Biobased Composites from Biobased-Polyethylene and Barley Thermomechanical Fibers: Micromechanics of Composites

Abstract

:1. Introduction

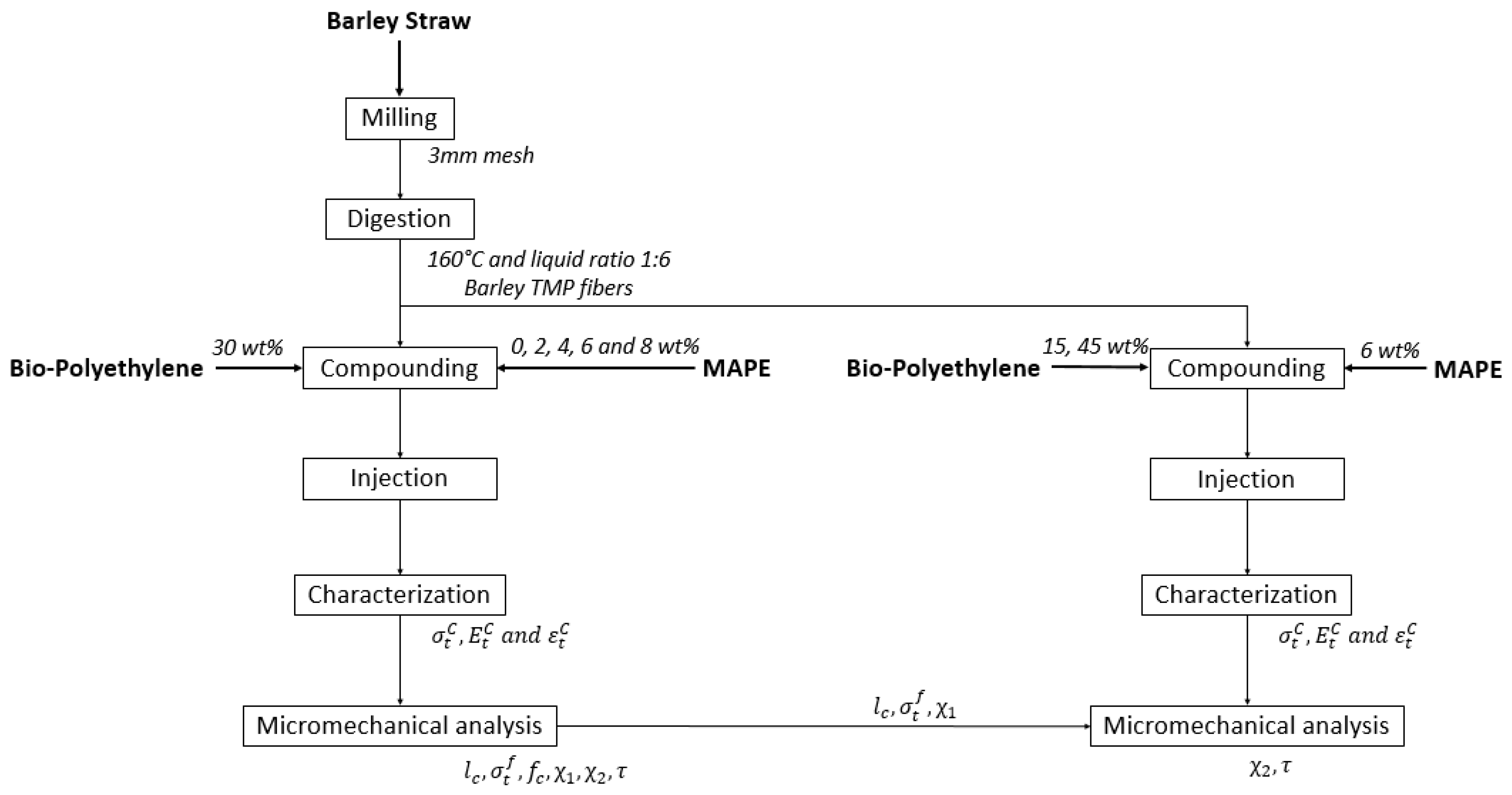

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

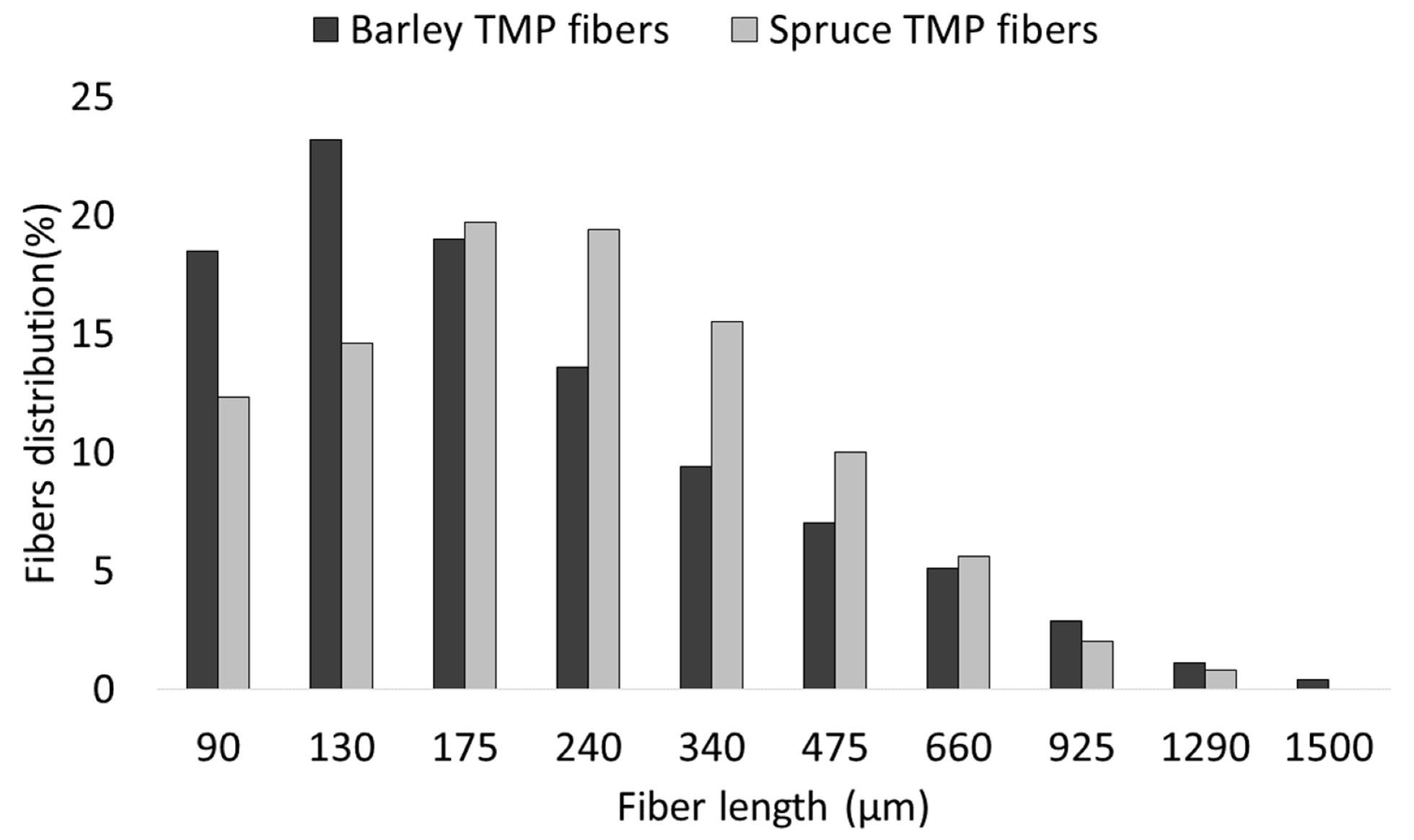

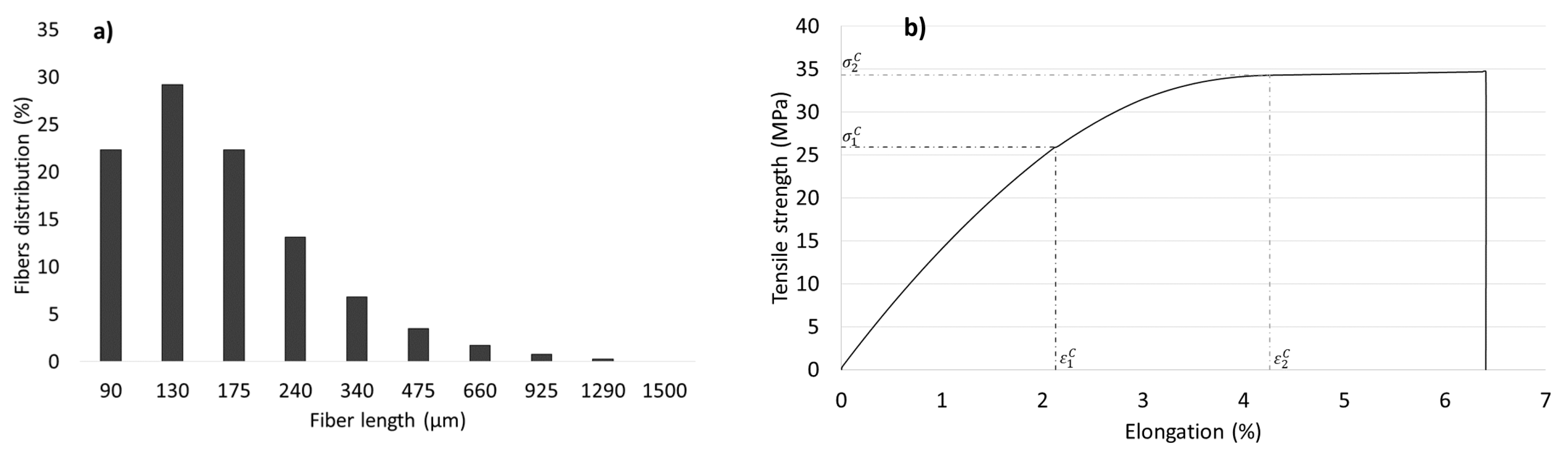

3.1. Fibers Assessment

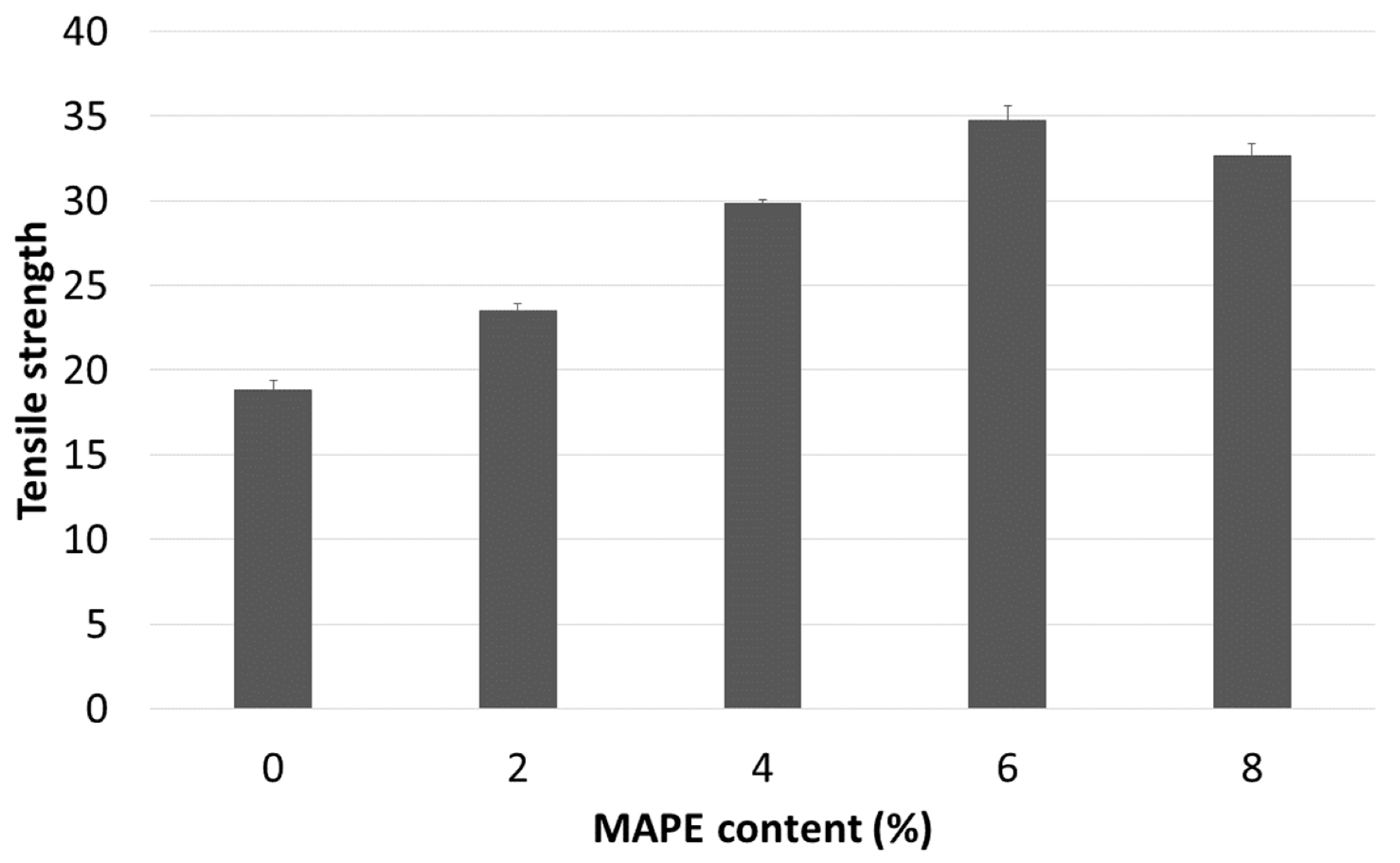

3.2. Coupling Agent Optimization

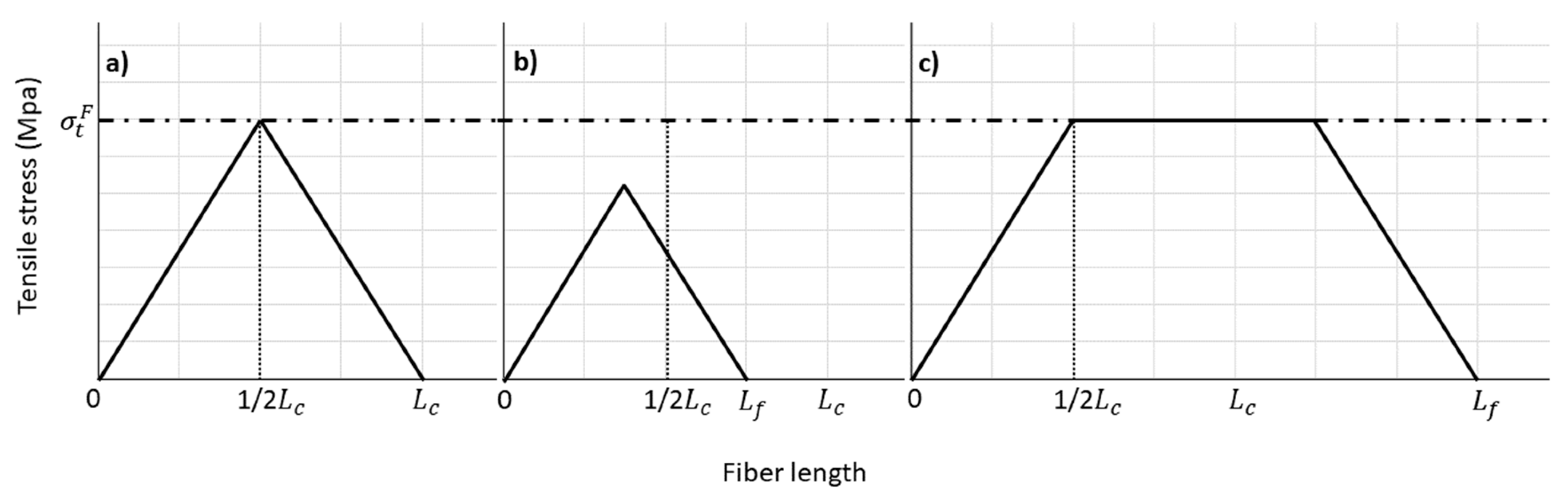

3.3. Mechanical Performance of Barley TMP/BioPE Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Zierdt, P.; Theumer, T.; Kulkarni, G.; Däumlich, V.; Klehm, J.; Hirsch, U.; Weber, A. Sustainable wood-plastic composites from bio-based polyamide 11 and chemically modified beech fibers. Sustain. Mater. Technol. 2015, 6, 6–14. [Google Scholar] [CrossRef]

- Balart, J.F.; García-Sanoguera, D.; Balart, R.; Boronat, T.; Sánchez-Nacher, L. Manufacturing and properties of biobased thermoplastic composites from poly(lactid acid) and hazelnut shell wastes. Polym. Compos. 2018, 39, 848–857. [Google Scholar] [CrossRef]

- Hoang, D.; Pham, T.; Nguyen, T.; An, H.; Kim, J. Organo-Phosphorus Flame Retardants for Poly(vinyl chloride)/Wood Flour Composite. Polym. Compos. 2018, 39, 961–970. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef] [Green Version]

- Dilkes-Hoffman, L.; Ashworth, P.; Laycock, B.; Pratt, S.; Lant, P. Public attitudes towards bioplastics—Knowledge, perception and end-of-life management. Resour. Conserv. Recycl. 2019, 151, 104479. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Franciszczak, P.; Meljon, A. High performance hybrid PP and PLA biocomposites reinforced with short man-made cellulose fibres and softwood flour. Compos. Part A Appl. Sci. Manuf. 2015, 74, 132–139. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Granda, L.; Tarres, Q.; Espinach, F.X.; Julian, F.; Mendes, A.; Delgado-Aguilar, M.; Mutje, P. Fully biodegradable polylactic composites reinforced with bleached softwood fibers. Cellul. Chem. Technol. 2016, 50, 417–422. [Google Scholar]

- Yusoff, R.B.; Takagi, H.; Nakagaito, A.N. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind. Crops Prod. 2016, 94, 562–573. [Google Scholar] [CrossRef]

- Brodin, M.; Vallejos, M.; Opedal, M.T.; Area, M.C.; Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Clean. Prod. 2017, 162, 646–664. [Google Scholar] [CrossRef]

- Ferrero, B.; Fombuena, V.; Fenollar, O.; Boronat, T.; Balart, R. Development of Natural Fiber-Reinforced Plastics (NFRP) Based on Biobased Polyethylene and Waste Fibers From Posidonia oceanica Seaweed. Polym. Polym. Compos. 2008, 36, 1378–1385. [Google Scholar] [CrossRef]

- Yang, H.S.; Kim, H.J.; Park, H.J.; Lee, B.J.; Hwang, T.S. Water absorption behavior and mechanical properties of lignocellulosic filler-polyolefin bio-composites. Compos. Struct. 2006, 72, 429–437. [Google Scholar] [CrossRef]

- Hurter, R.W. Nonwood fibres & moulded products. Pap. Technol. 2015, 56, 14–17. [Google Scholar]

- Espinosa, E.; Sánchez, R.; Otero, R.; Domínguez-Robles, J.; Rodríguez, A. A comparative study of the suitability of different cereal straws for lignocellulose nanofibers isolation. Int. J. Biol. Macromol. 2017, 103, 990–999. [Google Scholar] [CrossRef] [PubMed]

- Juárez, M.; Sánchez, R.; Espinosa, E.; Domínguez-Robles, J.; Bascón-Villegas, I.; Rodríguez, A. Environmentally friendly lignocellulose nanofibres from barley straw. Cellul. Chem. Technol. 2018, 52, 589–595. [Google Scholar]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Vargas, F.; González, Z.; Rojas, O.; Garrote, G.; Rodríguez, A. Barley Straw (Hordeum vulgare) as a supplementary raw material for eucalyptus camaldulensis and pinus sylvestris kraft pulp in the paper industry. BioResource 2015, 10, 3682–3693. [Google Scholar] [CrossRef] [Green Version]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Liu, N.C.; Baker, W.E. Reactive polymers for blend compatibilization. Adv. Polym. Technol. 1992, 11, 249–262. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Compos. Part B Eng. 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Böras, L.; Gatenhol, P. Surface composition and morphology of CTMP fibers. Holzforschung 1999, 53, 188–194. [Google Scholar] [CrossRef]

- Yang, H.S.; Wolcott, M.P.; Kim, H.S.; Kim, H.J. Thermal properties of lignocellulosic filler-thermoplastic polymer bio-composites. J. Therm. Anal. Calorim. 2005, 82, 157–160. [Google Scholar] [CrossRef]

- ISO 2144:2019–Paper, Board, Pulps and Cellulose Nanomaterials—Determination of Residue (Ash Content) on Ignition at 900 °C; International Organization for Standardization: Geneva, Switzerland, 2019.

- TAPPI T204cm-07–Solvent Extractives of Wood and Pulp; Standard-Specific Interst Group: Atlanta, GA, USA, 2007.

- ISO/DIS 21436–Determination of Lignin Content; International Organization for Standardization: Geneva, Switzerland, 2019.

- ASTM D618-13: Standard Practice for Conditioning Plastics for Testing; ASTM International: West Conshohocken, PA, USA, 2013.

- Marques, G.; Rencoret, J.; Gutiérrez, A.; del Río, J.C. Evaluation of the Chemical Composition of Different Non-Woody Plant Fibers Used for Pulp and Paper Manufacturing. Open Agric. J. 2014, 4, 93–101. [Google Scholar] [CrossRef] [Green Version]

- López, J.P.; Méndez, J.A.; Espinach, F.X.; Julián, F.; Mutjé, P.; Vilaseca, F. Tensile Strength Characteristics of Polypropylene Composites Reinforced with Stone Groundwood Fibers from Softwood. BioResources 2012, 7, 3188–3200. [Google Scholar] [CrossRef]

- Joffre, T.; Miettinen, A.; Berthold, F.; Gamstedt, E.K. X-ray micro-computed tomography investigation of fibre length degradation during the processing steps of short-fibre composites. Compos. Sci. Technol. 2014, 105, 127–133. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Wood-fiber-reinforced poly(lactic acid) composites: Evaluation of the physicomechanical and morphological properties. J. Appl. Polym. Sci. 2006, 102, 4856–4869. [Google Scholar] [CrossRef]

- Nygård, P.; Tanem, B.S.; Karlsen, T.; Brachet, P.; Leinsvang, B. Extrusion-based wood fibre-PP composites: Wood powder and pelletized wood fibres—A comparative study. Compos. Sci. Technol. 2008, 68, 3418–3424. [Google Scholar] [CrossRef]

- Vilaseca, F.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Pelach, M.; Lopez, J.P.; Mutje, P. Biocomposites from abaca strands and polypropylene. Part I: Evaluation of the tensile properties. Bioresour. Technol. 2010, 101, 387–395. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.; Méndez, J.A.; Vilaseca, F.; Delgado-Aguilar, M.; Mutjé, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene: Flexural characterisation, impact behaviour and water uptake properties. Compos. Part B Eng. 2016, 97, 176–182. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibers. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Chamorro-Trenado, M.À.; Soler, J.; Mutjé, P.; Vilaseca, F.; Espinach, F.X. Macro and micromechanical preliminary assessment of the tensile strength of particulate rapeseed sawdust reinforced polypropylene copolymer biocomposites for its use as building material. Constr. Build. Mater. 2018, 168, 422–430. [Google Scholar] [CrossRef]

- Mutje, P.; Vallejos, M.E.; Girones, J.; Vilaseca, F.; Lopez, A.; Lopez, J.P.; Mendez, J.A. Effect of maleated polypropylene as coupling agent for polypropylene composites reinforced with hemp strands. J. Appl. Polym. Sci. 2006, 102, 833–840. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Tarrés, Q.; Méndez, J.A.; Delgado-Aguilar, M.; Mutjé, P. Towards a good interphase between bleached kraft softwood fi bers and poly (lactic) acid. Compos. Part B Eng. 2016, 99, 514–520. [Google Scholar] [CrossRef]

- Korabel’nikov, Y.G.; Rashkovan, I.A. Strength and mechanism of freacture of composites randomly reinforced with short carbon fibres. Fibre Chem. 2006, 38, 142–146. [Google Scholar] [CrossRef]

- Fukuda, H.; Chou, T.-W. A probabilistic theory of the strength of short-fibre composites with variable fibre length and orientation. J. Mater. Sci. 1982, 1003–1011. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Young, R.A.; Clemons, C.; Rowell, R.M. Recycled Newspaper Fibers as Reinforcing Fillers in Thermoplastics: Part I-Analysis of Tensile and Impact Properties in Polypropylene. J. Reinf. Plast. Compos. 1994, 13, 54–67. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W. Tensile porperties of fibre-reinforced metals-copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–338. [Google Scholar] [CrossRef]

- Mittal, R.K.; Gupta, V.B.; Sharma, P. The effect of fibre ortientation on the interfacial shear stress in short fibre-reinforced polypropylene. J. Mater. Sci. 1987, 22, 1949–1955. [Google Scholar] [CrossRef]

- Bowyer, W.H.; Bader, H.G. On the reinforcement of thermoplastics by imperfectly aligned discontinuous fibres. J. Mater. Sci. 1972, 7, 1315–1321. [Google Scholar] [CrossRef]

- Pegoretti, A.; Della Volpe, C.; Detassis, M.; Migliaresi, C.; Wagner, H.D. Thermomechanical behaviour of interfacial region in carbon fibre/epoxy composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1067–1074. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L.; Farrell, R.L. Determination of interfacial shear strength of white rot fungi treated hemp fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1165–1171. [Google Scholar] [CrossRef]

- Rodriguez, M.; Rodriguez, A.; Bayer, J.; Vilaseca, F.; Girones, J.; Mutje, P. Determination of corn stalk fibers’ strength through modeling of the mechanical properties of its composites. BioResources 2010, 5, 2535–2546. [Google Scholar]

- Trigui, A.; Karkri, M.; Pena, L.; Boudaya, C.; Candau, Y.; Bouffi, S.; Vilaseca, F. Thermal and mechanical properties of maize fibres-high density polyethylene biocomposites. J. Compos. Mater. 2013, 47, 1387–1397. [Google Scholar] [CrossRef]

- Peña, L.; González, I.; Bayer, R.J.; El Mansouri, N.E.; Vilaseca, F. Mechanical behavior of thermo-mechanical corn stalk fibers in high density polyethylene composites. J. Biobased Mater. Bioenergy 2012, 6, 463–469. [Google Scholar] [CrossRef]

| Holocellulose (%) | Klason Lignin (%) | Extractives (%) | Ash (%) | Length 1 (μm) | Diameter (μm) | |

|---|---|---|---|---|---|---|

| Barley straw | 70.12 ± 0.54 | 16.45 ± 0.34 | 5.90 ± 0.76 | 7.1 ± 0.2 | – | – |

| Barley TMP fibers | 77.67 ± 0.61 | 15.30 ± 0.46 | 2.73 ± 0.12 | 4.3 ± 0.3 | 745 | 19.6 |

| Spruce TMP fibers | 73.75 ± 0.83 | 25.80 ± 0.22 | 0.25 ± 0.34 | 0.2 ± 0.2 | 978 | 24.7 |

| MAPE (%) | VF | (MPa) | (GPa) | (%) | (MPa) |

|---|---|---|---|---|---|

| 0 | 0 | 18.05 ± 0.74 | 1.06 ± 0.08 | 12.18 ± 0.34 | 18.05 |

| 0 | 0.233 | 18.82 ± 0.60 | 1.73 ± 0.10 | 2.88 ± 0.27 | 13.29 |

| 2 | 23.51 ± 0.39 | 1.76 ± 0.05 | 3.37 ± 0.15 | 14.19 | |

| 4 | 29.84 ± 0.19 | 1.85 ± 0.07 | 5.19 ± 0.22 | 16.27 | |

| 6 | 34.70 ± 0.90 | 2.14 ± 0.04 | 5.47 ± 0.31 | 16.44 | |

| 8 | 32.65 ± 0.69 | 1.93 ± 0.05 | 5.67 ± 0.17 | 16.55 |

| Barley TMP (%) | VF | (MPa) | (GPa) | (%) | (MPa) |

|---|---|---|---|---|---|

| 0 | 0 | 18.05 ± 0.74 | 1.06 ± 0.08 | 12.18 ± 0.34 | 18.05 |

| 15 | 0.111 | 25.2 ± 0.64 | 1.85 ± 0.06 | 7.65 ± 0.24 | 16.37 |

| 30 | 0.233 | 34.7 ± 0.90 | 2.59 ± 0.04 | 6.45 ± 0.31 | 16.76 |

| 45 | 0.367 | 43.1 ± 0.57 | 3.55 ± 0.05 | 4.69 ± 0.33 | 15.86 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serra-Parareda, F.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Vilaseca, F. Biobased Composites from Biobased-Polyethylene and Barley Thermomechanical Fibers: Micromechanics of Composites. Materials 2019, 12, 4182. https://doi.org/10.3390/ma12244182

Serra-Parareda F, Tarrés Q, Delgado-Aguilar M, Espinach FX, Mutjé P, Vilaseca F. Biobased Composites from Biobased-Polyethylene and Barley Thermomechanical Fibers: Micromechanics of Composites. Materials. 2019; 12(24):4182. https://doi.org/10.3390/ma12244182

Chicago/Turabian StyleSerra-Parareda, Ferran, Quim Tarrés, Marc Delgado-Aguilar, Francesc X. Espinach, Pere Mutjé, and Fabiola Vilaseca. 2019. "Biobased Composites from Biobased-Polyethylene and Barley Thermomechanical Fibers: Micromechanics of Composites" Materials 12, no. 24: 4182. https://doi.org/10.3390/ma12244182

APA StyleSerra-Parareda, F., Tarrés, Q., Delgado-Aguilar, M., Espinach, F. X., Mutjé, P., & Vilaseca, F. (2019). Biobased Composites from Biobased-Polyethylene and Barley Thermomechanical Fibers: Micromechanics of Composites. Materials, 12(24), 4182. https://doi.org/10.3390/ma12244182