Thermocapillary Marangoni Flows in Azopolymers

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

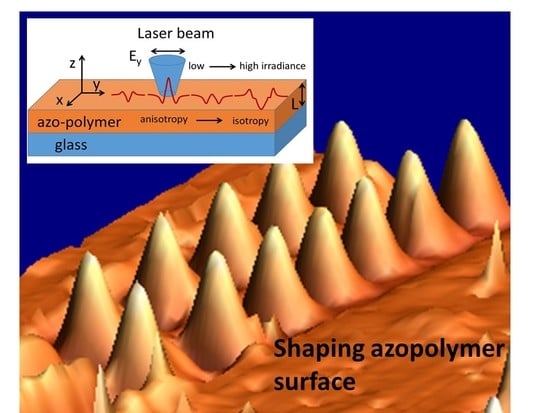

3.1. Analysis of Direct Laser Inscriptions in an Azopolymer

3.2. Simulation of Reliefs within an Optofluidization Model

3.3. Thermocapillary Marangoni Flows

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Nikolova, L.; Todorov, T.; Ivanov, M.; Andruzzi, F.; Hvilsted, S.; Ramanujam, P.S. Polarization holographic gratings in side-chain azobenzene polyesters with linear and circular photoanisotropy. Appl. Opt. 1996, 35, 3835–3840. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Natansohn, A.; Rochon, P. Photoinduced Motions in Azo-Containing Polymers. Chem. Rev. 2002, 102, 4139–4176. [Google Scholar] [CrossRef] [PubMed]

- Mahimwalla, Z.; Yager, K.G.; Mamiya, J.; Shihido, A.; Priimagi, A.; Barret, C.J. Azobenzenes photomechanics: Prospects and potential applications. Polym. Bull. 2012, 69, 967–1006. [Google Scholar] [CrossRef]

- Lee, S.; Kang, H.S.; Park, J.-K. Directional photofluidization lithography: Macro/nanostructural evolution by photofluidic motions of azobenzene materials. Adv. Mater. 2012, 24, 2069–2103. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Ikeda, T. Photocontrollable Liquid-Crystalline Actuators. Adv. Mat. 2011, 23, 2149–2180. [Google Scholar] [CrossRef] [PubMed]

- Sobolewska, A.; Miniewicz, A. Ananlysis of the kinetics of diffraction efficiency during the holographic grating recording in azobenzene functionalized polymers. J. Phys. Chem. B 2007, 111, 1536–1544. [Google Scholar] [CrossRef]

- Yadavalli, N.S.; Santer, S. In-situ atomic force microscopy study of the mechanism of surface relief grating formation in photosensitive polymer films. J. Appl. Phys. 2013, 113, 224304–224312. [Google Scholar] [CrossRef]

- Sobolewska, A.; Bartkiewicz, S.; Miniewicz, A.; Schab-Balcerzak, E. Polarization dependence of holographic grating recording in azobenzene-functionalized polymers monitored by visible and infrared light. J. Phys. Chem. B 2010, 114, 9751–9760. [Google Scholar] [CrossRef]

- Barrett, C.J.; Mamiya, J.; Yager, K.G.; Ikeda, T. Photo-mechanical effects in azobenzene-containing soft materials. Soft Matter 2007, 3, 1249–1261. [Google Scholar] [CrossRef]

- Saphiannikova, M.; Neher, D. Thermodynamic Theory of Light-Induced Material Transport in Amorphous Azobenzene Polymer Films. J. Phys. Chem. B 2005, 109, 19428–19436. [Google Scholar] [CrossRef]

- Ambrosio, A.; Marrucci, L.; Borbone, F.; Roviello, A.; Maddalena, P. Light-induced spiral mass transport in azo-polymer films under vortex-beam illumination. Nat. Commun. 2012, 3, 989. [Google Scholar] [CrossRef] [PubMed]

- Plain, J.; Wiederrecht, G.P.; Gray, S.K.; Royer, P.; Bachelot, R. Multiscale optical imaging of complex fields based on the use of azobenzene nanomotors. J. Phys. Chem. Lett. 2013, 4, 2124–2132. [Google Scholar] [CrossRef]

- Audorff, H.; Kreger, K.; Walker, R.; Haarer, D.; Kador, L.; Schmidt, H.-W. Holographic Gratings and data storage in azobenzene-containing block copolymers and molecular glasses. Adv. Polym. Sci. 2010, 228, 59–121. [Google Scholar]

- Hvilsted, S.; Andruzzi, F.; Kulinna, C.; Siesler, H.W.; Ramanujam, P.S. Novel Side-Chain Liquid Crystalline Polyester Architecture for Reversible Optical Storage. Macromolecules 1995, 28, 2172–2183. [Google Scholar] [CrossRef]

- Wang, C.; Fei, H.; Yang, Y.; Wei, Z.; Qiu, Y.; Chen, Y. Photoinduced anisotropy and polarization holography in azobenzene side-chain polymer. Opt. Commun. 1999, 159, 58–62. [Google Scholar] [CrossRef]

- Miniewicz, A.; Kochalska, A.; Mysliwiec, J.; Samoc, A.; Samoc, M.; Grote, J. Deoxyribonucleic acid-based photochromic material for fast dynamic holography. Appl. Phys. Lett. 2007, 91, 041118. [Google Scholar] [CrossRef] [Green Version]

- Mysliwiec, J.; Kochalska, A.; Miniewicz, A. Biopolymer-based material used in optical image correlation. Appl. Opt. 2008, 47, 1902–1906. [Google Scholar] [CrossRef]

- Tane, A.; Kajzar, F.; Zgarian, R.; Rau, I.; Grabarek, D.; Karpinski, P.; Miniewicz, A. Refractive index and surface relief grating formation in DNA based dye-doped films. Macromol. Res. 2013, 21, 331–337. [Google Scholar] [CrossRef]

- Pawlik, G.; Mitus, A.C.; Mysliwiec, J.; Miniewicz, A.; Grote, J.G. Photochromic dye semi-intercalation into DNA-based polymeric matrix: Computer modeling and experiment. Chem. Phys. Lett. 2010, 484, 321–323. [Google Scholar] [CrossRef]

- Karpinski, P.; Miniewicz, A. Optical phase conjugation in azo-dye doped chiral liquid crystal. Appl. Phys. Lett. 2012, 101, 161108. [Google Scholar] [CrossRef]

- Saint-Jalm, S.; Miniewicz, A.; Karpinski, P.; Jarek-Mikulska, U.; Galewski, Z. Photo-induced birefringence in a nematic liquid crystal mixture doped with light-switchable mesogenic azobenzene derivatives. J. Mol. Liq. 2012, 168, 21–27. [Google Scholar] [CrossRef]

- Miniewicz, A.; Orlikowska, H.; Sobolewska, A.; Bartkiewicz, S. Kinetics of thermal cis-trans isomerization in a phototropic azobenzene-based single-component liquid crystal in its nematic and isotropic phases. Phys. Chem. Chem. Phys. 2018, 4, 2904–2913. [Google Scholar] [CrossRef] [PubMed]

- Kunitake, T. Aqueous bilayer dispersions, cast multilayer films, and Langmuir-Blodgett films of azobenzene-containing amphiphiles. Coll. Surf. 1986, 19, 225–236. [Google Scholar] [CrossRef]

- Han, J.; Yan, D.; Shi, W.; Ma, J.; Yan, H.; Wei, M.; Evans, D.G.; Duanan, X. Layer-by-Layer Ultrathin Films of Azobenzene-Containing Polymer/Layered Double Hydroxides with Reversible Photoresponsive Behavior. J. Phys. Chem. B 2010, 114, 5678–5685. [Google Scholar] [CrossRef]

- Laschewsky, A.; Wischerhoff, E.; Kauranen, M.; Persoons, A. Polyelectrolyte multilayer assemblies containing nonlinear optical dyes. Macromolecules 2010, 30, 8304–8309. [Google Scholar] [CrossRef]

- Ichimura, K.; Oh, S.-K.; Nakagawa, M. Light-Driven Motion of Liquids on a Photoresponsive Surface. Science 2000, 288, 1624–1626. [Google Scholar] [CrossRef] [Green Version]

- Taunaumang, H.; Solyga, M.; Tija, M.O.; Miniewicz, A. On the efficient mixed amplitude and phase grating recording in vacuum deposited Disperse Red 1. Thin Solid Films 2004, 461/2, 316–324. [Google Scholar] [CrossRef]

- Barille, R.; Tajalli, P.; Zielinska, S.; Ortyl, E.; Kucharski, S.; Nunzi, J.M. Surface relief grating formation on nano-objects. Appl. Phys. Lett. 2009, 95, 053102. [Google Scholar] [CrossRef] [Green Version]

- Miniewicz, A.; Girones, J.; Karpinski, P.; Mossety-Leszczak, B.; Galina, H.; Dutkiewicz, M. Photochromic and nonlinear optical properties of azo-functionalized POSS nanoparticles dispersed in nematic liquic crystals. J. Mat. Chem. C 2014, 2, 432–440. [Google Scholar] [CrossRef]

- Rochon, P.; Batalla, E.; Natansohn, A. Optically induced surface gratings on azoaromatic polymer films. Appl. Phys. Lett. 1995, 66, 136–138. [Google Scholar] [CrossRef]

- Kim, D.Y.; Tripathy, S.K.; Li, L.; Kumar, J. Laser-induced holographic surface relief gratings on nonlinear optical polymer films. Appl. Phys. Lett. 1995, 66, 1166–1168. [Google Scholar] [CrossRef] [Green Version]

- Bian, S.; Liu, W.; Williams, J.; Samuelson, L.; Kumar, J.; Tripathy, S. Photoinduced surface relief grating on amorphous poly(4-phenylazophenol) films. Chem. Mater. 2000, 12, 1585–1590. [Google Scholar] [CrossRef]

- Fiorini, C.; Prudhomme, N.; de Veyrac, G.; Maurin, I.; Raimond, P.; Nunzi, J.-M. Molecular migration mechanism for laser induced surface relief grating formation. Synth. Met. 2000, 115, 121–125. [Google Scholar] [CrossRef]

- Ambrosio, A.; Girardo, S.; Camposeo, A.; Pisignano, D.; Maddalena, P. Controlling spontaneous surface structuring of azobenzene-containing polymers for large-scale nano-lithography of functional substrates. Appl. Phys. Lett. 2013, 102, 093102. [Google Scholar] [CrossRef] [Green Version]

- Barille, R.; Nunzi, J.-M.; Ahmadi-Kandjani, S.; Ortyl, E.; Kucharski, S. Cognitive ability experiment with photosensitive organic molecular thin films. Phys. Rev. Lett. 2006, 97, 048701. [Google Scholar] [CrossRef] [Green Version]

- Bobrovsky, A.; Mochalov, K.; Chistyakov, A.; Oleinikov, V.; Shibaev, V. AFM study of laser-induced crater formation in films of azobenzene-containing photochromic nematic polymer and cholesteric mixture. J. Photochem. Photobiol. 2014, A 275, 30–36. [Google Scholar] [CrossRef]

- Choi, J.; Jo, W.; Lee, S. Flexible and robust superomniphobic surfaces created by localized photofluidization of azopolymer pillars. ACS Nano 2017, 11, 7821–7828. [Google Scholar] [CrossRef]

- Marangoni, C. The principle of the surface viscosity of liquids established by Mr. J. Plateau. Il Nuovo Cimento Series 2 1872, 5/6, 239–273. (In Italian) [Google Scholar] [CrossRef]

- Ambrosio, A.; Maddalena, P.; Marrucci, L. Molecular Model for Light-Driven Spiral Mass Transport in Azopolymer Films. Phys. Rev. Lett. 2013, 110, 146102. [Google Scholar] [CrossRef]

- Sek, D.; Grabiec, E.; Miniewicz, A.; Sobolewska, A. Influence of poly(amide-imide)s structures on holographic grating recording. Proc. SPIE 2005, 5, 5724. [Google Scholar]

- Oscurato, S.L.; Salvatore, M.; Maddalena, P.; Ambrosio, A. From nanoscopic to macroscopic photo-driven motion in azobenzene-containing materials. Nanophotonics 2018, 7, 1387–1422. [Google Scholar] [CrossRef]

- Juan, M.L.; Plain, J.; Bachelot, R.; Royer, P.; Gray, S.K.; Wiederrecht, G.P. Multiscale model for photoinduced molecular motion in azo polymers. ACS Nano 2009, 3, 1573. [Google Scholar] [CrossRef] [PubMed]

- Lefin, P.; Fiorini, C.; Nunzi, J.-M. Anisotropy of the photo-induced translation diffusion of azobenzene dyes in polymer matrices. Pure Appl. Opt. 1998, 7, 71. [Google Scholar] [CrossRef]

- Bellini, B.; Ackermann, J.; Klein, H.; Grave, C.H.; Dumas, P.H.; Safarov, V. Light-induced molecular motion of azobenzene-containing molecules: A random-walk model. J. Phys. Condens. Matter 2006, 18, S1817. [Google Scholar] [CrossRef]

- Juan, M.L.; Plain, J.; Bachelot, R.; Royer, P.; Gray, S.K.; Wiederrecht, G.P. Stochastic model for photoinduced surface relief grating formation through molecular transport in polymer films. Appl. Phys. Lett. 2008, 93, 153304. [Google Scholar] [CrossRef]

- Pawlik, G.; Wysoczanski, T.; Mitus, A.C. Complex Dynamics of Photoinduced Mass Transport and Surface Relief Gratings Formation. Nanomaterials 2019, 9, 352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dradrach, K.; Bartkiewicz, S.; Miniewicz, A. Photonic vortices induced in a single-component phototropic liquid crystal. Phys. Chem. Chem. Phys. 2016, 18, 3832. [Google Scholar] [CrossRef]

- Miniewicz, A.; Quintard, C.; Orlikowska, H.; Bartkiewicz, S. On the origin of the driving force in the Marangoni propelled gas bubble trapping mechanism. Phys. Chem. Chem. Phys. 2017, 19, 18695. [Google Scholar] [CrossRef]

- Miniewicz, A.; Bartkiewicz, S.; Orlikowska, H.; Dradrach, K. Marangoni effect visualized in two dimensions Optical tweezers for gas bubbles. Sci. Rep. 2016, 6, 34787. [Google Scholar] [CrossRef] [Green Version]

- Kim, C.B.; Wistrom, J.C.; Ha, H.; Zhou, S.X.; Katsumata, R.; Jones, A.R.; Janes, D.W.; Miller, K.M.; Ellison, C.J. Marangoni instability driven surface relief grating in an azobenzene-containing polymer film. Macromolecules 2016, 49, 7069–7076. [Google Scholar] [CrossRef]

- Kitamura, I.; Oishi, K.; Hara, M.; Nagano, S.; Seki, T. Photoinitiated Marangoni flow morphing in a liquid crystalline polymer film directed by superinkjet printing patterns. Sci. Rep. 2019, 9, 2556. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elashnikov, R.; Fitl, P.; Svorcik, V.; Lyutakov, O. Patterning of ultrathin polymethylmethacrylate films by in-situ photodirecting of the Marangoni flow. Appl. Surf. Sci. 2017, 394, 562–568. [Google Scholar] [CrossRef]

- Dattler, D.; Fuks, G.; Heiser, J.; Moulin, E.; Perrot, A.; Yao, X.; Giuseppone, N. Design of Collective Motions from Synthetic Molecular Switches, Rotors, and Motors. Chem. Rev. 2020, 120, 310–433. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miniewicz, A.; Bartkiewicz, S.; Karpinski, P. Optical trapping mechanisms based on optothermal Marangoni effect. In Proceedings of the Optical Trapping and Optical Micromanipulation XVI, Proc. SPIE, San Diego, CA, USA, 11–15 August 2019. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miniewicz, A.; Sobolewska, A.; Piotrowski, W.; Karpinski, P.; Bartkiewicz, S.; Schab-Balcerzak, E. Thermocapillary Marangoni Flows in Azopolymers. Materials 2020, 13, 2464. https://doi.org/10.3390/ma13112464

Miniewicz A, Sobolewska A, Piotrowski W, Karpinski P, Bartkiewicz S, Schab-Balcerzak E. Thermocapillary Marangoni Flows in Azopolymers. Materials. 2020; 13(11):2464. https://doi.org/10.3390/ma13112464

Chicago/Turabian StyleMiniewicz, Andrzej, Anna Sobolewska, Wojciech Piotrowski, Pawel Karpinski, Stanislaw Bartkiewicz, and Ewa Schab-Balcerzak. 2020. "Thermocapillary Marangoni Flows in Azopolymers" Materials 13, no. 11: 2464. https://doi.org/10.3390/ma13112464

APA StyleMiniewicz, A., Sobolewska, A., Piotrowski, W., Karpinski, P., Bartkiewicz, S., & Schab-Balcerzak, E. (2020). Thermocapillary Marangoni Flows in Azopolymers. Materials, 13(11), 2464. https://doi.org/10.3390/ma13112464