New Constitutive Model for the Size Effect on Flow Stress Based on the Energy Conservation Law

Abstract

1. Introduction

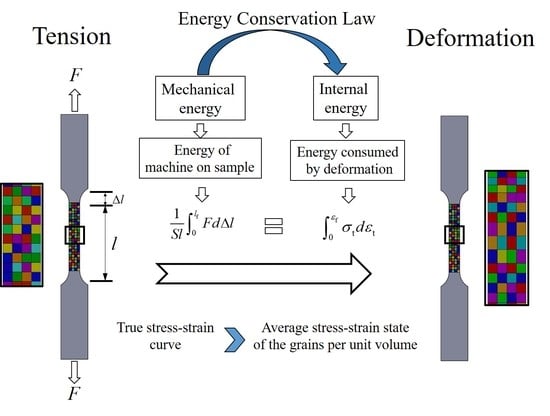

2. Application of Energy Conservation Law in Metal Forming

3. New Model Based on Energy Conservation

3.1. Model Establishment

3.2. Verification Based on Finite Element Simulation

3.3. Discussion

3.4. Application

3.4.1. Existing Flow Stress Constitutive Model

3.4.2. Optimized Flow Stress Constitutive Model

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lai, X.; Peng, L.; Hu, P.; Ni, J. Material behavior modelling in micro/meso-scale forming process with considering size/scale effects. Comp. Mater. Sci. 2008, 43, 1003–1009. [Google Scholar] [CrossRef]

- Meng, B.; Wang, W.H.; Zhang, Y.Y.; Wan, M. Size effect on plastic anisotropy in microscale deformation of metal foil. J. Mater. Process. Tech. 2019, 271, 46–61. [Google Scholar] [CrossRef]

- Gu, R.; Ngan, A.H.W. Size effect on the deformation behavior of duralumin micropillars. Scripta. Mater. 2013, 68, 861–864. [Google Scholar] [CrossRef]

- Geiger, M.; Vollertsen, F.; Kals, R. Fundamentals on the manufacturing of sheet metal microparts. Annal. CIRP 1996, 45, 277–282. [Google Scholar] [CrossRef]

- Engel, U.; Eckstein, R. Microfilming-from basic research to its realization. J. Mater. Process. Tech. 2002, 125–126, 35–44. [Google Scholar] [CrossRef]

- Leu, D.K. Distinguishing micro-scale from macro-scale tensile flow stress of sheet metals in microforming. Mater. Des. 2015, 87, 773–779. [Google Scholar] [CrossRef]

- Kim, G.Y.; Ni, J.; Koc, M. Modeling of the size effects on the behavior of metals in microscale deformation processes. ASME J. Manuf. Sci. Eng. 2007, 129, 470–476. [Google Scholar] [CrossRef]

- Keller, C.; Hug, E. Hall-Petch behaviour of Ni polycrystals with a few grains per thickness. Mater. Lett. 2008, 62, 1718–1720. [Google Scholar] [CrossRef]

- Keller, C.; Hug, E.; Retoux, R.; Feaugas, X. TEM study of dislocation patterns in near-surface and core regions of deformed nickel polycrystals with few grains across the cross section. Mech. Mater. 2010, 42, 44–54. [Google Scholar] [CrossRef]

- Janssen, P.J.M.; Keijser, T.H.D.; Geers, M.G.D. An experimental assessment of grain size effects in the uniaxial straining of thin Al sheet with a few grains across the thickness. Mater. Sci. Eng. A. 2006, 419, 238–248. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Aging of Mild Steel. Proc. Phys. Soc. Lond. Sect B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. Lond. 1953, 174, 25–28. [Google Scholar]

- Meng, B.; Fu, M.W. Size effect on deformation behavior and ductile fracture in microforming of pure copper sheets considering free surface roughening. Mater. Des. 2015, 83, 400–412. [Google Scholar] [CrossRef]

- Furushima, T.; Tsunezaki, H.; Manabe, K.I.; Alexsandrov, S. Ductile fracture and free surface roughening behaviors of pure copper foils for micro/meso-scale forming. Int. J. Mach. Tool. Manu. 2014, 76, 34–48. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, Y.S. Size dependence of flow stress and plastic behaviour in microforming of polycrystalline metallic materials. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2012, 226, 403–412. [Google Scholar] [CrossRef]

- Wang, C.J.; Xue, S.X.; Chen, G.; Zhang, P. Constitutive model based on dislocation density and ductile fracture of Monel 400 thin sheet under tension. Met. Mater. Int. 2017, 23, 264–271. [Google Scholar] [CrossRef]

- Lyu, H.; Ruimi, A.; Zbib, H.M. A dislocation-based model for deformation and size effect in multi-phase steels. Int. J. Plast. 2015, 72, 44–59. [Google Scholar] [CrossRef]

- Miyazaki, S.; Shibata, K.; Fujita, H. Effect of specimen thickness on mechanical properties of polycrystalline aggregates with various grain sizes. Acta. Metall. 1979, 27, 855–862. [Google Scholar] [CrossRef]

- Meyersm, M.A.; Ashworth, E. A model for the effect of grain size on the yield stress of metals. Philos. Mag. A. 1982, 46, 737–759. [Google Scholar] [CrossRef]

- Geiger, M.; Geißdörfer, S.; Engel, U. Mesoscopic model: Advanced simulation of microforming processes. Prod. Eng. 2007, 1, 79–84. [Google Scholar] [CrossRef]

- Molotnikov, A.; Lapovok, R.; Davies, C.H.J.; Cao, W.; Estrinabc, Y. Size effect on the tensile strength of fine-grained copper. Scripta. Mater. 2008, 59, 1182–1185. [Google Scholar] [CrossRef]

- Liu, J.G.; Fu, M.W.; Chan, W.L. A constitutive model for modeling of the deformation behavior in microforming with a consideration of grain boundary strengthening. Comp. Mater. Sci. 2012, 55, 85–94. [Google Scholar] [CrossRef]

- Keller, C.; Hug, E.; Feaugas, X. Microstructural size effects on mechanical properties of high purity nickel. Int. J. Plasticity. 2011, 27, 635–654. [Google Scholar] [CrossRef]

- Vollertsen, F. Effects on the deep drawing diagram in micro forming. Prod. Eng. 2012, 6, 11–18. [Google Scholar] [CrossRef]

- Hollomon, J.H. Tensile deformation. Trans. AIME 1945, 162, 268–290. [Google Scholar]

- Mahabunphachai, S.; Koç, M. Investigation of size effects on material behavior of thin sheet metals using hydraulic bulge testing at micro/meso-scales. J. Mach. Tools. Manuf. 2008, 48, 1014–1029. [Google Scholar] [CrossRef]

- Starink, M.J. Dislocation versus grain boundary strengthening in SPD processed metals: Non-causal relation between grain size and strength of deformed polycrystals. Mater. Sci. Eng. A. 2017, 705, 42–45. [Google Scholar] [CrossRef]

- Cordero, N.M.; Forest, S.; Busso, E.P.; Berbenni, S.; Cherkaouic, M. Grain size effects on plastic strain and dislocation density tensor fields in metal polycrystals. Comp. Mater. Sci. 2012, 52, 7–13. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W. Experimental studies and numerical modeling of the specimen and grain size effects on the flow stress of sheet metal in microforming. Mater. Sci. Eng. A. 2011, 528, 7674–7683. [Google Scholar] [CrossRef]

- Evers, L.P.; Brekelmans, W.A.M.; Geers, M.G.D. Scale dependent crystal plasticity framework with dislocation density and grain boundary effects. Int. J. Solids Struct. 2004, 41, 5209–5230. [Google Scholar] [CrossRef]

- Leu, D.-K. Modeling of Size Effect on Tensile Flow Stress of Sheet Metal in Microforming. J. Manuf. Sci. Eng. 2009, 131, 011002. [Google Scholar] [CrossRef]

- Lederer, M.; Gröger, V.; Khatibi, G.; Weiss, B. Size dependency of mechanical properties of high purity aluminium foils. Mater. Sci. Eng. A 2010, 527, 590–599. [Google Scholar] [CrossRef]

- Liu, M.Q.; Liu, Y.L.; Yan, Y.; Han, D.; Li, X.W. Thickness-dependent tensile and fatigue behavior of a single-slip-oriented Cu single crystal. Cryst. Res. Techmol. 2017, 52, 1700178. [Google Scholar] [CrossRef]

- Peng, L.; Xu, Z.; Gao, Z.; Fu, M.W. A constitutive model for metal plastic deformation at micro/meso scale with consideration of grain orientation and its evolution. Int. J. Mech. Sci. 2018, 138, 74–85. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, P.L.; Xu, Z.Y.; Yan, H.; Wang, J.M.; Wang, J.J. A constitutive model for thin sheet metal in micro-forming considering first order size effects. Mater. Des. 2010, 31, 1010–1014. [Google Scholar]

| Test | t (μm) | Annealing Temperature (°C) | d (μm) | t/d | K(MPa) | n | ε0 |

|---|---|---|---|---|---|---|---|

| 1 | 100 | 750 | 55.2 | 1.8 | 958.8 | 0.59 | 0.0043 |

| 2 | 100 | 850 | 66.7 | 1.5 | 968.2 | 0.61 | 0.0043 |

| 3 | 100 | 950 | 81.5 | 1.2 | 987.5 | 0.63 | 0.0043 |

| 4 | 100 | 1050 | 109.5 | 0.9 | 998.8 | 0.66 | 0.0043 |

| 5 | 100 | 1150 | 124.9 | 0.8 | 958.2 | 0.65 | 0.0043 |

| 6 | 200 | 750 | 73.0 | 2.7 | 1044.1 | 0.64 | 0.0043 |

| 7 | 200 | 850 | 81.0 | 2.5 | 1030.6 | 0.65 | 0.0043 |

| Annealed | n1 | n2 | n6 | K1(t/d)/(MPa) | K2(t/d)/(MPa) | K6(t/d)/(MPa) | ε0 |

|---|---|---|---|---|---|---|---|

| Initial | 0.59 | 0.61 | 0.64 | 958.8 | 968.2 | 1044.1 | 0.0043 |

| Modified | n = (n1 + n2 + n6)/3 = 0.61 | 988.5 | 978.4 | 1013.3 | 0.0043 | ||

| Test | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| t/d | 1.8 | 1.5 | 1.2 | 0.9 | 0.8 | 2.7 | 2.5 |

| (10−6 J) | 66.0 | 64.9 | 63.8 | 60.7 | 59.7 | 67.8 | 67.1 |

| Test | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| t/d | 1.8 | 1.5 | 1.2 | 0.9 | 0.8 | 2.7 | 2.5 |

| np | 0.61 | 0.62 | 0.63 | 0.64 | 0.66 | 0.60 | 0.61 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Wang, H.; Chen, G.; Zhu, Q.; Cui, L.; Zhang, P.; Dong, A. New Constitutive Model for the Size Effect on Flow Stress Based on the Energy Conservation Law. Materials 2020, 13, 2617. https://doi.org/10.3390/ma13112617

Wang C, Wang H, Chen G, Zhu Q, Cui L, Zhang P, Dong A. New Constitutive Model for the Size Effect on Flow Stress Based on the Energy Conservation Law. Materials. 2020; 13(11):2617. https://doi.org/10.3390/ma13112617

Chicago/Turabian StyleWang, Chuanjie, Haiyang Wang, Gang Chen, Qiang Zhu, Lingjiang Cui, Peng Zhang, and Anping Dong. 2020. "New Constitutive Model for the Size Effect on Flow Stress Based on the Energy Conservation Law" Materials 13, no. 11: 2617. https://doi.org/10.3390/ma13112617

APA StyleWang, C., Wang, H., Chen, G., Zhu, Q., Cui, L., Zhang, P., & Dong, A. (2020). New Constitutive Model for the Size Effect on Flow Stress Based on the Energy Conservation Law. Materials, 13(11), 2617. https://doi.org/10.3390/ma13112617