Multifunctional Performance of a Nano-Modified Fiber Reinforced Composite Aeronautical Panel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Preparation of the Unfilled Epoxy Matrix (Epoxy)

2.1.2. Preparation of the Epoxy Nanofilled Matrices

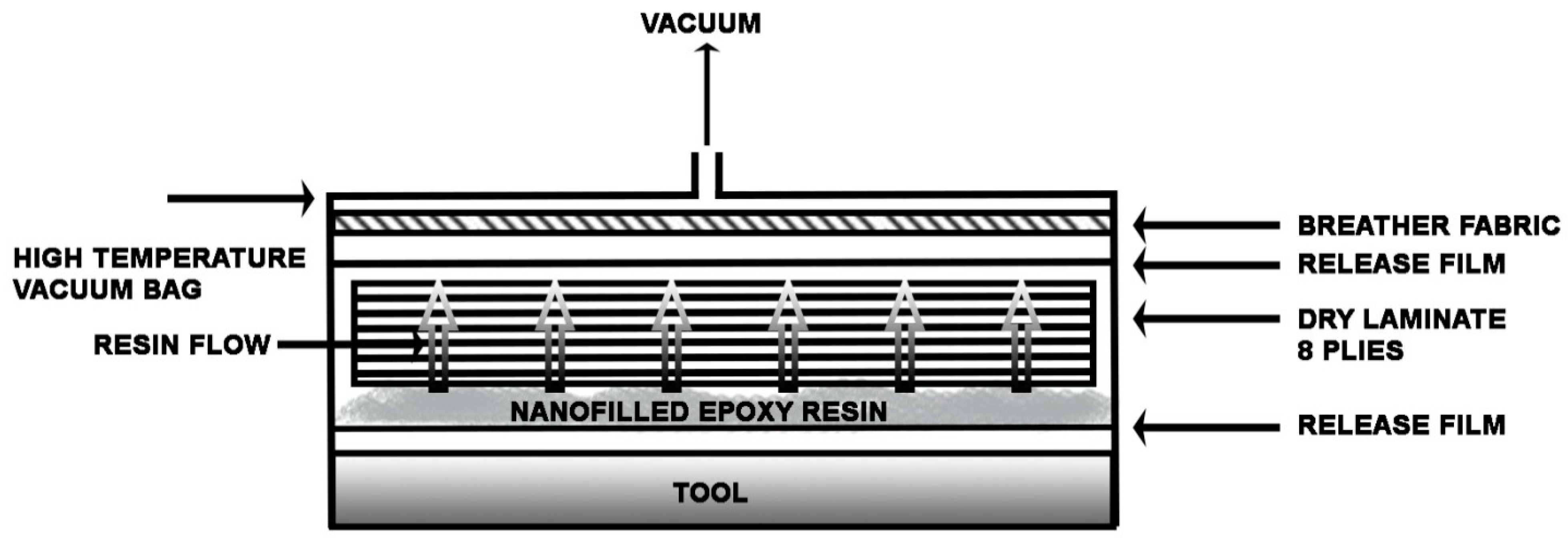

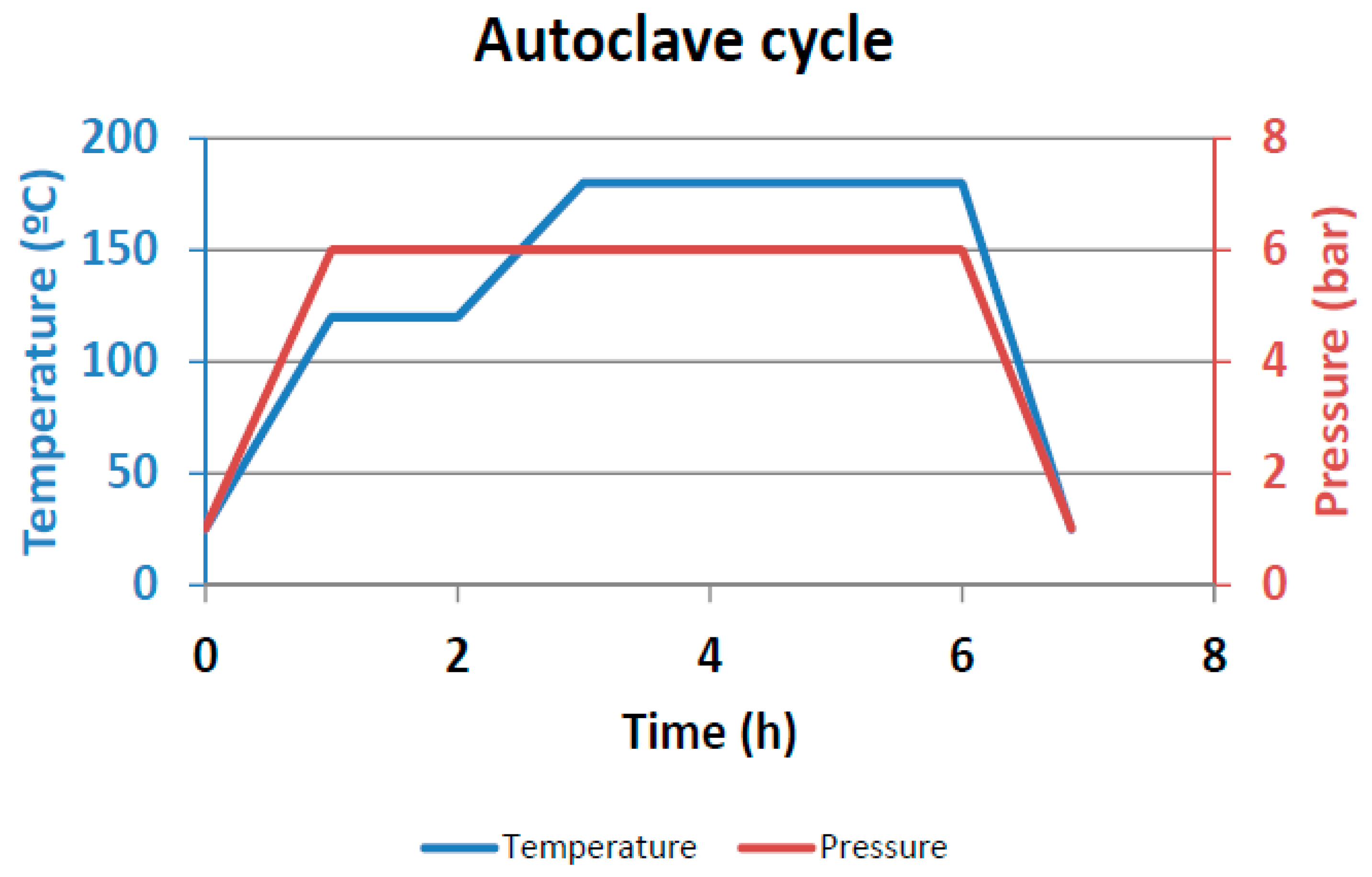

2.1.3. Manufacturing of the Carbon Fiber Reinforced Panel (CFRP)

2.2. Methods

2.2.1. Static Mechanical Test of Cured Epoxy Matrix

2.2.2. Dynamic Mechanical Tests

2.2.3. LOI Tests

2.2.4. Thermogravimetric Analysis (TGA)

2.2.5. Temperature Programmed Oxidation (TPO)

2.2.6. Vibro-Acoustic Characterization of the Carbon Fiber Reinforced Composite

3. Results and Discussion

3.1. Characterization of the Epoxy Matrix

3.1.1. Dynamic Mechanical Tests

3.1.2. Tensile Tests

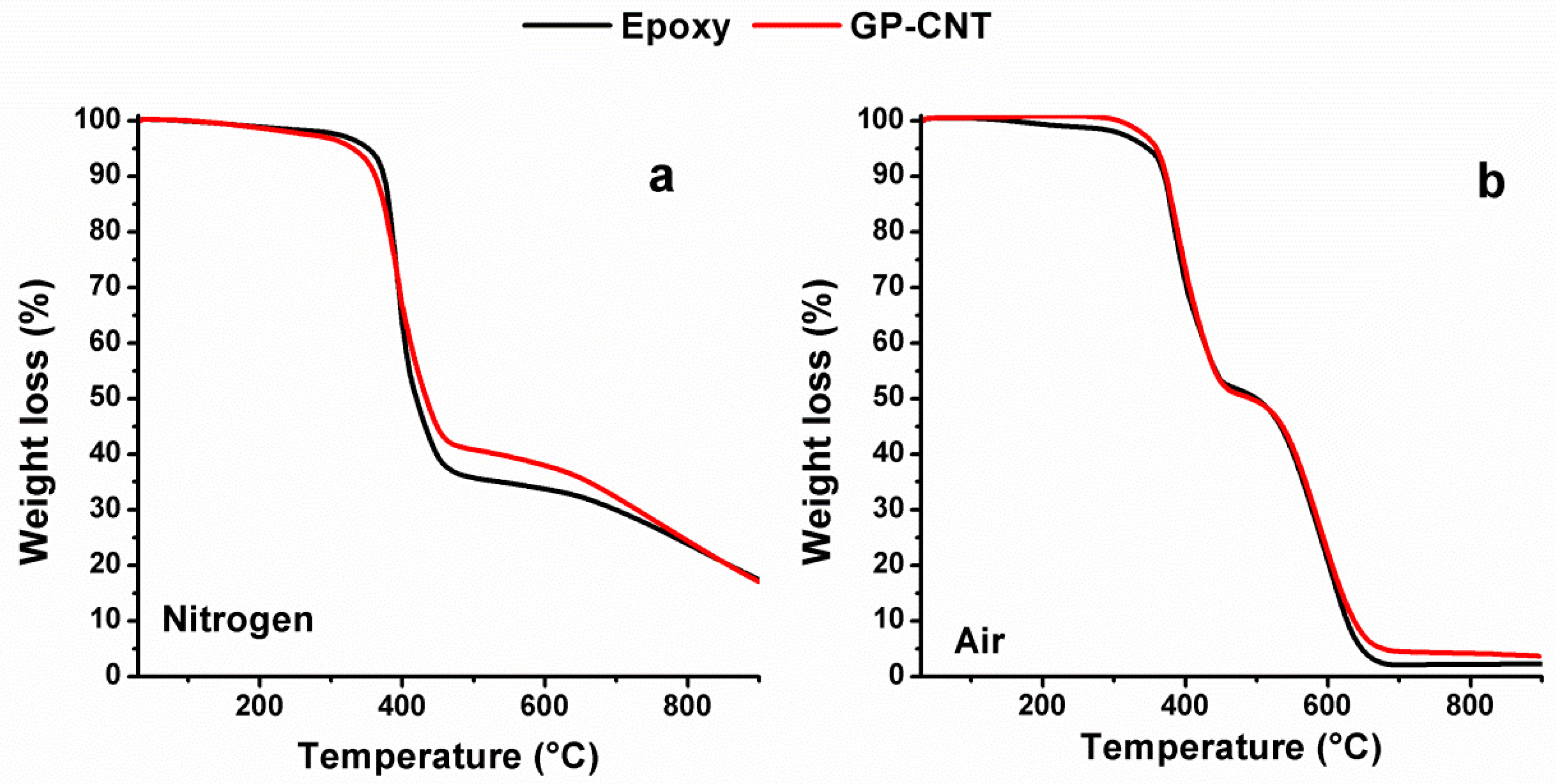

3.1.3. LOI Test, Thermogravimetric Analysis (TGA), Temperature Programmed Oxidation (TPO)

3.2. Characterization of the CFRP Panel

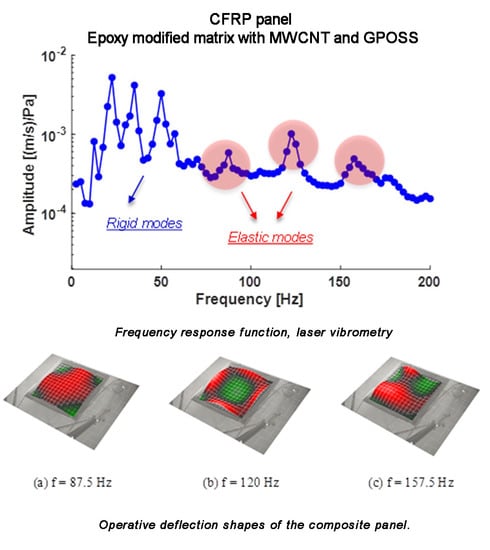

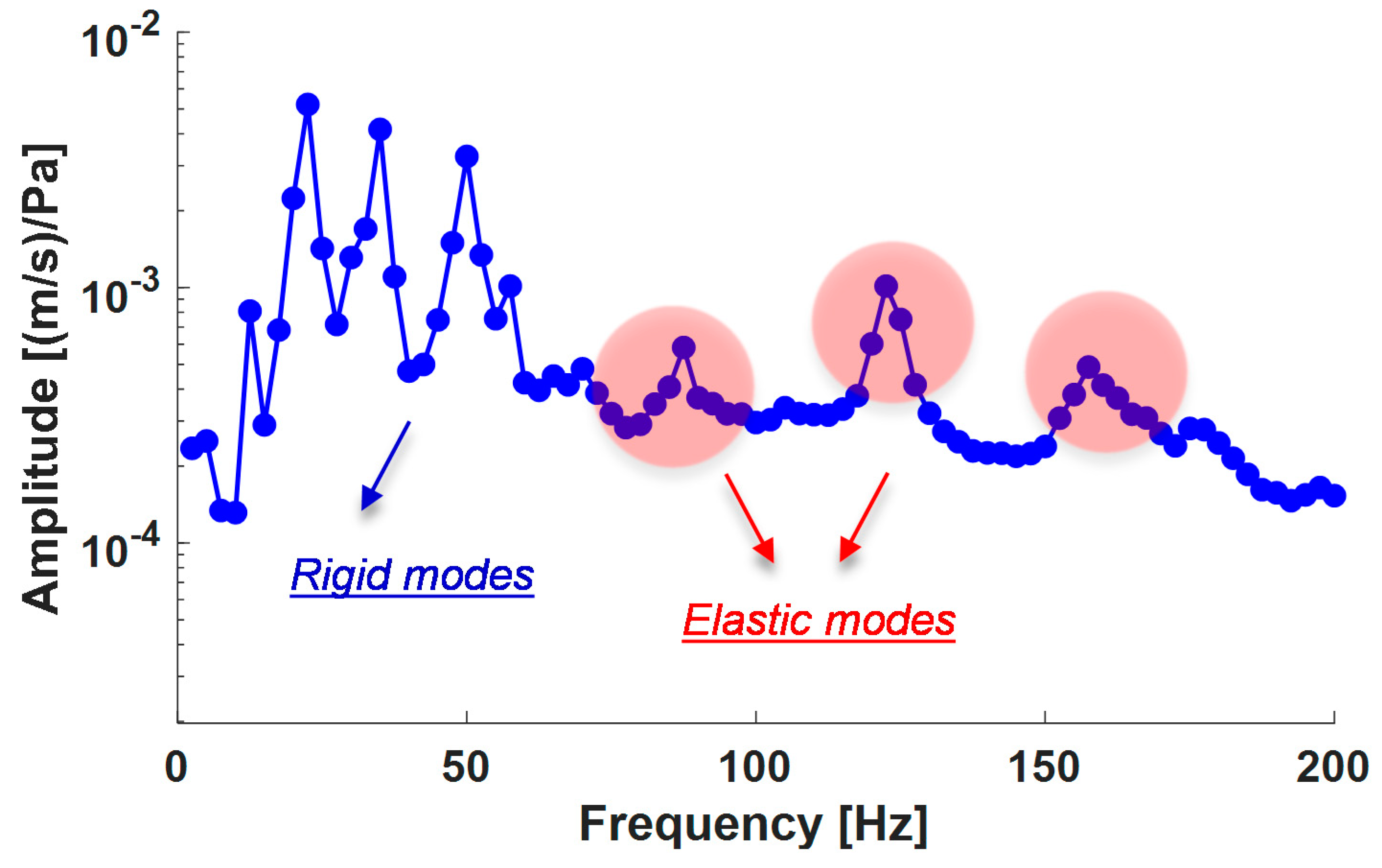

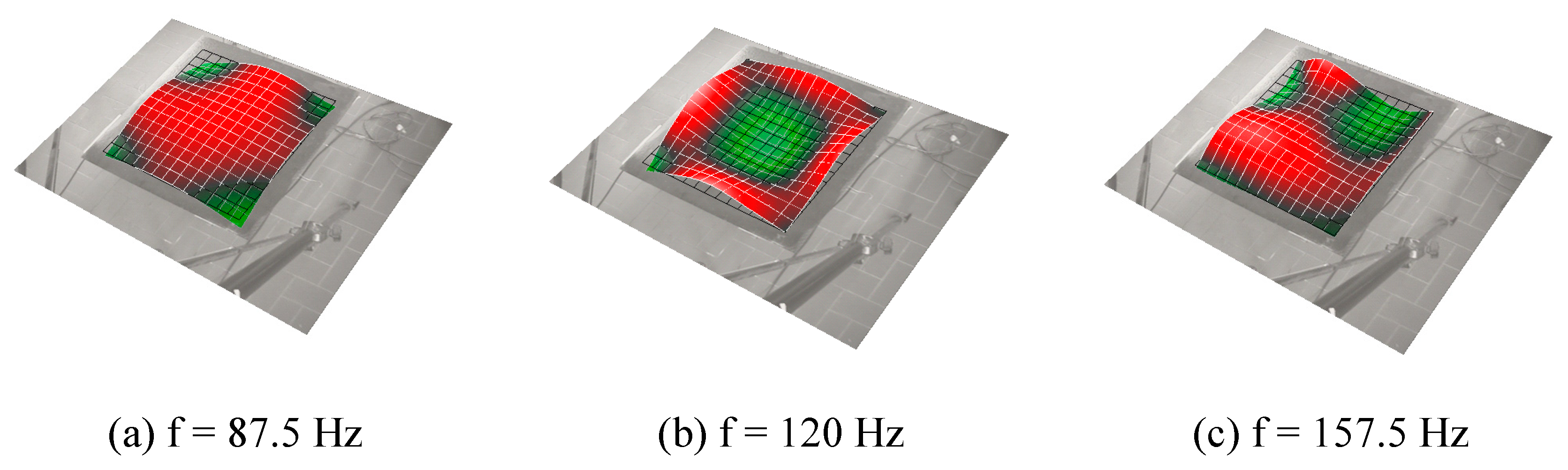

3.2.1. Dynamic Characterization of the Manufactured Panel

3.2.2. Sound Insulation Characterization

- Lp is the average sound pressure level inside the reverberating box

- LIn is the average sound intensity level

- Sm is the measuring grid total area

- S is the partition total area

4. Conclusions

- The introduction of the CNT and GPOSS fillers in the epoxy precursor synergically determines the formation of a fraction of the resin with a lower Tg, which represent a phase with greater mobility of chain segments, most probably closely linked to the filler. Moreover, it allows us to obtain, on the one hand, an effective load transfer distributed on the units inside the epoxy matrix, as evidenced by the increase of Young’s modulus and the maximum load at break, and on the other, an increase in the strain of breakpoint that could be ascribed to an increase in the flexible chains in the matrix tracts due to the presence of linear side groups in the GPOSS cage.

- The obtained LOI for Epoxy and GP-CNT are 27% and 30%, respectively, indicating that the simultaneous addition of GPOSS and CNT leads to a material with better flame properties.

- Although the thermal degradation of the GP-CNT system started at slightly lower temperatures with respect to the blank epoxy sample, the first stage process proceeded with a reduced rate and ended up with a considerably reduced weight loss of 55% compared with the weight loss of 65% for the blank Epoxy sample. Thermogravimetric analysis in air, showed that for both the samples with and without nanofillers, two main weight loss stages were clearly visible, centered respectively at about 420 °C and 550 °C. For both the samples, the first stage process ended up at 450 °C with a weight loss of about 50%. The second stage continued for both the samples up to about 700 °C with a final weight loss of about 99% for the unfilled epoxy sample and of 95% for GP-CNT sample.

- Results from the TPO experiment indicated that the presence of the nanofillers in GP-CNT anticipates all the oxidative processes. This effect has been ascribed to an increase in the thermal conductivity due to the presence of CNTs.

Author Contributions

Funding

Conflicts of Interest

References

- Flatau, A.; Chong, K. Dynamic smart material and structural systems. Eng. Struct. 2002, 24, 261–270. [Google Scholar] [CrossRef]

- Liu, F.; Zhou, X.; Pan, C.; Wang, L. A facile method to intimately contacted nanocomposites as thermoelectric materials: Noncovalent heterojunctions. J. Power Sources 2019, 412, 153–159. [Google Scholar] [CrossRef]

- Kang, I.; Heung, Y.Y.; Kim, J.H.; Lee, J.W.; Gollapudi, R.; Subramaniam, S.; Narasimhadevara, S.; Hurd, D.; Kirikera, G.R.; Shanov, V. Introduction to carbon nanotube and nanofiber smart materials. Compos. Part B Eng. 2006, 37, 382–394. [Google Scholar] [CrossRef]

- Zhu, W.; Bartos, P.J.; Porro, A. Application of nanotechnology in construction. Mater. Struct. 2004, 37, 649–658. [Google Scholar] [CrossRef]

- Chong, K.P. Nanoscience and engineering in mechanics and materials. J. Phys. Chem. Solids 2004, 65, 1501–1506. [Google Scholar] [CrossRef]

- Piscitelli, F.; Buonocore, G.G.; Lavorgna, M.; Verdolotti, L.; Pricl, S.; Gentile, G.; Mascia, L. Peculiarities in the structure—Properties relationship of epoxy-silica hybrids with highly organic siloxane domains. Polymer 2015, 63, 222–229. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Vertuccio, L.; Naddeo, C.; Barra, G.; Longo, P.; Lamberti, P.; Spinelli, G.; Nobile, M.R. Morphological, rheological and electrical properties of composites filled with carbon nanotubes functionalized with 1-pyrenebutyric acid. Compos. Part B Eng. 2018, 147, 12–21. [Google Scholar] [CrossRef]

- Salonitis, K.; Pandremenos, J.; Paralikas, J.; Chryssolouris, G. Multifunctional materials: Engineering applications and processing challenges. Int. J. Adv. Manuf. Technol. 2010, 49, 803–826. [Google Scholar] [CrossRef]

- Salonitis, K.; Pandremenos, J.; Paralikas, J.; Chryssolouris, G. Multifunctional materials used in automotive industry: A critical review. In Engineering against Fracture; Springer: Berlin, Germany, 2009; pp. 59–70. [Google Scholar]

- Momoda, L.A. The future of engineering materials: Multifunction for performance-tailored structures. In Frontiers of Engineering: Reports on Leading-Edge Engineering from the 2004 NAE Symposium on Frontiers of Engineering, 2005; National Academies Press: Washington, DC, USA, 2005; pp. 47–152. [Google Scholar]

- Liu, G.; Han, X.; Lam, K. Material characterization of fgm plates using elastic waves and an inverse procedure. J. Compos. Mater. 2001, 35, 954–971. [Google Scholar] [CrossRef]

- Leslie, A. The Future of Engineering Materials: Multifunction for Performance-Tailored Structures; SPIE: Bellingham, WA, USA, 2000; p. 176. [Google Scholar]

- Koo, J.H. Polymer Nanocomposites; McGraw-Hill Professional Pub.: New York, NY, USA, 2006. [Google Scholar]

- Moniruzzaman, M.; Winey, K.I. Polymer nanocomposites containing carbon nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Ramanathan, T.; Abdala, A.; Stankovich, S.; Dikin, D.; Herrera-Alonso, M.; Piner, R.; Adamson, D.; Schniepp, H.; Chen, X.; Ruoff, R. Functionalized graphene sheets for polymer nanocomposites. Nat. Nanotechnol. 2008, 3, 327–331. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/polymer nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, J.; Chen, X.; Weng, G.J. A monte carlo model with equipotential approximation and tunneling resistance for the electrical conductivity of carbon nanotube polymer composites. Carbon 2019, 146, 125–138. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Artigas, J.; Jiménez-Suárez, A.; Sánchez, M.; Güemes, A.; Ureña, A. Critical parameters of carbon nanotube reinforced composites for structural health monitoring applications: Empirical results versus theoretical predictions. Compos. Sci. Technol. 2019, 171, 44–53. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S.; Shah, S.P. Relationship between the carbon nanotube dispersion state, electrochemical impedance and capacitance and mechanical properties of percolative nanoreinforced opc mortars. Carbon 2019, 145, 218–228. [Google Scholar] [CrossRef]

- Herrera-Ramirez, J.M.; Perez-Bustamante, R.; Aguilar-Elguezabal, A. An overview of the synthesis, characterization, and applications of carbon nanotubes. In Carbon-Based Nanofillers and Their Rubber Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 47–75. [Google Scholar]

- Mamunya, Y.; Matzui, L.; Vovchenko, L.; Maruzhenko, O.; Oliynyk, V.; Pusz, S.; Kumanek, B.; Szeluga, U. Influence of conductive nano-and microfiller distribution on electrical conductivity and emi shielding properties of polymer/carbon composites. Compos. Sci. Technol. 2019, 170, 51–59. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Heijmans, T.; Van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3d printing of cnt-and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Zhang, W.; Xiong, H.; Wang, S.; Li, M.; Gu, Y. Electromagnetic characteristics of carbon nanotube film materials. Chin. J. Aeronaut. 2015, 28, 1245–1254. [Google Scholar] [CrossRef]

- Barra, G.; De Nicola, F.; De Vivo, B.; Egiziano, L.; Guadagno, L.; Lamberti, P.; Raimondo, M.; Spinelli, G.; Tucci, V.; Vertuccio, L.; et al. Enhanced electrical properties of carbon fiber reinforced composites obtained by an effective infusion process. In Proceedings of the 2014 IEEE 9th Nanotechnology Materials and Devices Conference (NMDC 2014), Aci Castello, Italy, 12–15 October 2014; pp. 88–91. [Google Scholar]

- Guadagno, L.; Naddeo, C.; Raimondo, M.; Barra, G.; Vertuccio, L.; Russo, S.; Lafdi, K.; Tucci, V.; Spinelli, G.; Lamberti, P. Influence of carbon nanoparticles/epoxy matrix interaction on mechanical, electrical and transport properties of structural advanced materials. Nanotechnology 2017, 28, 094001. [Google Scholar] [CrossRef]

- Raimondo, M.; Guadagno, L.; Vertuccio, L.; Naddeo, C.; Barra, G.; Spinelli, G.; Lamberti, P.; Tucci, V.; Lafdi, K. Electrical conductivity of carbon nanofiber reinforced resins: Potentiality of tunneling atomic force microscopy (tuna) technique. Compos. Part B Eng. 2018, 143, 148–160. [Google Scholar] [CrossRef]

- Lavorgna, M.; Romeo, V.; Martone, A.; Zarrelli, M.; Giordano, M.; Buonocore, G.; Qu, M.; Fei, G.; Xia, H. Silanization and silica enrichment of multiwalled carbon nanotubes: Synergistic effects on the thermal-mechanical properties of epoxy nanocomposites. Eur. Polym. J. 2013, 49, 428–438. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, Y.; Liu, X.; Lv, C.; Li, Y.; Wei, D.; Liu, Z. Carbon-nanomaterial-based flexible batteries for wearable electronics. Adv. Mater. 2019, 31, 1800716. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Li, N.; Childs, P. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Tan, X.; Wang, J.; Xu, Y.; Curran, R.; Raghunathan, S.; Gore, D.; Doherty, J. Cost-efficient materials in aerospace: Composite vs. aluminium. In Collaborative Product and Service Life Cycle Management for a Sustainable World; Springer: Berlin, Germany, 2008; pp. 259–266. [Google Scholar]

- Naddeo, C.; Vertuccio, L.; Barra, G.; Guadagno, L. Nano-charged polypropylene application: Realistic perspectives for enhancing durability. Materials 2017, 10, 943. [Google Scholar] [CrossRef] [PubMed]

- Pandey, J.K.; Reddy, K.R.; Kumar, A.P.; Singh, R. An overview on the degradability of polymer nanocomposites. Polym. Degrad. Stab. 2005, 88, 234–250. [Google Scholar] [CrossRef]

- Riccio, A.; Damiano, M.; Zarrelli, M.; Scaramuzzino, F. Three-dimensional modeling of composites fire behavior. J. Reinf. Plast. Compos. 2014, 33, 619–629. [Google Scholar] [CrossRef]

- Ricciardi, M.R.; Antonucci, V.; Giordano, M.; Zarrelli, M. Thermal decomposition and fire behavior of glass fiber–reinforced polyester resin composites containing phosphate-based fire-retardant additives. J. Fire Sci. 2012, 30, 318–330. [Google Scholar] [CrossRef]

- Piscitelli, F.; Scamardella, A.M.; Romeo, V.; Lavorgna, M.; Barra, G.; Amendola, E. Epoxy composites based on amino-silylated mmt: The role of interfaces and clay morphology. J. Appl. Polym. Sci. 2012, 124, 616–628. [Google Scholar] [CrossRef]

- Raimondo, M.; Russo, S.; Guadagno, L.; Longo, P.; Chirico, S.; Mariconda, A.; Bonnaud, L.; Murariu, O.; Dubois, P. Effect of incorporation of poss compounds and phosphorous hardeners on thermal and fire resistance of nanofilled aeronautic resins. RSC Adv. 2015, 5, 10974–10986. [Google Scholar] [CrossRef]

- Kadlec, M.; Hron, R.; Guadagno, L. Mechanical properties of a carbon fabric-reinforced epoxy composite with carbon nanotubes and a flame retardant. Int. J. Struct. Integr. 2016, 7, 630–644. [Google Scholar] [CrossRef]

- Polydoropoulou, P.V.; Katsiropoulos, C.V.; Pantelakis, S.G.; Raimondo, M.; Guadagno, L. A critical assessment of multifunctional polymers with regard to their potential use in structural applications. Compos. Part B Eng. 2019, 157, 150–162. [Google Scholar] [CrossRef]

- Martone, A.; Antonucci, V.; Zarrelli, M.; Giordano, M. A simplified approach to model damping behaviour of interleaved carbon fibre laminates. Compos. Part B Eng. 2016, 97, 103–110. [Google Scholar] [CrossRef]

- Martone, A.; Giordano, M.; Antonucci, V.; Zarrelli, M. Enhancing damping features of advanced polymer composites by micromechanical hybridization. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1663–1672. [Google Scholar] [CrossRef]

- Viscardi, M.; Arena, M.; Barra, G.; Guadagno, L. Structural performance analysis of smart carbon fiber samples supported by experimental investigation. Int. J. Mech. 2016, 10, 376–382. [Google Scholar]

- Viscardi, M.; Arena, M.; Barra, G.; Guadagno, L. Smart carbon-epoxy laminate with high dissipation properties for vibro-acoustic optimization in the turboprop aircraft. Int. J. Mech. 2017, 11, 51–57. [Google Scholar]

- Viscardi, M.; Arena, M.; Barra, G.; Vertuccio, L.; Ciminello, M.; Guadagno, L. Piezoresistive strain sensing of carbon nanotubes-based composite skin for aeronautical morphing structures. Proc. SPIE 2018, 10599, 105991C. [Google Scholar]

- Viscardi, M.; Arena, M.; Guadagno, L.; Vertuccio, L.; Barra, G. Multi-functional nanotechnology integration for aeronautical structures performance enhancement. Int. J. Struct. Integr. 2018, 9, 737–752. [Google Scholar] [CrossRef]

- Liu, Q.; Li, M.; Gu, Y.; Wang, S.; Zhang, Y.; Li, Q.; Gao, L.; Zhang, Z. Interlocked cnt networks with high damping and storage modulus. Carbon 2015, 86, 46–53. [Google Scholar] [CrossRef]

- Zhou, X.; Shin, E.; Wang, K.; Bakis, C. Damping characteristics of carbon nanotube based composites. In Proceedings of the ASME 2003 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, IL, USA, 2–6 September 2003; American Society of Mechanical Engineers: New York, NY, USA, 2003; pp. 1925–1935. [Google Scholar]

- Rajoria, H.; Jalili, N. Determination of strength and damping characteristics of carbon nanotube-epoxy composites. In Proceedings of the ASME 2004 International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004; American Society of Mechanical Engineers: New York, NY, USA, 2004; pp. 1461–1466. [Google Scholar]

- Rajoria, H.; Jalili, N. Passive vibration damping enhancement using carbon nanotube-epoxy reinforced composites. Compos. Sci. Technol. 2005, 65, 2079–2093. [Google Scholar] [CrossRef]

- Guadagno, L.; Vietri, U.; Raimondo, M.; Vertuccio, L.; Barra, G.; De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V.; De Nicola, F.; et al. Correlation between electrical conductivity and manufacturing processes of nanofilled carbon fiber reinforced composites. Compos. Part B Eng. 2015, 80, 7–14. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Vietri, U.; Barra, G.; Vertuccio, L.; Volponi, R.; Cosentino, G.; De Nicola, F.; Grilli, A.; Spena, P. Development of multifunctional carbon fiber reinforced composites (cfrcs)—Manufacturing process. AIP Conf. Proc. 2014, 1599, 461–464. [Google Scholar]

- Barra, G.; Vertuccio, L.; Vietri, U.; Naddeo, C.; Hadavinia, H.; Guadagno, L. Toughening of epoxy adhesives by combined interaction of carbon nanotubes and silsesquioxanes. Materials 2017, 10, 1131. [Google Scholar] [CrossRef] [PubMed]

- Guadagno, L.; Naddeo, C.; Raimondo, M.; Barra, G.; Vertuccio, L.; Sorrentino, A.; Binder, W.H.; Kadlec, M. Development of self-healing multifunctional materials. Compos. Part B Eng. 2017, 128, 30–38. [Google Scholar] [CrossRef]

- Kuo, S.-W.; Chang, F.-C. Poss related polymer nanocomposites. Prog. Polym. Sci. 2011, 36, 1649–1696. [Google Scholar] [CrossRef]

- Zhang, Z.; Gu, A.; Liang, G.; Ren, P.; Xie, J.; Wang, X. Thermo-oxygen degradation mechanisms of poss/epoxy nanocomposites. Polym. Degrad. Stab. 2007, 92, 1986–1993. [Google Scholar] [CrossRef]

- Wu, K.; Kandola, B.K.; Kandare, E.; Hu, Y. Flame retardant effect of polyhedral oligomeric silsesquioxane and triglycidyl isocyanurate on glass fibre-reinforced epoxy composites. Polym. Compos. 2011, 32, 378–389. [Google Scholar] [CrossRef]

- Wu, K.; Song, L.; Hu, Y.; Lu, H.; Kandola, B.K.; Kandare, E. Synthesis and characterization of a functional polyhedral oligomeric silsesquioxane and its flame retardancy in epoxy resin. Prog. Org. Coat. 2009, 65, 490–497. [Google Scholar] [CrossRef]

- Tang, Y.; Lewin, M. Migration and surface modification in polypropylene (pp)/polyhedral oligomeric silsequioxane (poss) nanocomposites. Polym. Adv. Technol. 2009, 20, 1–15. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Yang, R. Pyrolysis and fire behaviour of epoxy resin composites based on a phosphorus-containing polyhedral oligomeric silsesquioxane (dopo-poss). Polym. Degrad. Stab. 2011, 96, 1821–1832. [Google Scholar] [CrossRef]

- Romano, V.; Naddeo, C.; Guadagno, L.; Vertuccio, L. Thermal conductivity of epoxy nanocomposites filled with mwcnt and hydrotalcite clay: A preliminary study. AIP Conf. Proc. 2014, 1599, 410–413. [Google Scholar]

- Zargar, O.; Masoumi, A.; Moghaddam, A.O. Investigation and optimization for the dynamical behaviour of the vehicle structure. Int. J. Automot. Mech. Eng. 2017, 14, 4196–4210. [Google Scholar] [CrossRef]

- Bang, S.; Park, Y.; Kim, Y.; Shin, T.; Back, J.; Lee, S.K. Effect of the fiber lamination angle of a carbon-fiber, laminated composite plate roof on the car interior noise. Int. J. Automot. Technol. 2019, 20, 73–85. [Google Scholar] [CrossRef]

- Gur, Y.; Wagner, D. Damping properties and nvh modal analysis results of carbon fiber composite vehicle components. SAE Int. J. Mater. Manuf. 2017, 10, 198–205. [Google Scholar] [CrossRef]

- Koval, L.R. Sound transmission into a laminated composite cylindrical shell. J. Sound Vib. 1980, 71, 523–530. [Google Scholar] [CrossRef]

- Di Giulio, M.; Arena, G.; Paonessa, A. Vibro-acoustic behaviour of composite fuselage structures using embedded viscoelastic damping treatments. In Proceedings of the XX AIDAA Conference, Milan, Italy, 29 June–3 July 2009. [Google Scholar]

- Yuan, C.; Bergsma, O.; Beukers, A. Sound transmission loss prediction of the composite fuselage with different methods. Appl. Compos. Mater. 2012, 19, 865–883. [Google Scholar] [CrossRef]

- Wang, C.; Parrett, A. Damping Mass Effects on Panel Sound Transmission Loss. 0148-7191; SAE Technical Paper. In Proceedings of the SAE 2013 Noise and Vibration Conference and Exhibition, Grand Rapids, MI, USA, 20–23 May 2011. [Google Scholar]

| Sample Name | CNTs (wt%) | GPOSS (wt%) |

|---|---|---|

| Epoxy | - | - |

| GP | - | 5.0 |

| CNT | 0.5 | - |

| GP-CNT | 0.5 | 5.0 |

| Sample | Young’s Modulus (Mpa) | Tensile Strength at Break (Mpa) | Elongation at Break (%) |

|---|---|---|---|

| Epoxy | 2182.2 ± 120.5 | 17.3 ± 3.9 | 1.1 ± 0.1 |

| CNT | 3325.2 ± 80.3 | 22.2 ± 5.2 | 1.2 ± 0.1 |

| GP | 3076.5 ± 96.5 | 35.4 ± 4.8 | 1.6 ± 0.3 |

| GP-CNT | 3282.4 ± 62.7 | 38.1 ± 6.3 | 1.5 ± 0.2 |

| Sample | LOI % ASTM 2863 |

|---|---|

| Epoxy | 27 |

| GP | 33 |

| CNT | 28 |

| GP-CNT | 30 |

| Sample | T Onset (°C) | T Peak (°C) | T Offset (°C) | |||

|---|---|---|---|---|---|---|

| O2 | EPOXY | 360 | 491 | 610 | 852 | |

| GP-CNT | 330 | 460 | 618 | 770 | ||

| H2O | EPOXY | 330 | 439 | 645 | 835 | |

| GP-CNT | 290 | 388 | 610 | 750 | ||

| CH4 | EPOXY | 398 | 455 | 644 | ||

| GP-CNT | 340 | 411 | 536 | 615 | ||

| CO | EPOXY | 500 | 651 | 840 | ||

| GP-CNT | 452 | 653 | 747 | |||

| CO2 | EPOXY | 510 | 659 | 860 | ||

| GP-CNT | 452 | 653 | 754 | |||

| Resonance Frequency [Hz] | Modal Damping [%] |

|---|---|

| 87.5 | 2.53 |

| 120 | 2.81 |

| 157.5 | 3.14 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arena, M.; Viscardi, M.; Barra, G.; Vertuccio, L.; Guadagno, L. Multifunctional Performance of a Nano-Modified Fiber Reinforced Composite Aeronautical Panel. Materials 2019, 12, 869. https://doi.org/10.3390/ma12060869

Arena M, Viscardi M, Barra G, Vertuccio L, Guadagno L. Multifunctional Performance of a Nano-Modified Fiber Reinforced Composite Aeronautical Panel. Materials. 2019; 12(6):869. https://doi.org/10.3390/ma12060869

Chicago/Turabian StyleArena, Maurizio, Massimo Viscardi, Giuseppina Barra, Luigi Vertuccio, and Liberata Guadagno. 2019. "Multifunctional Performance of a Nano-Modified Fiber Reinforced Composite Aeronautical Panel" Materials 12, no. 6: 869. https://doi.org/10.3390/ma12060869

APA StyleArena, M., Viscardi, M., Barra, G., Vertuccio, L., & Guadagno, L. (2019). Multifunctional Performance of a Nano-Modified Fiber Reinforced Composite Aeronautical Panel. Materials, 12(6), 869. https://doi.org/10.3390/ma12060869