Elasto-Viscoplastic Material Model of a Directly-Cast Low-Carbon Steel at High Temperatures

Abstract

:1. Introduction

- Isothermal three-point bending of a sample in-situ, which means directly after solidification and controlled cooling,

- the cooling rate during solidification and thermal cycle is adjusted to the continuous casting process, and

- hence, the microstructure (e.g., grains, grain morphology, and precipitations) corresponds with the strand shell in the continuous casting process.

2. Methodology

2.1. Experimental Setup

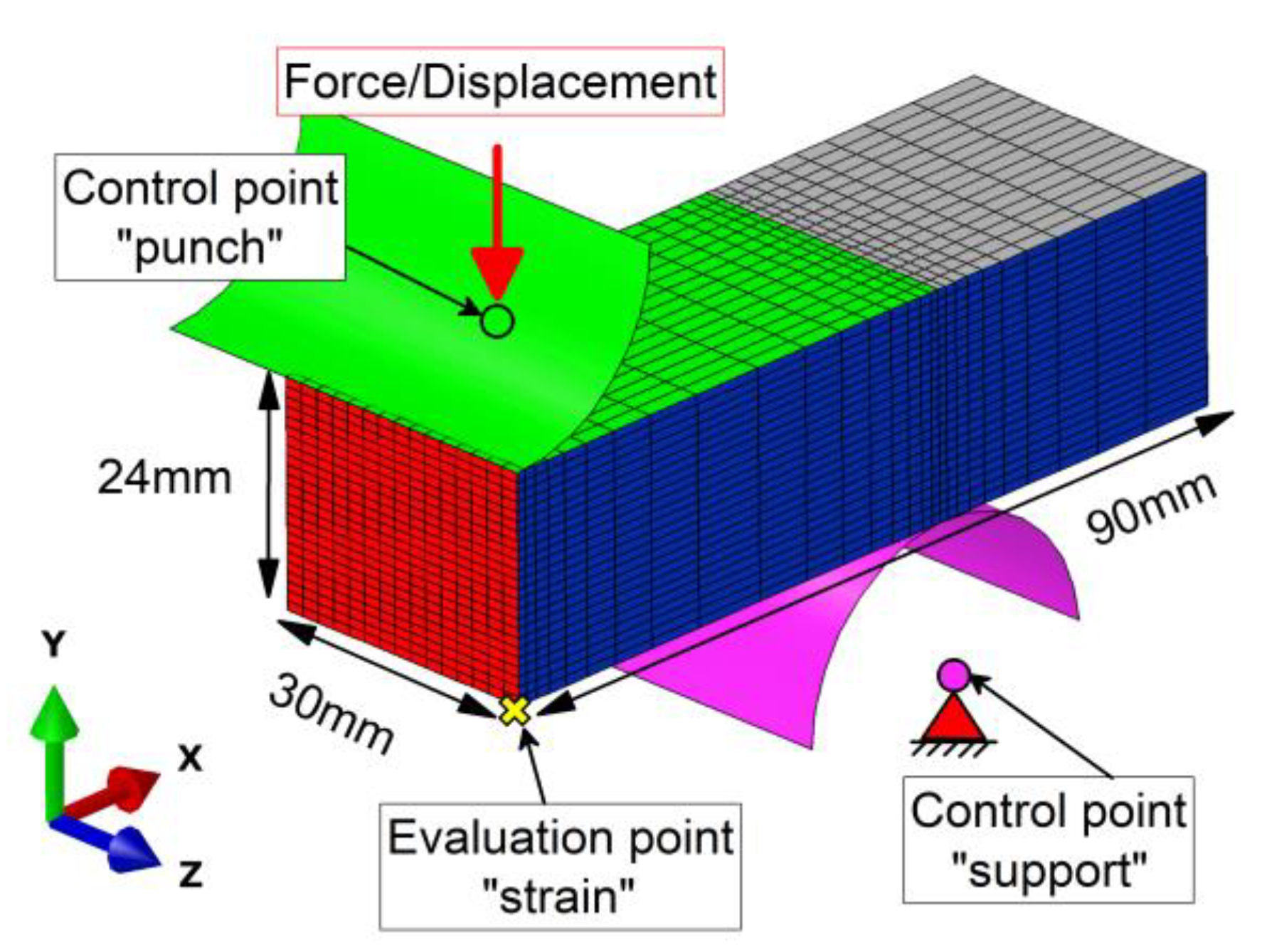

2.2. Simulation

2.2.1. Finite Element Model

2.2.2. Material Model

2.2.3. Determination of Material Parameters

3. Results

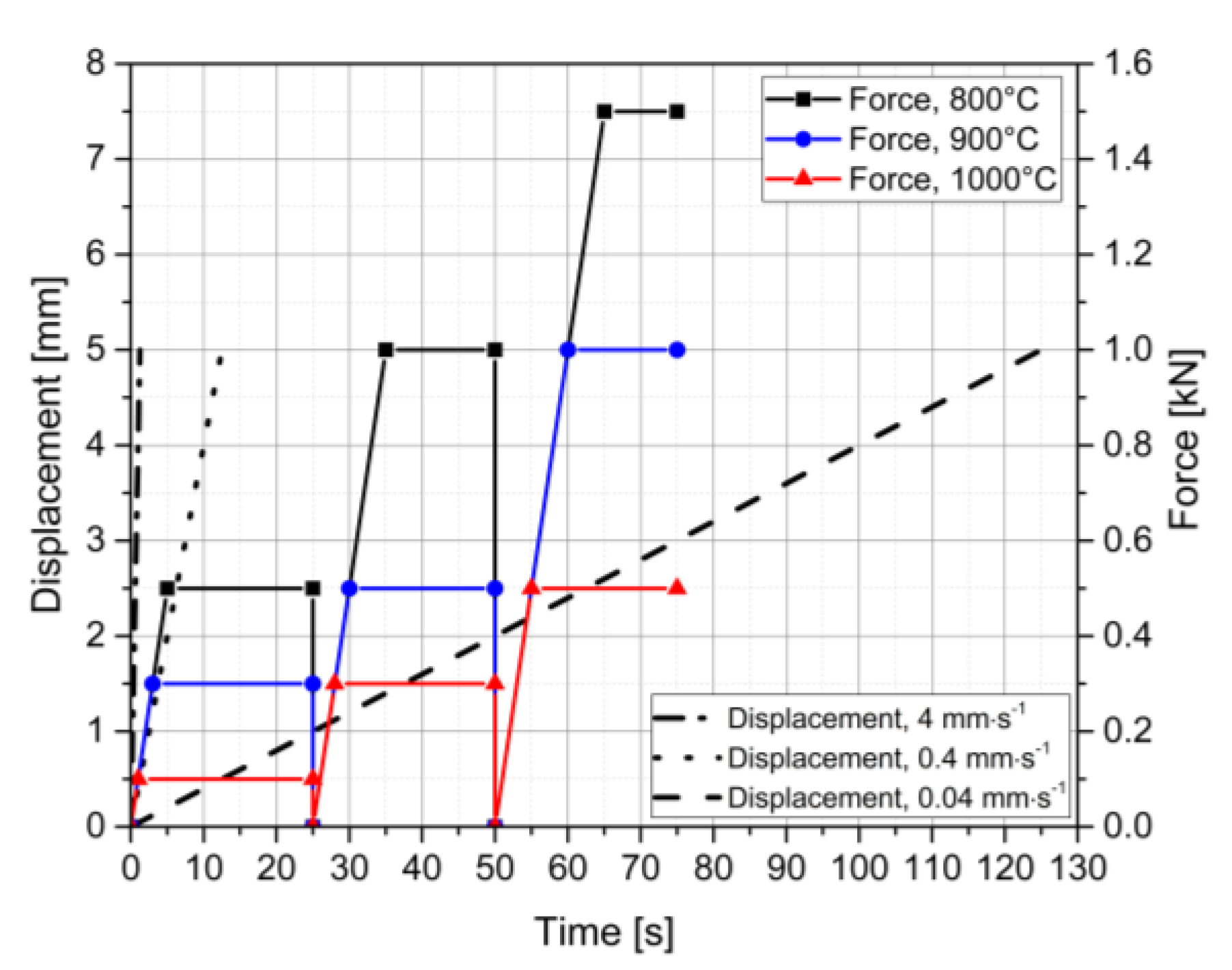

3.1. Experiment

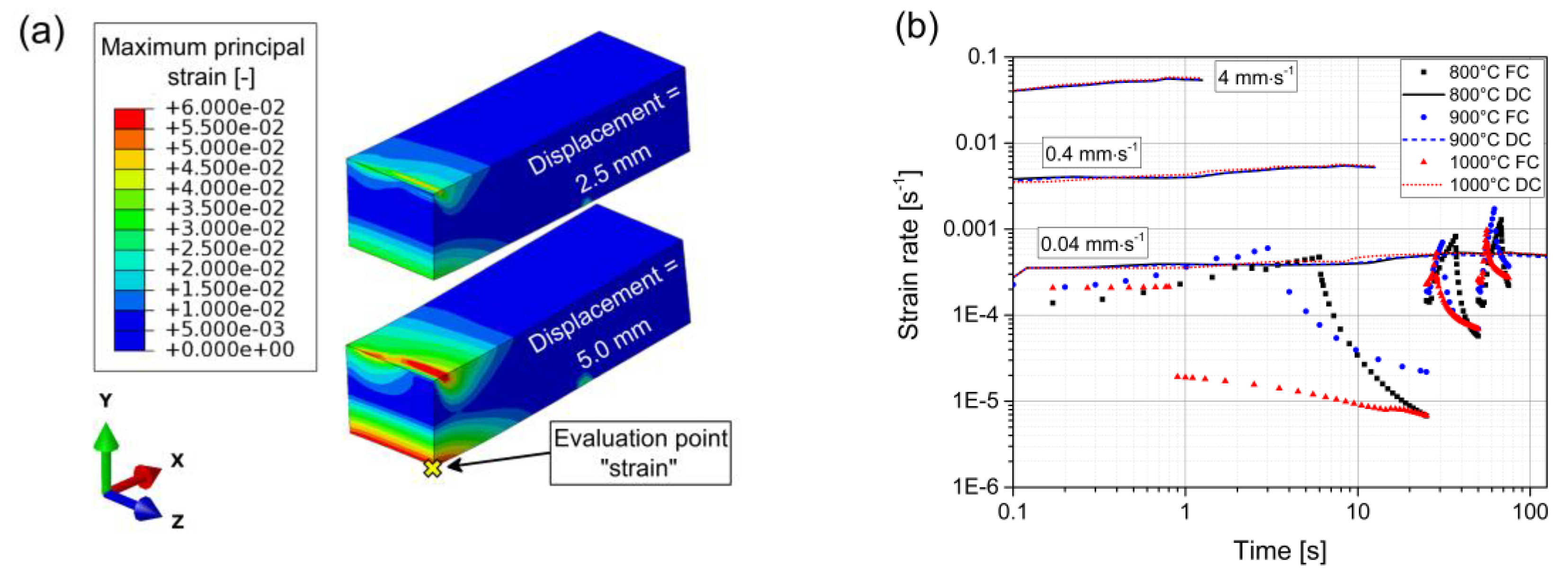

3.2. Model-Based Parameter Determination

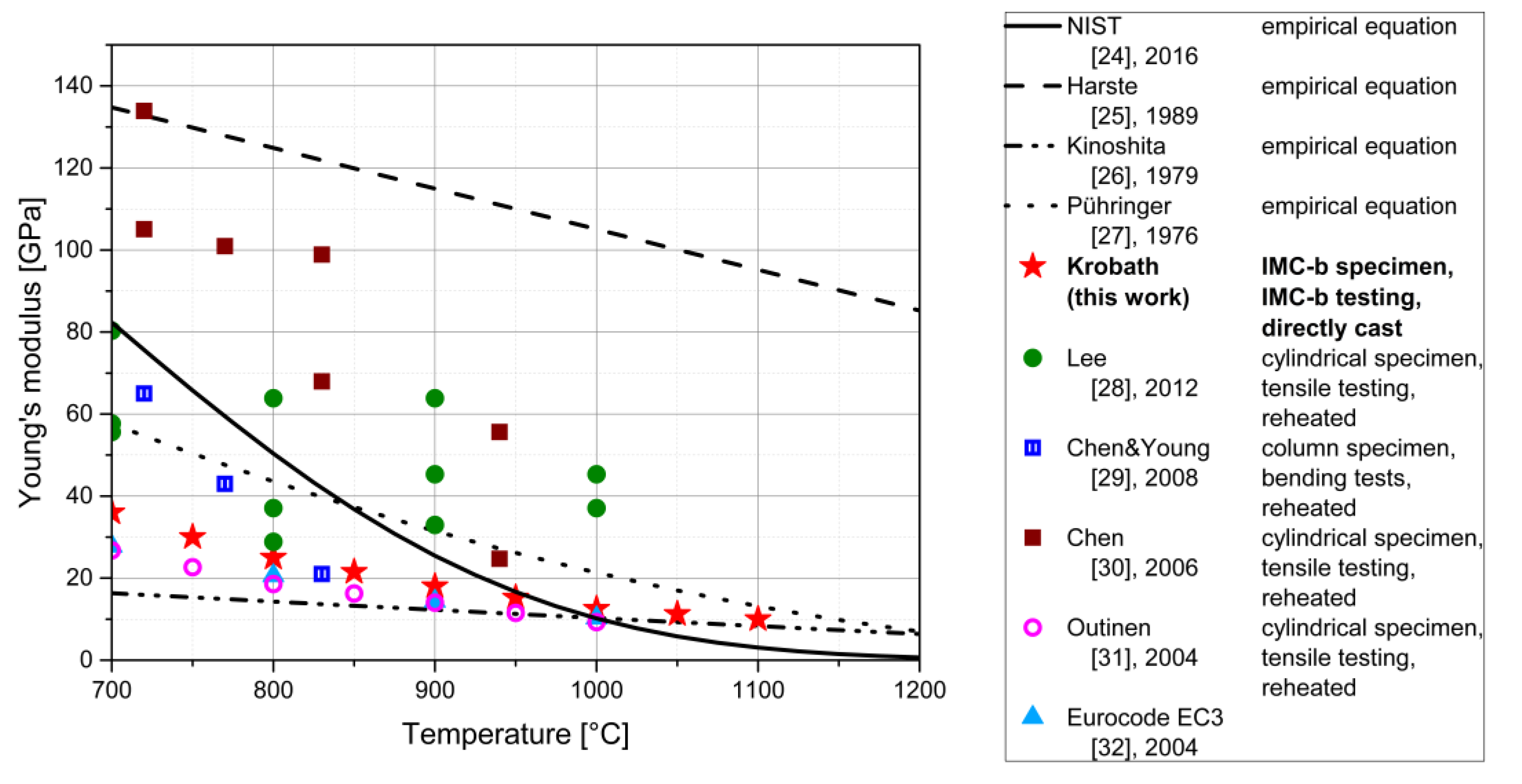

3.2.1. Elastic Properties

3.2.2. Viscoplastic Properties

4. Conclusions

- The microstructure and mechanical behavior greatly differ between directly-cast and reheated samples. The time-dependent mechanical responses vary by a factor of up to about two between these material states.

- The present work for the first time provides a material model for a directly-cast microstructure which is very similar to the material state in a continuous casting strand shell.

- The viscoplastic model accounts for cyclic plasticity effects. Considering cyclic material effects are crucial for accurate modelling, e.g., the straightening stage in continuous casting where numerous rolls introduce cyclic loading to the strand shell.

Author Contributions

Funding

Conflicts of Interest

References

- Li, C.; Thomas, B. Thermomechanical finite-element model of shell behavior in continuous casting of steel. Met. Mater. Trans. A 2004, 35, 1151–1172. [Google Scholar] [CrossRef]

- Liu, K.; Sun, H.; Lan, P.; Zhang, J. FEM Analysis of Soft Reduction Amount and its Internal Reduction Efficiency for Continuous Casting Railway Blooms. In Proceedings of the AISTech 2013, Pittsburgh, PA, USA, 6–9 May 2013; pp. 1427–1438. [Google Scholar]

- Leitner, R.; Fuchshuber, D.; Brugger, C.; Pennerstorfer, P. Digital Twin for continuous casters—The playground for metallurgists and process engineers, In Proceedings of the 4th ESTAD 2019, Düsseldorf, Germany, 24–28 June 2019.

- Anand, L. Constitutive Equations for the Rate-Dependent Deformation of Metals at Elevated Temperatures. J. Eng. Mater. Technol. 1982, 104, 12–17. [Google Scholar] [CrossRef]

- Koric, S.; Thomas, B. Thermo-mechanical models of steel solidification based on two elastic visco-plastic constitutive laws. J. Mater. Process. Technol. 2008, 197, 408–418. [Google Scholar] [CrossRef]

- Kozlowski, P.F.; Thomas, B.; Azzi, J.A.; Wang, H. Simple constitutive equations for steel at high temperature. Met. Mater. Trans. A 1992, 23, 903–918. [Google Scholar] [CrossRef]

- Bauschinger, J. Ueber die Veraenderung der Elastizitaetsgrenze und des Elastizitaetsmoduls verschiedener Metalle. Zivilingenieur 1881, 27, 289–348. [Google Scholar]

- Wray, P.J. Effect of carbon content on the plastic flow of plain carbon steels at elevated temperatures. Met. Mater. Trans. A 1982, 13, 125–134. [Google Scholar] [CrossRef]

- Suzuki, T.; Tacke, K.-H.; Wünnenberg, K.; Schwerdtfeger, K. Creep properties of steel at continuous casting temperature. Ironmak. Steelmak. 1988, 15, 90–100. [Google Scholar]

- Zappulla, M.L.; Cho, S.-M.; Koric, S.; Lee, H.-J.; Kim, S.-H.; Thomas, B. Multiphysics modeling of continuous casting of stainless steel. J. Mater. Process. Technol. 2020, 278, 116469. [Google Scholar] [CrossRef]

- Fachinotti, V.D.; Cardona, A. Constitutive models of steel under continuous casting conditions. J. Mater. Process. Technol. 2003, 135, 30–43. [Google Scholar] [CrossRef]

- Chaboche, J.-L. A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 2008, 24, 1642–1693. [Google Scholar] [CrossRef]

- Krajewski, P.; Krobath, R.; Bernhard, C.; Miettinen, J.; Louhenkilpi, S.; Ilie, S.; Schaden, T. A Novel Approach for the Simulation of Surface Crack Formation in Continuous Casting. BHM Berg Hüttenmännische Mon. 2014, 160, 109–116. [Google Scholar] [CrossRef]

- Krobath, R.; Bernhard, C.; Ilie, S.; Six, J.; Hahn, S.; Pennerstorfer, P. The Role of Grain Boundary Oxidation on Surface Crack Formation under Continuous Casting Conditions. BHM Berg Hüttenmännische Mon. 2019, 164, 461–465. [Google Scholar] [CrossRef] [Green Version]

- Krobath, R.; Bernhard, C. A new experimental setup for the simulation of surface crack formation in the continuous casting process. In Proceedings of the AISTech 2017, Nashville, TN, USA, 8–11 May 2017; pp. 1827–1837. [Google Scholar]

- Preßlinger, H.; Mayr, M.; Tragl, E.; Bernhard, C. Assessment of the Primary Structure of Slabs and the Influence on Hot- and Cold-Rolled Strip Structure. Steel Res. Int. 2006, 77, 107–115. [Google Scholar] [CrossRef]

- Krobath, R.; Bernhard, C.; Ilie, S.; Six, J.; Hahn, S. A new method for the experimental simulation of surface crack formation in continuous casting. Metall. Ital. 2017, 4, 5–13. [Google Scholar]

- Reiter, J.; Bernhard, C.; Presslinger, H. Austenite grain size in the continuous casting process: Metallographic methods and evaluation. Mater. Charact. 2008, 59, 737–746. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, H.; Huang, W.; Shi, B.; Tieu, A.K. Investigation on slab continuous straightening technology and deformation analysis. Int. J. Mater. Prod. Technol. 2013, 47, 126. [Google Scholar] [CrossRef]

- Abaqus 2018, Dassault Systemes Simulia Corp. 2018. Available online: https://www.3ds.com/ (accessed on 14 May 2020).

- Ohno, M.; Tsuchiya, S.; Matsuura, K. Microstructural Features and Formation Processes of As-cast Austenite Grain Structures in Hypoperitectic Carbon Steels. ISIJ Int. 2015, 55, 2374–2382. [Google Scholar] [CrossRef] [Green Version]

- Fuchs, N.; Krajewski, P.; Bernhard, C. In-situ Observation of Austenite Grain Growth in Plain Carbon Steels by Means of High-temperature Laser Scanning Confocal Microscopy. BHM Berg Hüttenmännische Mon. 2015, 160, 214–220. [Google Scholar] [CrossRef]

- Souissi, M.; Numakura, H. Elastic Properties of Fe–C and Fe–N Martensites. ISIJ Int. 2015, 55, 1512–1521. [Google Scholar] [CrossRef] [Green Version]

- Seif, M.; Main, J.; Weigand, J.; Sadek, F.; Choe, L.; Zhang, C.; Gross, J.L.; Luecke, W.; Mccolskey, D. Temperature-Dependent Material Modeling for Structural Steels: Formulation and Application; NIST Research Library: Gaithersburg, MD, USA, 2016.

- Harste, K. Untersuchungen zur Schrumpfung und zur Entstehung von mechanischen Spannungen während der Erstarrung und nachfolgender Abkühlung zylindrischer Blöcke aus Fe-C-Legierungen. Ph.D. Thesis, TU Clausthal, Clausthal-Zellerfeld, Germany, 1989. [Google Scholar]

- Kinoshita, K.; Emi, T.; Kasai, M. Thermal Elasto-plastic Stress Analysis of Solidifying Shell in Continuous Casting Mold. Tetsu-to-Hagane 1979, 65, 2022–2031. [Google Scholar] [CrossRef] [Green Version]

- Pühringer, O.M. Strand mechanics for continuous slab casting plants. Stahl Eisen 1976, 96, 279–284. [Google Scholar]

- Lee, J. Elevated-Temperature Properties of ASTM A992 Steel for Structural-Fire Engineering Analysis. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2012. [Google Scholar]

- Chen, J.; Young, B. Design of high strength steel columns at elevated temperatures. J. Constr. Steel Res. 2008, 64, 689–703. [Google Scholar] [CrossRef]

- Chen, J.; Young, B.; Uy, B. Behavior of High Strength Structural Steel at Elevated Temperatures. J. Struct. Eng. 2006, 132, 1948–1954. [Google Scholar] [CrossRef] [Green Version]

- Outinen, J.; Mäkeläinen, P. Mechanical properties of structural steel at elevated temperatures and after cooling down. Fire Mater. 2004, 28, 237–251. [Google Scholar] [CrossRef]

- ECS. Eurocode 3, Design of Steel Structures, General Rules, Structural Fire Design; European Committee for Standardization: Brussels, Belgium, 2005; Standard EN 1993-1-2. [Google Scholar]

| C | Si | Mn | P | S | Al | Fe |

|---|---|---|---|---|---|---|

| 0.17 | 0.4 | 1.55 | 0.01 | <0.004 | 0.03 | balance |

| Temperature [°C] | 800 | 900 | 1000 | |

|---|---|---|---|---|

| Elastic | Young’s modulus [MPa] | 25,000 | 18,000 | 12,500 |

| Poisson [-] | 0.34 | 0.35 | 0.36 | |

| Initial yield stress | R0 [MPa] | 0 | 0 | 0 |

| Kinematic hardening | C1 [MPa] | 7500 | 6000 | 2500 |

| γ1 [-] | 600 | 600 | 600 | |

| C2 [MPa] | 3500 | 2300 | 1500 | |

| γ2 [-] | 180 | 180 | 180 | |

| C3 [MPa] | 400 | 300 | 200 | |

| γ3 [-] | 30 | 30 | 30 | |

| Isotropic hardening | Q [MPa] | 80 | 50 | 50 |

| b [-] | 6.5 | 6 | 1 | |

| Static recovery | M1 [MPa] | 500 | 300 | 100 |

| m1 [-] | 3.8 | 2.6 | 3 | |

| M2 [MPa] | 320 | 240 | 180 | |

| m2 [-] | 2.8 | 2.5 | 1.8 | |

| M3 [MPa] | 400 | 250 | 250 | |

| m3 [-] | 3.45 | 3.3 | 3.5 | |

| Viscoplastic potential | K [MPa] | 40 | 56 | 75 |

| n [-] | 3.2 | 2.8 | 3.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krobath, M.; Krobath, R.; Bernhard, C.; Ecker, W. Elasto-Viscoplastic Material Model of a Directly-Cast Low-Carbon Steel at High Temperatures. Materials 2020, 13, 2281. https://doi.org/10.3390/ma13102281

Krobath M, Krobath R, Bernhard C, Ecker W. Elasto-Viscoplastic Material Model of a Directly-Cast Low-Carbon Steel at High Temperatures. Materials. 2020; 13(10):2281. https://doi.org/10.3390/ma13102281

Chicago/Turabian StyleKrobath, Martin, Roman Krobath, Christian Bernhard, and Werner Ecker. 2020. "Elasto-Viscoplastic Material Model of a Directly-Cast Low-Carbon Steel at High Temperatures" Materials 13, no. 10: 2281. https://doi.org/10.3390/ma13102281

APA StyleKrobath, M., Krobath, R., Bernhard, C., & Ecker, W. (2020). Elasto-Viscoplastic Material Model of a Directly-Cast Low-Carbon Steel at High Temperatures. Materials, 13(10), 2281. https://doi.org/10.3390/ma13102281