1. Introduction

Some conditions such as different environment, climate, heavy traffic, and tire pressure lead to various deteriorations in asphalt pavements. The most common deteriorations in pavements are the permanent deformations at high temperatures, fatigue cracks at intermediate temperatures, and thermal cracks at low temperatures [

1,

2,

3,

4,

5,

6,

7,

8]. Nowadays, asphalt binders are modified with various additives in order to prevent or reduce these deteriorations. Because the performance of an asphalt pavement is significantly affected by the low and high temperature performance of binders. For this reason, many natural and chemical additives have been used in recent years in order to improve some properties of conventional bitumens such as aging stability, thermal sensitivity, elastic behavior, and cracking resistance [

5,

9,

10,

11,

12].

Recently, the use of polymer-based additives has been greatly increased in bitumen modification. In particular, two main polymer types, elastomers, and plastomers have been widely used in studies. The plastomers have generally been used to improve the elastic properties of binders and to increase the permanent deformation resistance of the pavements. However, the elastomers have been used to improve the fatigue and low temperature crack resistance of the binders [

5,

13,

14,

15,

16,

17].

In this study, Reactive Terpolymer (Elvaloy®RET), an elastomeric polymer, has been used as a bitumen additive to determine its effects on the engineering properties of a soft consistency bitumen.

Reactive terpolymers are the polymers containing functional groups which can form chemical bonds with some bitumen components. These polymers form a network around the asphaltenes in the bitumen to form an integral compound and produce a chemical reaction with the bitumen [

17,

18,

19,

20,

21,

22,

23]. However, when these chemical bonds occur, a polymer bitumen gel may be formed which in this case does not have melting and dissolving properties and is completely useless [

18,

19,

22]. Therefore, it is desirable that the amount of terpolymer to be used in its modification has an upper limit to remain below the chemical gel point of the network [

18,

19,

21]. In some studies, this limit is considered to be 2–2.5% by weight, although it is stated that it may be less than 1% [

19,

22]. According to some researchers, much better results can be achieved with a bitumen containing a less reactive terpolymer group. Furthermore, the use of a higher content of terpolymer has been considered an economic disadvantage. It has also been reported in the studies that the use of terpolymers alone as a modifier is not ideal, because it may have a negative impact on the performance properties of binder due to the gelation [

18,

19,

20,

22]. When reactive terpolymers are used in bitumen modification, a certain amount of Polyphosphoric Acid (PPA) is usually added as a catalyst to accelerate the chemical reaction between bitumen and polymer in the mixture [

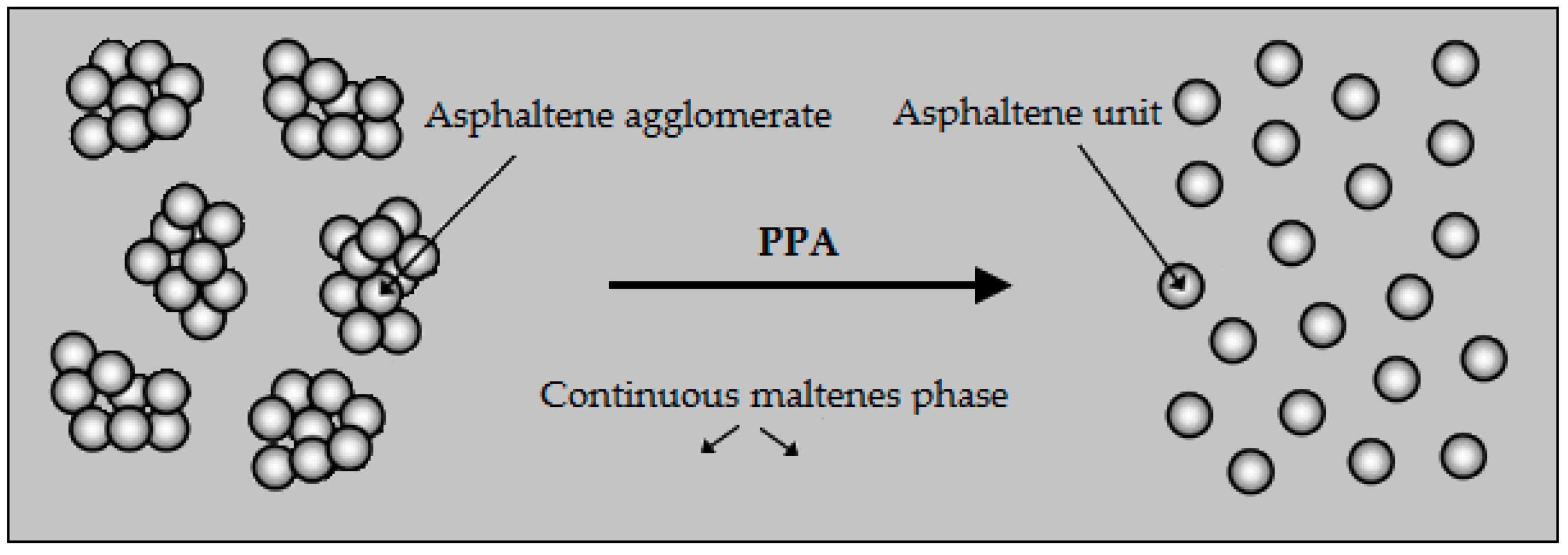

17,

18,

20,

23,

24]. When PPA is used in the bitumen–polymer mixture, the amount of polymer needed for the modification is reduced and the performance characteristics of the modified bitumen, such as permanent deformation, aging and fatigue resistance, increase positively [

17,

18,

19,

20,

21,

24].

In some previous studies, it has been stated that the use of terpolymer in bitumen modification increases the viscosity and softening point of binder and decreases its ductility and penetration [

25,

26,

27,

28,

29,

30,

31,

32]. In one of these studies, bitumens with different physical properties were modified with Elvaloy

®, and as a result, an increase of about 353% was observed in the viscosity of these bitumens [

30]. In a study using 0%, 1.5% and 2.0% Elvaloy

® according to the weight of bitumen, it was observed that the sensitivity of asphalt mixtures to moisture damage decreased significantly with the increase of Elvaloy

®. In the study, it was also determined that Elvaloy

® had a positive effect on the rutting performance of asphalt mixtures [

33]. In addition, the results of another study showed that a binder modified by reactive terpolymer improved the resistance to permanent deformation at high temperatures [

34]. In another study, which was carried out by using Elvaloy in bitumen modification, the optimum ratio of Elvaloy additive was determined as 1.0% in terms of rutting resistance and high and low temperature. In the study, this situation was explained by the polymer-linked binder formed by the chemical reaction between Elvaloy and binder. The study also revealed that the minimum mass loss among modified bitumens occurs in blends containing 1% Elvaloy [

32]. In many studies conducted to determine the mass loss or aging resistance of terpolymer-modified bitumens, it has been found that Elvaloy affects the aging resistance of bitumen very positively [

19,

20,

22,

28,

31]. In studies, this was explained as a result of the chemical reaction between the reactive terpolymer and the carboxylic acid groups present in the bitumen [

18,

20,

22,

32]. The studies showed that the internal structure of the modified bitumen exhibits a homogenous distribution as a result of the reaction between Elvaloy

®RET and binder, and consequently the problem of the decomposition which may occur through transportation and storage has disappeared [

3,

14,

17,

30,

35].

Furthermore, many studies have shown that the addition of Terpolymer in the bitumen causes an increase in the complex module of the modified bitumen, but a decrease in its phase angle. This indicates that Elvaloy

®-modified bitumens provide a general improvement in the rutting resistance of the pavements [

17,

18,

33,

35,

36,

37]. In a study in which rheological properties of bitumens modified with different polymers were investigated at low temperatures, it was found that the cracking resistance of the bitumens containing Elvaloy

®RET was lower than the others [

3]. However, in some studies it has been noted that the use of terpolymer in bitumen modification increases its high temperature performance without significantly damaging the low temperature performance of modified bitumen [

31,

32,

37]. In a study using B 100/150 bitumen and different Elvaloy ratios, the effects of Elvaloy

®RET on the physical and rheological properties of the bitumen were investigated. The results of the study showed that due to the increase in the amount of additive, the hardness of the modified bitumens increased and the temperature sensitivity decreased. Furthermore, although the low temperature performances of the modified bitumens were relatively low, their high temperature performances increased considerably [

38].

When the studies were examined, it was observed that terpolymers were used alone or in combination with PPA in two different ways in bitumen modification. It was also seen that the additive percentages of terpolymer were higher (1–6%) when it was used alone [

26,

27,

28,

29,

31,

32,

34], but were lower (0.4–1.6%) when it was used with PPA [

14,

17,

18,

20,

24,

25,

28,

30,

38]. Moreover, the terpolymers were generally used in a single percentage and in combination with another polymer [

17,

18,

20,

24,

28,

30,

31,

34]. Although there have been studies using different percentages of terpolymer in the modification, PPA has been used in only two of them [

25,

38]. In one of these studies, physical and chemical characterization of modified bitumen were examined [

25], while in the other study its physical and rheological properties were investigated [

38]. As a result, it was seen that the use of Elvaloy

®RET in different percentages and in combination with PPA was very limited, and a limited number of experiments were performed to determine the properties of Elvaloy-modified bitumen.

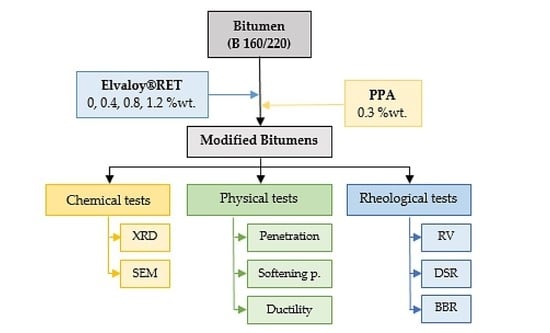

The aim of this study was to understand the effects of Elvaloy® 5160 additive on the physical, chemical, micro-structural, and rheological properties of B 160/220 bitumen with all aspects. In order to determine the characteristics of Elvaloy®-modified bitumens, tests such as X-Ray Diffraction (XRD), Scanning Electron Microscopy (SEM), penetration, softening point, ductility, Rotational Viscosity (RV), Dynamic Shear Rheometer (DSR), and Bending Beam Rheometer (BBR) were performed.

3. Results and Discussion

3.1. X-ray Diffraction

The morphology of Elvaloy®RET-modified bitumens was determined using the XRD characterization techniques. The X-ray diffraction patterns were obtained by a Rigaku Giegerflex D-Max/B powder diffractometer with CuKα radiation. Diffraction patterns (2θ = 2–80°) were recorded at room temperature with a step of 0.02°. The crystallographic structure of Elvaloy®RET, its presence in the bitumen blend, and its level of dispersion were evaluated using the patterns.

The XRD patterns obtained from neat and modified bitumens are given in

Figure 3,

Figure 4 and

Figure 5, respectively, for un-aged (original), RTFOT-aged, and PAV-aged samples.

As seen in

Figure 3, the XRD traces of the neat bitumen sample used in the experiment are consistent with those given in the literature. The structure is generally a macromolecular single amorphous structure. The wide band of 2-theta between 7.5 and 32.5 indicates that the structure is amorphous. However, the height of the peak shows that there are crystal shadows in the structure. At the point where the 2-theta is about 40, there is a relatively small amorphous phase in the structure. In summary, the neat bitumen has a macromolecular structure in two separate amorphous phases. The amorphous phase at the point where 2-theta is about 40 is located within the main macromolecular structure.

When 0.4% Elvaloy®RET is added to bitumen, there is no significant change in the macromolecular structure of the modified bitumen. However, when the amount of terpolymer in the bitumen blend increases, the number of counts decreases. That is, when the bitumen and Elvaloy®RET react chemically, the terpolymer group in the macromolecular structure absorbs X-rays. As a result, although the number of counts was 705 at the point where 2-theta was 20 for pure bitumen, these values were 435 and 300 respectively when 0.8% and 1.2% Elvaloy®RET were added to the bitumen. However, there is no significant change in the amorphous structure area around the point where the 2-theta is 40. This indicates that Elvaloy®RET interacts with the main macromolecular groups in the bitumen and exhibits a uniform distribution within the bitumen blend.

As seen in

Figure 4, when the XRD data of RTFOT-aged bitumen samples were examined, it was seen that the crystallinity in the structure decreased with the addition of Elvaloy

®RET into bitumen. Under short-term aging conditions, with the increase in the terpolymer, it is seen that the crystalline components in the mixture disappear and the amorphous structure of the terpolymer stands out. In other words, the amorphous structure of the products formed as a result of the bitumen-terpolymer reaction dominated the bitumen blend.

As seen in

Figure 5, in PAV-aged samples, the gaps between the components in the macromolecular structure have been closed by the effect of temperature and high pressure. In the region where the 2-teta was between 7.5–32.5, the semi-crystalline region was transformed into a completely amorphous structure, while the amorphous structure at the point where the 2-teta was about 40 was enlarged and spread according to the neat bitumen. However, when the Elvaloy

®RET ratio was 1.2%, the structure was transformed into a completely amorphous structure as a result of the macromolecular arrangement with the effect of pressure and temperature.

3.2. Scanning Electron Microscopy

SEM was used to investigate the microstructure of Elvaloy®RET-modified bitumens, to determine the distribution state of Elvaloy®RET in the neat bitumen, and to characterize the structure of the continuous and discontinuous phase. Surface imaging of all bitumen samples was performed using SEM (Zeiss EVO 50 Model) with a magnification of 1.0 K, electron acceleration voltage of 20 kV, and zooming of 20 µm.

SEM images obtained from neat and modified bitumens are shown in

Figure 6 for un-aged (original), RTFOT-aged, and PAV-aged samples.

As seen in

Figure 6(a1,b1,c1,d1), the SEM image of the pure bitumen coincides with the literature and it is seen that its structure is a homogeneous single phase. Considering the Elvaloy

®RET-bitumen interaction in the modified bitumens, it is seen that homogeneous structure is preserved at all three ratios. Elvaloy

®RET is known to be chemically reacted with bitumen. Therefore, the Elvaloy

®RET- bitumen mixture behaves as a single component. The XRD results also support this data, and the XRD peak intensity decreases due to the increased amount of Elvaloy

®RET.

Figure 6(a2,a3,b2,b3,c2,c3,d2,d3) shows that, as a result of the aging, the pure and modified- bitumen samples were transformed into an amorphous structure. Considering the aging conditions, it can be stated that the fraction missing in the binder is the component giving a crystalline feature to the structure. As the amount of Elvaloy

®RET in the bitumen increases, the decline of mass loss and the increase in the amorphous structure indicates that the terpolymer forms a bond with the amorphous groups rather than the crystalline groups. In the SEM images, structural changes were observed on the surface of modified bitumens compared to pure bitumen. It is thought that this is due to the fact that the molecular groups that leave the bitumen structure due to aging conditions change the surface geometry.

In conclusion, in the SEM images of short and long-term aged samples, homogeneity in the structure was clearly seen in terms of surface morphology. This was expected due to the bitumen-Elvaloy®RET reaction, and the XRD findings also supported this result. As a result of this reaction, the structure of the bitumen has become homogeneous and due to the removal of small groups of crystals as a result of aging, a homogenous amorphous macromolecular structure was formed.

3.3. Conventional Asphalt Tests

Basic physical properties of asphalt binders before and after the aging process were determined by conventional bitumen tests, and the results are shown in

Table 4. The table also shows the

PI values which are accepted as a measure of the temperature sensitivity of binders. In addition, the relationship between penetrations, softening points, penetration indexes of the un-aged and RTFOT-aged binders, and the additive amounts in the binder are given in

Figure 7,

Figure 8, and

Figure 9, respectively.

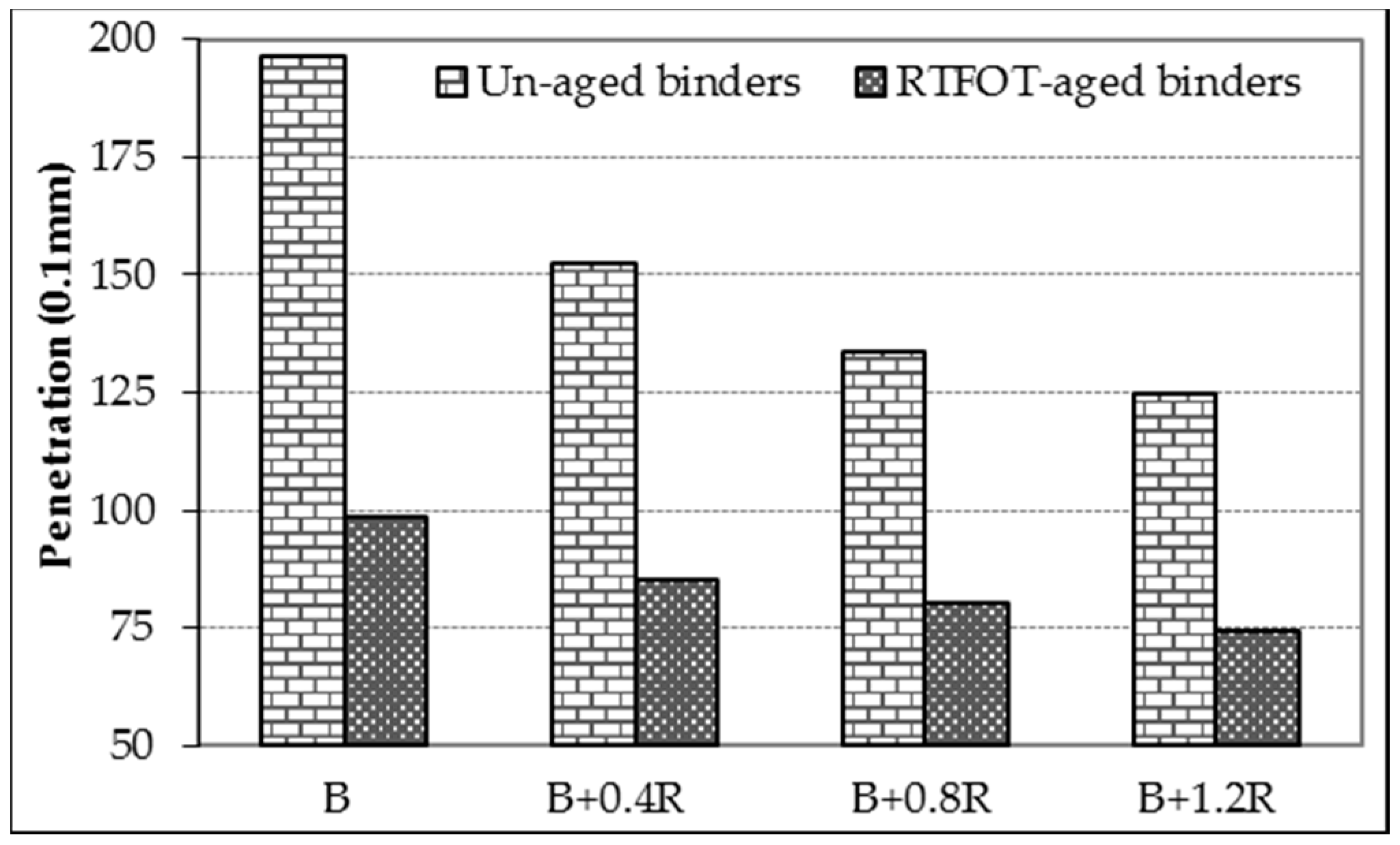

As seen in

Table 4 and

Figure 7 and

Figure 8, when the Elvaloy

®RET was added to the neat bitumen of 0.4%, 0.8%, and 1.2% by weight, its penetration values decreased by 22.5%, 31.9%, and 36.6% and ductility values by 19.7%, 35.1%, and 42.5%, respectively. On the other hand, the increase of Elvaloy

®RET content in the blend increased the softening point temperature of modified binder from 38.4 °C to 49.8 °C (i.e., 29.7% increase). The decrease in penetration and ductility as well as the increase in the softening point indicates a significant decrease in the temperature sensitivity of the bitumen and a significant increase in its stiffness. In addition, it was seen that the penetration class of pure B160/220 asphalt binder changed with the Elvaloy

®RET additive. In this case, it is possible to say that soft consistency binders used in colder climates can be used in warmer regions by adding Elvaloy

®RET at different rates.

Mass loss results showed that Elvaloy®-containing binders exhibited much less mass loss than neat bitumen, and that the loss of mass decreased with increasing Elvaloy® in the blend. This decrease was 20.5%, 48.7%, and 84.6%, respectively, depending on the additive amount. In this case, it can be said that the asphalt binders become less aged or harder with the addition of Elvaloy®RET. This also shows that the chemical reaction between bitumen and Elvaloy®RET improved the resistance of the modified bitumens to temperature and oxidation.

As seen in

Figure 9, when the effect of Elvaloy

®RET on the

PI of the binders is examined, it is seen that Elvaloy

®RET-modified bitumens have much higher

PI values compared to neat bitumen. This rate of increase was 67.4%, 168.4%, and 264.0%, respectively, depending on the additive amount. This indicates that Elvaloy

®-modified bitumens with higher

PI values are more resistant to cracking at low temperatures and permanent deformation at high temperatures [

29,

46].

When the results of RTFOT-aged binders were examined, it was observed that their penetration values decreased but softening point values increased, as in un-aged binders. In addition, compared to un-aged bitumens, the retained penetrations of the aged binders increased by 50%, 56%, 60%, and 60%; and the softening point values increased by 10.1 °C, 12.9 °C, 13.3 °C, and 14.5 °C, respectively. These results show that the neat and modified bitumens become naturally harder and less fluid after short-term aging, and as a result they are much less sensitive to temperature, especially at high temperatures.

3.4. Rotational Viscosity Test

The viscosity values of bitumens at high temperatures of 135 °C and 165 °C were determined using a Brookfield viscometer (DV-III). Based on these values, the mixing and compaction temperature ranges of the bitumens for the hot mixtures were determined by means of the temperature–viscosity graph shown in

Figure 10. The viscosity values (η), modification indexes (the η value of the modified bitumen was divided by the η value of the pure bitumen) and mixing-compaction temperature ranges of all binders are shown in

Table 5.

Figure 10 and

Table 5 demonstrate that the viscosity values, which characterize the required flow attributes of the binders to ensure safety in pumping and handling, have increased in parallel with the increase in Elvaloy

®RET. The increase rates are 48.0%, 84.3%, and 185.0% at 135 °C, and 35.3%, 68.7%, and 150.0% at 165 °C, respectively, compared to pure B 160/220 bitumen. Depending on the viscosity increases, the mixing and compaction temperatures of the modified bitumens increased by 2.4%, 4.7%, and 8.1% and 2.2%, 4.4%, and 7.7%, respectively. These results showed that the bitumen hardness increased significantly due to the increase in the amount of Elvaloy

® in the bitumen-additive blend.

3.5. Dynamic Shear Rheometer Test

In the study, the rheological properties (G*, δ) of all bitumens at intermediate and high service temperatures were identified by DSR device. According to the rutting parameters (G*/sin δ) of bitumens, performance grades were determined for high temperatures. In addition, fatigue resistance parameters (G*.sin δ) of binders were also evaluated for intermediate temperatures. The original (unaged) and aged DSR results of all binders for different temperatures are shown in

Table 6. For all binders, the relationship between temperature with G *, δ, G*/sin δ and G*.sin δ are shown in

Figure 11,

Figure 12,

Figure 13, and

Figure 14, respectively.

Table 6 and

Figure 11 show that the G* values have significantly increased in both aged and un-aged bitumens due to the increase of Elvaloy

®. However, as seen in

Figure 12, increases in the Elvaloy

® ratio caused a decrease in the phase angle values of the bitumens. This result shows that Elvaloy

®-modified bitumens behave as a more elastic solid. Increases in the complex modulus (G*) value, which is a measure of the total deformation resistance of a binder exposed to shear stresses, and decreases in the phase angle (δ) value, indicate that Elvaloy

®-modified binders are much more resistant to permanent deformations. This is because higher G* and lower δ values indicate an increase in permanent deformation resistance.

Figure 13 shows that the rutting parameter (G*/sin δ) values of Elvaloy

®-modified bitumens were significantly increased compared to the neat bitumen values at the same temperature. When the Superpave limit values were evaluated together, it was seen that the neat bitumen met the criteria requirements up to 56.5 °C but the high temperature performance level was 52 °C.

Similarly, the temperatures at which Elvaloy®RET-modified bitumens met the limits were determined as 60 °C, 65.5 °C, and 70.5 °C, respectively. According to these values, the performance temperatures of the modified binders were determined as 58 °C, 64 °C, and 70 °C, respectively. As a result, it was determined that the high temperature performance classes of all bitumens according to Superpave criteria were PG 52-Y, PG 58-Y, PG 64-Y, and PG 70-Y respectively. Furthermore, according to the neat bitumen, 6 °C, 12 °C, and 18 °C increments occurred at the performance temperatures of the modified bitumens, respectively. This means that when modified with 1.2% Elvaloy®RET, a pure bitumen, which should normally be used at a temperature of up to 52 °C, can be used at a temperature of up to 70 °C.

Furthermore, as seen in

Figure 14, the fatigue resistance parameter values of all binders (G*.sin δ) remained below the limit value of 5000 kPa. This indicates that the fatigue crack resistance of the modified bitumens is sufficient at intermediate temperatures. These results imply that binder-induced fatigue cracks may not occur in an asphalt pavement exposed to repeated traffic loads.

Based on the DSR test results, it was seen that the addition of the Elvaloy® increased the stiffness of bitumen and reduced the temperature sensitivity, but made it an elastic solid. As a result, it was determined that Elvaloy®RET modified bitumens had higher permanent deformation resistance at higher temperatures.

3.6. Bending Beam Rheometer Test

Creep stiffness (S) and creep ratio (m-value) values, which are considered as performance parameters of bitumens exposed to very low temperatures, were obtained by using a BBR tester. The BBR results of the neat and modified bitumens at different temperatures were obtained 60 s after the start of the test, and these results are given in

Table 7. In addition, the relationships of these parameters with temperature are given in

Figure 15 and

Figure 16.

As seen from

Table 7 and

Figure 15, the stiffness of modified bitumens increased at low temperatures due to the increase in the amount of Elvaloy

®RET. This means that bitumens containing Elvaloy

®RET exhibit a more rigid behavior. However, as seen in

Figure 16, the m-value values decreased with the increase of the additive rate. This means that there is a relative increase in the hardening speed of the Elvaloy

®RET-modified binders exposed to low temperatures. According to this result, it can be stated that cracking at low temperatures may occur in these binders. Tiis is because the rapid change in hardness due to the low temperature can create cracks in the binder under the accumulated thermal stresses.

Low temperature limits of the neat and modified binders according to Superpave specification limits (the creep stiffness is max 300 MPa, the m-value is min 0.3) were obtained as −28.5 °C, −25.0 °C, −22.5 °C, and −20.5 °C, respectively. However, low temperature performance levels of the binders were determined to be −28 °C, −22 °C, −22 °C, and −16 °C, respectively. According to these values, it was determined that the low temperature performance classes of all binders were PG X-28, PG X-22, PG X-22, and PG X-16 respectively. These temperature values show that the Elvaloy®RET additive has reduced the low temperature performance of the B 160/220 bitumen from −28 °C to −16 °C. However, the low temperature performance levels of 0.4% and 0.8% Elvaloy®RET-modified binders were similar, although they had different hardness and hardening speed.

As a result, when a bitumen containing Elvaloy®RET is used at very low temperatures, cracking resistance may be reduced or cracking resistance is increased when used at relatively high temperatures. In fact, this can be seen as a negative situation only when it is evaluated in terms of low temperature, but when examined together with high temperature it will be seen that it is not negative. This is because an asphalt binder which can perform at high performance both at very low temperatures and at very high temperatures has not been produced yet.

3.7. Effects of Elvaloy®RET on Performance Grading of B 160/220

The effects of the Elvaloy

® additive on the low (LT) and high (HT) temperature performance properties and performance grading of the B 160/220 bitumen are given in

Table 8.

As can be seen in

Table 8, the high and low temperature levels providing the specification limits of the pure B 160/220 bitumen are 56.5 °C and −28.5 °C. However, its high temperature level increased by 6.2%, 15.9%, and 24.8%, respectively, in parallel to the increase in Elvaloy

®RET. Due to these increases, the performance level of bitumen increased from 52 °C to 70 °C. This indicates that the bitumen is severely hardened with Elvaloy

®RET. However, its low temperature level decreased by 12.3%, 21.1%, and 28.1%. This reduction reduced the low temperature performance level of the bitumen from −28 °C to −16 °C. This can be met as a natural situation because hardening can lead to a reduction in the low temperature crack resistance of the bitumen. When the low and high temperature performance levels of bitumens are evaluated together, it is seen that their performance grades are PG 52-28, PG 58-22, PG 64-22, and PG 70-16 respectively. In this case, it can be said that 1.2% Elvaloy

®RET can provide a significant benefit to the pavement performance for high service temperatures.

Finally, compared to the neat bitumen, it is possible to conclude that the bitumens modified with the Elvaloy®RET perform better at high temperatures, but there is a decrease in their low temperature performance.