4.1. Effect of JF on UC Strength

Stress–strain curves for the natural soil and various JF-reinforced samples—

FxSyTz where

x = {0, 0.5, 1.0, 1.5},

y = {0}, and

z = {0}—are provided in

Figure 3. The stress–strain relationship for the natural soil sample demonstrated a rise–fall response with a visually-detectable peak point, thereby indicating a strain-softening behavior accompanied by a brittle sample failure. As a result of JF-reinforcement, the stress–strain locus progressively transitioned towards a strain-hardening character. In this case, the greater the JF content the more prominent the strain-hardening effect and hence the less dramatic (or the more ductile) the failures.

As demonstrated in

Figure 3, the greater the JF content the higher the peak UC strength up to

Fc = 1%, beyond of which JF-reinforcement was found to adversely influence strength development in the composite. The natural soil exhibited a peak UC strength of

qu = 82.15 kPa, while the samples reinforced with

Fc = 0.5% and 1% resulted in higher values of

qu = 119.35 kPa and 138.21 kPa, respectively. The higher JF inclusion of 1.5% changed the peak UC strength to 132.24 kPa, which still holds a notable advantage over the natural soil, as well as the sample reinforced with 0.5% JF. The axial strain at failure, denoted as

εu, is an indication of the material’s ductility; higher

εu values manifest a more ductile (or a less brittle) character. Improvement in ductility is often quantified by means of the deformability index

ID [

70]:

where

εuS = axial strain at failure for the stabilized soil sample; and

εuN = axial strain at failure for the control (or natural soil) sample.

The deformability index exhibited a monotonically-increasing trend with JF content, thus indicating that the greater the JF content the more ductile the sample’s response to compression. By definition, the natural soil corresponds to a deformability index of unity (εuN = 4.73%). As a result of JF-reinforcement, the deformability index exhibited a monotonically-increasing trend, and resulted in ID = 1.24, 1.39 and 1.81 (εuS = 5.88%, 6.57% and 8.55%) for Fc = 0.5%, 1% and 1.5%, respectively.

The secant modulus at 50% of the peak UC strength, denoted as

E50, is a measure of the material’s stiffness in the elastic compression domain [

22,

71]. The variations of

E50, as given in

Figure 3, exhibited a trend similar to that observed for the peak UC strength, peaking at

Fc = 1% and then slightly decreasing for the higher JF content of 1.5%. The natural soil and samples reinforced with 0.5%, 1% and 1.5% JF resulted in

E50 = 2.27 MPa, 3.35 MPa, 3.70 MPa and 3.67 MPa, respectively. The area under a typical stress–strain curve up to the peak point, defined as the energy stored by a sample undergoing deformation and referred to as peak strain energy, serves as a measure of the material’s toughness [

22,

72]. Unlike strength and stiffness, the development of toughness, similar to ductility, was consistently in favor of the JF inclusions, and displayed a monotonically-increasing trend with respect to JF content (see the

Eu values in

Figure 3). An increase in toughness warrants an increase in the peak UC strength and/or the axial strain at failure [

41,

57]. With regard to JF-reinforcement, both

qu and

εu contribute to the development of toughness; however, the greater the JF content the less prominent the strength’s contribution and hence the more significant the role of ductility. The natural soil resulted in

Eu = 2.36 kJ/m

3, while the samples reinforced with

Fc = 0.5%, 1% and 1.5% resulted in higher values of

Eu = 4.49 kJ/m

3, 6.11 kJ/m

3 and 8.32 kJ/m

3, respectively.

4.2. Effect of JF + GBFS on UC Strength

Typical stress–strain curves for the natural soil (

F0S0T0) and various GBFS-treated samples—

FxSyTz where

x = {0},

y = {3, 9}, and

z = {7, 28}—are provided in

Figure 4a. Unlike the JF-reinforced samples (see

Figure 3), the stress–strain responses for all GBFS-treated composites were seemingly strain-softening and hence accompanied by brittle failures. In general, the greater the GBFS content and/or the longer the curing period, the higher the developed strength and stiffness, and the more prominent the strain-softening character. Stress–strain curves for the natural soil (

F0S0T0) and various JF-reinforced samples treated with 6% GBFS—

FxSyTz where

x = {0, 0.5, 1.0, 1.5},

y = {6}, and

z = {7}—are provided in

Figure 4b. Much like the natural soil reinforced with JF (see

Figure 3), for any given GBFS content, an increase in JF content progressively transitioned the stress–strain locus towards a strain-hardening character. In this case, the greater the JF content the more pronounced the strain-hardening effect and hence the more ductile the failures.

Figure 5a,b illustrate the variations of peak UC strength against JF content for the natural soil and various GBFS-treated samples tested at 7 and 28 days of curing, respectively. Much like the natural soil reinforced with JF, for any given GBFS content and curing time, the peak UC strength increased with JF content up to

Fc = 1%; beyond 1% JF, the effect of JF-reinforcement adversely influenced strength development in the composite. For instance, the sample

F0S6T28 resulted in

qu = 191.32 kPa, while the inclusions of 0.5%, 1% and 1.5% JF, with the same 6% GBFS content and the same 28-day curing condition, resulted in

qu = 250.08 kPa, 327.42 kPa and 302.76 kPa, respectively. Moreover, for any given JF content, the greater the GBFS content and/or the longer the curing period, the higher the developed peak UC strength, following a monotonically-increasing trend. The sample

F1.0S0T0, for instance, exhibited a peak UC strength of

qu = 138.21 kPa. As a result of 3%, 6% and 9% GBFS inclusions, along with the same 1% JF content and a 7-day curing condition, the peak UC strength increased to 203.56 kPa, 273.68 kPa and 330.06 kPa, respectively. Similar mix designs cured for

Tc = 28 days exhibited significant improvements over their 7-day counterparts, as the aforementioned values increased to 248.65 kPa, 327.42 kPa and 443.21 kPa, respectively. The ASTM D4609–08 standard suggests a minimum improvement of 345 kPa in the natural soil’s peak UC strength (at

Tc = 28 days) as a criterion for characterizing an effective stabilization scheme [

34]. As demonstrated in

Figure 5b, the sample

F1.0S9T28 promotes a 361.06 kPa improvement in the peak UC strength and hence satisfies the aforementioned criterion.

The deformability index, a measure of the material’s ductility, was also calculated for various JF + GBFS mix designs, and the results are provided in

Figure 6a,b for the samples tested at

Tc = 7 and 28 days, respectively. Similar to the natural soil reinforced with JF, for any given GBFS content and curing time, the greater the JF content the higher the deformability index, following a monotonically-increasing trend. For any given JF content, however, the greater the GBFS content and/or the longer the curing period, the lower the developed ductility. The deformability index for various JF + GBFS blends was cross-checked with that of the natural soil (or

ID = 1) to arrive at the optimum cases. In this regard, nine cases (out of 28) manage to satisfy the

ID ≥ 1 criterion, and thus are deemed as optimum with respect to ductility improvement. The nine optimum cases and their corresponding

ID values include

F0.5S3T7 (

ID = 1.10),

F1.0S3T7 (

ID = 1.34),

F1.5S3T7 (

ID = 1.68),

F1.0S3T28 (

ID = 1.09),

F1.5S3T28 (

ID = 1.34),

F1.0S6T7 (

ID = 1.16),

F1.5S6T7 (

ID = 1.32),

F1.5S6T28 (

ID = 1.10), and

F1.5S9T7 (

ID = 1.08).

Figure 7a,b illustrate the variations of

E50 against JF content for the natural soil and various GBFS-treated samples tested at 7 and 28 days of curing, respectively. The variations of

E50 exhibited a trend similar to that observed for the peak UC strength given in

Figure 5. As such, for any given JF content, the development of stiffness was in favor of both the GBFS content and the curing time. As typical cases, the samples

F1.0S0T0,

F1.0S3T7,

F1.0S3T28,

F1.0S9T7 and

F1.0S9T28 resulted in

E50 = 3.70 MPa, 5.39 MPa, 7.81 MPa, 12.30 MPa and 18.92 MPa, respectively. Moreover, for any given GBFS content and curing time, stiffness enhancements were only notable for samples with up to 1% JF inclusions. In this regard, the samples

F0S6T28,

F0.5S6T28,

F1.0S6T28 and

F1.5S6T28, for instance, resulted in

E50 = 8.25 MPa, 9.47 MPa, 11.21 MPa and 10.23 MPa, respectively.

Figure 8a,b illustrate the variations of peak strain energy, a measure of the material’s toughness, against JF content for the natural soil and various GBFS-treated samples tested at 7 and 28 days of curing, respectively. The development of toughness was in favor of both the JF content and the GBFS treatments (i.e., GBFS content and/or curing time). For any given GBFS content and curing time, the greater the JF content the higher the peak strain energy, following a monotonically-increasing trend. For instance, the samples

F0S6T28,

F0.5S6T28,

F1.0S6T28 and

F1.5S6T28 resulted in peak strain energies of

Eu = 3.99 kJ/m

3, 6.30 kJ/m

3, 9.71 kJ/m

3 and 10.70 kJ/m

3, respectively. Similarly, for any given JF content, the greater the GBFS content and/or the longer the curing period, the higher the developed toughness. As typical cases, the sample

F1.0S0T0 resulted in

Eu = 6.11 kJ/m

3, while the aforementioned value increased to 8.02 kJ/m

3, 8.22 kJ/m

3, 8.78 kJ/m

3 and 9.88 kJ/m

3 for

F1.0S3T7,

F1.0S3T28,

F1.0S9T7 and

F1.0S9T28, respectively.

Figure 9a,b illustrate the variations of

E50 and

Eu against

qu for various JF + GBFS mix designs, respectively. The variations of

E50 were situated within the 0.054

qu <

E50 < 0.025

qu domain (

E50 in MPa, and

qu in kPa). For

Eu, however, a broader domain in the form of 0.063

qu <

Eu < 0.018

qu (

Eu in kJ/m

3, and

qu in kPa) was noted. The former, the

E50, exhibited a rather strong correlation with

qu. On the contrary, the peak strain energy was poorly correlated with the peak UC strength. In this regard, simple correlative models in the forms of

E50 = 0.038

qu (with R

2 = 0.836) and

Eu = 0.029

qu (with R

2 = 0.449) can be derived; the former can be implemented for indirect estimations of

E50.

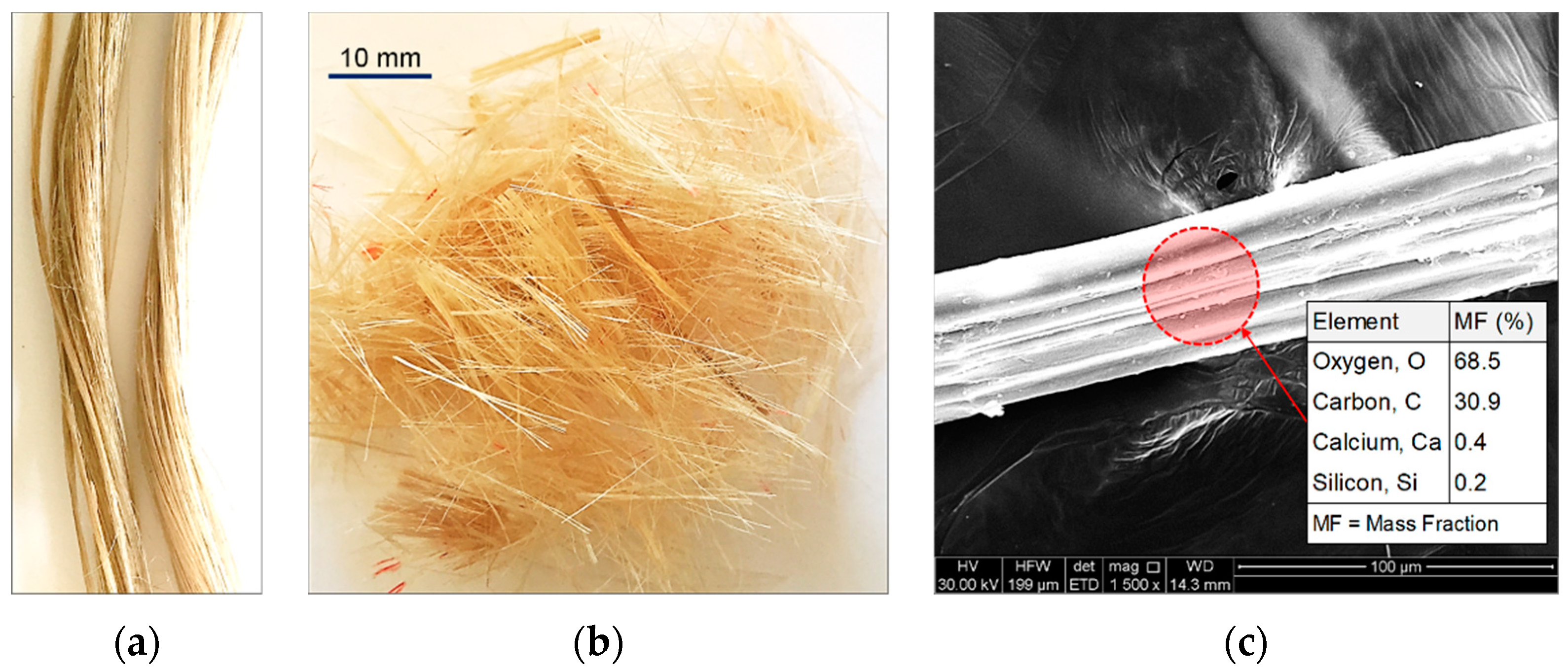

4.3. Stabilization Mechanisms and Microstructure Analysis

The JF inclusions are able to amend the soil fabric through improvements achieved in two aspects: (

i) frictional resistance generated at the soil–fiber interface, owing to the fiber’s rough surface texture; and (

ii) mechanical interlocking of soil particles and fibers [

1,

22,

40,

45,

48,

51,

57,

66]. The interfacial frictional resistance is a function of the soil–fiber contact area, with greater contact levels providing a higher resistance to bear the external loads. Consequently, this amending mechanism can be ascribed to the fiber content, meaning that the greater the number of included fiber units, i.e., increase in fiber content, the greater the contact levels achieved between the soil particles and fibers, and thus the higher the generated interfacial frictional resistance against UC loading. The second amending mechanism, the mechanical interlocking of soil particles and fibers, is achieved during sample preparation/compaction, and induces the composite’s adhesion by immobilizing the soil particles undergoing shearing. Quite clearly, the more effective/pronounced the achieved mechanical interlocking the higher the permanence against UC loading. Consequently, this amending mechanism is in line with the fiber content, and more importantly the fiber’s elongated form factor. In general, the greater the number of included fiber units, i.e., increase in fiber content, the greater the number of interlocked or enwrapped soil aggregates, and thus the higher the developed peak UC strength. It should be noted that the soil–fiber amending mechanisms, as described above, only hold provided that the fiber units do not cluster (or adhere to each other) during mixture preparation and compaction [

22,

54,

56,

73]. At high fiber contents, the behavior of the composite, at some points, may be governed by a dominant fiber-to-fiber interaction; this effect, commonly referred to as fiber-clustering, leads to a notable improvement in the sample’s ductility/deformability and toughness (see

Figure 6 and

Figure 8) while offsetting the desired soil-to-fiber interaction capable of improving the sample’s peak UC strength and stiffness. Fiber-clustering effects were evident for all samples containing 1.5% JF, as the previously-improved peak UC strength and stiffness manifested a notable decrease compared with similar mix designs containing 1% JF (see

Figure 5 and

Figure 7).

Calcium-based binders, in this case GBFS, initiate a series of short- and long-term chemical reactions in the soil–water medium, which alter the soil fabric into a unitary mass of improved mechanical performance. Short-term chemical reactions consist of cation exchange and flocculation–agglomeration; their amending roles are often negligible when paired with neutrally-charged soil particles such as gravels, sands and silts. For fine-grained soils containing a notable fraction of negatively-charged clay particles, however, short-term reactions lead to significant improvements in the soil’s plasticity/workability, early-age strength, swelling potential and consolidation capacity [

33,

74,

75,

76]. During short-term reactions, higher-valence cations substitute those of lower valence, and cations of larger ionic radius replace smaller cations of the same valence; the order of substitution follows the Hofmeister (or Lyotropic) series, i.e., Na

+ < K

+ << Mg

2+ < Ca

2+ [

77]. GBFS-treatment supplies the clay–water medium with additional calcium cations (Ca

2+), which immediately substitute cations of lower valence (e.g., sodium Na

+) and/or same-valence cations of smaller ionic radius (e.g., magnesium Mg

2+) in the vicinity of the clay particles. These cation exchanges lead to a decrease in the thickness of the Diffused Double Layers (DDLs), owing to the development of strong van der Waals bonds between adjacent clay particles in the matrix, which in turn promote aggregation and flocculation of the clay particles [

76,

78,

79]. Long-term chemical reactions, commonly referred to as pozzolanic reactions, are strongly time- and often temperature-dependent, meaning that their commencement and evolution require a certain and often long period of curing. During pozzolanic reactions, ionized calcium (Ca

2+) and hydroxide (OH

–) units, released from the water–binder complex, gradually react with silicate (SiO

2) and aluminate (Al

2O

3) units in the soil, thereby leading to the formation of strong cementation products/gels, namely Calcium–Silicate–Hydrates (CSH), Calcium–Aluminate–Hydrates (CAH) and Calcium–Aluminate–Silicate–Hydrates (CASH); these products encourage further solidification and flocculation of the soil particles, which in turn accommodate the development of a dense, uniform matrix coupled with enhanced strength performance [

31,

33,

76,

79]. It should be noted that the short- and long-term amending reactions, as described above, are generally in favor of a higher binder content; this general perception also complies with the results outlined in

Figure 5,

Figure 7 and

Figure 8.

The microstructure analysis was carried out using an SEM characterization scheme developed by Soltani et al. [

58].

Figure 10a–d illustrate SEM micrographs for the samples

F0S0T0 (natural soil),

F1.0S0T0,

F0S6T28 and

F1.0S6T28, respectively. The microstructure of the natural soil sample manifested a partly-dense, non-uniform matrix, accompanied by a notable number of large inter- and intra-assemblage pore-spaces, respectively, formed between and within the soil aggregates; such morphological features warrant the existence of an edge-to-edge dispersed fabric (see

Figure 10a). The microstructure of the JF-reinforced sample or

F1.0S0T0 exhibited a partly-dense but more uniform matrix, accompanied by a limited number of small intra-assemblage pore-spaces mainly distributed along the soil–fiber connection interface. In essence, the fiber units acted as physical anchors within the matrix, interlocking the neighboring soil aggregates and hence withstanding compressive stresses during shearing (see

Figure 10b). As a result of GBFS-treatment (see sample

F0S6T28 in

Figure 10c), the microstructure became even more uniform in nature, indicating aggregation and flocculation of the soil particles and hence the development of a fully-dense matrix with a dominant edge-to-face flocculated fabric. Prevalent cementation products were clearly visible between and within the soil aggregates, which portrayed a major role in eliminating the inter- and intra-assemblage pore-spaces in the matrix. As a result of JF-reinforcement and GBFS-treatment (see sample

F1.0S6T28 in

Figure 10d), the soil–fiber connection interface was markedly improved, as evident with the presence of fully-clothed fibers strongly embedded between and within the soil aggregates, which in turn led to a further improvement in the composite’s strength and stiffness.