1. Introduction

Due to their beneficial properties: their large specific rigidity, large elastic modulus, enhanced fatigue features, light weight, corrosion resistance, and reduced magnetic and acoustic signatures [

1] when compared to metals, Fiber Reinforced Composites (FRCs) are increasingly used in different types of industries. FRCs have also been used in the modeling and fabrication of various shapes pressure hulls including elliptical, cylindrical, spherical and ovoid because of their greater strength-to-weight ratio than metals and other alloys [

2]. Many studies are available concerning the optimization of composite pressure hulls featuring cylindrical and elliptical configurations. Nevertheless, as reported in the latest research, spherical and ovoid pressure hulls fabricated with steels and other metal alloys were shown to possess better characteristics than other types of pressure hulls. The spherical hull has a low buoyancy factor and the distribution of stress and displacement in its material is very effective [

3], and the most advantageous properties of the ovoid are high strength-to-weight ratio, high span to thickness ratio, good stability, and good material distribution [

3,

4]. Moreover, the design of composite pressure hulls mainly depends on the number of ply layers, fiber orientation angles and material systems. Therefore, it is very important to conduct optimization studies of the composite spherical pressure hull to further explore the benefits of using composites in its construction.

An inclusive literature survey on the optimization of different composite structures such as beams, plates and shells is given in [

5]. Different types of composite pressure hulls were optimized by combining the optimization algorithm with numerical analysis:

Pelletier and Vel [

6] used a genetic algorithm (GA) to achieve optimized designs of a graphite/epoxy cylindrical shell. Maximizing the axial and hoop rigidities and minimizing the mass were selected as objectives under material failure constraint. A graphite/epoxy cylindrical shell, where the objective function was the maximization of fundamental natural frequency and buckling load and the ply angle was used as a design variable was optimized by Topal [

7] using the Modified Feasible Direction (MFD) method. Messager et al. [

8] combined a standard GA with an analytical model of shell buckling to conduct optimization of carbon/epoxy, and glass/epoxy cylindrical pressure hulls for maximum buckling pressure. Shen et al. [

9] employed the Sub Problem Approximation (SPA) technique in ANSYS to perform optimization of a composite cylinder for submersible pressure hulls where maximization of design pressure was used as an objective function while buckling pressure and composite failure were used as constraints for the design optimization process. Fathallah et al. [

10] employed the Sub Problem Approximation (SPA) method in ANSYS to carry out a design optimization study of stiffened composite elliptical pressure hull to minimize the buoyancy factor

. The material and instability constraints of the optimization were Tsai-Wu and maximum stress composite failure criteria and buckling strength factors. In another study, Fathallah et al. [

11] used a similar approach for optimization of a stiffened elliptical composite submerged pressure hull with initial lay-ups [(0°/45°/−45°/90°)4]. The objective function and constraints were the same as used in [

10]. Liang et al. [

12] employed a Hybrid Genetic Algorithm (HGA) to optimize the PVC sandwich core composite submersible pressure hull. The constraints of the optimization were materials failure and shell buckling under hydrostatic pressure. They used three composite materials, graphite/epoxy, boron/epoxy, and glass/epoxy for modeling the face skin. R. Craven et al. [

13] conducted a conceptual design study of a submersible composite pressure hull in ABAQUS. Their study was aimed at reducing the weights of the carbon/epoxy and glass/epoxy composite pressure hulls while keeping composite failure and buckling strength as material and instability constraints.

Shen et al. [

14,

15], in similar studies, used a GA coupled with numerical analysis for design optimization of carbon/epoxy and carbon/epoxy, boron/epoxy, and glass/epoxy composite pressure hulls under hydrostatic pressure. The objective was to maximize the design pressure under constraints on material failure and buckling instability. The Tsai-Wu composite material failure criterion was used for modeling the composite failure. Li et al. [

16] developed a procedure for collaborative design optimization of a ring-stiffened composite pressure hull under material failure constraints. They adopted the ellipsoidal basis function neural network for replacing the finite element (FE) analysis in the optimization program.

Praveen et al. [

17] carried out a multi-objective design optimization of a composite cylindrical skirt under the combined effects of axial thrust and torque using a modified NSGA-II. The optimization was carried out for two material systems subjected to material and instability constraints. Wei et al. [

18], carried out a stacking sequence optimization for maximum buckling load using a GA coupled with FE analysis. Based on the stiffnesses ratios of the optimized stacking sequence, a stiffness coefficient-based procedure was developed and coupled with the GA to arrive at a stacking sequence close to that previously optimized. Talebitooti et al. [

19], developed a technique for a multi-objective design optimization of sound transmission loss for a composite cylindrical shell under a plane sound wave using NSGA-II and First-order Shear Deformation Theory (FSDT). A significant improvement in performance of the structure was obtained based on the maximization of the sound transmission and minimization of the weight. Rouhi et al. [

20], performed a buckling optimization study of a variable stiffness composite cylinder subjected to two bending loads at the opposite ends. They employed a compromised programing procedure for the combining of the two objectives (structure performance at the two opposite ends) into a single objective using different weight factors for each objective. Blom et al. [

21], conducted a design optimization study of a variable stiffness composite cylinder for maximum buckling pressure subjected to a bending load. The design methodology was implemented in ABAQUS for performing FE analysis. To reduce the analysis time, the FE analysis was then replaced with a surrogate model in the subsequent optimization of the composite cylinder under constraint on material failure. Khani et al. [

22] used a semi-analytical analysis coupled with a multi-level optimization approach for design optimization of fiber steered longitudinally stiffened composite cylinders subjected to bending moments. The optimization was carried out for achieving maximum buckling capacity under constraints on the material failure of the composite material. Imran et al. [

23], conducted a design optimization study of a submersible composite cylindrical pressure hull for maximum buoyancy factor subjected to constraint on material and buckling strengths. They used several lay-up arrangements and three unidirectional composite materials for modeling of the composite pressure hull. Some studies are also available on the optimization of composite spherical shells. Topal [

24], conducted frequency optimization of a composite spherical shell by using the Modified Feasible Direction (MFD) method and FE analysis. The maximization of frequency was used as the objective, and the fiber’s orientation angle was used as a design variable of the optimization study. Faris et al. [

25], optimized the ply thickness, fiber’s orientation angle and closed-loop control force of spherical and cylindrical composite shells. The objective was to minimize the dynamic response of the shells under constraints on thickness and control energy. The dynamic response of the shells was represented by the sum of the total elastic energy of the shells and a penalty function of the closed-loop control force.

Several studies looked into the non-linear buckling analysis of composite shells. However, based on the available literature, the research work done on the same subject was mostly restricted to composite cylindrical shells. Several techniques were used for carrying out non-linear buckling analysis and the incorporation methods and influence of different types of imperfections on the buckling behavior of the composite shell were studied in detail. Hilburger et al. [

26], carried out experimental and FE investigations to study the influence of imperfections on the buckling performance of graphite/epoxy cylinders under compression loading. They used both traditional and non-traditional imperfection approaches during the non-linear buckling analysis. Tsouvalis et al. [

27] performed a numerical and experimental study to investigate the influence of the geometric imperfection on the stability performance of composite cylinders subjected to hydrostatic pressure. The imperfection in the geometry of the composite cylinder was measured by measuring the thickness of the cylinder at 252 points located on the internal and external surfaces. In the FE model, the imperfection on both surfaces was modeled using the two-dimensional smooth cubic spline interpolation. The knockdown factor (KDF) as low as 0.6 was obtained based on the maximum size of the imperfection. Wagner et al. [

28] carried out a comprehensive study to calculate the robust knockdown factors (KDFs) of composite cylindrical and conical composite shells under axial load. They modeled the buckling experiments of Starnes et al. [

29] using the Single Boundary Perturbation Approach (SBPA) and the Single Perturbation Displacement Approach (SPDA) to demonstrate that these approaches could be efficiently used for the design of composite cylinders subjected to axial loads. They also compared the knockdown factors calculated for axially loaded cylinders from their earlier study, Wagner et al. [

30], with those calculated by different empirical approaches for similar cylinders. Castro el al. [

31] used geometric imperfection and lower bound approaches to determine the knockdown factors (KDFs) for composite cylinders subjected to axial compression. They compared the Single Perturbation Load Approach (SPLA) with four others routinely used geometric imperfection approaches. FE analysis employing the static analysis with artificial damping was carried out for analyzing the buckling behavior of the composite cylinders up to the post-buckling region. Khakimova et al. [

32] used the SPLA to determine the response of the conical composite structures to imperfection. The SPLA was applied to perfect structure and imperfect structure. The geometric imperfection in the structure was included using the thickness imperfection and mid-surface imperfection. It was concluded that the KDFs calculated employing the SPLA was less conservative than those determined by NASA. Wang et al. [

33] used the similitude transformation approach and scaling laws to carry out geometrically non-linear buckling analysis of shallow composite spherical shell. The similitude condition and the law for scaling the model was fulfilled by the direct application of the partial similarity transformation to the total energy equation of the system. Hao et al. [

34] carried out a numerical investigation on the effects of changing imperfection sizes on the buckling and post-buckling behavior of the stiffened shell of a hyperbolic generatrix shape. Based on the detailed results obtained in the first part, a surrogate optimization study was then carried out to determine the optimum parameters for the stiffened shell under the weight constraints. Wagner et al. [

35] developed a new design procedure known as single perturbation cutout approach (SPCA) for the calculation of the KDF for a thin spherical shell. In the new method, the geometric imperfection was replaced with cutouts in the shell. The proposed method was validated against a large volume of available test data and it was also concluded that the SPCA could also be used to assess the imperfection sensitivity of the composite spherical shell subjected to external pressure. Zang et al. [

36] employed a third-order shear deformation theory to carry out the non-linear buckling analysis of a laminated shallow spherical shell. The influence of imperfections on the buckling behavior of the composite spherical shell was investigated using a dimple shaped imperfection and a localized flattening on the surface of the shell.

There are no specific rules available in the open literature for carrying out non-linear buckling analysis of spherical pressure hulls constructed with composite materials. However, rules are available for non-linear buckling analysis of shells and pressure hulls constructed with steel and other alloys [

37,

38]. According to these rules, non-linear buckling analysis of the shells or pressure hulls constructed with steel and other alloys is conducted by using both geometric and material non-linearity with and without the incorporation of imperfection. Appendix E of the Chinese Classification Society Rules for Diving Systems and Submersibles [

37] describes the procedure for conducting the non-linear buckling analysis for the determination of the ultimate strength of the cylindrical and spherical pressure hull constructed with steel or other alloys. These rules also state that a non-linear FE analysis of the pressure hull is based on two imperfection analysis methods. In the first method, a linear buckling analysis of the perfect structure is performed to determine the first linear buckling mode. The linear buckling mode is then applied with an imperfection amplitude in the geometric non-linear analysis with material non-linearity and the ultimate strength of the pressure hull is determined. In the second method, which is known as the inherent geometric imperfection method, the imperfection is included in the pressure hull during the modeling process and the non-linear FE analysis is carried out directly to determine the ultimate strength of the pressure hull. In the inherent imperfection method, the imperfection may be included in any position of the spherical pressure hull, while the imperfection is included in the middle section of the cylindrical pressure hull. According to the author’s knowledge non-linear properties of Fiber Reinforced Plastic (FRP) composites such as carbon/epoxy, glass/epoxy and boron/epoxy are not available in the open literature. Therefore, non-linear buckling simulations of the composite spherical pressure hull are performed employing linear elastic material properties with geometric non-linearity and imperfections.

Several studies are available in the literature concerning buckling investigations of non-composite spherical pressure hulls. Both linear and non-linear buckling analyses with geometric and material non-linearity were used in the investigations of spherical hulls [

39,

40,

41,

42,

43,

44,

45,

46,

47,

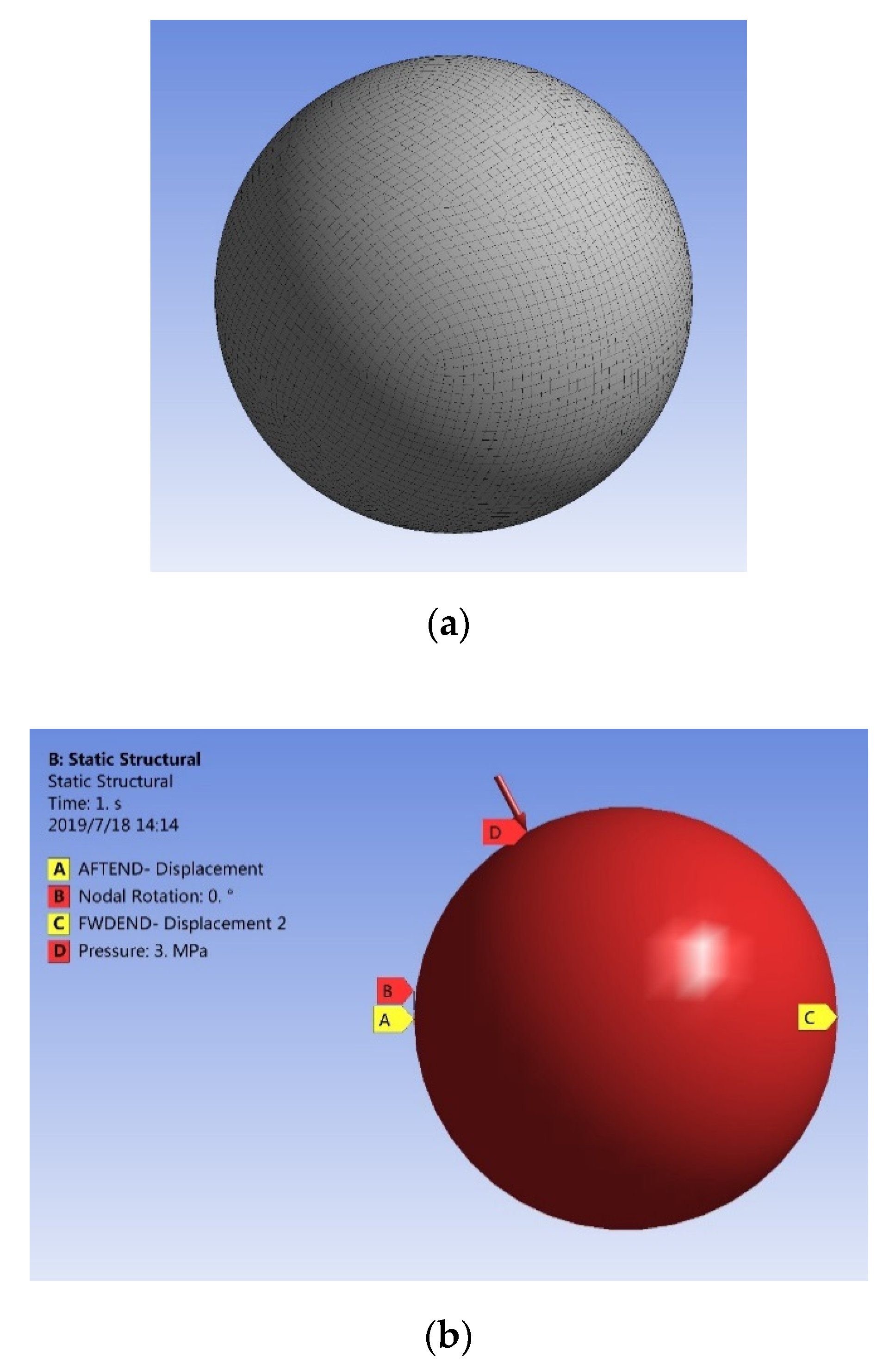

48]. However, the benefit of using composites in the construction of spherical hulls are not yet deeply investigated. In the present paper, an optimization study of a composite spherical pressure hull is performed as an attempt to further reduce its weight as compared to a spherical hull constructed with steels and other alloys. The optimization study is conducted in ANSYS employing a GA coupled with FE analysis [

49]. The optimum number of layers and angles of orientation are determined for laminates including, [0

S/90

T/0

U], [10

S/-10

T/90

U/-10

V/10

W], [β

1S/β

2T], [β

1S/β

2T/β

3U] and [β

1S/β

2T/β

3U/β

4V/β

5W] employing carbon/epoxy, glass/epoxy, and boron/epoxy. The minimization of the buoyancy factor

is selected as the design optimization objective subjected to constraints on Tsai-Wu and Tsai-Hill failure criteria and buckling strength factor. In the second part of this paper, non-linear buckling simulations of the composite spherical pressure hull are conducted to study the effect of imperfection size on the collapse depth of the pressure hull.

3. Results and Discussions

The results of the parametric study for a steel hull are presented in

Table 3. The buoyancy factor

for this hull was 0.17958. For a steel hull of 19 mm thickness, the maximum Von-Mises stress

was 368.73 MPa and the buckling strength factor

was equal to 3.1569.

The plot of convergence criteria and history plot for the buoyancy factor for a carbon/epoxy lay-up [β

1S/β

2T] are shown in

Figure 4 and

Figure 5. It can be observed from both plots that the optimization of a carbon/epoxy lay-up [β

1S/β

2T] converges after fulfilling the 70% Pareto percentage and 2% convergence stability criteria in 275 optimization runs. The comparison between the results of optimization for a carbon/epoxy composite lay-up [0

S/90

T/0

U] using ABAQUS and ISIGHT, and ANSYS is presented in

Table 4. It can be noted that the buoyancy factor

and buckling strength factor calculated using ABAQUS, ISIGHT, and ANSYS optimization studies closely follow each other. The results of design optimization of the spherical composite submersible pressure hull for all considered lay-ups and material systems are discussed in the following sections and listed in

Table 5,

Table 6,

Table 7,

Table 8 and

Table 9.

In the case of lay-ups [0

S/90

T/0

U] and [10

S/-10

T/90

U/-10

V/10

W], the number of each layer could take a value from 1 to 75. The results of lay-up [

0S/90T/0U] listed in

Table 5 demonstrates that the minimum buoyancy factor

of 0.06117 with

equal to 65.937% was computed for carbon/epoxy. The values of

,

and

of carbon/epoxy equaled 4.3119, 2.7085 and 1.7341 respectively. In the case of the glass/epoxy composite, the buoyancy factor

equaled 0.10143 with a decrease over the reference steel hull

= 43.518%. For glass/epoxy, the values of

,

and

were computed as 2.6486, 2.286 and 1.8912 respectively. Similarly, the buoyancy factor

for boron/epoxy was computed as 0.08452 with a decrease over the reference steel hull

= 52.934%. For the same material, the values of

,

and

were computed as 4.7244, 3.8957 and 2.3474 respectively. In the case of lay-up [0

S/90

T/0

U], the material and stability performance of boron/epoxy is better than both carbon/epoxy and glass/epoxy as it gives higher values of

,

and

as compared to them. Moreover, in an earlier study [

23], carbon/epoxy and boron/epoxy have also been demonstrated to have maximum decrease in buoyancy factor (

and higher material performance in the case of cylindrical pressure hulls modeled with the lay-up [0

S/90

T/0

U]. Similarly, in another study on the composite cylindrical hull modeled with the same lay-up, carbon/epoxy showed more weight reduction as compared to glass/epoxy for comparable stability performance [

13].

As can be noted from

Table 6, the minimum buoyancy factor

in the case of lay-up [10

S/-10

T/90

U/-10

V/10

W] was computed for carbon/epoxy equaling 0.084553 with a decrease over the reference steel hull

= 52.916%. The values of

,

and

of carbon/epoxy were computed as 2.2364, 1.7482 and 2.7296 respectively. The buoyancy factor

for glass/epoxy is 0.09418 with

= 47.555% and its values of

,

and

were determined as 2.03, 1.8142 and 1.7087 respectively. Similarly, the buoyancy factor

for boron/epoxy is 0.09901 with a decrease over the reference steel hull

= 44.865%. For the same material,

,

and

were computed as 3.8816, 3.523 and 3.1574 respectively. The decrease of buoyancy factor over the reference steel hull

of glass/epoxy is lower than that of carbon/epoxy and larger than that of boron/epoxy. Moreover, the values of

,

and

for boron/epoxy are greater than their respective values for both carbon/epoxy and glass/epoxy. This demonstrates that the material failure and buckling performance of boron/epoxy is better than that of carbon/epoxy and glass/epoxy. In an earlier study [

23] on the composite cylindrical pressure hull modeled with [10

S/-10

T/90

U/-10

V/10

W], boron/epoxy was shown to have a greater decrease in weight and larger factors of safety of failure criteria than carbon/epoxy and glass/epoxy with almost similar stability performance.

In the case of lay-ups [β

1S/β

2T], β

1S/β

2T/β

3U] and [β

1S/β

2T/β

3U/β

4V/β

5W] design optimization was performed for both the number of layers and orientation angles. During optimization, the orientation angle

β could take a value from 0° to 90° and the number of layers could take a value from 1 to 75. The results of optimization for lay-up [β

1S/β

2T] are presented in

Table 7. In the case of this lay-up, carbon/epoxy gave the minimum buoyancy factor

of 0.08275 with a decrease over the reference steel hull

= 53.920%. For carbon/epoxy,

,

and

were calculated as 1.914, 1.5361 and 2.5752 respectively. The value of buoyancy factor

for glass/epoxy was computed as 0.12075 with a decrease over the reference steel hull

= 32.759%. For the same material, the values of

,

and

were calculated as 2.0185, 1.7635 and 2.5894 respectively. In the case of boron/epoxy, the buoyancy factor

equaled 0.08693 with a decrease over the reference steel hull

= 51.592%. Similarly, for boron/epoxy, the values of

,

and

were determined as 2.1027, 1.6846 and 2.8753 respectively. In the case of the lay-up [β

1S/β

2T], the material failure and buckling performance was almost the same for all the three composites.

For lay-up [β

1S/β

2T/β

3U], the results of design optimization are presented in

Table 8. In the case of the same lay-up, the minimum buoyancy factor

was computed for boron/epoxy which equaled 0.094181 with a decrease over the reference steel hull

= 47.554%. The values of

,

and

of boron/epoxy, were calculated as 2.2841, 1.8729 and 2.8591 respectively. In the case of the same lay-up, the buoyancy factor

of 0.10434 with a decrease over the reference steel hull

= 41.897% was computed for carbon/epoxy, while its values of

,

and

were calculated as 1.8877, 1.786 and 5.6293 respectively. In the case of glass/epoxy, the buoyancy factor

equaled 0.1304 with

= 27.386%. For glass/epoxy,

,

and

were calculated as 1.6605, 1.530 and 3.2226 respectively. Moreover, the value of

for carbon/epoxy was larger than its respective value for both boron/epoxy and glass/epoxy. Similarly, based on the decrease in buoyancy factor

over the reference steel hull

, the performance of all three composites was better in lay-up [0

S/90

T/0

U] as compared to their performance in lay-up [β

1S/β

2T/β

3U]. In the case of lay-up [0

S/90

T/0

U], the values of

and

for all three composites were larger than their respective values in lay-up [β

1S/β

2T/β

3U], while all three composites had a greater value of

in lay-up [β

1S/β

2T/β

3U] as compared to its value in lay-up [0

S/90

T/0

U]. In the case of a cylindrical composite pressure hull [

23], the lay-up [0

S/90

T/0

U] was shown to have a better overall performance for all the studied composites as compared to lay-up [β

1S/β

2T/β

3U].

The results of the design optimization for lay-up [β

1S/β

2T/β

3U/β

4V/β

5W] are listed in

Table 9. For this lay-up the minimum buoyancy factor

of 0.10974 with a decrease over the reference steel hull

= 38.890%, was calculated for carbon/epoxy. For the same material, the values of

,

and

were calculated as 2.2364, 1.7482 and 2.7296 respectively. In the case of the same lay-up, both glass/epoxy and boron/epoxy had the same buoyancy factor

of 0.11833 with a decrease over the reference steel hull

= 34.107%. The values of

,

and

for glass/epoxy were calculated as 2.03, 1.8142 and 1.7087 respectively, while for boron/epoxy these values were calculated as 3.8816, 3.523 and 3.1574. For similar values of

, the material failure and buckling performance of boron/epoxy is better than that of both carbon/epoxy and glass/epoxy. Based on the decrease in buoyancy factor over the reference steel hull

, the performance of all three composites is better in lay-up [10

S/-10

T/90

U/-10

V/10

W] as compared to their performance in lay-up [β

1S/β

2T/β

3U/β

4V/β

5W]. Similarly, in the case of lay-up [10

S/-10

T/90

U/-10

V/10

W], the values of

and

for all three composites are larger than their respective values in lay-up [β

1S/β

2T/β

3U/β

4V/β

5W], while all three composites have a greater value of

in lay-up [β

1S/β

2T/β

3U/β

4V/β

5W] as compared to its value in lay-up [10

S/-10

T/90

U/-10

V/10

W].

5. Conclusions

This paper describes the design optimization study of the spherical composite pressure hull under hydrostatic pressure employing a genetic algorithm (GA) and finite element (FE) analysis performed in ANSYS. The design optimization study was conducted under constraints on both material failure and buckling instability. A non-linear buckling analysis was also conducted in ABAQUS considering geometric non-linearity and imperfection. Two types of imperfection methods, lowest mode and worst mode, were employed to investigate the effects of imperfection on the collapse depth and overall buckling behavior of the spherical composite pressure hull. The main findings of this research are presented below.

Genetic algorithm (GA) and FE analysis can be employed to identify optimum lay-up arrangements of the spherical composite pressure hull for fabrication or additional examinations such as non-linear buckling analysis and underwater explosion analysis, etc. The optimum designs should be obtained by considering both material failure and buckling instability. Non-linear buckling analysis should also be conducted to investigate the effects of imperfections on the overall buckling behavior of the spherical composite pressure hull.

A maximum decrease of 65.937% in buoyancy factor over an equivalent spherical steel hull was measured for carbon/epoxy. Furthermore, carbon/epoxy displayed larger decreases in buoyancy factor in the case of 4 out of a total of 5 lay-up arrangements. Boron/epoxy displayed a larger decrease in buoyancy factor in the case of 1 out of a total of 5 lay-up arrangements. The glass/epoxy composite showed less overall decrease over an equivalent steel hull in the buoyancy factor as compared to both carbon/epoxy and boron/epoxy.

The collapse depth of the composite spherical submersible pressure hull is deeply affected by the imperfection size. Moreover, the first or lowest buckling mode may not always be the worst buckling mode, especially in the case of closed space Eigenvalues as observed in the present study. Therefore, it is recommended to investigate several linear buckling modes to determine the worst buckling mode for accurately modeling the buckling and post-buckling behavior of the composite spherical pressure hull. In the case of lowest mode imperfection, at the 5 mm imperfection size, the collapse depth was 412.596 m. Similarly, the effect of imperfection size in the case of worst mode imperfection had greater effect on the collapse depth as compared to its effect in the case of lowest mode imperfection. In the case of worst mode imperfection, at the 5 mm size of imperfection, the collapse depth reduced from 522.39 m to 315.6018 m. Moreover, the theoretically calculated KDFs in the present study ranged from 0.93258 to 0.66093 for 1 to 10 mm first or lowest mode imperfections. Similarly, the KDFs ranged from 0.86217 to 0.39888 for 1 to 10 mm worst mode imperfections.