Experimental Studies on the Centrifugal MQL-CCA Method of Applying Coolant during the Internal Cylindrical Grinding Process

Abstract

:1. Introduction

2. Setup of Centrifugal MQL-CCA Method of Coolant Delivery during Internal Cylindrical Grinding Process

- A ZR-K 360° six-nozzle, omnidirectional, minimum quantity lubrication head;

- MQL head supply system, with compressed air and oil from the workpiece spindle side;

- A specially designed grinding wheel arbor;

- The system used to fix the ZR-K 360° head inside the rotating grinding wheel arbor;

- A special ceramic grinding wheel with dimensions of 40 mm × 20 mm × 26 mm, adapted to work with the hollow grinding arbor;

- As a lubricant, an oil was used called Cimtech® MQL from CIMCOOL® Fluid Technology, part of Milacron LLC.

3. Experimental Research on the Internal Cylindrical Grinding Process

3.1. Methodology of Experimental Research

- Hybrid method of cooling and lubrication of the grinding zone, integrating centrifugal minimum quantity lubrication method and cooling with compressed cooled air stream (abbreviation: centrifugal MQL + CCA);

- Centrifugal minimum quantity lubrication (abbreviation: centrifugal MQL);

- Compressed cooled air flow cooling (abbreviation: CCA);

- Cooling and lubrication of the oil-in-water emulsion applied by the flood method (abbreviation: flood method);

- Grinding without cooling and lubrication agents (abbreviation: dry grinding).

3.2. Results of Experimental Studies and Their Analysis

- Grinding process efficiency based on the average grinding power Pav, volumetric wear of the grinding wheel Vs, material removal Vw, and grinding ratio G;

- Thermal conditions of the grinding process on the basis of infrared thermal imaging measurements;

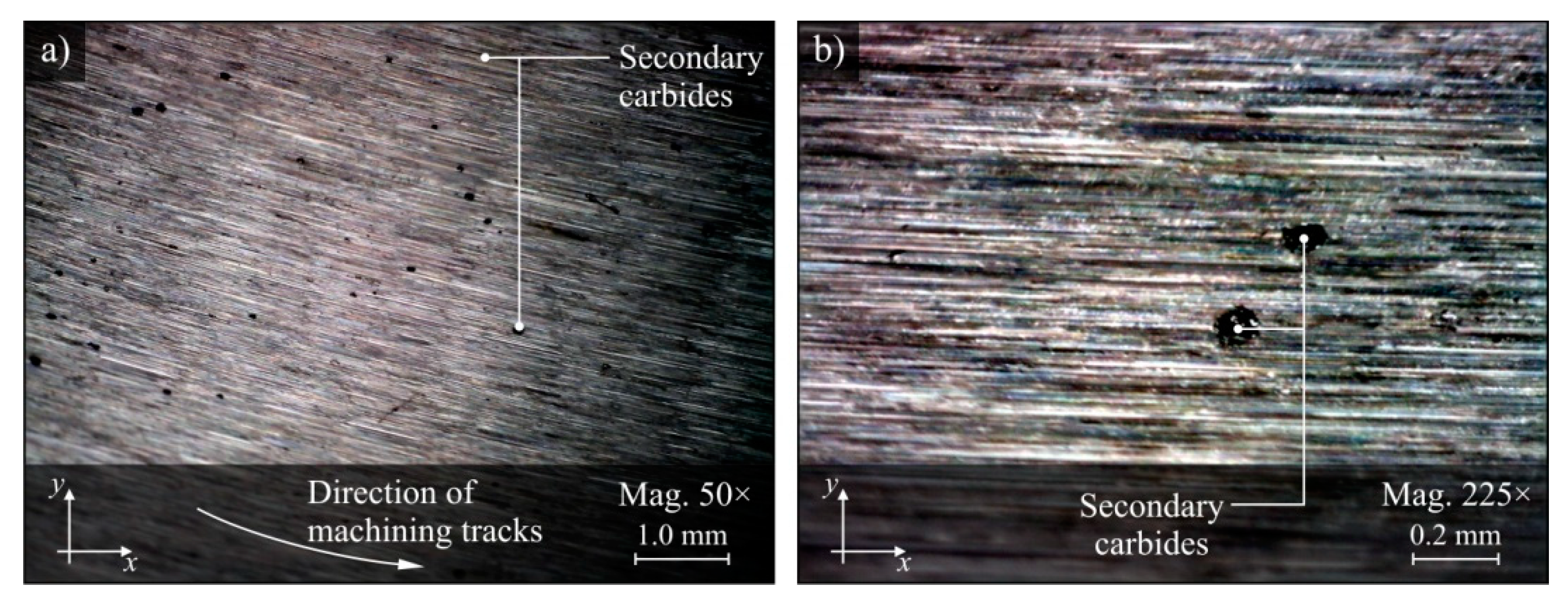

- Machined surface texture analysis;

- Residual stress in the surface layer of the ground surface determined by X-ray diffraction;

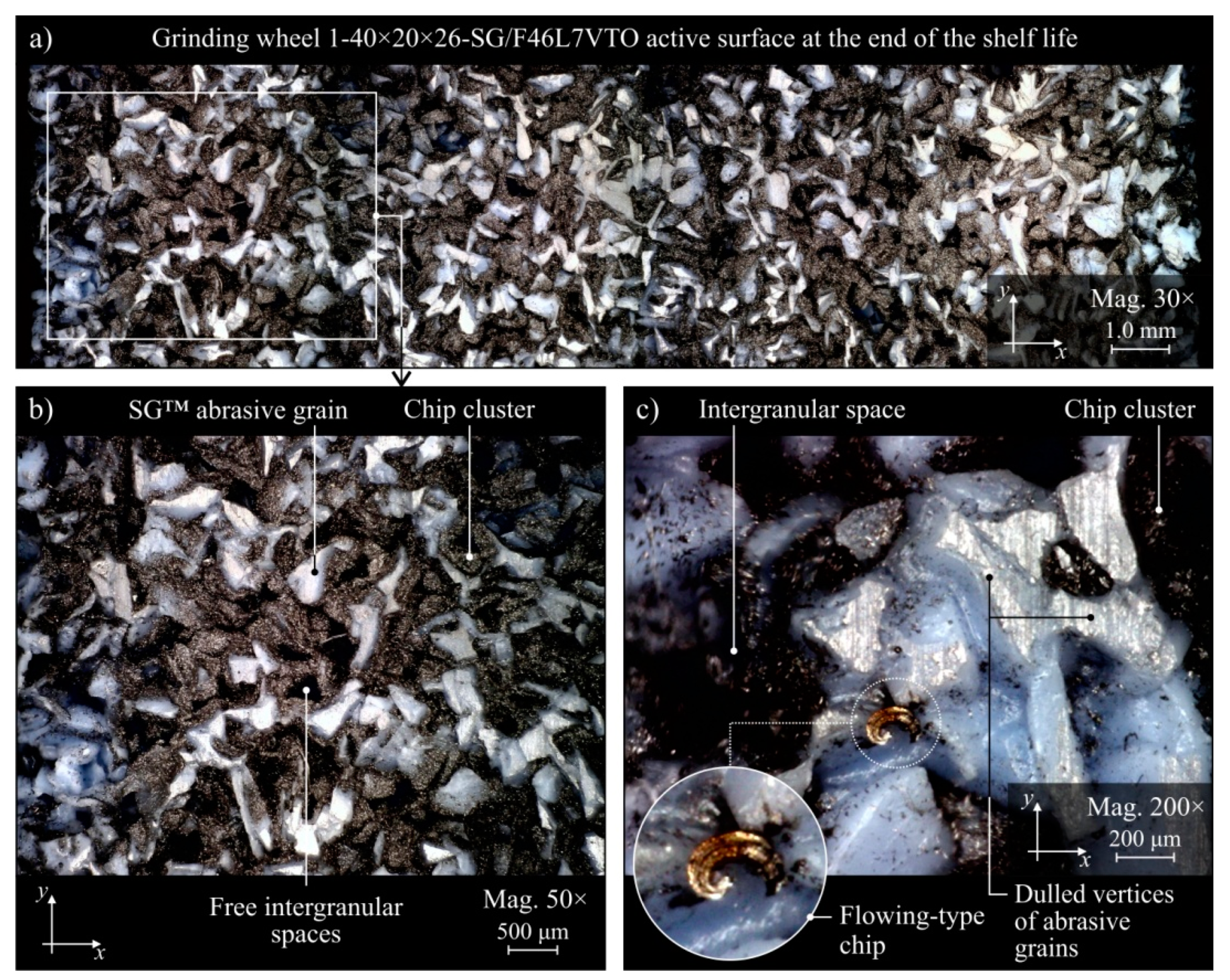

- Condition of the GWAS after grinding based on microtopography and microscopic images.

3.2.1. Evaluation of the Efficiency of the Grinding Process

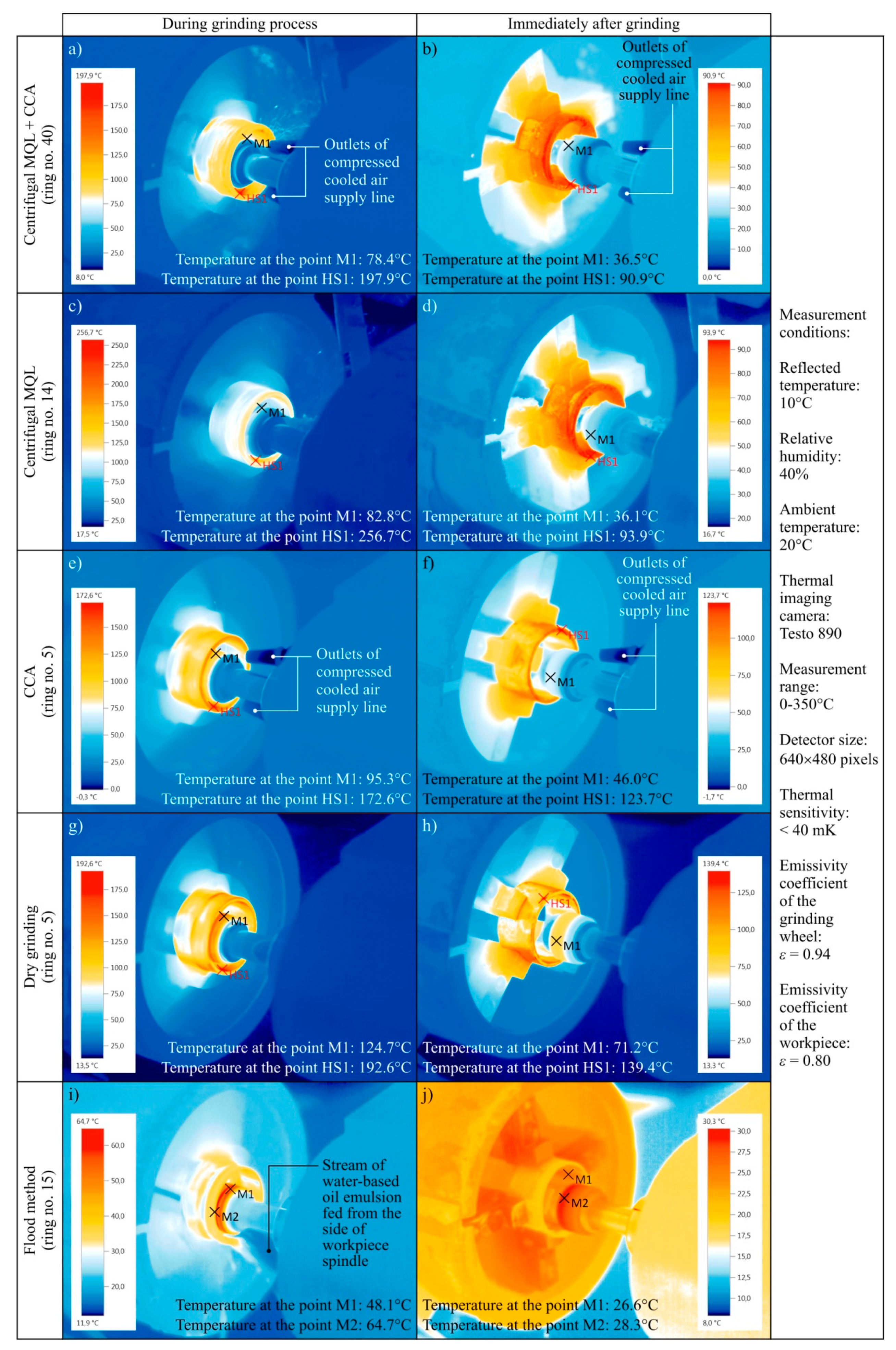

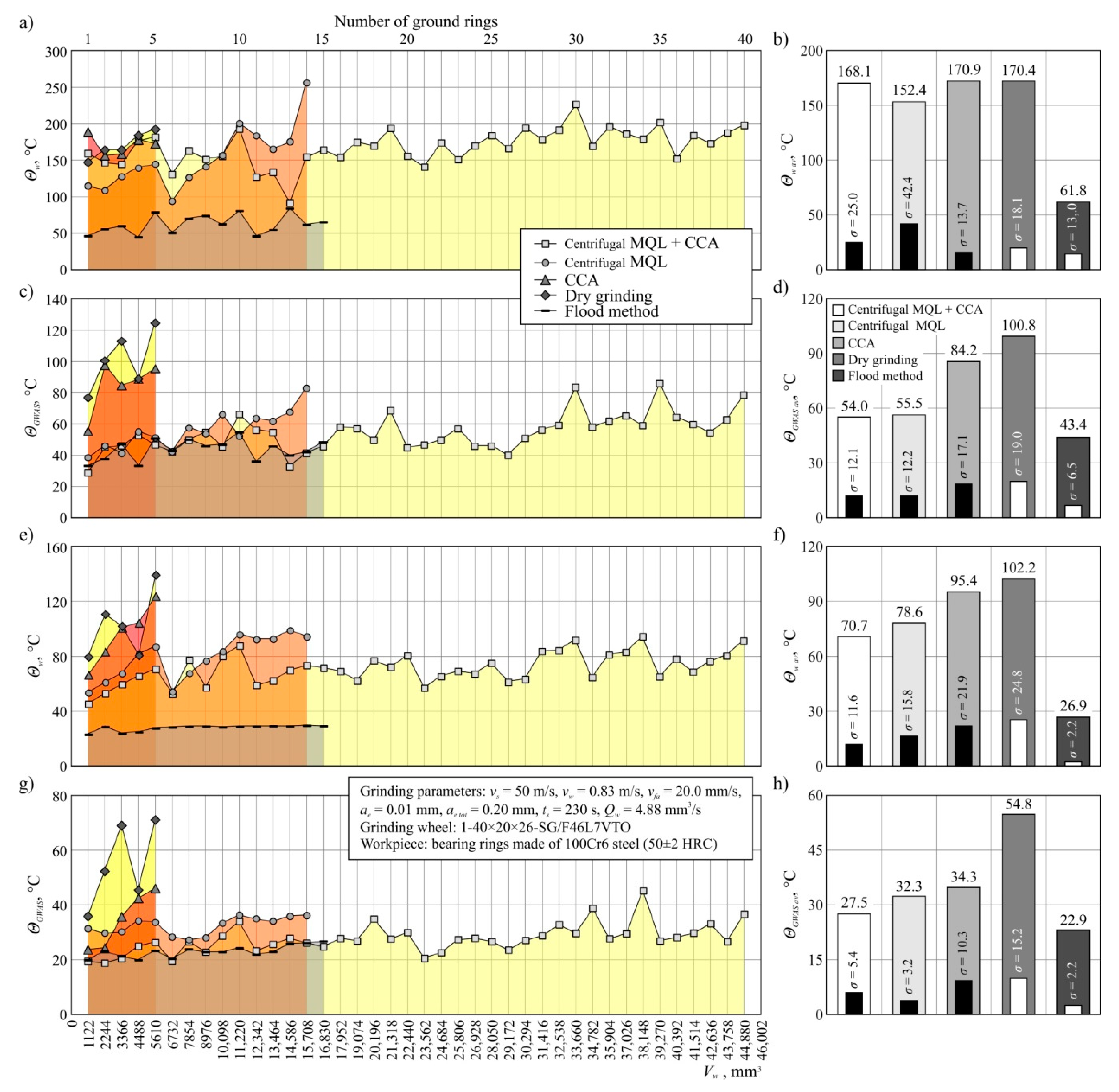

3.2.2. Evaluation of the Thermal Conditions of the Grinding Process on the Basis of Infrared Thermal Imaging Measurements

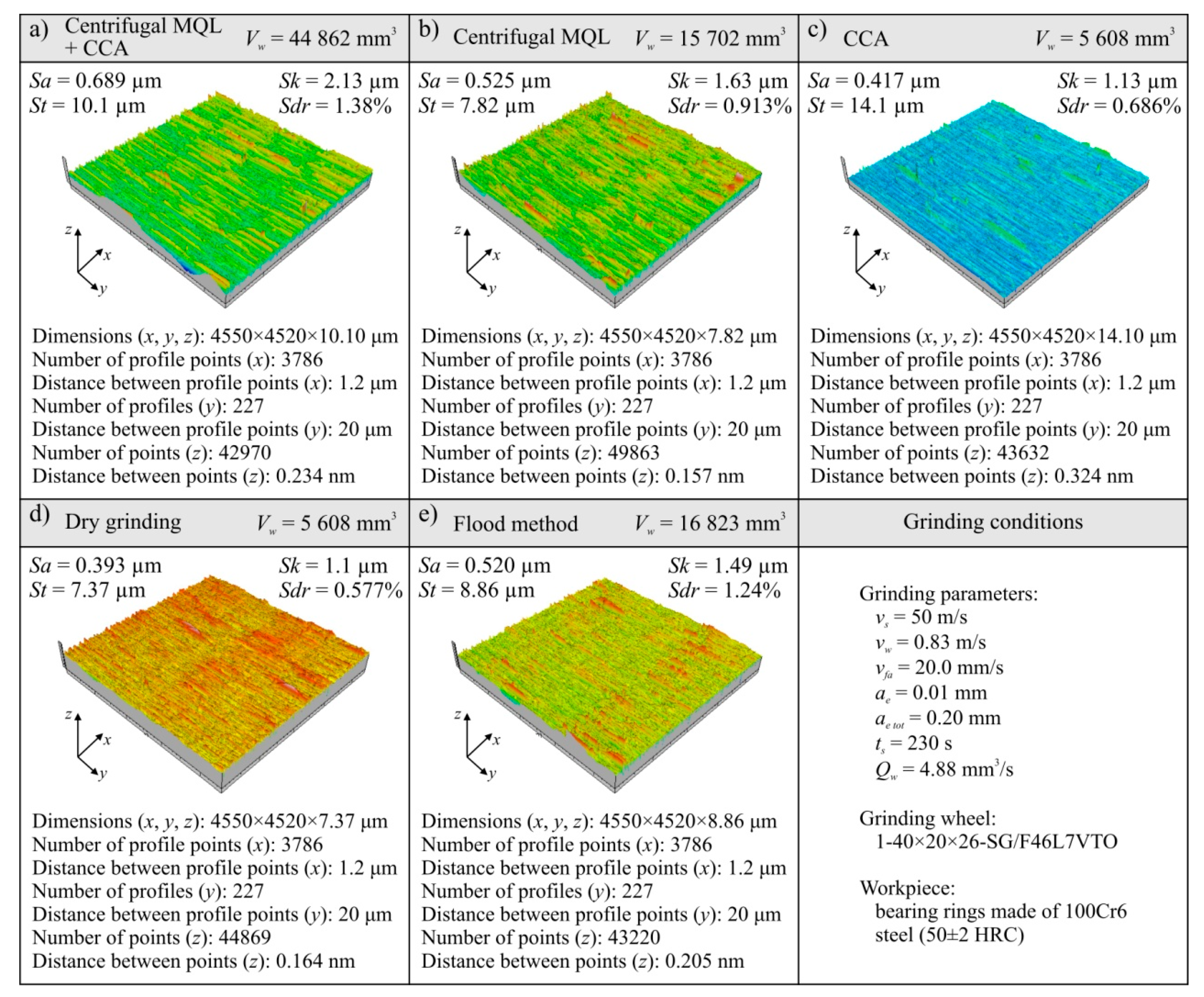

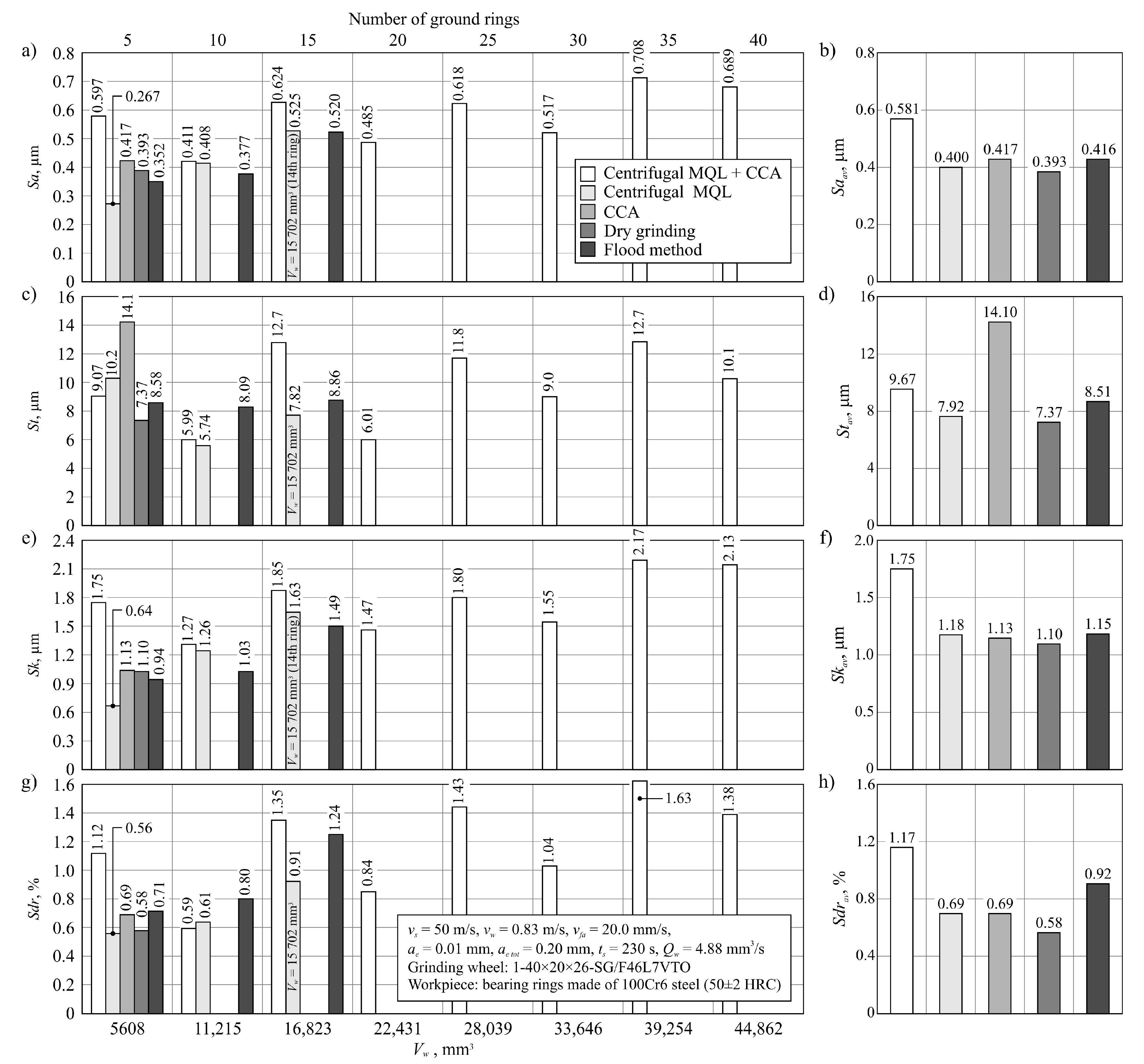

3.2.3. Machined Surface Roughness Analysis

3.2.4. Assessment of Residual Stress State in the Surface Layers of Ground Workpieces

3.2.5. Assessment of the Grinding Wheel Active Surface Condition after Grinding

4. Conclusions

- The application of the hybrid method allows the longest grinding wheel life among the five compared grinding types, which is about 2.7 times longer than the life of the flood cooled and centrifugal MQL grinding wheel, and as much as 8 times longer than the life of grinding wheels under the conditions of only CCA and dry grinding.

- In the case of hybrid grinding, the highest grinding ratio value G = 150.2 mm3/mm3 was obtained, which can be explained by the precise centrifugal supply of the lubricant (air–oil aerosol) through the pores of the grinding wheel to the grinding zone, and by the coolant (CCA stream) being directed before and directly behind the grinding zone.

- The application of simultaneous delivery of the air–oil aerosol and the CCA stream reduced the friction from the dulled grinding wheel vertices, resulting from the effective penetration of oil into the contact zone with the machined surface, while ensuring stable thermal conditions in the grinding zone. This limited the abrasive wear of the vertices of active abrasive grains, preserving their cutting ability over a longer period of operation.

- Temperature measurements carried out using the thermovision method showed that among the group of NDG methods (centrifugal MQL + CCA, centrifugal MQL, CCA), the newly developed hybrid method can be considered the most advantageous one, for which an approximately 30% lower value of Θw av = 70.7 °C and approximately 50% less lower value of ΘGWAS av = 27.5 °C were obtained in relation to the dry grinding results.

- Comparison of the texture parameters for particular grinding conditions showed slightly higher values for surfaces machined under cooling and lubrication conditions using the hybrid method, resulting from the significantly longer wheel life, which together with progressive wear, intensified the phenomenon of furrowing and formation of outflows accompanying the separation of the workpiece material in the form of chips, which had a negative effect on the roughness of the ground surface.

- The measurements of residual stresses on the surface layers of workpieces showed that in the y direction, consistent with the rotational movement of the wheel, the residual stresses in the surface layer were positive and gave values ranging from σy = 309,644 MPa. In the x direction (according to the axial feed of the grinding wheel fa) the values were significantly smaller, while for the centrifugal MQL method the measurement results were negative value (σx = −51 GPa), indicating the presence of compressive stress.

- The residual stress values in the surface layers of workpieces resulted from differences in cooling and lubrication conditions of the grinding zone; in the case of the hybrid cooling and lubrication method (centrifugal MQL + CCA), there was a phenomenon of intensive cooling of the area around the GWAS contact zone with the workpiece surface (similar to the flood method conditions), causing larger temperature drops resulting from rapid cooling of the machined surface than with the other methods included in the comparison.

- The quantitative and qualitative evaluation of the grinding of the GWAS with the hybrid method (centrifugal MQL + CCA) has confirmed the positive effect of the CCA flux in preventing the accumulation of chips in the grinding zone and their re-entry between the GWAS and the workpiece surface.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols | |

| ad | dressing allowance, mm |

| ae | working engagement (machining allowance), mm |

| ae tot | total working engagement (machining allowance), mm |

| bw | workpiece width, mm |

| Cp | heat capacity, kJ/kg·K |

| d0 | the interplane distance of the same network planes measured in a stress-free sample |

| ds | grinding wheel outer diameter, mm |

| dw | workpiece internal diameter, mm |

| dφ,ψ | the interplane distance of fixed network planes measured in the direction defined by angles φ and ψ in the deformed sample |

| E | Young’s modulus, GPa |

| F | grinding force, N |

| F’ | specific grinding force, N/mm |

| fa | grinding wheel axial feed, mm |

| G | grinding ratio, mm3/mm3 |

| id | number of dressing passes |

| nd | grinding wheel rotational speed while dressing, rpm |

| P | grinding power, W |

| Pav | average grinding power, W |

| QCCA | compressed cold air flow rate, dm3/min |

| Qd | diamond dresser mass, kt |

| QFM | flood method flow rate, L/min |

| QMQL | MQL method flow rate, mL/h |

| Qw | material removal rate, mm3/s |

| Q’w | specific material removal rate, mm3/s·mm |

| Ra | arithmetic mean deviation of the workpiece roughness profile, μm |

| Rz | maximum height of the roughness profile within a sampling length, μm |

| Sa | arithmetic mean deviation of the surface roughness, μm |

| Saav | average arithmetic mean deviation of the surface roughness, μm |

| Sdr | developed interfacial area ratio, % |

| Sdrav | average developed interfacial area ratio, % |

| Sk | roughness depth of the core, μm |

| Skav | average roughness depth of the core, μm |

| St | total height of the surface, μm |

| Stav | average total height of the surface, μm |

| ts | grinding time, s |

| Vs | grinding wheel volumetric wear, mm3 |

| Vw | material removal, mm3 |

| vfa | axial table feed speed while grinding, mm/s |

| vfd | axial table feed speed while dressing, mm/s |

| vs | grinding wheel peripheral speed, m/s |

| vw | workpiece peripheral speed, m/s |

| vs | grinding wheel peripheral speed, mm/s |

| vw | workpiece peripheral speed, mm/s |

| Greek symbols | |

| ΔP | grinding power gain, W |

| ΔPav | average grinding power gain, W |

| ε | emission coefficients for infrared thermal imaging measurements |

| εφ,ψ | deformation of the crystallographic network |

| λ | wavelength of the X-ray diffraction method radiation beam, nm |

| ΘGWAS | grinding wheel temperature, °C |

| ΘGWAS av | average grinding wheel temperature, °C |

| Θw | workpiece temperature, °C |

| Θw av | average workpiece temperature, °C |

| φ and ψ | the X-ray diffraction method direction angles, |

| σ | standard deviation |

| σx | residual stresses in the surface layer (x direction), MPa |

| σy | residual stresses in the surface layer (y direction), MPa |

| ν | Poison’s coefficient |

| Acronyms | |

| CAG | Cold Air Gun |

| CAMQL | Cold Air Minimum Quantity Lubrication |

| CAOM | Cold Air and Oil Mist |

| CCA | Compressed Cooled Air |

| CFD | Computational Fluid Dynamics |

| GWAS | Grinding Wheel Active Surface |

| MQC | Minimum Quantity Cooling |

| MQCL | Minimum Quantity Cooling Lubrication |

| MQL | Minimum Quantity Lubrication |

References

- Weinert, K.; Inasaki, I.; Sutherland, J.; Wakabayashi, T. Dry machining and minimum quantity lubrication. CIRP Ann. 2004, 53, 511–537. [Google Scholar] [CrossRef]

- Marinescu, I.D.; Dimitrov, B.; Gheorghiu, G.Z.; Grigorescu, A. Tribological aspects in utilization of superabrasives in metal cutting. In Proceedings of the 4th European Tribology Congress, Ecully, France, 9–12 September 1985. [Google Scholar]

- Marinescu, I.; Rowe, W.B.; Dimitrov, A.B.; Inasaki, I.; Dimitrov, B. Tribology of abrasive machining processes. J. Manuf. Sci. Eng. 2004, 126, 859. [Google Scholar] [CrossRef] [Green Version]

- Nadolny, K. Wear phenomena of grinding wheels with sol–gel alumina abrasive grains and glass–ceramic vitrified bond during internal cylindrical traverse grinding of 100Cr6 steel. Int. J. Adv. Manuf. Technol. 2014, 77, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Nadolny, K.; Kapłonek, W. The effect of wear phenomena of grinding wheels with sol-gel alumina on chip formation during internal cylindrical plunge grinding of 100Cr6 steel. Int. J. Adv. Manuf. Technol. 2016, 87, 501–517. [Google Scholar] [CrossRef] [Green Version]

- Sieniawski, J.; Nadolny, K. Experimental study on grinding wheel radial wear in surface grinding of steel CrV12 using a zonal centrifugal coolant provision system. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1452–1461. [Google Scholar] [CrossRef]

- Ramesh, K.; Yeo, S.H.; Zhong, Z.W.; Huang, H. Ecological grinding with chilled air as coolant. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 409–419. [Google Scholar] [CrossRef]

- Barczak, L.; Batako, A.D.; Morgan, M. A study of plane surface grinding under minimum quantity lubrication (MQL) conditions. Int. J. Mach. Tools Manuf. 2010, 50, 977–985. [Google Scholar] [CrossRef]

- Batako, A.D.; Tsiakoumis, V. An experimental investigation into resonance dry grinding of hardened steel and nickel alloys with element of MQL. Int. J. Adv. Manuf. Technol. 2014, 77, 27–41. [Google Scholar] [CrossRef]

- Bianchi, E.C.; Rodriguez, R.L.; Hildebrandt, R.A.; Lopes, J.C.; De Melo, H.J.; Da Silva, R.B.; De Aguiar, P.R. Plunge cylindrical grinding with the minimum quantity lubrication coolant technique assisted with wheel cleaning system. Int. J. Adv. Manuf. Technol. 2017, 95, 2907–2916. [Google Scholar] [CrossRef] [Green Version]

- Bianchi, E.C.; Sato, B.K.; Sales, A.R.; Lopes, J.C.; De Melo, H.J.; Sanchez, L.E.D.A.; Diniz, A.E.; Aguiar, P.R. Evaluating the effect of the compressed air wheel cleaning in grinding the AISI 4340 steel with CBN and MQL with water. Int. J. Adv. Manuf. Technol. 2017, 95, 2855–2864. [Google Scholar] [CrossRef] [Green Version]

- Chakule, R.R.; Chaudhari, S.S.; Talmale, P.S. Evaluation of the effects of machining parameters on MQL based surface grinding process using response surface methodology. J. Mech. Sci. Technol. 2017, 31, 3907–3916. [Google Scholar] [CrossRef]

- Davim, J.P. Machining: Fundamentals and Recent Advances; Springer: Berlin, Germany, 2008. [Google Scholar]

- Hadad, M. An experimental investigation of the effects of machining parameters on environmentally friendly grinding process. J. Clean. Prod. 2015, 108, 217–231. [Google Scholar] [CrossRef]

- Hadad, M.; Hadi, M. An investigation on surface grinding of hardened stainless steel S34700 and aluminum alloy AA6061 using minimum quantity of lubrication (MQL) technique. Int. J. Adv. Manuf. Technol. 2013, 68, 2145–2158. [Google Scholar] [CrossRef]

- Hadad, M.; Sharbati, A. Thermal aspects of environmentally friendly-MQL grinding process. Procedia CIRP 2016, 40, 509–515. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Ren, Y.; Jiang, W.; He, Z.; Deng, Z. Investigation on grind-hardening annealed AISI5140 steel with minimal quantity lubrication. Int. J. Adv. Manuf. Technol. 2016, 89, 1069–1077. [Google Scholar] [CrossRef]

- Morgan, M.; Barczak, L.M.; Batako, A.D. Temperatures in fine grinding with minimum quantity lubrication (MQL). Int. J. Adv. Manuf. Technol. 2011, 60, 951–958. [Google Scholar] [CrossRef]

- Rabiei, F.; Rahimi, A.; Hadad, M.; Ashrafijou, M. Performance improvement of minimum quantity lubrication (MQL) technique in surface grinding by modeling and optimization. J. Clean. Prod. 2015, 86, 447–460. [Google Scholar] [CrossRef]

- Sadeghi, M.H.; Haddad, M.J.; Tawakoli, T.; Emami, M. Minimal quantity lubrication-MQL in grinding of Ti–6Al–4V titanium alloy. Int. J. Adv. Manuf. Technol. 2008, 44, 487–500. [Google Scholar] [CrossRef]

- Sadeghi, M.H.; Hadad, M.J.; Tawakoli, T.; Vesali, A.; Emami, M. An investigation on surface grinding of AISI 4140 hardened steel using minimum quantity lubrication-MQL technique. Int. J. Mater. Form. 2010, 3, 241–251. [Google Scholar] [CrossRef]

- Da Silva, L.R.; Bianchi, E.C.; Catai, R.E.; Fusse, R.Y.; França, T.V.; Aguiar, P.R. Study on the behavior of the minimum quantity lubricant—MQL technique under different lubricating and cooling conditions when grinding ABNT 4340 steel. J. Braz. Soc. Mech. Sci. Eng. 2005, 27, 192–199. [Google Scholar] [CrossRef]

- Silva, L.R.; Bianchi, E.C.; Fusse, R.Y.; Catai, R.E.; Franca, T.V.; Aguiar, P.R. Analysis of surface integrity for minimum quantity lubricant—MQL in grinding. Int. J. Mach. Tools Manuf. 2007, 47, 412–418. [Google Scholar] [CrossRef]

- Tawakoli, T.; Hadad, M.J.; Sadeghi, M.H. Influence of oil mist parameters on minimum quantity lubrication—MQL grinding process. Int. J. Mach. Tools Manuf. 2010, 50, 521–531. [Google Scholar] [CrossRef]

- Tawakoli, T.; Hadad, M.; Sadeghi, M.H. Investigation on minimum quantity lubricant-MQL grinding of 100Cr6 hardened steel using different abrasive and coolant–lubricant types. Int. J. Mach. Tools Manuf. 2010, 50, 698–708. [Google Scholar] [CrossRef]

- Tawakoli, T.; Hadad, M.; Sadeghi, M.H.; Daneshi, A.; Sadeghi, B. Minimum quantity lubrication in grinding: Effects of abrasive and coolant–lubricant types. J. Clean. Prod. 2011, 19, 2088–2099. [Google Scholar] [CrossRef]

- Wójcik, R.; Nadolny, K. Effects of a variety of cutting fluids administered using the minimum quantity lubrication method on the surface grinding process for nickel-based alloys. J. Zhejiang Univ. A 2017, 18, 728–740. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 2015, 87, 930–940. [Google Scholar] [CrossRef]

- Zhang, D.; Li, C.; Zhang, Y.; Jia, D.; Zhang, X. Experimental research on the energy ratio coefficient and specific grinding energy in nanoparticle jet MQL grinding. Int. J. Adv. Manuf. Technol. 2015, 78, 1275–1288. [Google Scholar] [CrossRef]

- Priarone, P.C.; Robiglio, M.; Settineri, L.; Tebaldo, V. Effectiveness of minimizing cutting fluid use when turning difficult-to-cut alloys. Procedia CIRP 2015, 29, 341–346. [Google Scholar] [CrossRef]

- Ayoama, T. Development of a mixture supply system for machining with minimal quantity lubrication. CIRP Annals 2002, 51, 289–292. [Google Scholar] [CrossRef]

- Chandrasekaran, H.; Thuvander, A. Modelling tool stresses and temperature. Evaluation in turning using FEM. Mach. Sci. Technol. 1998, 2, 355–367. [Google Scholar] [CrossRef]

- Machado, A.R.; Wallbank, J. The effect of extremely low lubricant volumes in machining. Wear 1997, 210, 76–82. [Google Scholar] [CrossRef]

- Maruda, R.W.; Feldshtein, E.; Legutko, S.; Krolczyk, G.M. Analysis of contact phenomena and heat exchange in the cutting zone under minimum quantity cooling lubrication conditions. Arab. J. Sci. Eng. 2015, 41, 661–668. [Google Scholar] [CrossRef] [Green Version]

- Maruda, R.W.; Krolczyk, G.M.; Feldshtein, E.; Pusavec, F.; Szydlowski, M.; Legutko, S.; Sobczak-Kupiec, A. A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int. J. Mach. Tools Manuf. 2016, 100, 81–92. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Michalski, M.; Nieslony, P.; Wojciechowski, S. Structural and microhardness changes after turning of the AISI 1045 steel for minimum quantity cooling lubrication. J. Mater. Eng. Perform. 2016, 26, 431–438. [Google Scholar] [CrossRef] [Green Version]

- Maruda, R.W.; Legutko, S.; Krolczyk, G.M.; Raos, P. Influence of cooling conditions on the machining process under MQCL and MQL conditions. Teh. Vjesn. Tech. Gaz. 2015, 22, 965–970. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Li, J.; Wang, Y. Tool life and cutting forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. J. Clean. Prod. 2012, 32, 81–87. [Google Scholar] [CrossRef]

- Hadad, M.; Tawakoli, T.; Sadeghi, M.H.; Sadeghi, B. Temperature and energy partition in minimum quantity lubrication-MQL grinding process. Int. J. Mach. Tools Manuf. 2012, 54, 10–17. [Google Scholar] [CrossRef]

- Saberi, A.; Rahimi, A.; Parsa, H.; Ashrafijou, M.; Rabiei, F. Improvement of surface grinding process performance of CK45 soft steel by minimum quantity lubrication (MQL) technique using compressed cold air jet from vortex tube. J. Clean. Prod. 2016, 131, 728–738. [Google Scholar] [CrossRef]

- Choi, H.Z.; Lee, S.-W.; Jeong, H.D. The cooling effects of compressed cold air in cylindrical grinding with alumina and CBN wheels. J. Mater. Process. Technol. 2002, 127, 155–158. [Google Scholar] [CrossRef]

- Nguyen, T.; Zhang, L. An assessment of the applicability of cold air and oil mist in surface grinding. J. Mater. Process. Technol. 2003, 140, 224–230. [Google Scholar] [CrossRef]

- Stachurski, W.; Nadolny, K. Influence of the condition of the surface layer of a hob cutter sharpened using the MQL-CCA hybrid method of coolant provision on its operational wear. Int. J. Adv. Manuf. Technol. 2018, 98, 2185–2200. [Google Scholar] [CrossRef] [Green Version]

- Stachurski, W.; Sawicki, J.; Wójcik, R.; Nadolny, K. Influence of application of hybrid MQL-CCA method of applying coolant during hob cutter sharpening on cutting blade surface condition. J. Clean. Prod. 2018, 171, 892–910. [Google Scholar] [CrossRef]

- Yui, A.; Terashima, M. Abrasive Technology; World Scientific: Singapore, 1999; pp. 394–399. [Google Scholar]

- Rabiei, F.; Rahimi, A.; Hadad, M.J.; Saberi, A. Experimental evaluation of coolant-lubricant properties of nanofluids in ultrasonic assistant MQL grinding. Int. J. Adv. Manuf. Technol. 2017, 93, 3935–3953. [Google Scholar] [CrossRef]

- Ravuri, B.P.; Goriparthi, B.K.; Srikant, R.; Gopal, A.V. Performance evaluation of grinding wheels impregnated with graphene nanoplatelets. Int. J. Adv. Manuf. Technol. 2015, 85, 2235–2245. [Google Scholar] [CrossRef]

- Tawakoli, T.; Hadad, M.; Sadeghi, M.; Daneshi, A.; Stockert, S.; Rasifard, A. An experimental investigation of the effects of workpiece and grinding parameters on minimum quantity lubrication—MQL grinding. Int. J. Mach. Tools Manuf. 2009, 49, 924–932. [Google Scholar] [CrossRef]

- Damasceno, R.F.; Ruzzi, R.D.S.; França, T.; De Melo, H.J.; Da Silva, R.B.; Aguiar, P.R.; Bianchi, E.C. Performance evaluation of various cooling-lubrication techniques in grinding of hardened AISI 4340 steel with vitrified bonded CBN wheel. Int. J. Adv. Manuf. Technol. 2017, 92, 3795–3806. [Google Scholar] [CrossRef] [Green Version]

- Rowe, W.B.; Morgan, M.N.; Qi, H.; Zheng, H. The effect of deformation on the contact area in grinding. CIRP Ann. 1993, 42, 409–412. [Google Scholar] [CrossRef]

- Simões, R.; Bianchi, E.C.; Oikawa, M.H.; De Aguiar, P.R.; Júnior, R.D.; Canarim, R.C. Evaluation of different methods of cooling-lubrication in cylindrical grinding of advanced ceramic dip. Mater. Res. 2014, 17, 1201–1212. [Google Scholar] [CrossRef]

- Ebbrell, S.; Woolley, N.; Tridimas, Y.; Allanson, D.; Rowe, W.B. The effects of cutting fluid application methods on the grinding process. Int. J. Mach. Tools Manuf. 2000, 40, 209–223. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.; Gomes, R.; Peixoto, C. Experimental studies on drilling of aluminium (AA1050) under dry, minimum quantity of lubricant, and flood-lubricated conditions. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1605–1611. [Google Scholar] [CrossRef]

- Hafenbraedl, D.; Malkin, S. Technology environmentally correct for intern cylindrical grinding. Mach. Met. Mag. 2001, 426, 40–55. [Google Scholar]

- Cetin, M.H.; Ozcelik, B.; Kuram, E.; Demirbas, E. Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by taguchi method. J. Clean. Prod. 2011, 19, 2049–2056. [Google Scholar] [CrossRef]

- Oliveira, D.D.J.; Guermandi, L.G.; Bianchi, E.C.; Diniz, A.E.; De Aguiar, P.R.; Canarim, R.C. Improving minimum quantity lubrication in CBN grinding using compressed air wheel cleaning. J. Mater. Process. Technol. 2012, 212, 2559–2568. [Google Scholar] [CrossRef] [Green Version]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—Part I: Application on machining technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- Li, C.H.; Hou, Y.L.; Xiu, S.C.; Cai, G.Q. Application of lubrication theory to neardry-green grinding-feasibility analysis. Adv. Mater. Res. 2008, 44, 135–142. [Google Scholar]

- Lee, P.-H.; Lee, S.W. Experimental characterization of micro-grinding process using compressed chilly air. Int. J. Mach. Tools Manuf. 2011, 51, 201–209. [Google Scholar] [CrossRef]

- Liu, N.-M.; Chiang, K.-T.; Hung, C.-M. Modeling and analyzing the effects of air-cooled turning on the machinability of Ti–6Al–4V titanium alloy using the cold air gun coolant system. Int. J. Adv. Manuf. Technol. 2012, 67, 1053–1066. [Google Scholar] [CrossRef]

- Choi, H.; Lee, S.; Jeong, H. A comparison of the cooling effects of compressed cold air and coolant for cylindrical grinding with a CBN wheel. J. Mater. Process. Technol. 2001, 111, 265–268. [Google Scholar] [CrossRef]

- Kieraś, S.; Nadolny, K. Overview of the centrifugal methods of provision the grinding fluid to the grinding zone. J. Mech. Energy Eng. 2017, 1, 7–14. [Google Scholar]

- Vortec: Cold Air Guns. Available online: https://www.vortec.com/cold-air-guns (accessed on 5 February 2020).

- Nadolny, K. State of the art in production, properties and applications of the microcrystalline sintered corundum abrasive grains. Int. J. Adv. Manuf. Technol. 2014, 74, 1445–1457. [Google Scholar] [CrossRef] [Green Version]

- Kieraś, S.; Jakubowski, M.; Nadolny, K. Simulation studies on centrifugal MQL-CCA method of applying coolant during internal cylindrical grinding process. Materials 2020, in press. [Google Scholar]

- Herman, D. Glass and glass-ceramic binder obtained from waste material for binding alundum abrasive grains into grinding wheels. Ceram. Int. 1998, 24, 515–520. [Google Scholar] [CrossRef]

- Heřman, D.; Plichta, J.; Karpinski, T. Effect of glass-crystalline and amorphous binder application to abrasive tools made of microcrystalline alumina grains type SG. Wear 1997, 209, 213–218. [Google Scholar] [CrossRef]

- Nadolny, K.; Herman, D. Effect of vitrified bond microstructure and volume fraction in the grinding wheel on traverse internal cylindrical grinding of Inconel® alloy 600. Int. J. Adv. Manuf. Technol. 2015, 81, 905–915. [Google Scholar] [CrossRef] [Green Version]

- Hobson, T. Talysurf CLI 3D Surface Profiling Systems; Taylor-Hobson Ltd.: Leicester, UK, 2005. [Google Scholar]

- Dino-Lite Edge AM7915MZT Specification. Available online: http://www.dino-lite.com/products_detail.php?index_id=130 (accessed on 8 February 2020).

- Emissivity Values for Common Materials. Available online: http://www.infrared-thermography.com/material-1.htm (accessed on 5 February 2020).

- Table of Total Emissivity. Available online: http://www.monarchinstrument.com/pdfs/TableofEmissivity.pdf (accessed on 3 February 2020).

- Klocke, F. Manufacturing Processes 2, Grinding, Honing, Lapping; Springer: Berlin, Germany, 2009. [Google Scholar]

- Sieniawski, J.; Nadolny, K. The effect upon grinding fluid demand and workpiece quality when an innovative zonal centrifugal provision method is implemented in the surface grinding of steel CrV12. J. Clean. Prod. 2016, 113, 960–972. [Google Scholar] [CrossRef]

| Cooling and Lubrication Method | Type of Medium | Heat Capacity Cp, kJ/kg·K |

|---|---|---|

| Flood method (usually 3–5% oil-in-water emulsion) | Water | 4.18 |

| MQL (air–oil aerosol) | Oil | 1.92 |

| Air | 1.04 |

| Process | Reciprocal, peripheral internal cylindrical grinding | ||||

| Grinding Machine | Universal grinding machine RUP 28P manufactured by Mechanical Works Tarnów SA | ||||

| Grinding Wheel | 1-40 × 20 × 26-SG/F46L7VTO | ||||

| Grinding Parameters | vs = 50 m/s, vw = 0.83 m/s, vfa = 20.0 mm/s, ae = 0.01 mm, ae tot = 0.20 mm, ts = 230 s; Qw = 4.88 mm3/s | ||||

| Workpiece | Internal surfaces of bearing rings made of 100Cr6 steel (50 ± 2 HRC), internal diameter: dw = 51 mm, width: bw = 35 mm | ||||

| Cooling and Lubricating | Centrifugal MQL + CCA | Centrifugal MQL | CCA | Flood method | Dry grinding |

| Lubricating Agent | Centrifugally delivered air–oil aerosol (through a grinding wheel) | Centrifugally delivered air–oil aerosol (through a grinding wheel) | – | 5% aqueous solution of Castrol Syntilo RHS oil delivered by the flood method with working pressure of 0.12 MPa and flow rate QFM = 4.0 L/min | – |

| Head: ZR-K 360° | Head: ZR-K 360° | ||||

| Supply air pressure: 0.6 MPa | Supply air pressure: 0.6 MPa | ||||

| Oil: Cimtech® MQL | Oil: Cimtech® MQL | ||||

| QMQL = 350 mL/h | QMQL = 350 mL/h | ||||

| Cooling Agent | Compressed cooled air | – | Compressed cooled air | ||

| Nozzle: Vortec 610 | Nozzle: Vortec 610 | ||||

| Supply pressure: 0.6 MPa | Supply pressure: 0.6 MPa | ||||

| QCCA = 49.8 dm3/min | QCCA = 49.8 dm3/min | ||||

| Temperature of CCA: −5 °C | Temperature of CCA: −5 °C | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nadolny, K.; Kieraś, S. Experimental Studies on the Centrifugal MQL-CCA Method of Applying Coolant during the Internal Cylindrical Grinding Process. Materials 2020, 13, 2383. https://doi.org/10.3390/ma13102383

Nadolny K, Kieraś S. Experimental Studies on the Centrifugal MQL-CCA Method of Applying Coolant during the Internal Cylindrical Grinding Process. Materials. 2020; 13(10):2383. https://doi.org/10.3390/ma13102383

Chicago/Turabian StyleNadolny, Krzysztof, and Seweryn Kieraś. 2020. "Experimental Studies on the Centrifugal MQL-CCA Method of Applying Coolant during the Internal Cylindrical Grinding Process" Materials 13, no. 10: 2383. https://doi.org/10.3390/ma13102383

APA StyleNadolny, K., & Kieraś, S. (2020). Experimental Studies on the Centrifugal MQL-CCA Method of Applying Coolant during the Internal Cylindrical Grinding Process. Materials, 13(10), 2383. https://doi.org/10.3390/ma13102383