Effects of the Thickness of N,N′-diphenyl-N,N′-di(m-tolyl)-benzidine on the Electro-Optical Characteristics of Organic Light-Emitting Diodes

Abstract

:1. Introduction

2. Experiment

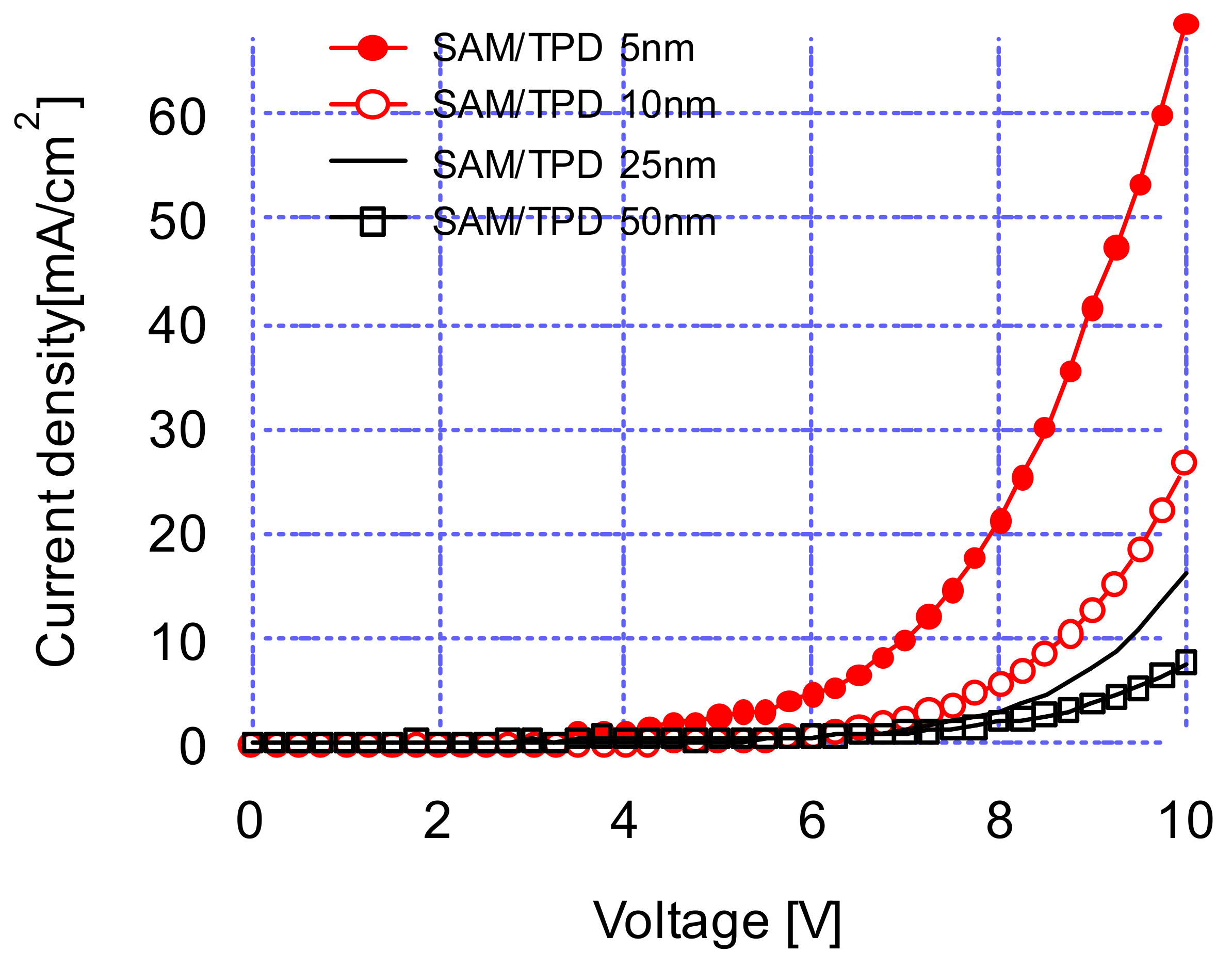

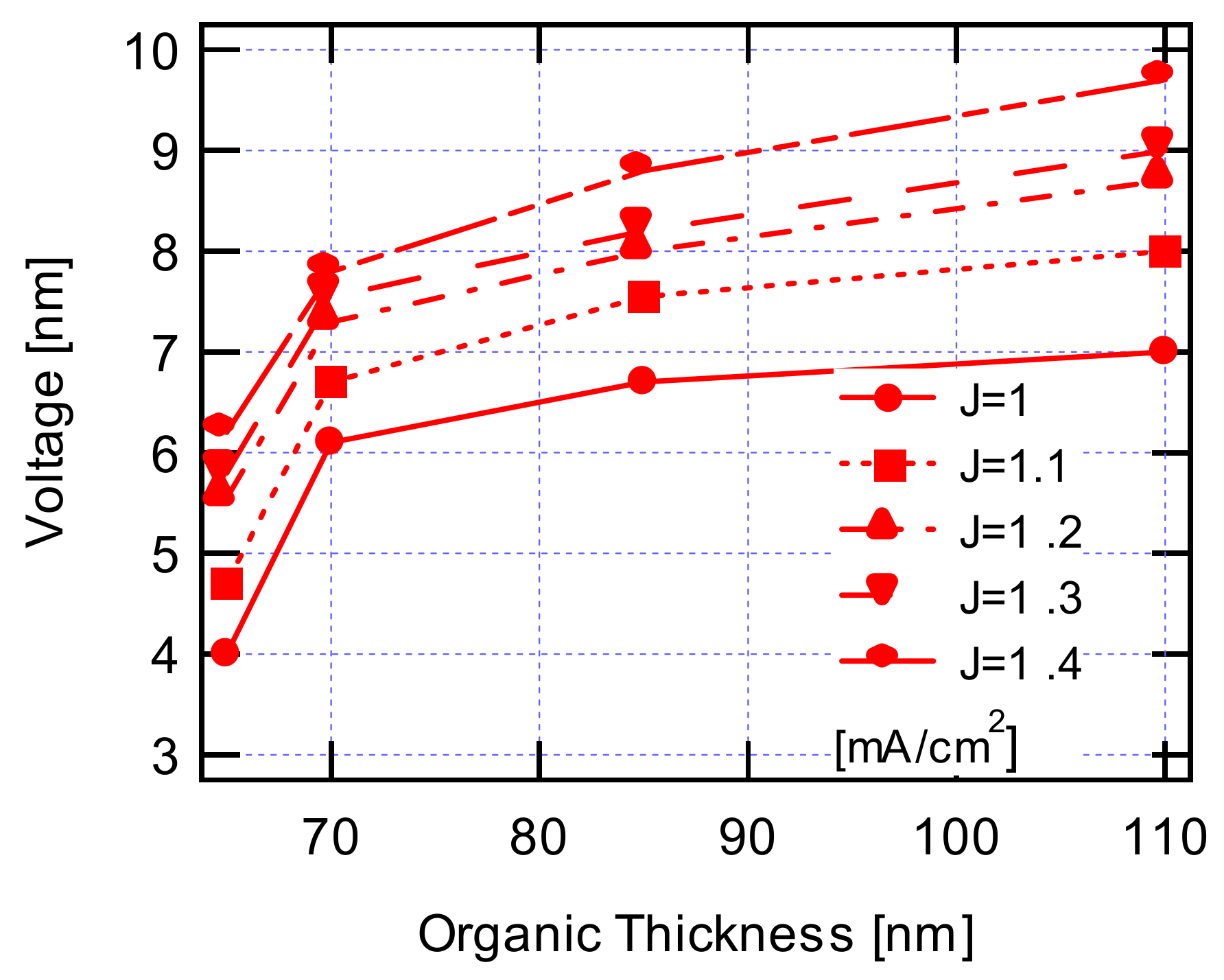

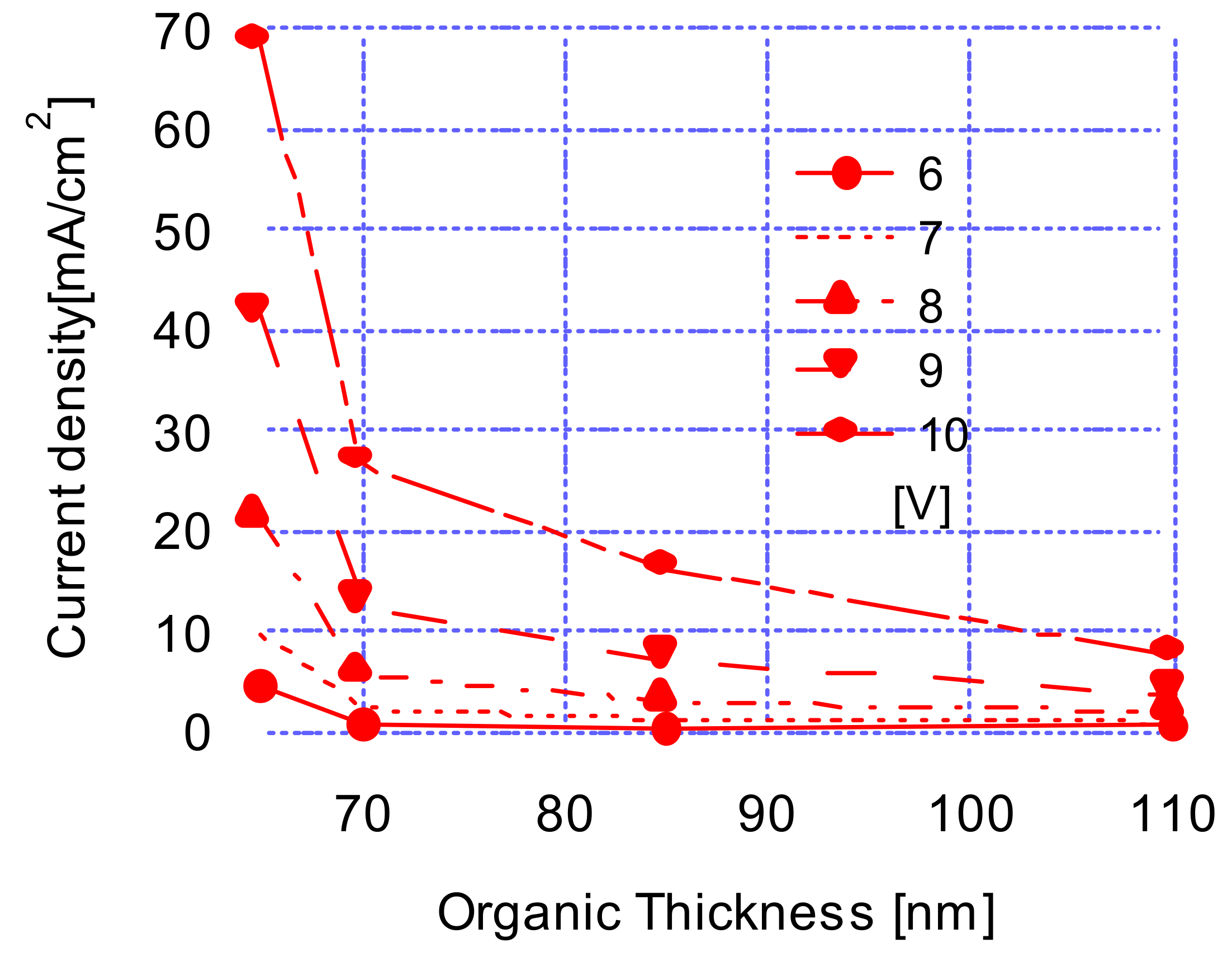

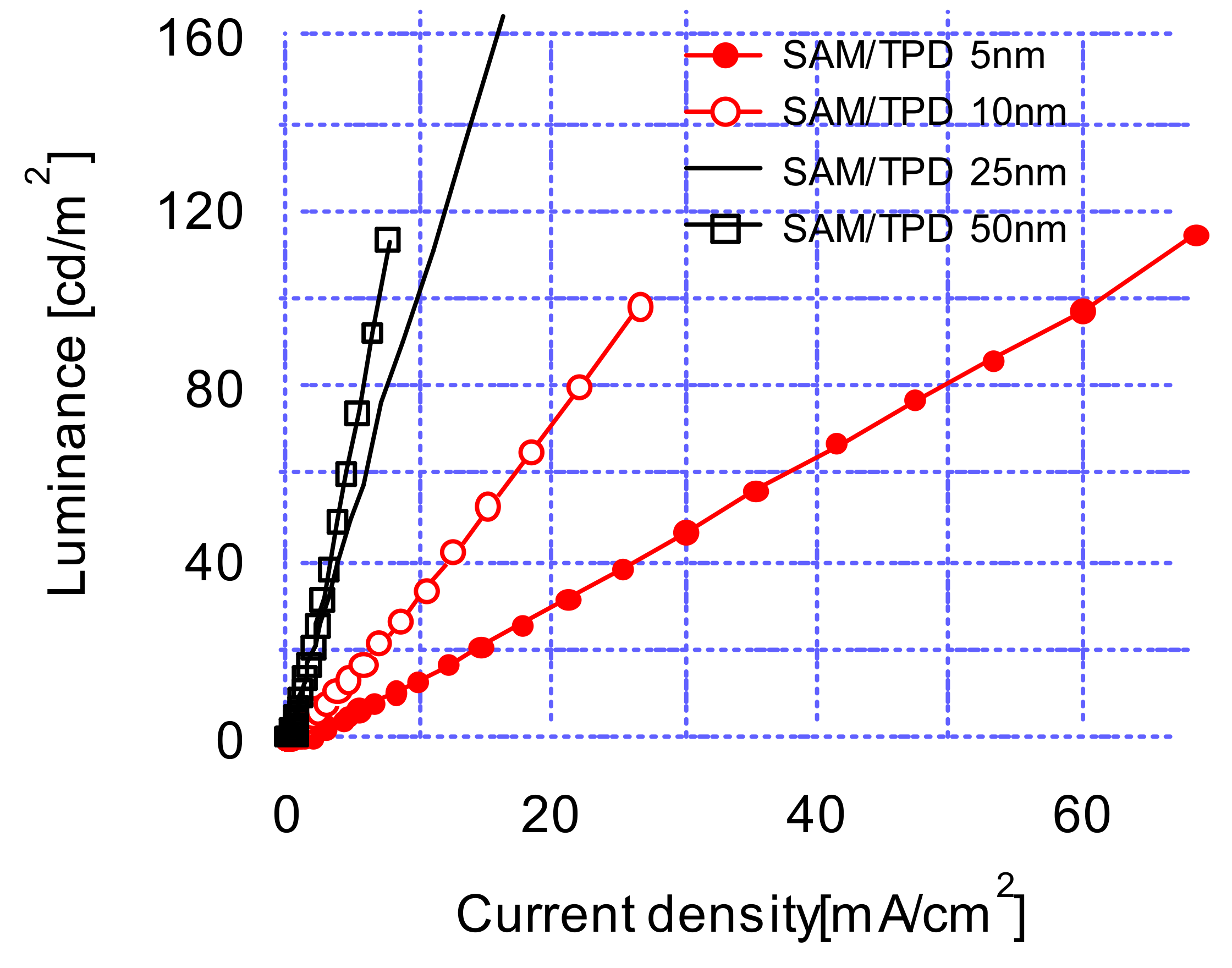

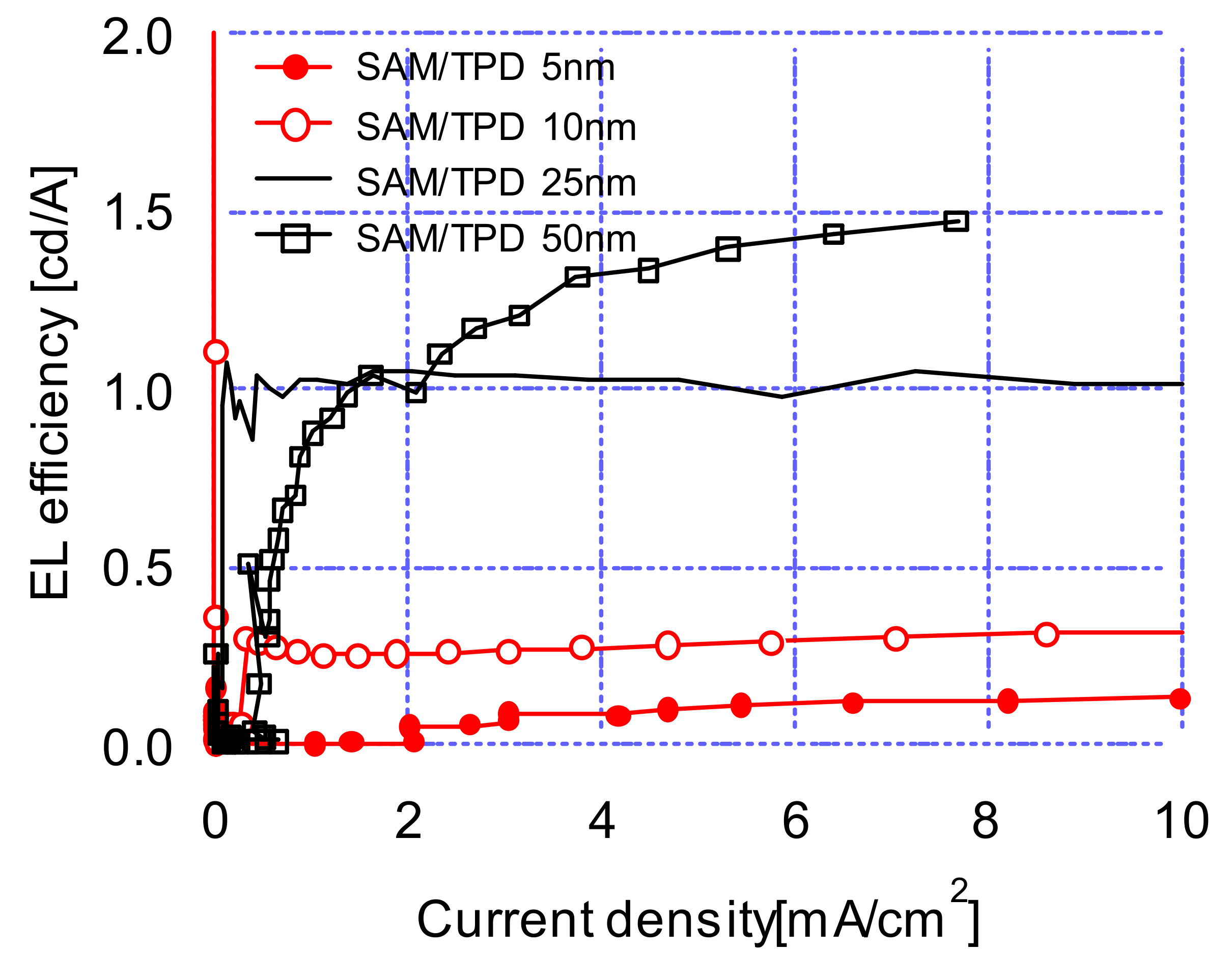

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Geffroy, B.; Roy, P.L.; Prat, C. Organic light-emitting diode (OLED) technology: Materials, devices and display technologies. Polym. Int. 2006, 55, 572–582. [Google Scholar] [CrossRef]

- Peng, H.J.; Zhu, X.L.; Sun, J.X.; Xie, Z.; Wong, M.; Kwok, H. Efficient organic light-emitting diode using semitransparent silver as anode. Appl. Phy. Lett. 2005, 87, 173505. [Google Scholar] [CrossRef]

- Kumar, G.; Li, Y.D.; Biring, S.; Lin, Y.N.; Liu, S.W.; Chang, C.H. Highly efficient ITO-free organic light-emitting diodes employing a roughened ultra-thin silver electrode. Org. Electron. 2017, 42, 52–58. [Google Scholar] [CrossRef]

- Lee, H.G.; Hwang, Y.W.; Won, T.Y. Effect of inserting a hole injection layer in organic light-emitting diodes: A numerical approach. J. Korean Phys. Soc. 2015, 66, 100–103. [Google Scholar] [CrossRef]

- Shirota, Y.; Noda, T.; Ogawa, H. Organic light-emitting diodes using novel emitting amorphous molecular materials. Proc. SPIE Int. Soc. Opt. Eng. 1999, 3797, 158–169. [Google Scholar]

- Park, S.G.; Tatsuo, M. Electrical conduction behavior of organic lightemitting diodes using fluorinated self-assembled monolayer with molybdenum oxide-doped hole transporting layer. Luminescence 2015, 30, 416–419. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xie, F.; Zhang, S.; Hou, J.; Choy, W.C.H. MoOx and V2Ox as hole and electron transport layers through functionalized intercalation in normal and inverted organic optoelectronic devices. Light Sci. Appl. 2015, 4, e273. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, Y.; Qin, H.; Hu, S.; Wu, Q.; Zhao, Y. Buffer-modified n/p-type and p/n-type planar organic heterojunctions as charge generation layers for high performance tandem organic light-emitting diodes. Synth. Met. 2017, 228, 45–51. [Google Scholar] [CrossRef]

- Tao, Y.; Wub, K.; Huang, K.; Perng, T. Odd-even modulation of electrode work function with self-assembled layer: Interplay of energy barrier and tunneling distance on charge injection in organic light-emitting. Org. Electron. 2011, 12, 602–608. [Google Scholar] [CrossRef]

- Oh, E.; Park, S.; Jeong, J.; Kang, S.J.; Lee, H.; Yi, Y. Energy level alignment at the interface of NPB/HAT-CN/graphene for flexible organic light-emitting diodes. Chem. Phys. Lett. 2017, 668, 64–68. [Google Scholar] [CrossRef]

- Aziz, H.; Popovic, Z.D.; Hu, N.X.; Hor, A.M.; Xu, G. Degradation mechanism of small molecule-based organic light-emitting devices. Science 1999, 283, 1900–1902. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Bae, T.S.; Heo, W.S.; Joo, T.H.; Song, K.D.; Park, H.G.; Ryu, S.Y. Effects of gold-nanoparticle surface and vertical coverage by conducting polymer between indium tin oxide and the hole transport layer on organic light-emitting diodes. ACS Appl. Mater. Interfaces 2015, 7, 15031–15041. [Google Scholar] [CrossRef] [PubMed]

- Rhee, S.H.; Kim, S.H.; Kim, H.S.; Shin, J.Y.; Bastola, J.; Ryu, S.Y. Heavily doped, charge-balanced fluorescent organic light-emitting diodes from direct charge trapping of dopants in emission layer. ACS Appl. Mater. Interfaces 2015, 7, 16750–16759. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Kok, W.C. Thermally activated delayed fluorescence host for high performance organic light-emitting diodes. Sci. Rep. 2018, 8, 8832-1–8832-6. [Google Scholar]

- Huang, T.; Wei, J.; Lian, D. Recent progress in solution processable TADF materials for organic light-emitting diodes. J. Mater. Chem. C 2018, 6, 5577–5596. [Google Scholar] [CrossRef]

- Tagare, J.; Dubey, D.K.; Jou, J.H.; Vaidyanathan, S. Synthesis, photophysical, theoretical and electroluminescence study of triphenylamine-imidazole based blue fluorophores for solution-processed organic light emitting diodes. Dyes Pigments 2019, 160, 944–956. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.-G.; Lee, W.J.; Song, M.J.; Shin, J.; Kim, T.W. Effects of the Thickness of N,N′-diphenyl-N,N′-di(m-tolyl)-benzidine on the Electro-Optical Characteristics of Organic Light-Emitting Diodes. Materials 2019, 12, 966. https://doi.org/10.3390/ma12060966

Park S-G, Lee WJ, Song MJ, Shin J, Kim TW. Effects of the Thickness of N,N′-diphenyl-N,N′-di(m-tolyl)-benzidine on the Electro-Optical Characteristics of Organic Light-Emitting Diodes. Materials. 2019; 12(6):966. https://doi.org/10.3390/ma12060966

Chicago/Turabian StylePark, Sang-Geon, Won Jae Lee, Min Jong Song, Johngeon Shin, and Tae Wan Kim. 2019. "Effects of the Thickness of N,N′-diphenyl-N,N′-di(m-tolyl)-benzidine on the Electro-Optical Characteristics of Organic Light-Emitting Diodes" Materials 12, no. 6: 966. https://doi.org/10.3390/ma12060966