Effect of Porosity on Dynamic Mechanical Properties and Impact Response Characteristics of High Aluminum Content PTFE/Al Energetic Materials

Abstract

1. Introduction

2. Experimental Methods

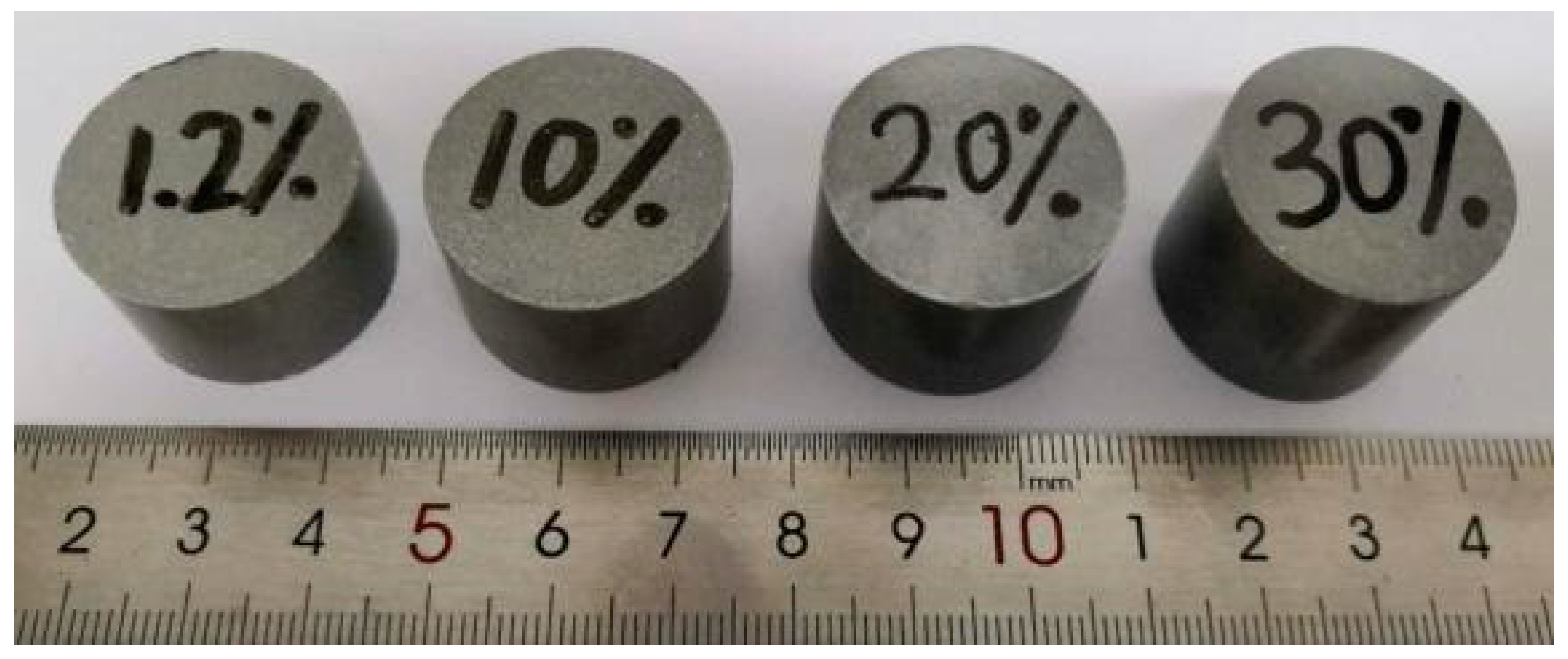

2.1. Material Preparation

2.2. Material Properties

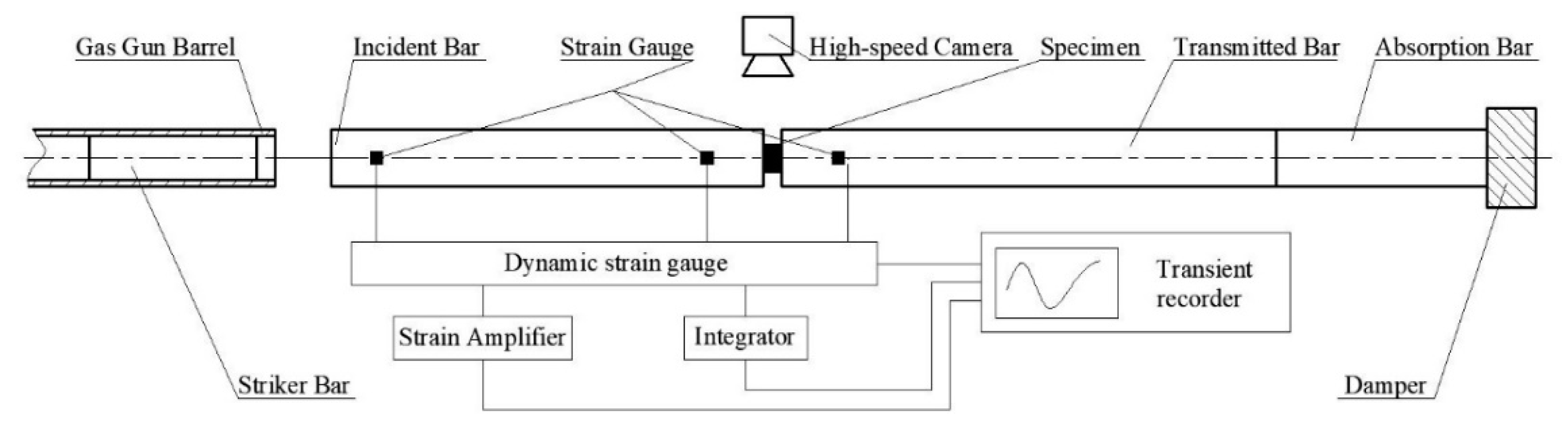

2.3. Dynamic Loading Experiment

3. Results and Discussion

3.1. Impact Response Characteristics of Porous PTFE/Al Energetic Materials

3.1.1. Impact Reaction of Porous PTFE/Al

3.1.2. Impact Reaction of Porous PTFE/Al

3.2. Dynamic Compression Mechanical Properties of Porous PTFE/Al Energetic Materials

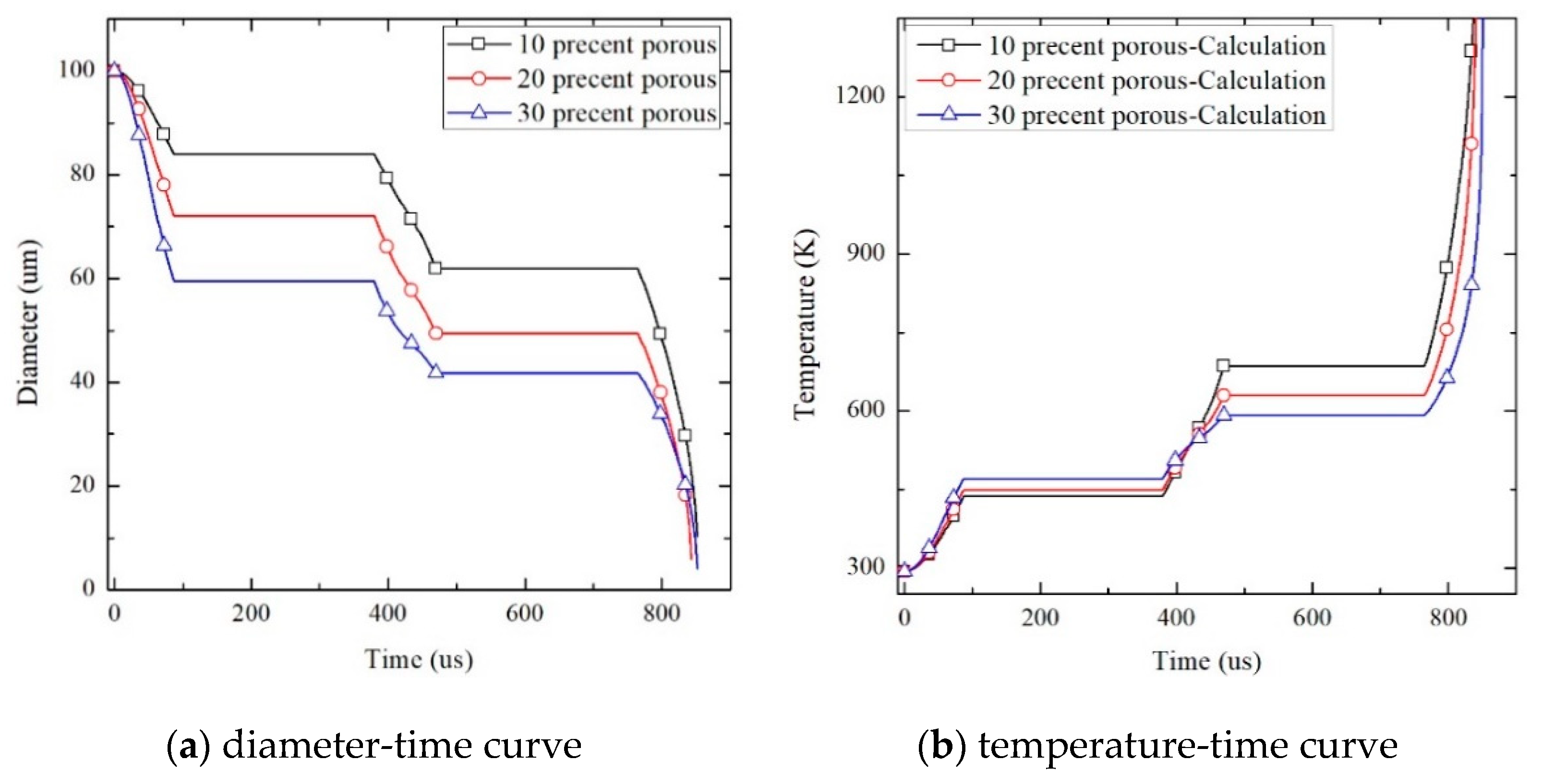

3.3. Ignition Reaction Mechanism of PTFE / Al with Temperature Rise

- (1)

- The flow field near the hole is spherically symmetric;

- (2)

- The viscoplastic region and the melting region are dense and incompressible;

- (3)

- Approximate shock loading process with constant pressure P at the outer boundary of the cell;

- (4)

- The PTFE/Al composite material melts at the melting point of PTFE, and the temperature rise near the hole is related to the radius.

4. Conclusions

- (1)

- Under dynamic compressive loading conditions, PTFE/Al energetic materials exhibit strain rate effects. At the same strain rate, as the porosity increases from 1.2% to 30%, the yield strength of the material decreases from 29.4~49.8 MPa to 14.6~26.0 MPa, and the compressive strength of the material decreases from 60.3~78.6 MPa to 30.2~40.5 MPa. Failure strains at strain rates of 4040~4413 s−1, 5000~5204 s−1, 5668~5918 s−1 are about 0.31, 0.39, 0.48, respectively.

- (2)

- With the increase of porosity, the ignition delay time of the material is basically unchanged, while the reaction duration generally becomes gradually shorter. When the strain rate is 5600~6000 s−1, the ignition delay time is basically maintained between 850 and 900 μs. When the porosity is increased from 1.2% to 30%, the reaction duration is reduced from 3300 to 1550 μs, which is reduced by about 39.6%.

- (3)

- There is a critical strain rate for the reaction of PTFE/Al energetic materials. When the strain rate is lower than this value, the reaction will not occur. The material response has the optimal porosity with the lowest critical strain rate, the optimal porosity of the high aluminum content PTFE/Al energetic material (50/50 mass ratio, size of specimens Φ8 × 5 mm) with a porosity of 1.2%, 10%, 20%, and 30% measured by experiments is 10%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Koch, E.C. Metal-Fluorocarbon Based Energetic Materials; Wiley-VCH Verlag Gmbh & Co. KGa A: Weinheim, Germany, 2012; pp. 6–17. [Google Scholar]

- Shen, Y. The Chemical and Mechanical Behaviors of Polymer/Reactive Metal Systems under High Strain Rates. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2012. [Google Scholar]

- Wu, J.-X.; Fang, X.; Gao, Z.-R.; Wang, H.-X.; Huang, J.-Y.; Wu, S.-Z.; Li, Y.-C. Investigation on Mechanical Properties and Reaction Characteristics of Al-PTFE Composites with Different Al Particle Size. Adv. Mater. Sci. Eng. 2018, 2018, 2767863. [Google Scholar] [CrossRef]

- McGregor, N.M.; Sutherland, G.T. Plate Impact Experiments on a Porous Teflflon-Aluminum Mixture. Shock Compress. Condens. Matter 2003, 706, 1001–1004. [Google Scholar]

- Dolgoborodov, A.Y.; Makhov, M.N.; Kolbanev, I.V.; StreletskiÏ, A.N.; Fortov, V.E. Detonation in an Aluminum-Teflflon Mixture. JETP Lett. 2005, 81, 311–314. [Google Scholar] [CrossRef]

- Koch, E.-C.; Webb, R.; Weiser, V. Review on Thermo chemical Codes; NATO-Munitions Safety Information Analysis Center: Brussels, Belgium, 2009. [Google Scholar]

- Feng, B.; Li, Y.-C.; Wu, S.-Z.; Wang, H.-X.; Tao, Z.-M.; Fang, X. A crack-induced initiation mechanism of Al-PTFE under quasi-static compression and the investigation of influencing factors. Mater. Des. 2016, 108, 411–417. [Google Scholar] [CrossRef]

- Nielson, D.B.; Tanner, R.L.; Lund, G.K. High Strength Reactive Materials and Methods of Making. U.S. Patent 7,307,117, 11 December 2007. [Google Scholar]

- Zhang, J. Research on Damage Remanufacturing on Ni-base Superalloys with High Al+Ti Content by Powder Metallurgy Method. Ph.D. Thesis, Northeastern University, Shenyang, China, 2015; pp. 49–53. (In Chinese). [Google Scholar]

- Cai, J.; Walley, S.; Hunt, R.; Proud, W.; Nesterenko, V.; Meyers, M. High-strain, high-strain-rate flow and failure in PTFE/Al/W granular composites. Mater. Sci. Eng. A 2008, 472, 308–315. [Google Scholar] [CrossRef]

- Duan, Z.-P.; Wen, L.-J.; Liu, Y.; Ou, Z.-C.; Huang, F.-L.; Zhang, Z.-Y. A Pore Collapse Model for Hot-spot Ignition in Shocked Multi-component Explosives. Int. J. Nonlinear Sci. Numer. Simul. 2010, 11, 19–24. [Google Scholar] [CrossRef]

- Field, J.E.; Swallowe, G.M.; Heavens, S.N. Ignition Mechanisms of Explosives during Mechanical Deformation. Proc. R. Soc. A Math. Phys. Eng. Sci. 1982, 382, 231–244. [Google Scholar] [CrossRef]

- Field, J.E. Hot spot ignition mechanisms for explosives. Acc. Chem. Res. 1992, 25, 489–496. [Google Scholar] [CrossRef]

- Winter, R.E.; Field, J.E. The Role of Localized Plastic Flow in the Impact Initiation of Explosives. Proc. R. Soc. A Math. Phys. Eng. Sci. 1975, 343, 399–413. [Google Scholar] [CrossRef]

- Kornfeld, M.; Suvorov, L. On the Destructive Action of Cavitation. J. Appl. Phys. 1944, 15, 495. [Google Scholar] [CrossRef]

- Kang, J.; Butler, P.; Baer, M. A thermomechanical analysis of hot spot formation in condensed-phase, energetic materials. Combust. Flame 1992, 89, 117–139. [Google Scholar] [CrossRef]

- Carroll, M.M.; Kim, K.T.; Nesterenko, V.F. The effect of temperature on viscoplastic pore collapse. J. Appl. Phys. 1986, 59, 1962–1967. [Google Scholar] [CrossRef]

- Whitworth, N.J. Mathematical and Numerical Modeling of Shock Initiation in Heterogeneous Solid Explosives. Ph.D. Thesis, Cranfield University, Bedfordshire, UK, 2008. [Google Scholar]

- Zhang, Z.; Shi, H.; Fangyun, L.; Wenhui, Z. Viscoplastic Collapse Mechanism of Hot-spot Formation in Porous TNT Explosives. Chin. J. Energetic Mater. 1994, 2, 36–48. (In Chinese) [Google Scholar]

- Meyers, M.A. Mechanical Behavior of Materials; Prentice Hall: Upper Saddle River, NJ, USA, 1998; pp. 62–97. [Google Scholar]

- Frey, R.B. The initiation of explosive charges by rapid shear. In Proceedings of the 7th Symposium on Detonation, Annapolis, MD, USA, 16–19 June 1981; pp. 36–42. [Google Scholar]

| Properties | Particle Size | Density | Softening Point | Melting Point |

|---|---|---|---|---|

| Value | 100 μm | 0.9 g/cm3 | 155 °C | 165 °C |

| Manufacturer | Zhongliansuhua Company, Dongguan, China | |||

| PTFE/Al | Masses before Sintering (g) | Masses after Sintering (g) | Balance Masses (g) | Masses of Additives (g) | Theoretical Porosity (%) | Measured Porosity (%) | Error (%) |

|---|---|---|---|---|---|---|---|

| Specimen 1 | 17.75 | 17.73 | 0.02 | 0 | 1.2 | 1.1 | 8.3 |

| Specimen 2 | 17.88 | 17.03 | 0.85 | 0.9 | 10 | 10.85 | 8.5 |

| Specimen 3 | 17.95 | 16.12 | 1.83 | 1.88 | 20 | 21.23 | 6.2 |

| Specimen 4 | 17.82 | 14.71 | 3.11 | 3.24 | 30 | 32.86 | 9.5 |

| Material Properties | Strain Rate (s−1) | Yield Strength (MPa) | Compressive Strength (MPa) | Failure Strain | Ignition Delay Time (µs) | Reaction Duration Time (µs) |

|---|---|---|---|---|---|---|

| PTFE/Al (Porosity 1.2%) | 4040 | 29.4 | 62.8 | 0.28 | Unreacted | - |

| 4413 | 32.2 | 60.3 | 0.34 | Unreacted | - | |

| 5000 | 38.8 | 70.5 | 0.37 | Unreacted | - | |

| 5183 | 36.7 | 67.8 | 0.34 | Unreacted | - | |

| 5668 | 45.0 | 78.6 | 0.51 | 900 | 2250 | |

| 5741 | 49.8 | 74.1 | 0.52 | 850 | 3300 | |

| PTFE/Al (Porosity 10%) | 4103 | 27.9 | 45.6 | 0.34 | Unreacted | - |

| 4146 | 33.2 | 46.0 | 0.32 | Unreacted | - | |

| 5121 | 28.9, | 48.7 | 0.31 | 850 | 250 | |

| 5159 | 28.0 | 49.5 | 0.32 | 900 | 100 | |

| 5698 | 36.2 | 54.6 | 0.45 | 850 | 1800 | |

| 5703 | 32.7 | 55.3 | 0.44 | 850 | 1600 | |

| PTFE/Al (Porosity 20%) | 4158 | 20.3 | 39.2 | 0.29 | Unreacted | - |

| 4199 | 26.4 | 40.3 | 0.29 | Unreacted | - | |

| 5127 | 31.3 | 46.8 | 0.40 | Unreacted | - | |

| 5154 | 23.2 | 44.9 | 0.38 | Unreacted | - | |

| 5744 | 32.8 | 47.6 | 0.51 | 850 | 2050 | |

| 5918 | 32.4 | 49.8 | 0.49 | 850 | 2200 | |

| PTFE/Al (Porosity 30%) | 4323 | 19.9 | 30.2 | 0.33 | Unreacted | - |

| 4355 | 14.6 | 31.5 | 0.33 | Unreacted | - | |

| 5195 | 21.7 | 36.6 | 0.43 | Unreacted | - | |

| 5204 | 15.7 | 36.7 | 0.4 | Unreacted | - | |

| 5698 | 26.0 | 39.2 | 0.49 | 850 | 1550 | |

| 5763 | 23.1 | 40.5 | 0.45 | 850 | 1800 |

| PTFE/Al Parameter | Value | Parameter | Value | |

|---|---|---|---|---|

| Yield stress Y (MPa) | Porosity 10% | 17.70 | Viscosity μ (Pa·s) | 1010 |

| Porosity 20% | 15.97 | Melting point temperature Tm (K) | 600 | |

| Porosity 30% | 12.62 | Activation temperature Em (K) | 3880 * | |

| Theoretical density ρT (Kg/m3) | 2.42 | Heat capacity coefficient Cv (J/g/k) | 1.59 | |

| Hole initial diameter a0 (μm) | 100 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Cai, S.; Mao, L.; Wang, Z. Effect of Porosity on Dynamic Mechanical Properties and Impact Response Characteristics of High Aluminum Content PTFE/Al Energetic Materials. Materials 2020, 13, 140. https://doi.org/10.3390/ma13010140

Jiang C, Cai S, Mao L, Wang Z. Effect of Porosity on Dynamic Mechanical Properties and Impact Response Characteristics of High Aluminum Content PTFE/Al Energetic Materials. Materials. 2020; 13(1):140. https://doi.org/10.3390/ma13010140

Chicago/Turabian StyleJiang, Chunlan, Shangye Cai, Liang Mao, and Zaicheng Wang. 2020. "Effect of Porosity on Dynamic Mechanical Properties and Impact Response Characteristics of High Aluminum Content PTFE/Al Energetic Materials" Materials 13, no. 1: 140. https://doi.org/10.3390/ma13010140

APA StyleJiang, C., Cai, S., Mao, L., & Wang, Z. (2020). Effect of Porosity on Dynamic Mechanical Properties and Impact Response Characteristics of High Aluminum Content PTFE/Al Energetic Materials. Materials, 13(1), 140. https://doi.org/10.3390/ma13010140