Study on Low-Velocity Impact Damage and Residual Strength of Reinforced Composite Skin Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

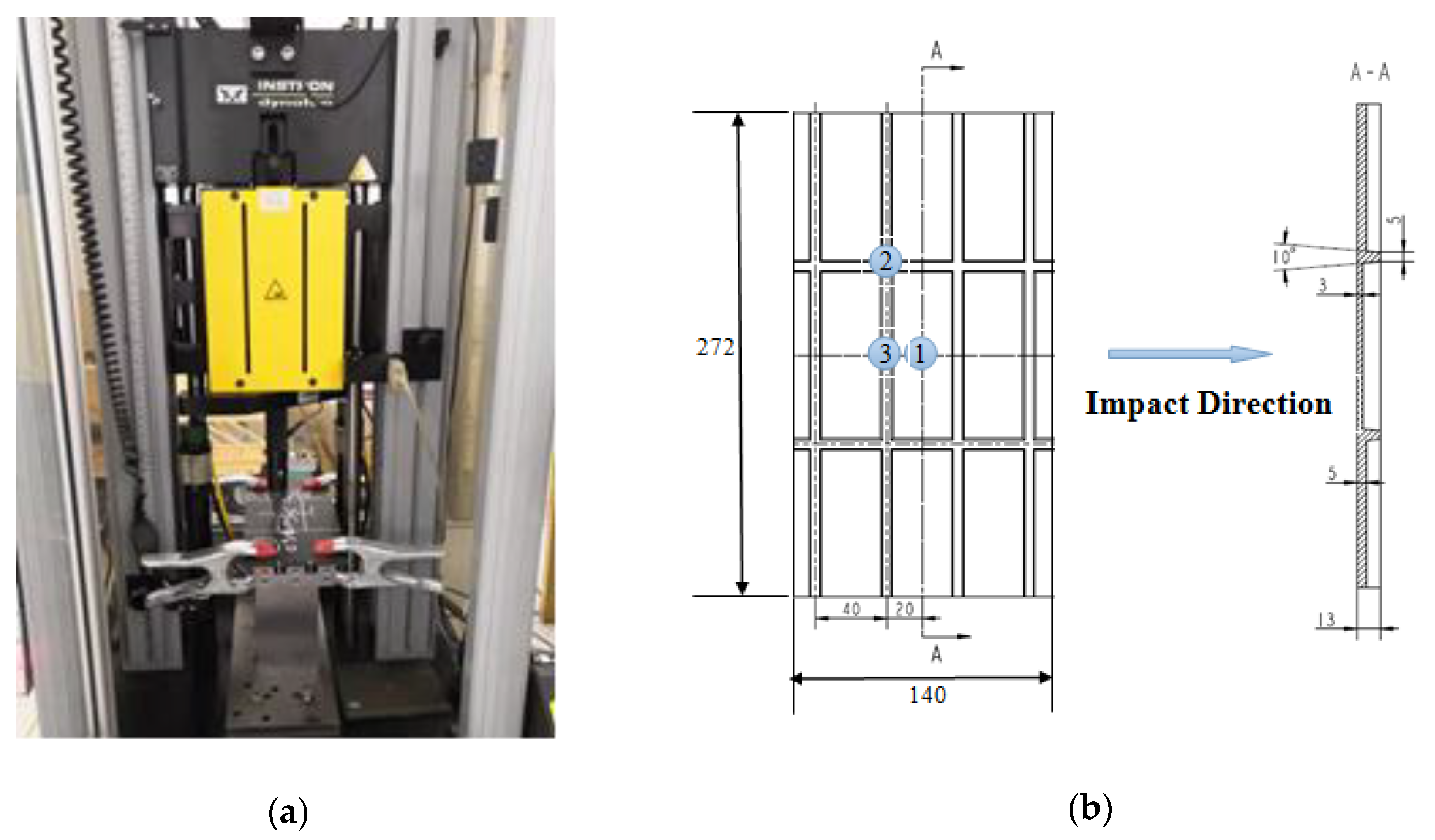

2.2.1. Low-Velocity Impact Test

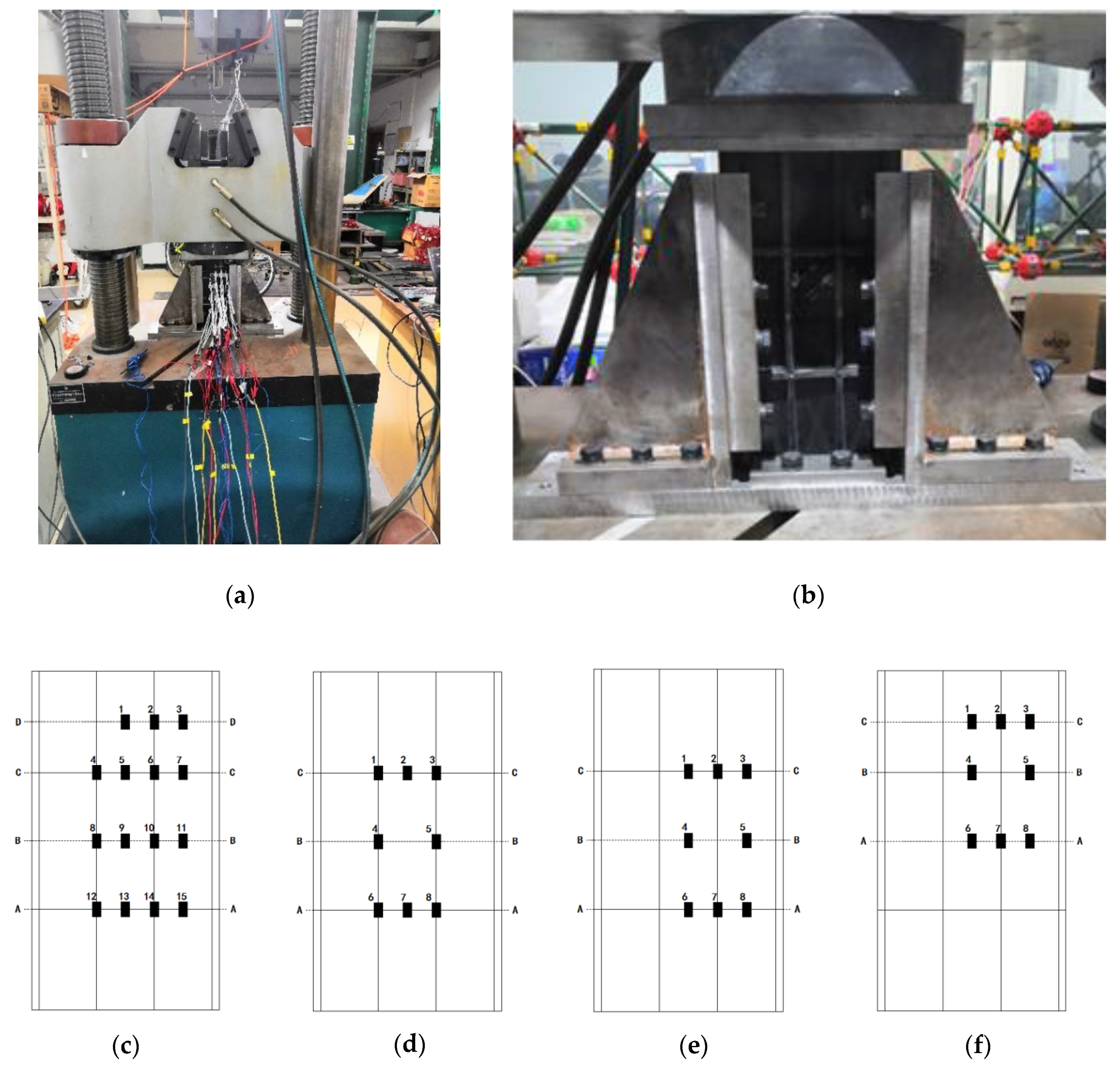

2.2.2. Compression Test after Impact

3. Results

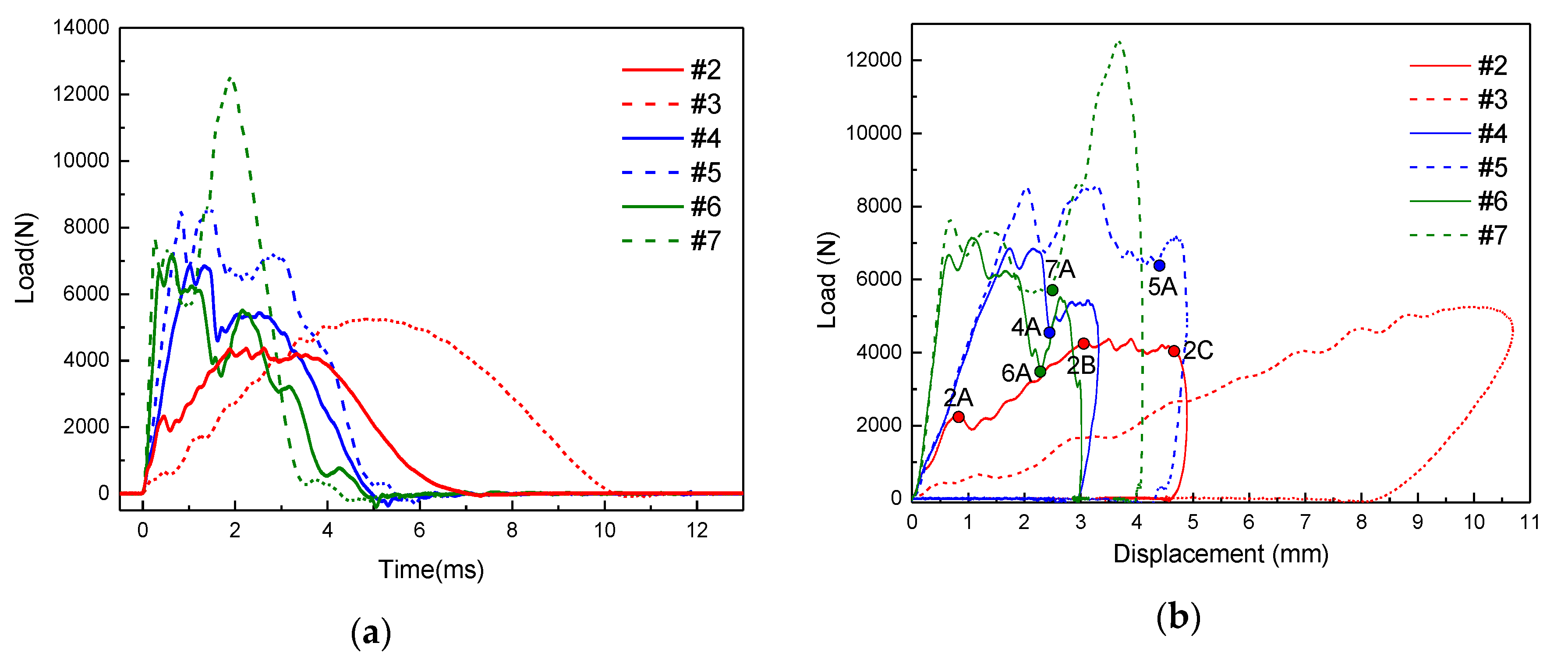

3.1. Impact Response

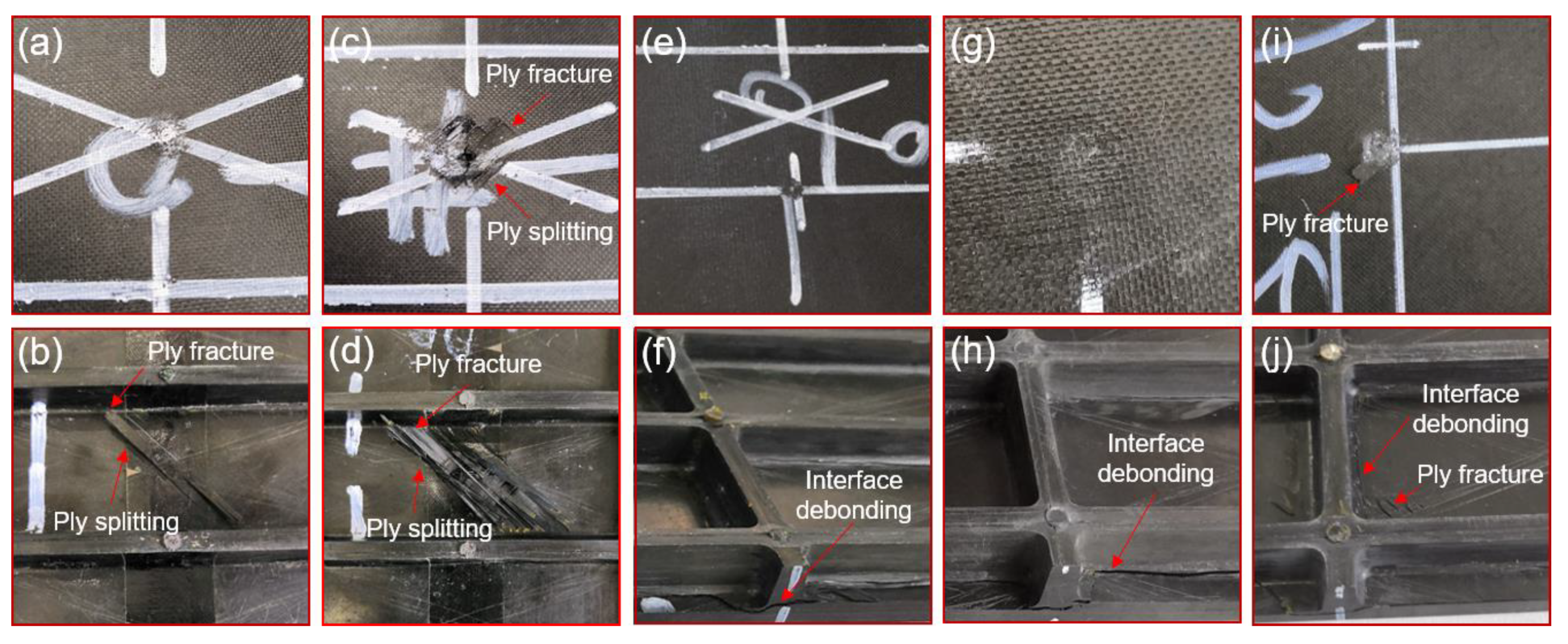

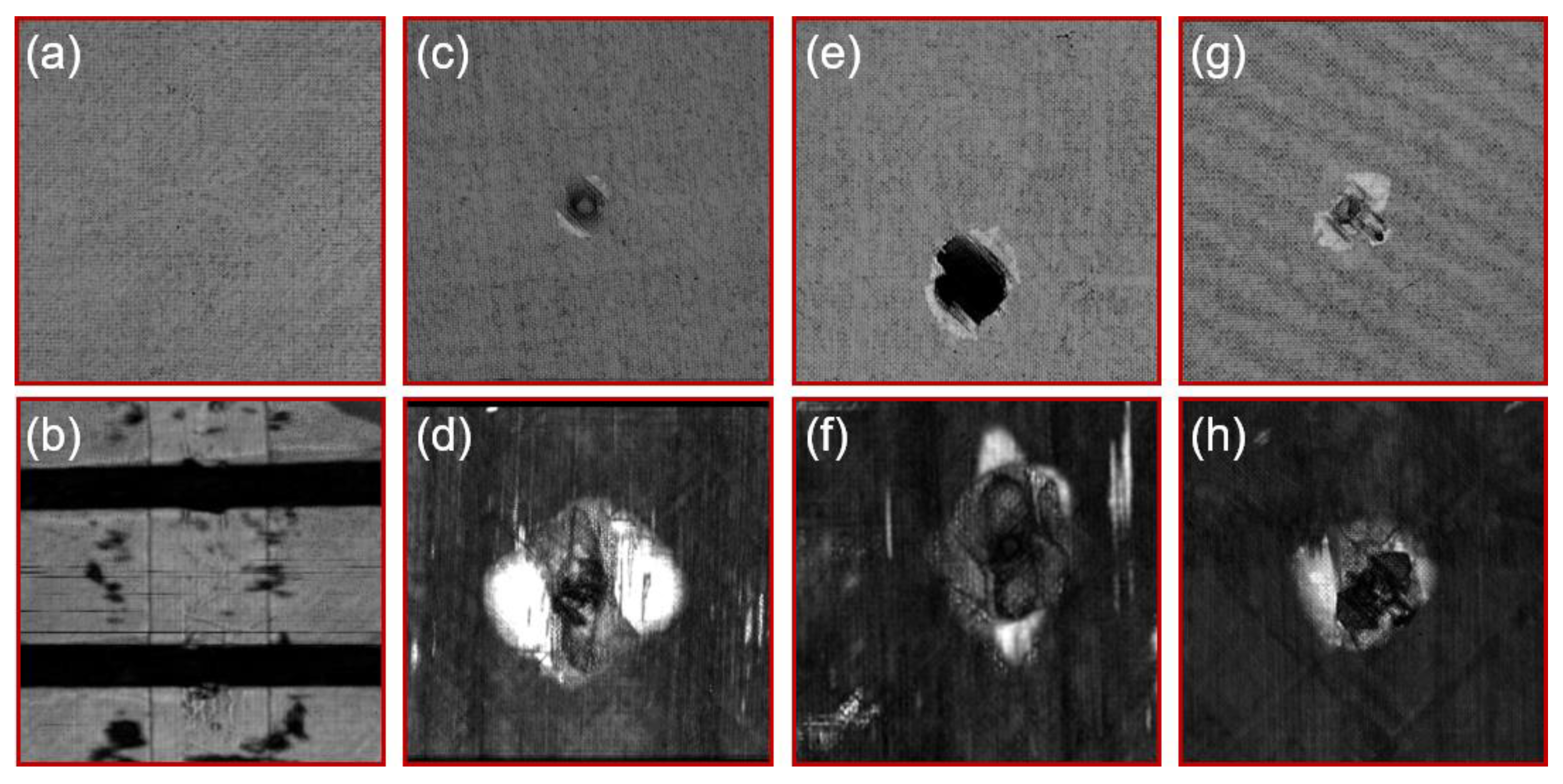

3.2. External Damage

3.3. Internal Damage

4. Discussions

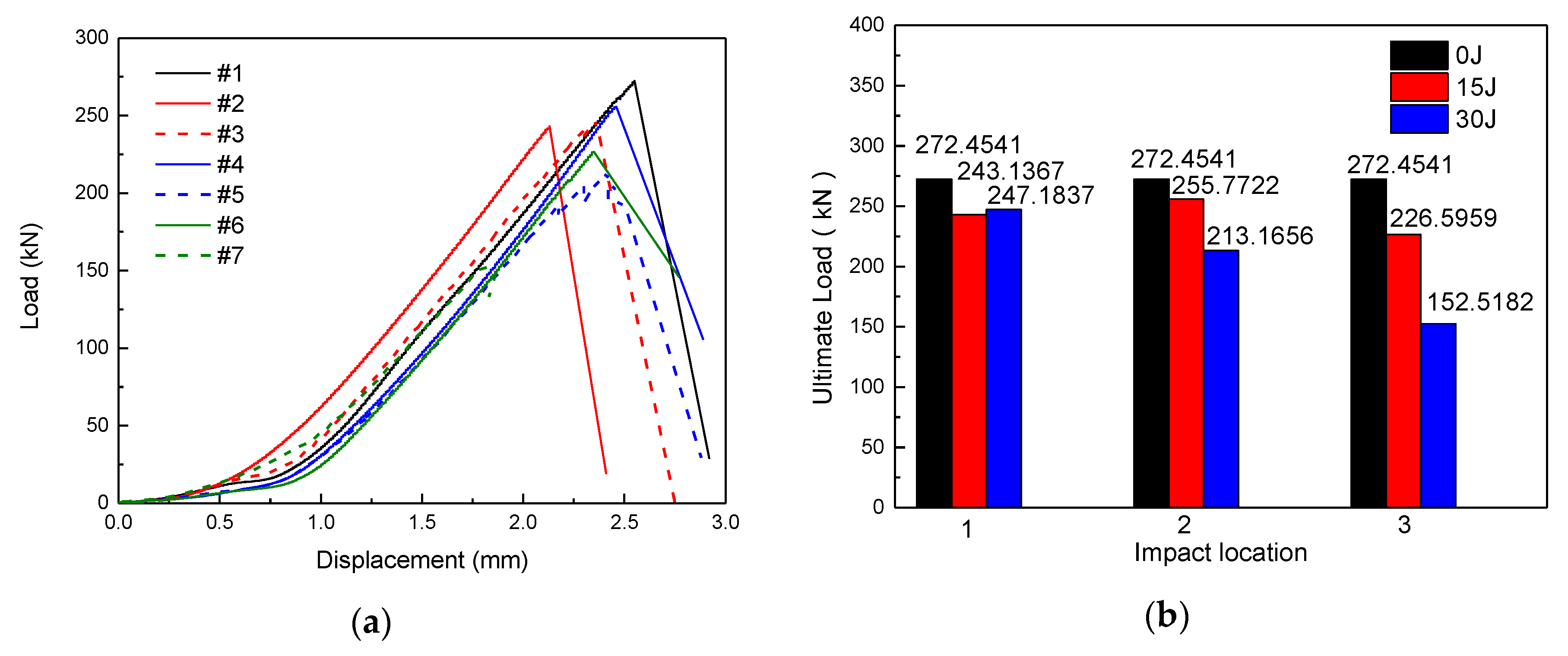

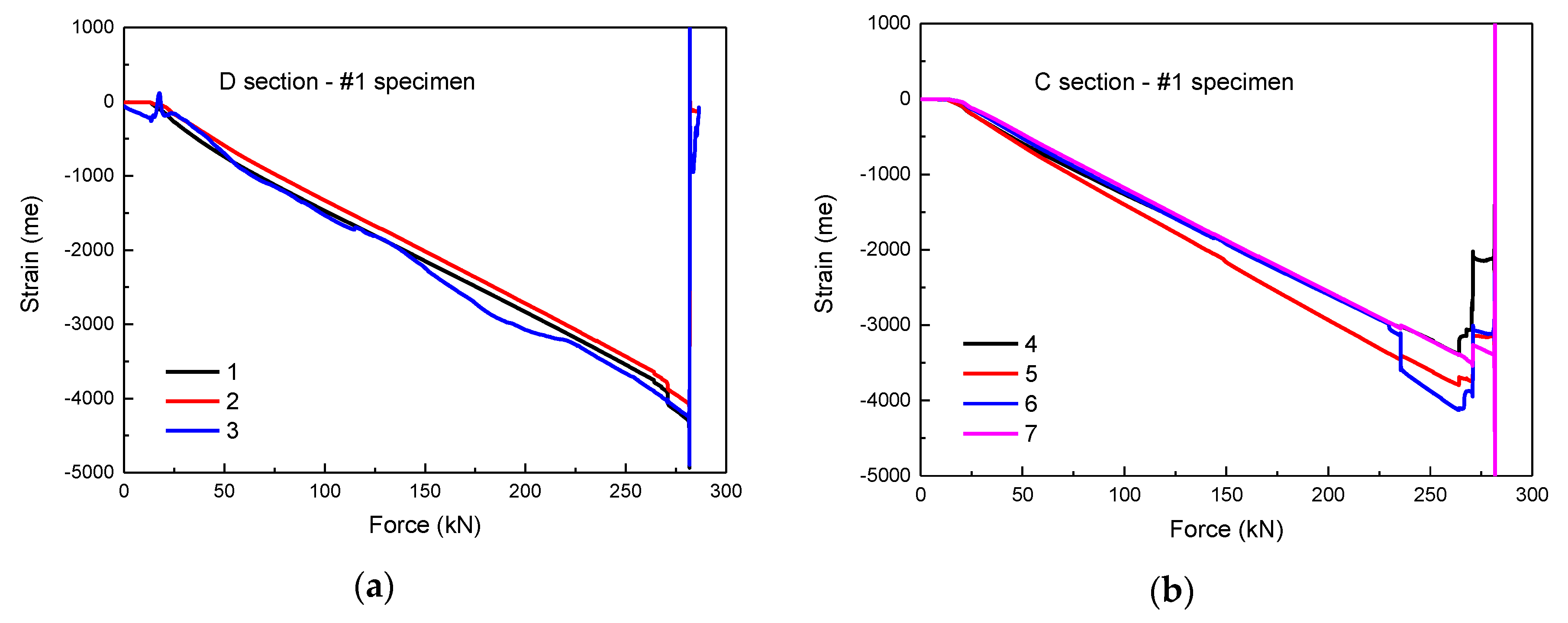

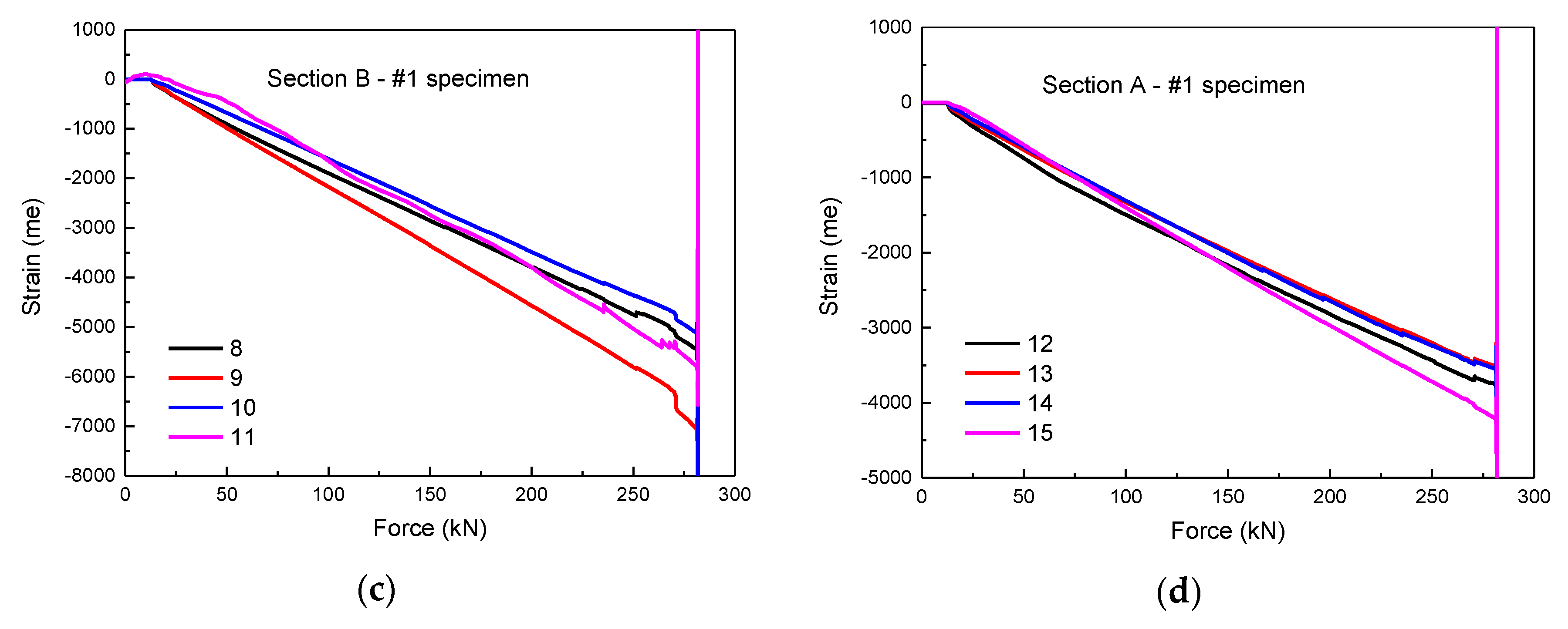

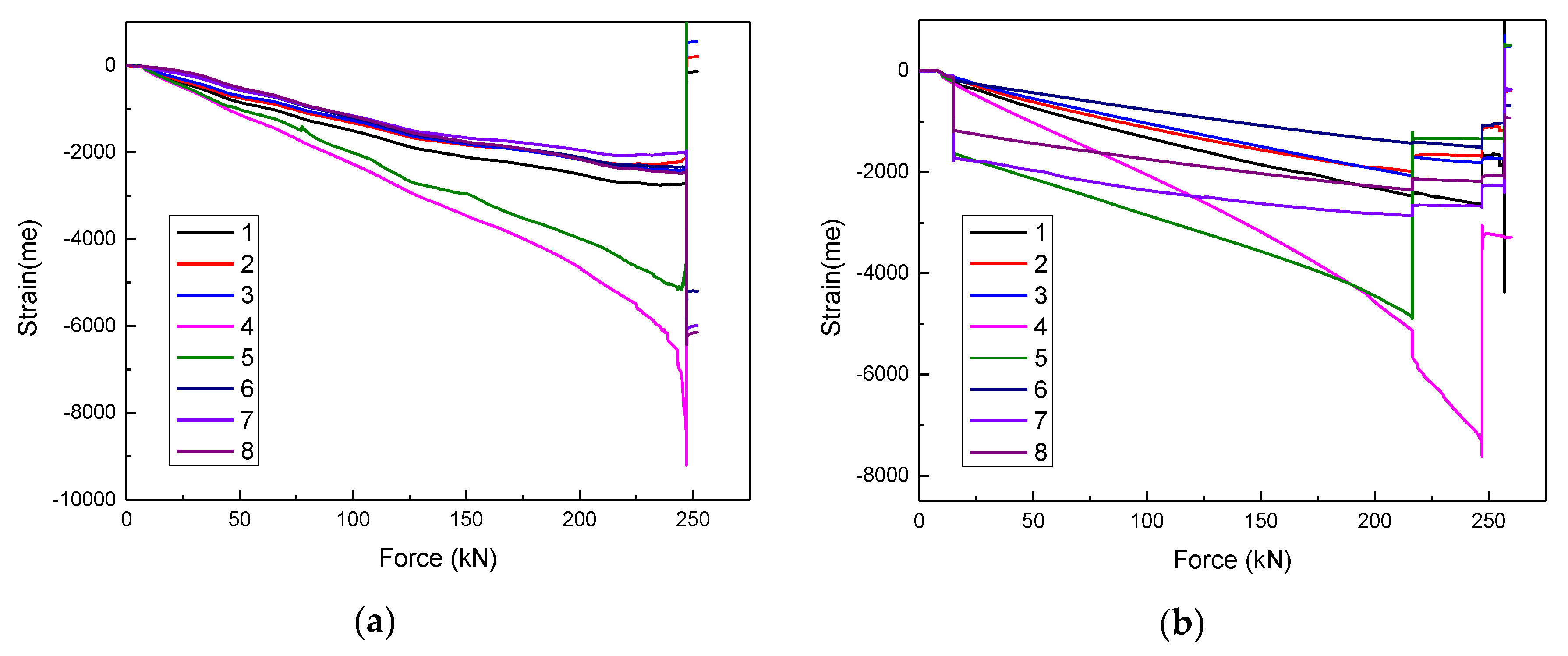

4.1. Analysis of Load–Displacement Curve and Strain

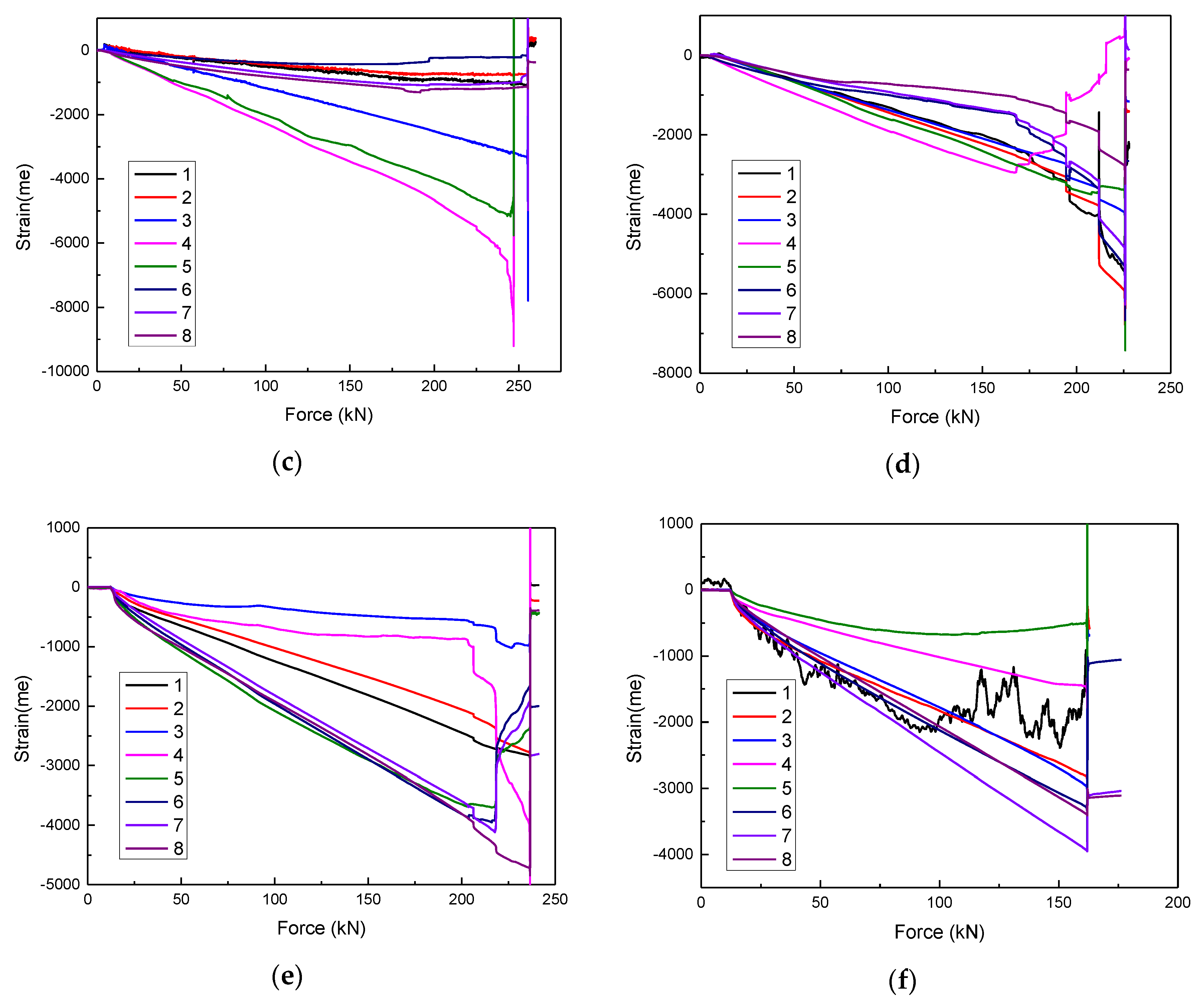

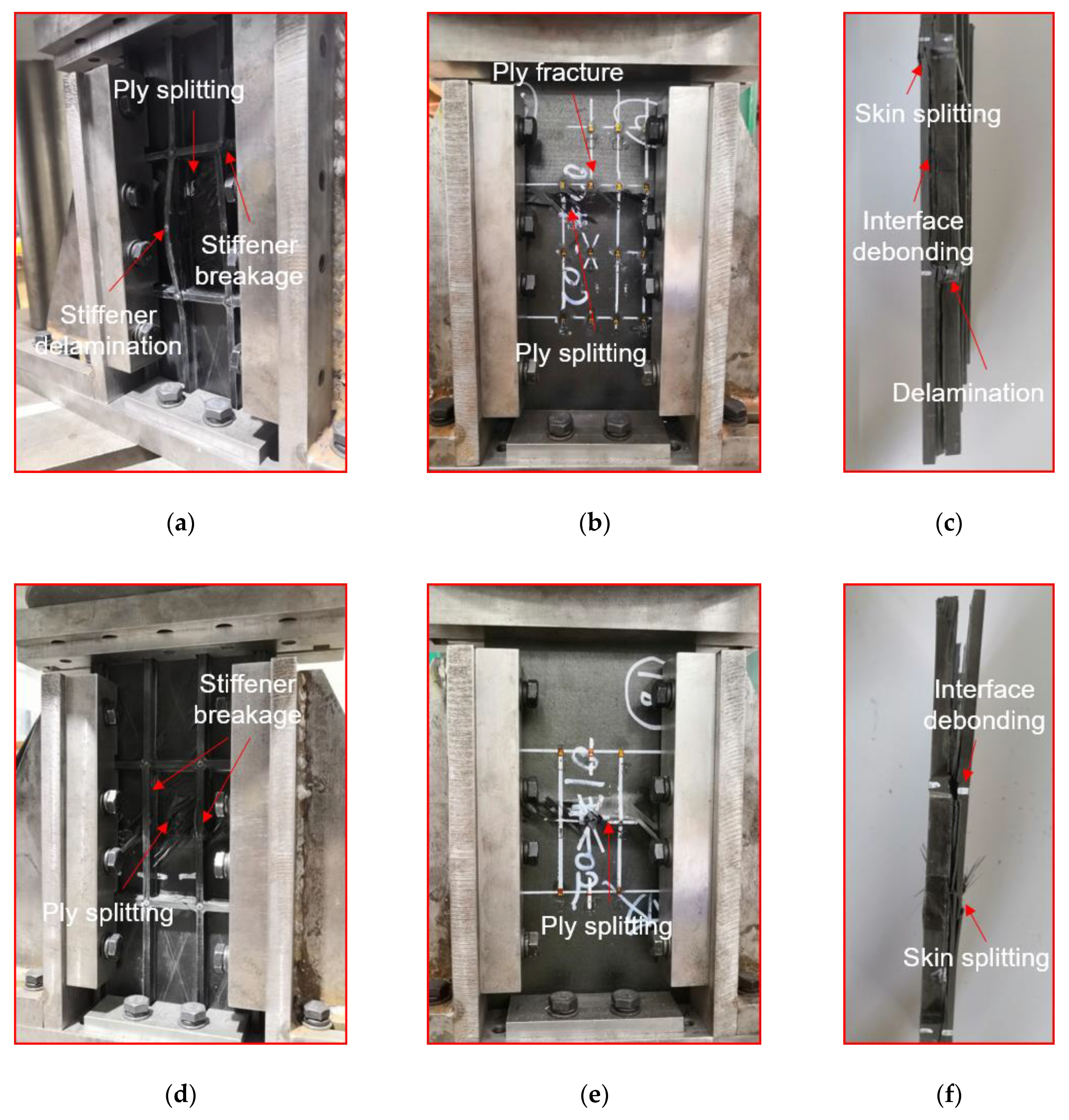

4.2. Compression Failure Mode and Failure Morphology Analysis

5. Conclusions

- While the impact point is at the center of the skin surface, most of the impact energy is absorbed by the skin, the damage of the skin is the most severe, and there is no debonding between the skin and the stiffeners. Moreover, when the impact point is located at the corresponding point of the midpoint of a single stiffener and the corresponding point to the intersection of the two stiffeners, part of the impact energy is absorbed by the stiffeners. The damage area of the skin reduced while there exists the debonding between the skin and the stiffeners. In addition, the damage area formed by the impact in the skin is usually “elliptical”.

- Through the compression test of the reinforced composite skin structure after the impact, it is concluded that the impact has an influence on the bearing capacity and failure modes of the reinforced skin structure. The test results show that the bearing capacity of the specimen decreases after impact in a certain range: the bearing capacity of the specimen is negatively correlated with the impact energy. The impact points at the center of the skin surface and the corresponding point of the midpoint of a single stiffener have little effect on the bearing capacity. However, the bearing capacity of the specimens with the impact point of the corresponding point to the intersection of the two stiffeners has a significant decline.

- Compared with intact specimen, the impact does not change the compression failure mode of the specimens, and all types of specimen failure are caused by the stiffener fracture and the skin delamination.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huybrechts, S.M.; Meink, T.E.; Wegner, P.M.; Ganley, J.M. Manufacturing theory for advanced grid stiffened structures. Compos. Part A Appl. Sci. Manuf. 2002, 33, 155–161. [Google Scholar] [CrossRef]

- Vasiliev, V.; Barynin, V.; Razin, A. Anisogrid composite lattice structures—Development and aerospace applications. Compos. Struct. 2012, 94, 1117–1127. [Google Scholar] [CrossRef]

- Peng, X.; Ye, T.; Li, J.; Wu, H.; Jiang, S.; Chen, G. Multi-scale uncertainty quantification of composite laminated plate considering random and interval variables with data driven PCE method. Mech. Adv. Mater. Struc. 2020, 1–11. [Google Scholar] [CrossRef]

- Ji, C.; Wang, B.; Hu, J.; Zhang, C.; Sun, Y. Effect of different preparation methods on mechanical behaviors of carbon fiber-reinforced PEEK-Titanium hybrid laminates. Polym. Test. 2020, 85, 106462. [Google Scholar] [CrossRef]

- Hu, J.; Li, F.; Wang, B.; Zhang, H.; Ji, C.; Wang, S.; Zhou, Z. A two-step combination strategy for significantly enhancing the interfacial adhesion of CF/PPS composites: The liquid-phase oxidation followed by grafting of silane coupling agent. Compos. Part B Eng. 2020, 191, 107966. [Google Scholar] [CrossRef]

- Peng, X.; Guo, Y.; Qiu, C.; Wu, H.; Li, J.; Chen, G.; Jiang, S.; Liu, Z. Reliability optimization design for composite laminated plate considering multiple types of uncertain parameters. Eng. Optim. 2020, 1–16. [Google Scholar] [CrossRef]

- Wang, H.; Vu-Khanh, T. Fracture Mechanics and Mechanisms of Impact-Induced Delamination in Laminated Composites. J. Compos. Mater. 1995, 29, 156–178. [Google Scholar] [CrossRef]

- Reis, L.; Freitas, M. Damage growth analysis of low velocity impacted composite panels. Compos. Struct. 1997, 38, 509–515. [Google Scholar] [CrossRef]

- Cantwell, W.J.; Morton, J. The impact resistance of composite materials—A review. Composites 1991, 22, 347–362. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, S.; Wang, B.; Liu, A.; Ma, L.; Wu, L.; Zhou, Z. Fabrication and compression properties of continuous carbon fiber reinforced polyether ether ketone thermoplastic composite sandwich structures with lattice cores. J. Sandw. Struct. Mater. 2020. [Google Scholar] [CrossRef]

- Tan, X.; Wang, B.; Zhu, S.; Chen, S.; Yao, K.; Xu, P.; Wu, L.; Sun, Y. Novel multidirectional negative stiffness mechanical metamaterials. Smart Mater. Struct. 2019, 29, 015037. [Google Scholar] [CrossRef]

- Chen, S.; Wang, B.; Zhu, S.; Tan, X.; Hu, J.; Lian, X.; Wang, L.; Wu, L. A novel composite negative stiffness structure for recoverable trapping energy. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105697. [Google Scholar] [CrossRef]

- Tan, D.; Li, L.; Yin, Z.; Li, D.; Zhu, Y.; Zheng, S. Ekman boundary layer mass transfer mechanism of free sink vortex. Int. J. Heat Mass Transf. 2020, 150, 119250. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, S.; Chen, Y.; Chen, J.; Hu, P.; Wu, H.; Zhou, Y. Thickness-twist waves in the nanoplates with flexoelectricity. Mech. Adv. Mater. Struct. 2020, 1–8. [Google Scholar] [CrossRef]

- Yazdani, M.; Rahimi, G. The Effects of Helical Ribs’ Number and Grid Types on the Buckling of Thin-walled GFRP-stiffened Shells under Axial Loading. J. Reinf. Plast. Compos. 2010, 29, 2568–2575. [Google Scholar] [CrossRef]

- Shi, S.; Sun, Z.; Ren, M.; Chen, H.; Hu, X. Buckling resistance of grid-stiffened carbon-fiber thin-shell structures. Compos. Part B Eng. 2013, 45, 888–896. [Google Scholar] [CrossRef]

- Shi, S.; Sun, Z.; Ren, M.; Chen, H.; Hu, X. Buckling response of advanced grid stiffened carbon–fiber composite cylindrical shells with reinforced cutouts. Compos. Part B Eng. 2013, 44, 26–33. [Google Scholar] [CrossRef]

- Liu, D.; Bai, R.; Wang, R.; Lei, Z.; Yan, C. Experimental study on compressive buckling behavior of J-stiffened composite panels. Opt. Lasers Eng. 2019, 120, 31–39. [Google Scholar] [CrossRef]

- Ostré, B.; Bouvet, C.; Lachaud, F.; Minot, C.; Aboissiere, J. Edge impact damage scenario on stiffened composite structure. J. Compos. Mater. 2015, 49, 1599–1612. [Google Scholar] [CrossRef]

- Greenhalgh, E.; Meeks, C.; Clarke, A.; Thatcher, J. The effect of defects on the performance of post-buckled CFRP stringer-stiffened panels. Compos. Part A Appl. Sci. Manuf. 2003, 34, 623–633. [Google Scholar] [CrossRef]

- Greenhalgh, E.; Bishop, S.M.; Bray, D.; Hughes, D.; Lahiff, S.; Millson, B. Characterisation of impact damage in skin-stringer composite structures. Compos. Struct. 1996, 36, 187–207. [Google Scholar] [CrossRef]

- Greenhalgh, E.; Singh, S.; Hughes, D.; Roberts, D. Impact damage resistance and tolerance of stringer stiffened composite structures. Plast. Rubber Compos. 1999, 28, 228–251. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, H.; Tan, X.; He, Y.; An, T.; Zheng, J. Effect of impact damage positions on the buckling and post-buckling behaviors of stiffened composite panel. Compos. Struct. 2016, 155, 184–196. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Kreikemeier, J.; Wille, T. An analytical scaling approach for low-velocity impact on composite structures. Compos. Struct. 2018, 187, 71–84. [Google Scholar] [CrossRef]

- Tan, R.; Guan, Z.; Sun, W.; Liu, Z.; Xu, J. Experiment investigation on impact damage and influences on compression behaviors of single T-stiffened composite panels. Compos. Struct. 2018, 203, 486–497. [Google Scholar] [CrossRef]

- Mishra, R.; Wiener, J.; Militky, J.; Petru, M.; Tomkova, B.; Novotna, J. Compression resilience and impact resistance of fiber-reinforced sandwich composites. Polym. Adv. Technol. 2019, 30, 3073–3082. [Google Scholar] [CrossRef]

- Gustin, J.; Joneson, A.; Mahinfalah, M.; Stone, J. Low velocity impact of combination Kevlar/carbon fiber sandwich composites. Compos. Struct. 2005, 69, 396–406. [Google Scholar] [CrossRef]

- Soto, A.; González, E.V.; Maimí, P.; Mayugo, J.A.; Pasquali, P.R.; Camanho, P.P. A methodology to simulate low velocity impact and compression after impact in large composite stiffened panels. Compos. Struct. 2018, 204, 223–238. [Google Scholar] [CrossRef]

- Feng, Y.; He, Y.; Zhang, H.; Tan, X.; An, T.; Zheng, J. Effect of fatigue loading on impact damage and buckling/post-buckling behaviors of stiffened composite panels under axial compression. Compos. Struct. 2017, 164, 248–262. [Google Scholar] [CrossRef]

- Wiggenraad, J.F.M.; Zhang, X.; Davies, G.A.O. Impact damage prediction and failure analysis of heavily loaded, blade-stiffened composite wing panels. Compos. Struct. 1999, 45, 81–103. [Google Scholar] [CrossRef]

| Properties | Value | |

|---|---|---|

| Longitudinal Young’s modulus | E11 | 148 GPa |

| Transverse Young’s modulus | E22 = E33 | 10.5 GPa |

| Shear modulus | G12 = G13 | 5.6 GPa |

| G23 | 3.5 GPa | |

| Poisson’s ratio | 12=13 | 0.31 |

| 23 | 0.2 | |

| Longitudinal compressive strength | Yc | 1555 MPa |

| Transverse compressive strength | Xc | 247 MPa |

| Plane shear strength | S | 91.5 MPa |

| Fiber volume fraction | Vf | 60% |

| Ply thickness | d | 0.125 mm |

| Specimen Number | Impact Energy [J] | Impact Position |

|---|---|---|

| #1 | / | / |

| #2 | 15 | 1 |

| #3 | 30 | 1 |

| #4 | 15 | 2 |

| #5 | 30 | 2 |

| #6 | 15 | 3 |

| #7 | 30 | 3 |

| Specimen Number | Scan Depth [mm] | Damage Area [mm2] |

|---|---|---|

| #2 | 1.5 | 342 |

| #5 | 1.5 | 197 |

| #7 | 1.5 | 93 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhang, Q.; Jia, J.; Ji, C.; Wang, B.; Yan, S. Study on Low-Velocity Impact Damage and Residual Strength of Reinforced Composite Skin Structure. Materials 2020, 13, 2573. https://doi.org/10.3390/ma13112573

Li H, Zhang Q, Jia J, Ji C, Wang B, Yan S. Study on Low-Velocity Impact Damage and Residual Strength of Reinforced Composite Skin Structure. Materials. 2020; 13(11):2573. https://doi.org/10.3390/ma13112573

Chicago/Turabian StyleLi, Hanhua, Qiuhua Zhang, Jiale Jia, Chunming Ji, Bing Wang, and Shi Yan. 2020. "Study on Low-Velocity Impact Damage and Residual Strength of Reinforced Composite Skin Structure" Materials 13, no. 11: 2573. https://doi.org/10.3390/ma13112573

APA StyleLi, H., Zhang, Q., Jia, J., Ji, C., Wang, B., & Yan, S. (2020). Study on Low-Velocity Impact Damage and Residual Strength of Reinforced Composite Skin Structure. Materials, 13(11), 2573. https://doi.org/10.3390/ma13112573