Nanomechanical and Topochemical Changes in Elm Wood from Ancient Timber Constructions in Relation to Natural Aging

Abstract

1. Introduction

2. Materials and Methods

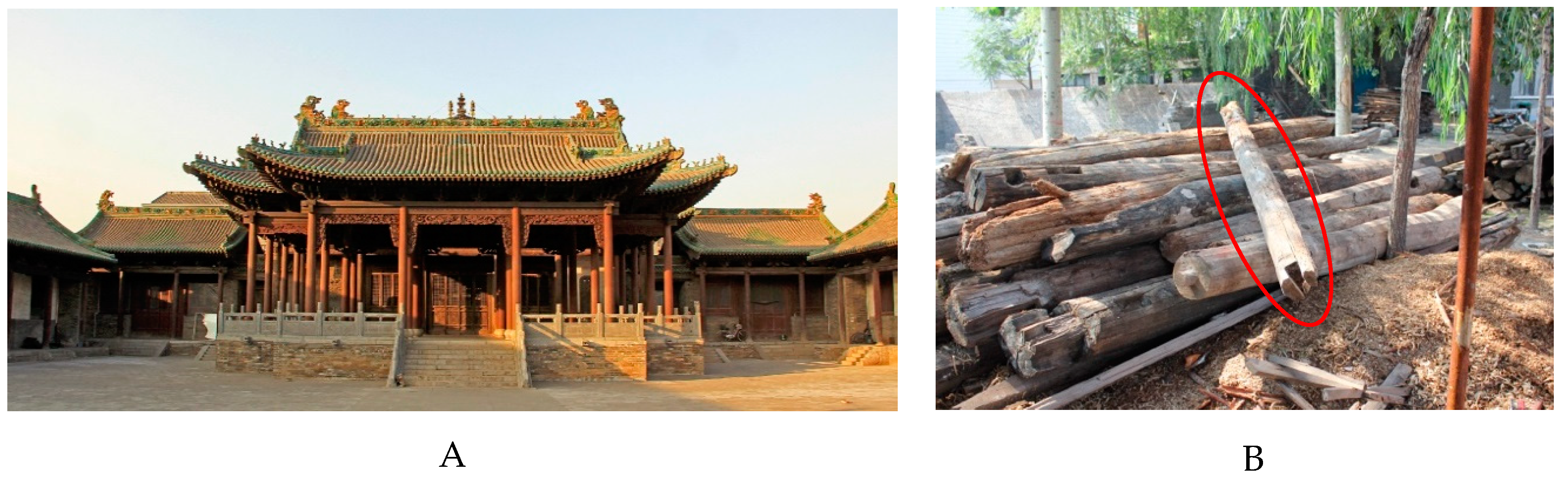

2.1. Materials

2.2. Method

2.2.1. The Fabrication of Test Samples

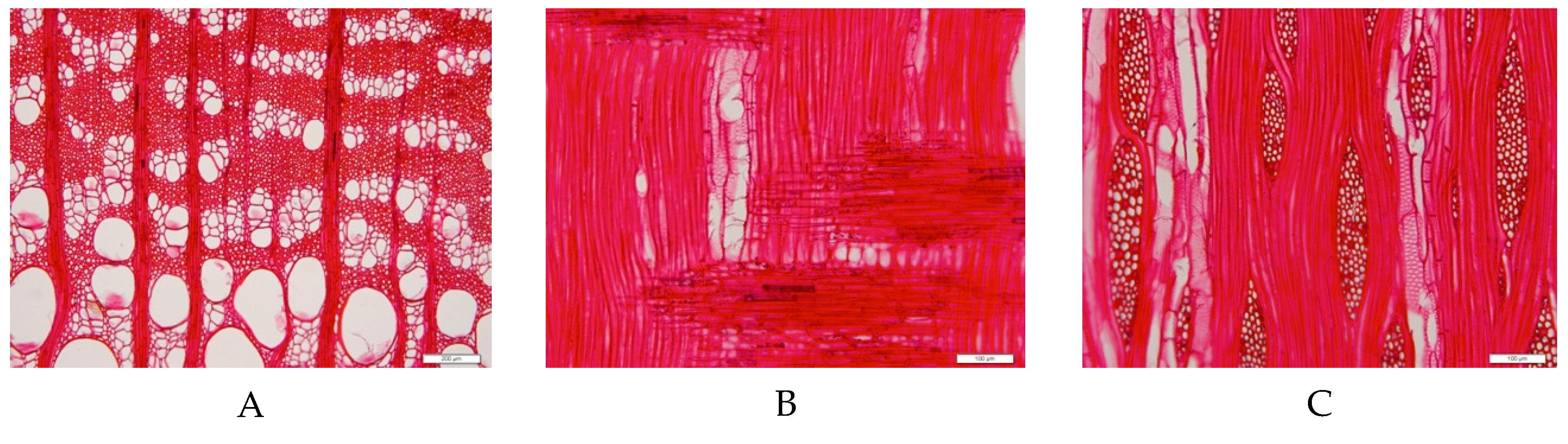

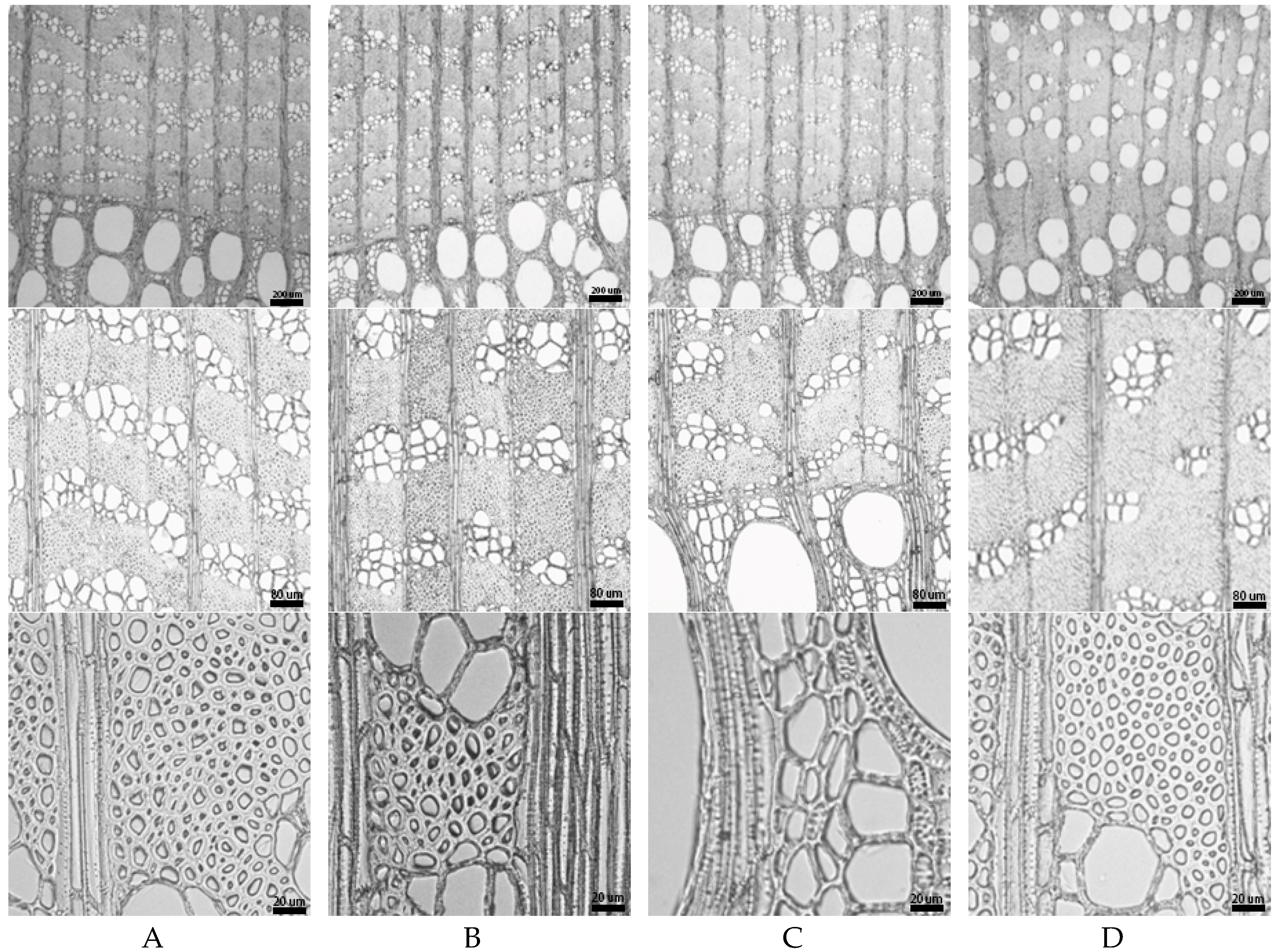

2.2.2. Wood Identification and Transversal Microscopical Structure Analysis

2.2.3. Compositional Analysis

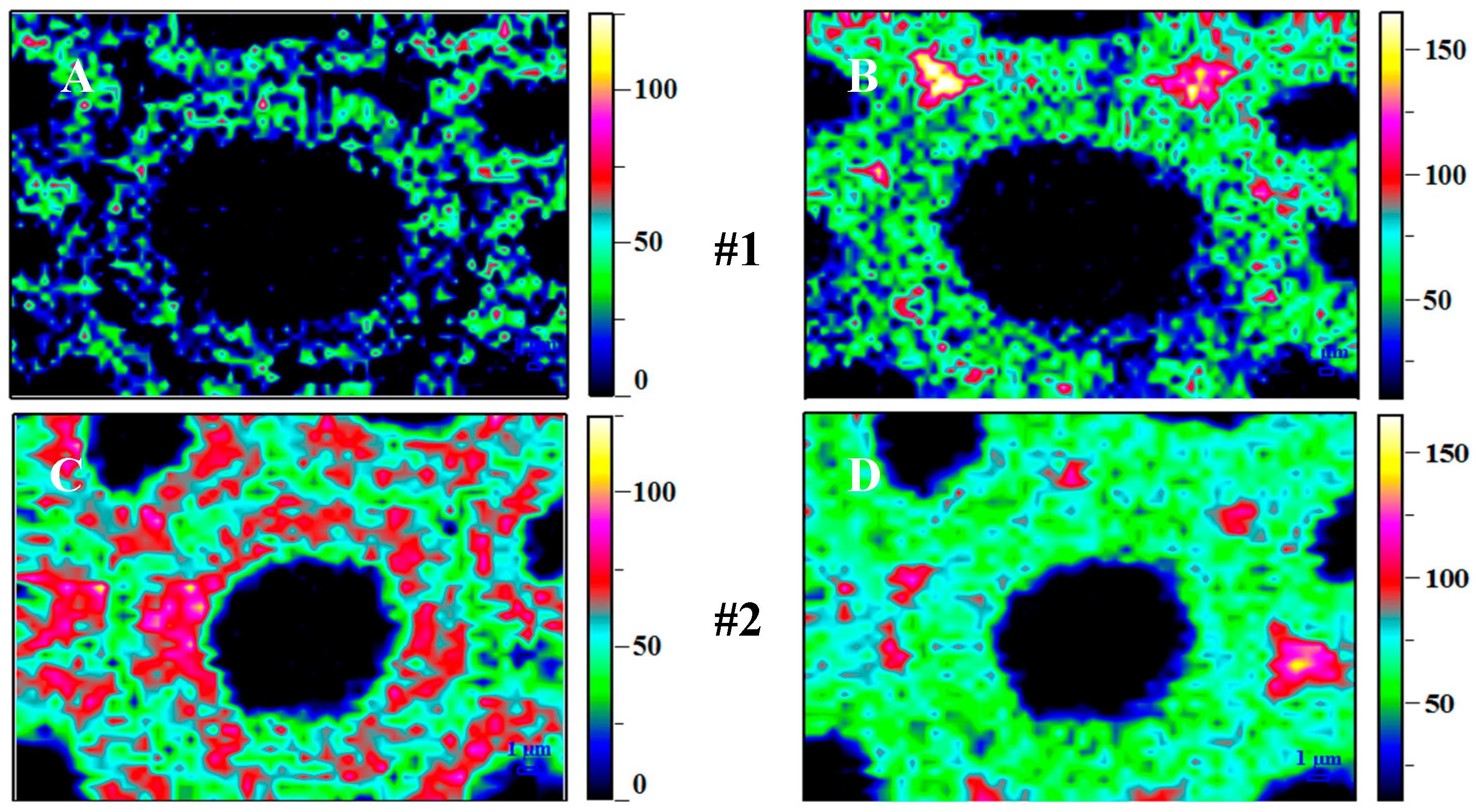

2.2.4. Topochemical Distribution by Confocal Raman Microscopy

2.2.5. Scanning Electron Microscopy (SEM)

2.2.6. Nanoindentation (NI)

3. Results and Discussion

3.1. Wood Identification

3.2. The Effect of Aging on Micro-/Ultra-Scope Structure Properties

3.3. The Effect of Aging on Chemical Composition and Distribution

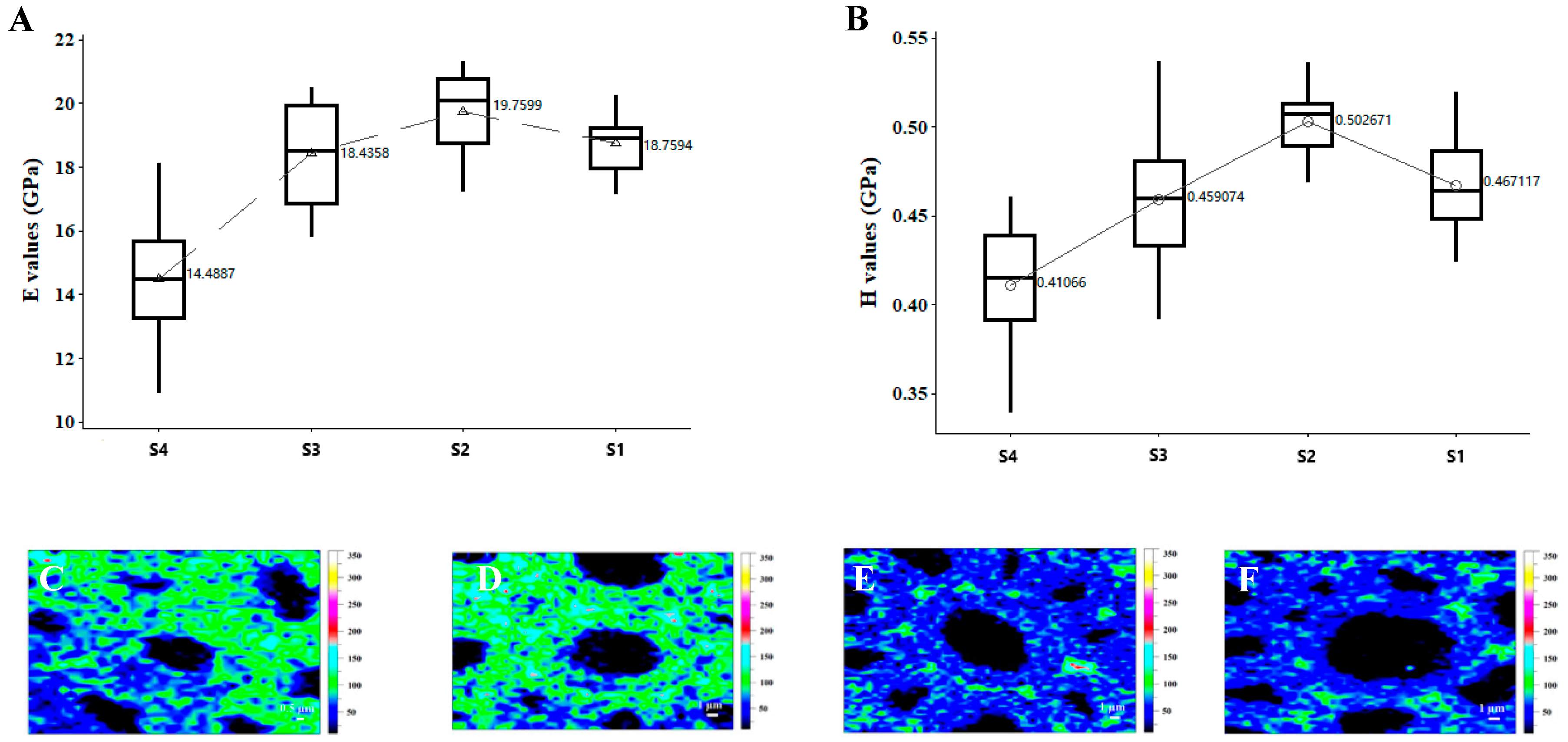

3.4. The Effect of Aging on Micromechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Borgin, K. Inherent durability of wood. Rec. Annu. Br. Wood Preserv. Assoc. 1973, 1973, 105–126. [Google Scholar]

- Borgin, K.; Corbertt, K. The hydrophobic properties of bark extractives. Wood Sci. Technol. 1971, 5, 190–199. [Google Scholar] [CrossRef]

- Unger, A.; Schniewind, A.P.; Unger, W. Conservation of Wood Artifacts: A Handbook; Springer: Berlin, Germany, 2001. [Google Scholar]

- Guo, J.; Zhou, H.; Stevanic, J.S.; Dong, M.; Yu, M.; Salmén, L.; Yin, Y. Effects of ageing on the cell wall and its hygroscopicity of wood in ancient timber construction. Wood Sci. Technol. 2018, 52, 131–147. [Google Scholar] [CrossRef]

- Salmén, L.; Stevanic, J.S.; Olsson, A.-M. Contribution of lignin to the strength properties in wood fibres studied by dynamic FTIR spectroscopy and dynamic mechanical analysis (DMA). Holzforschung 2016, 70, 1155–1163. [Google Scholar] [CrossRef]

- Meng, Y. Methods for Characterizing Mechanical Properties of Wood Cell Walls via Nanoindentation. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2010. [Google Scholar]

- Cavalli, A.; Cibecchini, D.; Togni, M.; Sousa, H.S. A review on the mechanical properties of aged wood and salvaged timber. Constr. Build. Mater. 2016, 114, 681–687. [Google Scholar] [CrossRef]

- Borgin, K.; Faix, O.; Schweers, W. The effect of aging on lignins of wood. Wood Sci. Technol. 1975, 9, 207–211. [Google Scholar] [CrossRef]

- Kačík, F.; Šmíra, P.; Kačíková, D.; Reinprecht, L.; Nasswettrová, A. Chemical Changes in Fir Wood from Old Buildings Due to Ageing. Cellul. Chem. Technol. 2014, 48, 79–88. [Google Scholar]

- Wheeler, E.; Baas, P.; Gasson, P. IAWA list of microscopic features for hardwood identification. IAWA J. Int. Assoc. Wood Anat. 1989, 10, 219–332. [Google Scholar]

- Dong, M.; Zhou, H.; Jiang, X.; Lu, Y.; Wang, W.; Yin, Y. Wood used in ancient timber architecture in Shanxi Province, China. IAWA J. 2017, 38, 182–200. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of structural carbohydrates and lignin in biomass. Lab. Anal. Proced. 2004, 1617, 1–16. [Google Scholar]

- Gierlinger, N.; Keplinger, T.; Harrington, M. Imaging of plant cell walls by confocal Raman microscopy. Nat. Protoc. 2012, 7, 1694–1708. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Ma, J.; Ji, Z.; Zhang, X.; Ramaswamy, S.; Xu, F.; Sun, R. Dilute acid pretreatment differentially affects the compositional and architectural features of Pinus bungeana Zucc. compression and opposite wood tracheid walls. Ind. Crops Prod. 2014, 62, 196–203. [Google Scholar] [CrossRef]

- Li, H.-Y.; Sun, S.-N.; Wang, C.-Z.; Sun, R.-C. Structural and dynamic changes of lignin in Eucalyptus cell walls during successive alkaline ethanol treatments. Ind. Crops Prod. 2015, 74, 200–208. [Google Scholar] [CrossRef]

- Tze, W.T.Y.; Wang, S.; Rials, T.G.; Pharr, G.M.; Kelley, S.S. Nanoindentation of wood cell walls: Continuous stiffness and hardness measurements. Compos. Part A Appl. Sci. Manuf. 2007, 38, 945–953. [Google Scholar] [CrossRef]

- Konnerth, J.; Gierlinger, N.; Keckes, J.; Gindl, W. Actual versus apparent within cell wall variability of nanoindentation results from wood cell walls related to cellulose microfibril angle. J. Mater. Sci. 2009, 44, 4399–4406. [Google Scholar] [CrossRef]

- Yin, Y.; Berglund, L.; Salmén, L. Effect of Steam Treatment on the Properties of Wood Cell Walls. Biomacromolecules 2011, 12, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar]

- Wu, Y.; Wang, S.; Zhou, D.; Xing, C.; Zhang, Y.; Cai, Z. Evaluation of elastic modulus and hardness of crop stalks cell walls by nano-indentation. Bioresour. Technol. 2010, 101, 2867–2871. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, S.; Zhou, D.; Xing, C.; Zhang, Y. Use of nanoindentation and SilviScan to determine the mechanical properties of 10 hardwood species. Wood Fiber Sci. 2009, 41, 64–73. [Google Scholar]

- Wang, X.; Deng, Y.; Wang, S.; Min, C.; Meng, Y.; Pham, T.; Ying, Y. Evaluation of the effects of compression combined with heat treatment by nanoindentation (NI) of poplar cell walls. Holzforschung 2014, 68, 167–173. [Google Scholar] [CrossRef]

- Xing, C.; Wang, S.; Pharr, G.M.; Groom, L.H. Effect of thermo-mechanical refining pressure on the properties of wood fibers as measured by nanoindentation and atomic force microscopy. Holzforschung 2008, 62, 230–236. [Google Scholar]

- Oron, A.; Liphschitz, N.; Held, B.W.; Galili, E.; Klein, M.; Linker, R.; Blanchette, R.A. Characterization of archaeological waterlogged wooden objects exposed on the hyper-saline Dead Sea shore. J. Archaeol. Sci. Rep. 2016, 9, 73–86. [Google Scholar] [CrossRef]

- Sonderegger, W.; Kránitza, K.; Bues, C.-T.; Niemz, P. Aging effects on physical and mechanical properties of spruce, fir and oak wood. J. Cult. Herit. 2015, 16, 883–889. [Google Scholar] [CrossRef]

- Yu, Y.; Fei, B.; Wang, H.; Tian, G. Longitudinal mechanical properties of cell wall of Masson pine (Pinus massoniana Lamb) as related to moisture content: A nanoindentation study. Holzforschung 2011, 65, 121–126. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Du, G.; Wu, Z.; Meng, Y. Variation in physical and mechanical properties of hemp stalk fibers along height of stem. Ind. Crops Prod. 2013, 42, 344–348. [Google Scholar] [CrossRef]

- Jarvis, M.C.; Mccann, M.C. Macromolecular biophysics of the plant cell wall: Concepts and methodology. Plant Physiol. Biochem. 2000, 38, 1–13. [Google Scholar] [CrossRef]

- Gindl, W.; Gupta, H.S.; Grünwald, C. Lignification of spruce tracheid secondary cell walls related to longitudinal hardness and modulus of elasticity using nano-indentation. Can. J. Bot. 2002, 80, 1029–1033. [Google Scholar] [CrossRef]

- Guo, J.; Song, K.; Salmén, L.; Yin, Y. Changes of wood cell walls in response to hygro-mechanical steam treatment. Carbohydr. Polym. 2015, 115, 207–214. [Google Scholar] [CrossRef] [PubMed]

| Num. | Ara | Gal | Glc | Xyl | Man | ASL | AIL |

|---|---|---|---|---|---|---|---|

| 1 | 0.0% | 0.6% | 40.3% | 13.9% | 2.3% | 8.5% | 34.5% |

| 2 | 0.0% | 0.5% | 38.5% | 14.6% | 1.9% | 5.6% | 38.9% |

| 3 | 0.3% | 0.8% | 41.7% | 18.2% | 2.9% | 1.6% | 34.5% |

| 4 | 0.3% | 0.8% | 43.3% | 18.7% | 3.1% | 1.3% | 32.5% |

| 5 | 0.4% | 0.9% | 42.3% | 19.6% | 2.9% | 1.7% | 32.2% |

| 6 | 0.6% | 0.9% | 42.4% | 19.8% | 2.6% | 1.8% | 32.1% |

| 7 | 0.4% | 0.8% | 42.3% | 20.2% | 3.1% | 1.5% | 31.7% |

| 8 | 0.5% | 0.7% | 43.7% | 18.6% | 3.7% | 1.6% | 31.2% |

| 9 | 0.3% | 0.7% | 44.8% | 17.3% | 3.8% | 1.6% | 31.4% |

| 10 | 0.3% | 0.8% | 44.3% | 17.8% | 3.5% | 1.8% | 31.5% |

| 11 | 0.3% | 0.7% | 45.3% | 18.7% | 3.6% | 1.6% | 29.8% |

| 12 | 0.3% | 0.6% | 45.8% | 18.1% | 3.4% | 1.6% | 30.2% |

| 13 | 0.3% | 0.8% | 44.7% | 17.7% | 3.6% | 1.7% | 31.2% |

| 14 | 0.3% | 0.8% | 46.3% | 17.7% | 3.3% | 1.6% | 29.9% |

| 15 | 0.3% | 0.9% | 46.4% | 17.5% | 2.7% | 1.6% | 30.5% |

| 16 | 0.4% | 0.9% | 46.7% | 17.6% | 2.7% | 1.6% | 30.1% |

| 17 | 0.3% | 0.7% | 47.0% | 18.4% | 3.1% | 1.4% | 29.0% |

| 18 | 0.3% | 0.8% | 46.6% | 18.1% | 2.8% | 1.7% | 29.8% |

| 19 | 0.3% | 0.8% | 46.5% | 18.8% | 2.8% | 1.6% | 29.3% |

| 20 | 0.3% | 0.9% | 47.3% | 18.7% | 2.4% | 1.7% | 28.8% |

| 21 | 0.4% | 1.3% | 43.6% | 19.4% | 2.4% | 2.2% | 30.8% |

| 22 | 0.3% | 0.8% | 43.7% | 17.0% | 1.8% | 2.1% | 34.3% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, L.; Wang, K.; Wang, W.; Guo, J.; Zhou, H. Nanomechanical and Topochemical Changes in Elm Wood from Ancient Timber Constructions in Relation to Natural Aging. Materials 2019, 12, 786. https://doi.org/10.3390/ma12050786

Han L, Wang K, Wang W, Guo J, Zhou H. Nanomechanical and Topochemical Changes in Elm Wood from Ancient Timber Constructions in Relation to Natural Aging. Materials. 2019; 12(5):786. https://doi.org/10.3390/ma12050786

Chicago/Turabian StyleHan, Liuyang, Kun Wang, Weibin Wang, Juan Guo, and Haibin Zhou. 2019. "Nanomechanical and Topochemical Changes in Elm Wood from Ancient Timber Constructions in Relation to Natural Aging" Materials 12, no. 5: 786. https://doi.org/10.3390/ma12050786

APA StyleHan, L., Wang, K., Wang, W., Guo, J., & Zhou, H. (2019). Nanomechanical and Topochemical Changes in Elm Wood from Ancient Timber Constructions in Relation to Natural Aging. Materials, 12(5), 786. https://doi.org/10.3390/ma12050786