Artificial Neural Networks in Classification of Steel Grades Based on Non-Destructive Tests

Abstract

:1. Introduction

- (a) Random nature, which is their objective property and because of imperfections in the structure of the material. This circumstance requires the involvement of the apparatus of probability theory and mathematical statistics for the organization of control and certification of products;

- (b) The interdependence of mechanical properties, which requires the simultaneous determination of a set of strength characteristics on any part of the structure;

- (c) The dependence of mechanical properties on the loading history, which takes place in operation and transforms a random variable into a random function.

2. Materials and Methods

- The dimensions of the device are significantly reduced, which makes it available in any part of the structure;

- For most designs, dynamic loading is more dangerous than static;

- The reaction of the material to the dynamic effect is more informative, which allows not only to evaluate the mechanical properties but also to develop effective technological operations (shot blasting, surface-plastic deformation, explosion, etc.);

- φ change in the strain rate during testing can noticeably change the mechanical properties of the material, which is associated with a transition to another mechanical state (for example, in metals, from plastic-viscous to brittle; in polymers, from highly elastic to elastic). The appearance of a viscous-brittle fracture is extremely dangerous for metals since it leads to cracking and fracture. A viscous-brittle breach can only be predicted based on appropriate tests.

- Low speeds (up to 10 m/s). It is generally accepted (Fridman [33]) that, in this case, wave processes and inertial forces do not significantly affect the reaction of the material and can be neglected. Most quasi-static impact models are applicable for this speed range. At the same time, it is incorrect to assume that the low strain rate does not affect the mechanical properties of the material. As experiments [34,35] show, the dynamic properties of the material (yield and strength limits, elongation and narrowing) significantly (up to two times) differ from static ones, which is associated with the processes of nucleation, development, and movement of dislocations, as well as with the diffusion rate chemical and physical processes, both inside the loaded body, and at the border with the environment.

- High speeds (from 10 to 100 m/s). In this case, the inertial resistance of the material is substantial; the unevenness of the stress and strain states is great. The resistance of a material to pushing a solid striker into it increases in proportion to the square of the speed according to the lawwhere:—the resistance at low speed; —static component; —the speed of the striker; and n—empirical coefficients depending on the speed of the striker; —the density of the half-space material.

- Ultrahigh and hyper high speeds (from 100 m/s and above). At ultra-high speeds, the resistance increases even more, sometimes reaching an elastic modulus. It is generally accepted that at such rates, the hydrodynamic theory of flow is applicable to the material.

3. Results

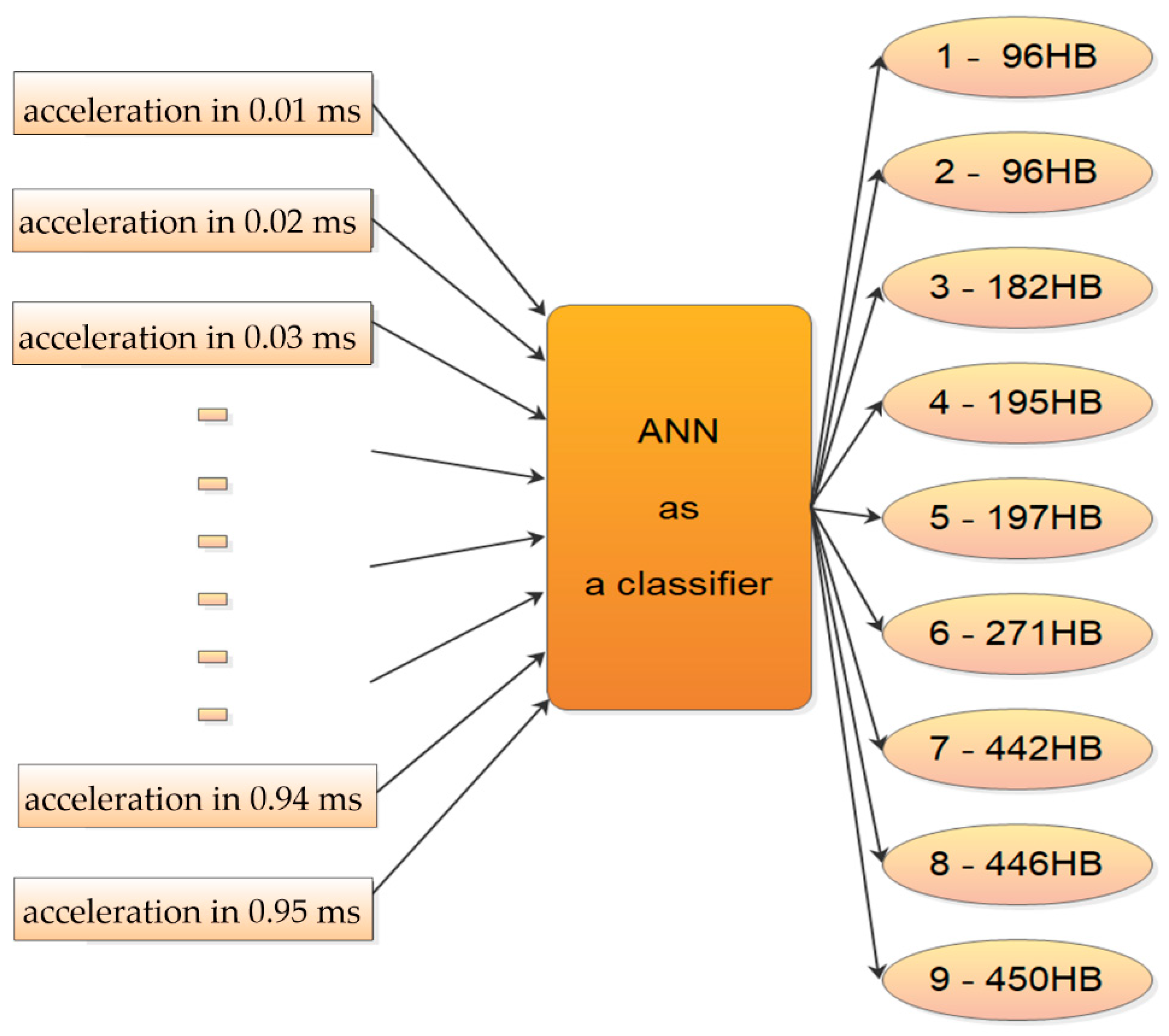

- The automatic search for ten of the best classifying networks (out of 1000 found);

- The manual choice, at least eight ANNs (out of ten proposed) providing a high level of correct classification in every subset (training, testing and validating);

- Making predictions for all 67 cases based on the ensemble of the chosen networks (retaining information which case belongs to each subset).

4. Discussion

- If the result from Step 1 classified the sample to grey class, the class of steel is 1 96 HB with 100% confidence (it stops the reasoning), if not, take Step 2;

- If the result from Step 2 classified the sample to grey class, the class of steel is 2 96 HB with 100% confidence (it stops the reasoning), if not, take Step 3;

- If the result from Step 3 classified the sample to grey class, the class of steel is 3 182 HB with 100% confidence (it stops the reasoning). Five out of 42 classifications in Step 3 are incorrect i.e., falsely classified to 4 195 HB (but at this moment, it is assumed that Step 3 classified to the grey class; it stops the procedure). If Step 3 classified the sample to the violet class, take Step 4;

- If the result from Step 4 classified the sample to grey class, the class of steel is 4 195 HB with confidence (it stops the procedure). In six cases out of 48 it can belong to 5 197 HB. If the sample is classified to the violet class, go to Step 5;

- If Step 5 classified the sample to the grey class, the sample is 5 197 HB in 100% confidence (there is one case falsely classified to the violet class, but for this moment it is assumed that Step 5 classified the sample to the grey class); if Step 5 classified the sample to the violet class, go to Step 6;

- If Step 6 classified the sample to the grey class, the sample is 6 271 HB in 100% confidence, if not, go to Step 7;

- If Step 7 classified the sample to the grey class, the sample is 7 442 HB with confidence (it stops the procedure). This one case from class 9 450 HB can be classified as belonging to the grey class. If the sample is classified to the violet class, go to Step 8;

- If Step 8 classified the sample to the grey class, the sample is 8 446 HB with confidence, if not (the class pointed by Step 8 is violet) the sample belongs to 9 450 HB with confidence equals to (this ends the procedure).

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Time in ms | 1 96 HB | 2 96 HB | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | Test 6 | Test 7 | Test 8 | Test 9 | Test 10 | Test 11 | Test 12 | Test 13 | Test 14 | |

| 0.01 | −0.3508 | −1.2392 | −0.7800 | −0.3720 | −0.7948 | 0.3948 | −1.3889 | −0.7233 | −0.2569 | −0.8946 | −0.1574 | −0.6031 | −0.1621 | −0.7674 |

| 0.02 | 0.8505 | 0.2169 | 0.9772 | 1.3952 | 0.5525 | 1.8073 | −0.3889 | 0.7866 | 1.0193 | 0.6470 | 0.9928 | 0.8598 | 1.1990 | 0.6386 |

| 0.03 | 2.3081 | 1.8648 | 2.7355 | 3.2623 | 2.1400 | 3.4737 | 0.8846 | 2.3011 | 2.4683 | 2.1594 | 2.3879 | 2.3138 | 2.7697 | 2.0471 |

| 0.04 | 4.0649 | 3.7459 | 4.5665 | 5.2294 | 3.9830 | 5.3565 | 2.4212 | 3.8948 | 4.1433 | 3.7607 | 4.0571 | 3.8592 | 4.5581 | 3.5759 |

| 0.05 | 5.8770 | 5.7252 | 6.4610 | 7.0958 | 5.7402 | 6.8921 | 4.0692 | 5.6010 | 5.6715 | 5.5750 | 5.5447 | 5.5855 | 6.1406 | 5.2862 |

| 0.06 | 7.8200 | 7.6150 | 8.2141 | 8.8518 | 7.4882 | 8.4192 | 5.7667 | 7.2728 | 7.2566 | 7.1956 | 7.0766 | 7.2469 | 7.7005 | 6.8505 |

| 0.07 | 9.7782 | 9.4424 | 9.8919 | 10.5500 | 9.2761 | 10.0778 | 7.4713 | 8.8498 | 8.9049 | 8.7501 | 8.7189 | 8.8507 | 9.3372 | 8.4491 |

| 0.08 | 11.2408 | 10.9870 | 11.4036 | 11.9153 | 10.6403 | 11.2272 | 9.0468 | 10.2758 | 10.1794 | 10.2998 | 9.9402 | 10.3225 | 10.6131 | 9.9714 |

| 0.09 | 12.4967 | 12.2547 | 12.5650 | 13.0021 | 11.8679 | 12.3611 | 10.4838 | 11.4529 | 11.3794 | 11.4537 | 11.1498 | 11.4954 | 11.8388 | 11.2015 |

| 0.10 | 13.5303 | 13.3822 | 13.5697 | 13.9052 | 12.9176 | 13.2439 | 11.7424 | 12.4812 | 12.3719 | 12.5519 | 12.1794 | 12.5813 | 12.8921 | 12.4534 |

| 0.11 | 14.0830 | 14.0312 | 14.1076 | 14.3014 | 13.4789 | 13.6249 | 12.6816 | 13.1811 | 12.9867 | 13.3765 | 12.7508 | 13.3403 | 13.4690 | 13.3283 |

| 0.12 | 14.4026 | 14.3853 | 14.1923 | 14.3610 | 13.8520 | 13.9797 | 13.3673 | 13.6478 | 13.4576 | 13.7732 | 13.2762 | 13.8063 | 13.9224 | 13.9195 |

| 0.13 | 14.3485 | 14.4396 | 14.1381 | 14.2186 | 13.8872 | 13.8809 | 13.8853 | 13.9450 | 13.6332 | 14.1298 | 13.5053 | 14.1770 | 14.1208 | 14.3962 |

| 0.14 | 13.8763 | 13.8507 | 13.5035 | 13.4419 | 13.4531 | 13.2876 | 13.9832 | 13.6443 | 13.3486 | 13.9755 | 13.2832 | 13.9750 | 13.7603 | 14.2588 |

| 0.15 | 13.1391 | 12.9529 | 12.5113 | 12.3016 | 12.7237 | 12.3974 | 13.7171 | 13.0927 | 12.7166 | 13.3392 | 12.8608 | 13.4170 | 13.0586 | 13.8311 |

| 0.16 | 11.9428 | 11.7584 | 11.2767 | 10.8988 | 11.5043 | 11.0035 | 13.0962 | 12.1645 | 11.6494 | 12.4444 | 11.9743 | 12.5036 | 11.9368 | 13.0117 |

| 0.17 | 10.3662 | 10.1259 | 9.5892 | 9.0303 | 9.9132 | 9.4642 | 11.9338 | 10.7371 | 10.2645 | 10.9936 | 10.6956 | 11.0684 | 10.4768 | 11.5979 |

| 0.18 | 8.6348 | 8.4701 | 7.8503 | 7.2157 | 8.2931 | 7.8269 | 10.5571 | 9.3761 | 8.8065 | 9.3850 | 9.3225 | 9.6272 | 8.9571 | 10.1864 |

| 0.19 | 6.6833 | 6.5507 | 5.9265 | 5.2652 | 6.4434 | 5.8484 | 8.9920 | 7.6853 | 7.1061 | 7.6878 | 7.6431 | 7.9364 | 7.1844 | 8.4579 |

| 0.22 | 4.6213 | 4.3220 | 3.7560 | 3.0096 | 4.4085 | 3.8055 | 7.1724 | 5.6273 | 5.2234 | 5.6248 | 5.7770 | 5.8720 | 5.1271 | 6.3478 |

| 0.21 | 2.5593 | 2.1925 | 1.6386 | 1.0427 | 2.3965 | 1.6632 | 5.2772 | 3.6783 | 3.2178 | 3.5421 | 3.8399 | 3.7848 | 3.0005 | 4.3294 |

| 0.22 | 0.4300 | −0.0323 | −0.5883 | −0.9692 | 0.2011 | −0.5579 | 3.2044 | 1.4385 | 0.9883 | 1.4271 | 1.6349 | 1.4458 | 0.7932 | 2.0115 |

| 0.23 | −1.5755 | −2.2013 | −2.6915 | −3.1130 | −1.9471 | −2.4908 | 1.0298 | −0.7383 | −1.1490 | −0.7774 | −0.5461 | −0.8400 | −1.2988 | −0.3248 |

| 0.24 | −3.3927 | −4.0719 | −4.4561 | −4.9430 | −3.7743 | −4.2951 | −1.0532 | −2.5237 | −3.0815 | −2.6818 | −2.5856 | −2.7677 | −3.1282 | −2.2338 |

| 0.25 | −5.1410 | −5.8582 | −6.1562 | −6.7084 | −5.4778 | −5.9781 | −2.9906 | −4.3841 | −4.8812 | −4.4363 | −4.5134 | −4.6636 | −4.8291 | −4.1654 |

| 0.26 | −6.7028 | −7.4217 | −7.5659 | −8.2543 | −6.9447 | −7.3340 | −4.6446 | −5.9917 | −6.3977 | −6.0862 | −6.0945 | −6.3345 | −6.3415 | −5.9272 |

| 0.27 | −8.1060 | −8.7440 | −8.8247 | −9.3883 | −8.1872 | −8.6371 | −6.1539 | −7.3377 | −7.7813 | −7.4611 | −7.5246 | −7.7622 | −7.7313 | −7.3619 |

| 0.28 | −9.4308 | −10.0618 | −10.0734 | −10.4814 | −9.4013 | −9.8474 | −7.6005 | −8.7289 | −9.0939 | −8.7920 | −8.8773 | −9.1603 | −9.0241 | −8.8288 |

| 0.29 | −10.5393 | −11.1304 | −11.0829 | −11.4828 | −10.4654 | −10.8252 | −8.8542 | −9.8390 | −10.2159 | −10.0130 | −9.9946 | −10.3412 | −10.1753 | −10.0420 |

| 0.30 | −11.5197 | −12.0557 | −12.0217 | −12.3401 | −11.4168 | −11.7797 | −10.0379 | −10.8211 | −11.2662 | −11.0119 | −11.0858 | −11.3907 | −11.2828 | −10.9799 |

| 0.31 | −12.4276 | −12.9317 | −12.8454 | −13.1442 | −12.2413 | −12.5273 | −11.1095 | −11.8173 | −12.1609 | −11.9450 | −12.0340 | −12.4034 | −12.2643 | −11.9874 |

| 0.32 | −13.1572 | −13.5257 | −13.3978 | −13.7140 | −12.8621 | −13.0696 | −11.9939 | −12.5192 | −12.8999 | −12.7198 | −12.7691 | −13.1876 | −13.0484 | −12.8375 |

| 0.33 | −13.8296 | −14.0679 | −13.8539 | −14.1916 | −13.4695 | −13.6546 | −12.8243 | −13.2000 | −13.5708 | −13.3268 | −13.4831 | −13.8349 | −13.7340 | −13.5538 |

| 0.34 | −14.3406 | −14.4953 | −14.1230 | −14.6030 | −13.8975 | −14.0229 | −13.5214 | −13.7844 | −14.0340 | −13.8729 | −13.9197 | −14.3207 | −14.1727 | −14.1770 |

| 0.35 | −14.5470 | −14.5914 | −14.1781 | −14.7470 | −14.0830 | −14.2091 | −14.0271 | −14.1316 | −14.3557 | −14.2004 | −14.1699 | −14.5892 | −14.3925 | −14.4972 |

| 0.36 | −14.5844 | −14.6381 | −14.2405 | −14.6969 | −14.2147 | −14.3101 | −14.4621 | −14.4428 | −14.5312 | −14.3326 | −14.4048 | −14.7493 | −14.5105 | −14.6901 |

| 0.37 | −14.4179 | −14.5078 | −14.0968 | −14.4076 | −14.0738 | −14.1258 | −14.6925 | −14.4777 | −14.4379 | −14.3133 | −14.3944 | −14.6952 | −14.4241 | −14.7291 |

| 0.38 | −14.1370 | −14.1243 | −13.8027 | −13.9065 | −13.8475 | −13.8117 | −14.6622 | −14.2696 | −14.2433 | −14.0602 | −14.2411 | −14.4195 | −14.1716 | −14.4826 |

| 0.39 | −13.8485 | −13.7296 | −13.4501 | −13.4287 | −13.7780 | −13.3996 | −14.4699 | −14.0689 | −13.9123 | −13.7201 | −13.9522 | −14.0385 | −13.7795 | −14.1539 |

| 0.40 | −13.4108 | −13.2112 | −12.9393 | −12.9001 | −13.4401 | −12.7873 | −14.0537 | −13.6463 | −13.3969 | −13.2759 | −13.4237 | −13.4918 | −13.2149 | −13.6420 |

| 0.41 | −12.8457 | −12.5340 | −12.3927 | −12.1717 | −12.8061 | −12.1068 | −13.5315 | −13.1215 | −12.7578 | −12.6833 | −12.8352 | −12.7506 | −12.4988 | −12.8958 |

| 0.42 | −12.1135 | −11.6385 | −11.6675 | −11.0288 | −11.9395 | −11.1055 | −12.9520 | −12.4983 | −11.8153 | −11.9529 | −12.0885 | −11.7198 | −11.4634 | −11.9564 |

| 0.43 | −11.0301 | −10.2406 | −10.5175 | −9.2847 | −10.5545 | −9.5836 | −12.0917 | −11.3041 | −10.3739 | −10.8004 | −10.8922 | −10.1670 | −9.8849 | −10.4850 |

| 0.44 | −9.5532 | −8.3835 | −8.9507 | −7.1051 | −8.7744 | −7.6217 | −10.8090 | −9.6128 | −8.4383 | −9.1383 | −9.2107 | −8.1262 | −7.8192 | −8.4506 |

| 0.45 | −7.6392 | −6.1882 | −6.9483 | −4.6887 | −6.7327 | −5.1849 | −9.0098 | −7.4556 | −6.0595 | −7.1354 | −7.0192 | −5.7195 | −5.3124 | −6.0490 |

| 0.46 | −5.4027 | −3.8942 | −4.7510 | −2.2925 | −4.3576 | −2.7023 | −6.7391 | −4.9239 | −3.4959 | −4.8757 | −4.5910 | −3.1895 | −2.6107 | −3.4388 |

| 0.47 | −3.2150 | −1.9201 | −2.7452 | −0.2548 | −1.9743 | −0.7200 | −4.3031 | −2.4895 | −1.1295 | −2.6682 | −2.2772 | −0.9511 | −0.2487 | −1.0755 |

| 0.48 | −1.3537 | −0.4604 | −1.0882 | 1.2331 | −0.0636 | 0.6779 | −1.9638 | −0.4664 | 0.6644 | −0.8344 | −0.3370 | 0.7829 | 1.4233 | 0.6640 |

| 0.49 | −0.0197 | 0.3326 | −0.0765 | 1.9724 | 1.2048 | 1.3128 | −0.1305 | 0.9604 | 1.6997 | 0.5222 | 0.9591 | 1.8669 | 2.3408 | 1.6887 |

| 0.50 | 0.6677 | 0.5075 | 0.2580 | 2.0366 | 1.8408 | 1.3407 | 0.9929 | 1.6566 | 2.0878 | 1.2477 | 1.6501 | 2.2716 | 2.5009 | 1.9937 |

| 0.51 | 0.8367 | 0.3152 | 0.1343 | 1.7155 | 1.8535 | 1.1203 | 1.5336 | 1.8055 | 1.9503 | 1.4441 | 1.8406 | 2.1861 | 2.1010 | 1.7834 |

| 0.52 | 0.5985 | −0.1124 | −0.2818 | 1.1456 | 1.4203 | 0.7647 | 1.5087 | 1.5650 | 1.4699 | 1.3166 | 1.6210 | 1.7222 | 1.5094 | 1.2562 |

| 0.53 | 0.1303 | −0.6313 | −0.7335 | 0.5439 | 0.8309 | 0.3870 | 1.1750 | 1.1395 | 0.9172 | 0.9978 | 1.1871 | 1.0692 | 0.8477 | 0.5620 |

| 0.54 | −0.3245 | −1.0681 | −1.1115 | −0.0063 | 0.1972 | −0.0103 | 0.8045 | 0.7045 | 0.3472 | 0.6773 | 0.6634 | 0.4405 | 0.1106 | −0.1577 |

| 0.55 | −0.6910 | −1.4494 | −1.4329 | −0.5581 | −0.3517 | −0.4505 | 0.3825 | 0.1827 | −0.2499 | 0.3279 | 0.1131 | −0.1455 | −0.5373 | −0.8970 |

| 0.56 | −0.9896 | −1.7407 | −1.6249 | −0.9836 | −0.7490 | −0.8670 | −0.0263 | −0.2929 | −0.7310 | −0.0752 | −0.3886 | −0.6692 | −1.1158 | −1.5602 |

| 0.57 | −1.1976 | −1.8756 | −1.6752 | −1.2610 | −1.0854 | −1.3114 | −0.4193 | −0.6743 | −1.1324 | −0.4515 | −0.8065 | −1.1864 | −1.7550 | −2.0869 |

| 0.58 | −1.3647 | −1.9545 | −1.5906 | −1.4943 | −1.4219 | −1.7427 | −0.8208 | −1.0598 | −1.5448 | −0.8914 | −1.2074 | −1.7475 | −2.3526 | −2.5807 |

| 0.59 | −1.4384 | −2.0300 | −1.4279 | −1.6775 | −1.7623 | −2.1186 | −1.2239 | −1.4209 | −1.9299 | −1.4040 | −1.6931 | −2.2437 | −2.8396 | −2.9521 |

| 0.60 | −1.4041 | −2.0266 | −1.3440 | −1.9150 | −2.0661 | −2.5143 | −1.7111 | −1.8554 | −2.2981 | −1.9499 | −2.1960 | −2.6556 | −3.1733 | −3.0968 |

| 0.61 | −1.3492 | −1.9665 | −1.2788 | −2.1657 | −2.3251 | −2.7982 | −2.1818 | −2.3611 | −2.6362 | −2.5233 | −2.6053 | −2.9164 | −3.2964 | −3.0249 |

| 0.62 | −1.2609 | −1.9140 | −1.2218 | −2.3148 | −2.5498 | −3.0312 | −2.6226 | −2.8212 | −2.9062 | −2.9745 | −2.9410 | −2.9787 | −3.2550 | −2.7111 |

| 0.63 | −1.2222 | −1.8655 | −1.2379 | −2.4515 | −2.6831 | −3.2369 | −2.9838 | −3.1759 | −3.0726 | −3.2797 | −3.0963 | −2.8884 | −3.0999 | −2.2936 |

| 0.64 | −1.3158 | −1.8113 | −1.2863 | −2.5665 | −2.7330 | −3.3120 | −3.1130 | −3.3470 | −3.1230 | −3.4071 | −3.0222 | −2.6443 | −2.8405 | −1.9470 |

| 0.65 | −1.5280 | −1.6588 | −1.4295 | −2.6633 | −2.7229 | −3.3558 | −3.0649 | −3.3440 | −3.1239 | −3.3022 | −2.8818 | −2.3568 | −2.5823 | −1.7194 |

| 0.66 | −1.8571 | −1.5695 | −1.6994 | −2.8779 | −2.6072 | −3.3159 | −2.8781 | −3.2242 | −3.0594 | −3.0833 | −2.6878 | −2.1918 | −2.4045 | −1.5895 |

| 0.67 | −2.2396 | −1.8809 | −2.0206 | −3.1185 | −2.4687 | −3.2008 | −2.6023 | −2.9585 | −2.9180 | −2.7776 | −2.5049 | −2.1406 | −2.2733 | −1.5016 |

| 0.68 | −2.5877 | −2.3709 | −2.3691 | −3.3168 | −2.3928 | −3.1196 | −2.3447 | −2.7025 | −2.7616 | −2.5334 | −2.4303 | −2.1539 | −2.1533 | −1.4824 |

| 0.69 | −2.8138 | −2.7133 | −2.6961 | −3.5357 | −2.3501 | −3.0241 | −2.1321 | −2.5188 | −2.6466 | −2.4917 | −2.4401 | −2.1917 | −2.0552 | −1.5275 |

| 0.70 | −2.9685 | −2.9626 | −2.9447 | −3.6362 | −2.3522 | −2.9676 | −2.0262 | −2.3632 | −2.5909 | −2.5046 | −2.4711 | −2.1259 | −1.9332 | −1.5846 |

| 0.71 | −3.2304 | −3.0116 | −3.1274 | −3.5612 | −2.3492 | −2.9356 | −1.9933 | −2.3150 | −2.5793 | −2.5404 | −2.5056 | −1.9918 | −1.7936 | −1.6428 |

| 0.72 | −3.4333 | −2.9509 | −3.1296 | −3.3693 | −2.3199 | −2.8330 | −1.9620 | −2.2611 | −2.5823 | −2.5512 | −2.4881 | −1.8562 | −1.7602 | −1.6454 |

| 0.73 | −3.4392 | −3.1198 | −3.0231 | −3.1085 | −2.2874 | −2.7147 | −1.9553 | −2.1328 | −2.5088 | −2.4279 | −2.4224 | −1.7003 | −1.7661 | −1.5876 |

| 0.74 | −3.3273 | −3.2600 | −3.0058 | −2.5753 | −2.1907 | −2.5562 | −1.8805 | −2.0171 | −2.3369 | −2.3162 | −2.3092 | −1.5387 | −1.4640 | −1.5654 |

| 0.75 | −3.0449 | −3.1512 | −2.9814 | −1.8205 | −2.0708 | −2.3796 | −1.7914 | −1.8852 | −2.1638 | −2.2423 | −2.1504 | −1.4223 | −1.1909 | −1.5505 |

| 0.76 | −2.7082 | −3.0758 | −2.8684 | −1.5481 | −2.0045 | −2.2545 | −1.7358 | −1.7201 | −1.9901 | −2.1220 | −2.0496 | −1.3304 | −1.4245 | −1.4687 |

| 0.77 | −2.5245 | −3.0472 | −2.6986 | −1.7668 | −1.8476 | −2.0923 | −1.6282 | −1.6145 | −1.8138 | −2.0424 | −1.9681 | −1.2928 | −1.7178 | −1.3945 |

| 0.78 | −2.3700 | −2.9247 | −2.4498 | −2.0337 | −1.6652 | −1.9292 | −1.5386 | −1.5121 | −1.6768 | −1.9553 | −1.8850 | −1.3613 | −1.8804 | −1.3908 |

| 0.79 | −2.1836 | −2.7952 | −2.2168 | −2.3743 | −1.6457 | −1.8377 | −1.5581 | −1.4660 | −1.5704 | −1.8425 | −1.8794 | −1.4436 | −2.0532 | −1.4393 |

| 0.80 | −2.0526 | −2.6406 | −2.1312 | −2.3773 | −1.6643 | −1.8020 | −1.6210 | −1.5108 | −1.5028 | −1.7435 | −1.8737 | −1.5182 | −1.8096 | −1.4778 |

| 0.81 | −1.9809 | −2.4471 | −2.1086 | −2.0006 | −1.7231 | −1.8703 | −1.6795 | −1.5905 | −1.4979 | −1.6326 | −1.8689 | −1.6918 | −1.4664 | −1.5507 |

| 0.82 | −1.9246 | −2.2852 | −2.1256 | −1.9560 | −1.8530 | −1.9456 | −1.7023 | −1.7434 | −1.5317 | −1.6559 | −1.8896 | −1.8638 | −1.5435 | −1.6715 |

| 0.83 | −1.8900 | −2.1526 | −2.1747 | −2.0227 | −1.8602 | −1.9381 | −1.7025 | −1.8891 | −1.5561 | −1.8345 | −1.8590 | −1.9526 | −1.5767 | −1.8218 |

| 0.84 | −1.9113 | −2.0537 | −2.2965 | −1.9196 | −1.7826 | −1.9620 | −1.7442 | −1.9696 | −1.5407 | −1.9365 | −1.8990 | −2.0199 | −1.5450 | −2.0060 |

| 0.85 | −1.9911 | −2.0360 | −2.4771 | −1.9145 | −1.7811 | −2.0019 | −1.8875 | −2.0642 | −1.5820 | −1.9270 | −2.0148 | −1.9990 | −1.6569 | −2.1361 |

| 0.86 | −2.1012 | −2.0623 | −2.5879 | −1.8938 | −1.9250 | −2.0153 | −2.0510 | −2.0667 | −1.7908 | −1.9167 | −2.0780 | −1.9026 | −1.7782 | −2.1361 |

| 0.87 | −2.2421 | −2.1319 | −2.7133 | −1.9511 | −2.1811 | −2.0648 | −2.1117 | −2.0298 | −2.0483 | −1.8995 | −2.1293 | −1.9301 | −1.8639 | −2.1432 |

| 0.88 | −2.3820 | −2.2239 | −2.8869 | −2.0721 | −2.3306 | −2.0814 | −2.1188 | −2.0587 | −2.2263 | −1.9662 | −2.1274 | −1.9967 | −1.9220 | −2.2337 |

| 0.89 | −2.4926 | −2.3198 | −2.9723 | −2.0656 | −2.3612 | −2.0662 | −2.1449 | −2.0355 | −2.3018 | −2.0885 | −2.0752 | −2.0227 | −1.9416 | −2.3037 |

| 0.90 | −2.5867 | −2.4120 | −3.0267 | −2.1226 | −2.3470 | −2.0741 | −2.2245 | −2.0425 | −2.2386 | −2.1511 | −2.1131 | −2.0658 | −1.9675 | −2.3131 |

| 0.91 | −2.6910 | −2.4719 | −3.1898 | −2.1939 | −2.3154 | −2.0315 | −2.4313 | −2.1044 | −2.1440 | −2.1610 | −2.1997 | −2.1234 | −2.0051 | −2.3130 |

| 0.92 | −2.1239 | −2.2543 | −2.2711 | −2.0503 | −1.9348 | −2.0259 | −1.8800 | −1.9112 | −1.8927 | −1.8921 | −1.9187 | −1.7769 | −1.7492 | −1.7491 |

| 0.93 | −1.5368 | −2.0359 | −1.3407 | −1.9229 | −1.6527 | −2.0330 | −1.3000 | −1.7140 | −1.6796 | −1.6716 | −1.6491 | −1.4032 | −1.5061 | −1.1764 |

| 0.94 | −0.7921 | −1.2895 | −1.2721 | −2.6260 | 0.5191 | −2.8470 | 1.6742 | 0.5498 | −0.0008 | −0.6604 | −0.7771 | 0.9204 | 0.6572 | 0.7244 |

| 0.95 | −1.5758 | −2.1094 | −1.3804 | −1.8510 | −1.8914 | −1.8825 | −1.6178 | −1.5831 | −1.7069 | −1.8067 | −1.7338 | −1.2666 | −1.4849 | −1.0078 |

| Time in ms | 3 182 HB | 4 195 HB | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test 15 | Test 16 | Test 17 | Test 18 | Test 19 | Test 20 | Test 21 | Test 22 | Test 23 | Test 24 | Test 25 | Test 26 | Test 27 | Test 28 | |

| 0.01 | 1.0241 | 0.6706 | 1.1855 | 0.2205 | 0.3973 | 1.4264 | 0.3206 | 1.0076 | 0.8720 | 0.4529 | 0.4140 | 0.6482 | 0.3978 | 0.9311 |

| 0.02 | 2.2977 | 1.9553 | 2.4047 | 1.4995 | 1.7847 | 2.5947 | 1.5576 | 2.2042 | 2.0833 | 1.7314 | 1.6128 | 1.8970 | 1.7056 | 2.0816 |

| 0.03 | 3.7904 | 3.4366 | 3.8641 | 2.8606 | 3.1753 | 4.0711 | 2.9386 | 3.5765 | 3.4379 | 3.1192 | 2.9144 | 3.2380 | 3.0284 | 3.4279 |

| 0.04 | 5.4545 | 5.0924 | 5.5458 | 4.3733 | 4.6482 | 5.7239 | 4.5409 | 5.0956 | 4.9668 | 4.5995 | 4.3622 | 4.6936 | 4.4007 | 4.9558 |

| 0.05 | 6.8893 | 6.4856 | 6.9800 | 5.9314 | 6.2235 | 7.1600 | 6.1283 | 6.3705 | 6.2793 | 6.0889 | 5.8567 | 6.0575 | 5.8848 | 6.3129 |

| 0.06 | 8.2741 | 7.9314 | 8.3636 | 7.4058 | 7.6714 | 8.5827 | 7.6411 | 7.7116 | 7.5823 | 7.5373 | 7.2884 | 7.4195 | 7.2409 | 7.6799 |

| 0.07 | 9.6664 | 9.4431 | 9.7985 | 8.9399 | 9.1222 | 9.9085 | 9.1652 | 9.1457 | 8.9921 | 8.9683 | 8.6950 | 8.8453 | 8.5914 | 9.1440 |

| 0.08 | 10.7088 | 10.5453 | 10.8420 | 10.2980 | 10.4819 | 10.9572 | 10.4275 | 10.2038 | 10.0584 | 10.2165 | 9.9735 | 9.9741 | 9.8639 | 10.2728 |

| 0.09 | 11.6724 | 11.6038 | 11.8549 | 11.4179 | 11.5287 | 12.0459 | 11.5720 | 11.2385 | 11.0858 | 11.2827 | 11.0851 | 11.0120 | 10.8651 | 11.2987 |

| 0.10 | 12.3896 | 12.4433 | 12.6386 | 12.5082 | 12.4850 | 12.7578 | 12.6323 | 12.0223 | 11.9497 | 12.2094 | 12.0585 | 11.9485 | 11.8109 | 12.1338 |

| 0.11 | 12.7888 | 12.9033 | 13.0057 | 13.2077 | 13.0965 | 13.1954 | 13.3329 | 12.4408 | 12.4573 | 12.8006 | 12.6843 | 12.5141 | 12.4435 | 12.5742 |

| 0.12 | 13.1480 | 13.2763 | 13.3512 | 13.7059 | 13.4375 | 13.6396 | 13.8662 | 12.8335 | 12.8832 | 13.2149 | 13.1278 | 12.9612 | 12.7980 | 12.9618 |

| 0.13 | 13.0642 | 13.3181 | 13.2368 | 14.1432 | 13.7371 | 13.5637 | 14.1728 | 12.8896 | 12.9834 | 13.5163 | 13.4107 | 13.1963 | 13.0599 | 13.1270 |

| 0.14 | 12.5683 | 12.8985 | 12.6374 | 14.0152 | 13.4958 | 13.0993 | 13.9871 | 12.5168 | 12.6016 | 13.2582 | 13.1932 | 12.8319 | 12.8483 | 12.8061 |

| 0.15 | 11.7492 | 12.0906 | 11.7985 | 13.4797 | 12.8071 | 12.2927 | 13.4449 | 11.8192 | 11.9448 | 12.5438 | 12.6800 | 12.1563 | 12.2629 | 12.1311 |

| 0.16 | 10.4373 | 10.8242 | 10.3998 | 12.5406 | 11.7857 | 10.9163 | 12.3889 | 10.6689 | 10.8699 | 11.5162 | 11.7385 | 11.1215 | 11.3682 | 10.9785 |

| 0.17 | 8.9711 | 9.2705 | 8.7530 | 11.0360 | 10.2098 | 9.4183 | 10.8435 | 9.2328 | 9.4153 | 10.0043 | 10.2961 | 9.6744 | 9.9718 | 9.4565 |

| 0.18 | 7.3222 | 7.6177 | 7.0942 | 9.4320 | 8.5480 | 7.7963 | 9.2312 | 7.6714 | 7.8885 | 8.3783 | 8.7850 | 8.2113 | 8.4499 | 7.8671 |

| 0.19 | 5.4168 | 5.7248 | 5.0969 | 7.6529 | 6.7974 | 5.8618 | 7.4293 | 5.8683 | 6.0798 | 6.6162 | 7.0158 | 6.4768 | 6.7785 | 6.0684 |

| 0.22 | 3.4637 | 3.6340 | 3.0365 | 5.5332 | 4.6937 | 3.8105 | 5.3607 | 3.9497 | 4.0022 | 4.5537 | 4.9736 | 4.4521 | 4.8244 | 4.1051 |

| 0.21 | 1.3805 | 1.5359 | 0.9903 | 3.3818 | 2.6169 | 1.6024 | 3.2472 | 1.9627 | 1.9565 | 2.4704 | 2.9525 | 2.4772 | 2.8707 | 2.1008 |

| 0.22 | −0.8081 | −0.6435 | −1.2471 | 1.0990 | 0.5028 | −0.6378 | 0.9659 | −0.1239 | −0.1740 | 0.3343 | 0.7561 | 0.3760 | 0.8083 | −0.0668 |

| 0.23 | −2.9356 | −2.7992 | −3.3606 | −1.2426 | −1.7023 | −2.7449 | −1.3629 | −2.1777 | −2.3088 | −1.8698 | −1.4615 | −1.7504 | −1.3691 | −2.2483 |

| 0.24 | −5.0143 | −4.7895 | −5.3478 | −3.3427 | −3.6833 | −4.7803 | −3.5245 | −4.1903 | −4.2319 | −3.9181 | −3.5420 | −3.7060 | −3.3779 | −4.2825 |

| 0.25 | −6.8872 | −6.6925 | −7.2063 | −5.3627 | −5.5781 | −6.6325 | −5.5859 | −6.0961 | −6.0668 | −5.8852 | −5.5600 | −5.6735 | −5.3452 | −6.2087 |

| 0.26 | −8.4975 | −8.4123 | −8.7179 | −7.2332 | −7.3371 | −8.2647 | −7.4398 | −7.7467 | −7.7499 | −7.6792 | −7.3314 | −7.4065 | −7.1584 | −7.9166 |

| 0.27 | −9.9570 | −9.8796 | −10.1076 | −8.8037 | −8.7999 | −9.7606 | −9.0459 | −9.2091 | −9.2133 | −9.1575 | −8.8755 | −8.8484 | −8.6692 | −9.4365 |

| 0.28 | −11.2125 | −11.1803 | −11.3601 | −10.2482 | −10.1894 | −11.0625 | −10.5179 | −10.5021 | −10.5495 | −10.5446 | −10.2948 | −10.1983 | −10.0920 | −10.8030 |

| 0.29 | −12.2912 | −12.2941 | −12.3502 | −11.5255 | −11.4444 | −12.1990 | −11.7601 | −11.6534 | −11.7061 | −11.7669 | −11.4845 | −11.3392 | −11.3256 | −11.9675 |

| 0.30 | −13.2574 | −13.2548 | −13.2851 | −12.5975 | −12.4585 | −13.1682 | −12.7717 | −12.6919 | −12.7246 | −12.7186 | −12.5548 | −12.3103 | −12.3292 | −12.9301 |

| 0.31 | −14.0197 | −14.0147 | −13.9890 | −13.5836 | −13.3535 | −13.8843 | −13.6488 | −13.4695 | −13.6003 | −13.5383 | −13.4939 | −13.1671 | −13.2191 | −13.6772 |

| 0.32 | −14.5538 | −14.5595 | −14.4097 | −14.3272 | −13.9592 | −14.3976 | −14.2559 | −14.0418 | −14.2819 | −14.1040 | −14.1151 | −13.7207 | −13.8418 | −14.2109 |

| 0.33 | −14.9085 | −14.9402 | −14.7495 | −14.7490 | −14.2618 | −14.7193 | −14.6814 | −14.4017 | −14.6879 | −14.4041 | −14.5104 | −14.0376 | −14.2291 | −14.5079 |

| 0.34 | −15.0106 | −15.0503 | −14.7704 | −14.9648 | −14.4330 | −14.8378 | −14.9872 | −14.5205 | −14.7093 | −14.5200 | −14.6655 | −14.1554 | −14.4323 | −14.5582 |

| 0.35 | −14.9091 | −14.9312 | −14.5298 | −14.9346 | −14.3518 | −14.7371 | −14.9945 | −14.4925 | −14.4640 | −14.3931 | −14.5510 | −14.0159 | −14.3904 | −14.4044 |

| 0.36 | −14.6871 | −14.5999 | −14.1931 | −14.7106 | −14.0851 | −14.3525 | −14.7674 | −14.3095 | −14.0163 | −14.0805 | −14.2948 | −13.7011 | −14.1645 | −14.0647 |

| 0.37 | −14.2676 | −13.9874 | −13.5535 | −14.3697 | −13.7082 | −13.7155 | −14.3934 | −13.9236 | −13.3122 | −13.5779 | −13.8460 | −13.2172 | −13.7539 | −13.4207 |

| 0.38 | −13.4515 | −12.9638 | −12.4821 | −13.7322 | −12.9558 | −12.6294 | −13.6578 | −13.0170 | −12.1427 | −12.5989 | −12.9660 | −12.3012 | −12.9524 | −12.2434 |

| 0.39 | −11.9797 | −11.2954 | −10.8209 | −12.5349 | −11.6208 | −10.8815 | −12.3704 | −11.0963 | −10.2355 | −10.9684 | −11.4245 | −10.7423 | −11.5645 | −10.3696 |

| 0.40 | −9.7880 | −8.9718 | −8.4619 | −10.6707 | −9.6460 | −8.4534 | −10.4612 | −8.2280 | −7.6187 | −8.6956 | −9.1332 | −8.6015 | −9.5212 | −7.8789 |

| 0.41 | −6.9809 | −6.1630 | −5.6361 | −8.1014 | −7.0619 | −5.4515 | −7.9499 | −4.8619 | −4.5660 | −5.9393 | −6.2616 | −5.9435 | −7.0104 | −4.9859 |

| 0.42 | −3.8633 | −3.1246 | −2.7351 | −4.9658 | −4.1996 | −2.2803 | −5.0426 | −1.5384 | −1.4857 | −2.9906 | −3.1929 | −3.1477 | −4.3205 | −2.0521 |

| 0.43 | −0.9933 | −0.3846 | −0.2298 | −1.7445 | −1.4607 | 0.4746 | −2.1242 | 1.0895 | 1.0989 | −0.2762 | −0.4497 | −0.7346 | −1.7374 | 0.4070 |

| 0.44 | 1.2761 | 1.7215 | 1.5922 | 0.9382 | 0.7679 | 2.5271 | 0.4118 | 2.8500 | 2.9079 | 1.8294 | 1.6342 | 1.1588 | 0.5168 | 2.1955 |

| 0.45 | 2.8046 | 3.1079 | 2.6740 | 2.8350 | 2.2910 | 3.7249 | 2.3357 | 3.8782 | 3.8120 | 3.1558 | 2.9737 | 2.4664 | 2.3135 | 3.2196 |

| 0.46 | 3.4633 | 3.6364 | 2.9963 | 3.8381 | 3.1096 | 4.0690 | 3.4538 | 4.1651 | 3.8821 | 3.6428 | 3.5959 | 3.0866 | 3.3620 | 3.4632 |

| 0.47 | 3.4779 | 3.5595 | 2.8690 | 4.0629 | 3.2790 | 3.8944 | 3.7588 | 3.8819 | 3.5015 | 3.5332 | 3.7196 | 3.2300 | 4.0745 | 3.2422 |

| 0.48 | 3.1329 | 3.1227 | 2.5635 | 3.9620 | 3.1483 | 3.3670 | 3.7527 | 3.2703 | 2.9244 | 3.1593 | 3.4599 | 3.0132 | 4.4904 | 2.8411 |

| 0.49 | 2.4612 | 2.3953 | 2.0952 | 3.5203 | 2.8818 | 2.6181 | 3.9307 | 2.5782 | 2.3599 | 2.6474 | 2.8148 | 2.4712 | 3.7031 | 2.3167 |

| 0.50 | 1.7220 | 1.6426 | 1.5833 | 2.6170 | 2.3184 | 1.9134 | 3.5776 | 2.0003 | 1.9233 | 2.0705 | 2.0666 | 1.8828 | 2.3575 | 1.8430 |

| 0.51 | 1.0685 | 1.0023 | 1.0982 | 1.6614 | 1.6433 | 1.3426 | 2.4312 | 1.4794 | 1.5128 | 1.5143 | 1.3762 | 1.3425 | 1.3140 | 1.4889 |

| 0.52 | 0.5545 | 0.4984 | 0.6711 | 0.8940 | 1.0874 | 1.0010 | 1.3238 | 1.1375 | 1.0764 | 1.0519 | 0.8952 | 0.9327 | 0.3385 | 1.1511 |

| 0.53 | 0.3689 | 0.3198 | 0.4593 | 0.4948 | 0.7026 | 0.9161 | 0.4150 | 0.9945 | 0.6330 | 0.8105 | 0.7512 | 0.6957 | 0.1610 | 0.8992 |

| 0.54 | 0.3701 | 0.3438 | 0.4684 | 0.6097 | 0.6506 | 0.8690 | −0.1442 | 0.7754 | 0.1520 | 0.7198 | 0.7276 | 0.5340 | 0.6441 | 0.7056 |

| 0.55 | 0.3724 | 0.3897 | 0.5578 | 0.8129 | 0.7451 | 0.7867 | 0.0879 | 0.5389 | −0.2266 | 0.6581 | 0.6496 | 0.3953 | 0.4737 | 0.5525 |

| 0.56 | 0.3999 | 0.4193 | 0.5436 | 0.8420 | 0.7489 | 0.6725 | 0.5285 | 0.2682 | −0.5217 | 0.5800 | 0.5339 | 0.2264 | 0.2133 | 0.4695 |

| 0.57 | 0.2762 | 0.2579 | 0.3414 | 0.6844 | 0.7035 | 0.3303 | 0.7447 | −0.2142 | −0.8400 | 0.3716 | 0.2894 | −0.0227 | 0.3768 | 0.3791 |

| 0.58 | −0.0013 | −0.1196 | −0.0070 | 0.3786 | 0.5969 | −0.1329 | 1.0817 | −0.6598 | −1.1420 | 0.0232 | −0.0265 | −0.3189 | 0.5683 | 0.2577 |

| 0.59 | −0.3200 | −0.6048 | −0.4719 | 0.0380 | 0.3648 | −0.6585 | 1.2583 | −1.0586 | −1.4309 | −0.3736 | −0.3437 | −0.6952 | 0.8638 | 0.0483 |

| 0.60 | −0.7678 | −1.1576 | −0.9408 | −0.4773 | 0.0047 | −1.2296 | 0.9229 | −1.5217 | −1.7106 | −0.8129 | −0.7391 | −1.1187 | 1.0501 | −0.2620 |

| 0.61 | −1.2624 | −1.6441 | −1.3537 | −1.1086 | −0.5171 | −1.6621 | 0.3495 | −1.8915 | −1.9476 | −1.3017 | −1.1287 | −1.4763 | 0.9823 | −0.5168 |

| 0.62 | −1.7866 | −2.0458 | −1.8405 | −1.6689 | −1.0997 | −2.0458 | −0.1309 | −2.2105 | −2.1560 | −1.7323 | −1.5098 | −1.8184 | 0.6963 | −0.7695 |

| 0.63 | −2.3662 | −2.4333 | −2.3228 | −2.2928 | −1.6290 | −2.4527 | −0.6028 | −2.4289 | −2.2536 | −2.1038 | −1.8777 | −2.0681 | 0.1204 | −1.0817 |

| 0.64 | −2.8126 | −2.7945 | −2.7158 | −2.7788 | −2.0277 | −2.7637 | −1.1690 | −2.5112 | −2.2106 | −2.4752 | −2.1526 | −2.1640 | −0.4913 | −1.4241 |

| 0.65 | −3.1126 | −3.1147 | −3.1084 | −3.0169 | −2.3647 | −2.9696 | −1.7628 | −2.5769 | −2.0920 | −2.7987 | −2.3459 | −2.1704 | −1.1612 | −1.8744 |

| 0.66 | −3.2951 | −3.2709 | −3.3439 | −3.1762 | −2.6723 | −2.9586 | −2.3031 | −2.5698 | −1.8604 | −2.9198 | −2.4431 | −2.0924 | −2.0180 | −2.3006 |

| 0.67 | −3.3421 | −3.2242 | −3.3646 | −3.0784 | −2.7950 | −2.7490 | −2.7532 | −2.4110 | −1.6114 | −2.8016 | −2.4021 | −1.9657 | −2.7354 | −2.5757 |

| 0.68 | −3.3129 | −3.0135 | −3.2965 | −2.7851 | −2.7896 | −2.4751 | −3.0918 | −2.1140 | −1.3743 | −2.4766 | −2.2411 | −1.8433 | −3.2779 | −2.7380 |

| 0.69 | −3.1039 | −2.6083 | −3.0053 | −2.4853 | −2.6596 | −2.0632 | −3.2328 | −1.6332 | −1.0548 | −1.9909 | −1.9618 | −1.6700 | −3.6594 | −2.7403 |

| 0.70 | −2.6855 | −2.1838 | −2.5416 | −2.0758 | −2.3379 | −1.5990 | −3.1682 | −1.1598 | −0.5558 | −1.5436 | −1.6854 | −1.4296 | −3.6246 | −2.6226 |

| 0.71 | −2.2242 | −1.7318 | −2.0485 | −1.6367 | −2.0341 | −0.8936 | −2.9390 | −0.9010 | −0.1942 | −1.2590 | −1.4605 | −1.2008 | −3.3703 | −2.4136 |

| 0.72 | −1.7814 | −1.0786 | −1.5225 | −1.2016 | −1.7730 | −0.2984 | −2.5250 | −0.6875 | −0.2735 | −1.0257 | −1.1905 | −0.9599 | −2.9640 | −2.0855 |

| 0.73 | −1.4687 | −0.7549 | −1.0414 | −0.6626 | −1.4397 | −0.3834 | −1.9909 | −0.5811 | −0.5518 | −0.8113 | −1.0090 | −0.7521 | −2.4117 | −1.7288 |

| 0.74 | −1.2936 | −0.8873 | −0.7513 | −0.0752 | −1.1878 | −0.6331 | −1.3403 | −0.7314 | −0.8434 | −0.6672 | −0.9104 | −0.6782 | −2.0136 | −1.4291 |

| 0.75 | −1.0529 | −0.9791 | −0.7756 | 0.1913 | −1.0204 | −0.8074 | −0.6387 | −0.8592 | −1.0944 | −0.4613 | −0.7985 | −0.7062 | −1.6203 | −1.1963 |

| 0.76 | −0.9076 | −1.1389 | −1.0224 | −0.1020 | −0.8879 | −0.9670 | −0.2839 | −0.8691 | −1.0515 | −0.3059 | −0.7927 | −0.7582 | −1.1810 | −1.0266 |

| 0.77 | −0.9246 | −1.2726 | −1.1887 | −0.5570 | −0.8573 | −0.7240 | −0.4359 | −0.9238 | −0.9179 | −0.4095 | −0.8131 | −0.8210 | −0.9058 | −0.9020 |

| 0.78 | −0.8949 | −1.0855 | −1.2327 | −0.9056 | −0.7420 | −0.5313 | −0.7910 | −0.8362 | −1.0092 | −0.6415 | −0.7563 | −0.8446 | −0.6498 | −0.8030 |

| 0.79 | −0.9579 | −1.0806 | −1.1994 | −1.0730 | −0.5451 | −0.7536 | −1.0642 | −0.7231 | −1.0237 | −0.8337 | −0.7344 | −0.8120 | −0.4396 | −0.7434 |

| 0.80 | −1.0830 | −1.2774 | −1.0829 | −0.9091 | −0.5898 | −0.8687 | −1.0903 | −0.7975 | −0.9207 | −0.9383 | −0.7221 | −0.8310 | −0.3956 | −0.7129 |

| 0.81 | −1.0857 | −1.3056 | −1.1167 | −0.8210 | −0.7544 | −0.9170 | −0.9039 | −0.8094 | −0.8935 | −0.9243 | −0.7047 | −0.9126 | −0.4036 | −0.6964 |

| 0.82 | −1.1494 | −1.3876 | −1.2538 | −1.0627 | −0.9081 | −0.9889 | −0.7885 | −0.7952 | −0.8633 | −0.9230 | −0.7985 | −0.9437 | −0.5506 | −0.6937 |

| 0.83 | −1.2701 | −1.4657 | −1.2309 | −1.1534 | −1.0893 | −1.0109 | −0.8548 | −0.8805 | −0.8094 | −1.0226 | −0.9238 | −0.9232 | −0.7637 | −0.6998 |

| 0.84 | −1.3138 | −1.4368 | −1.2240 | −1.1064 | −1.1143 | −1.0540 | −0.9228 | −0.9530 | −0.7891 | −1.1360 | −1.0217 | −0.9350 | −0.9308 | −0.7722 |

| 0.85 | −1.4221 | −1.4169 | −1.3022 | −1.1312 | −1.0050 | −1.0597 | −0.8866 | −0.9900 | −0.7377 | −1.1526 | −1.0585 | −0.9155 | −1.1120 | −0.9444 |

| 0.86 | −1.5215 | −1.3367 | −1.2538 | −1.0406 | −1.0014 | −1.0355 | −0.8515 | −0.9854 | −0.7296 | −1.0912 | −0.9868 | −0.8724 | −1.2032 | −1.0692 |

| 0.87 | −1.5374 | −1.2553 | −1.2545 | −0.8965 | −1.0130 | −1.0291 | −0.9081 | −0.9533 | −0.7522 | −1.0227 | −0.8940 | −0.8936 | −1.2586 | −1.1161 |

| 0.88 | −1.5483 | −1.2597 | −1.3109 | −0.8504 | −0.9822 | −0.9849 | −0.9355 | −0.9995 | −0.7448 | −0.9519 | −0.8538 | −0.9109 | −1.3412 | −1.1288 |

| 0.89 | −1.4805 | −1.2065 | −1.2474 | −0.7803 | −0.9816 | −0.9634 | −0.9220 | −1.0506 | −0.7908 | −0.8567 | −0.8256 | −0.9162 | −1.3048 | −1.0933 |

| 0.90 | −1.3793 | −1.1806 | −1.2471 | −0.7402 | −0.9828 | −0.9829 | −0.9451 | −1.0696 | −0.8449 | −0.7475 | −0.8370 | −0.9451 | −1.2369 | −1.0774 |

| 0.91 | −1.3388 | −1.1955 | −1.2408 | −0.7792 | −1.0074 | −0.9760 | −0.9220 | −1.1184 | −0.9317 | −0.6140 | −0.8332 | −0.9489 | −1.2268 | −1.1080 |

| 0.92 | −1.2346 | −1.1288 | −1.1406 | −0.8329 | −0.8221 | −0.7993 | −0.7676 | −0.8144 | −0.7636 | −0.7929 | −0.7787 | −0.7977 | −0.8343 | −0.8301 |

| 0.93 | −1.1131 | −1.0759 | −1.0677 | −0.8417 | −0.6297 | −0.6391 | −0.6672 | −0.5038 | −0.5968 | −0.9846 | −0.7470 | −0.6557 | −0.4412 | −0.5193 |

| 0.94 | −2.4231 | −3.3709 | −3.3569 | −2.8063 | −3.2125 | −2.6181 | −2.8568 | −2.7464 | −1.2112 | −2.5890 | −1.9694 | −2.3275 | −4.1899 | −3.3133 |

| 0.95 | −0.9386 | −1.0114 | −0.7852 | −0.6483 | −0.5878 | −0.5889 | −0.5980 | −0.5086 | −0.8834 | −0.7230 | −0.6458 | −0.5804 | −0.3247 | −0.4183 |

| Time in ms | 5 197 HB | 6 271 HB | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test 29 | Test 30 | Test 31 | Test 32 | Test 33 | Test 34 | Test 35 | Test 36 | Test 37 | Test 38 | Test 39 | Test 40 | Test 41 | Test 42 | |

| 0.01 | −1.1294 | 0.1727 | 0.3115 | 1.2366 | 0.6164 | 0.1690 | 0.6784 | 0.6217 | 0.8492 | 0.8258 | 0.6108 | 0.4785 | 0.7953 | 1.4463 |

| 0.02 | −1.1038 | 1.3373 | 1.5678 | 2.4553 | 1.7463 | 1.1842 | 1.8125 | 1.7094 | 1.8773 | 1.9867 | 1.5164 | 1.5319 | 1.9428 | 2.5517 |

| 0.03 | −0.6581 | 2.5633 | 2.8607 | 3.7877 | 3.0288 | 2.4530 | 3.0687 | 3.0019 | 3.1037 | 3.2994 | 2.6733 | 2.6804 | 3.2090 | 3.7786 |

| 0.04 | 0.1587 | 3.9078 | 4.2482 | 5.2974 | 4.4605 | 3.9586 | 4.4607 | 4.4362 | 4.5334 | 4.7595 | 4.0372 | 3.9159 | 4.5611 | 5.1321 |

| 0.05 | 1.2163 | 5.3719 | 5.7597 | 6.6693 | 5.8284 | 5.4383 | 5.9353 | 5.8856 | 5.7993 | 6.1615 | 5.4027 | 5.2144 | 5.8158 | 6.3942 |

| 0.06 | 2.5163 | 6.7862 | 7.1328 | 7.9894 | 7.2787 | 6.9207 | 7.3703 | 7.3169 | 7.0856 | 7.5825 | 6.7978 | 6.5291 | 7.1146 | 7.6050 |

| 0.07 | 4.0121 | 8.1441 | 8.4749 | 9.3437 | 8.7075 | 8.4267 | 8.6936 | 8.6186 | 8.4236 | 8.9703 | 8.1883 | 7.8349 | 8.3578 | 8.7476 |

| 0.08 | 5.4994 | 9.4191 | 9.7280 | 10.3932 | 9.7855 | 9.6717 | 9.8608 | 9.7215 | 9.4135 | 10.0054 | 9.3332 | 8.9690 | 9.3868 | 9.7012 |

| 0.09 | 7.0590 | 10.4685 | 10.7253 | 11.3713 | 10.8278 | 10.8472 | 10.8879 | 10.6897 | 10.3407 | 10.9155 | 10.3675 | 9.9209 | 10.3566 | 10.5801 |

| 0.10 | 8.5796 | 11.3826 | 11.6899 | 12.1883 | 11.7403 | 11.8956 | 11.7029 | 11.4890 | 11.1331 | 11.7249 | 11.2135 | 10.7364 | 11.1351 | 11.2093 |

| 0.11 | 9.8369 | 12.0645 | 12.3245 | 12.6849 | 12.3278 | 12.6145 | 12.3118 | 12.0055 | 11.6060 | 12.1977 | 11.7134 | 11.2680 | 11.6826 | 11.6530 |

| 0.12 | 10.9754 | 12.5439 | 12.7116 | 13.1348 | 12.7873 | 13.2142 | 12.8092 | 12.3484 | 12.0401 | 12.5819 | 12.1661 | 11.6840 | 12.0718 | 12.0187 |

| 0.13 | 11.9028 | 12.9177 | 13.0738 | 13.2068 | 13.0134 | 13.5986 | 13.0117 | 12.5834 | 12.2564 | 12.8488 | 12.4243 | 12.0442 | 12.2919 | 12.0430 |

| 0.14 | 12.5803 | 12.9239 | 12.9410 | 12.7562 | 12.7921 | 13.5972 | 12.8695 | 12.4953 | 12.0530 | 12.5966 | 12.3740 | 12.0398 | 12.1132 | 11.7562 |

| 0.15 | 13.1454 | 12.5506 | 12.4129 | 11.9936 | 12.2756 | 13.1960 | 12.3392 | 11.9426 | 11.5298 | 11.9331 | 11.9836 | 11.7020 | 11.5188 | 11.0866 |

| 0.16 | 13.4768 | 11.7866 | 11.5675 | 10.7462 | 11.3996 | 12.3090 | 11.2914 | 10.9637 | 10.5997 | 10.8619 | 11.0458 | 10.9348 | 10.5814 | 9.9315 |

| 0.17 | 13.4323 | 10.6126 | 10.2030 | 9.2494 | 10.1296 | 10.9807 | 9.9780 | 9.6178 | 9.2852 | 9.3098 | 9.7408 | 9.7239 | 9.2337 | 8.5796 |

| 0.18 | 13.0249 | 9.2250 | 8.7096 | 7.7039 | 8.6729 | 9.3808 | 8.4563 | 7.9786 | 7.7233 | 7.6100 | 8.1517 | 8.3646 | 7.6391 | 6.9537 |

| 0.19 | 12.1829 | 7.6506 | 7.0103 | 5.8304 | 6.9794 | 7.6176 | 6.7428 | 6.1039 | 5.9766 | 5.8024 | 6.3632 | 6.7257 | 5.8868 | 5.1375 |

| 0.22 | 10.8599 | 5.9031 | 4.9749 | 3.7958 | 5.0560 | 5.7204 | 4.9306 | 4.1240 | 4.0979 | 3.7898 | 4.5704 | 4.8948 | 3.9574 | 3.3070 |

| 0.21 | 9.2654 | 3.9977 | 3.0238 | 1.7324 | 3.0300 | 3.6461 | 2.9223 | 2.0484 | 2.1653 | 1.7069 | 2.6389 | 2.9579 | 1.9416 | 1.2216 |

| 0.22 | 7.5577 | 1.9501 | 1.0004 | −0.4321 | 0.9033 | 1.5010 | 0.8744 | −0.1375 | 0.1523 | −0.4610 | 0.5648 | 0.7444 | −0.0996 | −0.8568 |

| 0.23 | 5.6941 | −0.1238 | −1.1517 | −2.4874 | −1.2310 | −0.6577 | −1.1666 | −2.2189 | −1.9577 | −2.7079 | −1.5262 | −1.3914 | −2.1999 | −2.8162 |

| 0.24 | 3.6733 | −2.2669 | −3.1159 | −4.4641 | −3.2743 | −2.8177 | −3.2652 | −4.3048 | −4.1171 | −4.9122 | −3.7156 | −3.3959 | −4.2898 | −4.8633 |

| 0.25 | 1.5655 | −4.3557 | −5.1242 | −6.3922 | −5.2478 | −4.8411 | −5.1803 | −6.4820 | −6.2049 | −6.9777 | −5.7906 | −5.4511 | −6.2835 | −6.7563 |

| 0.26 | −0.6402 | −6.2194 | −6.9907 | −8.0747 | −7.0379 | −6.6940 | −6.9455 | −8.3630 | −8.0979 | −8.8317 | −7.6063 | −7.2783 | −8.1014 | −8.5212 |

| 0.27 | −2.8702 | −7.9260 | −8.4500 | −9.5564 | −8.6175 | −8.4112 | −8.5591 | −9.9887 | −9.7732 | −10.5088 | −9.3066 | −8.9709 | −9.7262 | −10.1795 |

| 0.28 | −4.9071 | −9.4138 | −9.8508 | −10.8597 | −10.0382 | −9.9137 | −9.8707 | −11.4881 | −11.2225 | −11.9489 | −10.7805 | −10.5664 | −11.1305 | −11.4869 |

| 0.29 | −6.7514 | −10.6922 | −11.1121 | −11.9057 | −11.2837 | −11.2557 | −11.0785 | −12.6802 | −12.4798 | −13.1143 | −12.0454 | −11.8679 | −12.3552 | −12.5735 |

| 0.30 | −8.4518 | −11.8823 | −12.1125 | −12.8164 | −12.3472 | −12.3920 | −12.1254 | −13.6832 | −13.5248 | −14.0578 | −13.1817 | −12.9779 | −13.3330 | −13.4860 |

| 0.31 | −9.9207 | −12.8562 | −13.0665 | −13.5244 | −13.2258 | −13.2975 | −12.9672 | −14.4828 | −14.2992 | −14.6946 | −14.0031 | −13.8473 | −13.9156 | −14.1568 |

| 0.32 | −11.2144 | −13.5828 | −13.7453 | −14.0384 | −13.8573 | −14.0906 | −13.7193 | −14.9559 | −14.8458 | −15.0597 | −14.5898 | −14.4255 | −14.2505 | −14.6786 |

| 0.33 | −12.3812 | −14.1297 | −14.1395 | −14.4629 | −14.2551 | −14.6368 | −14.1598 | −15.2281 | −15.1503 | −15.2714 | −15.0069 | −14.7483 | −14.3288 | −14.9248 |

| 0.34 | −13.3012 | −14.4204 | −14.3951 | −14.6804 | −14.4366 | −14.9434 | −14.2887 | −15.2810 | −15.1746 | −15.2420 | −15.0826 | −14.7614 | −14.1514 | −14.9292 |

| 0.35 | −14.0658 | −14.4963 | −14.3514 | −14.6214 | −14.4374 | −15.0612 | −14.2496 | −15.0009 | −14.9846 | −14.8830 | −14.9376 | −14.6347 | −13.8309 | −14.6808 |

| 0.36 | −14.6249 | −14.3896 | −14.1588 | −14.3083 | −14.2767 | −14.8744 | −13.9434 | −14.1910 | −14.3700 | −13.9113 | −14.4202 | −14.1651 | −13.0084 | −13.6653 |

| 0.37 | −14.8613 | −14.0586 | −13.8459 | −13.5997 | −13.8967 | −14.4957 | −13.5269 | −12.4828 | −12.9563 | −12.0844 | −13.1692 | −12.8745 | −11.3657 | −11.7995 |

| 0.38 | −14.9268 | −13.5007 | −13.1393 | −12.3890 | −13.1549 | −13.8075 | −12.7886 | −10.0657 | −10.6921 | −9.5256 | −11.2428 | −10.8213 | −9.1530 | −9.2167 |

| 0.39 | −14.7879 | −12.4248 | −11.8840 | −10.6010 | −11.8153 | −12.3863 | −11.2983 | −7.1891 | −7.6555 | −6.4193 | −8.6321 | −8.0106 | −6.5054 | −6.0310 |

| 0.40 | −14.4118 | −10.6287 | −9.9919 | −8.2053 | −9.8285 | −10.2812 | −9.1664 | −4.0090 | −4.1769 | −3.1488 | −5.5269 | −4.6658 | −3.7470 | −2.8589 |

| 0.41 | −13.8210 | −8.2615 | −7.4842 | −5.4458 | −7.3125 | −7.5653 | −6.4773 | −0.9943 | −0.9463 | −0.2931 | −2.6092 | −1.5373 | −1.4278 | −0.1671 |

| 0.42 | −12.6406 | −5.4727 | −4.7468 | −2.7538 | −4.5177 | −4.3916 | −3.5418 | 1.5665 | 1.5950 | 1.9731 | −0.0924 | 1.0623 | 0.3864 | 2.0029 |

| 0.43 | −10.7762 | −2.6586 | −2.2531 | −0.5036 | −1.9529 | −1.3254 | −1.0023 | 3.4312 | 3.2904 | 3.4686 | 2.1674 | 2.9328 | 1.6649 | 3.3677 |

| 0.44 | −8.4751 | −0.1839 | −0.1064 | 1.0767 | 0.1211 | 1.2660 | 0.9850 | 4.2548 | 4.0438 | 3.9352 | 3.7059 | 3.7574 | 2.2985 | 3.8345 |

| 0.45 | −5.7903 | 1.8957 | 1.7064 | 2.0432 | 1.6367 | 3.0916 | 2.2617 | 4.1775 | 4.4353 | 4.3004 | 5.3213 | 4.0921 | 2.5428 | 4.5756 |

| 0.46 | −3.1348 | 3.3337 | 3.0277 | 2.8446 | 2.5277 | 3.9462 | 2.7374 | 4.0286 | 4.7875 | 4.7328 | 6.0185 | 4.5143 | 2.5758 | 4.8495 |

| 0.47 | −0.9222 | 4.0313 | 3.7886 | 3.5474 | 2.9584 | 4.0313 | 2.7586 | 3.7609 | 4.1828 | 3.9754 | 4.2140 | 4.1590 | 2.4140 | 3.6190 |

| 0.48 | 0.9472 | 4.1231 | 3.9118 | 3.7025 | 3.0847 | 3.6905 | 2.4302 | 2.8204 | 2.7168 | 2.5828 | 2.1094 | 2.9501 | 2.0875 | 2.2895 |

| 0.49 | 2.4417 | 3.6395 | 3.9710 | 3.9532 | 2.8567 | 3.2073 | 1.9511 | 1.6712 | 1.3563 | 1.4662 | 0.9519 | 1.8069 | 1.5377 | 1.1901 |

| 0.50 | 3.4300 | 2.8118 | 3.5563 | 3.5108 | 2.6698 | 2.6836 | 1.5638 | 0.8003 | 0.3376 | 0.4742 | 0.2535 | 0.8923 | 0.9702 | 0.2538 |

| 0.51 | 3.9125 | 1.9739 | 2.2223 | 1.5174 | 2.7227 | 2.0354 | 1.1299 | 0.2541 | 0.1619 | 0.4147 | 0.9154 | 0.5929 | 0.6867 | 0.5981 |

| 0.52 | 3.7802 | 1.2311 | 1.0051 | 0.0194 | 2.2121 | 1.2518 | 0.7836 | 0.5251 | 0.7993 | 1.0885 | 1.6409 | 1.1134 | 0.7335 | 1.1867 |

| 0.53 | 3.2132 | 0.7474 | 0.1632 | −0.4367 | 1.1991 | 0.5049 | 0.6585 | 1.2144 | 1.1357 | 1.1660 | 1.0563 | 1.4285 | 1.0631 | 1.0061 |

| 0.54 | 2.3422 | 0.5417 | −0.4024 | −0.5516 | 0.3809 | 0.0940 | 0.5111 | 1.3396 | 1.1261 | 1.1251 | 1.0543 | 1.2670 | 1.3727 | 1.1703 |

| 0.55 | 1.4048 | 0.4262 | 0.0364 | −0.0348 | −0.2757 | 0.0856 | 0.3698 | 1.1604 | 1.3047 | 1.3745 | 1.5582 | 1.2178 | 1.3237 | 1.4501 |

| 0.56 | 0.6945 | 0.3742 | 0.4889 | 0.4284 | −0.4035 | 0.1935 | 0.2296 | 0.9422 | 1.4967 | 1.5096 | 1.6137 | 1.1892 | 1.0495 | 1.4704 |

| 0.57 | 0.1120 | 0.3992 | 0.1358 | 0.5114 | 0.3189 | 0.2246 | −0.0657 | 0.5389 | 1.5031 | 1.5278 | 1.3360 | 0.9061 | 0.7610 | 1.3360 |

| 0.58 | −0.1230 | 0.4009 | 0.3836 | 1.0911 | 0.9606 | 0.1090 | −0.3754 | 0.3930 | 1.3357 | 1.4299 | 0.9238 | 0.4531 | 0.5436 | 1.0570 |

| 0.59 | 0.1552 | 0.3471 | 1.1363 | 1.7386 | 1.1846 | −0.1531 | −0.6352 | 0.7463 | 1.0942 | 1.2673 | 0.7099 | 0.3785 | 0.4762 | 0.7784 |

| 0.60 | 0.4573 | 0.2301 | 1.4822 | 1.8288 | 1.3644 | −0.3965 | −0.8658 | 1.0888 | 0.8156 | 0.8474 | 0.8027 | 0.6156 | 0.3557 | 0.3942 |

| 0.61 | 0.6651 | −0.0376 | 1.4630 | 1.0983 | 1.2402 | −0.6699 | −1.0593 | 1.0614 | 0.3435 | 0.1840 | 0.8441 | 0.6616 | −0.0277 | 0.0322 |

| 0.62 | 0.7530 | −0.4071 | 1.1263 | 0.3293 | 0.7597 | −1.1920 | −1.3225 | 0.6324 | −0.1454 | 0.0160 | 0.4798 | 0.5450 | −0.5733 | 0.0872 |

| 0.63 | 0.6756 | −0.8608 | 0.3080 | 0.2411 | 0.3116 | −1.8230 | −1.6407 | −0.1580 | −0.2138 | 0.1624 | −0.1779 | 0.1185 | −1.0287 | 0.2419 |

| 0.64 | 0.7969 | −1.3935 | −0.3816 | −0.0200 | −0.0413 | −2.3806 | −1.8887 | −1.0405 | −0.0858 | 0.0197 | −0.3579 | −0.7280 | −1.2017 | 0.1787 |

| 0.65 | 1.0020 | −1.9286 | −0.9273 | −0.8292 | −0.5560 | −2.7642 | −2.0556 | −1.7532 | −0.1932 | −0.2768 | 0.0596 | −1.3553 | −1.1963 | −0.0736 |

| 0.66 | 1.0661 | −2.3496 | −1.7718 | −1.8788 | −1.1309 | −2.8375 | −2.0629 | −2.2562 | −0.4739 | −1.0452 | 0.3329 | −1.7136 | −1.1446 | −0.6501 |

| 0.67 | 0.8932 | −2.6578 | −2.5326 | −2.8088 | −1.6209 | −2.7337 | −1.9713 | −2.5048 | −1.0634 | −2.0634 | 0.2301 | −2.2053 | −0.9855 | −1.3713 |

| 0.68 | 0.2666 | −2.8981 | −3.0208 | −3.2815 | −2.0773 | −2.6112 | −1.8468 | −2.6009 | −1.8684 | −2.4316 | −0.3552 | −2.4969 | −1.0307 | −1.7553 |

| 0.69 | −0.5637 | −2.9621 | −3.3212 | −3.1953 | −2.4030 | −2.4328 | −1.6568 | −2.5663 | −2.2241 | −2.5751 | −1.2460 | −2.3762 | −1.2306 | −1.9756 |

| 0.70 | −1.2877 | −2.8161 | −3.3290 | −2.9747 | −2.6510 | −2.2148 | −1.4688 | −2.3224 | −2.3669 | −2.7852 | −1.6280 | −2.1144 | −1.1262 | −2.2547 |

| 0.71 | −1.9832 | −2.5563 | −3.1678 | −2.9398 | −2.8306 | −1.8783 | −1.1209 | −1.9921 | −2.5753 | −2.6137 | −1.6718 | −1.6597 | −0.8860 | −2.3360 |

| 0.72 | −2.5576 | −2.1261 | −2.8400 | −2.9102 | −2.7760 | −1.3778 | −0.7029 | −1.5505 | −2.4977 | −2.2466 | −1.9069 | −1.1301 | −0.5914 | −2.1623 |

| 0.73 | −2.9941 | −1.6855 | −2.2369 | −2.5881 | −2.5675 | −0.7705 | −0.5392 | −0.9939 | −2.1790 | −1.6820 | −2.0148 | −0.8582 | −0.1085 | −1.8858 |

| 0.74 | −3.2758 | −1.4112 | −1.6431 | −1.9636 | −2.2641 | −0.0887 | −0.4869 | −0.6951 | −1.7796 | −0.9806 | −1.9517 | −0.7084 | 0.0198 | −1.5117 |

| 0.75 | −3.1215 | −1.1479 | −1.2102 | −1.2181 | −1.8310 | 0.0783 | −0.4941 | −0.6065 | −1.2953 | −0.5946 | −1.8023 | −0.6073 | −0.2592 | −1.1713 |

| 0.76 | −2.5548 | −0.9666 | −0.9239 | −0.7278 | −1.5016 | −0.2761 | −0.6536 | −0.5358 | −0.9238 | −0.4689 | −1.4438 | −0.6778 | −0.4006 | −1.0230 |

| 0.77 | −1.9314 | −0.8563 | −0.8304 | −0.6732 | −1.2786 | −0.5947 | −0.6671 | −0.5753 | −0.6993 | −0.4520 | −1.1887 | −0.8043 | −0.4782 | −0.9480 |

| 0.78 | −1.4243 | −0.6764 | −0.8005 | −0.8252 | −1.0510 | −0.8364 | −0.5868 | −0.5975 | −0.5953 | −0.5342 | −1.1540 | −0.9065 | −0.6057 | −0.9144 |

| 0.79 | −1.1352 | −0.5937 | −0.8017 | −0.9330 | −1.0001 | −0.8626 | −0.6333 | −0.5548 | −0.6674 | −0.5983 | −1.1773 | −1.0264 | −0.6656 | −0.9656 |

| 0.80 | −1.0285 | −0.5718 | −0.7797 | −0.8797 | −1.0301 | −0.6093 | −0.6835 | −0.5079 | −0.7255 | −0.6777 | −1.2433 | −1.1295 | −0.7829 | −1.0314 |

| 0.81 | −0.8130 | −0.5436 | −0.7068 | −0.8252 | −1.0441 | −0.6267 | −0.7374 | −0.4282 | −0.7979 | −0.7596 | −1.1675 | −1.1904 | −0.9407 | −1.0473 |

| 0.82 | −0.4919 | −0.6780 | −0.6944 | −0.9182 | −1.0963 | −0.8920 | −0.8405 | −0.4945 | −0.8758 | −0.7820 | −0.9878 | −1.1886 | −0.9701 | −1.0078 |

| 0.83 | −0.3252 | −0.7663 | −0.7220 | −1.1771 | −1.1641 | −0.9536 | −0.9484 | −0.6670 | −0.8111 | −0.8004 | −0.9080 | −1.1298 | −0.9462 | −0.9574 |

| 0.84 | −0.4131 | −0.7683 | −0.7922 | −1.3981 | −1.2436 | −0.9637 | −1.0101 | −0.7517 | −0.7688 | −0.7697 | −0.8364 | −1.0178 | −0.8720 | −0.8723 |

| 0.85 | −0.7292 | −0.8427 | −0.9449 | −1.4282 | −1.3213 | −1.0130 | −0.9785 | −0.8331 | −0.7811 | −0.7237 | −0.8296 | −0.8956 | −0.7233 | −0.7664 |

| 0.86 | −1.0335 | −0.8806 | −1.0786 | −1.3419 | −1.3058 | −1.0028 | −0.9255 | −0.8723 | −0.7282 | −0.7240 | −0.7803 | −0.8122 | −0.5627 | −0.7122 |

| 0.87 | −1.1244 | −0.9067 | −1.1302 | −1.1381 | −1.2249 | −0.9181 | −0.8835 | −0.8119 | −0.7253 | −0.6846 | −0.6021 | −0.7568 | −0.4639 | −0.6181 |

| 0.88 | −1.0809 | −0.9914 | −1.1426 | −0.9030 | −1.1385 | −0.8694 | −0.8003 | −0.7961 | −0.6956 | −0.6247 | −0.5969 | −0.6628 | −0.4126 | −0.5471 |

| 0.89 | −1.0673 | −1.0219 | −1.0733 | −0.8815 | −1.0880 | −0.8157 | −0.7329 | −0.7668 | −0.5736 | −0.5943 | −0.6728 | −0.4681 | −0.4307 | −0.6585 |

| 0.90 | −1.1964 | −1.0289 | −1.0113 | −0.8608 | −1.0749 | −0.7290 | −0.7031 | −0.6816 | −0.5477 | −0.5609 | −0.6976 | −0.3105 | −0.4863 | −0.7656 |

| 0.91 | −1.4426 | −1.0707 | −1.0689 | −0.7782 | −1.0731 | −0.6733 | −0.6285 | −0.6623 | −0.5306 | −0.5760 | −0.8613 | −0.3913 | −0.5708 | −0.8450 |

| 0.92 | −0.7746 | −0.7906 | −0.7820 | −0.8010 | −0.8261 | −0.7904 | −0.7508 | −0.5121 | −0.4980 | −0.4531 | −0.5132 | −0.4694 | −0.4538 | −0.4796 |

| 0.93 | −0.0713 | −0.5231 | −0.5030 | −0.8242 | −0.5514 | −0.8841 | −0.9259 | −0.3659 | −0.5114 | −0.3137 | −0.0659 | −0.5291 | −0.3447 | −0.0992 |

| 0.94 | −1.1839 | −2.7572 | −2.3438 | −3.5213 | −3.5239 | −2.1381 | −1.4911 | −1.9692 | −1.8520 | −1.5684 | −1.9514 | −2.9357 | −0.8362 | −2.9083 |

| 0.95 | −0.4163 | −0.5819 | −0.6282 | −0.7508 | −0.4265 | −0.7119 | −0.9160 | −0.3234 | −0.4950 | −0.3847 | −0.1032 | −0.8520 | −0.5335 | −0.3500 |

| Time in ms | 7 442 HB | 9 450 HB | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test 43 | Test 44 | Test 45 | Test 46 | Test 47 | Test 48 | Test 61 | Test 62 | Test 63 | Test 64 | Test 65 | Test 66 | Test 67 | |

| 0.01 | 0.5310 | 1.5310 | 2.1721 | 1.3565 | 2.0705 | 1.0174 | 1.2351 | 1.6769 | 1.1465 | 1.0299 | 1.7893 | 1.7294 | 1.5844 |

| 0.02 | 1.7356 | 2.5026 | 3.3487 | 2.4904 | 3.0820 | 2.1811 | 2.3817 | 2.7515 | 2.1879 | 2.1175 | 2.7420 | 2.5872 | 2.4110 |

| 0.03 | 2.9221 | 3.6822 | 4.5714 | 3.6106 | 4.2566 | 3.2649 | 3.5420 | 3.8992 | 3.3134 | 3.1755 | 3.8927 | 3.6518 | 3.4974 |

| 0.04 | 4.1775 | 5.0672 | 5.8772 | 4.8586 | 5.6508 | 4.3506 | 4.6687 | 5.1921 | 4.5339 | 4.2971 | 5.2576 | 4.9039 | 4.7909 |

| 0.05 | 5.5557 | 6.2752 | 7.0595 | 6.1856 | 6.8724 | 5.6498 | 5.8069 | 6.3876 | 5.8430 | 5.6288 | 6.4882 | 5.9918 | 5.8755 |

| 0.06 | 6.8266 | 7.5220 | 8.1553 | 7.2884 | 8.0108 | 6.8175 | 6.9782 | 7.5100 | 7.1099 | 6.8062 | 7.6827 | 7.1242 | 7.0053 |

| 0.07 | 8.0409 | 8.7609 | 9.2392 | 8.4639 | 9.2085 | 7.9336 | 8.0732 | 8.7430 | 8.3056 | 7.9386 | 8.8760 | 8.2404 | 8.1743 |

| 0.08 | 9.1583 | 9.6139 | 10.0057 | 9.4733 | 9.9654 | 9.0802 | 9.0172 | 9.6041 | 9.3753 | 9.1082 | 9.6931 | 9.0320 | 8.9948 |

| 0.09 | 9.9602 | 10.3334 | 10.5934 | 10.0824 | 10.5869 | 9.8383 | 9.7856 | 10.2674 | 10.1888 | 9.8824 | 10.4420 | 9.7962 | 9.7746 |

| 0.10 | 10.5699 | 10.7938 | 10.9588 | 10.7267 | 11.0627 | 10.4817 | 10.3969 | 10.9195 | 10.8448 | 10.5534 | 11.0664 | 10.3034 | 10.3079 |

| 0.11 | 10.9085 | 11.0357 | 11.1224 | 11.0450 | 11.2198 | 10.8961 | 10.7780 | 11.1408 | 11.2622 | 11.0375 | 11.3201 | 10.5735 | 10.5466 |

| 0.12 | 11.1002 | 11.2840 | 11.3049 | 11.1726 | 11.4472 | 11.0634 | 11.0516 | 11.3237 | 11.4927 | 11.2242 | 11.5573 | 10.8244 | 10.8336 |

| 0.13 | 11.2510 | 11.3083 | 11.1987 | 11.4114 | 11.4438 | 11.3124 | 11.2508 | 11.4678 | 11.7170 | 11.4730 | 11.6300 | 10.8229 | 10.9428 |

| 0.14 | 11.1077 | 11.0301 | 10.7199 | 11.1844 | 10.9749 | 11.2203 | 11.0455 | 11.1179 | 11.6345 | 11.4486 | 11.3312 | 10.7048 | 10.8257 |

| 0.15 | 10.6523 | 10.3773 | 9.8069 | 10.5550 | 10.1731 | 10.7681 | 10.5730 | 10.4918 | 11.1612 | 11.0280 | 10.7318 | 10.2867 | 10.4677 |

| 0.16 | 9.6154 | 9.1790 | 8.2920 | 9.6267 | 8.8225 | 9.9967 | 9.7397 | 9.3935 | 10.2878 | 10.2929 | 9.5410 | 9.2538 | 9.5539 |

| 0.17 | 8.0625 | 7.6180 | 6.5559 | 8.2315 | 7.0863 | 8.6302 | 8.3727 | 7.7643 | 8.8118 | 8.9999 | 7.9072 | 7.9296 | 8.2933 |

| 0.18 | 6.3067 | 5.7791 | 4.7668 | 6.5654 | 5.2363 | 7.0501 | 6.9021 | 6.0132 | 7.0587 | 7.4167 | 6.1287 | 6.3031 | 6.8350 |

| 0.19 | 4.1982 | 3.6570 | 2.7757 | 4.4831 | 3.1475 | 5.3392 | 5.1896 | 3.9872 | 5.1296 | 5.6297 | 4.0798 | 4.4012 | 5.0256 |

| 0.22 | 2.0583 | 1.5591 | 0.7546 | 2.1798 | 1.0738 | 3.3165 | 3.1818 | 1.8810 | 2.9723 | 3.5540 | 1.9923 | 2.5553 | 3.1416 |

| 0.21 | 0.0348 | −0.3919 | −1.4602 | 0.1037 | −0.9641 | 1.3775 | 1.3108 | −0.0758 | 0.8804 | 1.5403 | −0.0970 | 0.6622 | 1.2476 |

| 0.22 | −2.2006 | −2.3948 | −3.7914 | −1.9126 | −3.1061 | −0.6000 | −0.6501 | −2.2354 | −1.2695 | −0.5391 | −2.3520 | −1.3642 | −0.8206 |

| 0.23 | −4.2927 | −4.4302 | −5.9162 | −3.7499 | −5.0902 | −2.7841 | −2.6539 | −4.2859 | −3.4351 | −2.7260 | −4.3834 | −3.2699 | −2.7651 |

| 0.24 | −6.2904 | −6.5494 | −7.8932 | −5.4740 | −7.0259 | −4.8090 | −4.4220 | −6.1980 | −5.4099 | −4.6952 | −6.3287 | −5.2003 | −4.6200 |

| 0.25 | −8.4114 | −8.6391 | −9.6763 | −7.4496 | −8.9397 | −6.8103 | −6.3106 | −8.2216 | −7.4309 | −6.6938 | −8.3357 | −7.1458 | −6.5199 |

| 0.26 | −10.1316 | −10.4217 | −11.2644 | −9.1967 | −10.5275 | −8.7646 | −8.1506 | −9.8717 | −9.3331 | −8.6069 | −10.0313 | −8.8676 | −8.2442 |

| 0.27 | −11.6171 | −11.9636 | −12.7307 | −10.6027 | −11.9463 | −10.3244 | −9.7486 | −11.2796 | −10.9464 | −10.1608 | −11.5633 | −10.4376 | −9.8807 |

| 0.28 | −12.9948 | −13.1844 | −13.8692 | −11.9241 | −13.1805 | −11.6598 | −11.2967 | −12.6313 | −12.4383 | −11.6788 | −12.8932 | −11.7646 | −11.3713 |

| 0.29 | −13.9468 | −14.1302 | −14.6647 | −12.7729 | −13.9928 | −12.7620 | −12.5970 | −13.5038 | −13.5677 | −12.9469 | −13.7735 | −12.8024 | −12.5114 |

| 0.30 | −14.6997 | −14.9807 | −15.2540 | −14.0213 | −14.6327 | −13.5430 | −13.5743 | −14.2144 | −14.3103 | −13.8291 | −14.4640 | −13.6924 | −13.4630 |

| 0.31 | −15.1959 | −15.4429 | −15.5377 | −15.4075 | −15.0244 | −14.1450 | −14.3323 | −14.7813 | −14.8898 | −14.5907 | −14.9432 | −14.2683 | −14.1674 |

| 0.32 | −15.1209 | −15.4884 | −15.5758 | −15.2435 | −14.8996 | −14.4643 | −14.6719 | −14.8740 | −15.1303 | −14.9576 | −15.0417 | −14.4745 | −14.5462 |

| 0.33 | −14.4913 | −15.0201 | −14.8647 | −13.9461 | −14.0992 | −14.4846 | −14.5925 | −14.5685 | −15.0037 | −14.9762 | −14.6365 | −14.3635 | −14.6722 |

| 0.34 | −12.9527 | −13.5455 | −12.9124 | −11.6866 | −12.3606 | −13.8939 | −13.8278 | −13.4169 | −14.2314 | −14.5383 | −13.3186 | −13.5863 | −14.1329 |

| 0.35 | −10.4811 | −11.2289 | −10.0287 | −8.3700 | −9.7726 | −12.2895 | −12.1160 | −11.3444 | −12.5112 | −13.1043 | −11.1127 | −12.0876 | −12.7253 |

| 0.36 | −7.4555 | −8.2702 | −6.4609 | −5.5461 | −6.5771 | −9.9109 | −9.8190 | −8.6872 | −10.0348 | −10.9182 | −8.1590 | −10.0195 | −10.6993 |

| 0.37 | −4.1503 | −4.8043 | −2.8520 | −3.0428 | −3.1872 | −7.0859 | −7.0968 | −5.4487 | −6.9656 | −8.1535 | −4.7274 | −7.3355 | −8.0336 |

| 0.38 | −1.1993 | −1.5825 | 0.0460 | −0.0991 | −0.2162 | −4.3241 | −4.3130 | −2.1102 | −3.7431 | −5.1090 | −1.5228 | −4.2196 | −5.0760 |

| 0.39 | 1.0818 | 1.0908 | 2.3646 | 2.3090 | 2.1399 | −2.0541 | −1.9396 | 0.9225 | −0.8238 | −2.5009 | 1.1425 | −1.0012 | −2.3303 |

| 0.40 | 2.6315 | 3.0372 | 4.0174 | 3.9575 | 3.4711 | −0.0736 | 0.1834 | 3.4007 | 1.7286 | −0.1600 | 3.0658 | 1.9127 | 0.1819 |

| 0.41 | 3.2809 | 3.9331 | 4.4555 | 4.7520 | 4.2964 | 1.5749 | 1.8789 | 4.6664 | 3.5910 | 1.9210 | 3.8732 | 3.9384 | 2.1648 |

| 0.42 | 3.3618 | 3.9910 | 5.4872 | 4.7060 | 5.4704 | 2.7717 | 2.8973 | 5.0856 | 4.4557 | 3.4633 | 4.2547 | 4.8033 | 3.4630 |

| 0.43 | 3.1222 | 4.6972 | 5.9914 | 4.2058 | 5.2092 | 3.5734 | 3.4511 | 5.1718 | 5.2488 | 4.4542 | 4.8496 | 5.3312 | 4.1659 |

| 0.44 | 2.6413 | 5.0333 | 4.0372 | 3.3556 | 3.6195 | 4.9262 | 3.6465 | 4.4035 | 5.5220 | 4.9406 | 4.5361 | 5.1115 | 4.8530 |

| 0.45 | 2.2510 | 3.5760 | 2.2204 | 2.6300 | 2.5554 | 5.2410 | 3.9831 | 3.2825 | 4.4405 | 4.9390 | 3.3661 | 3.7749 | 4.9014 |

| 0.46 | 1.8296 | 2.0983 | 1.0659 | 2.1478 | 1.4078 | 3.5674 | 3.7780 | 2.3857 | 3.1586 | 3.8773 | 2.3561 | 2.5506 | 3.6273 |

| 0.47 | 1.3410 | 1.0648 | −0.1054 | 1.6718 | 0.8879 | 2.0880 | 2.5717 | 1.5161 | 2.0702 | 2.2845 | 1.4283 | 1.5459 | 2.2876 |

| 0.48 | 0.9275 | 0.1555 | 0.5736 | 1.4810 | 1.6990 | 0.9067 | 1.6124 | 1.2118 | 1.0817 | 1.3647 | 1.0181 | 0.8419 | 1.3807 |

| 0.49 | 0.3920 | 0.7401 | 1.5505 | 1.3387 | 1.6663 | 0.0044 | 0.9790 | 1.4140 | 1.0568 | 0.8304 | 1.4449 | 1.2682 | 0.6831 |

| 0.50 | −0.1619 | 1.5825 | 0.9543 | 0.9559 | 1.1702 | 0.8554 | 0.6107 | 1.4132 | 1.3798 | 0.8321 | 1.5780 | 1.7834 | 1.0383 |

| 0.51 | −0.5984 | 1.1094 | 0.9648 | 0.5363 | 1.5010 | 1.5379 | 1.1898 | 1.4071 | 1.1932 | 1.5733 | 1.2979 | 1.6886 | 1.6158 |

| 0.52 | −1.1009 | 1.0154 | 1.3570 | −0.0350 | 1.6146 | 1.0373 | 1.5732 | 1.4702 | 1.2618 | 1.7357 | 1.3433 | 1.8536 | 1.4067 |

| 0.53 | −1.5084 | 1.3160 | 1.3423 | −0.5908 | 1.5286 | 1.5200 | 1.3704 | 1.4866 | 1.5007 | 1.6181 | 1.4761 | 1.9551 | 1.6062 |

| 0.54 | −1.7937 | 1.3049 | 1.3512 | −0.8554 | 1.5983 | 2.1441 | 1.6664 | 1.5524 | 1.5840 | 1.9860 | 1.4772 | 1.8009 | 1.9683 |

| 0.55 | −2.0772 | 1.2418 | 1.4793 | −1.1303 | 1.5357 | 2.1678 | 1.9385 | 1.4630 | 1.5342 | 2.0889 | 1.3997 | 1.6175 | 1.9202 |

| 0.56 | −2.2322 | 1.3187 | 1.5753 | −1.0672 | 1.4698 | 2.1874 | 1.9154 | 1.4699 | 1.4646 | 1.9019 | 1.3841 | 1.4908 | 1.8610 |

| 0.57 | −2.3295 | 1.3201 | 1.5433 | −0.2154 | 1.3653 | 2.1394 | 1.8790 | 1.5378 | 1.4743 | 1.8017 | 1.3524 | 1.4704 | 1.7301 |

| 0.58 | −2.1174 | 1.2273 | 1.3784 | −0.1578 | 1.1299 | 1.7775 | 1.6591 | 1.4106 | 1.3597 | 1.6237 | 1.2094 | 1.4486 | 1.4182 |

| 0.59 | −1.5670 | 1.1304 | 1.1854 | −0.9463 | 0.9875 | 1.4467 | 1.3554 | 1.4187 | 1.1614 | 1.4377 | 1.0885 | 1.4074 | 1.3205 |

| 0.60 | −1.3067 | 0.9595 | 0.9536 | −1.1736 | 0.8380 | 1.0283 | 1.0792 | 1.4221 | 1.0231 | 1.3223 | 0.9518 | 1.3843 | 1.2568 |

| 0.61 | −1.2078 | 0.7357 | 0.6898 | −1.2728 | 0.6605 | 0.5272 | 0.7991 | 1.2152 | 0.9186 | 1.1314 | 0.7236 | 1.3447 | 1.1372 |

| 0.62 | −1.1191 | 0.5397 | 0.4638 | −1.1101 | 0.5890 | 0.3329 | 0.6793 | 1.0741 | 0.9250 | 1.0150 | 0.5857 | 1.3767 | 1.1619 |

| 0.63 | −1.2923 | 0.3195 | 0.1700 | −0.2469 | 0.4522 | 0.3559 | 0.5324 | 0.8318 | 0.9591 | 1.0214 | 0.4836 | 1.3335 | 1.0938 |

| 0.64 | −1.2239 | 0.1010 | −0.0996 | −0.0373 | 0.3180 | 0.5078 | 0.2941 | 0.5030 | 0.8162 | 1.0107 | 0.3535 | 1.1311 | 0.9729 |

| 0.65 | −0.9537 | −0.0332 | −0.1910 | −0.4493 | 0.3056 | 0.7660 | 0.1904 | 0.3501 | 0.6484 | 0.9363 | 0.3191 | 0.8805 | 0.9151 |

| 0.66 | −0.9679 | −0.1497 | −0.2319 | −0.2914 | 0.2319 | 0.8493 | 0.0520 | 0.1628 | 0.5410 | 0.7154 | 0.2678 | 0.5553 | 0.6795 |

| 0.67 | −0.9464 | −0.2161 | −0.2455 | −0.1145 | 0.2250 | 0.8442 | −0.0367 | −0.0164 | 0.4559 | 0.4903 | 0.2056 | 0.2828 | 0.4582 |

| 0.68 | −0.9299 | −0.2360 | −0.2018 | −0.3420 | 0.2625 | 0.8222 | 0.0704 | −0.0591 | 0.4445 | 0.5054 | 0.2633 | 0.1832 | 0.4127 |

| 0.69 | −1.1066 | −0.2547 | −0.2204 | −0.6407 | 0.2168 | 0.6357 | 0.0866 | −0.1655 | 0.3513 | 0.5894 | 0.2977 | 0.0857 | 0.3995 |

| 0.70 | −1.2470 | −0.2385 | −0.2151 | −0.7358 | 0.2688 | 0.4816 | 0.1108 | −0.1667 | 0.1520 | 0.5905 | 0.3166 | 0.0267 | 0.4909 |

| 0.71 | −1.3604 | −0.1973 | −0.1064 | −0.8421 | 0.3276 | 0.3577 | 0.2217 | −0.0261 | 0.0410 | 0.4669 | 0.3752 | 0.0532 | 0.4628 |

| 0.72 | −1.4420 | −0.1479 | 0.0049 | −0.9003 | 0.2999 | 0.2074 | 0.1784 | 0.0445 | 0.0219 | 0.2396 | 0.3432 | 0.0430 | 0.2907 |

| 0.73 | −1.3854 | −0.0820 | 0.1003 | −0.8521 | 0.3033 | 0.2055 | 0.1484 | 0.1906 | 0.0216 | 0.1819 | 0.3329 | 0.1032 | 0.2777 |

| 0.74 | −1.3334 | −0.0294 | 0.1072 | −0.8612 | 0.2443 | 0.1808 | 0.1918 | 0.3027 | 0.0480 | 0.3153 | 0.3241 | 0.2594 | 0.3162 |

| 0.75 | −1.2965 | 0.0034 | −0.0113 | −0.7844 | 0.1888 | 0.0944 | 0.1638 | 0.3006 | 0.0000 | 0.3865 | 0.2551 | 0.3983 | 0.3852 |

| 0.76 | −1.2220 | −0.0125 | −0.1315 | −0.5636 | 0.2353 | 0.1224 | 0.2008 | 0.3775 | −0.0444 | 0.3882 | 0.2332 | 0.5289 | 0.4934 |

| 0.77 | −1.1536 | −0.0724 | −0.1690 | −0.3459 | 0.2056 | 0.1080 | 0.1494 | 0.3979 | 0.0154 | 0.3064 | 0.1992 | 0.5709 | 0.3828 |

| 0.78 | −1.1054 | −0.0994 | −0.1753 | −0.1244 | 0.1698 | 0.1591 | 0.0004 | 0.3466 | 0.0656 | 0.1637 | 0.1477 | 0.5037 | 0.2545 |

| 0.79 | −1.0348 | −0.1275 | −0.1945 | 0.0372 | 0.1638 | 0.3234 | −0.0179 | 0.3594 | 0.1458 | 0.1495 | 0.1381 | 0.4437 | 0.2451 |

| 0.80 | −0.9309 | −0.1944 | −0.2523 | 0.0555 | 0.0791 | 0.3891 | −0.0413 | 0.2802 | 0.2204 | 0.2205 | 0.0968 | 0.3760 | 0.2237 |

| 0.81 | −0.8782 | −0.2559 | −0.3674 | 0.1163 | 0.0722 | 0.4548 | −0.0674 | 0.2077 | 0.2112 | 0.2548 | 0.0740 | 0.2840 | 0.2758 |

| 0.82 | −0.8799 | −0.3127 | −0.4610 | 0.4002 | 0.1045 | 0.4923 | −0.0123 | 0.1864 | 0.2429 | 0.2234 | 0.0960 | 0.2210 | 0.2685 |

| 0.83 | −0.8652 | −0.3641 | −0.4403 | 0.6187 | 0.0414 | 0.3792 | −0.0126 | 0.0569 | 0.2957 | 0.1046 | 0.1020 | 0.1198 | 0.1114 |

| 0.84 | −0.8422 | −0.3873 | −0.3571 | 0.4492 | 0.0380 | 0.3017 | 0.0348 | −0.0082 | 0.2897 | 0.0182 | 0.1368 | −0.0272 | 0.0232 |

| 0.85 | −0.8763 | −0.3833 | −0.2902 | 0.1346 | 0.0564 | 0.2063 | 0.1649 | −0.0158 | 0.3119 | 0.0232 | 0.1762 | −0.1002 | −0.0159 |

| 0.86 | −0.8791 | −0.3871 | −0.2487 | −0.1341 | 0.0315 | 0.0833 | 0.2183 | −0.0681 | 0.2728 | 0.0789 | 0.2013 | −0.1310 | −0.0198 |

| 0.87 | −0.8734 | −0.3662 | −0.2147 | −0.2944 | 0.1040 | 0.0703 | 0.2799 | −0.0392 | 0.1845 | 0.1270 | 0.2709 | −0.1525 | 0.0871 |

| 0.88 | −0.9283 | −0.2920 | −0.2097 | −0.1851 | 0.1461 | −0.0070 | 0.3044 | −0.0058 | 0.1656 | 0.0794 | 0.3160 | −0.1169 | 0.1166 |

| 0.89 | −0.9281 | −0.2369 | −0.2222 | −0.0814 | 0.1370 | −0.1346 | 0.2705 | −0.0065 | 0.1234 | 0.0024 | 0.3142 | −0.0747 | 0.0861 |

| 0.90 | −0.9274 | −0.2369 | −0.2154 | −0.2295 | 0.1722 | −0.1827 | 0.2658 | 0.0848 | 0.0775 | −0.0052 | 0.3373 | −0.0433 | 0.1054 |

| 0.91 | −1.0244 | −0.2696 | −0.3018 | −0.3589 | 0.1075 | −0.2981 | 0.2243 | 0.1163 | 0.0382 | −0.0643 | 0.3213 | 0.0017 | 0.0573 |

| 0.92 | −0.7310 | −0.0159 | −0.0094 | 0.0099 | 0.2357 | 0.2113 | 0.1953 | 0.2334 | 0.2614 | 0.2367 | 0.2566 | 0.2608 | 0.2466 |

| 0.93 | −0.4258 | 0.2120 | 0.3018 | 0.3850 | 0.4138 | 0.7864 | 0.1931 | 0.4007 | 0.4622 | 0.5866 | 0.2116 | 0.5126 | 0.4695 |

| 0.94 | −11.7999 | 1.6557 | 1.2981 | −9.6857 | 2.2359 | 2.6358 | 0.2286 | 2.3493 | 2.2694 | 3.2621 | 2.4877 | 3.6893 | 3.2959 |

| 0.95 | −0.4979 | 0.1323 | 0.0871 | 0.3547 | 0.3024 | 0.7396 | 0.1439 | 0.4634 | 0.2935 | 0.5731 | 0.1135 | 0.6909 | 0.4391 |

| Time in ms | 8 446 HB | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test 49 | Test 50 | Test 51 | Test 52 | Test 53 | Test 54 | Test 55 | Test 56 | Test 57 | Test 58 | Test 59 | Test 60 | |

| 0.01 | 1.3368 | 1.7362 | 1.4114 | 2.1965 | 1.1621 | 1.9785 | 1.5047 | 1.2461 | 1.9580 | 2.1968 | 1.4002 | 1.8195 |

| 0.02 | 2.5311 | 2.7178 | 2.3282 | 3.1953 | 2.1926 | 2.9612 | 2.5334 | 2.2980 | 2.9030 | 3.2490 | 2.5555 | 2.7753 |

| 0.03 | 3.7230 | 3.9426 | 3.4086 | 4.3761 | 3.2903 | 4.1411 | 3.7258 | 3.4022 | 4.0579 | 4.4176 | 3.6635 | 3.9213 |

| 0.04 | 5.0490 | 5.3770 | 4.6977 | 5.7456 | 4.4951 | 5.5248 | 5.0831 | 4.5969 | 5.4006 | 5.6583 | 4.8731 | 5.2761 |

| 0.05 | 6.5246 | 6.6372 | 5.9614 | 6.8741 | 5.7438 | 6.6436 | 6.2919 | 5.8612 | 6.5652 | 6.8206 | 6.2016 | 6.4083 |

| 0.06 | 7.7362 | 7.8462 | 7.1852 | 8.0246 | 6.9424 | 7.7668 | 7.4399 | 7.0501 | 7.7195 | 7.9714 | 7.3185 | 7.5279 |

| 0.07 | 8.9419 | 9.0832 | 8.4201 | 9.1813 | 8.1568 | 8.9140 | 8.6059 | 8.1897 | 8.8162 | 9.0170 | 8.4774 | 8.7309 |

| 0.08 | 9.9822 | 9.9305 | 9.4248 | 9.8596 | 9.1940 | 9.6242 | 9.4795 | 9.2161 | 9.6244 | 9.7505 | 9.4557 | 9.5066 |

| 0.09 | 10.6025 | 10.6508 | 10.2483 | 10.4866 | 9.9750 | 10.3312 | 10.2030 | 9.9472 | 10.3692 | 10.3464 | 10.0592 | 10.1810 |

| 0.10 | 11.2569 | 11.1741 | 10.8351 | 10.8864 | 10.6118 | 10.7982 | 10.7700 | 10.5230 | 10.7320 | 10.7039 | 10.6901 | 10.6699 |

| 0.11 | 11.5855 | 11.3744 | 11.1594 | 10.9594 | 10.8958 | 10.9530 | 11.0240 | 10.8535 | 10.9169 | 10.9069 | 10.9048 | 10.8004 |

| 0.12 | 11.7154 | 11.6038 | 11.4092 | 11.2033 | 11.0967 | 11.1881 | 11.1733 | 10.9906 | 11.1451 | 11.1075 | 11.0172 | 10.9874 |

| 0.13 | 11.9057 | 11.6738 | 11.5060 | 11.1557 | 11.2994 | 11.1546 | 11.2170 | 11.1557 | 11.0605 | 10.9915 | 11.2386 | 10.9933 |

| 0.14 | 11.6038 | 11.4129 | 11.4325 | 10.6640 | 11.1818 | 10.7721 | 10.9549 | 10.9936 | 10.8232 | 10.6012 | 10.9198 | 10.6398 |

| 0.15 | 10.8834 | 10.7277 | 10.9821 | 9.9097 | 10.8014 | 10.0730 | 10.3699 | 10.4562 | 10.1476 | 9.7911 | 10.3654 | 10.0347 |

| 0.16 | 9.7415 | 9.4165 | 9.8975 | 8.4837 | 9.8933 | 8.7889 | 9.3037 | 9.5468 | 8.7938 | 8.4207 | 9.3889 | 8.8890 |

| 0.17 | 8.0190 | 7.7091 | 8.4692 | 6.7755 | 8.4610 | 7.2033 | 7.7588 | 8.1091 | 7.2668 | 6.8348 | 7.7254 | 7.3354 |

| 0.18 | 6.1813 | 5.8239 | 6.7188 | 4.9707 | 6.8646 | 5.4476 | 6.0341 | 6.4433 | 5.4881 | 4.9623 | 5.9900 | 5.5522 |

| 0.19 | 4.1664 | 3.7237 | 4.6979 | 2.7793 | 4.9477 | 3.3917 | 4.0667 | 4.5284 | 3.4270 | 2.8829 | 3.9941 | 3.4251 |

| 0.22 | 1.9578 | 1.6212 | 2.6976 | 0.7291 | 2.8982 | 1.3729 | 1.9649 | 2.4137 | 1.4714 | 0.9122 | 1.8344 | 1.3561 |

| 0.21 | −0.1471 | −0.4901 | 0.5960 | −1.3079 | 0.9624 | −0.6765 | −0.0737 | 0.4149 | −0.6101 | −1.1539 | −0.0784 | −0.5742 |

| 0.22 | −2.3333 | −2.7169 | −1.6519 | −3.5469 | −1.1483 | −2.8489 | −2.2823 | −1.6875 | −2.7580 | −3.2080 | −2.1837 | −2.6297 |

| 0.23 | −4.5081 | −4.7939 | −3.7810 | −5.4371 | −3.1838 | −4.7897 | −4.3839 | −3.7608 | −4.6392 | −5.0966 | −4.2494 | −4.5436 |

| 0.24 | −6.5570 | −6.7873 | −5.8813 | −7.3408 | −5.0976 | −6.6682 | −6.2325 | −5.6460 | −6.5340 | −7.0332 | −6.0996 | −6.5083 |

| 0.25 | −8.6581 | −8.7431 | −7.9394 | −9.2192 | −7.1462 | −8.4820 | −8.0822 | −7.6120 | −8.3802 | −8.8157 | −8.0827 | −8.5549 |

| 0.26 | −10.5029 | −10.4048 | −9.6892 | −10.6412 | −8.9526 | −9.9503 | −9.7316 | −9.3686 | −9.9961 | −10.3661 | −9.8059 | −10.1655 |

| 0.27 | −11.9703 | −11.8805 | −11.2631 | −12.0583 | −10.5308 | −11.2722 | −11.1963 | −10.8236 | −11.5457 | −11.8200 | −11.2611 | −11.5443 |

| 0.28 | −13.2778 | −13.1101 | −12.6393 | −13.2174 | −11.9998 | −12.3637 | −12.5144 | −12.2242 | −12.7869 | −12.9506 | −12.6347 | −12.7021 |

| 0.29 | −14.2368 | −13.9645 | −13.6365 | −13.8981 | −13.0962 | −13.1626 | −13.4253 | −13.2752 | −13.6495 | −13.7947 | −13.5518 | −13.4438 |

| 0.30 | −14.8908 | −14.6316 | −14.4063 | −14.5481 | −13.9548 | −13.9051 | −14.0958 | −14.0007 | −14.3523 | −14.4265 | −14.2297 | −14.1194 |

| 0.31 | −15.3502 | −15.0110 | −14.9110 | −14.8519 | −14.5939 | −14.3221 | −14.5647 | −14.5813 | −14.6943 | −14.6875 | −14.7283 | −14.5647 |

| 0.32 | −15.3002 | −15.0423 | −15.0421 | −14.6503 | −14.8120 | −14.3867 | −14.6706 | −14.7819 | −14.7346 | −14.6000 | −14.7897 | −14.5049 |

| 0.33 | −14.5442 | −14.5356 | −14.7626 | −13.8014 | −14.6860 | −13.9175 | −14.2672 | −14.5211 | −14.2328 | −13.8708 | −14.4049 | −13.8879 |

| 0.34 | −12.9696 | −13.0498 | −13.6624 | −11.8941 | −13.8030 | −12.4637 | −12.9277 | −13.4932 | −12.6894 | −12.1522 | −13.0684 | −12.3315 |

| 0.35 | −10.5125 | −10.8204 | −11.7157 | −9.2286 | −11.9680 | −10.2790 | −10.6849 | −11.4227 | −10.3544 | −9.5601 | −10.6284 | −9.9742 |

| 0.36 | −7.3775 | −8.0354 | −9.1531 | −6.0056 | −9.4490 | −7.4946 | −7.8054 | −8.4693 | −7.4116 | −6.1450 | −7.4570 | −7.1329 |

| 0.37 | −4.0122 | −4.8639 | −6.1511 | −2.6207 | −6.2227 | −4.3475 | −4.5607 | −4.8935 | −4.1729 | −2.4848 | −3.8126 | −4.0093 |

| 0.38 | −0.9162 | −1.8166 | −3.1166 | 0.2017 | −2.9122 | −1.5155 | −1.5980 | −1.4080 | −1.2597 | 0.6208 | −0.4355 | −1.1067 |

| 0.39 | 1.6370 | 0.9187 | −0.2211 | 2.4815 | −0.1159 | 0.8476 | 0.8630 | 1.4551 | 1.2910 | 3.0050 | 2.1563 | 1.3953 |

| 0.40 | 3.4081 | 3.0562 | 2.2305 | 3.7190 | 2.1322 | 2.5874 | 2.8113 | 3.5551 | 3.0722 | 4.1273 | 3.8931 | 3.2397 |

| 0.41 | 4.1826 | 4.1981 | 3.7578 | 4.3422 | 3.5056 | 3.6055 | 3.8680 | 4.4410 | 4.0321 | 4.7417 | 4.3672 | 4.1358 |

| 0.42 | 4.5483 | 4.5249 | 4.4236 | 5.4565 | 3.8111 | 4.4258 | 4.3567 | 4.7237 | 5.5037 | 5.7208 | 5.1260 | 5.5662 |

| 0.43 | 4.5872 | 4.9506 | 5.2383 | 5.1269 | 4.1623 | 5.0816 | 5.2726 | 5.1200 | 5.6040 | 5.0361 | 5.5562 | 5.9627 |

| 0.44 | 3.6547 | 5.3066 | 5.4039 | 3.3932 | 4.6931 | 4.7785 | 5.1153 | 4.4380 | 3.8116 | 3.1539 | 3.9342 | 4.1191 |

| 0.45 | 2.5453 | 4.4579 | 4.1415 | 2.2800 | 4.0980 | 3.6027 | 3.3788 | 3.0239 | 2.6493 | 1.9994 | 2.3544 | 2.6528 |

| 0.46 | 1.8468 | 2.9619 | 2.7900 | 1.1325 | 2.8614 | 2.3936 | 1.9624 | 2.0328 | 1.5932 | 0.8338 | 1.3625 | 1.4906 |

| 0.47 | 1.2647 | 1.7357 | 1.6678 | 0.6827 | 1.9091 | 1.5324 | 0.9383 | 1.1089 | 0.8454 | 0.5821 | 0.3574 | 0.4992 |

| 0.48 | 1.3149 | 0.7260 | 0.8012 | 1.6514 | 0.9867 | 1.3017 | 0.4483 | 0.8810 | 1.6974 | 1.6626 | 0.9564 | 1.4167 |

| 0.49 | 1.6963 | 0.6582 | 1.1445 | 1.7349 | 0.8106 | 1.6533 | 1.3073 | 1.5298 | 1.8932 | 1.7218 | 1.7995 | 2.1035 |

| 0.50 | 1.5928 | 1.2450 | 1.5931 | 1.3031 | 1.4457 | 1.7222 | 1.8630 | 1.6413 | 1.2183 | 1.3448 | 1.2965 | 1.5068 |

| 0.51 | 1.5735 | 1.1796 | 1.2166 | 1.6397 | 1.4619 | 1.2962 | 1.4484 | 1.4203 | 1.5343 | 1.6700 | 1.3395 | 1.7626 |

| 0.52 | 1.7305 | 1.0197 | 1.2586 | 1.7380 | 1.1867 | 1.0556 | 1.5022 | 1.5472 | 1.7418 | 1.7109 | 1.6551 | 2.0010 |

| 0.53 | 1.6317 | 1.2986 | 1.5889 | 1.6965 | 1.3407 | 1.0703 | 1.7048 | 1.5979 | 1.6089 | 1.6364 | 1.6057 | 1.7863 |

| 0.54 | 1.5025 | 1.4514 | 1.6807 | 1.6902 | 1.4537 | 1.0857 | 1.6198 | 1.6263 | 1.4731 | 1.6302 | 1.5990 | 1.6010 |

| 0.55 | 1.3557 | 1.4082 | 1.6110 | 1.5468 | 1.3601 | 1.0784 | 1.3952 | 1.6246 | 1.3338 | 1.5710 | 1.5237 | 1.3685 |

| 0.56 | 1.2403 | 1.4106 | 1.5405 | 1.4615 | 1.3542 | 1.0912 | 1.2715 | 1.5763 | 1.3666 | 1.4883 | 1.4823 | 1.1722 |

| 0.57 | 1.1911 | 1.3576 | 1.3771 | 1.2791 | 1.3450 | 0.9935 | 1.1518 | 1.5000 | 1.3277 | 1.2449 | 1.4619 | 1.0420 |

| 0.58 | 0.9917 | 1.1826 | 1.1586 | 1.0544 | 1.2167 | 0.9211 | 0.9870 | 1.3156 | 1.1225 | 0.9880 | 1.2176 | 0.8604 |

| 0.59 | 0.7661 | 1.0006 | 1.0157 | 0.9765 | 1.0929 | 0.9968 | 0.9017 | 1.1631 | 0.9791 | 0.8446 | 0.9757 | 0.7442 |

| 0.60 | 0.6674 | 0.8115 | 0.8490 | 0.7698 | 0.9430 | 0.9692 | 0.7658 | 1.0173 | 0.8457 | 0.6606 | 0.7786 | 0.6211 |

| 0.61 | 0.5341 | 0.6354 | 0.6592 | 0.5877 | 0.7373 | 0.8358 | 0.5669 | 0.7653 | 0.8096 | 0.4987 | 0.5361 | 0.5323 |

| 0.62 | 0.4400 | 0.5735 | 0.5620 | 0.5320 | 0.5960 | 0.6990 | 0.4248 | 0.5596 | 0.8448 | 0.3785 | 0.4377 | 0.5888 |

| 0.63 | 0.3701 | 0.5778 | 0.4575 | 0.3394 | 0.4217 | 0.5593 | 0.3326 | 0.3719 | 0.7139 | 0.1836 | 0.3266 | 0.5820 |

| 0.64 | 0.2051 | 0.6245 | 0.4379 | 0.2497 | 0.2718 | 0.5458 | 0.3028 | 0.1753 | 0.5318 | 0.1190 | 0.1356 | 0.5214 |

| 0.65 | 0.1483 | 0.6076 | 0.5047 | 0.2552 | 0.2210 | 0.5622 | 0.3291 | 0.1246 | 0.4124 | 0.1414 | 0.0786 | 0.4970 |

| 0.66 | 0.1661 | 0.4807 | 0.4860 | 0.1483 | 0.1755 | 0.4355 | 0.3230 | 0.0623 | 0.3319 | 0.1589 | 0.0204 | 0.3722 |

| 0.67 | 0.1300 | 0.3899 | 0.4420 | 0.1561 | 0.1953 | 0.3195 | 0.2591 | −0.0225 | 0.3564 | 0.2358 | 0.0034 | 0.2874 |

| 0.68 | 0.1619 | 0.3329 | 0.3841 | 0.1851 | 0.2582 | 0.2383 | 0.1631 | 0.0184 | 0.3508 | 0.2676 | 0.0544 | 0.2849 |

| 0.69 | 0.1890 | 0.3174 | 0.2881 | 0.1380 | 0.2714 | 0.1678 | 0.0803 | 0.0665 | 0.2965 | 0.2560 | 0.0284 | 0.1870 |

| 0.70 | 0.1869 | 0.3361 | 0.2652 | 0.2042 | 0.2877 | 0.2410 | 0.0527 | 0.1064 | 0.3168 | 0.3093 | 0.0414 | 0.1375 |

| 0.71 | 0.2831 | 0.2290 | 0.2630 | 0.2263 | 0.3419 | 0.3081 | 0.0695 | 0.1683 | 0.3289 | 0.3226 | 0.1263 | 0.1373 |

| 0.72 | 0.3154 | 0.0776 | 0.1979 | 0.2271 | 0.3771 | 0.2715 | 0.0517 | 0.1471 | 0.4065 | 0.3268 | 0.1191 | 0.1064 |

| 0.73 | 0.3285 | 0.0382 | 0.1366 | 0.2730 | 0.3980 | 0.2184 | 0.0124 | 0.1517 | 0.5146 | 0.3631 | 0.1652 | 0.1513 |

| 0.74 | 0.3393 | 0.0493 | 0.0888 | 0.1739 | 0.3859 | 0.1344 | 0.0296 | 0.2070 | 0.4463 | 0.2850 | 0.1847 | 0.1373 |

| 0.75 | 0.2393 | 0.1356 | 0.1127 | 0.1037 | 0.3309 | 0.0950 | 0.0606 | 0.1863 | 0.3617 | 0.1801 | 0.1186 | 0.0390 |

| 0.76 | 0.1850 | 0.1913 | 0.1880 | 0.1136 | 0.2729 | 0.0937 | 0.1220 | 0.1973 | 0.3387 | 0.1028 | 0.1214 | 0.0081 |

| 0.77 | 0.1644 | 0.1096 | 0.2016 | 0.0273 | 0.2298 | 0.0184 | 0.1566 | 0.1735 | 0.2441 | −0.0007 | 0.1075 | −0.0405 |

| 0.78 | 0.0922 | 0.0382 | 0.1600 | 0.0055 | 0.1896 | −0.0502 | 0.0983 | 0.0380 | 0.2159 | −0.0355 | 0.0744 | −0.0338 |

| 0.79 | 0.0687 | 0.0472 | 0.0972 | 0.0168 | 0.1594 | −0.0652 | 0.0929 | −0.0239 | 0.1850 | −0.0201 | 0.1092 | 0.0625 |

| 0.80 | 0.0093 | 0.0972 | 0.0445 | −0.0594 | 0.1211 | −0.0574 | 0.1661 | −0.0380 | 0.0531 | −0.0504 | 0.0665 | 0.0448 |

| 0.81 | −0.0960 | 0.1778 | 0.0862 | −0.0437 | 0.1143 | 0.0245 | 0.2464 | −0.0780 | 0.0244 | −0.0365 | 0.0090 | 0.0221 |

| 0.82 | −0.0885 | 0.1977 | 0.1439 | −0.0434 | 0.1334 | 0.0712 | 0.2985 | −0.0370 | 0.0339 | 0.0045 | 0.0150 | 0.0412 |

| 0.83 | −0.0851 | 0.1592 | 0.1215 | −0.1109 | 0.1354 | 0.0813 | 0.2046 | −0.0229 | 0.0157 | 0.0266 | −0.0283 | −0.0053 |

| 0.84 | −0.0753 | 0.1273 | 0.0981 | −0.0992 | 0.1566 | 0.1687 | −0.0068 | −0.0479 | 0.0655 | 0.0906 | 0.0188 | 0.0184 |

| 0.85 | −0.0091 | 0.1025 | 0.0683 | −0.0927 | 0.1921 | 0.2695 | −0.1347 | 0.0007 | 0.0890 | 0.1126 | 0.0625 | 0.0591 |

| 0.86 | 0.0454 | 0.1184 | 0.0587 | −0.0711 | 0.2365 | 0.3442 | −0.1382 | 0.0201 | 0.1186 | 0.1244 | 0.0121 | 0.0349 |

| 0.87 | 0.1239 | 0.1435 | 0.0999 | 0.0203 | 0.2721 | 0.3697 | −0.0696 | 0.0161 | 0.2078 | 0.1760 | 0.0218 | 0.0793 |

| 0.88 | 0.1990 | 0.1703 | 0.1136 | 0.0552 | 0.2531 | 0.3072 | 0.0308 | 0.0527 | 0.2522 | 0.1682 | 0.0387 | 0.1046 |

| 0.89 | 0.2380 | 0.2266 | 0.1123 | 0.1001 | 0.2338 | 0.2269 | 0.0915 | 0.0495 | 0.2989 | 0.1730 | 0.0106 | 0.0846 |

| 0.90 | 0.2548 | 0.2606 | 0.0840 | 0.1602 | 0.2200 | 0.1874 | 0.1101 | 0.0568 | 0.3113 | 0.1740 | 0.0742 | 0.1208 |

| 0.91 | 0.2088 | 0.2221 | −0.0060 | 0.1222 | 0.1965 | 0.1359 | 0.1190 | 0.0150 | 0.2340 | 0.0878 | 0.0862 | 0.0530 |

| 0.92 | 0.2115 | 0.2347 | 0.2157 | 0.2006 | 0.2237 | 0.2238 | 0.2023 | 0.2447 | 0.2549 | 0.2159 | 0.2016 | 0.2163 |

| 0.93 | 0.2478 | 0.2350 | 0.4584 | 0.3145 | 0.2678 | 0.3179 | 0.2907 | 0.4755 | 0.2950 | 0.3866 | 0.3739 | 0.4242 |

| 0.94 | 0.5909 | 1.4713 | 1.3054 | 0.6648 | 2.0111 | 1.7833 | 0.4078 | 1.2812 | 3.0372 | 1.9155 | 0.7339 | 1.2923 |

| 0.95 | 0.1430 | 0.1645 | 0.3562 | 0.2893 | 0.3127 | 0.3147 | 0.3331 | 0.2346 | 0.1471 | 0.3958 | 0.3659 | 0.2546 |

References

- Tabor, D. The Hardness of Metals; Clarendon Press: Oxford, UK, 1951. [Google Scholar]

- Williams, J. Analytical models of scratch hardness. Tribol. Int. 1996, 29, 675–694. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, K.; Wang, Y.; Liu, G.; Sun, J.; Zhang, L. Unraveling the correlation between Hall-Petch slope and peak hardness in metallic nanolaminates. Int. J. Plast. 2017, 96, 120–134. [Google Scholar] [CrossRef]

- Song, M.; Sun, C.; Chen, Y.; Shang, Z.; Li, J.; Fan, Z.; Hartwig, K.T.; Zhang, X. Grain refinement mechanisms and strength-hardness correlation of ultra-fine grained grade 91 steel processed by equal channel angular extrusion. Int. J. Press. Vessel. Pip. 2019, 172, 212–219. [Google Scholar] [CrossRef] [Green Version]

- Lee, A.; Komvopoulos, K. Dynamic spherical indentation of strain hardening materials with and without strain rate dependent deformation behavior. Mech. Mater. 2019, 133, 128–137. [Google Scholar] [CrossRef]

- Aizikovich, S.; Vasil’Ev, A.; Volkov, S. The axisymmetric contact problem of the indentation of a conical punch into a half-space with a coating inhomogeneous in depth. J. Appl. Math. Mech. 2015, 79, 500–505. [Google Scholar] [CrossRef]

- Vasiliev, A.S.; Volkov, S.; Belov, A.; Litvinchuk, S.; Aizikovich, S. Indentation of a hard transversely isotropic functionally graded coating by a conical indenter. Int. J. Eng. Sci. 2017, 112, 63–75. [Google Scholar] [CrossRef]

- Beskopylny, A.; Veremeenko, A.; Kadomtseva, E.; Beskopylnaia, N. Non-destructive test of steel structures by conical indentation. MATEC Web Conf. 2017, 129, 2046. [Google Scholar] [CrossRef] [Green Version]

- Beskopylny, A.; Onishkov, N.; Korotkin, V.I. Assessment of the Fatigue Durability of the Rolling Contact. In Advances in Intelligent Systems and Computing; Springer Science and Business Media LLC: Cham, Swiezerland, 2017; Volume 692, pp. 184–191. [Google Scholar] [CrossRef]

- Beskopylny, A.; Veremeenko, A.; Kadomtseva, E.; Anysz, H. Monitoring of metal structures with the dynamic methods. In Proceedings of the XV International Scientific-Technical Conference “Dynamic of Technical Systems” (DTS-2019) AIP Conf. Proc., Rostov-on-Don, Russia, 11–13 September 2019; Volume 2188, p. 060011. [Google Scholar] [CrossRef]

- Beskopylny, A.; Veremeenko, A.; Kadomtseva, E.; Shilov, A. Dynamic response of a plate laying on elastic base during the impact of a conical indenter. MATEC Web Conf. 2018, 196, 01001. [Google Scholar] [CrossRef]

- Wang, M.; Wu, J.; Wu, H.; Zhang, Z.; Fan, H. A Novel Approach to Estimate the Plastic Anisotropy of Metallic Materials Using Cross-Sectional Indentation Applied to Extruded Magnesium Alloy AZ31B. Materials 2017, 10, 1065. [Google Scholar] [CrossRef] [Green Version]

- Trzepieciński, T.; Lemu, H.G. A Three-Dimensional Elastic-Plastic Contact Analysis of Vickers Indenter on a Deep Drawing Quality Steel Sheet. Materials 2019, 12, 2153. [Google Scholar] [CrossRef] [Green Version]

- Felipe-Sesé, L.; López-Alba, E.; Hannemann, B.; Schmeer, S.; Díaz, F. A Validation Approach for Quasistatic Numerical/Experimental Indentation Analysis in Soft Materials Using 3D Digital Image Correlation. Materials 2017, 10, 722. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Komvopoulos, K. Dynamic Indentation of an Elastic-Plastic Multi-Layered Medium by a Rigid Cylinder. J. Tribol. 2004, 126, 18–27. [Google Scholar] [CrossRef]

- Li, Q.; Pohrt, R.; Lyashenko, I.A.; Popov, V.L. Boundary element method for nonadhesive and adhesive contacts of a coated elastic half-space. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 234, 73–83. [Google Scholar] [CrossRef] [Green Version]

- Patel, D.K.; Kalidindi, S.R. Correlation of spherical nanoindentation stress-strain curves to simple compression stress-strain curves for elastic-plastic isotropic materials using finite element models. Acta Mater. 2016, 112, 295–302. [Google Scholar] [CrossRef] [Green Version]