Tailoring a Silver Paste for Additive Manufacturing of Co-Fired Ferrite Magnetic Components

Abstract

:1. Introduction

2. Materials and Methods

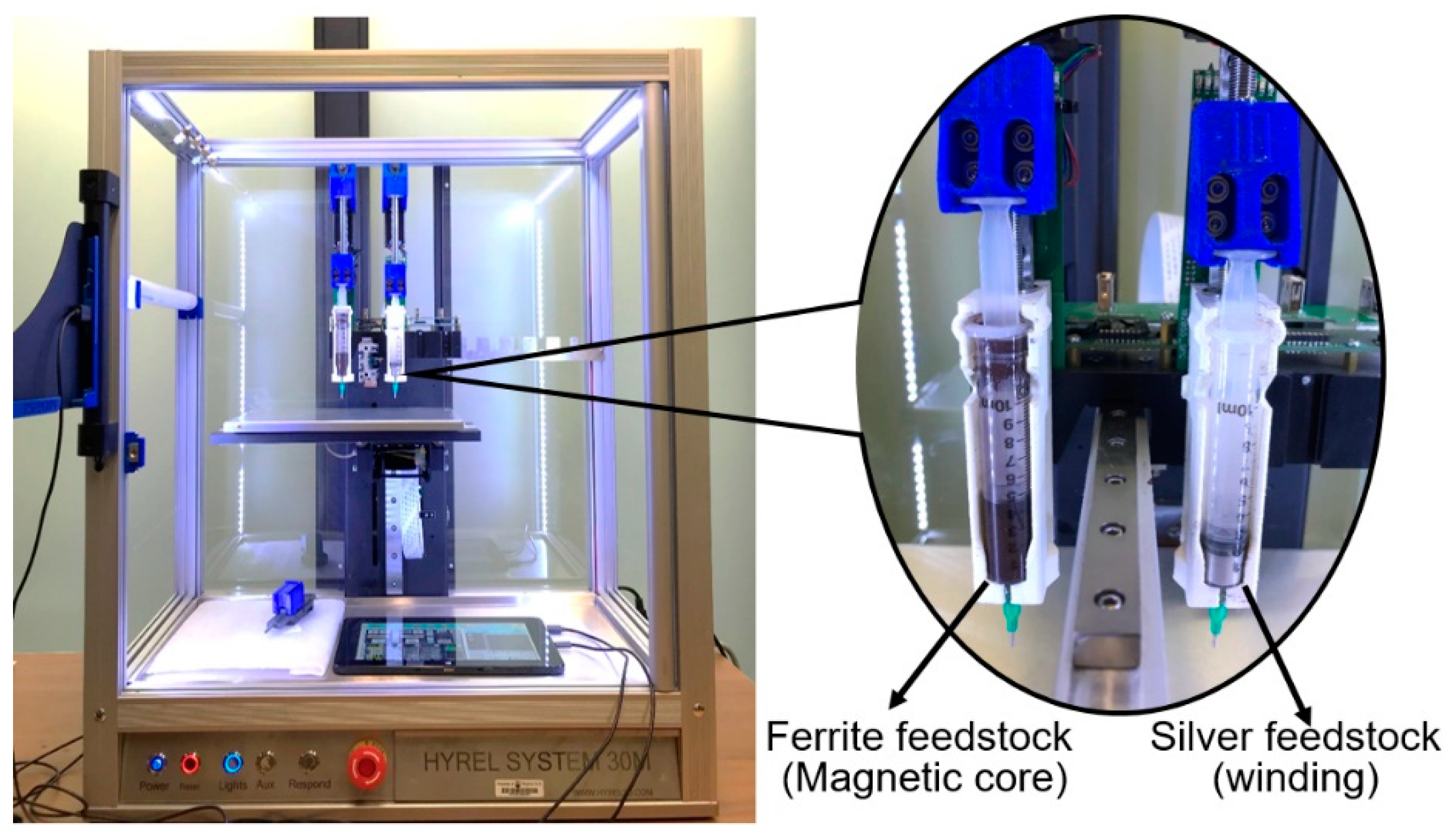

2.1. The 3D-Printing Platform

2.2. Preparation of Ferrite and Silver Feedstock

2.3. Measurements of Densification Shrinkage

2.4. Measurements of the DC Electrical Resistivity of Sintered Silver

2.5. Measurements of Relative Permeability

2.6. Measurements of Ferrite–Silver Bonding Strength

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ge, T.; Yan, Y.; Lu, G.-Q.; Ngo, K. Over-Molded Inductor (OMI)—Feasibility Demonstration in a DC–DC Converter. IEEE Trans. Ind. Electron. 2017, 64, 5738–5740. [Google Scholar] [CrossRef]

- Cui, H.; Ngo, K.D.; Moss, J.; Lim, M.H.F.; Rey, E. Inductor geometry with improved energy density. IEEE Trans. Power Electron. 2014, 29, 5446–5453. [Google Scholar] [CrossRef]

- Djuric, S.; Stojanovic, G.; Damnjanovic, M.; Radovanovic, M.; Laboure, E. Design, modeling, and analysis of a compact planar transformer. IEEE Trans. Magn. 2012, 48, 4135–4138. [Google Scholar] [CrossRef]

- Xu, D.; Ngo, K. Optimal constant-flux-inductor design for a 5 kW boost converter. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 2436–2443. [Google Scholar]

- Li, Q.; Dong, Y.; Lee, F.C.; Gilham, D.J. High-density low-profile coupled inductor design for integrated point-of-load converters. IEEE Trans. Power Electron. 2013, 28, 547–554. [Google Scholar] [CrossRef]

- Dong, Y.; Zhou, J.; Lee, F.C.; Xu, M.; Wang, S. Twisted core coupled inductors for microprocessor voltage regulators. IEEE Trans. Power Electron. 2008, 23, 2536–2545. [Google Scholar] [CrossRef]

- Yang, R.S.; Hanson, A.J.; Perreault, D.J.; Sullivan, C.R. A low-loss inductor structure and design guidelines for high-frequency applications. In Proceedings of the Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; pp. 579–586. [Google Scholar]

- Qiu, J.; Hanson, A.J.; Sullivan, C.R. Design of toroidal inductors with multiple parallel foil windings. In Proceedings of the 2013 IEEE 14th Workshop on Control and Modeling for Power Electronics (COMPEL), Salt Lake City, UT, USA, 23–26 June 2013; pp. 1–6. [Google Scholar]

- Khatri, B.; Lappe, K.; Noetzel, D.; Pursche, K.; Hanemann, T. A 3D-printable polymer-metal soft-magnetic functional composite—Development and characterization. Materials 2018, 11, 189. [Google Scholar] [CrossRef] [PubMed]

- Jhong, K.J.; Huang, W.-C.; Lee, W.H. Microstructure and Magnetic Properties of Magnetic Material Fabricated by Selective Laser Melting. Phys. Procedia 2016, 83, 818–824. [Google Scholar] [CrossRef] [Green Version]

- Clay, G. Printing 3D Magnetic Composite Structures with Arbitrary Anisotropy Using UV-Curable Magnetic Ink. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2016. [Google Scholar]

- Jakus, A.E.; Taylor, S.L.; Geisendorfer, N.R.; Dunand, D.C.; Shah, R.N. Metallic architectures from 3D-printed powder-based liquid inks. Adv. Funct. Mater. 2015, 25, 6985–6995. [Google Scholar] [CrossRef]

- Wang, Y.; Castles, F.; Grant, P.S. 3D printing of NiZn ferrite/ABS magnetic composites for electromagnetic devices. MRS Online Proc. Libr. Arch. 2015, 1788, 29–35. [Google Scholar] [CrossRef]

- Chinthavali, M. Additive manufacturing technology for power electronics applications. In Proceedings of the Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016. [Google Scholar]

- Kobayashi, K.; Ikuta, K. Three-dimensional magnetic microstructures fabricated by microstereolithography. Appl. Phys. Lett. 2008, 92, 262505. [Google Scholar] [CrossRef]

- Yasui, M.; Ikeuchi, M.; Ikuta, K. 3D remote controllable nano actuation system for cell handling and micro surgery. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; pp. 1117–1120. [Google Scholar]

- Yan, Y. Design Methodology and Materials for Additive Manufacturing of Magnetic Components. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2017. [Google Scholar]

- Kang, B.J.; Lee, C.K.; Oh, J.H. All-inkjet-printed electrical components and circuit fabrication on a plastic substrate. Microelectron. Eng. 2012, 97, 251–254. [Google Scholar] [CrossRef]

- Kazimierczuk, M.K. High-Frequency Magnetic Components; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Goldman, A. Magnetic Components for Power Electronics; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Lu, G.Q.; Sutterlin, R.C.; Gupta, T.K. Effect of mismatched sintering kinetics on camber in a low-temperature cofired ceramic package. J. Am. Ceram. Soc. 1993, 76, 1907–1914. [Google Scholar] [CrossRef]

- Choi, M.S.; Kim, S.H.; Kim, Y.H.; Kim, I.W.; Jeong, S.J.; Song, J.S.; Lee, J.S. Application of Ag–ceramic composite electrodes to low firing piezoelectric multilayer ceramic actuators. J. Electroceram. 2008, 20, 225–229. [Google Scholar] [CrossRef]

- Zuo, R.; Li, L.; Gui, Z.; Hu, X.; Ji, C. Effects of Additives on the Interfacial Microstructure of Cofired Electrode-Ceramic Multilayer Systems. J. Am. Ceram. Soc. 2002, 85, 787–793. [Google Scholar] [CrossRef]

- Zuo, R.; Li, L.; Gui, Z. Effects of BaTiO3 additive on densification mechanism of silver–palladium paste. Mater. Chem. Phys. 2002, 74, 182–186. [Google Scholar] [CrossRef]

- Chou, C.H.; Chen, S.Y.; Cheng, S.Y. Role of Metall-Organic Precursor-doped Silver Paste in Low Temperature Co-Fired Ceramics. Jpn. J. Appl. Phys. 2000, 39, 544. [Google Scholar] [CrossRef] [Green Version]

- Sutterlin, R.C.; Lu, G.Q.; Gupta, T.K. Cosintering of gold/LTCC [low-temp. cofirable glass-ceramic] substrates: Development of camber and via defects. Ceram. Trans. 1993, 33, 435. [Google Scholar]

- Liu, L.; Ge, T.; Ngo, K.D.; Mei, Y.; Lu, G.-Q. Ferrite Paste Cured with Ultraviolet Light for Additive Manufacturing of Magnetic Components for Power Electronics. IEEE Magn. Lett. 2018, 9, 1–5. [Google Scholar] [CrossRef]

- Liu, L.; Ding, C.; Lu, S.; Ge, T.; Yan, Y.; Mei, Y.; Ngo, K.D.; Lu, G.Q. Design and additive manufacturing of multi-permeability magnetic cores. IEEE Trans. Ind. Appl. 2018, 54, 3541–3547. [Google Scholar] [CrossRef]

- Available online: https://imagej.net/Welcome (accessed on 9 March 2019).

- Yan, Y.; Ngo, K.D.; Mei, Y.; Lu, G.-Q. Additive manufacturing of magnetic components for power electronics integration. In Proceedings of the 2016 International Conference on Electronics Packaging (ICEP), Sapporo, Japan, 20–22 April 2016; pp. 368–371. [Google Scholar]

- Oshiro, O.; Tsujimoto, H.; Shirae, K. A novel miniature planar inductor. IEEE Trans. Magn. 1987, 23, 3759–3761. [Google Scholar] [CrossRef]

- Ouyang, Z.; Acanski, M.; Popovic, J.; Ferreira, J.; Thomsen, O.C.; Andersen, M.A. Design considerations of very low profile coupled inductors for flexible photovoltaic module. In Proceedings of the 2012 7th International Conference on Integrated Power Electronics Systems (CIPS), Nuremberg, Germany, 6–8 March 2012; pp. 1–8. [Google Scholar]

- Sasada, I.; Yamaguchi, T.; Harada, K.; Notohara, Y. Planar inductors using NiZn ferrite thin plates and the application to high-frequency DC-DC converters. IEEE Trans. Magn. 1993, 29, 3231–3233. [Google Scholar] [CrossRef]

- Sato, T.; Hasegawa, M.; Mizoguchi, T.; Sahashi, M. Study of high power planar inductor. IEEE Trans. Magn. 1991, 27, 5277–5279. [Google Scholar] [CrossRef]

- Secor, E.B.; Ahn, B.Y.; Gao, T.Z.; Lewis, J.A.; Hersam, M.C. Rapid and versatile photonic annealing of graphene inks for flexible printed electronics. Adv. Mater. 2015, 27, 6683–6688. [Google Scholar] [CrossRef] [PubMed]

- Roberson, D.A.; Wicker, R.B.; Murr, L.E.; Church, K.; MacDonald, E. Microstructural and process characterization of conductive traces printed from Ag particulate inks. Materials 2011, 4, 963–979. [Google Scholar] [CrossRef] [PubMed]

- Available online: http://www.gwent.org/home.html (accessed on 9 March 2019).

- Available online: https://www.voxel8.com (accessed on 9 March 2019).

- Available online: https://www.nano-di.com/materials#metal (accessed on 9 March 2019).

- Mitschke, F. Skin Effect. In Fiber Optics; Springer: Berlin, Germany, 2016; pp. 317–318. [Google Scholar]

- Wojda, R.P.; Kazimierczuk, M.K. Analytical optimization of solid–round-wire windings. IEEE Trans. Ind. Electron. 2013, 60, 1033–1041. [Google Scholar] [CrossRef]

| Types of Ag | Average Electrical Resistivity of Three Samples (Ω·m) | Standard Deviation |

|---|---|---|

| Bulk Ag (reference) | 1.59 × 10−8 | \ |

| As-received Ag after sintering | 1.96 × 10−8 | 0.056 |

| Sintered Ag feedstock with 5 wt % ferrite | 2.87 × 10−8 | 0.026 |

| Sintered Ag feedstock with 10 wt % ferrite | 3.07 × 10−8 | 0.097 |

| Types of Ag | Average Relative Permeability of Three Samples | Standard Deviation |

|---|---|---|

| As-received Ag after sintering | 1 | 0.1 |

| Sintered Ag feedstock with 5 wt % ferrite | 0.96 | 0.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Ding, C.; Mei, Y.; Lu, G. Tailoring a Silver Paste for Additive Manufacturing of Co-Fired Ferrite Magnetic Components. Materials 2019, 12, 817. https://doi.org/10.3390/ma12050817

Liu L, Ding C, Mei Y, Lu G. Tailoring a Silver Paste for Additive Manufacturing of Co-Fired Ferrite Magnetic Components. Materials. 2019; 12(5):817. https://doi.org/10.3390/ma12050817

Chicago/Turabian StyleLiu, Lanbing, Chao Ding, Yunhui Mei, and Guoquan Lu. 2019. "Tailoring a Silver Paste for Additive Manufacturing of Co-Fired Ferrite Magnetic Components" Materials 12, no. 5: 817. https://doi.org/10.3390/ma12050817

APA StyleLiu, L., Ding, C., Mei, Y., & Lu, G. (2019). Tailoring a Silver Paste for Additive Manufacturing of Co-Fired Ferrite Magnetic Components. Materials, 12(5), 817. https://doi.org/10.3390/ma12050817