Effects of Pre-Stretching on Creep Behavior, Mechanical Property and Microstructure in Creep Aging of Al-Cu-Li Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

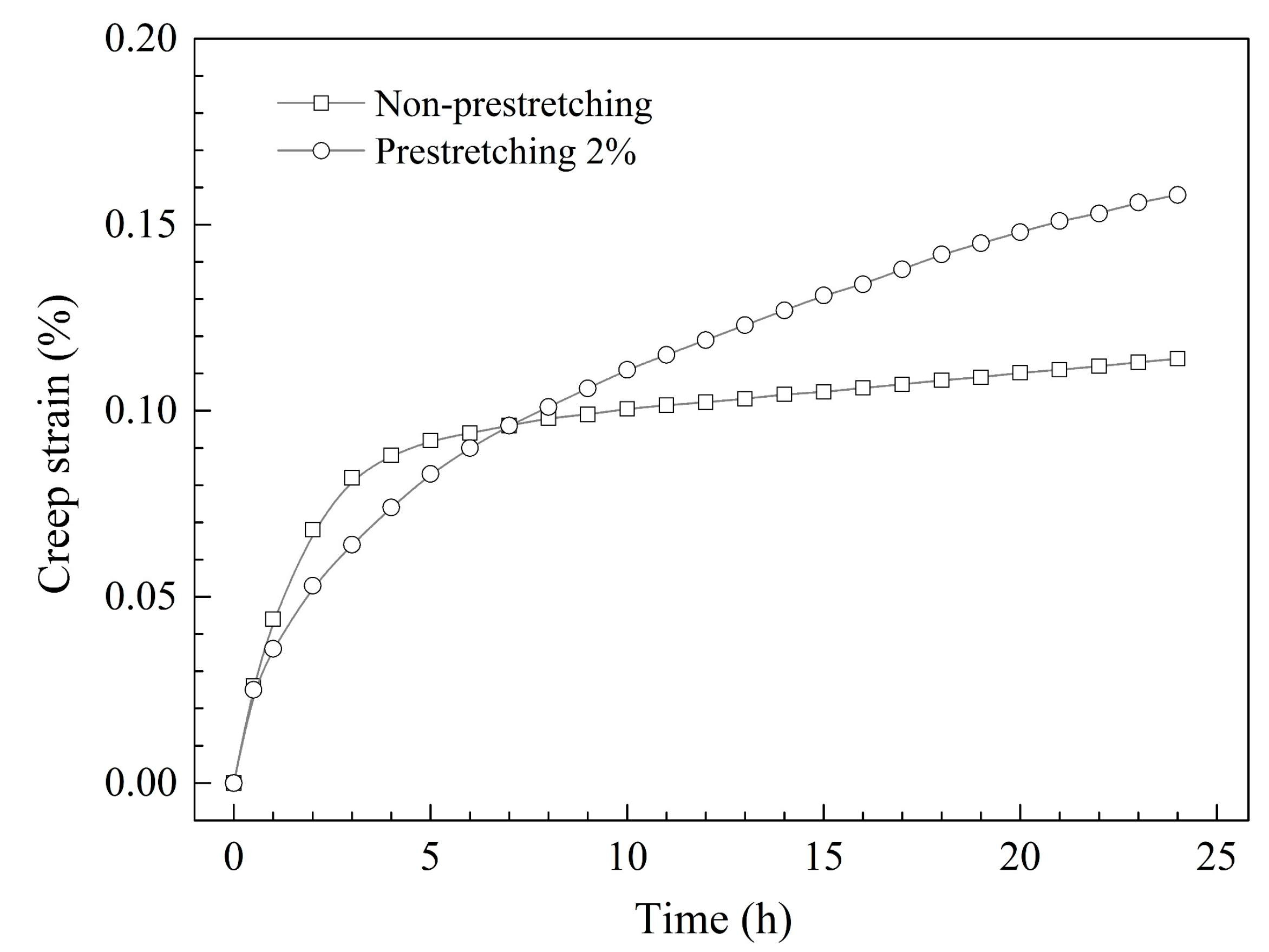

3.1. Creep Behavior

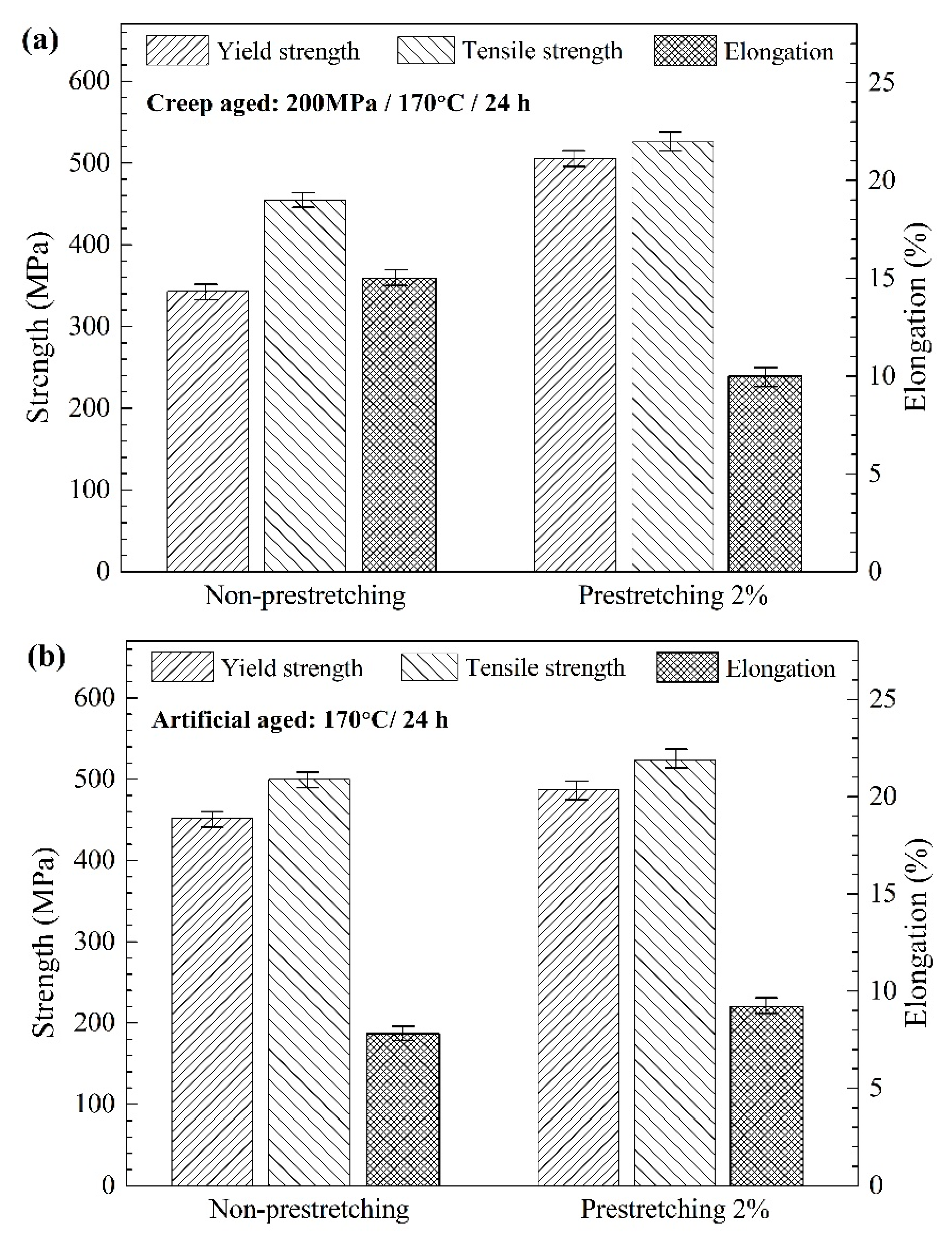

3.2. Mechanical Property

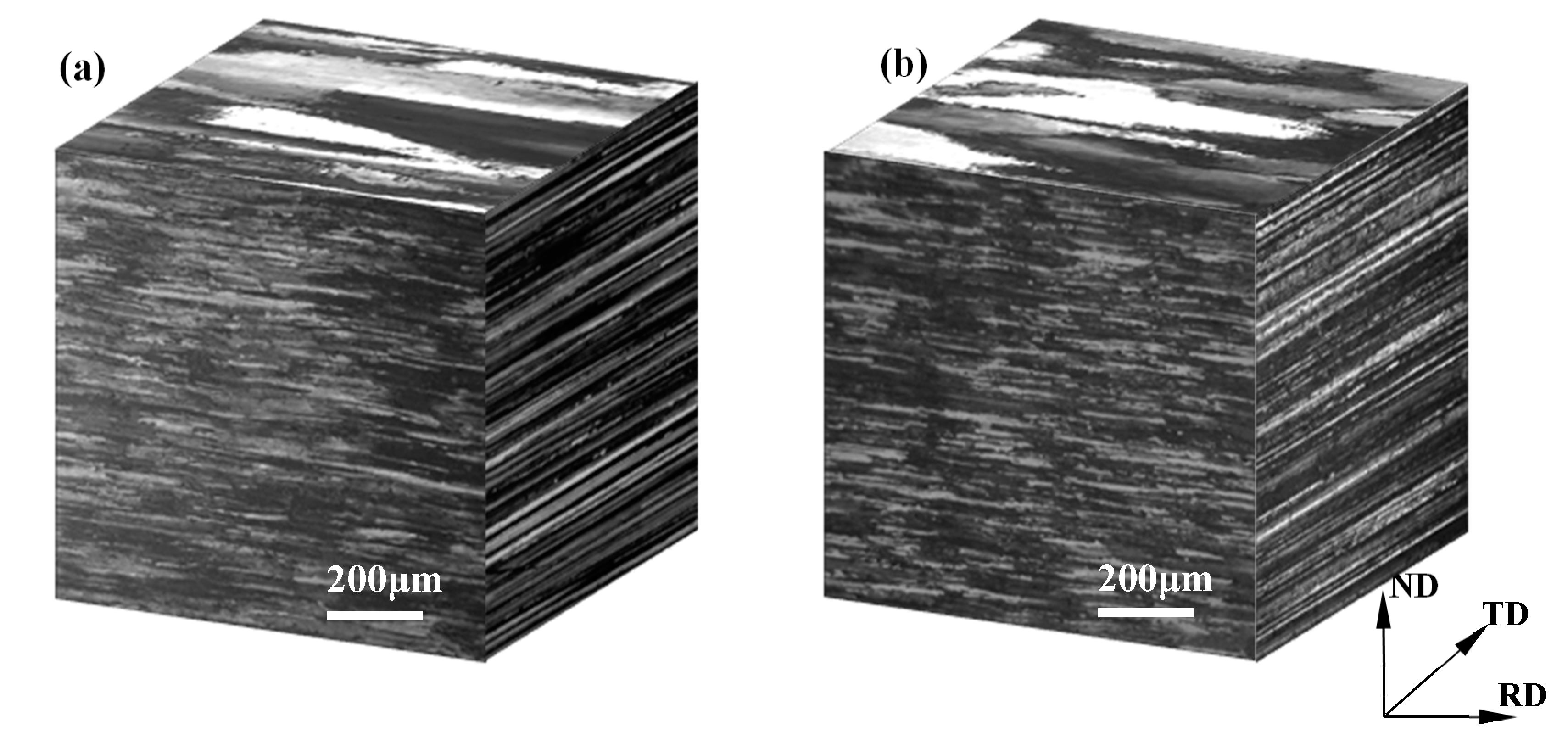

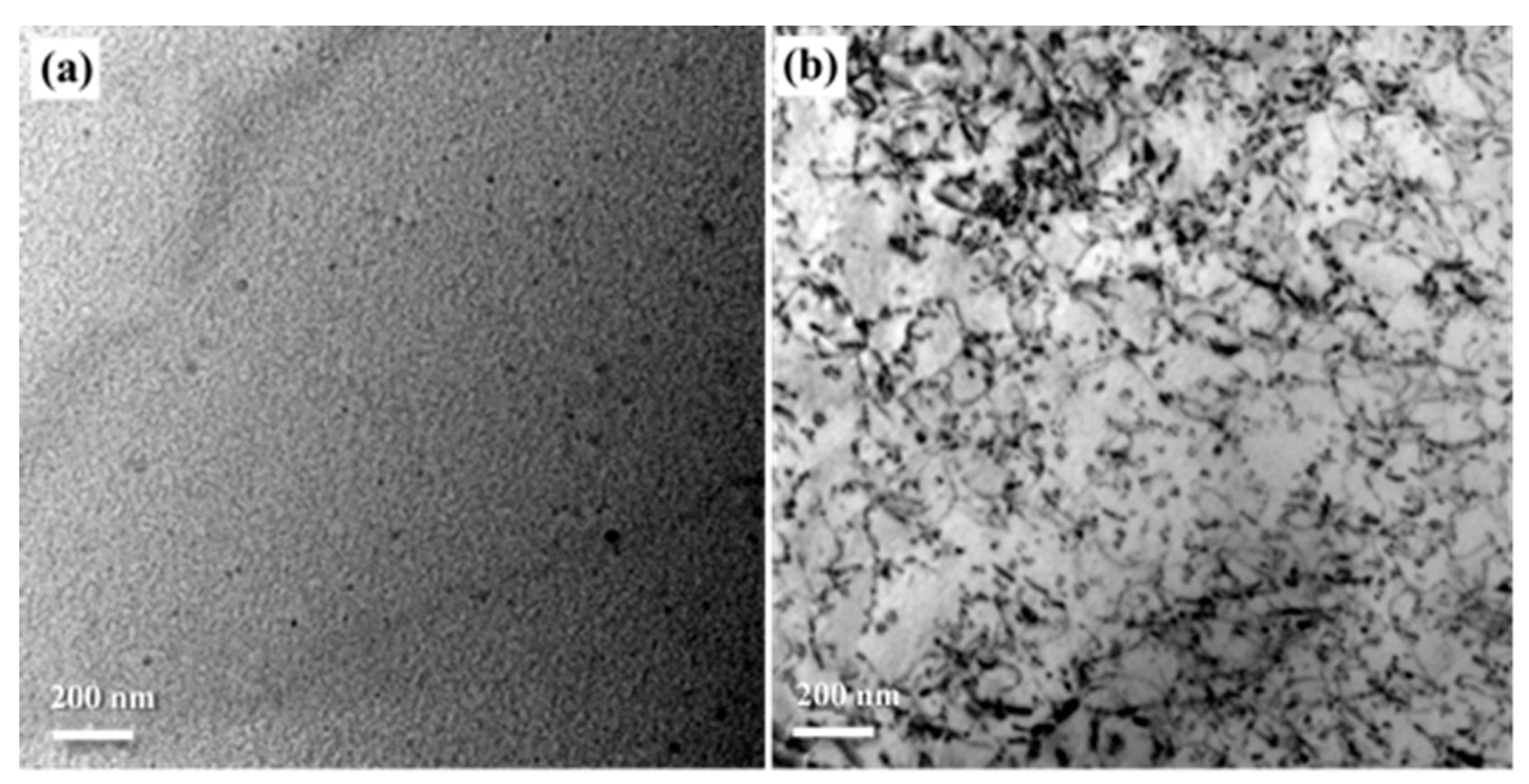

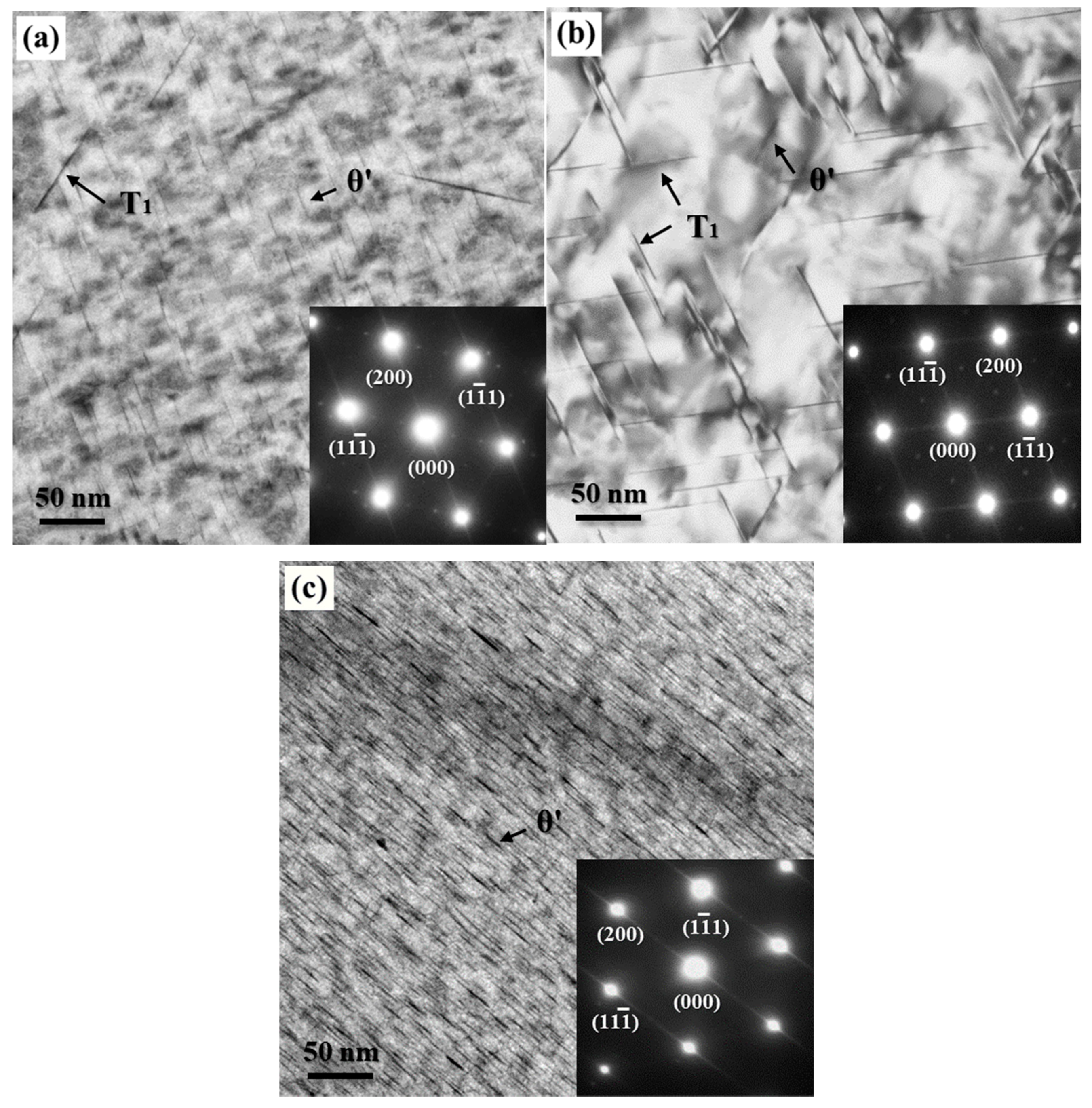

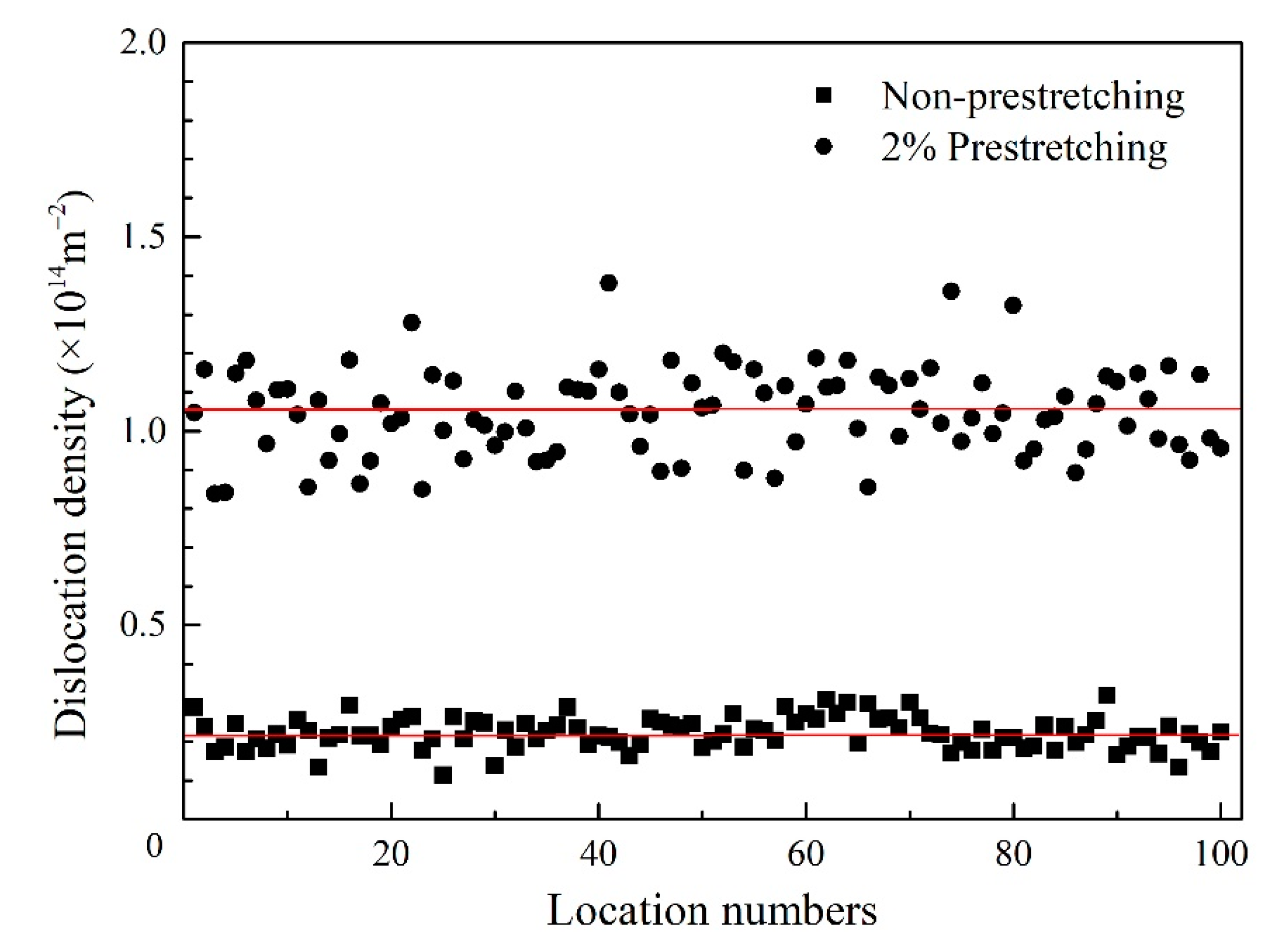

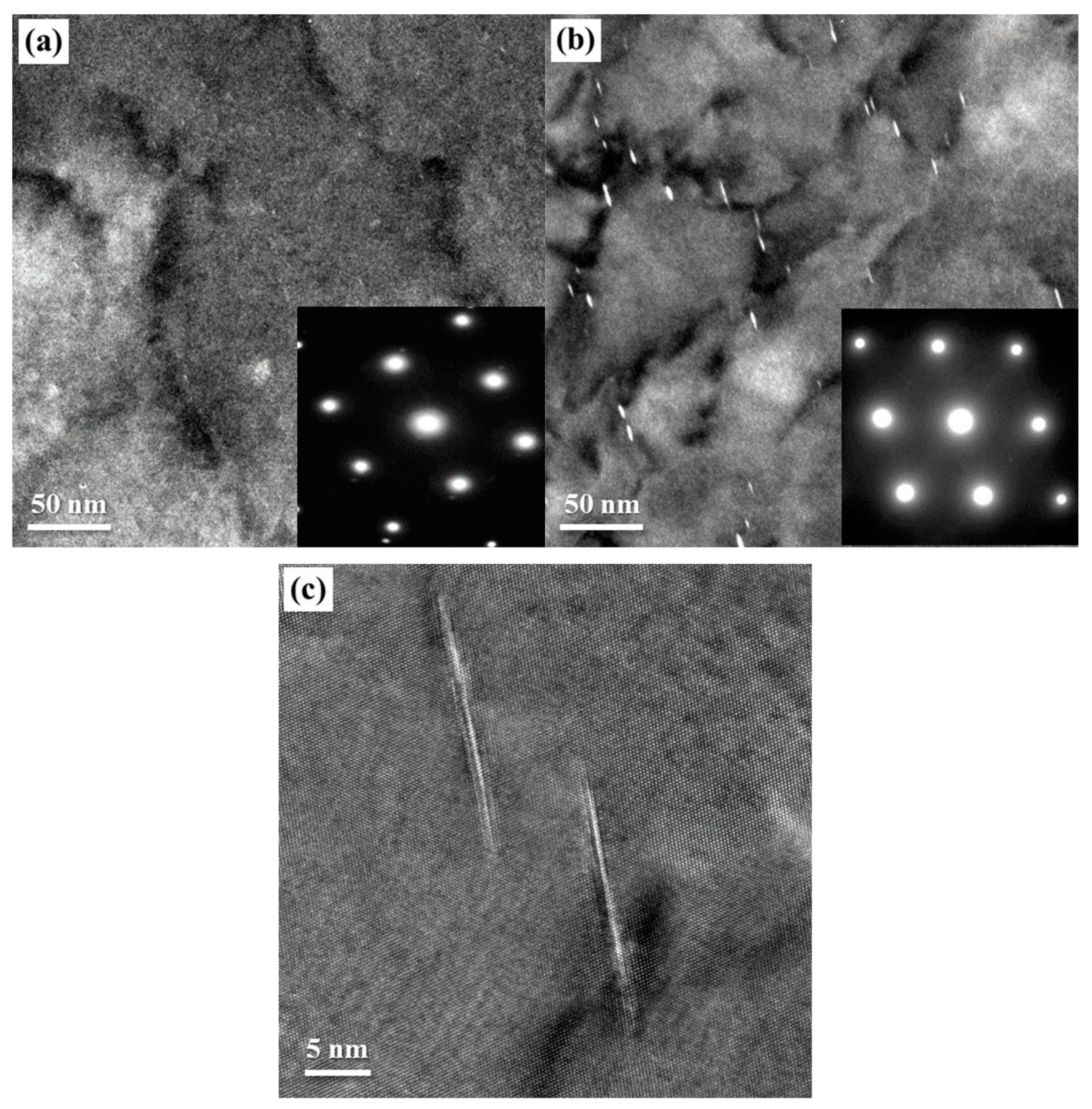

3.3. Microstructures

4. Discussion

4.1. Pre-Stretching and Creep Strain

4.2. Pre-Stretching and Precipitation

5. Conclusions

- (1)

- The total creep strain of the Al-Cu-Li alloy can be improved by effective pre-stretching. In the intermediate slower creep stage, the creep strain of the pre-stretched specimen becomes lower than the non-pre-stretched one, primarily due to the earlier starting time of this stage. The lower creep strain soon catches up with the latter, because of the lower decrease rate and longer intermediate duration.

- (2)

- The strength property of the pre-stretched Al-Cu-Li alloy specimen is much higher than the non-pre-stretched one after the same creep aging treatment. In contrast to the artificial aging process, the strength increase appears much larger, as the yield strength rises by 47%. The strength property of the non-pre-stretched Al-Cu-Li alloy specimen was significantly decreased by the creep aging process, but the room-temperature mechanical property of the creep-aged specimens with 2% pre-stretching is very close to the artificially aged specimens, and even slightly higher than the latter.

- (3)

- Pre-stretching introduces lots of mobile dislocations which benefit the increase of the creep deformation, but the increasing dislocation density will accelerate the nucleation and growth of the precipitates as well. Premature T1 precipitation has a great blocking effect on the dislocation motion in the early creep stage, resulting in a markedly lower decrease rate but longer duration in the intermediate slower creep stage.

- (4)

- The constitution of aging precipitates in the creep-aged specimens can be significantly changed by different pre-stretching states. The precipitates of the pre-stretched specimen are mainly composed of the T1 phase, while the θ’ phase consists of the main precipitates in the non-pre-stretched specimen. A small amount of T1 precipitates in the non-pre-stretched specimen leads to the decreasing amount and widening phase spacing of θ’ precipitates by consuming Cu atoms in the matrix, so that the strengthening effect appears lower than in the others. Except for the initial dislocations, the dislocation motion in the creep aging process is also a favorable factor to precipitate the T1 phase.

Author Contributions

Funding

Conflicts of Interest

References

- Rioja, R.J.; Liu, J. The Evolution of al-li base products for aerospace and space applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Ahmed, B.; Wu, S.J. Aluminum Lithium Alloys (Al-Li-Cu-X)-New generation material for aerospace applications. Appl. Mech. Mater. 2014, 440, 104–111. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Prasad, N.E.; Gokhale, A.A.; Wanhill, R.J.H. Aluminum-Lithium Alloys: Processing, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2014; pp. 27–58. [Google Scholar]

- Cassada, W.A.; Shiflet, G.J.; Starke, E.A. Mechanism of Al2CuLi (T1) nucleation and growth. Metall. Mater. Trans. A 1991, 22, 287–297. [Google Scholar] [CrossRef]

- Noble, B.; Thompson, G.E. T1(Al2CuLi) precipitation in aluminum–copper–lithium alloys. Met. Sci. J. 1972, 6, 167–174. [Google Scholar] [CrossRef]

- Csontos, A.A.; Starke, E.A. The effect of inhomogeneous plastic deformation on the ductility and fracture behavior of age hardenable aluminum alloys. Int. J. Plast. 2005, 21, 1097–1118. [Google Scholar] [CrossRef]

- Cassada, W.A.; Shiflet, G.J.; Starke, E.A. The effect of plastic deformation on Al2CuLi (T1) precipitation. Metall. Mater. Trans. A 1991, 22, 299–306. [Google Scholar] [CrossRef]

- Kim, J.D.; Park, J.K. Effect of stretching on the precipitation kinetics of an Al-2.0Li-2.8Cu-0.5Mg(-0.13Zr) alloy. Metall. Mater. Trans. A 1993, 24, 2613–2621. [Google Scholar] [CrossRef]

- Gable, B.M.; Zhu, A.W.; Csontos, A.A.; Starke, E.A. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al–Li–Cu–X alloy. J. Light Met. 2001, 1, 1–14. [Google Scholar] [CrossRef]

- Ma, Y.L.; Li, J.F.; Liu, G.R.; Liu, D.Y.; Ye, Z.H.; Wang, J.X.; Zheng, Z.Q. Microstructural evolution and mechanical properties of 2195 Al-Li alloy during T8 re-aging at various temperatures following re-solution. Chi. J. Nonferrous Met. 2017, 27, 234–242. [Google Scholar]

- Muñoz-Morris, M.A.; Morris, D.G. Microstructure control during severe plastic deformation of Al–Cu–Li and the influence on strength and ductility. Mater. Sci. Eng. A Struct. 2011, 528, 3445–3454. [Google Scholar] [CrossRef]

- Muñoz-Morris, M.A.; Morris, D.G. Severe plastic deformation processing of Al–Cu–Li alloy for enhancing strength while maintaining ductility. Scr. Mater. 2010, 63, 304–307. [Google Scholar] [CrossRef]

- Dorin, T.; Deschamps, A.; De Geuser, F.; Sigli, C. Quantification and modelling of the microstructure/strength relationship by tailoring the morphological parameters of the T1 phase in an Al–Cu–Li alloy. Acta Mater. 2014, 75, 134–146. [Google Scholar] [CrossRef]

- Zhan, L.; Lin, J.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tools Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

- Ribeiro, F.C.; Marinho, E.P.; Inforzat, D.J.; Costa, P.R. Creep age forming: A short review of fundaments and applications. J. Achiev. Mater. Manuf. Eng. 2010, 43, 353–361. [Google Scholar]

- Watcham, K. Airbus A380 takes creep age-forming to new heights. Mater. World 2004, 12, 10–11. [Google Scholar]

- Zhang, J.; Wang, C.; Zhang, Y.; Deng, Y. Effects of creep aging upon Al-Cu-Li alloy: Strength, toughness and microstructure. J. Alloys Compd. 2018, 764, 452–459. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Deng, Y.; Zhang, X. Effect of deformation degree on the creep age forming of 7475 aluminum alloy: The feasibility of the extended deformation range. Mater. Sci. Eng. A Struct. 2016, 664, 126–134. [Google Scholar] [CrossRef]

- Chen, P.S.; Kuruvilla, A.K.; Malone, T.W.; Stanton, W.P. The effects of artificial aging on the microstructure and fracture toughness of Al-Cu-Li alloy 2195. J. Mater. Eng. Perform. 1998, 7, 682–690. [Google Scholar] [CrossRef]

- Pešička, J.; Kužel, R.; Dronhofer, A.; Eggeler, G. The evolution of dislocation density during heat treatment and creep of tempered martensite ferritic steels. Acta Mater. 2003, 51, 4847–4862. [Google Scholar] [CrossRef]

- Kang, S.J.; Kim, T.H.; Yang, C.W.; Lee, J.I.; Park, E.S.; Noh, T.W.; Kim, M. Atomic structure and growth mechanism of T1 precipitate in Al–Cu–Li–Mg–Ag alloy. Scr. Mater. 2015, 109, 68–71. [Google Scholar] [CrossRef]

- Gao, Z.; Liu, J.Z.; Chen, J.H.; Duan, S.Y.; Liu, Z.R.; Ming, W.Q.; Wu, C.L. Formation mechanism of precipitate T1 in AlCuLi alloys. J. Alloys Compd. 2015, 624, 22–26. [Google Scholar] [CrossRef]

- Deng, Y.; Bai, J.; Wu, X.; Huang, G.; Cao, L.; Huang, L. Investigation on formation mechanism of T1 precipitate in an Al-Cu-Li alloys. J. Alloys Compd. 2017, 723, 661–666. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Zr | Ag | Li | Other | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.03 | 0.04 | 4.1 | 0.04 | 0.28 | 0.13 | 0.26 | 0.9 | <0.1 | Bal |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Jiang, Z.; Xu, F.; Chen, M. Effects of Pre-Stretching on Creep Behavior, Mechanical Property and Microstructure in Creep Aging of Al-Cu-Li Alloy. Materials 2019, 12, 333. https://doi.org/10.3390/ma12030333

Zhang J, Jiang Z, Xu F, Chen M. Effects of Pre-Stretching on Creep Behavior, Mechanical Property and Microstructure in Creep Aging of Al-Cu-Li Alloy. Materials. 2019; 12(3):333. https://doi.org/10.3390/ma12030333

Chicago/Turabian StyleZhang, Jin, Zhen Jiang, Fushun Xu, and Mingan Chen. 2019. "Effects of Pre-Stretching on Creep Behavior, Mechanical Property and Microstructure in Creep Aging of Al-Cu-Li Alloy" Materials 12, no. 3: 333. https://doi.org/10.3390/ma12030333

APA StyleZhang, J., Jiang, Z., Xu, F., & Chen, M. (2019). Effects of Pre-Stretching on Creep Behavior, Mechanical Property and Microstructure in Creep Aging of Al-Cu-Li Alloy. Materials, 12(3), 333. https://doi.org/10.3390/ma12030333