Scholar] [CrossRef]

- EN 12390-5. Testing Hardened Concrete–Part 5: Flexural Strength of Test Specimens; BSI-British Standard Institution: London, UK, 2019. [Google Scholar]

- Walvaren, J. Model Code 2010, Final Drafts. In FIB Bulletins; FIB International: Lausanne, Switzerland, 2012; Volume 1, p. 105. [Google Scholar]

- JCI-SF6. Method of Test for Shear Strength of Fibre Reinforced Concrete; Joint Commission International: Oakbrook Terrace, IL, USA, 1984; pp. 57–59. [Google Scholar]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Compressive and Flexural Strength of Fiber-Reinforced Foamed Concrete: Effect of Fiber Content, Curing Conditions and Dry Density. Constr. Build. Mater. 2019, 198, 479–493. [Google Scholar] [CrossRef]

- Bagherzadeh, R.; Pakravan, H.R.; Sadeghi, A.H.; Latifi, M.; Merati, A.A. An Investigation on Adding Polypropylene Fibers to Reinforce Lightweight Cement Composites (LWC). J. Eng. Fibers Fabr. 2012, 7, 13–21. [Google Scholar] [CrossRef]

| Aggregate | Fineness Modulus by | Median Diameter | Bulk Density | Water | |||

|---|---|---|---|---|---|---|---|

| Hummel | Abrams | Kuczynski | Loose | Compacted | Absorptivity | ||

| mH [-] | mA [-] | mK [-] | dm [mm] | [kg/m3] | [kg/m3] | [%] | |

| ECCA | 915.57 | 5.98 | 0.50 | 6.48 | 318.8 | 345.8 | 36 |

| WRCFA | 587.83 | 2.16 | 0.62 | 0.41 | 1183.8 | 1489.2 | 46 |

| Nominal | FIER | Aspect Ratio | Density | |

|---|---|---|---|---|

| Length [mm] | Diameter [mm] | [-] | [-] | [kg/m3] |

| 30.8 | 0.73 | 169.4 | 42.3 | 7800 |

| WRCFA [kg/m3] | ECCA [kg/m3] | Cement [kg/m3] | Fiber [kg/m3] | ||

|---|---|---|---|---|---|

| dry | 378.38 | 247.07 | 320.49 | Vf = 0.5% | 39.0 |

| soaked | 700.71 | 386.05 | - | Vf = 1.0% | 78.0 |

| absorbed water | 322.33 | 138.98 | - | Vf = 1.5% | 117.0 |

| Vf [%] | Slump [mm] | Consistency Class (EN 12350-2) |

|---|---|---|

| 0.0% | 80.0 | S2 |

| 0.5% | 70.0 | S2 |

| 1.0% | 70.0 | S2 |

| 1.5% | 32.5 | S1 |

| Specimens | Density [kg/m3] | ||||

|---|---|---|---|---|---|

| Shape | Size [mm] | Vf = 0.0% | Vf = 0.5% | Vf = 1.0% | Vf = 1.5% |

| Cubes | 100 × 100 × 100 | 1356.99 | 1405.06 | 1434.94 | 1480.00 |

| Cylinders | Φ150 × 300 | 1370.86 | 1413.00 | 1444.63 | 1500.21 |

| Beams | 150 × 150 × 600 | 1372.03 | 1444.15 | 1471.31 | 1474.45 |

| Mean value | 1366.63 | 1420.74 | 1450.29 | 1484.89 | |

| Properties | Vf [%] | |||

|---|---|---|---|---|

| 0.0 | 0.5 | 1.0 | 1.5 | |

| fLOP [MPa] | 1.42 * | 1.76 | 1.69 | 1.65 |

| Residual Strength | ||||

| fR1 [MPa] | n/a | 0.83 | 2.28 | 2.46 |

| fR2 [MPa] | n/a | 0.72 | 1.82 | 2.12 |

| fR3 [MPa] | n/a | 0.61 | 1.48 | 1.61 |

| fR4 [MPa] | n/a | 0.50 | 1.17 | 1.25 |

| Strength Class and Reinforcement Substitution According to fib Model Code | ||||

| fR3/fR1 | n/a | 0.66 | 0.65 | 0.65 |

| fR1/fLOP | n/a | 0.53 | 1.35 | 1.49 |

| Class according to fib Model Code | n/a | 0.5a | 2.0a | 2.0a |

| Reinforcement substitution | n/a | enabled | enabled | enabled |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hornakova, M.; Katzer, J.; Kobaka, J.; Konecny, P. Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process. Materials 2019, 12, 4152. https://doi.org/10.3390/ma12244152

Hornakova M, Katzer J, Kobaka J, Konecny P. Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process. Materials. 2019; 12(24):4152. https://doi.org/10.3390/ma12244152

Chicago/Turabian StyleHornakova, Marie, Jacek Katzer, Janusz Kobaka, and Petr Konecny. 2019. "Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process" Materials 12, no. 24: 4152. https://doi.org/10.3390/ma12244152