Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review

Abstract

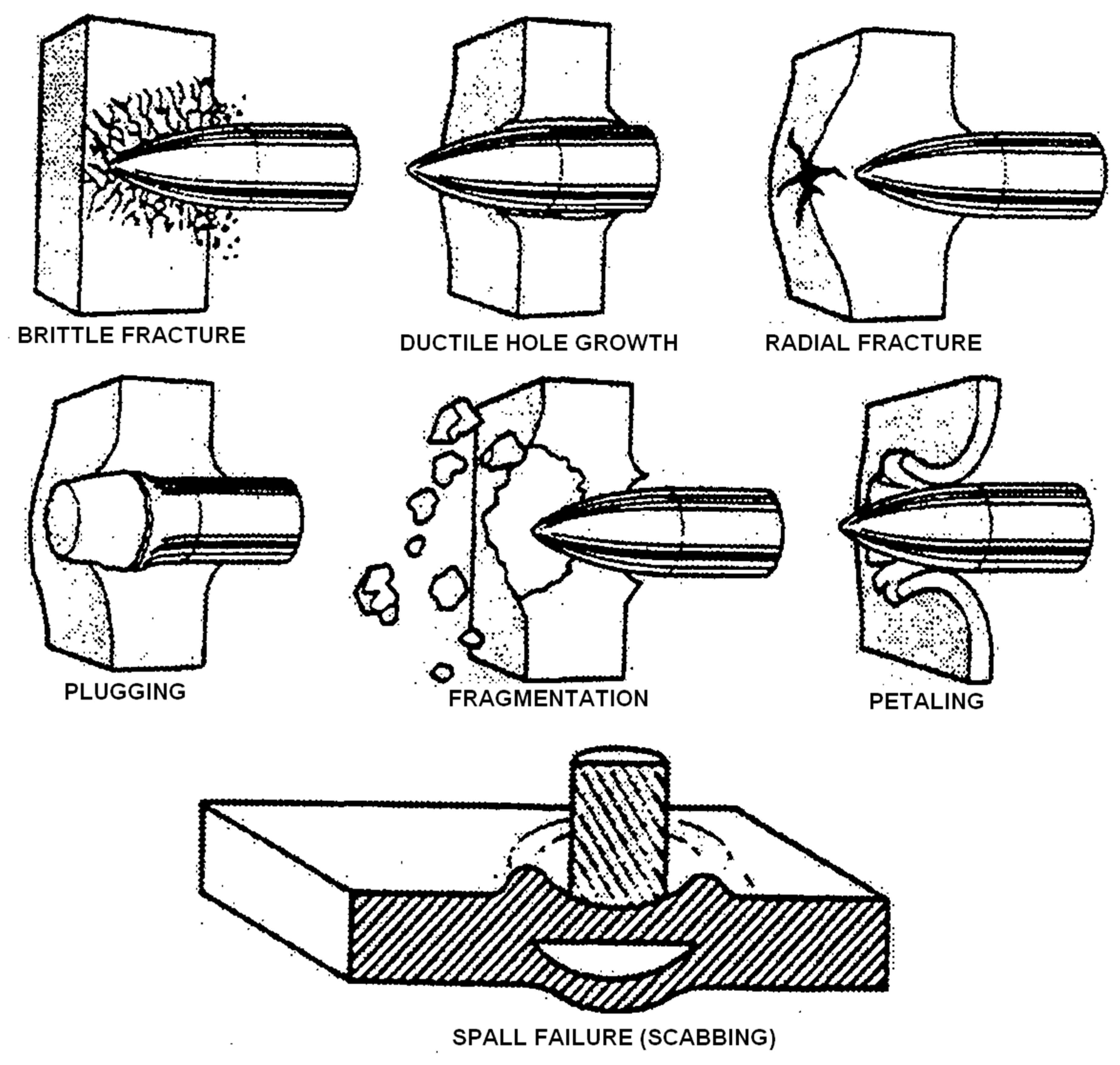

1. Introduction

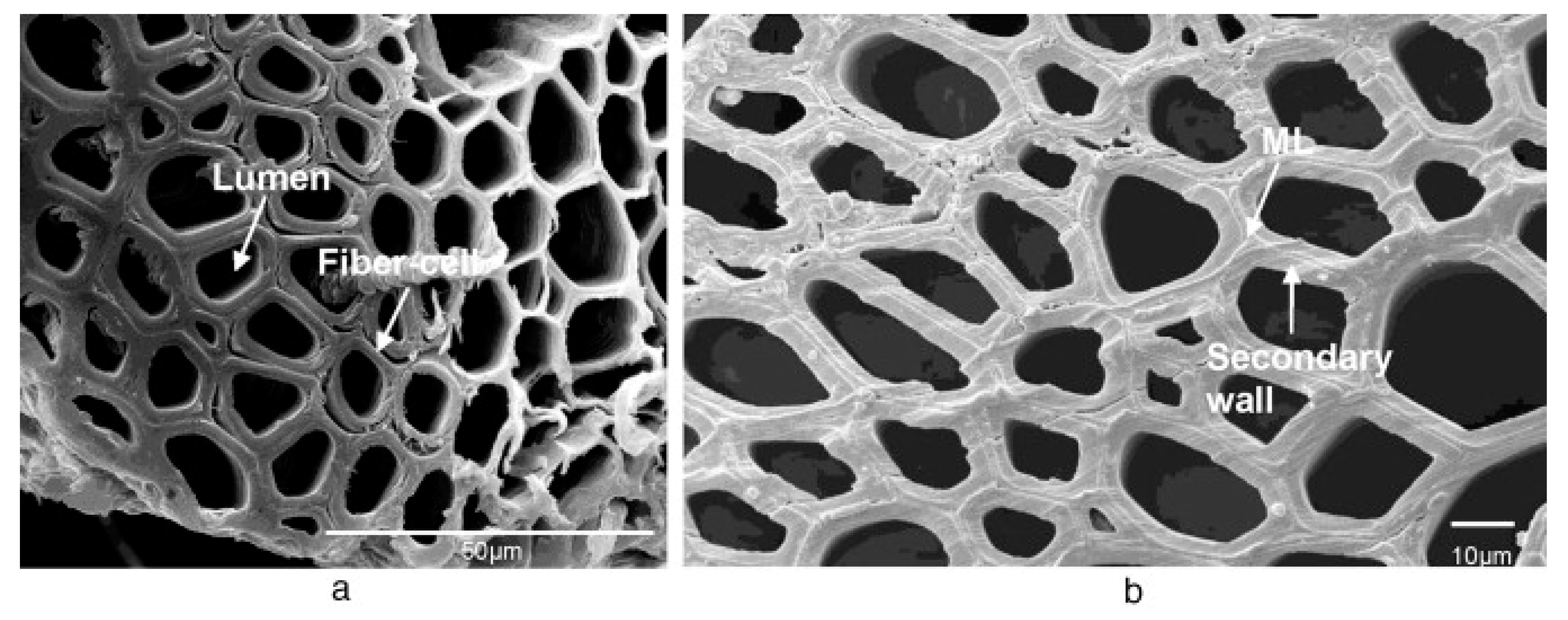

2. Using Carbon Fibers in Combination with Others in Composites

3. Studies on Hybrid Composites Including Carbon and Natural Fibers

4. Conclusions

Funding

Conflicts of Interest

References

- Kretsis, G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Yu, H.N.; Longan, M.L.; Jalalvand, M.; Wisnom, M.R.; Potter, K.D. Pseudo-ductility in intermingled carbon/glass hybrid composites with highly aligned discontinuous fibres. Compos. Part A 2015, 73, 35–44. [Google Scholar] [CrossRef]

- Wan, Y.Z.; Chen, G.C.; Huang, Y.; Li, Q.J.; Zhou, F.G.; Xin, J.Y.; Wang, Y.L. Characterization of three-dimensional braided carbon/Kevlar hybrid composites for orthopedic usage. Mater. Sci. Eng. A 2005, 398, 227–232. [Google Scholar] [CrossRef]

- Qiu, Y.; Schwartz, P. Micromechanical behavior of Kevlar-149/S-glass hybrid seven-fiber microcomposites: I. Tensile strength of the hybrid composite. Compos. Sci. Technol. 1993, 47, 289–301. [Google Scholar] [CrossRef]

- Pegoretti, A.; Fabbri, E.; Migliaresi, C.; Pilati, F. Intraply and interply hybrid composites based on E-glass and poly(vinyl alcohol) woven fabrics: Tensile and impact properties. Polym. Int. 2004, 53, 1290–1297. [Google Scholar] [CrossRef]

- Fan, Z.; Tsakiropoulos, P.; Miodownik, A.P. A generalized law of mixture. J. Mater. Sci. 1994, 29, 141–150. [Google Scholar] [CrossRef]

- Deák, T.; Czigány, T. Chemical composition and mechanical properties of basalt and glass fibers: A comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Charlet, K.; Eve, S.; Jernot, J.P.; Gomina, M.; Breard, J. Tensile deformation of a flax fiber. Procedia Eng. 2009, 1, 233–236. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.F.M.; Silva, F.A.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mäder, E.; Yu, C.Y.; Hu, X. Tensile properties of short-glass-fiber- and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Hajnalka, H.; Racz, I.; Anandjiwala, R.D. Development of hemp fibre reinforced polypropylene composites. J. Thermoplast. Compos. Mater. 2008, 21, 165–174. [Google Scholar]

- Holbery, J.; Houston, D. Natural-Fiber-Reinforced Polymer Composites in Automotive Applications. Jom 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Li, Y.; Hu, C.; Yu, Y. Interfacial studies of sisal fiber reinforced high density polyethylene (HDPE) composites. Compos. Part A 2008, 39, 570–578. [Google Scholar] [CrossRef]

- Pandita, S.D.; Yuan, X.; AManan, M.A.; Lau, C.H.; Subramanian, C.S.; Wei, J. Evaluation of jute/glass hybrid composite sandwich: Water resistance, impact properties and life cycle assessment. J. Reinf. Plast. Compos. 2014, 33, 14–25. [Google Scholar] [CrossRef]

- Assarar, M.; Zouari, W.; Sabhi, H.; Ayada, R.; Berthelot, J.M. Evaluation of the damping of hybrid carbon–flax reinforced composites. Compos. Struct. 2015, 132, 148–154. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Ferrante, L.; Valente, M.; Valente, T.; Lampani, L.; Gaudenzi, P.; Cioffi, S.; Iannace, S.; Sorrentino, L. Drop-weight impact behaviour of woven hybrid basalt–carbon/epoxy composites. Compos. Part B 2014, 59, 204–220. [Google Scholar] [CrossRef]

- Matthews, F.L.; Roshan, A.A.; Phillips, L.N. The bolt bearing strength of glass/carbon hybrid composites. Composites 1982, 13, 225–227. [Google Scholar] [CrossRef]

- Harris, B.; Bunsell, A.R. Impact properties of glass fibre/carbon fibre hybrid composites. Composites 1975, 6, 197–201. [Google Scholar] [CrossRef]

- Onal, L.; Adanur, S. Effect of stacking sequence on the mechanical properties of glass–carbon hybrid composites before and after impact. J. Ind. Text. 2002, 31, 255–271. [Google Scholar] [CrossRef]

- Hosur, M.V.; Adbullah, M.; Jeelani, S. Studies on the low-velocity impact response of woven hybrid composites. Compos. Struct. 2005, 67, 253–262. [Google Scholar] [CrossRef]

- Zhang, J.; Chaisombat, K.; He, S.; Wang, C.H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Des. 2012, 36, 75–80. [Google Scholar] [CrossRef]

- Pandya, K.S.; Veerraju, C.; Naik, N.K. Hybrid composites made of carbon and glass woven fabrics under quasi-static loading. Mater. Des. 2011, 32, 4094–4099. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Nisini, E.; Santulli, C.; Liverani, A. Mechanical and impact characterization of hybrid composite laminates with carbon, basalt and flax fibres. Compos. Part B 2017, 127, 92–99. [Google Scholar] [CrossRef]

- Cuinat-Guerraz, N.; Dumont, M.J.; Hubert, P. Environmental resistance of flax/bio-based epoxy and flax/polyurethane composites manufactured by resin transfer moulding. Compos. Part A 2016, 88, 140–147. [Google Scholar] [CrossRef]

- Di Landro, L.; Janszen, G. Composites with hemp reinforcement and bio-based epoxy matrix. Compos. Part B 2014, 67, 220–226. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. Flexural and impact behaviour of carbon/basalt fibers hybrid laminates. J. Compos. Mater. 2014, 48, 1121–1130. [Google Scholar] [CrossRef]

- Subagia, I.D.G.A.; Kim, Y. A study on flexural properties of carbon-basalt/epoxy hybrid composites. J. Mech. Sci. Technol. 2013, 27, 987–992. [Google Scholar] [CrossRef]

- Subagia, I.D.G.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Kyong Shon, H. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Nisini, E.; Santulli, C.; Ceruti, A.; Liverani, A. High speed impact properties of carbon-basalt-flax DHEC composites compared with pure carbon fibre composites. Compos. Struct. 2018, 192, 165–172. [Google Scholar] [CrossRef]

- Le Guen, J.; Newman, R.H.; Fernyhough, A.; Emms, G.W.; Staiger, M.P. The damping–modulus relationship in flax–carbon fibre hybrid composites. Compos. Part B 2016, 89, 27–33. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrieb, R.; Mac Mullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Tirillò, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical behavior of carbon/flax hybrid composites for structural applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef]

- Bagheri, Z.S.; El Sawi, I.; Schemitsch, E.H.; Zdero, R.; Bougherara, H. Biomechanical properties of an advanced new carbon/flax/epoxy composite material for bone plate applications. J. Mech. Behav. Biomed. Mater. 2013, 20, 398–406. [Google Scholar] [CrossRef]

- Scutaru, M.L.; Baba, M. Investigation of the mechanical properties of hybrid carbon-hemp laminated composites used as thermal insulation for different industrial applications. Adv. Mech. Eng. 2014, 6. [Google Scholar] [CrossRef]

- Noorunnisa Khanam, P.; Abdul Khalil, P.S.; Jawaid, M.; Ramachandra Reddy, G.; Surya Narayana, C.; Venkata Naidu, S. Sisal/carbon fibre reinforced hybrid composites: Tensile, flexural and chemical resistance properties. J. Polym. Environ. 2010, 18, 727–733. [Google Scholar] [CrossRef]

- Anuar, H.; Ahmad, S.H.; Rasid, R.; Ahmad, A.; Wan Busu, W.N. Mechanical properties and dynamic mechanical analysis of thermoplastic natural rubber reinforced short carbon fiber and kenaf fiber hybrid composites. J. Appl. Polym. Sci. 2008, 107, 4043–4052. [Google Scholar] [CrossRef]

- Paik, J.K.; Won, S.H. On deformation and perforation of ship structures under ballistic impacts. Ships Offshore Struct. 2007, 2, 217–226. [Google Scholar] [CrossRef]

- Yin, W.; Cui, J.; Xia, G.; Jin, R.; Xia, S.; Liu, S. The development of new sandwich thermal insulation composite wall based on the housing industrialization. Appl. Mech. Mater. 2013, 291–294, 997–1000. [Google Scholar] [CrossRef]

| Fiber | Diameter (µm) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Density (g/cm³) | References |

|---|---|---|---|---|---|

| Carbon | 5–10 | 2000–5000 | 200–600 | 1.8 | [11] |

| E-glass | 7–25 | 1950–3500 | 70–80 | 2.55 | [12] |

| S-glass | 8–12 | 4500–4700 | 75–90 | 2.5 | [13] |

| Kevlar | 12 | 3000–3150 | 63–67 | 1.4 | [13] |

| Basalt | 10–20 | 2800–3100 | 80–90 | 2.6–2.7 | [11] |

| Flax | 12–20 | 400–600 | 12–25 | 1.2–1.5 | [11] |

| Hemp | 25–500 | 300–700 | 20–70 | 1.3–1.5 | [14] |

| Sisal | 11–22 | 350–700 | 7–22 | 1.4–1.5 | [15] |

| Kenaf | 30–40 | 150–250 | 10–20 | 1.1–1.2 | [11] |

| Jute | 17–20 | 350–780 | 20–30 | 1.3 | [8] |

| Coir | 10–24 | 550–650 | 4–6 | 1.2 | [13] |

| Fiber Textiles (Plain Weave) | Approximate Price ($/kg) (January 2019, Elaborated from Alibaba) |

|---|---|

| Carbon | 35–60 |

| E-glass | 1–2 |

| S-glass | 3–7 |

| Kevlar | 50–150 |

| Basalt | 20–70 |

| Flax | 12–20 |

| Hemp | 5–13 |

| Kenaf | 1–3 |

| Jute | 0.50–1.50 |

| Sisal | 1.50–2.50 |

| Coir | 3–8 |

| Fibers other than Carbon | Matrix | Evaluations | References | Main Conclusions |

|---|---|---|---|---|

| Basalt | Epoxy | Interlaminar shear strength, Charpy impact strength | [30] | Flexural moduli of the hybrid composites followed the rule of mixtures. Ultimate properties and Charpy impact tests revealed positive deviations and therefore synergistic effects, due to the presence of both carbon and basalt fibers. The introduction of basalt fibers in the carbon fiber laminates promoted an increase of the adsorbed impact energy, avoiding catastrophic failure. |

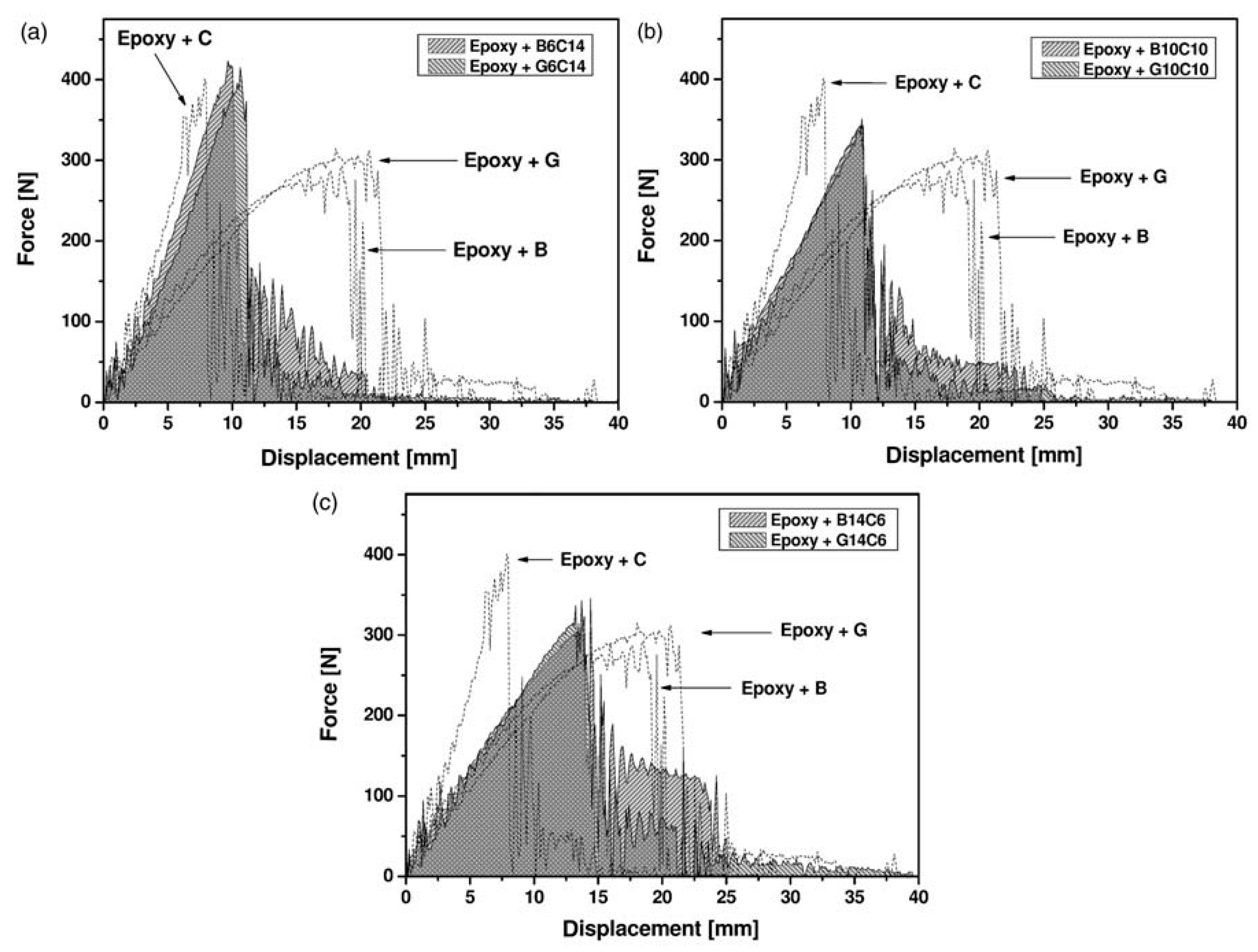

| Basalt | Epoxy | Low speed impactFour-point flexural (pre- and post-impact) | [18] | In impact loading, the basalt fiber hybridization enhances peak force while preventing penetration. This is due to the higher ductility of basalt fibers that results in a wider damaged area and more energy absorption. Sandwich laminates are superior in terms of static properties (flexural and interlaminar shear yet more sensitive than intercalated hybrids to the effect of impact damage. |

| Basalt | Epoxy | Flexural | [31] | Application of the hybrid mixture law led to observing that differences between the calculated and experimental values for the flexural properties were less than 5% for all sandwich hybrids. |

| Basalt | Epoxy | Flexural | [32] | Higher flexural strength and stiffness were obtained by stacking carbon fiber layer at the compressive side. The best performance was obtained by sandwiching foru basalt fiber layers between three carbon fiber layers on each side |

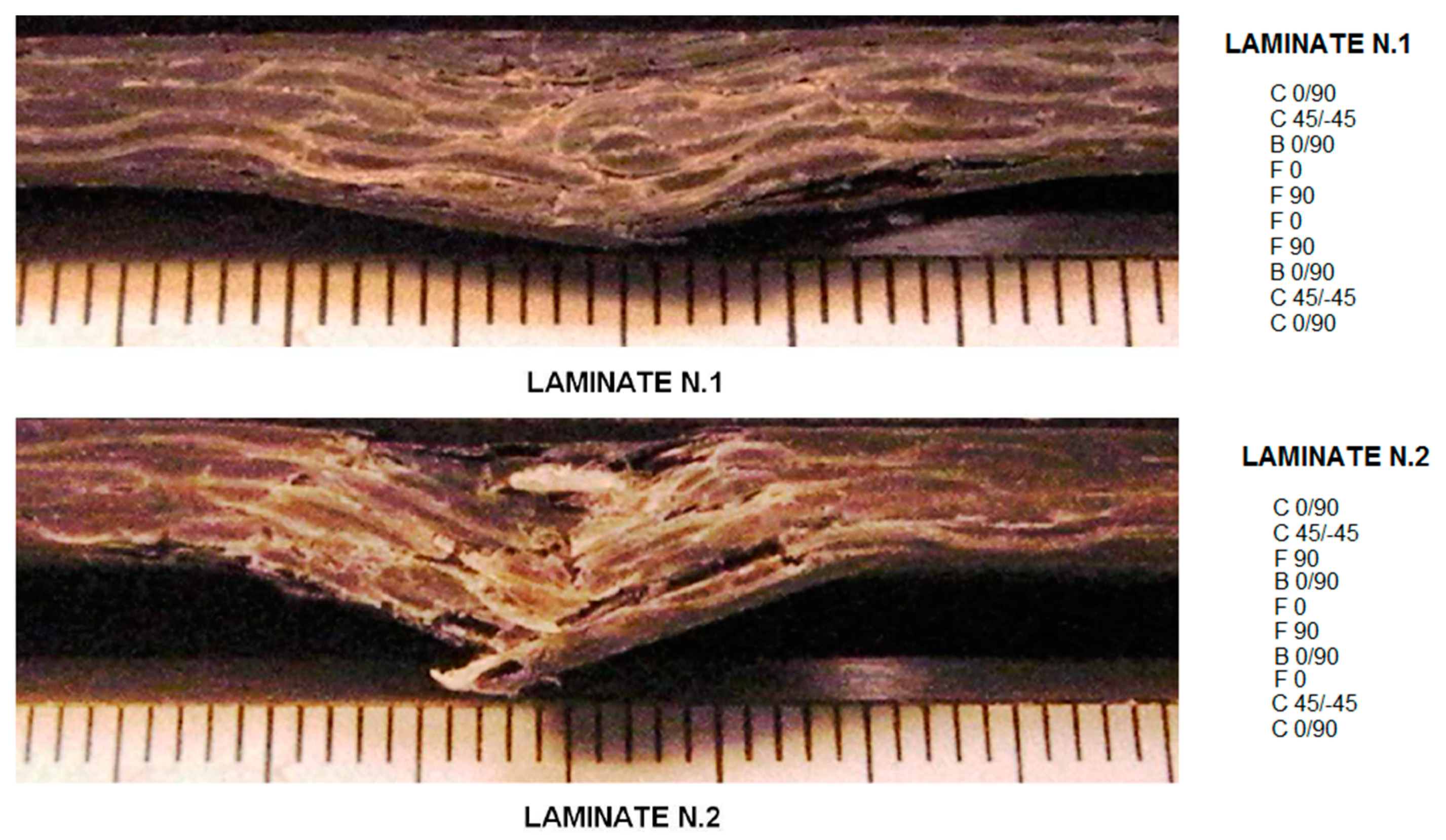

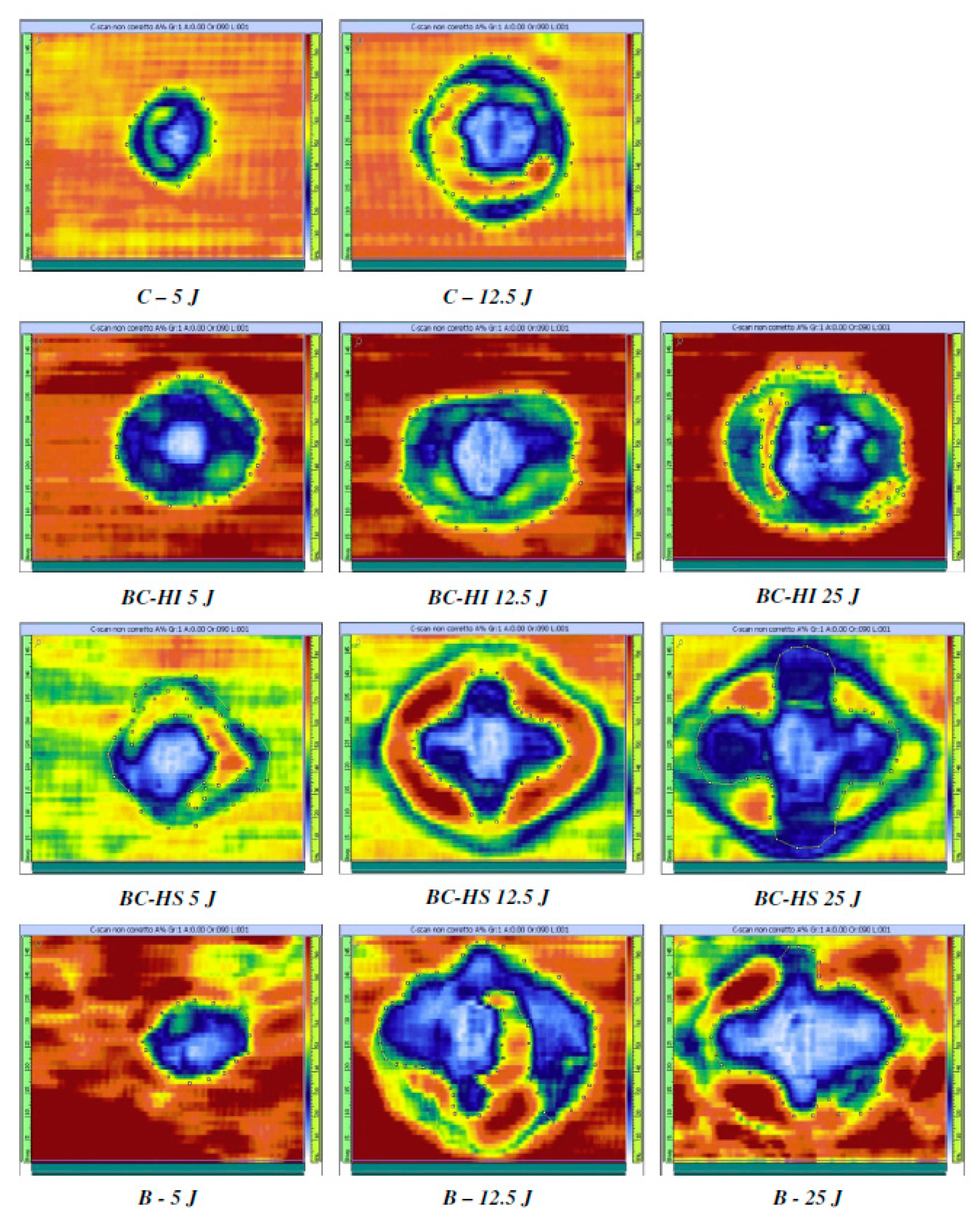

| Basalt and flax | Epoxy | Tensile, flexural, interlaminar shear strength test, falling weight impact | [27] | Differences in terms of mechanical and impact performance between selecting an either sandwich or intercalated performance for the laminates, keeping basalt fibers on the outer surfaces were in general terms quite limited. Of course, intercalation increases the complexity of manufacturing, which suggests their application should be limited to specific cases, for example for the need to better disperse damage |

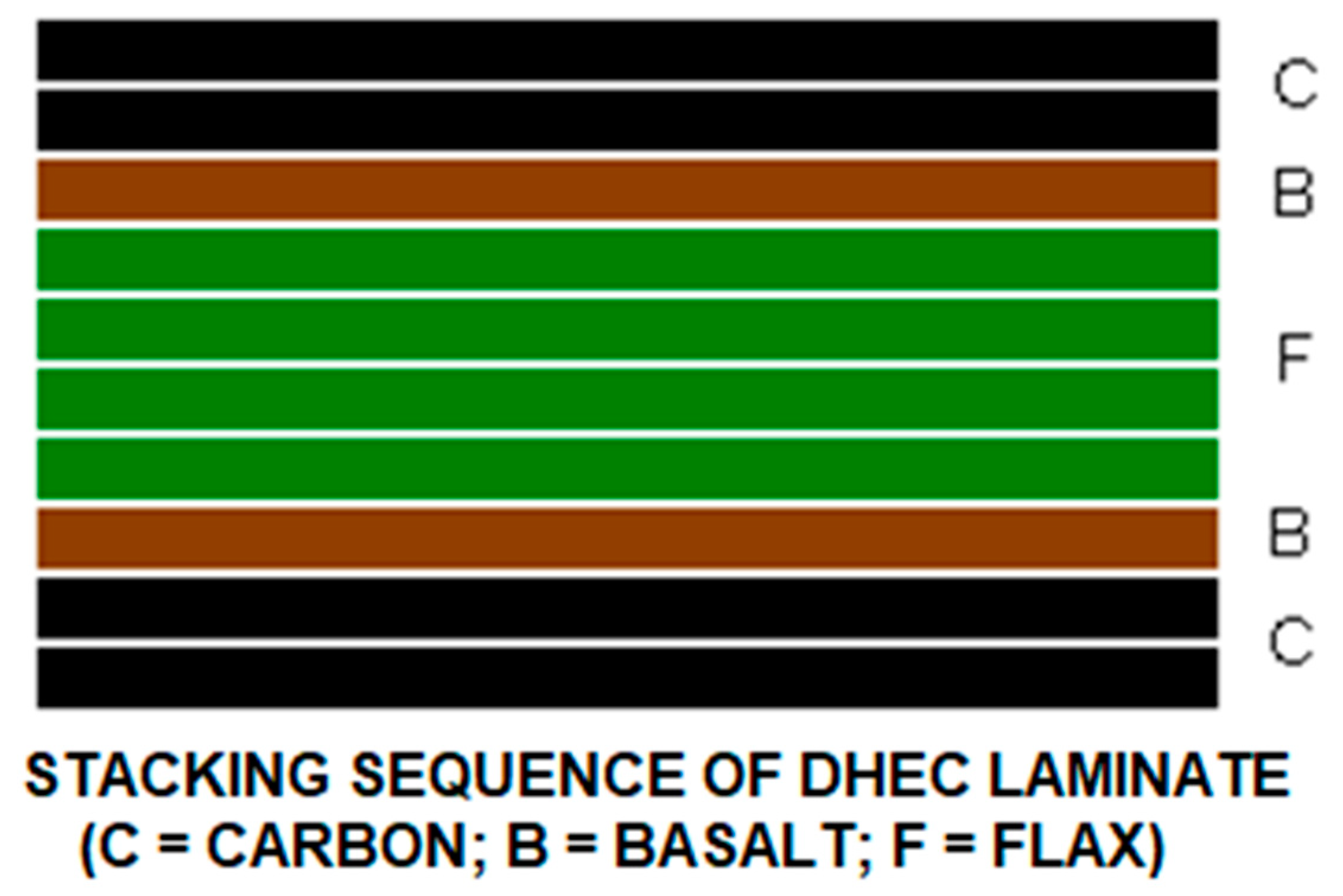

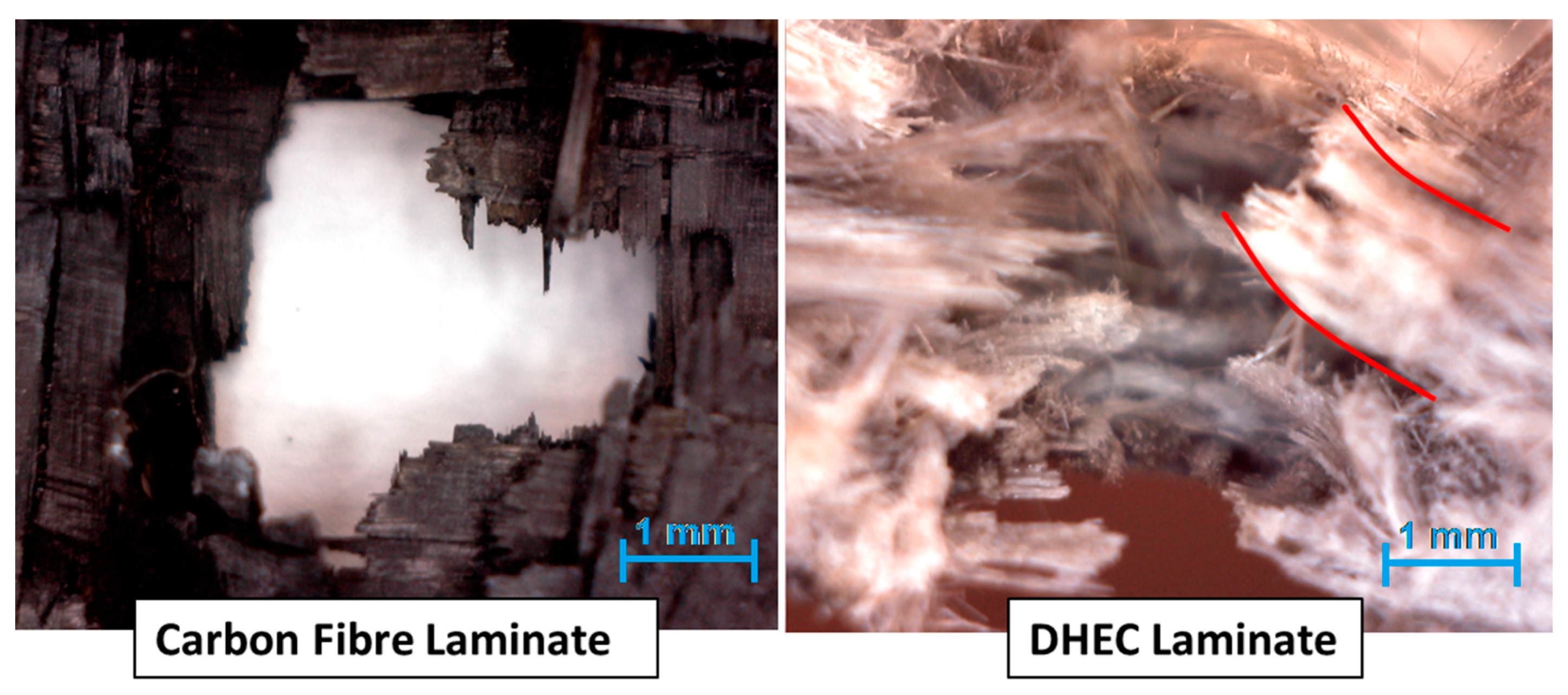

| Basalt and flax | Polyurea | Tensile, flexural, interlaminar shear strength, high speed impact | [33] | The hybrid with basalt and flax showed a significantly improved mode for energy absorption during ballistic impact with respect to carbon fiber laminates with comparable properties (hence lower thickness). This was due to the different damage progression and improved ductility. |

| Flax | Epoxy | Tensile, flexural. damping loss, elastic modulus by vibration | [34] | The application of the rule of hybrid mixtures (ROHM) was proposed for carbon–flax hybrids, obtaining positive deviations for experimental results, except for flexural data |

| Flax | Epoxy | Damping modeling | [17] | The major role of the position of flax fiber layers into hybrids as for flexural and damping properties was highlighted |

| Flax | Epoxy | Tensile, flexural, thermal degradation, water absorption | [35] | Comparisons for carbon fiber laminates with two types of flax/carbon hybrids laminates including either cross-ply (CP) or unidirectional (UD) flax fabric indicates that hybrids with UD flax were competitive with carbon fiber laminates as for level of water absorption. The elongation at break was increased by hybridization, though critical behaviors were indicated by higher weight loss in hybrids during thermal degradation |

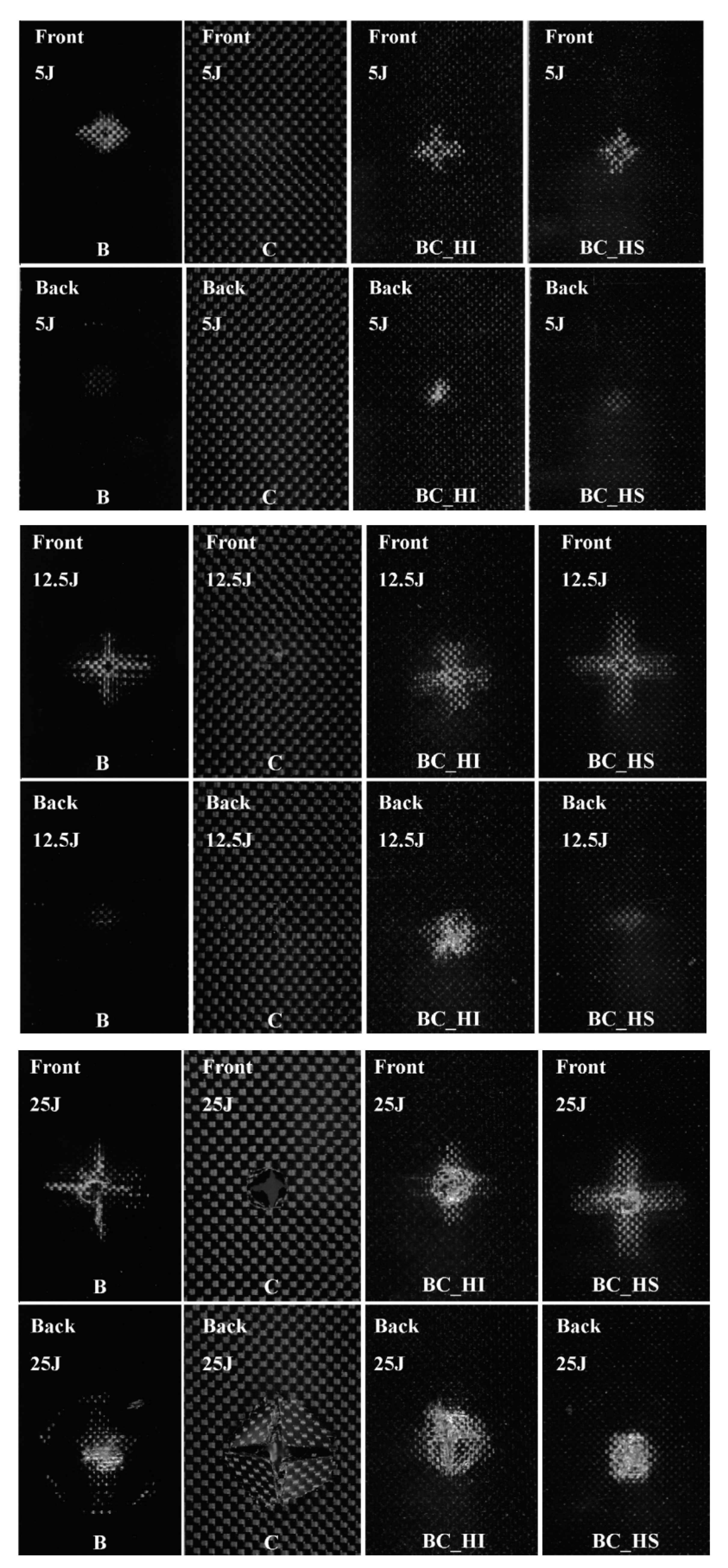

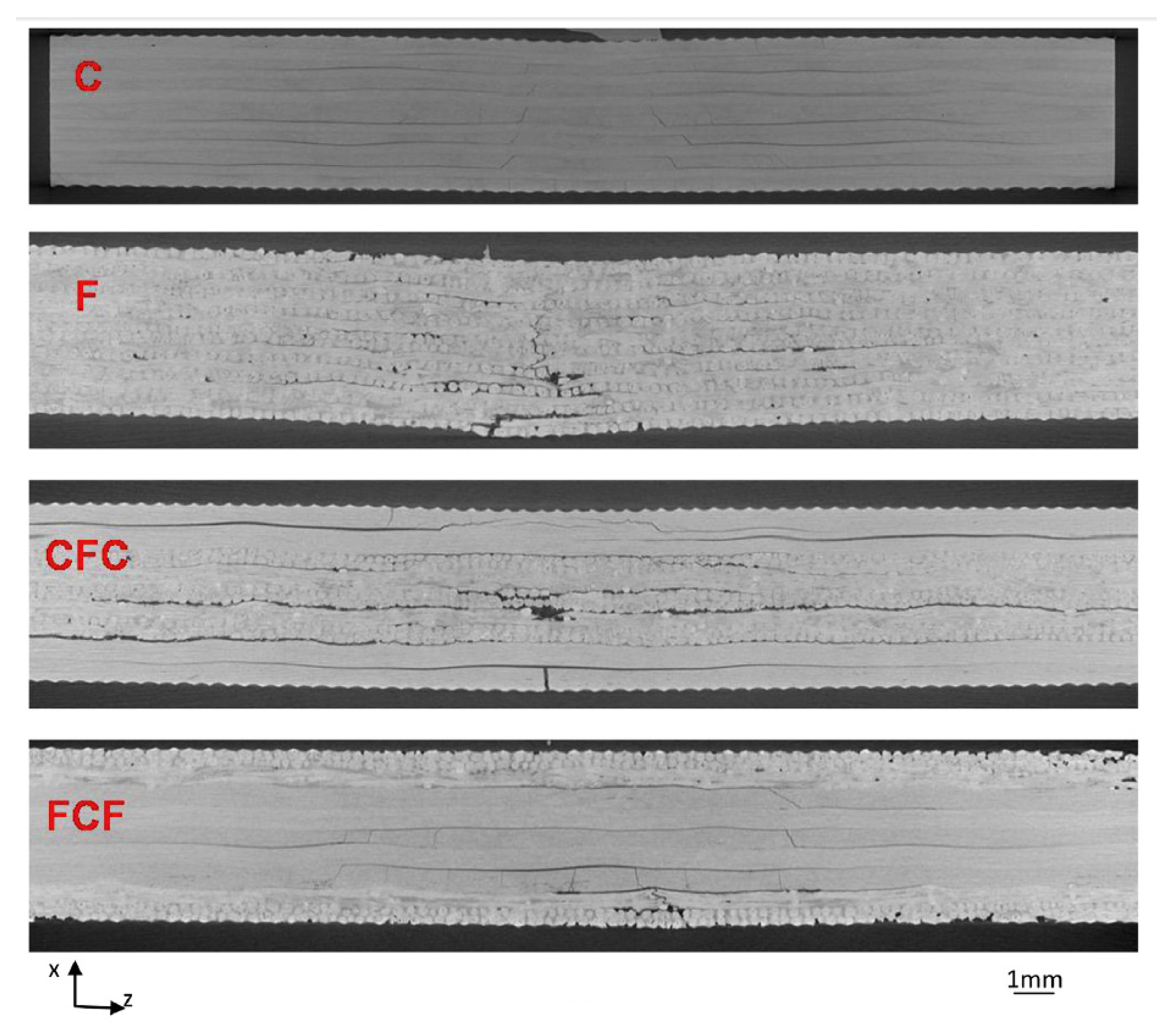

| Flax | Epoxy | Four-point flexural, low speed impact | [36] | The work compared carbon/flax hybrid laminates having either flax or carbon on the outer surfaces (FCF or CFC). It was confirmed the superiority of the latter as for flexural performance, whereas with impact with no penetration in the presence of flax on the outside allows for better dispersing damage in the laminate |

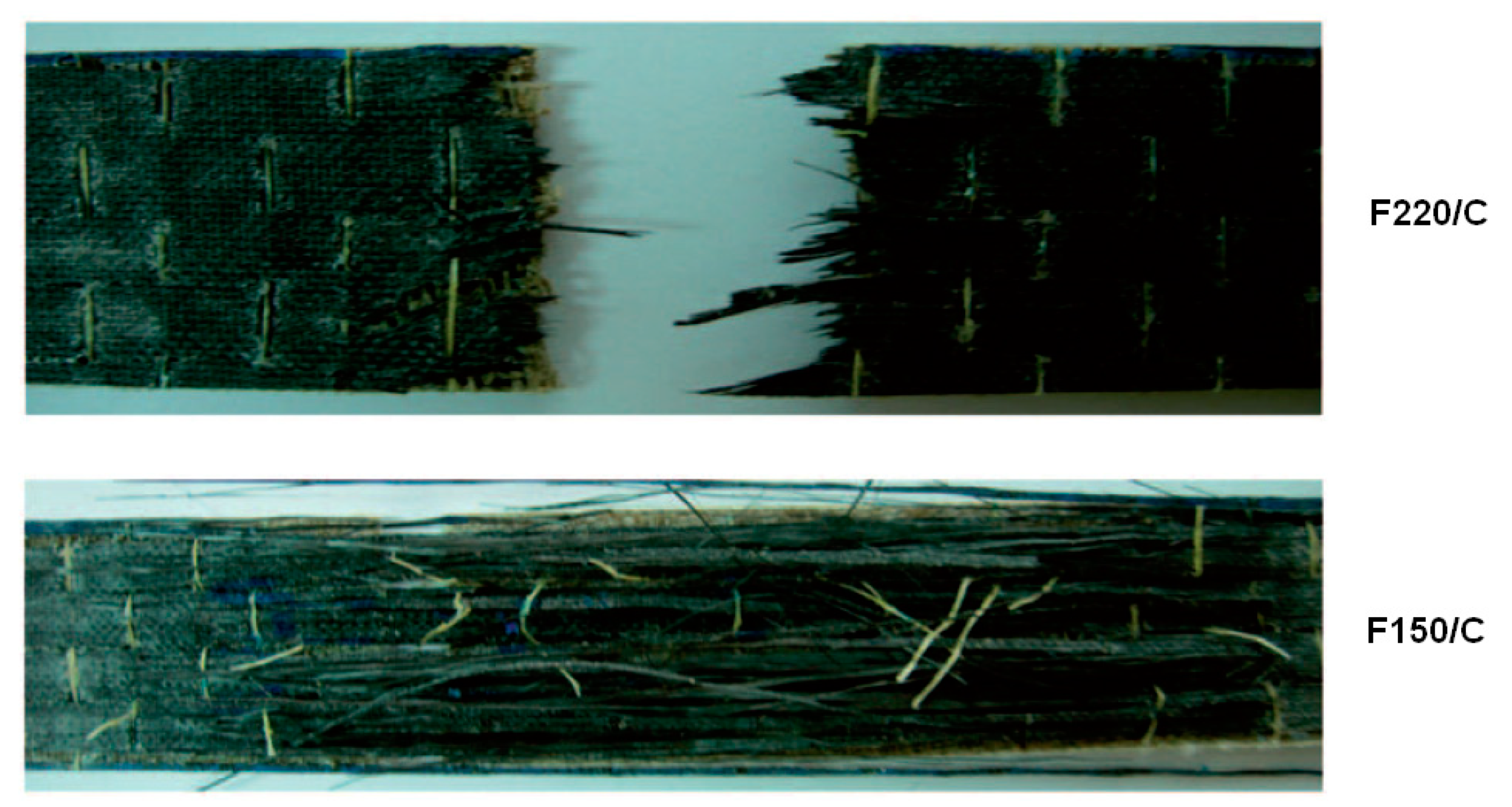

| Flax | Epoxy | Tensile, flexural | [37] | The study was based on the comparison of the effect of two different stacking sequences (150 and 200 g/m2) for flax fabric introduction. The former proved superior for tensile and flexural performance of the hybrid. |

| Flax | Epoxy | Tension, three-point bending, Rockwell hardness | [38] | The hybrids were closer in structure to human cortical bone than orthopedic metal plates, an ultimate tensile strength and modulus of 399.8 MPa and 41.7 GPa, and an ultimate flexural strength and modulus of 510.6 MPa and 57.4 GPa, respectively. |

| Hemp | Unsaturated polyester | Low speed impact | [39] | Falling weight impact resistance was provided for these laminates (4 mm thickness) up to an impact velocity of 3 m/s |

| Sisal | Unsaturated polyester | Tensile, flexural, chemical resistance | [40] | Alkali treatment by boiled sodium hydroxide solution improved tensile and flexural properties also in the sisal/carbon fiber with respect to the untreated fiber reinforcement. This was attributed to hemicellulose removal. |

| Kenaf | Thermoplastic rubber | Flexural, impact, dynamic mechanical analysis | [41] | Flexural strength and stiffness increased up to 15% of global volume of fibers, then declined, while impact strength showed an increase even for 20% global volume of fibers. |

| Reinforcement (Total 20 Layers) (Epoxy Matrix) | ILSS (MPa) |

|---|---|

| G20 | 59.7 ± 1.4 |

| B20 | 60. 2 ± 0.9 |

| C20 | 55.7 ± 2.1 |

| B6C14 | 45.2 ± 0.9 |

| G6C14 | 43.5 ± 1.3 |

| B10C10 | 46.9 ± 0.6 |

| G10C10 | 45.9 ± 2.0 |

| B14C6 | 53.2 ± 1.0 |

| G14C6 | 54.0 ± 0.5 |

| a. Flexural Properties for Flax and Flax/Carbon Laminates | ||

| Laminate | E (GPa) | σ (MPa) |

| F150 | 7.41 ± 0.39 | 76.42 ± 3.59 |

| F220 | 5.35 ± 0.21 | 61.05 ± 2.28 |

| F150/C | 23.84 ± 0.74 | 160.42 ± 10.46 |

| F220/C | 14.41 ± 1.38 | 85.00 ± 5.38 |

| b. Tensile Properties for Flax and Flax/Carbon Laminates | ||

| Laminate | E (GPa) | σ (MPa) |

| F150 | 1.79 ± 0.04 | 78.63 ± 1.41 |

| F220 | 4.5 ± 0.15 | 90.43 ± 1.47 |

| F150/C | 6.48 ± 0.32 | 288.03 ± 30.23 |

| F220/C | 5.09 ± 0.34 | 172.4 ± 25.5 |

| Laminate | Stacking Sequence | Number of Flax Layers | Number of Carbon Layers | Total Fibre Volume Fraction (%) |

|---|---|---|---|---|

| F | [(0/90)4/0]s | 18 | - | 56 ± 0.1 |

| C | [(0/90)3/0]s | - | 14 | 59 ± 0.1 |

| FCF | [(02/902)F/[(02/902)C/0C]S | 8 | 10 | 62 ± 0.1 |

| CFC | [(02/902)C/[(02/902)F/0F]S | 10 | 8 | 60 ± 0.1 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santulli, C. Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review. Materials 2019, 12, 517. https://doi.org/10.3390/ma12030517

Santulli C. Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review. Materials. 2019; 12(3):517. https://doi.org/10.3390/ma12030517

Chicago/Turabian StyleSantulli, Carlo. 2019. "Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review" Materials 12, no. 3: 517. https://doi.org/10.3390/ma12030517

APA StyleSantulli, C. (2019). Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review. Materials, 12(3), 517. https://doi.org/10.3390/ma12030517