The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Technology of Recycled Aggregate Production

3.1. The Origin of Concrete Rubble

3.2. The Preliminary Crushing of the Samples

3.3. Primary Crushing of Concrete Rubble

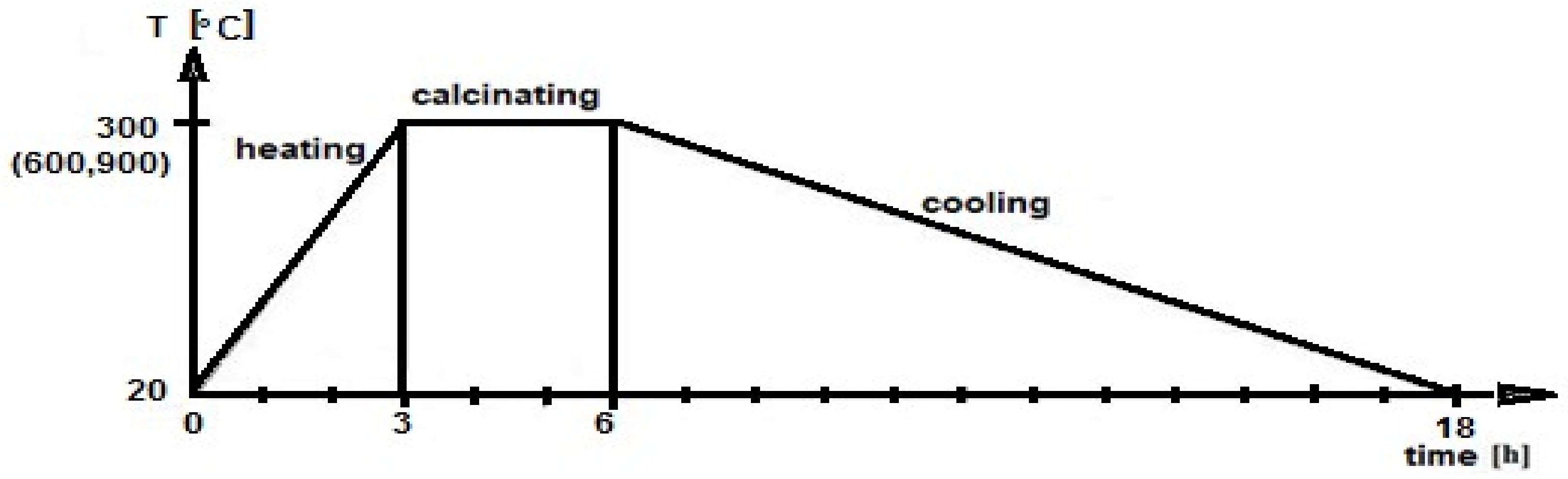

3.4. The Thermal Treatment of Recycled Concrete Aggregate

3.5. The Mechanical Treatment of Recycled Concrete Aggregate

3.6. Impact of Thermo-Mechanical Treatment on the Amount of Separated Cement Mortar

4. Preparation of a Research Plan

4.1. Selection of Variables and Development of the Experiment Plan

4.2. The Composition of the Concrete Mixtures

5. Test Results and Discussion

5.1. Properties of Used Aggregates

5.2. Properties of Concrete Mixture

5.3. Properties of Hardened Concrete

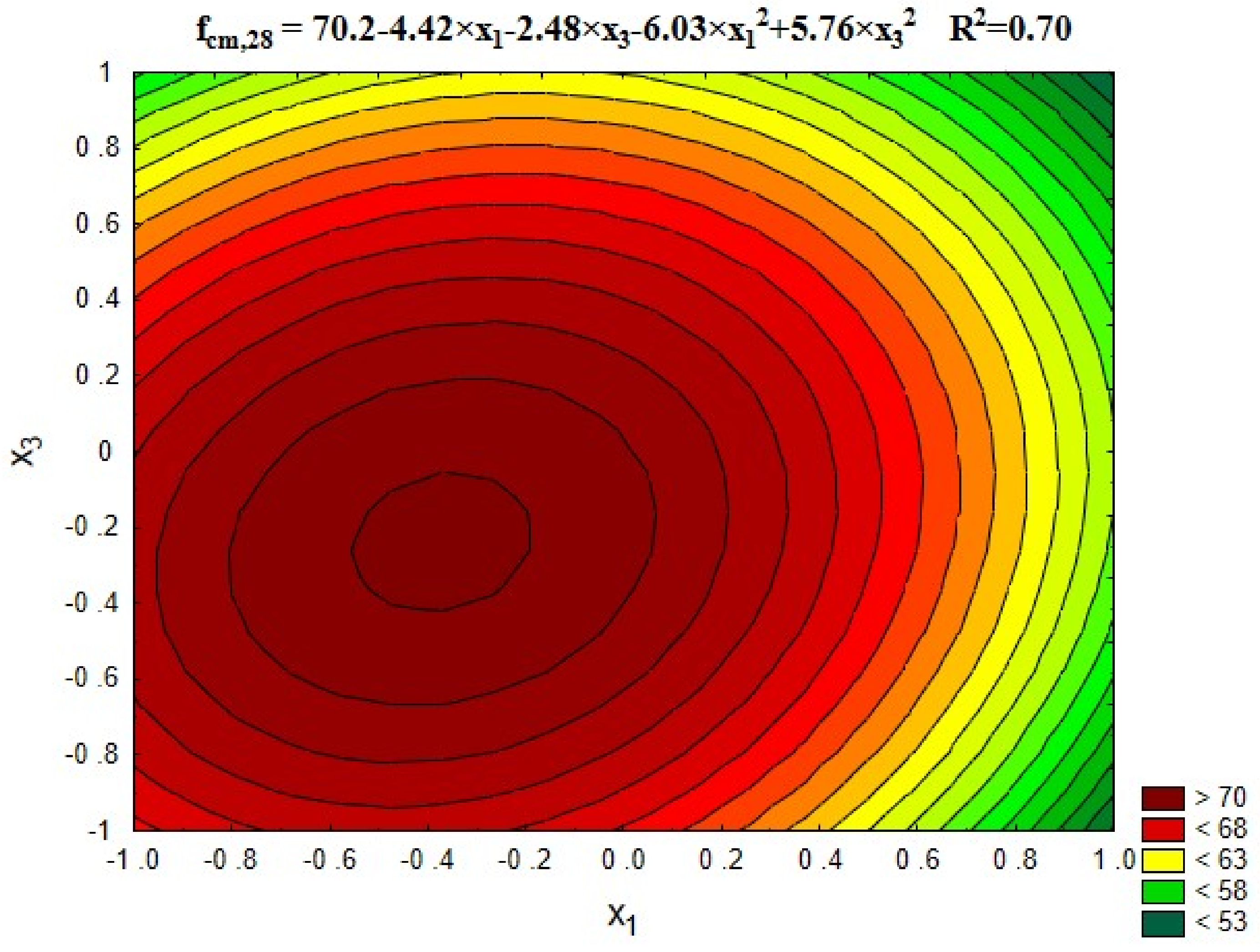

5.3.1. Compressive Strength

5.3.2. Flexural Strength

5.3.3. Young’s Modulus E

5.3.4. Volume Density

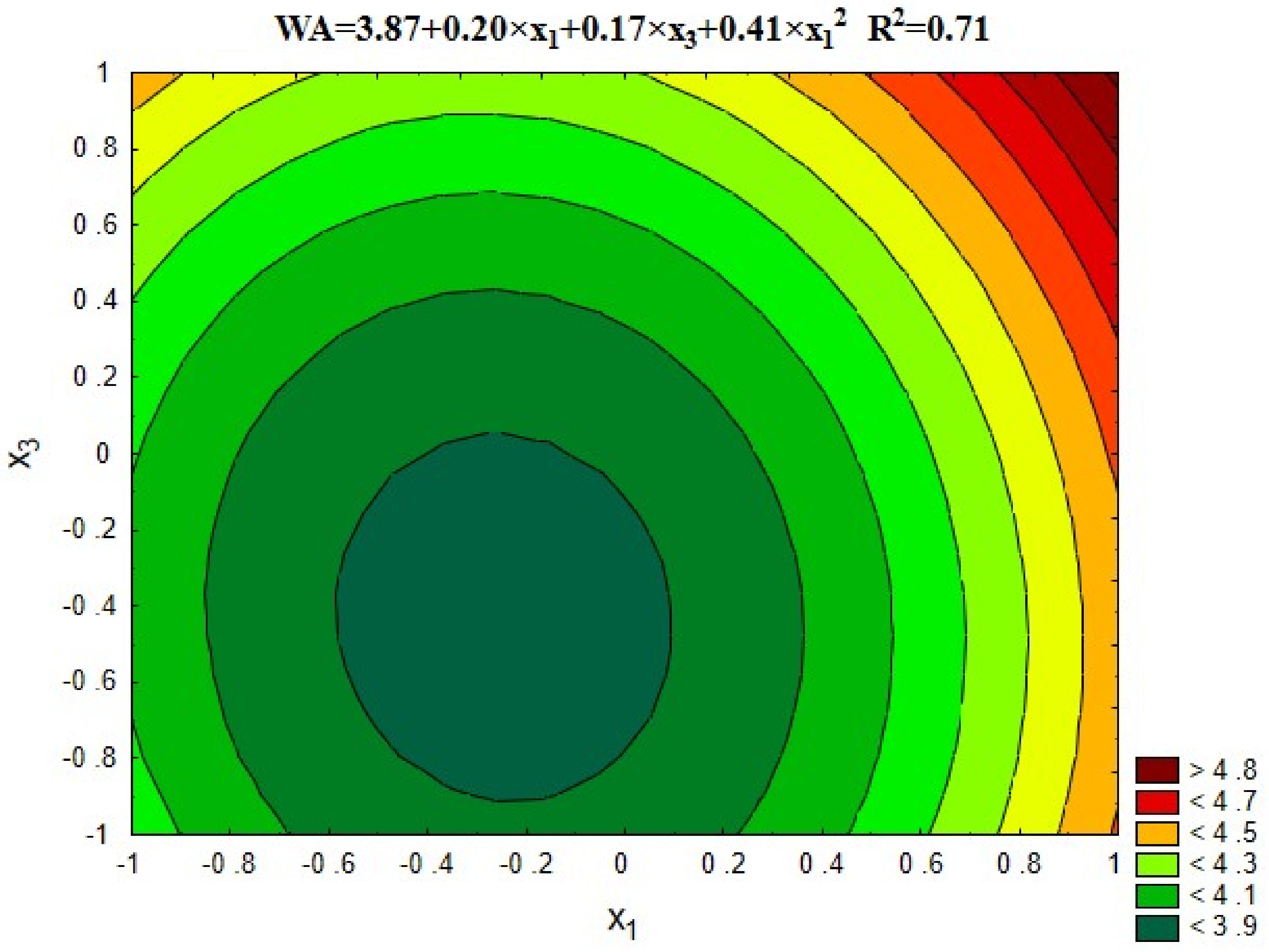

5.3.5. Water Absorption

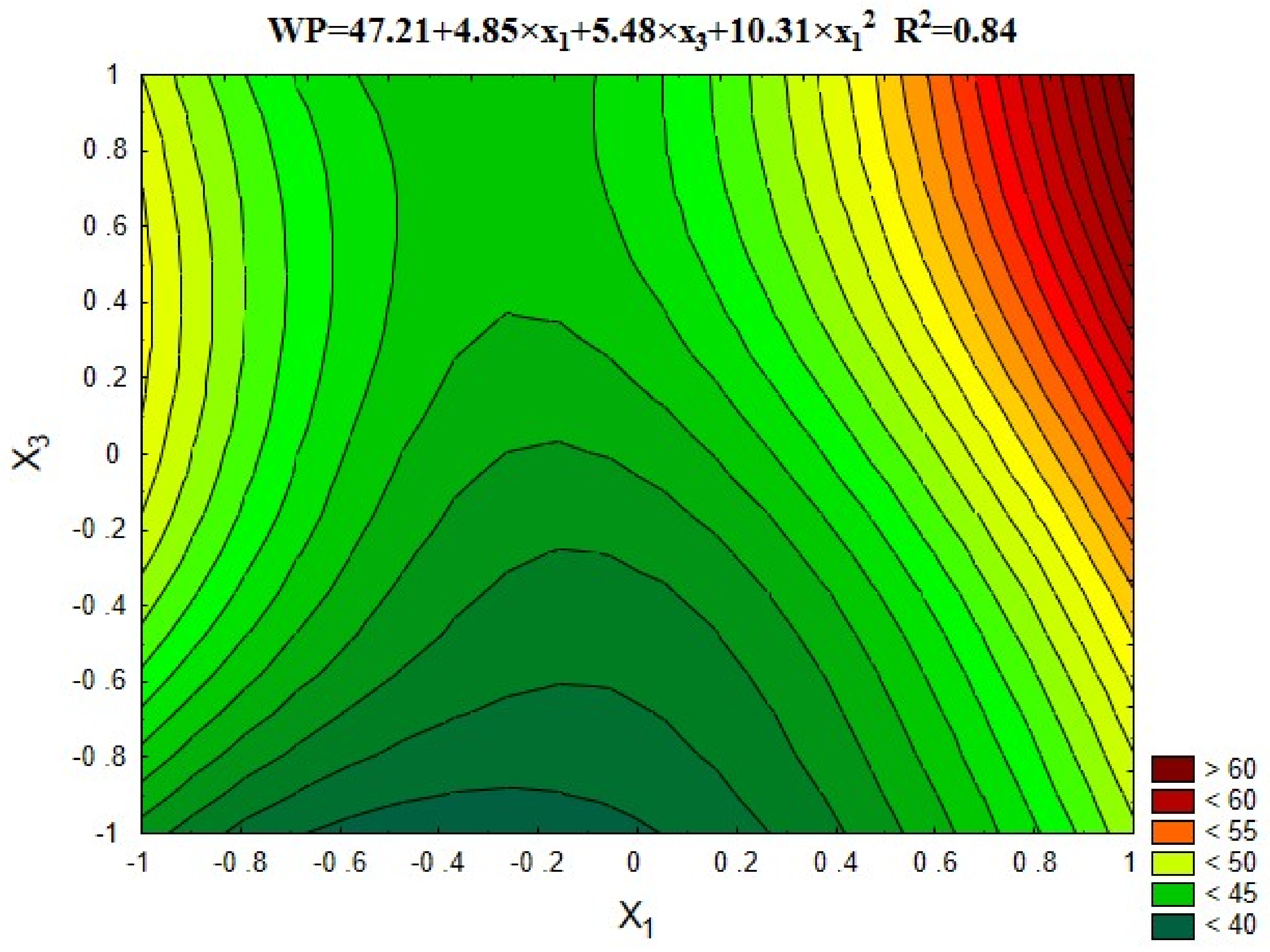

5.3.6. Water Permeability (Depth of Penetration)

5.3.7. Water Capillarity

6. Structure and Microstructure Tests

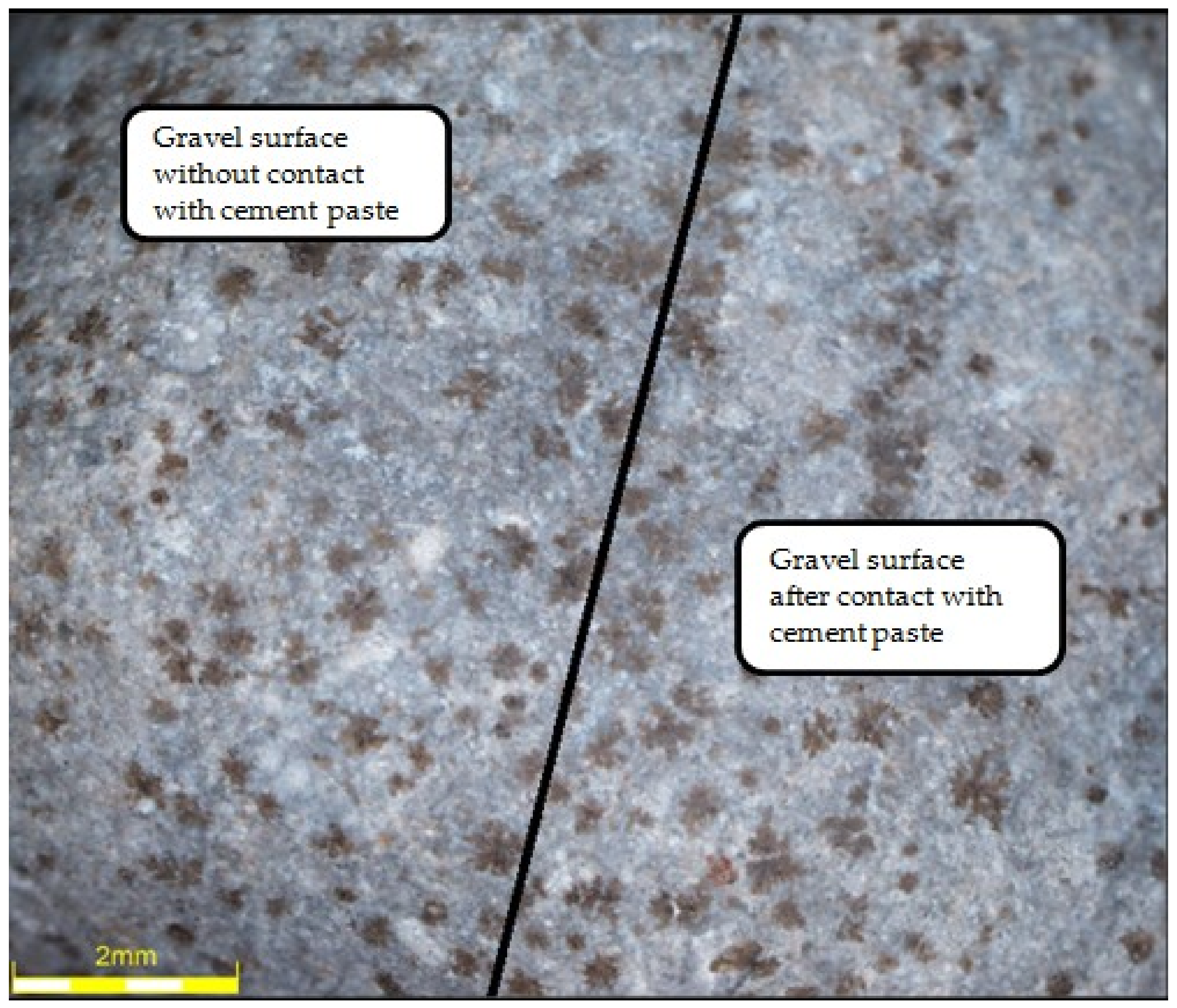

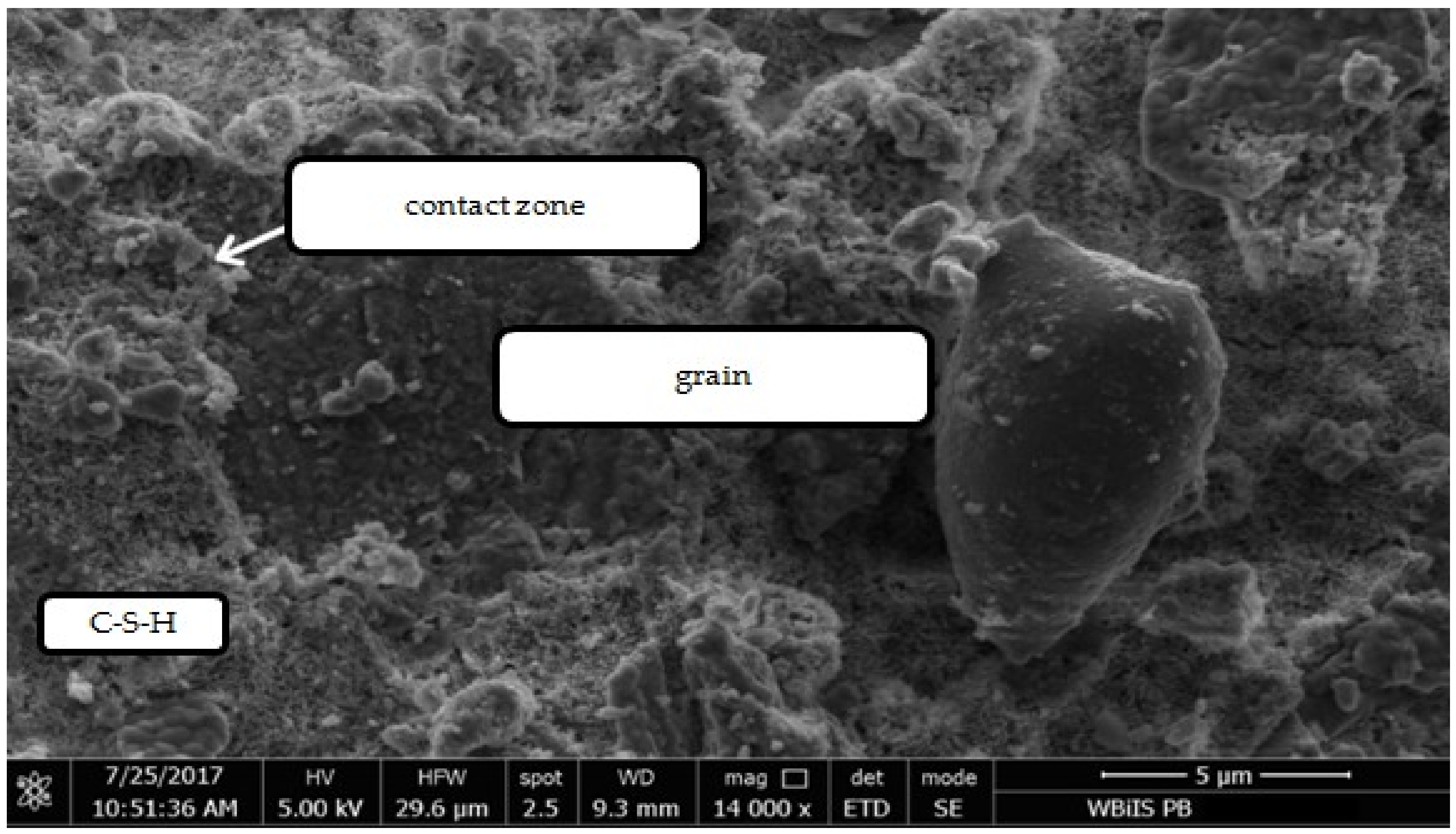

6.1. Optical and Scanning Microscopy

6.2. X-Ray Diffraction

7. Conclusions

8. Patent

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Rodríguez-Robles, D.; Van den Heede, P.; De Belie, N. Life cycle assessment applied to recycled aggregate concrete. In New Trends in Eco-Efficient and Recycled Concrete, 1st ed.; De Brito, J., Agrela, F., Eds.; Wood head Publishing: Sawston, Cambridge, UK, 2019; pp. 207–256. [Google Scholar]

- Fernández-Ledesma, E.; Jiménez, J.R.; Ayuso, J.; Corinaldesi, V.; Iglesias-Godino, F.J. A proposal for the maximum use of recycled concrete sand in masonry mortar design. Mater. Constr. 2016, 66, 75. [Google Scholar] [CrossRef]

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Rodríguez-Robles, D.; García-González, J.; Juan-Valdés, A.; Morán-del Pozo, J.M.; Guerra-Romero, M.I. Overview regarding construction and demolition waste in Spain. Environ. Technol. 2015, 36, 3060–3070. [Google Scholar] [CrossRef] [PubMed]

- Evangelista, L.; Guedes, M. Microstructural studies on recycled aggregate concrete. In New Trends in Eco-Efficient and Recycled Concrete, 1st ed.; De Brito, J., Agrela, F., Eds.; Woodhead Publishing: Sawston, Cambridge, UK, 2019; pp. 425–451. [Google Scholar]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2019, 23, 872–877. [Google Scholar] [CrossRef]

- Agrela, F.; De Juan, M.S.; Ayuso, J.; Geraldes, V.L.; Jiménez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef] [PubMed]

- González-Fonteboa, B.; Seara-Paz, S.; de Brito, J.; González-Taboada, I.; Martínez-Abella, F.; Vasco-Silva, R. Recycled concrete with coarse recycled aggregate. An overview and analysis. Mater. Constr. 2018, 68, 151. [Google Scholar] [CrossRef]

- Abreu, V.; Evangelista, L.; de Brito, J. The effect of multi-recycling on the mechanical performance of coarse recycled aggregates concrete. Constr. Build. Mater. 2018, 188, 480–489. [Google Scholar] [CrossRef]

- Tam, V.W.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Abhiram, K.; Manoj, B. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Constr. Build. Mater. 2016, 111, 611–617. [Google Scholar] [CrossRef]

- Pandurangan, K.; Dayanithy, A.; Prakash, S.O. Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, B.; Kim, K.S.; Kim, J.M. Quality improvement of recycled aggregates using the acid treatment method and the strength characteristics of the resulting mortar. J. Mater. Cycles Waste 2017, 19, 968–976. [Google Scholar] [CrossRef]

- Kim, Y.C.; Choi, Y.W. Utilization of waste concrete powder as a substitution material for cement. Constr. Build. Mater. 2012, 30, 500–504. [Google Scholar] [CrossRef]

- Schoon, J.; De Buysser, K.; Van Driessche, I.; De Belie, N. Fines extracted from recycled concrete as alternative raw material for Portland cement clinker production. Cement Concrete Comp. 2015, 58, 70–80. [Google Scholar] [CrossRef]

- Kalinowska-Wichrowska, K. The use of fine waste material for the future of sustainable construction. Tech. Sci. 2018, 2, 149–156. [Google Scholar]

- Pawluczuk, E. Recycled concrete powder as partial cement replacement in fine-grained concrete. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference (SGEM 2017), Albena, Bulgaria, 29 June–5 July 2017; Volume 17, Issue 41. pp. 169–176. [Google Scholar] [CrossRef]

- Chen, Y.-L.; Wang, S.-R.; Ni, J.; Azzam, R.; Fernández-Steeger, T.M. An experimental study of the mechanical properties of granite after high temperature exposure based on mineral characteristics. Eng. Geol. 2017, 220, 234–242. [Google Scholar] [CrossRef]

- Xu, X.-L.; Gao, F.; Shen, X.-M.; Xie, H.-P. Mechanical characteristics and microcosmic mechanisms of granite under temperature loads. J. China Univ. Min. Technol. 2008, 18, 413–417. [Google Scholar] [CrossRef]

- EN 1992-1-1. Eurocode 2: Design of Concrete Structures; Part 1-1: General rules and rules for buildings; European Committee for Standardisation: Brussels, Belgium, 2004.

- Pacheco, J.; de Brito, J.; Ferreira, J.; Soares, D. Flexural Load Tests of Full-Scale Recycled Aggregates Concrete Structures. Constr. Build. Mater. 2015, 101, 65–71. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Establishing a Relationship between Modulus of Elasticity and Compressive Strength of Recycled Aggregate Concrete. J. Clean. Prod. 2016, 112, 2171–2186. [Google Scholar] [CrossRef]

- Dilbas, H.; Cakir, O.; Simsek, M. Recycled Aggregate Concretes (RACs) for Structural Use: An Evaluation on Elasticity Modulus and Energy Capacities. Int. J. Civil. Eng. 2017, 15, 247–261. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cement Concrete Comp. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Enhancing the Durability Properties of Concrete Prepared with Coarse Recycled Aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, A.A. Use of recycled fine aggregate in concretes with durable requirements. Waste Manag. 2011, 31, 2336–2340. [Google Scholar] [CrossRef] [PubMed]

- Lijuan, K.; Yuanbo, D. Interfacial Interaction of Aggregate-Cement Paste in Concrete. J. Wuhan Univ. Technol. Mat. Sci. Ed. 2015, 30, 117–121. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education: London, UK, 2011; ISBN 978-0-273-75580-7. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer: Dordrecht, The Netherlands, 2014; ISBN 978-94-007-7944-0. [Google Scholar]

- Pawluczuk, E. A fine fraction from the recycled concrete as an addition in the cement composites. Sci. Rev. Eng. Environ. Sci. 2018, 27, 338–347. [Google Scholar] [CrossRef]

- Pawluczuk, E. Ecological aspect of waste concrete fines application as cement replacement in fine-grained composites. J. Econ. Environ. 2017, 3, 108–118. [Google Scholar]

- Chai, L.; Monismith, C.L.; Harvey, J. Re-Cementation of Crushed Material in Pavement Bases; Institute of Transportation Studies, University of California: Berkeley, CA, USA, 2009; pp. 1–28. [Google Scholar]

- Poon, C.S.; Kou, S.C.; Lam, S. Use of recycled aggregates in molded concrete bricks and blocks. Cement Concrete Res. 2002, 16, 281–289. [Google Scholar] [CrossRef]

- Paige-Green, P. Preliminary evaluation of the reuse of cementitious materials. In Proceedings of the 29th Annual Southern African Transport Conference, Pretoria, South Africa, 16–19 August 2010; pp. 520–529. [Google Scholar]

- Shui, Z.; Xuan, D.; Wan, H.; Cao, B. Rehydration reactivity of recycled mortar from concrete waste experienced to thermal treatment. Constr. Build. Mater. 2008, 22, 1723–1729. [Google Scholar] [CrossRef]

- Bołtryk, M.; Kalinowska-Wichrowska, K.; Pawluczuk, E. Method for separation of set cement mortar from coarse aggregate and for crushing that mortar, and the device for the application of this method, PAT.229887. Available online: http://regserv.uprp.pl/register/application?number=P.417362 (accessed on 1 December 2018).

| Component | Content |

|---|---|

| Sulphate Resistant Cement CEM I 42.5 N HSR/NA, kg | 360 |

| Sand 0–2 mm, kg | 641 |

| Granite 2–8 mm, kg | 450 |

| Granite 8–16 mm, kg | 720 |

| Plasticizer, dm3 | 3.2 |

| Superplasticizer, dm3 | 2.48 |

| Air-entraining admixtures, dm3 | 2.98 |

| Water, dm3 | 144 |

| Average Compressive Strength (MPa) | Standard Deviation | Concrete Class | Average Flexural Strength (MPa) | Standard Deviation |

|---|---|---|---|---|

| 67.0 | 8.56 | C 35/45 | 7.61 | 0.58 |

| Temperature (°C) | Mechanical Treatment Time (min) | The Amount of Separated Cement Mortar (mass %) |

|---|---|---|

| 300 | 5 | 24 |

| 300 | 10 | 32 |

| 300 | 15 | 36 |

| 600 | 5 | 35 |

| 600 | 10 | 38 |

| 600 | 15 | 42 |

| 900 | 5 | 81 |

| 900 | 10 | 95 |

| 900 | 15 | 96 |

| X1 | Temperature of Recycled Aggregate Heat Treatment | 300 | 600 | 900 | °C |

|---|---|---|---|---|---|

| X2 | Mechanical treatment time | 5 | 10 | 15 | min |

| X3 | Amount of recycled aggregate fraction 4–16 mm | 20 | 40 | 60 | % |

| Series | Real Variables | Coded Variables | ||||

|---|---|---|---|---|---|---|

| X1 (°C) | X2 (min) | X3 (%) | x1 | x2 | x3 | |

| 1 | 300 | 15 | 40 | −1 | 1 | 0 |

| 2 | 600 | 10 | 20 | 0 | 0 | −1 |

| 3 | 900 | 15 | 20 | 1 | 1 | −1 |

| 4 | 300 | 5 | 60 | −1 | −1 | 1 |

| 5 | 900 | 15 | 60 | 1 | 1 | 1 |

| 6 | 600 | 5 | 40 | 0 | −1 | 0 |

| 7 | 300 | 15 | 60 | −1 | 1 | 1 |

| 8 | 300 | 5 | 20 | −1 | −1 | −1 |

| 9 | 900 | 5 | 60 | 1 | −1 | 1 |

| 10 | 900 | 5 | 20 | 1 | −1 | −1 |

| 11 | 300 | 10 | 40 | −1 | 0 | 0 |

| 12 | 300 | 15 | 20 | −1 | 1 | −1 |

| 13 | Control with RCAwt | 60 | - | - | - | |

| 14 | Control with NA (granite) | - | - | - | ||

| Component | Unit | Concrete Mix Composition According to Different Amount of RCA (%) | |||

|---|---|---|---|---|---|

| 0% | 20% | 40% | 60% | ||

| Cement CEM I 42.5R | kg/m3 | 400 | 400 | 400 | 400 |

| w/c | - | 0.40 | 0.40 | 0.40 | 0.40 |

| Water | dm3/m3 | 158.0 | 158.0 | 158.0 | 158.0 |

| Superplasticizer | dm3/m3 | 2.0 | 2.0 | 2.0 | 2.0 |

| Sand 0–2 mm | kg/m3 | 659.4 | 659.4 | 659.4 | 659.4 |

| Gravel 2–4 mm | kg/m3 | 164.9 | 164.9 | 164.9 | 164.9 |

| Granite4–8 mm | kg/m3 | 453.6 | 362.9 | 272.2 | 181.4 |

| Granite 8–16 mm | kg/m3 | 721.6 | 577.3 | 433.0 | 288.7 |

| RCA 4–8 mm | kg/m3 | 0.0 | 82.9 | 165.8 | 248.7 |

| RCA 8–16 mm | kg/m3 | 0.0 | 131.9 | 263.8 | 395.7 |

| Type of Aggregate | Calcination Temperature (°C) | Bulk Density in the Dry State (g/cm3) | Bulk Density in the Saturated Surface Dry (g/cm3) | Water Absorption (%) |

|---|---|---|---|---|

| RCA 4–8 mm | 300 | 1.21 | 1.26 | 3.80 |

| RCA 8–16 mm | 300 | 1.19 | 1.24 | 3.48 |

| RCA 4–8 mm | 600 | 1.26 | 1.29 | 3.11 |

| RCA 8–16 mm | 600 | 1.24 | 1.26 | 3.70 |

| RCA 4–8 mm | 900 | 1.16 | 1.20 | 6.00 |

| RCA 8–16 mm | 900 | 1.14 | 1.21 | 8.00 |

| RCAwt 4–8 mm | - | 0.93 | 1.10 | 6.85 |

| RCAwt 8–16 mm | - | 0.92 | 1.08 | 7.83 |

| NA 4–8 mm | - | 1.30 | 1.31 | 1.30 |

| NA 8–16 mm | - | 1.28 | 1.29 | 1.30 |

| Series | Slump Test (mm) | Consistency Class | Density of the Mixture (kg/m3) |

|---|---|---|---|

| 1 | 175 | S4 | 2374 |

| 2 | 200 | S4 | 2340 |

| 3 | 170 | S4 | 2334 |

| 4 | 175 | S4 | 2290 |

| 5 | 0 | - | 2281 |

| 6 | 185 | S4 | 2370 |

| 7 | 200 | S4 | 2356 |

| 8 | 180 | S4 | 2372 |

| 9 | 0 | - | 2275 |

| 10 | 160 | S4 | 2331 |

| 11 | 180 | S4 | 2353 |

| 12 | 200 | S4 | 2391 |

| 13 | 140 | S3 | 2340 |

| 14 | 225 | S5 | 2420 |

| Series | fcm,28 (MPa) | Concrete class | ffm,28 (MPa) | E (GPa) | D (kg/m3) | WA (%) | WP (mm) | WC (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 71.50 | C55/67 | 7.60 | 37.8 | 2318.00 | 4.0 | 50 | 3.08 |

| 2 | 68.00 | C50/60 | 7.74 | 37.2 | 2290.00 | 3.9 | 40 | 3.06 |

| 3 | 51.00 | C35/45 | 7.07 | 34.6 | 2259.67 | 4.6 | 50 | 3.20 |

| 4 | 57.00 | C45/55 | 8.26 | 35.2 | 2234.67 | 4.5 | 55 | 3.25 |

| 5 | 46.75 | C30/37 | 6.63 | 33.0 | 2231.50 | 4.8 | 65 | 3.68 |

| 6 | 70.00 | C55/67 | 8.59 | 37.7 | 2281.00 | 4.0 | 43 | 2.98 |

| 7 | 66.25 | C50/60 | 8.53 | 36.5 | 2284.67 | 4.4 | 45 | 3.10 |

| 8 | 73.50 | C55/67 | 7.53 | 36.6 | 2294.67 | 4.2 | 43 | 3.21 |

| 9 | 59.25 | C45/55 | 6.82 | 36.4 | 2224.67 | 5.0 | 63 | 3.97 |

| 10 | 56.50 | C45/55 | 6.88 | 35.2 | 2279.67 | 4.5 | 48 | 3.00 |

| 11 | 67.50 | C50/60 | 7.91 | 36.9 | 2282.67 | 4.1 | 52 | 3.48 |

| 12 | 59.00 | C40/50 | 7.17 | 37.0 | 2299.00 | 4.2 | 43 | 3.15 |

| 13 | 55.25 | C35/45 | 6.79 | 34.0 | 2249.33 | 5.6 | 65 | 4.19 |

| 14 | 60.50 | C50/60 | 5.98 | 38.5 | 2313.33 | 3.7 | 48 | 3.11 |

| Properties | Equations | R2 |

|---|---|---|

| Compressive strength, fcm, MPa | = 70.2 − 4.42 × x1 − 2.48 × x3 − 6.03 × x12 − 5.76 × x32 − 2.86 × x1x2 + 3.09 × x2x3 | 0.70 |

| Flexural strength, ffm, MPa | = 8.21 − 0.49 × x1 + 0.21 × x3 − 0.92 × x12 − 0.32 × x1 × x3 | 0.69 |

| Young’s modules, E, GPa | = 37.54 − 0.75 × x1 − 0.29 × x3 − 1.24 × x12 − 0.74 × x1 × x2 | 0.70 |

| Volume density, D, kg/m3 | = 2281 – 16.4 × x1 − 21.4 × x3 − 10.6 × x1x2 | 0.68 |

| Water absorption, WA, % | = 3.87 + 0.20 × x1 + 0.17 × x3 + 0.41 × x12 | 0.71 |

| Water permeability, WP, mm | = 47.21 + 4.85 × x1 + 5.48 × x3 + 10.31 × x12 | 0.84 |

| Water capillarity, C, % | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawluczuk, E.; Kalinowska-Wichrowska, K.; Bołtryk, M.; Jiménez, J.R.; Fernández, J.M. The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials 2019, 12, 367. https://doi.org/10.3390/ma12030367

Pawluczuk E, Kalinowska-Wichrowska K, Bołtryk M, Jiménez JR, Fernández JM. The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials. 2019; 12(3):367. https://doi.org/10.3390/ma12030367

Chicago/Turabian StylePawluczuk, Edyta, Katarzyna Kalinowska-Wichrowska, Michał Bołtryk, José Ramón Jiménez, and José María Fernández. 2019. "The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete" Materials 12, no. 3: 367. https://doi.org/10.3390/ma12030367

APA StylePawluczuk, E., Kalinowska-Wichrowska, K., Bołtryk, M., Jiménez, J. R., & Fernández, J. M. (2019). The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials, 12(3), 367. https://doi.org/10.3390/ma12030367