Evaluation of the Environmental Benefits Associated with the Addition of Olive Pomace in the Manufacture of Lightweight Aggregates

Abstract

:1. Introduction

2. Methodology

2.1. Life Cycle Assessment of Lightweight Aggregates Containing Olive Pomace

2.1.1. Objective and Scope Definition

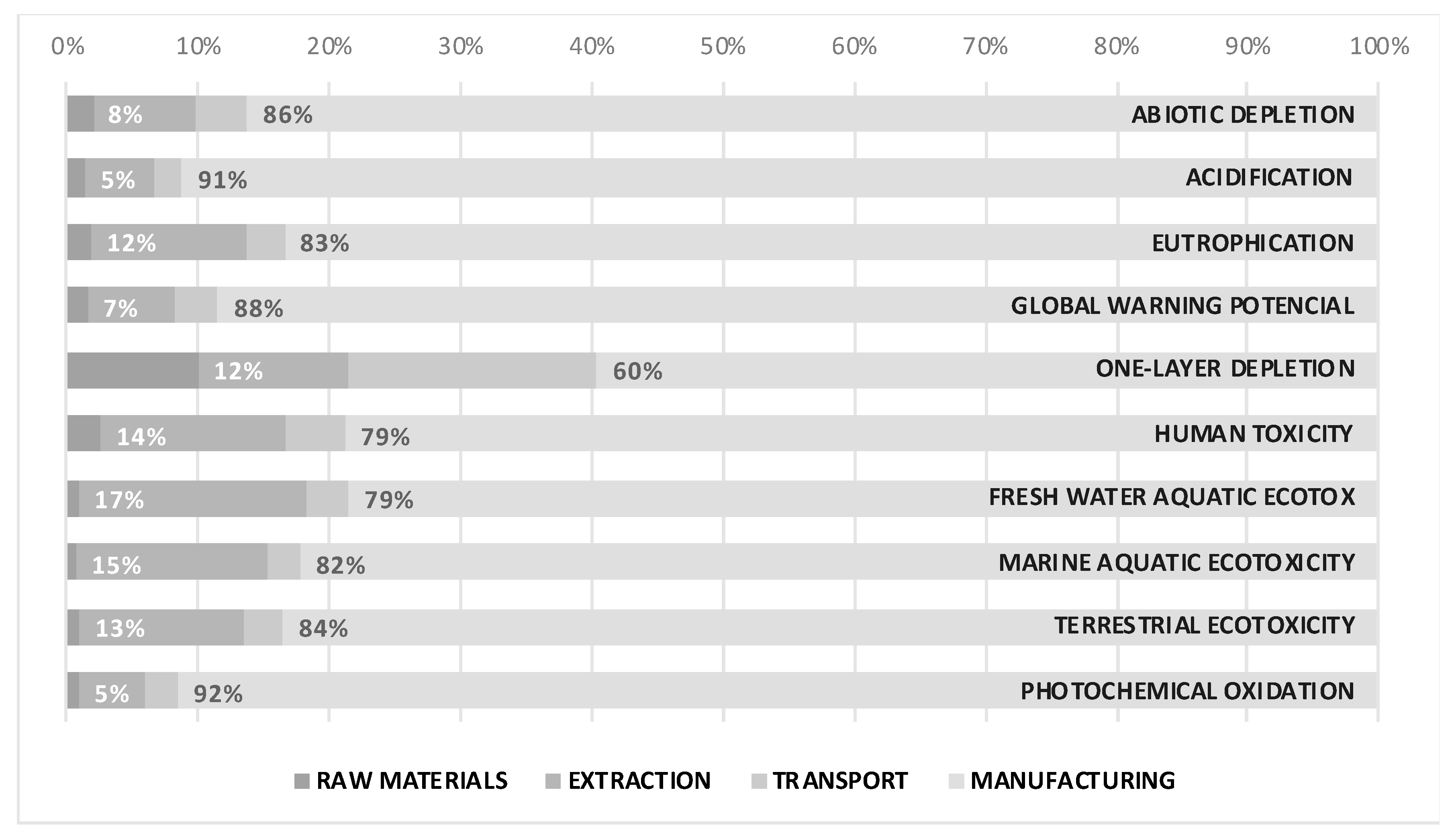

- Raw materials, which would contain both the clay and the OP residue, as well as the water needed for the process. In this stage, the obtaining of the waste has been considered as a process with no environmental load, since otherwise the impact associated with obtaining it would be added to the manufacture of the LWA.

- Extraction, which would contain the processes related to the occupation of the land used by the quarry, as well as the energy required for the extraction of the clay.

- Transport of the raw material to the factory has been determined so that the transfer of the raw material would take place within a radius of 50 km, assimilating the transport of the waste to the corresponding part of the clay it replaces, in cases where it affects.

- Manufacture of the final product, considering the raw materials needed to complete the final product, the energy consumed for this purpose, and the emissions into the air and water.

2.1.2. Systems Limits and Scenarios

- LWA scenario without residue (SW-0OP): These aggregates have been manufactured using only clay as raw material. In the raw material phase, only processes related to the clay and water used have been considered. For the manufacture of 1 kg of aggregate, an initial quantity of clay of 1.1 kg is required. The manufacturing stage would include all processes related to the shaping of the final product, including additional materials such as packaging film or transport pallets, the energy required and the emissions produced. These aggregates were sintered at 1205 °C for 4 min, maintaining the aggregates in the preheating zone for 1 min.

- LWA scenario with 1.25 wt% OP (SW-1.25OP): This scenario corresponds to the lowest waste content in the aggregate, so the raw material and manufacturing stages would have been altered to modify the data affecting the new variable. These aggregates were sintered at 1195 °C for 4 min, plus 1 min in the preheating zone.

- LWA scenario with 2.5 wt% OP (SW-2.5OP): This mixture was studied in more depth due to the good performance obtained in the previous work [20]. The temperatures and study times were 1140, 1160 and 1180 °C; for 4, 8 and 16 min, and 1 min of preheating. Therefore, a total of nine types of samples were analyzed. The phases of raw materials and manufacturing have been modified to take into account the new addition values and sintering conditions.

- LWA scenario with 5 wt% OP (SW-5OP): As in the case of 1.25 wt% OP, the corresponding steps have been modified to adjust to the new addition values. These aggregates were sintered at 1180 °C for 4 min. As in the other scenarios, the dwell time of the aggregates in the preheating zone was 1 min.

2.1.3. Life Cycle Inventory Analysis

2.1.4. Life Cycle Impact Assessment Methodology

2.1.5. Contribution and Influence Analysis

3. Results and Discussion

3.1. Impact Analysis of Lightweight Aggregates Without Residue

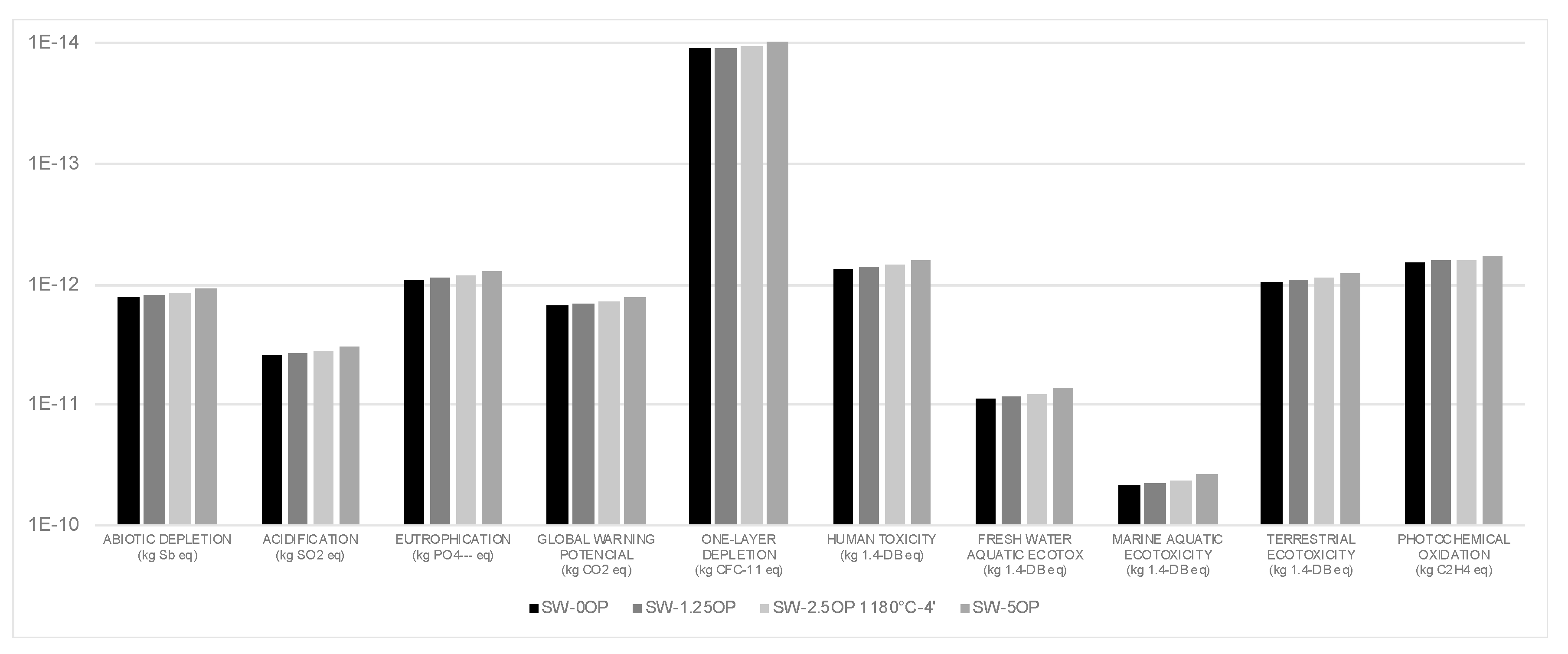

3.2. Impact Analysis of Lightweight Aggregates Containing Olive Pomace

3.3. Standardized Analysis of Aggregates without Residue and Lightweight Aggregates Containing Olive Pomace

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eliche-Quesada, D.; Corpas-Iglesias, F.A.; Pérez-Villarejo, L.; Iglesias-Godino, F.J. Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr. Build. Mater. 2012, 34, 275–284. [Google Scholar] [CrossRef]

- European Commission. Report from the Commission to the Council and the European Parliament on Implementation of the Community Waste Legislation; COM 2006, 406 (final, Brussels); European Commission: Brussels, Belgium, 2006. [Google Scholar]

- ANEFA. El Sector (The Aggregate Sector in Spain). Asociación Nacional de Empresarios Fabricantes de Áridos. 2018. Available online: http://www.aridos.org/el-sector/ (accessed on 14 May 2019).

- ESCSI. Applications. Expanded Shale, Clay and Slate Institute. Available online: 2018. https://www.escsi.org/applications/ (accessed on 14 May 2019).

- Ayati, B.; Ferrándiz-Mas, V.; Newport, D.; Cheeseman, C. Use of clay in the manufacture of lightweight aggregate. Constr. Build. Mater. 2018, 162, 124–131. [Google Scholar] [CrossRef]

- Dondi, M.; Cappelletti, P.; D’Amore, M.; de Gennaro, R.; Graziano, S.F.; Langella, A.; Raimondo, M.; Zanelli, C. Lightweight aggregates from waste materials: Reappraisal of expansion behavior and prediction schemes for bloating. Constr. Build. Mater. 2016, 127, 394–409. [Google Scholar] [CrossRef]

- IOC. International Olive Council—World Olive Oil Figures. 2019. Available online: http://www.internationaloliveoil.org/estaticos/view/131-world-olive-oil-figures (accessed on 26 May 2019).

- AGAPA. Evaluación de la Producción y usos de los Subproductos de las Agroindustrias del Olivar en Andalucía; Agencia de Gestión Agraria y Pesquera de Andalucía—Junta de Andalucía; Unión Europea: Fondo Europeo Agrícola de Desarrollo Rural: Sevilla, Spain, 2015. [Google Scholar]

- Arjona, R.; García, A.; Ollero, P. The drying of alpeorujo, a waste product of the olive oil mill industry. J. Food Eng. 1999, 41, 229–234. [Google Scholar] [CrossRef]

- De la Casa, J.A.; Romero, I.; Jiménez, J.; Castro, E. Fired clay masonry units production incorporating two-phase olive mill waste (alperujo). Ceram. Int. 2012, 38, 5027–5037. [Google Scholar] [CrossRef]

- Williams, O.; Eastwick, C.; Kingman, S.; Giddings, D.; Lormor, S.; Lester, E. Overcoming the caking phenomenon in olive mill wastes. Ind. Crops Prod. 2017, 101, 92–102. [Google Scholar] [CrossRef]

- Consejería de Agricultura, Pesca y Desarrollo Rural, 2017. Aforo de Producción de Olivar en Andalucía—Campaña 2017–2018. Available online: http://www.juntadeandalucia.es/export/drupaljda/Presentación_OLIVAR_2017-2018.pdf (accessed on 12 June 2019).

- Nastri, A.; Ramieri, N.A.; Abdayem, R.; Piccaglia, R.; Marzadori, C.; Ciavatta, C. Olive pulp and its effluents suitability for soil amendment. J. Hazard. Mater. 2006, 138, 211–217. [Google Scholar] [CrossRef]

- Borja, R.; Raposo, F.; Rincón, B. Treatment technologies of liquid and solid wastes from two-phase olive oil mills. Grasas Aceites 2006, 57, 32–46. [Google Scholar] [CrossRef]

- De la Casa, J.A.; Lorite, M.; Jiménez, J.; Castro, E. Valorisation of wastewater from two-phase olive oil extraction in fired clay brick production. J. Hazard. Mater. 2009, 169, 271–278. [Google Scholar] [CrossRef]

- Mekki, H.; Anderson, M.; Benzina, M.; Ammar, E. Valorization of olive mill wastewater by its incorporation in building bricks. J. Hazard. Mater. 2008, 158, 308–315. [Google Scholar] [CrossRef]

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044. Environmental Management-Life Cycle Assessment-Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Maroto, J.M.; Uceda-Rodríguez, M.; Cobo-Ceacero, C.J.; Calerode Hoces, M.; MartínLara, M.A.; Cotes-Palomino, T.; López García, A.B.; Martínez-García, C. Recycling of ‘alperujo’ (olive pomace) as a key component in the sintering of lightweight aggregates. J. Clean. Prod. 2019, 239, 118041. [Google Scholar] [CrossRef]

- AENOR. Áridos Ligeros. Parte 1: Áridos Ligeros Para Hormigón, Mortero e Inyectado. UNE Normalización Española: S.n.; UNE-EN 13055-1:2003; AENOR: Madrid, Spain, 2003. [Google Scholar]

- AENOR. Áridos Ligeros. Parte 2: Áridos Ligeros Para Mezclas Bituminosas, Tratamientos Superficiales y Aplicaciones en Capas Tratadas y no Tratadas. s.l.: UNE Normalización Española; UNE-EN 13055-2:2005; AENOR: Madrid, Spain, 2005. [Google Scholar]

- Napolano, L.; Menna, C.; Graziano, S.F.; Asprone, D.; D’Amore, M.; De Gennaro, R.; Dondi, M. Environmental life cycle assessment of lightweight concrete to support recycled materials selection for sustainable design. Constr. Build. Mater. 2016, 119, 370–384. [Google Scholar] [CrossRef]

- Ingrao, C.; Selvaggi, R.; Valenti, F.; Matarazzo, A.; Pecorino, B.; Arcidiacono, C. Life cycle assessment of expanded clay granulate production using different fuels. Resour. Conserv. Recycl. 2019, 114, 398–409. [Google Scholar] [CrossRef]

- Frischknecht, R.; Rebitzer, G. The ecoinvent database system: A comprehensive web-based LCA database. J. Cleaner Prod. 2005, 13, 1337–1343. [Google Scholar] [CrossRef]

- Aryan, Y.; Yadav, P.; Ranjan Samadder, S. Life Cycle Assessment of the existing and proposed plastic waste management options in India: A case study. J. Clean. Prod. 2019, 211, 1268–1283. [Google Scholar] [CrossRef]

- Ahameda, A.; Yin, K.; Ng, B.J.H.; Rena, F.; Changa, V.W.C.; Wang, J.Y. Life cycle assessment of the present and proposed food waste management technologies from environmental and economic impact perspectives. J. Clean. Prod. 2016, 131, 607–614. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafie, S.; Omid, M.; Mousazadeh, H.; Clark, S. Environmental impact assessment of tomato and cucumber cultivation in greenhouses using life cycle assessment and adaptive neuro-fuzzy inference system. J. Clean. Prod. 2014, 73, 183–192. [Google Scholar] [CrossRef]

- De Belie, N.; Soutsos, M.; Gruyaert, E. Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials; Springer: Cham, Switzerland, 2018; ISBN 978-3-31-970606-1. [Google Scholar] [CrossRef]

- Feely, R.A.; Sabine, C.L.; Lee, K.; Berelson, W.; Kleypas, J.; Fabry, V.J.; Millero, F.J. Impact of Anthropogenic CO2 on the CaCO3 System in the Oceans. Science 2004, 305, 362–366. [Google Scholar] [CrossRef] [Green Version]

- Duarte, C.M.; Alonso, S.; Benito, G.; Dachs, J.; Montes, C.; Pardo, M.; Ríos, A.F.; Simó, R.; Valladares, F. Cambio Global. Impacto de la Actividad Humana Sobre el Sistema Tierra; CSIC: Madrid, Spain, 2006; ISBN 978-8-40-008452-3. Available online: http://aeclim.org/wp-content/uploads/2016/01/Cambio_global.pdf (accessed on 5 July 2019).

- Sabine, C.L.; Feely, R.A.; Gruber, N.; Key, R.M.; Lee, K.; Bullister, J.L.; Wanninkhof, R.; Wong, C.S.; Wallace, D.W.R.; Tilbrook, B.; et al. The Oceanic Sink for Anthropogenic CO2. Science 2004, 305, 367–371. [Google Scholar] [CrossRef] [Green Version]

- Pulselli, R.M.; Ridolfi, R.; Rugani, B.; Tiezzi, E. Application of life cycle assessment to the production of man-made crystal glass. Int. J. Life Cycle Assess. 2009, 14, 490–501. [Google Scholar] [CrossRef]

- Konstantzos, G.E.; Malamis, D.; Sotiropoulos, A.; Loizidou, M. Environmental profile of an innovative household biowaste dryer system based on Life Cycle Assessment. Waste Manag. Res. 2018, 37, 48–58. [Google Scholar] [CrossRef] [PubMed]

- Behrooznia, L.; Sharifi, M.; Alimardani, R.; Mousavi-Avval, S.H. Sustainability analysis of landfilling and composting-landfilling for municipal solid waste management in the north of Iran. J. Clean. Prod. 2018, 203, 1028–1038. [Google Scholar] [CrossRef]

- Heijungs, R.; Guinée, J.; Kleijn, R. Bias in normalization: Causes, consequences, detection and remedies. Int. J. Life Cycle Assess. 2007, 12, 211. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, L.; Li, F.; Peng, J. Recycled aggregates from construction and demolition wastes as alternative filling materials for highway subgrades in China. J. Clean. Prod. 2020, 255, 120223. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

| Elementary Flow | Units | SW-0OP | SW-1.25OP | SW-2.5OP | SW-5OP | LCIA Dataset | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1140°C-4′ | SW-5OP | LCIA Dataset | 1160°C-4′ | 1160°C-8′ | 1160°C-16′ | 1180°C-4′ | 1180°C-8′ | 1180°C-16′ | ||||||

| Extraction and transport of raw materials | ||||||||||||||

| Clay | kg | 1.1 | 1.08625 | 1.0725 | 1.0725 | 1.0725 | 1.0725 | 1.0725 | 1.0725 | 1.0725 | 1.0725 | 1.0725 | 1.045 | Clay {GLO}| market for | Alloc Def, U |

| Olive pomace | kg | - | 0.01375 | 0.0275 | 0.0275 | 0.0275 | 0.0275 | 0.0275 | 0.0275 | 0.0275 | 0.0275 | 0.0275 | 0.055 | - |

| Water | m3 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | 0.0000736 | Water, well, in ground, ES |

| kg | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | 0.0134 | Tap water {GLO}| market group for | Alloc Def, U | |

| Transport raw materials | tkm | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | 0.0747 | Transport, freight, lorry, 16-32 tons {GLO}| market for | Alloc Def, U |

| Extraction plant | p | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | 2.00 × 10−10 | Clay pit infrastructure {GLO}| market for | Alloc Def, U |

| Energy and material inputs at LWA manufacturing plant | ||||||||||||||

| Electricity | kWh | 0.028881403 | 0.022153249 | 0.015425095 | 0.017592282 | 0.019882295 | 0.015423668 | 0.017590141 | 0.019880155 | 0.015421528 | 0.017588001 | 0.019878014 | 0.001957372 | Electricity, medium voltage {GLO}| market group for | Alloc Def, U |

| Heat | MJ | 2.549810045 | 2.482528506 | 2.415246966 | 2.606578178 | 2.808809101 | 2.415232697 | 2.606556773 | 2.808787697 | 2.415211292 | 2.606535369 | 2.808766293 | 2.280569731 | Heat, district or industrial, other than natural gas {GLO}| market group for | Alloc Def, U |

| Packaging film | kg | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | 0.0004813 | Packaging film, low density polyethylene {GLO}| market for | Alloc Def, U |

| Linerboard | kg | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 | Linerboard {RoW}| market for linerboard | Alloc Def, U |

| Direct emissions due to thermal transformation of raw materials | ||||||||||||||

| Water | m3 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | 0.0000067 | Emissions to air - Water/m3 |

| CO2 | m3 | 0.178700361 | 0.200883398 | 0.223066435 | 0.223066435 | 0.223066435 | 0.223066435 | 0.223066435 | 0.223066435 | 0.223066435 | 0.223066435 | 0.223066435 | 0.26743251 | Emissions to air - CO2 |

| Water | m3 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | 0.00008568 | Emissions to water - Water, RoW |

| Impact Categories | Units | SW-0OP | SW-1.25OP | SW-2.5OP | SW-5OP | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1140 °C-4′ | 1140 °C-8′ | 1140 °C-16′ | 1160 °C-4′ | 1160 °C-8′ | 1160 °C-16′ | 1180 °C-4′ | 1180 °C-8′ | 1180 °C-16′ | |||||

| Abiotic Depletion | kg Sb eq | 0.002161234 | 0.002077781 | 0.001994337 | 0.002142637 | 0.002299367 | 0.00199432 | 0.002142597 | 0.002299337 | 0.001994299 | 0.002142577 | 0.002299317 | 0.001827312 |

| Acidification | kg SO2 eq | 0.002594284 | 0.002505764 | 0.002417241 | 0.002601725 | 0.002796714 | 0.002417226 | 0.002601697 | 0.002796684 | 0.002417198 | 0.002601669 | 0.002796664 | 0.00224004 |

| Eutrophication | kg PO43- eq | 0.000465992 | 0.000445684 | 0.000425377 | 0.000457324 | 0.000491096 | 0.000425375 | 0.000457321 | 0.000491093 | 0.000425371 | 0.000457318 | 0.00049108 | 0.000384734 |

| Global Warning Potential | kg CO2 eq | 0.37264414 | 0.35890716 | 0.34517018 | 0.37125078 | 0.39881666 | 0.34516729 | 0.37124644 | 0.39881232 | 0.34516293 | 0.37124209 | 0.39880797 | 0.31767305 |

| One-Layer Depletion | kg CFC-11 eq | 1.11172 × 10−8 | 1.07023 × 10−8 | 1.02875 × 10−8 | 1.08366 × 10−8 | 1.14169 × 10−8 | 1.02875 × 10−8 | 1.08365 × 10−8 | 1.14168 × 10−8 | 1.02873 × 10−8 | 1.08363 × 10−8 | 1.14166 × 10−8 | 9.45718 × 10−8 |

| Human Toxicity | kg 1.4-DB eq | 0.13830491 | 0.13372685 | 0.12914876 | 0.13772516 | 0.14678997 | 0.1291478 | 0.13772372 | 0.14678853 | 0.12914637 | 0.13772227 | 0.14678709 | 0.11998492 |

| Fresh Water Aquatic Ecotox | kg 1.4-DB eq | 0.0667779 | 0.06375513 | 0.06073238 | 0.06514047 | 0.06979952 | 0.06073174 | 0.06513951 | 0.06979857 | 0.06073078 | 0.06513855 | 0.06979761 | 0.05468174 |

| Marine Aquatic Ecotoxicity | kg 1.4-DB eq | 145.8228294 | 139.47 | 133.1171707 | 143.0092696 | 153.4645963 | 133.1158261 | 143.0072527 | 153.4625794 | 133.1138082 | 143.0052358 | 153.4605625 | 120.4007532 |

| Terrestrial Ecotoxicity | kg 1.4-DB eq | 0.000862918 | 0.000830666 | 0.000798401 | 0.000856102 | 0.000917088 | 0.000798398 | 0.000856098 | 0.000917084 | 0.000798384 | 0.000856084 | 0.00091707 | 0.000733829 |

| Photochemical Oxidation | kg C2H4 eq | 0.000121395 | 0.000117406 | 0.000113417 | 0.00012204 | 0.000131142 | 0.000113416 | 0.000122039 | 0.000131142 | 0.000113416 | 0.000122029 | 0.000131141 | 0.000105438 |

| Impact Categories | Units | SW-0OP | SW-1.25OP | SW-2.5OP | SW-5OP | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1140 °C-4′ | 1140 °C-8′ | 1140 °C-16′ | 1160 °C-4′ | 1160 °C-8′ | 1160 °C-16′ | 1180 °C-4′ | 1180 °C-8′ | 1180 °C-16′ | |||||

| Abiotic Depletion | kg Sb eq | 1.26436 × 10−12 | 1.21555 × 10−12 | 1.16664 × 10−12 | 1.25348 × 10−12 | 1.34509 × 10−12 | 1.16664 × 10−12 | 1.25347 × 10−12 | 1.34508 × 10−12 | 1.16663 × 10−12 | 1.25337 × 10−12 | 1.34507 × 10−12 | 1.06898 × 10−12 |

| Acidification | kg SO2 eq | 3.8655 × 10−12 | 3.73354 × 10−12 | 3.60169 × 10−12 | 3.87654 × 10−12 | 4.1671 × 10−12 | 3.60168 × 10−12 | 3.87653 × 10−12 | 4.16709 × 10−12 | 3.60157 × 10−12 | 3.87651 × 10−12 | 4.16708 × 10−12 | 3.33762 × 10−12 |

| Eutrophication | kg PO43- eq | 9.2733 × 10−13 | 8.8692 × 10−13 | 8.46507 × 10−13 | 9.10079 × 10−13 | 9.77278 × 10−13 | 8.46503 × 10−13 | 9.10072 × 10−13 | 9.77262 × 10−13 | 8.46486 × 10−13 | 9.10056 × 10−13 | 9.77255 × 10−13 | 7.65627 × 10−13 |

| Global Warning Potential | kg CO2 eq | 1.47568 × 10−12 | 1.42123 × 10−12 | 1.36687 × 10−12 | 1.47013 × 10−12 | 1.57936 × 10−12 | 1.36687 × 10−12 | 1.47013 × 10−12 | 1.57925 × 10−12 | 1.36686 × 10−12 | 1.47012 × 10−12 | 1.57925 × 10−12 | 1.25794 × 10−12 |

| One-Layer Depletion | kg CFC-11 eq | 1.13395 × 10−14 | 1.09163 × 10−14 | 1.04932 × 10−14 | 1.10532 × 10−14 | 1.16451 × 10−14 | 1.04931 × 10−14 | 1.10531 × 10−14 | 1.1645 × 10−14 | 1.0493 × 10−14 | 1.10529 × 10−14 | 1.16449 × 10−14 | 9.64632 × 10−15 |

| Human Toxicity | kg 1.4-DB eq | 7.35789 × 10−13 | 7.11423 × 10−13 | 6.8707 × 10−13 | 7.32694 × 10−13 | 7.80924 × 10−13 | 6.87068 × 10−13 | 7.32691 × 10−13 | 7.80911 × 10−13 | 6.87055 × 10−13 | 7.32688 × 10−13 | 7.80908 × 10−13 | 6.3832 × 10−13 |

| Fresh Water Aquatic Ecotox | kg 1.4-DB eq | 8.88149 × 10−12 | 8.47943 × 10−12 | 8.07746 × 10−12 | 8.66366 × 10−12 | 9.28336 × 10−12 | 8.07726 × 10−12 | 8.66356 × 10−12 | 9.28316 × 10−12 | 8.07726 × 10−12 | 8.66336 × 10−12 | 9.28306 × 10−12 | 7.27265 × 10−12 |

| Marine Aquatic Ecotoxicity | kg 1.4-DB eq | 4.57879 × 10−11 | 4.37936 × 10−11 | 4.17983 × 10−11 | 4.49048 × 10−11 | 4.81877 × 10−11 | 4.17981 × 10−11 | 4.49044 × 10−11 | 4.81874 × 10−11 | 4.17977 × 10−11 | 4.49031 × 10−11 | 4.81861 × 10−11 | 3.78059 × 10−11 |

| Terrestrial Ecotoxicity | kg 1.4-DB eq | 9.40584 × 10−13 | 9.05425 × 10−13 | 8.70263 × 10−13 | 9.33153 × 10−13 | 9.99628 × 10−13 | 8.7025 × 10−13 | 9.33138 × 10−13 | 9.99614 × 10−13 | 8.70245 × 10−13 | 9.33133 × 10−13 | 9.99609 × 10−13 | 7.99871 × 10−13 |

| Photochemical Oxidation | kg C2H4 eq | 6.66466 × 10−13 | 6.44573 × 10−13 | 6.2268 × 10−13 | 6.69973 × 10−13 | 7.19962 × 10−13 | 6.22679 × 10−13 | 6.69971 × 10−13 | 7.19961 × 10−13 | 6.22667 × 10−13 | 6.69959 × 10−13 | 7.19949 × 10−13 | 5.78854 × 10−13 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uceda-Rodríguez, M.; López-García, A.B.; Moreno-Maroto, J.M.; Cobo-Ceacero, C.J.; Cotes-Palomino, M.T.; Martínez García, C. Evaluation of the Environmental Benefits Associated with the Addition of Olive Pomace in the Manufacture of Lightweight Aggregates. Materials 2020, 13, 2351. https://doi.org/10.3390/ma13102351

Uceda-Rodríguez M, López-García AB, Moreno-Maroto JM, Cobo-Ceacero CJ, Cotes-Palomino MT, Martínez García C. Evaluation of the Environmental Benefits Associated with the Addition of Olive Pomace in the Manufacture of Lightweight Aggregates. Materials. 2020; 13(10):2351. https://doi.org/10.3390/ma13102351

Chicago/Turabian StyleUceda-Rodríguez, Manuel, Ana B. López-García, José Manuel Moreno-Maroto, Carlos Javier Cobo-Ceacero, María Teresa Cotes-Palomino, and Carmen Martínez García. 2020. "Evaluation of the Environmental Benefits Associated with the Addition of Olive Pomace in the Manufacture of Lightweight Aggregates" Materials 13, no. 10: 2351. https://doi.org/10.3390/ma13102351

APA StyleUceda-Rodríguez, M., López-García, A. B., Moreno-Maroto, J. M., Cobo-Ceacero, C. J., Cotes-Palomino, M. T., & Martínez García, C. (2020). Evaluation of the Environmental Benefits Associated with the Addition of Olive Pomace in the Manufacture of Lightweight Aggregates. Materials, 13(10), 2351. https://doi.org/10.3390/ma13102351