Resistance of External Thermal Insulation Composite Systems with Rendering (ETICS) to Hail

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- thermal insulation made of expanded polystyrene (EPS) with tensile strength perpendicular to the front planes ≥100 kPa, thickness of 50 mm,

- glass fiber mesh with tensile strength, after aging for 28 days in an alkaline environment (in accordance with ETAG 004/2013 [16] point 5.6.7.1.2), ≥20 N/mm, with the maximum reduction of this strength up to 50% in relation to the value before the action of aging factors; mass per unit area- 160 g/m2, mesh sizes: (3.5 × 3.5) mm

- acrylic rendering composed of sand, acrylic binder, silicone resin, mineral fillers, and additives; grain size: 1.5 mm, with bulk density 1.85 g/cm3.

- Set I: cement-based dry mixture mixed with water in the amount of 0.20 l/kg, density 1.40 g/cm3, ca. 98.9–99.9% ash content after roasting the mixture at temperature at 450 °C, dry mixture consumption of 3. 0 kg/m2, thickness (3.0–4.0) mm.

- Set II: polymer dispersion, mineral fillers, organic additives, density 1.70 g/cm3, dry matter content 70.2–85.8%, 69.2–76.4% ash content after roasting the mixture at temperature 450 °C and 64.5–71.3% after roasting the mixture at temperature 900 °C; consumption of 4.5 kg/m2, thickness (3.0–4.0) mm.

- Set III: cement-based dry mixture mixed with water in the amount of 0.30 l/kg, density 1.25 g/cm3, ca. 98.5–99.5% ash content after roasting the mixture at temperature at 450 °C, dry mixture consumption of 3.5 kg/m2, thickness (3.0–4.0) mm.

- Set IV: cement-based dry mixture mixed with water in the amount of 0.27 l/kg, density 1.40 g/cm3, 97.5–99.5% ash content after roasting the mixture at temperature at 450 °C; dry mixture consumption of ca. 4.0 kg/m2, thickness (3.0–4.0) mm.

2.2. Sample Preparation

2.3. Methods of Tests

2.3.1. Resistance to Hail

- the test samples represented the actual arrangement of the render coating,

- the test was carried out at (23 ± 2) °C, i.e., with no additional cooling of the sample surface,

- hail impact was simulated with a polyamide ball with a (40 ± 0.5) mm diameter and (38.5 ± 0.5) g weight, with a smooth surface, by hitting the sample surface on the plaster side at a 90° angle against the evaluated set plane, at a variable velocity. The speed causing damage to the sample was determined by the method of successive approximations, changing the speed of the ball every 1 m/s, starting from 5 m/s,

- the maximum velocity at which no damage/puncture of the render coating occurred was the test result, as the mean values obtained for 10 tested samples.

2.3.2. Resistance to Hard Body Impact

3. Results

4. Discussion

5. Conclusions

- ➢

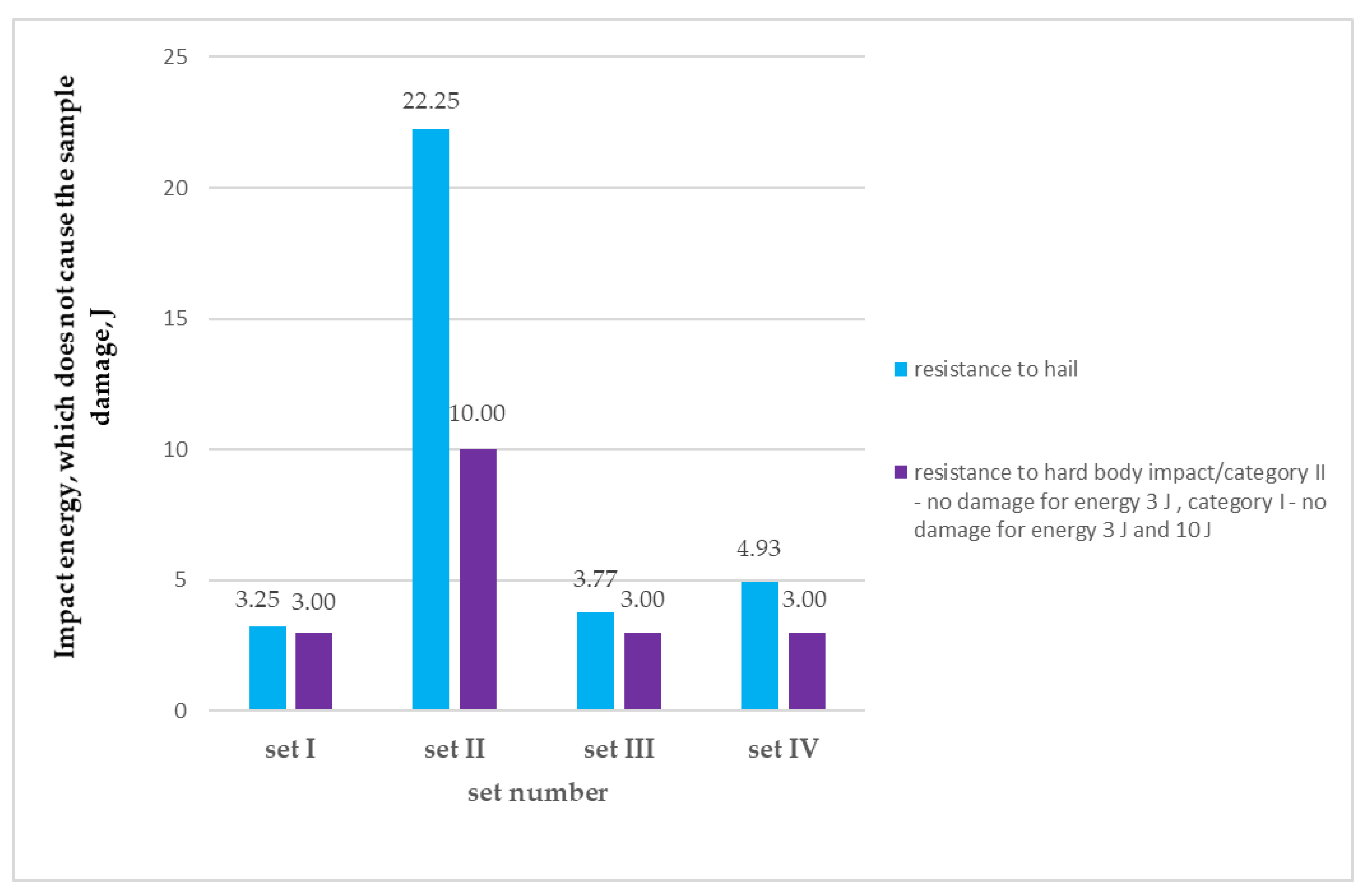

- There is a relationship between the results of puncture resistance tests obtained according to the hail puncture resistance test method presented in this manuscript and hard body impact test according to the method described in ETAG 004 [16].

- ➢

- Hail puncture resistance tests help to evaluate precisely the resistance of thermal insulation sets for damage as a result of a hit of heavy objects of permanent (non-deformable) shape, or sharp edges, with greater accuracy than the hard body impact test.

- ➢

- Thermal insulation system sets with dispersion adhesive in the reinforcement demonstrate greater resistance to damage as a result of hail hit than the sets with cement-based adhesives.

- ➢

- Mass per unit area of the reinforcing mesh used in the system is not significant to affect to hail resistance of the system.

Author Contributions

Funding

Conflicts of Interest

References

- Paterson, D.A.; Sankaran, R. Hail impact on building envelopes. J. Wind Eng. Ind. Aerodyn. 1994, 53, 229–246. [Google Scholar] [CrossRef]

- Kunz, M.; Sander, J.; Kottmeier, C. Recent trends of thunderstorm and hailstorm frequency and their relations to atmospheric characteristics in southwest Germany. Int. J. Climatol. 2009, 29, 2283–2297. [Google Scholar] [CrossRef] [Green Version]

- Flueler, P.; Stucki, M.; Guastala, F.; Egli, T. Hail impact resistant building materials, testing, evaluation and classification. In Proceedings of the 11th DBMC Durability of Building Materials, Istanbul, Turkey, 11–14 May 2008; pp. 249–265. [Google Scholar]

- Berthet, C.; Dessens, J.; Sanchez, J.L. Regional and yearly variations of hail frequency and intensity in France. Atmos. Res. 2011, 100, 391–400. [Google Scholar] [CrossRef]

- Eccel, E.; Cau, P.; Riemann-Campe, K.; Biasioli, F. Quantitative hail monitoring in an alpine area: 35-year climatology and links with atmospheric variables. Int. J. Climatol. 2011, 32, 503–517. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. External Thermal Insulation Composite Systems (ETICS). In An Evaluation of Hygrothermal Behaviour, 1st ed.; Springer International Publishing: New York, NY, USA, 2016. [Google Scholar]

- Kuenzel, H.; Kuenzel, H.M.; Sedlbauer, K. Long-term performance of external thermal insulation systems (etics). Acta Archit. 2006, 5, 11–24. [Google Scholar]

- VKF. Prufbestimmung Nr.08:Putz auf Aussendammung. Vereiningung Kantonaler Feuerversicherungen; Scweeizerisches Hagelschutzeregister HSR: Bern, Switzerland, 2011. [Google Scholar]

- Zirkelbach, D.; Kuenzel, H.M.; Slanina, P. Einfluss von undichtheiten bei der Sanierung von Plattenbauten mit Waurmedaumm-Verbundsystemen. (Effects of rain water leakage on concrete sandwich panels retrofitted with exterior insulation systems). Wta-Alm. 2008, S, 285–297. [Google Scholar]

- Stazi, F.; Di Perna, C.; Munafò, P. Durability of 20-year-old external insulation and assessment of various types of retrofitting to meet new energy regulations. Energy Build. 2009, 41, 721–731. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. Experimental study of the hygrothermal behaviour of External Thermal Insulation Composite Systems (ETICS). Build. Environ. 2013, 63, 31–39. [Google Scholar] [CrossRef]

- Amaro, B.; Saraiva, D.; de Brito, J.; Flores-Colen, I. Inspection and diagnosis system of ETICS on walls. Constr. Build. Mater. 2013, 47, 1257–1267. [Google Scholar] [CrossRef]

- De Freitas, S.S.; de Freitas, V.P. Cracks on ETICS along thermal insulation joints: Case study and a pathology catalogue. Struct. Surv. 2016, 34, 57–72. [Google Scholar] [CrossRef]

- Samuelson, I.; Jansson, A. Putsade Regelväggar [ETICS on Framework Walls]; SP Rapport 2009:16; SP Technical Research Institute of Sweden: Borås, Sweden, 2009. [Google Scholar]

- Duarte, C. A Europa das argamassas e dos ETICS. Tendências, perspectivas e oportunidades. [The Europe of mortars and ETICS. Trends, perspectives and opportunities]. In Proceedings of the IX SBTA—Brazilian Symposium on Mortars Technology, Belo Horizonte, Brazil, 18 May 2011; pp. 7–16. [Google Scholar]

- ETAG 004. Guideline for European Technical Approval of External Thermal Insulation Composite Systems with Rendering; European Organisation for Technical Approvals (EOTA): Brussels, Belgium, 2011. [Google Scholar]

- Conditions for a Building Product Performance Evaluation WO-KOT/04/01, ed. 1—ETICS with Mineral Wool Products (In Polish: Warunki Oceny Właściwości Użytkowych Wyrobu Budowlanego WO-KOT/04/01, część 1, Złożone Zestawy Izolacji Cieplnej z Wyprawami Tynkarskimi (ETICS) z Zastosowaniem Wyrobów z Wełny Mineralnej (MW)); Building Research Institute: Warsaw, Poland, 2018.

- Conditions for a Building Product Performance Evaluation WO-KOT/04/02, ed. 1—ETICS with EPS Products (in Polish: Warunki Oceny Właściwości Użytkowych Wyrobu Budowlanego WO-KOT/04/02, Złożone Zestawy Izolacji Cieplnej z Wyprawami Tynkarskimi (ETICS) z Zastosowaniem Wyrobów ze Styropianu EPS); Building Research Institute: Warsaw, Poland, 2018.

- Virgo Sulakatko, V.; Vogdt, F.U. Construction Process Technical Impact Factors on Degradation of the External Thermal Insulation Composite System. Sustainability 2018, 10, 3900. [Google Scholar] [CrossRef] [Green Version]

- Kvande, T.; Bakken, N.; Bergheim, E.; Thue, J.V. Durability of ETICS with Rendering in Norway—Experimental and Field Investigations. Buildings 2018, 8, 93. [Google Scholar] [CrossRef] [Green Version]

- Nilica, R.; Harmuth, H. Mechanical and fracture mechanical characterization of building materials used for external thermal insulation composite systems. Cem. Concr. Res. 2005, 35, 1641–1645. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, J.; Lam, N.; Zhang, L.; Gad, E. An innovative procedure for estimating contact force during impact. Int. J. Appl. Mech. 2014, 6, 31. [Google Scholar] [CrossRef]

- Perera, S. Modelling Impact Actions of Flying and Falling Objects. Ph.D. Thesis, University of Melbourne, Melbourne, Australia, 2017. [Google Scholar]

- Heymsfield, A.J.; Giammanco, I.M.; Wright, R. Terminal velocities and kinetic energies of natural hailstones. Geophys. Res. Lett. 2014, 41, 8666–8672. [Google Scholar] [CrossRef]

- Dozek, N.; Groenemeijer, P.; Feurstein, B.; Holzer, A.M. Overview of ESSL’s severe convective storms research using the European Severe Weather Database ESWD. Atmos. Res. 2009, 93, 575–586. [Google Scholar] [CrossRef] [Green Version]

- Steinbauer, V.; Kaufmann, J.; Zurbriggen, R.; Buhler, T.; Herwegh, M. Tracing hail stone impact on external thermal insulation composite systems(ETICS)—An evaluation of standard admission impact tests by means of hight—Speed-camera recordings. Int. J. Impact Eng. 2017, 109, 354–356. [Google Scholar] [CrossRef] [Green Version]

- Sudoł, E.; Dębski, D.; Zamorowska, R.; Francke, B. Impact resistance of external thermal insulation systems. In Proceedings of the “Matbud”—8th Scientific-Technical Conference on Material Problems in Civil Engineering, Kraków, Poland, 25–27 June 2018; pp. 1–8. [Google Scholar]

- EN 13163 Thermal Insulation Products for Buildings—Factory Made Expanded Polystyrene (EPS) Products—Specification; European Committee for Standardization (CEN): Belgium, Brussels, 2016.

- Zamorowska, R.; Francke, B. The Impact of Material Solutions on the Functional Properties of Thermal Insulation sysTems (in Polish: Wpływ Rozwiązań Materiałowych na Kształtowanie Właściwości Użytkowych Złożonych Systemów Ociepleń); Science and Research Paper No. NZM 052; Building Research Institute: Warsaw, Poland, 2017. [Google Scholar]

- EN 13583 Flexible Sheets for Waterproofing. Bitumen, Plastic and Rubber Sheets for Roof Waterproofing; Hail Resistance; European Committee for Standardization (CEN): Belgium, Brussels, 2012. [Google Scholar]

| Set no | Insulation Product | Base Coat | Glass Fiber Mesh | Mesh Sizes, mm | Finishing Coat | |

|---|---|---|---|---|---|---|

| Kind of Mesh | Total Mass per Unit Area, g/m2 | |||||

| Set IIa | characterized above as A | polymer dispersion characterized above in set II | With double mash characterized above as B, i.e.,: 2 × B | 320 | First and second layer: 3.5 × 3.5 | characterized above as C |

| Set IIb | with combination of mashes, i.e.,: characterized above as B + D | 490 | First layer: 3.5 × 3.5; Second layer: 6.6 × 8.9 | |||

| Set Number | Tests Results after | |

|---|---|---|

| Impact 3 Joule | Impact 10 Joule | |

| Set I | no deterioration of 5 tested samples |

|

| Set II | no deterioration of 5 tested samples | no deterioration of 5 tested samples |

| Set III | no deterioration of 5 tested samples |

|

| Set IV | no deterioration of 5 tested samples |

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Francke, B.; Zamorowska, R. Resistance of External Thermal Insulation Composite Systems with Rendering (ETICS) to Hail. Materials 2020, 13, 2452. https://doi.org/10.3390/ma13112452

Francke B, Zamorowska R. Resistance of External Thermal Insulation Composite Systems with Rendering (ETICS) to Hail. Materials. 2020; 13(11):2452. https://doi.org/10.3390/ma13112452

Chicago/Turabian StyleFrancke, Barbara, and Renata Zamorowska. 2020. "Resistance of External Thermal Insulation Composite Systems with Rendering (ETICS) to Hail" Materials 13, no. 11: 2452. https://doi.org/10.3390/ma13112452

APA StyleFrancke, B., & Zamorowska, R. (2020). Resistance of External Thermal Insulation Composite Systems with Rendering (ETICS) to Hail. Materials, 13(11), 2452. https://doi.org/10.3390/ma13112452