Evaluation of Carbon Nanotube Incorporation in Cementitious Composite Materials

Abstract

:1. Introduction

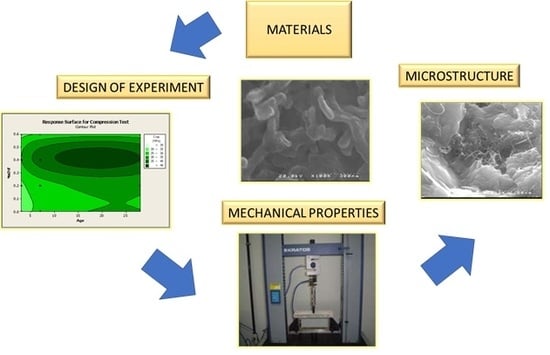

2. Experimental Design

2.1. Material Characteristics

- Portland cement CEM I 52.5 R UNC-EM 197-1 manufactured by Cimento Molins Industrial S.A., Barcelona, Spain;

- Sand from Arids Catalunya S.A., Barcelona, Spain;

- Potable water from the Water and Sanitation Company of Barcelona, Barcelona, Spain;

- Superplasticiser (SP) polycarboxylate ADVA Flow 401 produced by GRACE Construction Products according to European Standard EN 934-2.28 [28];

- Carbon nanotubes produced and supplied by the Nanomaterials Laboratory of Physics, Department of Universidade Federal de Minas Gerais (UFMG), Brazil. The nanotubes were produced by chemical deposition in vapor phase and identified by MWCNT HP2627. They have the following characteristics: type—multi-walled carbon nanotubes (MWCNTs); weight—60 g, purity >93%; other carbon structures <2%; contaminants <5% of catalyst powder type MgOCo-Fe; and external diameter dimensions, 99% of the CNTs, between 5 and 60 nm and an estimated length between 5 and 30 µm.

2.2. Cement Mortar Compositions

2.3. Cement Mortar Production and Specimen Preparation

- (1)

- Cement and sand were weighed on a precision balance (Gram brand, model ST-4000, with a maximum capacity of 4000 g and accuracy of 0.1 g);

- (2)

- Sand and cement were mixed manually until acquiring a homogeneous appearance;

- (3)

- Water and SP were weighed on the same balance. SP and water were then mixed manually in a plastic container for about 5 min;

- (4)

- Nanotubes were weighed on the same balance. CNTs were then added to the water and SP mixture [Sikora 2018] and mixed by hand with a glass rod for 5 min;

- (5)

- Dispersion of the nanotubes and homogenization of the CNTs occurred and they were submitted to a physical and chemical procedure involving sonication, to deagglomerate the CNT bundles, for 60 min (see Figure 1). For this purpose, we used “ultrasonic P2000 clinging qteck Gmbh (Gemarny)” equipment;

- (6)

- Cement and sand (previously mixed) were poured into the mixer containing the mixture of the water, SP, and CNT after 15 min of mixing.

2.4. Mechanical Properties

2.5. Physico-Chemical Performance and Non-Destructive Tests

3. Results and Discussion

3.1. Compressive Strength

3.2. Compressive Stress Versus Strain

3.3. Tensile Stress

3.4. Flexural Load–Deflexion Relationship

3.5. Non-Destructive Test (DME—Dynamic Modulus of Elasticity)

3.6. Porosity, Density and SEM Observations

4. Conclusions

- The addition of 0.40 wt % of cement of carbon nanotubes (CN4) resulted in cement mortar with the best performance compared to the reference mixture, achieving an increase of approximately 40% compressive strength, 30% tensile strength, 15% flexural strength and a denser microstructure.

- The composites with the addition of 0.20 and 0.60 wt % CNT did not present the same level of improvement as the 0.40 wt % CNT, compared to the reference (0.00 wt % cement).

- The stress–strain curves of all specimens showed single peak behavior, which indicated the limited strain capacity of both the reference and the CNT mixtures, indicating that under compressive stress this material was brittle.

- The porosity measurements were performed to obtain additional information about the microstructure of the new compounds, incorporating nanotubes and 0.40% CNT produced the lowest pore percentage compared to other cement mortars.

- Analyzed SEM images showed the densification of the CNT cementitious matrices. This should be attributed to the lower porosity and the bridging effect of the carbon nanotube. As a result, better mechanical performance was obtained at 0.40 wt % CNT.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Singh, A.; Prabhu, T.R.; Sanjay, A.; Koti, V. An Overview of Processing and Properties of CU/CNT Nano Composites. Mater. Today Proc. 2017, 4, 3872–3881. [Google Scholar] [CrossRef]

- Durán, N.; Mattoso, L.H.; Morais, P.C. Nanotechnology—Introduction, Preparation and Characterization of Nanomaterials and Application Examples; Editora Artliber: São Paulo, Brazil, 2006; p. 208. (In Portuguese) [Google Scholar]

- Güneyisi, E.; Gesoǧlu, M.; Algin, Z.; Mermerdaş, K. Optimization of concrete mixture with hybrid blends of metakaolin and fly ash using response surface method. Compos. Part B Eng. 2014, 60, 707–715. [Google Scholar] [CrossRef]

- Eftekhari, M.; Mohammadi, S. Multiscale dynamic fracture behavior of the carbon nanotube reinforced concrete under impact loading. Int. J. Eng. 2016, 87, 55–64. [Google Scholar] [CrossRef]

- Hüsken, G.; Brouwers, H. A new mix design concept for earth-moist concrete: A theoretical and experimental study. Cem. Concr. Res. 2008, 38, 1246–1259. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Ruan, Y.; Han, B.; Yu, X.; Zhang, W.; Wang, D. Carbon nanotubes reinforced reactive powder concrete. Compos. A Appl. Sci. Manuf. 2018, 112, 371–382. [Google Scholar] [CrossRef]

- de Morais, J.F.; Haddad, A.N.; Catarina, A.; Evangelista, J. Experimental Analysis of Carbon Nanotubes in Cementitious Materials Composites. J. Nanotechnol. Mater. Sci. 2017, 4, 39–51. [Google Scholar] [CrossRef]

- Horszczaruk, E. Properties of Cement-Based Composites Modified with Magnetite Nanoparticles: A Review. Materials 2019, 12, 326. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Tu, J.; Zhang, X. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes. Mater. Sci. Eng. A 2001, 313, 83–87. [Google Scholar] [CrossRef]

- Wagner, H.D.; Lourie, O.; Feldman, Y.; Tenne, R. Stress-induced fragmentation of multiwall carbon nanotubes in a polymer matrix. Appl. Phys. Lett. 1998, 72, 188–190. [Google Scholar] [CrossRef]

- Raki, L.; Beaudoin, J.; Alizadeh, R.; Makar, J.; Sato, T. Cement and Concrete Nanoscience and Nanotechnology. Materials 2010, 3, 918–942. [Google Scholar] [CrossRef]

- Angulo, V.J.; Ligero, V.C.; Rico, D.P. Mortar and Concrete Reinforced with Nanomaterials. Nanotechnol. Constr. 2009, 3, 383–388. [Google Scholar]

- Balaguru, P.; Chong, K. Nanotechnology and Concrete: Research Opportunities. In Proceedings of the ACI Session on Nanotechnology of Concrete: Recent Developments and Future Perspectives, Denver, CO, USA, 7 November 2006; pp. 15–28. [Google Scholar] [CrossRef]

- Li, H.; Zhang, M.-H.; Ou, J.-P. Flexural fatigue performance of concrete containing nano-particles for pavement. Int. J. 2007, 29, 1292–1301. [Google Scholar] [CrossRef]

- Hunashyal, A.M.; Tippa, S.V.; Quadri, S.S.; Banapurmath, N.R. Experimental Investigation on Effect of Carbon Nanotubes and Carbon Fibres on the Behavior of Plain Cement Mortar Composite Round Bars under Direct Tension. ISRN Nanotechnol. 2011, 2011, 1–6. [Google Scholar] [CrossRef]

- Han, B.; Yang, Z.; Shi, X.; Yu, X. Transport properties of carbon-nanotube/cement composites. J. Mater. Eng. Perform. 2013, 22, 184–189. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, M.A.B. Effect of Carbon Nanotube Size on Compressive Strengths of Nanotube Reinforced Cementitious Composites. J. Mater. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Lelusz, M. Carbon nanotubes influence on the compressive strength of cement composites. Tech. Trans. 2014, 5–11. [Google Scholar]

- Manzur, T.; Yazdani, N. Optimum mix ratio for carbon nanotubes in cement mortar. KSCE J. Civ. Eng. 2015, 19, 1405–1412. [Google Scholar] [CrossRef]

- Campillo, I.; Guerrero, A.; Dolado, J.S.; Porro, A.; Ibáñez, J.A.; Goñi, S. Improvement of initial mechanical strength by nanoalumina in belite cements. Mater. Lett. 2007, 61, 1889–1892. [Google Scholar] [CrossRef]

- Chan, L.Y.; Andrawes, B. Finite element analysis of carbon nanotube/cement composite with degraded bond strength. Comput. Mater. Sci. 2010, 47, 994–1004. [Google Scholar] [CrossRef]

- Shah, S.P.; Hou, P.; Konsta-Gdoutos, M.S. Nano-modification of cementitious material: Toward a stronger and durable concrete. J. Sustain. Cem. Mater. 2015, 5, 1–22. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Hu, Y.; Shenderova, O.A.; Hu, Z.; Padgett, C.W.; Brenner, D.W. Carbon nanostructures for advanced composites. Rep. Prog. Phys. 2006, 69, 1847–1895. [Google Scholar] [CrossRef]

- EN 934-2 Admixtures for Concrete, Mortar and Grout Part 2. Concrete Admixtures—Definitions and Requirements; European Standard: Brussels, Belgium, 1998.

- EN 196-1 Methods of Testing Cement—Part 1: Determination of Strength; European Standard: Brussels, Belgium, 2016.

- EN 14579. Natural Stone Test Methods. Determination of Sound Speed Propagation; European Standard: Brussels, Belgium, 2004.

- Montgomery, D.C. Introduction to Statistical Quality Control, 7th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Chaipanich, A.; Rianyoi, R.; Nochaiya, T. The effect of carbon nanotubes and silica fume on compressive strength and flexural strength of cement mortars. Mater. Today Proc. 2017, 4, 6065–6071. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N. Strength enhancement of cement mortar with carbon nanotubes: Early results and potential. J. Transp. Res. Board 2010, 102–108. [Google Scholar] [CrossRef]

- Reales, O.A.M.; Filho, R.D.T. A review on the chemical, mechanical and microstructural characterization of carbon nanotubes-cement based composites. Constr. Build. Mater. 2017, 154, 697–710. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Li, W.-W.; Ji, W.-M.; Wang, Y.-C.; Liu, Y.; Shen, R.-X.; Xing, F.; Mancusi, G. Investigation on the Mechanical Properties of a Cement-Based Material Containing Carbon Nanotube under Drying and Freeze-Thaw Conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Seo, J.T.; Konsta-gdoutos, M.S.; Hersam, M.C.; Shah, S.P. Cement & Concrete Composites Highly concentrated carbon nanotube admixture for nano-fiber reinforced cementitious materials. Cem. Concr. Compos. 2012, 34, 612–617. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J. Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr. Build. Mater. 2019, 198, 70–81. [Google Scholar] [CrossRef]

- Dalla, P.T.; Tragazikis, I.K.; Exarchos, D.A.; Dassios, K.G.; Barkoula, N.M.; Matikas, T.E. Effect of Carbon Nanotubes on Chloride Penetration in Cement Mortars. Appl. Sci. 2019, 9, 1032. [Google Scholar] [CrossRef]

- Makar, J.M.; Chan, G.W. Growth of Cement Hydration Products on Single-Walled Carbon Nanotubes. J. Am. Ceram. Soc. 2009, 92, 1303–1310. [Google Scholar] [CrossRef]

- Morsy, M.; Alsayed, S.; Aqel, M. Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar. Constr. Build. Mater. 2011, 25, 145–149. [Google Scholar] [CrossRef]

| Sand | Cement | Water | SP (1%) | Carbon Nanotube (CNT) |

|---|---|---|---|---|

| 1200 | 400 | 200 | 4 | 0 |

| 1200 | 400 | 200 | 4 | 0.8 |

| 1200 | 400 | 200 | 4 | 1.6 |

| 1200 | 400 | 200 | 4 | 2.4 |

| MINITAB-Design Table | ||||||||

|---|---|---|---|---|---|---|---|---|

| StdOrder | RunOrder | PtType | Blocks | % CNT | Age | σc (MPa) | σtr (MPa) | DEM (GPa) |

| 1 | 1 | 1 | 1 | 0.0 | 3 | 22.23 | 2.85 | 21.821 |

| 2 | 2 | 1 | 1 | 0.0 | 7 | 26.60 | 2.69 | 21.759 |

| 3 | 3 | 1 | 1 | 0.0 | 28 | 29.10 | 2.98 | 22.713 |

| 4 | 4 | 1 | 1 | 0.2 | 3 | 23.57 | 2.80 | 22.238 |

| 5 | 5 | 1 | 1 | 0.2 | 7 | 30.65 | 3.13 | 22.051 |

| 6 | 6 | 1 | 1 | 0.2 | 28 | 28.54 | 3.45 | 22.904 |

| 7 | 7 | 1 | 1 | 0.4 | 3 | 29.27 | 3.18 | 26.821 |

| 8 | 8 | 1 | 1 | 0.4 | 7 | 35.58 | 3.34 | 26.809 |

| 9 | 9 | 1 | 1 | 0.4 | 28 | 40.39 | 4.34 | 28.626 |

| 10 | 10 | 1 | 1 | 0.6 | 3 | 23.46 | 2.88 | 20.989 |

| 11 | 11 | 1 | 1 | 0.6 | 7 | 24.83 | 3.17 | 23.956 |

| 12 | 12 | 1 | 1 | 0.6 | 28 | 25.81 | 3.06 | 25.685 |

| 13 | 13 | 1 | 1 | 0.0 | 3 | 26.75 | 2.32 | 21.743 |

| 14 | 14 | 1 | 1 | 0.0 | 7 | 24.87 | 2.74 | 22.046 |

| 15 | 15 | 1 | 1 | 0.0 | 28 | 30.04 | 3.34 | 23.521 |

| 16 | 16 | 1 | 1 | 0.2 | 3 | 22.11 | 2.69 | 21.470 |

| 17 | 17 | 1 | 1 | 0.2 | 7 | 26.18 | 3.22 | 22.729 |

| 18 | 18 | 1 | 1 | 0.2 | 28 | 32.45 | 3.63 | 22.611 |

| 19 | 19 | 1 | 1 | 0.4 | 3 | 29.49 | 3.22 | 27.045 |

| 20 | 20 | 1 | 1 | 0.4 | 7 | 38.39 | 3.61 | 27.274 |

| 21 | 21 | 1 | 1 | 0.4 | 28 | 38.77 | 4.12 | 28.613 |

| 22 | 22 | 1 | 1 | 0.6 | 3 | 23.68 | 2.64 | 22.377 |

| 23 | 23 | 1 | 1 | 0.6 | 7 | 27.54 | 2.70 | 24.975 |

| 24 | 24 | 1 | 1 | 0.6 | 28 | 27.36 | 3.18 | 25.011 |

| 25 | 25 | 1 | 1 | 0.0 | 3 | 19.04 | 3.53 | 21.341 |

| 26 | 26 | 1 | 1 | 0.0 | 7 | 27.35 | 3.25 | 21.612 |

| 27 | 27 | 1 | 1 | 0.0 | 28 | 31.61 | 3.26 | 22.960 |

| 28 | 28 | 1 | 1 | 0.2 | 3 | 26.15 | 3.05 | 22.008 |

| 29 | 29 | 1 | 1 | 0.2 | 7 | 26.06 | 2.82 | 21.914 |

| 30 | 30 | 1 | 1 | 0.2 | 28 | 31.81 | 3.72 | 21.883 |

| 31 | 31 | 1 | 1 | 0.4 | 3 | 30.71 | 3.38 | 27.259 |

| 32 | 32 | 1 | 1 | 0.4 | 7 | 37.59 | 4.13 | 28.040 |

| 33 | 33 | 1 | 1 | 0.4 | 28 | 40.54 | 4.08 | 28.897 |

| 34 | 34 | 1 | 1 | 0.6 | 3 | 22.41 | 2.63 | 23.460 |

| 35 | 35 | 1 | 1 | 0.6 | 7 | 24.26 | 3.09 | 24.669 |

| 36 | 36 | 1 | 1 | 0.6 | 28 | 27.05 | 3.58 | 25.152 |

| Age | Compressive Strength (MPa) (Average) | |||

|---|---|---|---|---|

| CN0 | CN2 | CN4 | CN6 | |

| 3 days | 22.67 | 23.94 | 29.82 | 23.18 |

| 7 days | 26.27 | 27.63 | 37.19 | 25.54 |

| 28 days | 30.25 | 30.93 | 39.90 | 26.74 |

| Age | Splitting Tensile Strength (MPa) (Average) | |||

|---|---|---|---|---|

| CN0 | CN2 | CN4 | CN6 | |

| 3 days | 2.90 | 2.85 | 3.26 | 2.72 |

| 7 days | 2.89 | 3.06 | 3.69 | 2.99 |

| 28 days | 3.19 | 3.60 | 4.18 | 3.27 |

| CN0 | CN0 | CN0 | CN4 | CN4 | CN4 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Load (kN) | Def. (mm) | Load (kN) | Def. (mm) | Load (kN) | Def. (mm) | Load (kN) | Def. (mm) | Load (kN) | Def. (mm) | Load (kN) | Def. (mm) |

| 0.0440 | 2.83 | 0.5405 | 3.06 | 1.7723 | 3.33 | 0.0314 | 1.66 | 0.1885 | 1.84 | 0.8107 | 2.22 |

| 0.0566 | 2.84 | 0.5719 | 3.07 | 1.8477 | 3.34 | 0.0314 | 1.66 | 0.2137 | 1.86 | 0.8233 | 2.24 |

| 0.0691 | 2.85 | 0.6159 | 3.08 | 1.9043 | 3.35 | 0.0377 | 1.66 | 0.2388 | 1.88 | 0.8610 | 2.26 |

| 0.0754 | 2.85 | 0.6662 | 3.10 | 1.9169 | 3.36 | 0.0440 | 1.67 | 0.2640 | 1.89 | 0.8862 | 2.29 |

| 0.0754 | 2.86 | 0.6976 | 3.11 | 1.9294 | 3.37 | 0.0503 | 1.67 | 0.3080 | 1.91 | 0.9050 | 2.31 |

| 0.0880 | 2.87 | 0.7542 | 3.13 | 1.9483 | 3.38 | 0.0503 | 1.67 | 0.3582 | 1.93 | 1.0307 | 2.34 |

| 0.1006 | 2.88 | 0.7982 | 3.14 | 1.9609 | 3.40 | 0.0628 | 1.68 | 0.3959 | 1.94 | 1.1375 | 2.36 |

| 0.1194 | 2.89 | 0.8673 | 3.16 | 1.9671 | 3.41 | 0.0628 | 1.69 | 0.4588 | 1.96 | 1.2758 | 2.38 |

| 0.1320 | 2.90 | 0.9239 | 3.17 | 1.9609 | 3.42 | 0.0691 | 1.69 | 0.4902 | 1.98 | 1.4141 | 2.40 |

| 0.1445 | 2.91 | 0.9679 | 3.18 | 1.9169 | 3.44 | 0.0691 | 1.70 | 0.5531 | 1.99 | 1.5209 | 2.42 |

| 0.1571 | 2.92 | 1.0307 | 3.20 | 1.8729 | 3.45 | 0.0754 | 1.71 | 0.6033 | 2.01 | 1.6780 | 2.44 |

| 0.1823 | 2.93 | 1.0873 | 3.21 | 1.7912 | 3.47 | 0.0754 | 1.72 | 0.6850 | 2.03 | 1.7912 | 2.45 |

| 0.2074 | 2.94 | 1.1627 | 3.22 | 1.6655 | 3.49 | 0.0817 | 1.72 | 0.7416 | 2.04 | 1.9357 | 2.47 |

| 0.2388 | 2.95 | 1.2381 | 3.24 | 1.6089 | 3.51 | 0.0817 | 1.74 | 0.8045 | 2.06 | 2.0740 | 2.48 |

| 0.2828 | 2.97 | 1.2884 | 3.25 | 1.5775 | 3.54 | 0.0943 | 1.75 | 0.8484 | 2.08 | 2.1682 | 2.49 |

| 0.3142 | 2.98 | 1.3701 | 3.26 | 1.6215 | 3.56 | 0.1006 | 1.76 | 0.8547 | 2.09 | 2.2814 | 2.50 |

| 0.3582 | 2.99 | 1.4329 | 3.27 | 2.0928 | 3.58 | 0.1131 | 1.77 | 0.8107 | 2.11 | 2.3631 | 2.51 |

| 0.3897 | 3.00 | 1.5083 | 3.29 | 2.3694 | 3.60 | 0.1257 | 1.78 | 0.8045 | 2.13 | 2.4699 | 2.52 |

| 0.4336 | 3.02 | 1.5838 | 3.30 | 2.4573 | 3.61 | 0.1383 | 1.80 | 0.7982 | 2.15 | 2.5768 | 2.53 |

| 0.4714 | 3.03 | 1.6466 | 3.31 | 2.5453 | 3.63 | 0.1445 | 1.81 | 0.7919 | 2.17 | 2.6396 | 2.54 |

| 0.5028 | 3.04 | 1.7157 | 3.32 | 2.6145 | 3.64 | 0.1697 | 1.83 | 0.7919 | 2.19 | 2.7276 | 2.55 |

| 2.7842 | 2.55 | ||||||||||

| 2.9959 | 2.56 | ||||||||||

| Samples | Measurements | Results | ||||

|---|---|---|---|---|---|---|

| Wet Weight (g) | Saturated Weight (g) | Dry Weight (g) | Apparent Density (g/cm3)s | Density (g/cm3) | Porosity (%) | |

| CN0-S1 | 63.06 | 132.76 | 118.20 | 1.87 | 2.44 | 23.10 |

| CN0-S2 | 65.34 | 140.49 | 125.98 | 1.93 | 2.48 | 22.20 |

| Average | 64.20 | 136.63 | 122.09 | 1.90 | 2.46 | 22.65 |

| CN2-S1 | 55.96 | 120.02 | 107.53 | 1.92 | 2.47 | 22.30 |

| CN2-S2 | 85.73 | 185.44 | 165.96 | 1.94 | 2.51 | 22.70 |

| Average | 70.85 | 152.73 | 136.75 | 1.93 | 2.49 | 22.50 |

| CN4-S1 | 31.88 | 71.93 | 65.94 | 2.07 | 2.55 | 18.80 |

| CN4-S2 | 60.12 | 132.41 | 120.52 | 2.00 | 2.50 | 19.80 |

| Average | 46.00 | 102.17 | 93.23 | 2.04 | 2.52 | 19.30 |

| CN6-S1 | 39.64 | 83.42 | 74.15 | 1.87 | 2.44 | 23.40 |

| CN6-S1 | 60.53 | 127.71 | 113.02 | 1.87 | 2.47 | 24.30 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evangelista, A.C.J.; de Morais, J.F.; Tam, V.; Soomro, M.; Di Gregorio, L.T.; Haddad, A.N. Evaluation of Carbon Nanotube Incorporation in Cementitious Composite Materials. Materials 2019, 12, 1504. https://doi.org/10.3390/ma12091504

Evangelista ACJ, de Morais JF, Tam V, Soomro M, Di Gregorio LT, Haddad AN. Evaluation of Carbon Nanotube Incorporation in Cementitious Composite Materials. Materials. 2019; 12(9):1504. https://doi.org/10.3390/ma12091504

Chicago/Turabian StyleEvangelista, Ana Catarina Jorge, Jorge Fernandes de Morais, Vivian Tam, Mahfooz Soomro, Leandro Torres Di Gregorio, and Assed N. Haddad. 2019. "Evaluation of Carbon Nanotube Incorporation in Cementitious Composite Materials" Materials 12, no. 9: 1504. https://doi.org/10.3390/ma12091504

APA StyleEvangelista, A. C. J., de Morais, J. F., Tam, V., Soomro, M., Di Gregorio, L. T., & Haddad, A. N. (2019). Evaluation of Carbon Nanotube Incorporation in Cementitious Composite Materials. Materials, 12(9), 1504. https://doi.org/10.3390/ma12091504