Forms of Damage of Bricks Subjected to Cyclic Freezing and Thawing in Actual Conditions

Abstract

:1. Introduction

2. Scope of Research

2.1. Materials Tested

2.2. Purpose of the Research

3. Methods

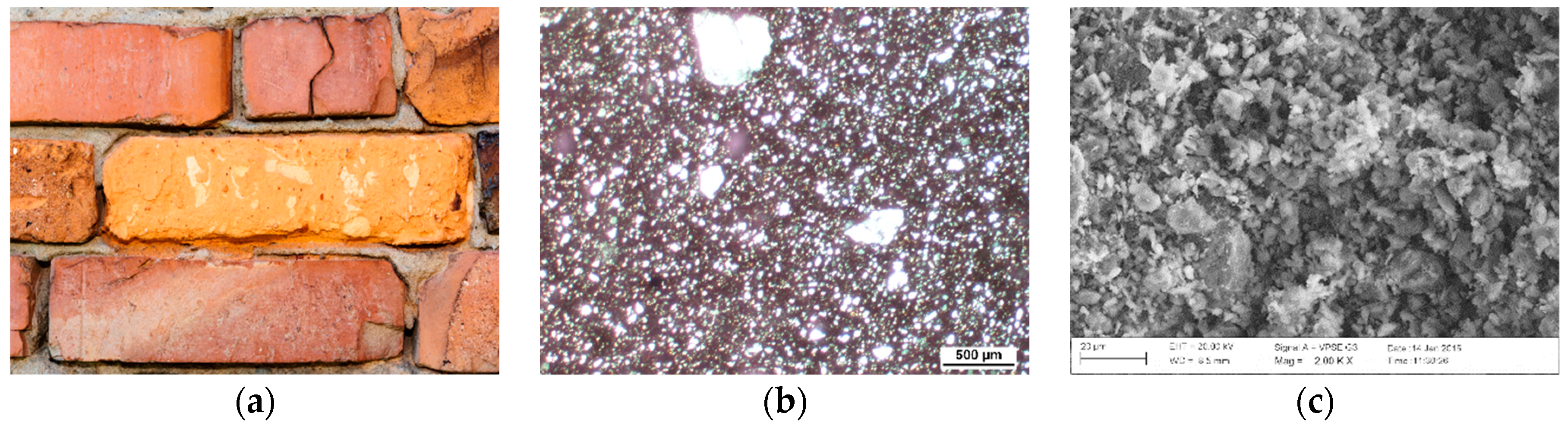

3.1. Photographic Documentation

3.2. Petrographic Observations by Optical Microscope

3.3. Observations by Scanning Microscopy with Elemental Analysis

3.4. Determination of the Structure of Porosity by Mercury Porosimetry

3.5. Compressive Strength, Tensile Strength and Density Testing

4. Results and Analysis

4.1. Macroscopic, Petrographic and Microstructural Characteristics of the Forms of Damage of Bricks

- Surface powdering progressing into the material; the product of disintegration of the material is brick crumbled into powder. The samples were labelled as P1, P2 and P3;

- Surface flaking progressing into the material; distinct layers of flakes occur on the surface and fall off. The samples were labelled as F4, F5 and F6;

- Cracking, which takes place within the volume of the brick and is not only associated with the superficial layers. This results in formation of deep scratches and consequently chunks of material that wedge each other and fall off after some time. The samples were labelled as C7, C8 and C9.

4.2. The Structure of Porosity

4.3. Results of Compressive Strength, Tensile Strength and Density Testing

5. Discussion of Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maage, M. Frost resistance and pore size distribution in bricks. Mater. Struct. 1984, 17, 345–350. [Google Scholar] [CrossRef]

- Perrin, B.; Vu, N.A.; Multon, S.; Voland, T.; Ducroquetz, C. Mechanical behaviour of fired clay materials subjected to freeze–thaw cycles. Constr. Build. Mater. 2011, 25, 1056–1064. [Google Scholar] [CrossRef]

- Abdrakhimov, Z.; Abdrakhimova, S. Chemical-elemental, phase composition and porosity structure of ceramic samples from Cham tower (Vietnam) more than 1000 y/o. Glass Ceram. 2018, 75, 33–38. [Google Scholar] [CrossRef]

- Abdrakhimov, Z.; Abdrakhimova, S. Phase composition and porosity structure of ceramic bricks more than 100 years old: Catholic church, Iverskiy monastery, and church of the nativity in Samara Oblast. Glass Ceram. 2016, 73, 42–45. [Google Scholar] [CrossRef]

- Bergman, K. Kurzer Uberblick uber den Derzeitingen Stand der Frostforschung; Ziegelindustrie: Gütersloh, Germany, 1958; p. 4. [Google Scholar]

- Elert, K.; Cultrone, G.; Navarro, C.R.; Pardo, E.S. Durability of bricks used in the conservation of historic buildings—Influence of composition and microstructure. J. Cult. Herit. 2003, 4, 91–99. [Google Scholar] [CrossRef]

- Hansen, W.; Kung, J.H. Pore structure and frost durability of clay bricks. Mater. Struct. 1988, 21, 443–447. [Google Scholar] [CrossRef]

- Herget, F.A.; Crooks, R.W.; Winslow, D.N. Variability within single projects of physical properties of face brick as related to potential durability. In Proceedings of the 6th Canadian Masonry Conference, Department of Civil Engineering, University of Saskatchewan, Saskatoon, SK, Canada, 15–17 June 1992; Volume 2, pp. 417–428. Available online: https://www.worldcat.org/title/proceedings-6th-canadian-masonry-symposium-15-17-june-1992-department-of-civil-engineering-university-of-saskatchewan-saskatoon-saskatchewan-canada/oclc/70476722 (accessed on 18 March 2019).

- Nieminen, P.; Romu, P. Porosity and frost resistance of clay bricks. In Brick and Block Masonry; de Courcy, J.W., Ed.; Elsevier Applied Science: London, UK, 1988; Volume 1, pp. 103–109. [Google Scholar]

- Wardeh, G.; Perrin, B. Freezing–thawing phenomena in fired clay materials and consequences on their durability. Constr. Build. Mater. 2008, 22, 820–828. [Google Scholar] [CrossRef]

- Winslow, D. Predicting the durability of paving bricks. J. Test. Eval. 1991, 19, 29–33. [Google Scholar] [CrossRef]

- Koniorczyk, M.; Gawin, D.; Schrefler, B. Multiphysics for spalling prediction of brick due to in pore salt. Comput. Struct. 2018, 196, 233–245. [Google Scholar] [CrossRef]

- Ravaglioli, A. Evaluation of frost resistance of pressed ceramic products based on the dimensional distribution pores. Trans. Br. Ceram. Soc. 1976, 76, 92–95. [Google Scholar]

- Robinson, G.C. The relation between pore structure and durability of bricks. Ceram. Bull. 1984, 63, 295–300. [Google Scholar]

- Winslow, D.N.; Kilgour, C.L.; Crooks, R.W. Predicting the durability of bricks. J. Test. Eval. 1988, 16, 527–531. [Google Scholar] [CrossRef]

- Bellanger, M.; Homand, F.; Remy, J.M. Water behaviour in limestones as a function of pore structure: Application to frost resistance of some lorraine limestones. Eng. Geol. 1993, 36, 99–108. [Google Scholar] [CrossRef]

- Cultrone, G.; Sebastian, E.; Elerta, K.; Jose´ de la Torreb, M.; Cazallaa, O. Rodriguez–Navarroa, C. Influence of mineralogy and firing temperature on the porosity of bricks. J. Eeur. Ceram. Soc. 2004, 24, 547–564. [Google Scholar] [CrossRef]

- Scherer, G.W. Crystallisation in pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Madso, F.E. Tegl SOM Byggemateriale, Fremstilling og Egenskaper; Mur-Sentret: Oslo, Norway, 1979. [Google Scholar]

- Tang, Y.; Shao, Z.; Xu, T. Pore structure of Acient Chinese bricks under environmental vicissitudes. J. Civ. Eng. 2016, 20, 1895–1902. [Google Scholar] [CrossRef]

- Matysek, P.; Stryszewska, T.; Kańka, S. Experimental Research of Masonry Compressive Strength in The Auschwitz II—Birkenau Former Death Camp Buildings. Eng. Fail. Anal. 2016, 68, 263–274. [Google Scholar] [CrossRef]

- Matysek, P.; Stryszewska, T.; Kańka, S.; Witkowski, M. The influence of water saturation on mechanical properties of ceramic bricks—Tests on 19th-century and contemporary bricks. Mater. Struct. 2016, 66, 95. [Google Scholar] [CrossRef]

- Venice Charter (International Restoration Charter). In Proceedings of the Second Congress of Architects and Specialists of Historic Buldings, Venice, Italy, 25–31 May 1964.

- ASTM C62-00 Standard Specification for Building Brick (Solid Masonry Units Made from Clay or Shale); American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

| Component | Mineral | Powdering | Flaking | Cracking | Standard | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | F4 | F5 | F6 | C7 | C8 | C9 | S10 | S11 | S12 | ||

| Volume Fraction [%] | |||||||||||||

| Mineral grains | Quartz | 31.2 | 31.3 | 31.3 | 35.2 | 23.4 | 34.5 | 26.3 | 24.3 | 31.0 | 28.9 | 32.4 | 31.9 |

| Alkali feldspars | 2.9 | 0.0 | 0.0 | 0.7 | 0.0 | 0.0 | 0.3 | 0.0 | 4.2 | 1.9 | 2.0 | 0.0 | |

| Plagioclase | 1.5 | 3.0 | 0.9 | 1.4 | 0.0 | 4.6 | 2.4 | 0.6 | 0.0 | 3.9 | 0.0 | 4.7 | |

| Sericite | 22.9 | 16.9 | 6.6 | 17.1 | 16.1 | 14.4 | 15.3 | 29.1 | 7.4 | 5.8 | 5.6 | 5.9 | |

| Crumbs of rock | Chert | 0.0 | 0.0 | 1.0 | 0.0 | 3.7 | 0.0 | 0.0 | 0.0 | 1.4 | 0.0 | 0.0 | 0.0 |

| Slate quartz-sericite | 0.0 | 1.5 | 0.0 | 0.7 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Clay | 2.0 | 0.0 | 8.1 | 0.0 | 5.1 | 5.2 | 0.0 | 0.0 | 6.1 | 4.8 | 5.0 | 7.0 | |

| Aggregates | - | 60.5 | 52.7 | 47.9 | 60.1 | 48.3 | 58.7 | 37.4 | 54.0 | 50.1 | 45.3 | 45.0 | 50.5 |

| Aggregates of the other components | Hydroxides of iron | 1.0 | 5.0 | 5.0 | 1.8 | 1.5 | 0.0 | 2.1 | 3.3 | 1.9 | 0.0 | 0.0 | 0.0 |

| Charred organic substance | 0.0 | 0.0 | 0.0 | 0.0 | 2.2 | 0.0 | 3.2 | 1.2 | 2.8 | 2.9 | 0.0 | 0.0 | |

| Calcite | 0.0 | 0.0 | 4.4 | 0.0 | 0.0 | 0.0 | 6.7 | 0.9 | 5.6 | 0.0 | 0.0 | 0.0 | |

| Binder | - | 38.5 | 42.3 | 42.9 | 43.1 | 48.0 | 41.4 | 43.7 | 40.6 | 39.9 | 51.9 | 54.9 | 50.4 |

| Sum | - | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Form of Damage | Sample Identification | Compressive Strength [MPa] | Tensile Strength [MPa] | Bulk Density [g/cm3] |

|---|---|---|---|---|

| Powdering | P1 | 10.6 | 1.3 | 1.69 |

| P2 | 11.1 | 0.9 | 1.63 | |

| P3 | 14.5 | 1.5 | 1.67 | |

| Flaking | F4 | 31.5 | 3.6 | 1.80 |

| F5 | 36.3 | 4.1 | 1.78 | |

| F6 | 24.3 | 1.9 | 1.67 | |

| Cracking | C7 | 35.8 | 3.2 | 1.79 |

| C8 | 37.5 | 3.8 | 1.69 | |

| C9 | 39.7 | 3.3 | 1.81 | |

| Standard | S10 | 20.2 | 1.7 | 1.76 |

| S11 | 31.1 | 3.8 | 1.76 | |

| S12 | 43.0 | 5.1 | 1.86 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stryszewska, T.; Kańka, S. Forms of Damage of Bricks Subjected to Cyclic Freezing and Thawing in Actual Conditions. Materials 2019, 12, 1165. https://doi.org/10.3390/ma12071165

Stryszewska T, Kańka S. Forms of Damage of Bricks Subjected to Cyclic Freezing and Thawing in Actual Conditions. Materials. 2019; 12(7):1165. https://doi.org/10.3390/ma12071165

Chicago/Turabian StyleStryszewska, Teresa, and Stanisław Kańka. 2019. "Forms of Damage of Bricks Subjected to Cyclic Freezing and Thawing in Actual Conditions" Materials 12, no. 7: 1165. https://doi.org/10.3390/ma12071165

APA StyleStryszewska, T., & Kańka, S. (2019). Forms of Damage of Bricks Subjected to Cyclic Freezing and Thawing in Actual Conditions. Materials, 12(7), 1165. https://doi.org/10.3390/ma12071165