Static and Fatigue Behavior of Rubber-Sleeved Stud Shear Connectors as Part of Field-Cast Ultra-High Performance Concrete Connections

Abstract

:1. Introduction

2. Experiment Description

2.1. Push-Out Test Program

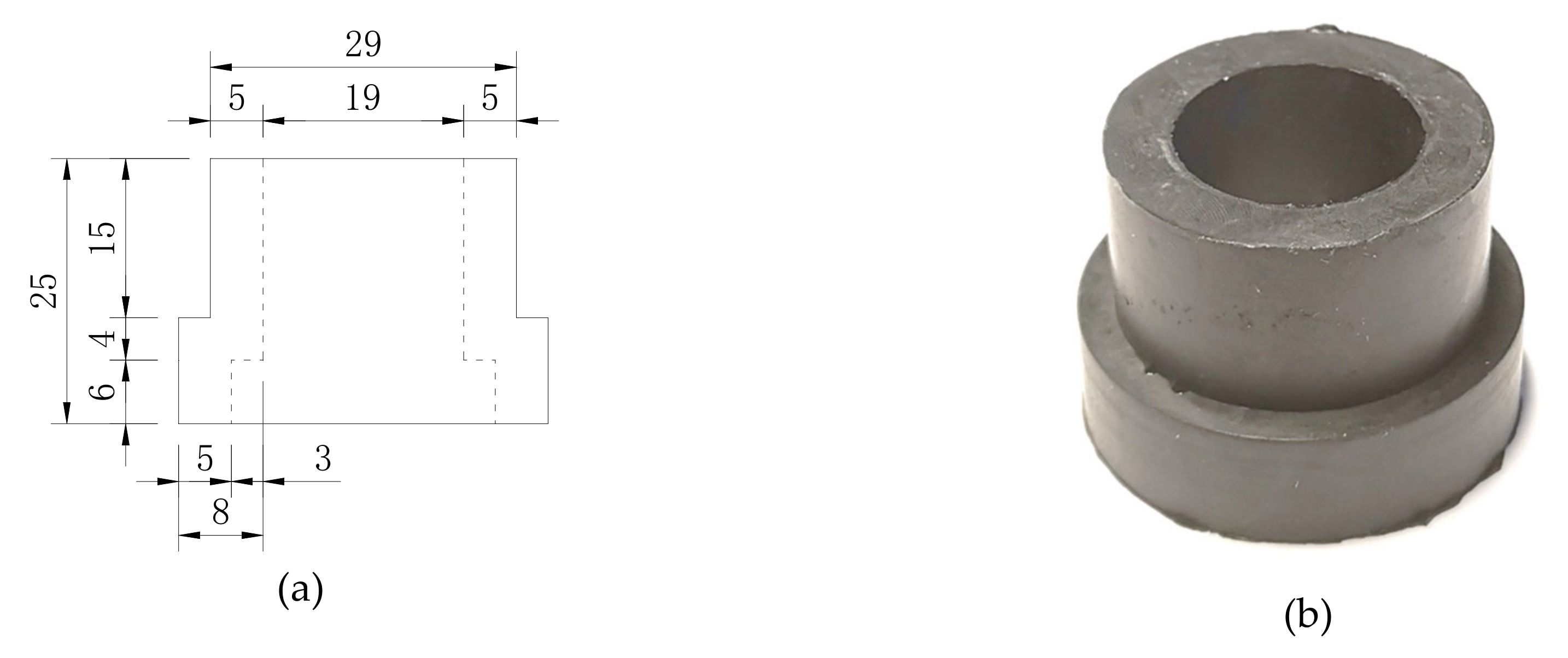

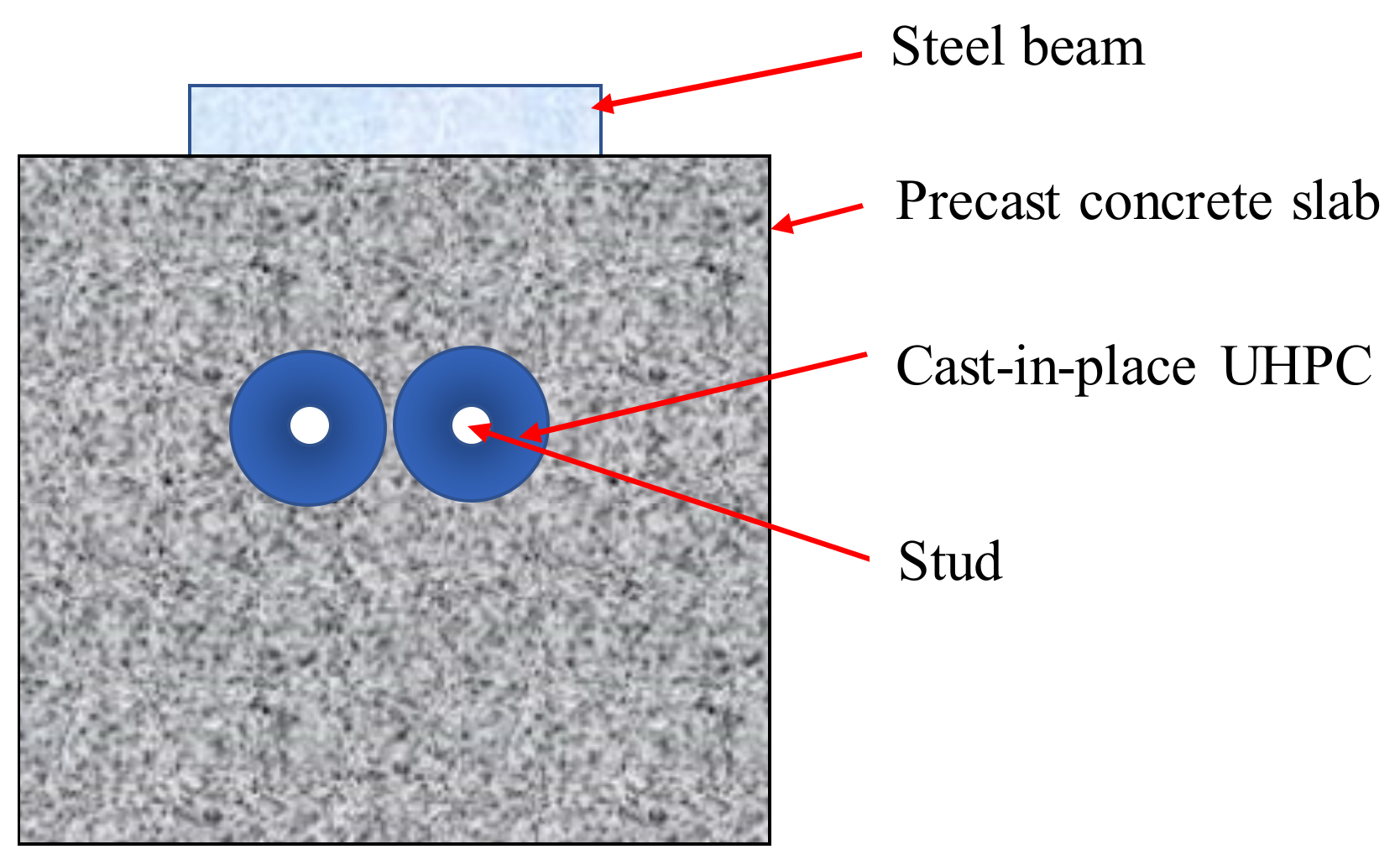

2.1.1. Test Specimens

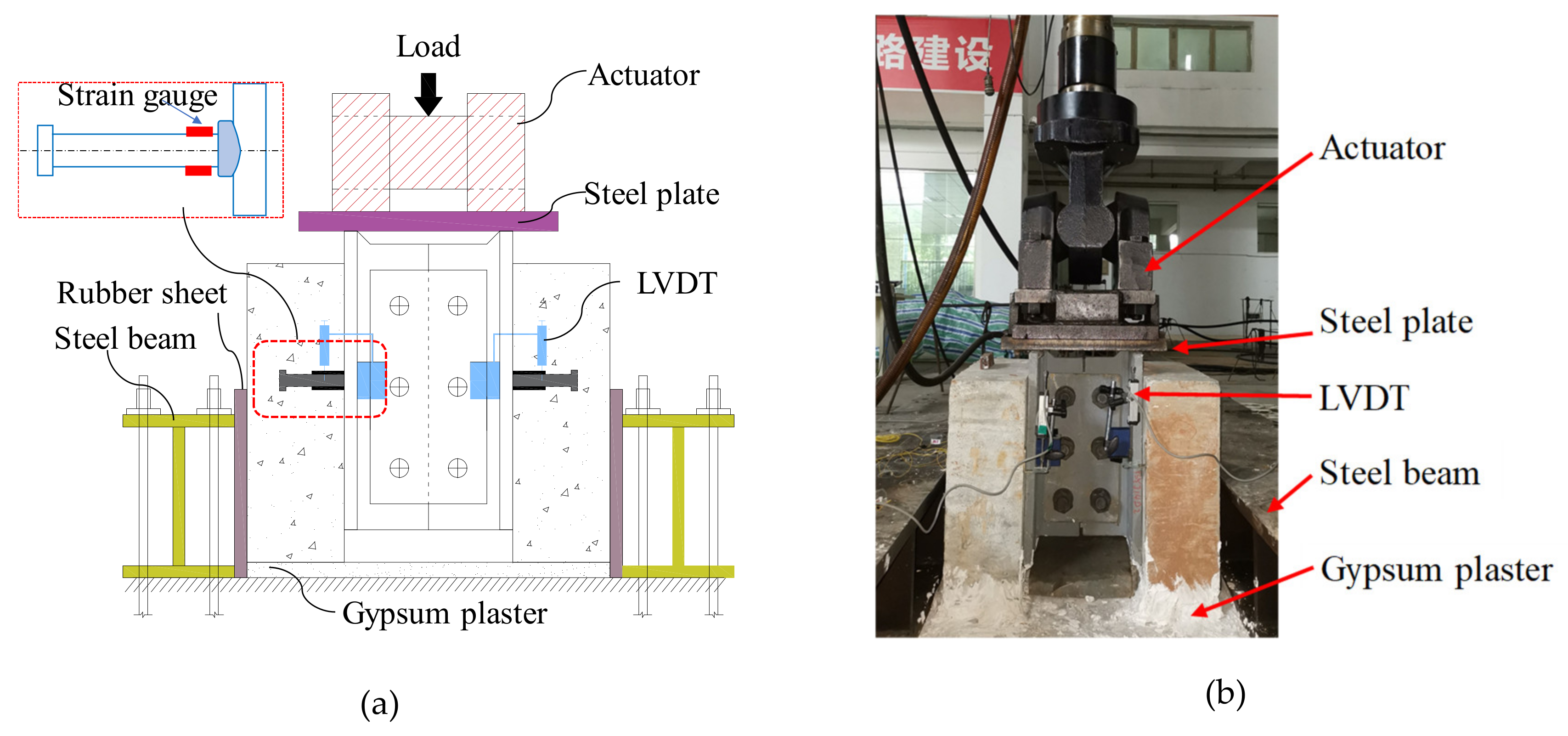

2.1.2. Test Setup

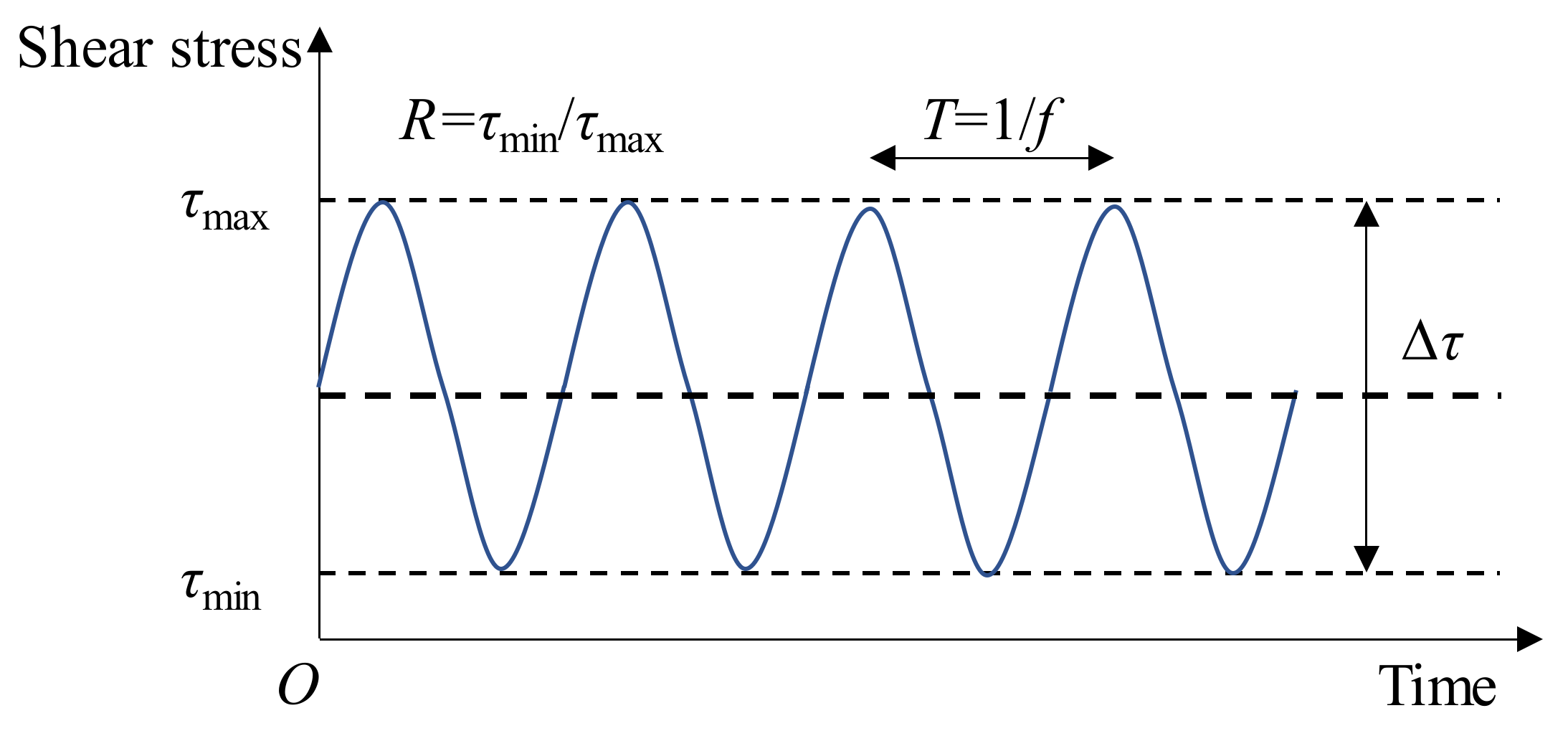

2.1.3. Loading and Measurement Scheme

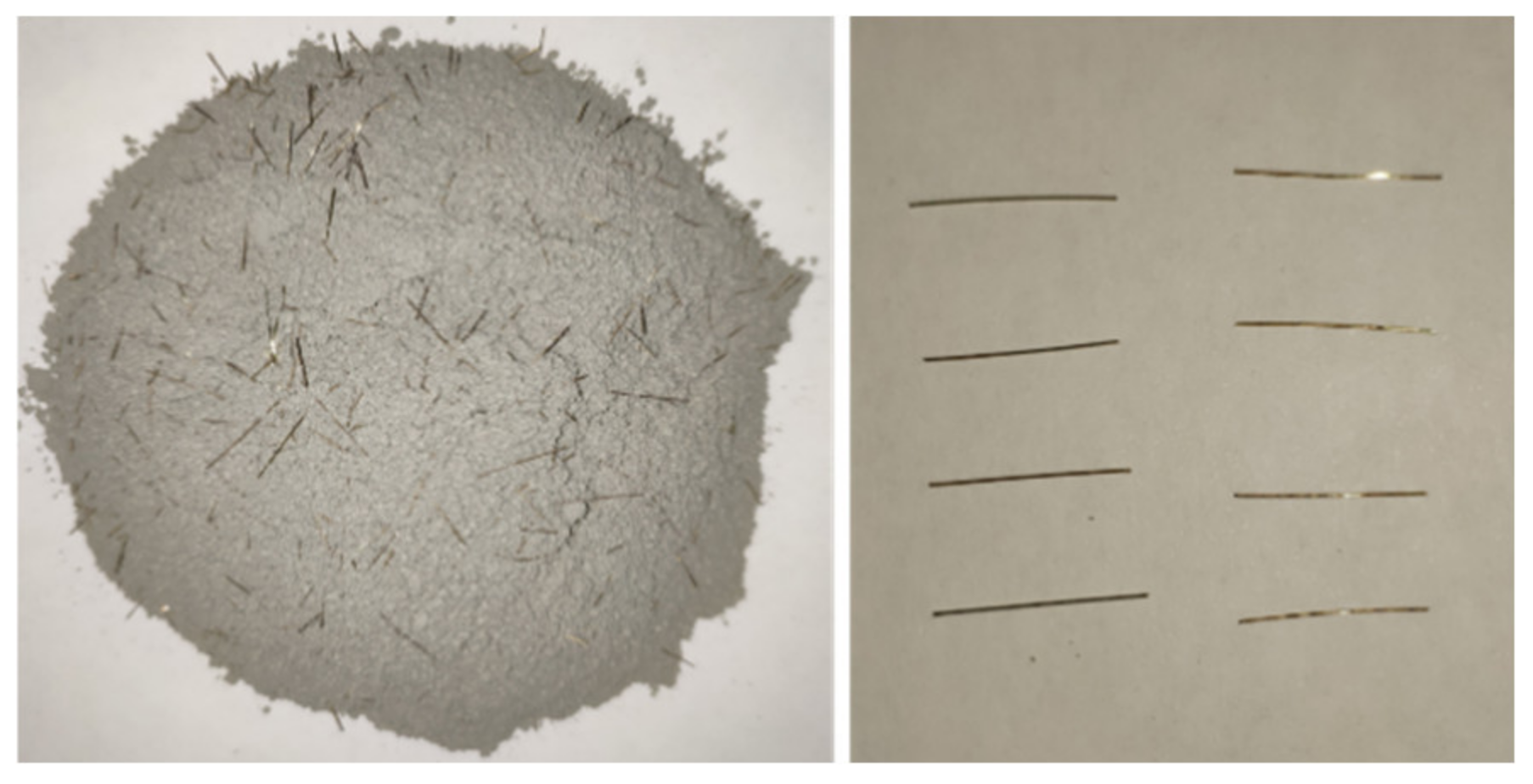

2.2. Specimen Fabrication

2.3. Material Properties

3. Static Behavior

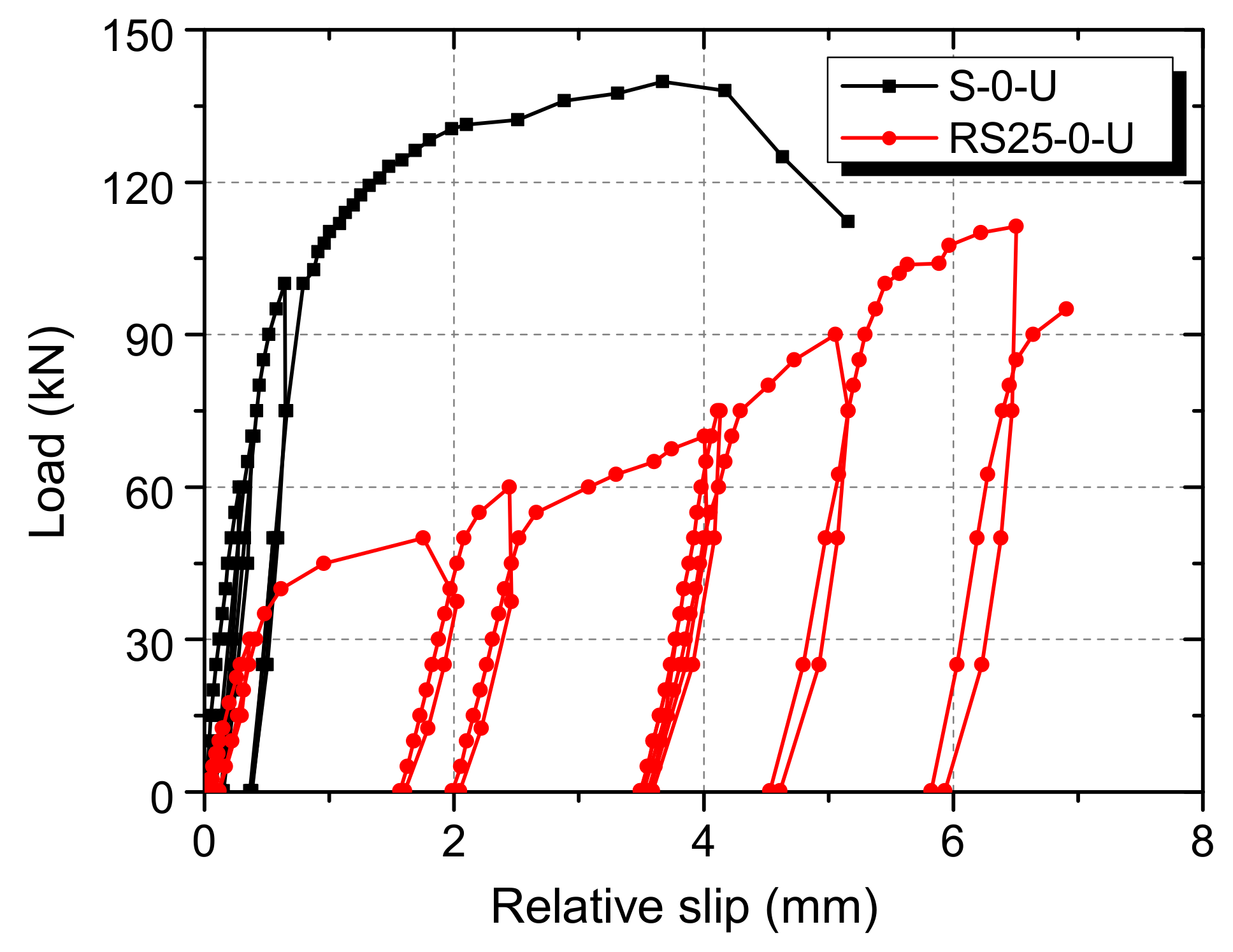

3.1. Load–Slip Curve

3.2. Shear Strength

3.3. Shear Stiffness

4. Fatigue Behavior

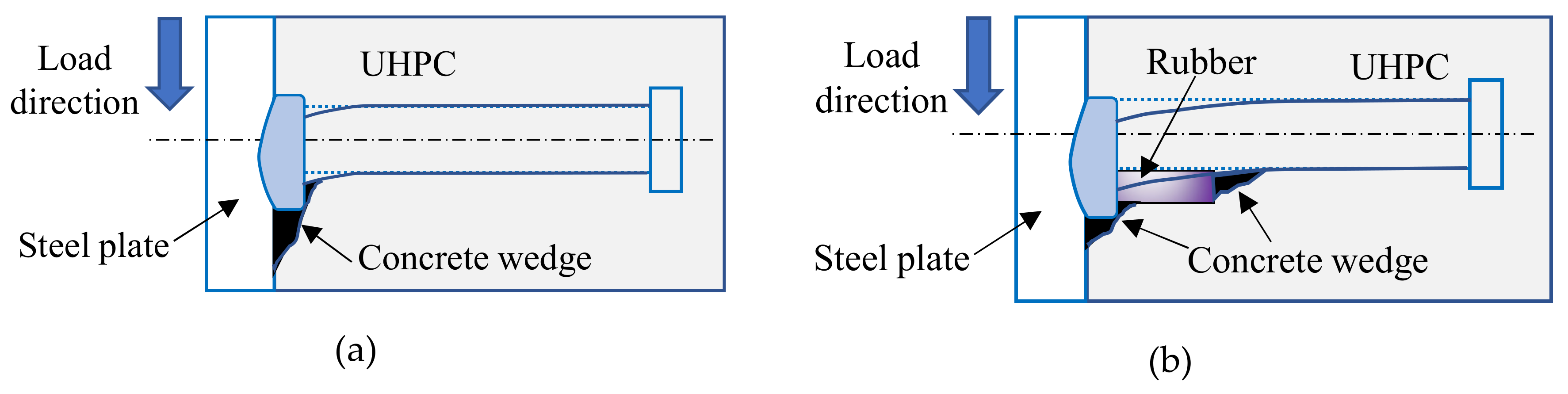

4.1. Fatigue Failure Modes

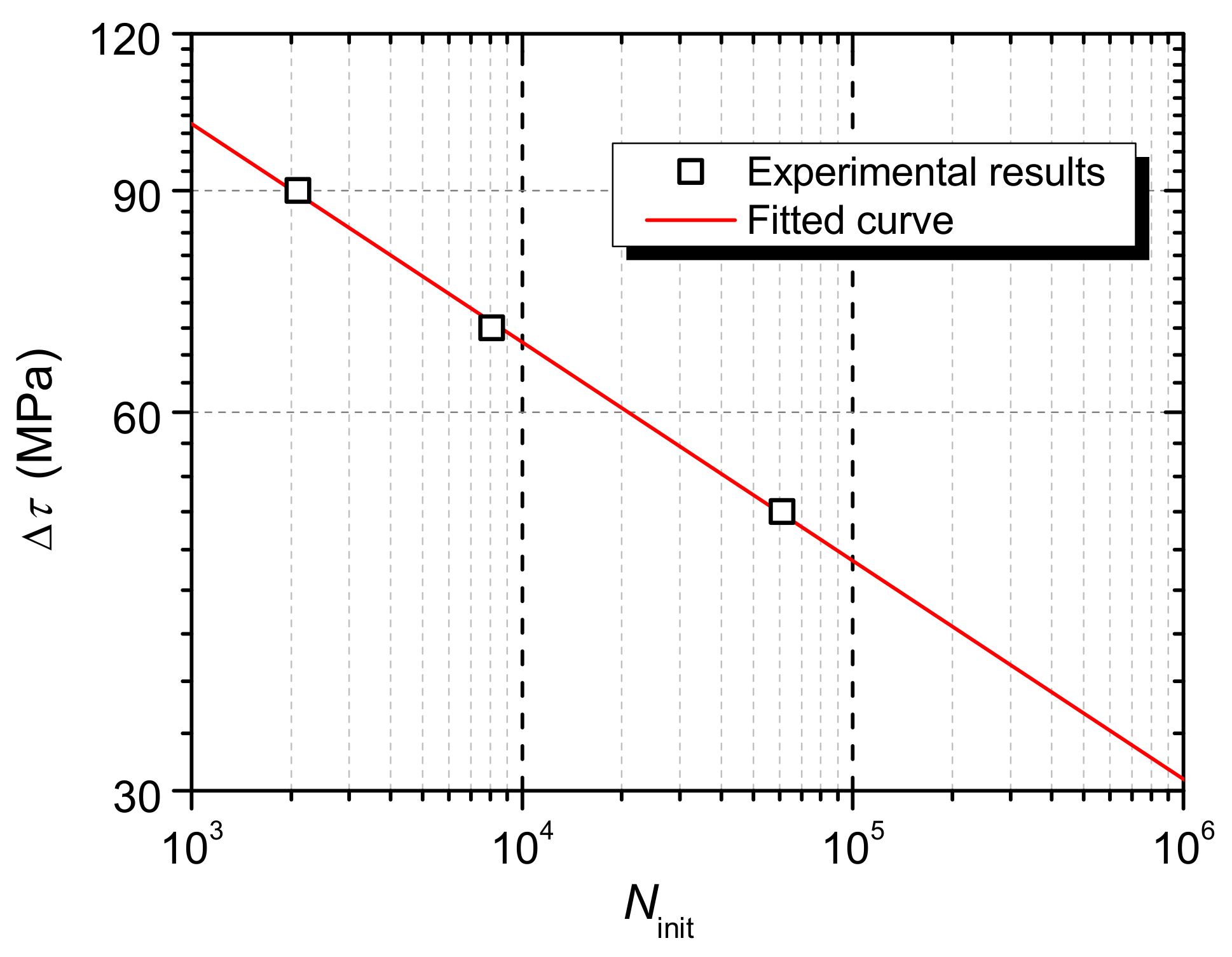

4.2. S-N Results

4.3. Results of Strain Gauges

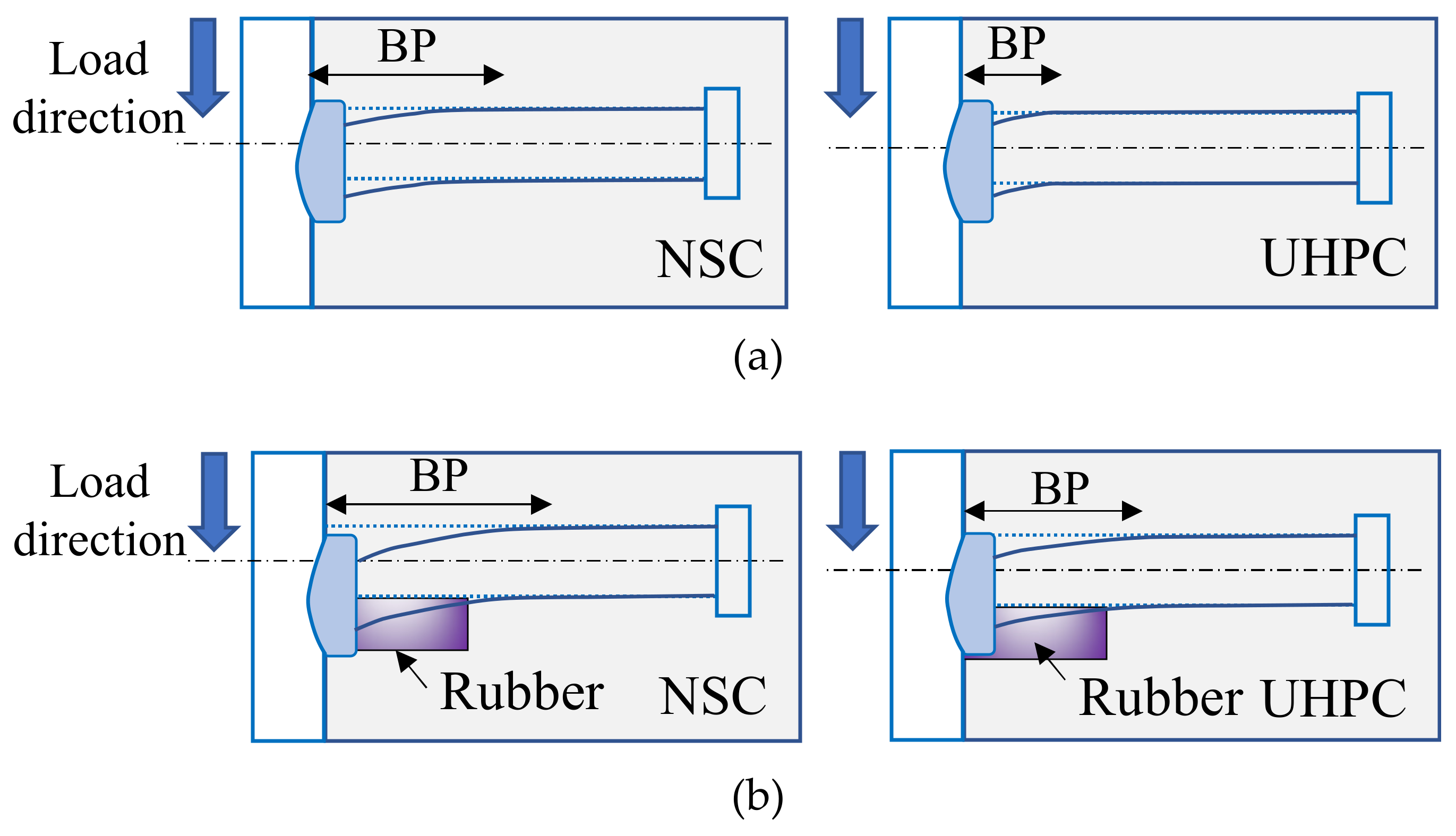

4.4. Results of Relative Slip and Discussion

4.4.1. Results of Relative Slip

4.4.2. Maximum Dynamic Relative Slip Evolution Law

5. Conclusions

- The slip capacities of ordinary stud and rubber-sleeved stud shear connectors are 4.6 mm and 6.9 mm, respectively. Rubber sleeves effectively improve the ductility of the shear connector in UHPC. Rubber-sleeved stud shear connectors have sufficient deformation capacity and can be used to achieve the plastic behavior of the field-cast UHPC connections in steel and concrete composite structures.

- Compared to ordinary stud shear connectors, UHPC with high compressive strength has a relatively small effect on improving the shear strength of the rubber-sleeve stud shear connector. When calculating its shear strength, it is not necessary to consider the favorable effect of UHPC and welded collars.

- The shear stiffness of the stud shear connector in UHPC decreases with the rubber sleeve height. The weld collar has less contribution to the increase in shear stiffness of the rubber-sleeved stud, and the increase in shear stiffness due to UHPC would decrease with the rubber sleeve height.

- The fatigue failure mode of the rubber-sleeve stud shear connector in UHPC is similar to that in NSC. Moreover, the S-N curve for the rubber-sleeved stud shear connector in NSC can well predict the fatigue life of the shear connector in UHPC.

- The results of strain gauges at stud roots were obtained. The change in the sign of the strain is supposed to be caused by the initiation and propagation of the fatigue crack. By taking the number of fatigue cycles when the sign of the strain starts to change as the crack initiation life, it was found that the crack initiation process consumes a small proportion of the fatigue life, which is about 5%. The crack initiation life decreases with the stress range, and a fitting formula is obtained.

- The evolution law of dynamic relative slip of rubber-sleeved stud shear connectors in UHPC are similar to those in NSC. Though UHPC improves the restraint to the stud deformation, the influence of rubber sleeves is still decisive in determining the fatigue behavior of rubber-sleeve stud shear connectors.

Author Contributions

Funding

Conflicts of Interest

References

- Shim, C.S.; Lee, P.G.; Chang, S.P. Design of shear connection in composite steel and concrete bridges with precast decks. J. Constr. Steel Res. 2001, 57, 203–219. [Google Scholar] [CrossRef]

- Morcous, R.G. Design of shear pocket connection in full-depth precast concrete deck systems. Eng. Struct. 2019, 179, 367–386. [Google Scholar]

- Bian, C.J.; Wang, Y. Mechanical and damage mechanisms of reinforced ultra high performance concrete under tensile loading. Constr. Build. Mater. 2019, 226, 259–279. [Google Scholar] [CrossRef]

- Wang, Y.H.; Yu, J.; Liu, J.P.; Chen, Y.F. Shear behavior of shear stud groups in precast concrete decks. Eng. Struct. 2019, 187, 73–84. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Hu, J.; Ma, H. Feasibility study of ECC with self-healing capacity applied on long-span steel bridge deck overlay. Int. J. Pavement Eng. 2019, 20, 884–893. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Qian, S.Z.; Ma, H. Investigating mechanical properties and self-healing behavior of micro-cracked ECC with different volume of fly ash. Constr. Build. Mater. 2014, 52, 17–23. [Google Scholar] [CrossRef]

- Xu, C.; Sugiura, K. Parametric push-out analysis on group studs shear connector under effect of bending-induced concrete cracks. J. Constr. Steel Res. 2013, 89, 86–97. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, Z.G. Paving an engineered cementitious composite (ECC) overlay on concrete airfield pavement for reflective cracking resistance. Constr. Build. Mater. 2020, 252, 119048. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Yuvaraj, A.; Di, J.; Qian, S.Z. Matrix design of light weight, high strength, high ductility ECC. Constr. Build. Mater. 2019, 210, 188–197. [Google Scholar] [CrossRef]

- Zhou, M.; Lu, W.; Song, J.; Lee, G.C. Application of ultra-high performance concrete in bridge engineering. Constr. Build. Mater. 2018, 186, 1256–1267. [Google Scholar] [CrossRef]

- Graybeal, B. Design and Construction of Field-Cast UHPC Connections; FHWA: Washington, DC, USA, 2014. [Google Scholar]

- Graybeal, B. Ultra-high-performance concrete connections for precast concrete bridge decks. PCI J. 2014, 59, 48–62. [Google Scholar] [CrossRef]

- Tazarv, M.; Bohn, L.; Wehbe, N. Rehabilitation of longitudinal joints in double-tee girder bridges. J. Bridge Eng. 2019, 24, 04019044. [Google Scholar] [CrossRef]

- Gautam, B.G.; Xiang, Y.; Liao, X.; Qiu, Z.; Guo, S. Experimental investigation of a slip in high-performance steel-concrete small box girder with different combinations of group studs. Materials 2019, 12, 2781. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, C.; Song, J.; Zhang, N.; Lee, G.C. Seismic performance of precast prestressed concrete bridge girders using field-cast ultrahigh-performance concrete connections. J. Bridge Eng. 2019, 24, 04019046. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Q.; Yao, Y.; Qi, J.; Xiu, H. Static behavior of grouped large headed stud-UHPC shear connectors in composite structures. Compos. Struct. 2018, 206, 202–214. [Google Scholar] [CrossRef]

- Dieng, L.; Marchand, P.; Gomes, F.; Tessier, C.; Toutlemonde, F. Use of UHPFRC overlay to reduce stresses in orthotropic steel decks. J. Constr. Steel Res. 2013, 89, 30–41. [Google Scholar] [CrossRef]

- Kim, J.S.; Kwark, J.; Joh, C.; Yoo, S.W.; Lee, K.C. Headed stud shear connector for thin ultrahigh-performance concrete bridge deck. J. Constr. Steel Res. 2015, 108, 23–30. [Google Scholar] [CrossRef]

- Luo, Y.; Hoki, K.; Hayashi, K.; Nakashima, M. Behavior and strength of headed stud-SFRCC shear connection. I: Experimental study. J. Struct. Eng. 2016, 142, 1–10. [Google Scholar] [CrossRef]

- Cao, J.; Shao, X.; Deng, L.; Gan, Y. Static and fatigue behavior of short-headed studs embedded in a thin ultrahigh-performance concrete layer. J. Bridge Eng. 2017, 22, 04017005. [Google Scholar] [CrossRef]

- European Committee for Standardization. Eurocode 4: Design of Composite Steel and Concrete Structures, Part 1-1: General Rules and Rules for Buildings; CEN: Brussel, Belgium, 2010. [Google Scholar]

- Wang, J.Y.; Guo, J.Y.; Jia, L.J.; Chen, S.M.; Dong, Y. Push-out tests of demountable headed stud shear connectors in steel-UHPC composite structures. Compos. Struct. 2017, 170, 69–79. [Google Scholar] [CrossRef]

- Qi, J.; Hu, Y.; Wang, J.; Li, W. Behavior and strength of headed stud shear connectors in ultra-high performance concrete of composite bridges. Front. Struct. Civ. Eng. 2019, 13, 1138–1149. [Google Scholar] [CrossRef]

- Bullo, S.; Di Marco, R. A simplified method for assessing the ductile behaviour of stud connectors in composite beams with high strength concrete slab. J. Constr. Steel Res. 2004, 60, 1387–1408. [Google Scholar] [CrossRef]

- Xu, X.Q.; Liu, Y.Q. Analytical and numerical study of the shear stiffness of rubber-sleeved stud. J. Constr. Steel Res. 2016, 123, 68–78. [Google Scholar] [CrossRef]

- Xu, X.Q.; Liu, Y.Q.; He, J. Study on mechanical behavior of rubber-sleeved studs for steel and concrete composite structures. Constr. Build. Mater. 2014, 53, 533–546. [Google Scholar] [CrossRef]

- Zhuang, B.Z.; Liu, Y.Q.; Yang, F. Experimental and numerical study on deformation performance of Rubber-Sleeved Stud connector under cyclic load. Constr. Build. Mater. 2018, 192, 179–193. [Google Scholar] [CrossRef]

- Zhuang, B.Z.; Liu, Y.Q. Study on the composite mechanism of large Rubber-Sleeved Stud connector. Constr. Build. Mater. 2019, 211, 869–884. [Google Scholar] [CrossRef]

- Xu, X.Q.; Zhou, X.H.; Liu, Y.Q. Behavior of rubber-sleeved stud shear connectors under fatigue loading. Constr. Build. Mater. 2020, 224, 118386. [Google Scholar] [CrossRef]

- Hunan Provincial Department of Housing and Urban Rural Construction. DBJ 43/T 325-2017 Technical Specification for Reactive Powder Concrete Structures; China Architecture & Building Press: Beijing, China, 2018. (In Chinese) [Google Scholar]

- An, L.; Cederwall, K. Push-out tests on studs in high strength and normal strength concrete. J. Constr. Steel Res. 1996, 36, 15–29. [Google Scholar] [CrossRef]

- Döinghaus, P.; Goralski, C.; Will, N. Design rules for composite structures with high performance steel and high performance concrete, High performance materials in bridges. In Proceedings of the International Conference United Engineering Foundation, Kona, HI, USA, 29 July–3 August 2001; pp. 139–149. [Google Scholar]

- GB/T 0433-2002. Cheese Head Suds for Arc Stud Welding; China Standardization Press: Beijing, China, 2003. (In Chinese) [Google Scholar]

- Xu, X.Q.; Liu, Y.Q. Analytical prediction of the deformation behavior of headed studs in monotonic push-out tests. Adv. Struct. Eng. 2019, 22, 1711–1726. [Google Scholar] [CrossRef]

| Specimens | hr/ mm | tr/ mm | τmin/ MPa | τmax/ MPa | Δτ/ MPa | Vmin/ kN | Vmax/ kN | ΔV/ kN | R | f/ Hz |

|---|---|---|---|---|---|---|---|---|---|---|

| S-0-U | — | — | — | — | — | — | — | — | — | — |

| RS25-0-U | 25 | 5 | — | — | — | — | — | — | — | — |

| RS25-50-U | 25 | 5 | 12.0 | 62.0 | 50.0 | 3.4 | 17.6 | 14.2 | 0.19 | 4 |

| RS25-70-U | 25 | 5 | 12.0 | 82.0 | 70.0 | 3.4 | 23.2 | 19.8 | 0.15 | 4 |

| RS25-90-U | 25 | 5 | 12.0 | 102.0 | 90.0 | 3.4 | 28.9 | 25.5 | 0.12 | 4 |

| Cement | Water | Sand | Stone | Water-Reducing Agent |

|---|---|---|---|---|

| 605.7 | 202.9 | 545.1 | 1090.2 | 6.1 |

| Cubic Compressive Strength | Prism Compressive Strength | Tensile Splitting Strength |

|---|---|---|

| 51.35 | 38.78 | 3.33 |

| Hardness (Shore A) | Elongation (%) | Tensile Strength (MPa) | Brittleness Temperature (°C) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|

| 45 | 404 | ≥18 | −40 | 7.89 |

| Specimen | Test Results | Calculated Results | |||

|---|---|---|---|---|---|

| Shear Strength (kN) | Shear Stiffness (kN/mm) | Ratio of the Stiffnesses | ηwc When fc’ = 9 9.9MPa | Ratio of the Stiffnesses | |

| S-0-U | 139.8 | 235.4 | 0.376 | 2.27 | 0.426 |

| RS25-0-U | 111.3 | 88.6 | 0.21 | ||

| Specimens | Δτ/ MPa | τmin/ MPa | τmax/ MPa | R | Ninit,Exp./ ×103 Cycles | Nf,Exp./ ×103 Cycles | Nf,Cal./ kN | |

|---|---|---|---|---|---|---|---|---|

| RS25-50-U | 50.0 | 12.0 | 62.0 | 0.19 | 61.2 | 938.0 | 0.065 | 758.2 |

| RS25-70-U | 70.0 | 12.0 | 82.0 | 0.15 | 8.1 | 189.0 | 0.043 | 218.3 |

| RS25-90-U | 90.0 | 12.0 | 102.0 | 0.12 | 2.1 | 66.3 | 0.032 | 86.2 |

| Specimens | ΔV/ kN | Vu/ kN | ΔV/Vu | δ/ mm/cycle | logδ |

|---|---|---|---|---|---|

| RS25-50-U | 14.18 | 111.3 | 0.11 | 9.130 × 10−7 | −6.040 |

| RS25-70-U | 19.85 | 111.3 | 0.16 | 9.125 × 10−6 | −5.040 |

| RS25-90-U | 25.53 | 111.3 | 0.21 | 5.966 × 10−5 | −4.224 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Xu, X. Static and Fatigue Behavior of Rubber-Sleeved Stud Shear Connectors as Part of Field-Cast Ultra-High Performance Concrete Connections. Materials 2020, 13, 2269. https://doi.org/10.3390/ma13102269

Zhang Z, Xu X. Static and Fatigue Behavior of Rubber-Sleeved Stud Shear Connectors as Part of Field-Cast Ultra-High Performance Concrete Connections. Materials. 2020; 13(10):2269. https://doi.org/10.3390/ma13102269

Chicago/Turabian StyleZhang, Zhigang, and Xiaoqing Xu. 2020. "Static and Fatigue Behavior of Rubber-Sleeved Stud Shear Connectors as Part of Field-Cast Ultra-High Performance Concrete Connections" Materials 13, no. 10: 2269. https://doi.org/10.3390/ma13102269