Effects of Steelmaking Slag and Moisture on Electrical Properties of Concrete

Abstract

1. Introduction

2. Experimental Program

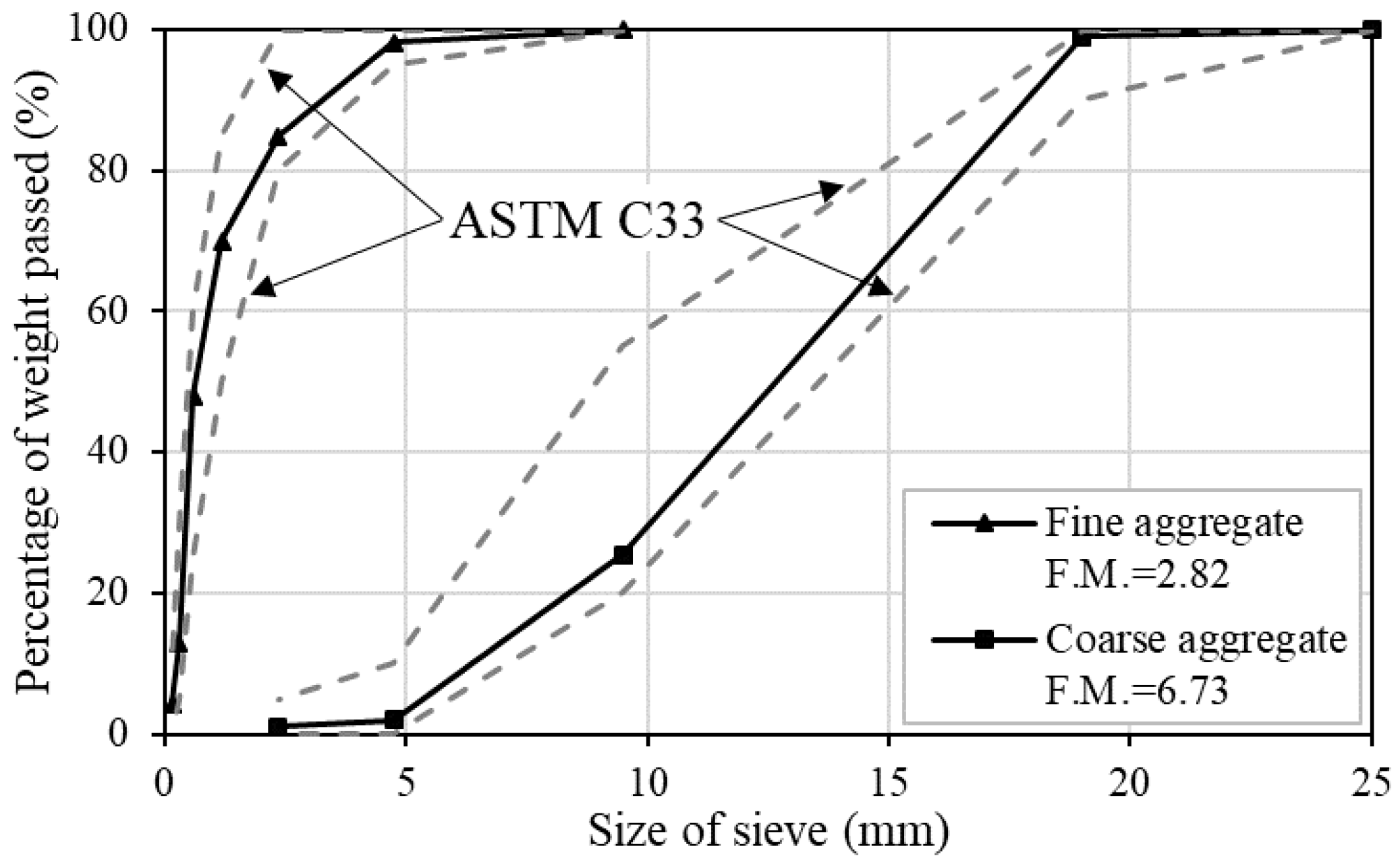

2.1. Mix Designs, Materials, and Specimen Preparation

2.2. Measurement of Electrical Resistance and Self-Sensing Capacity

3. Experimental Results and Discussion

3.1. Strength Properties of Concrete Containing Steelmaking Slag

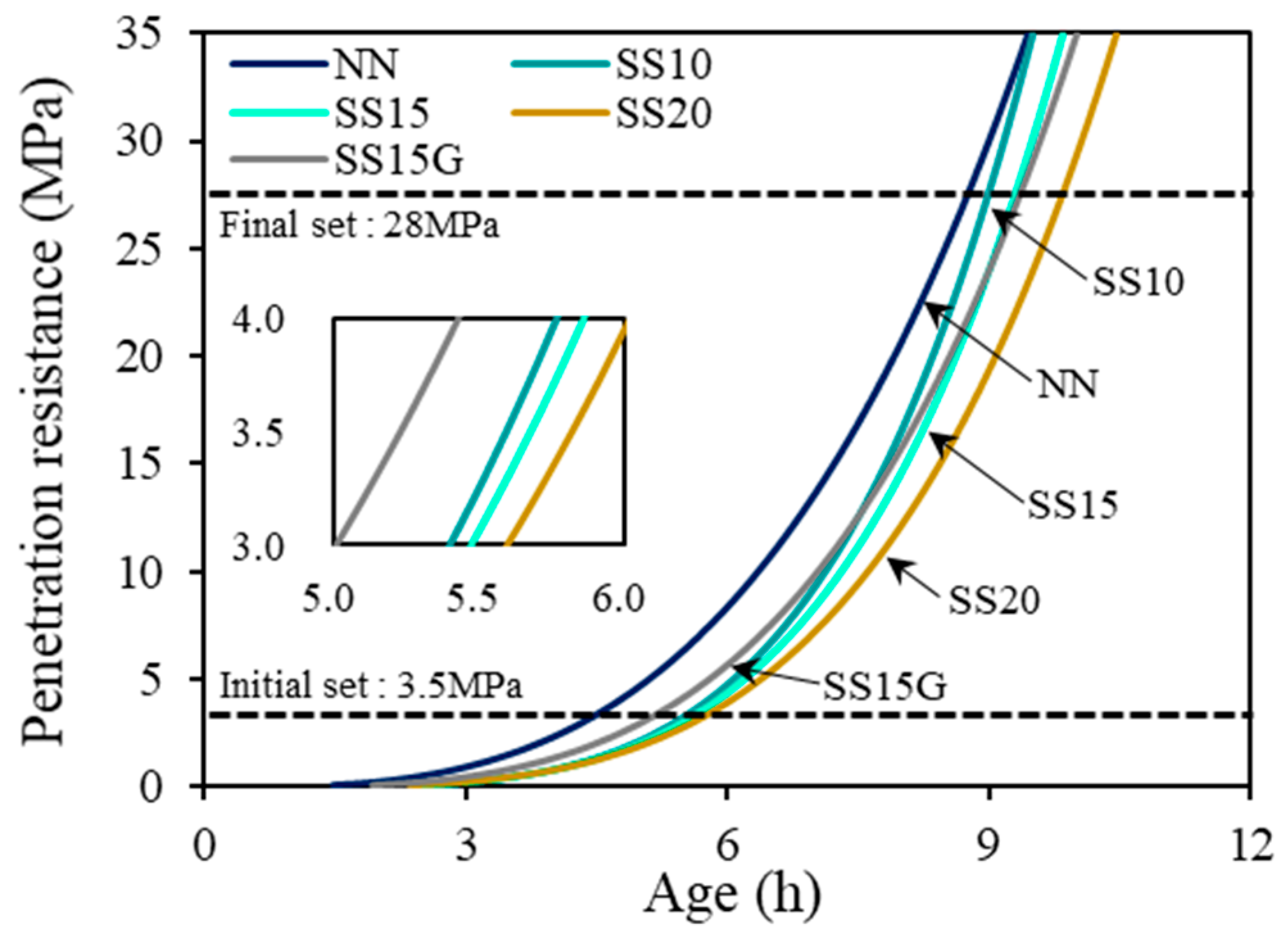

3.1.1. Setting Times

3.1.2. Compressive Strength

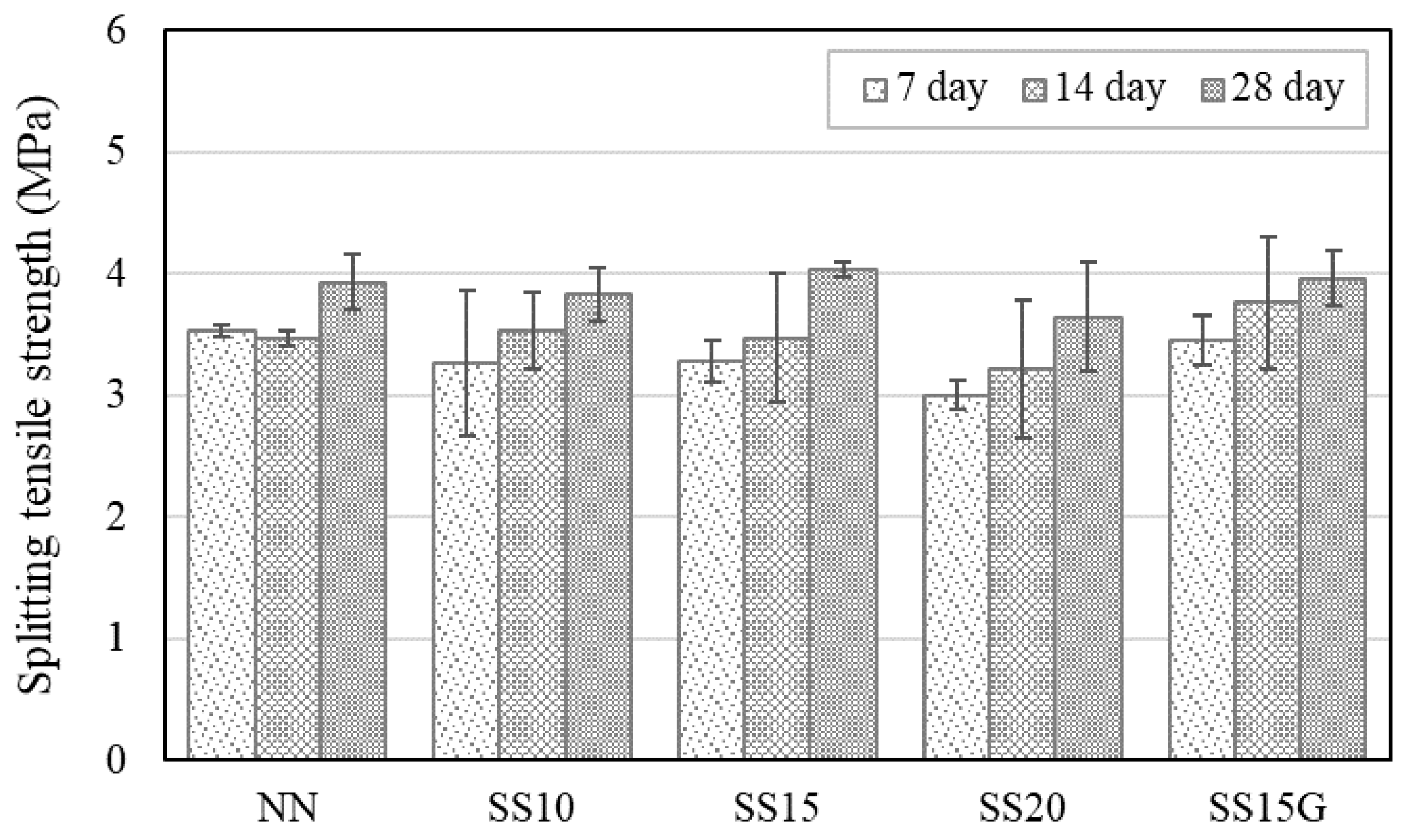

3.1.3. Splitting Tensile Strength

3.2. Electrical Properties of Concrete Containing Steelmaking Slag

3.2.1. Electrical Resistivity

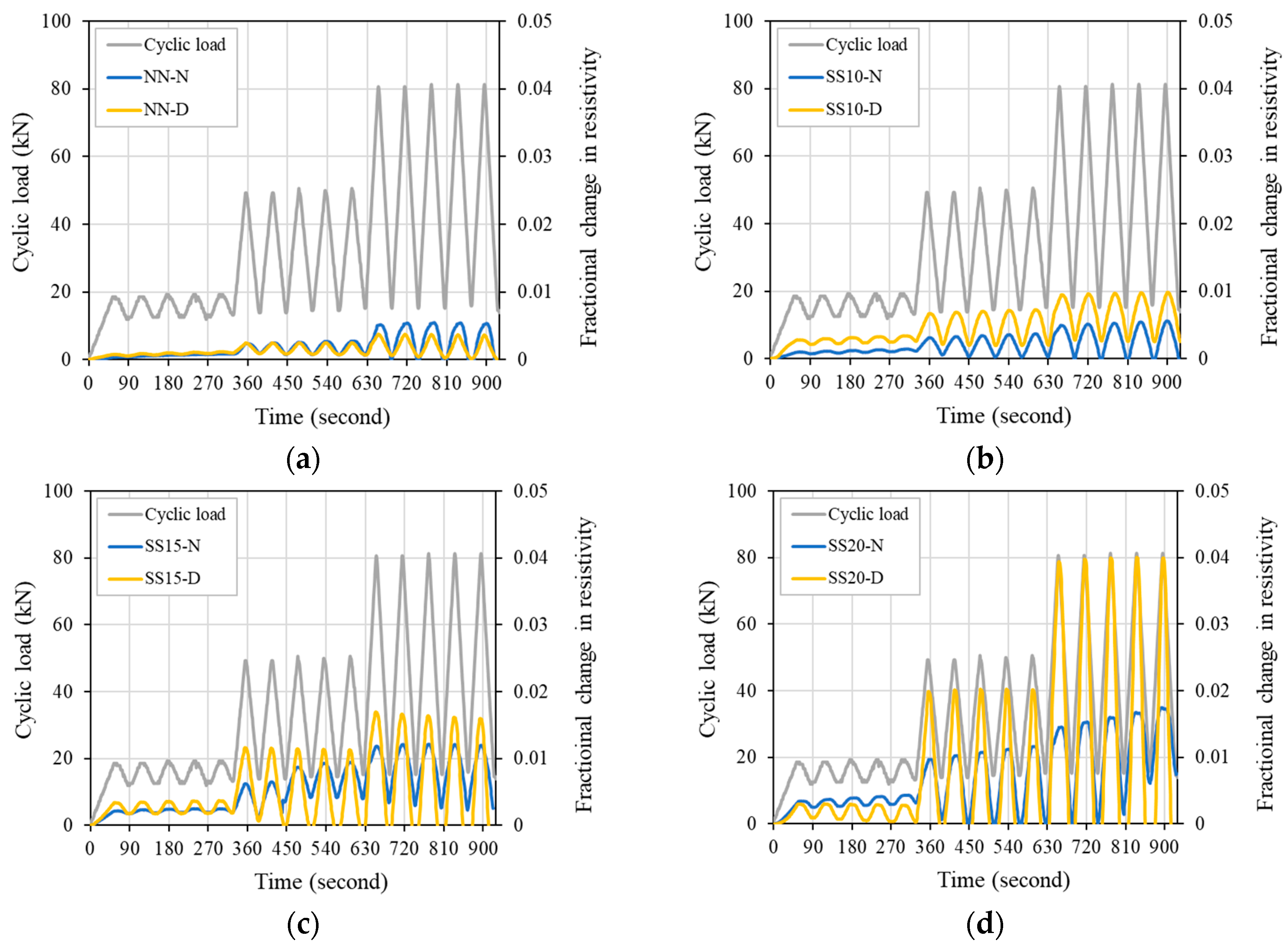

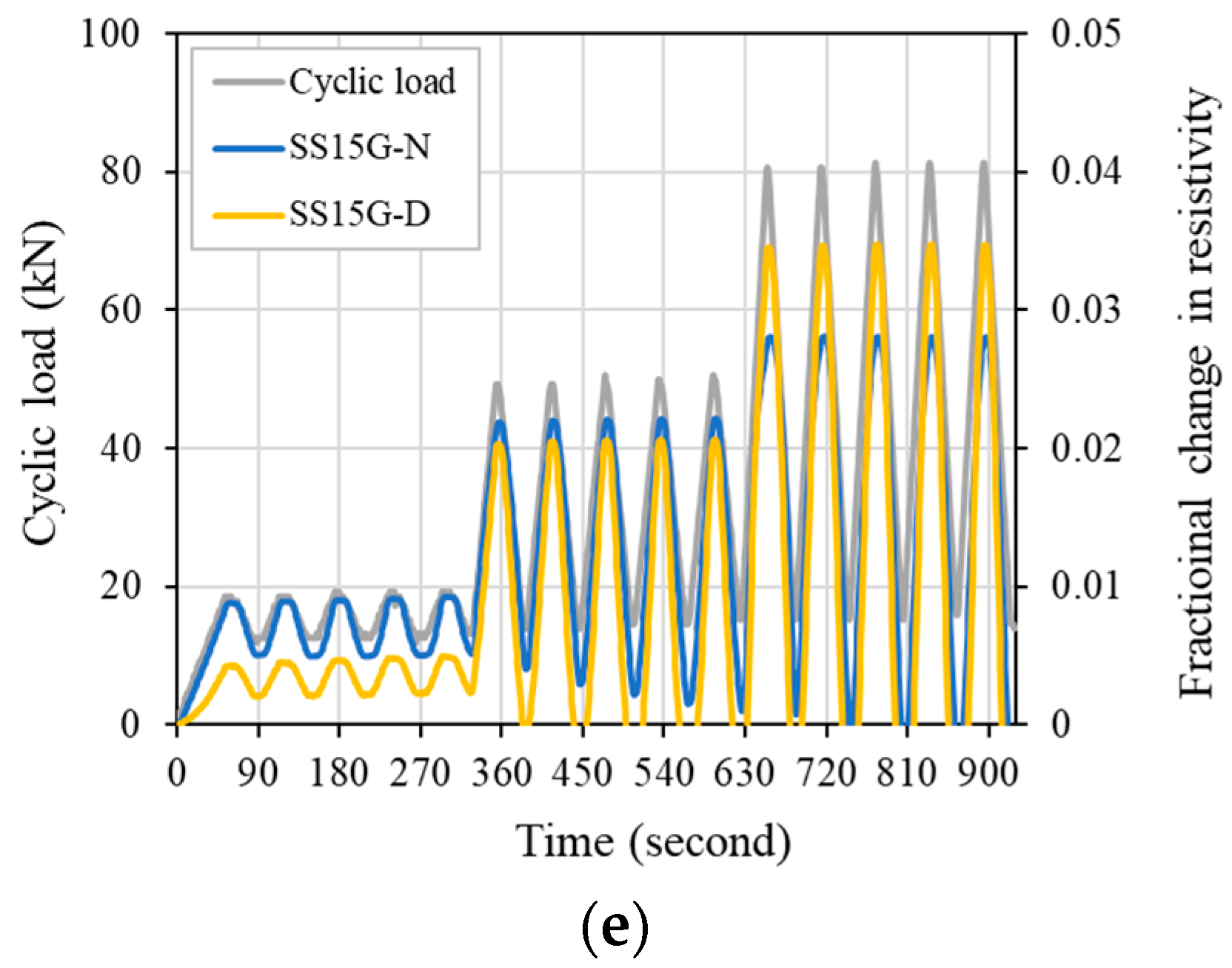

3.2.2. Electrical Piezoresistivity

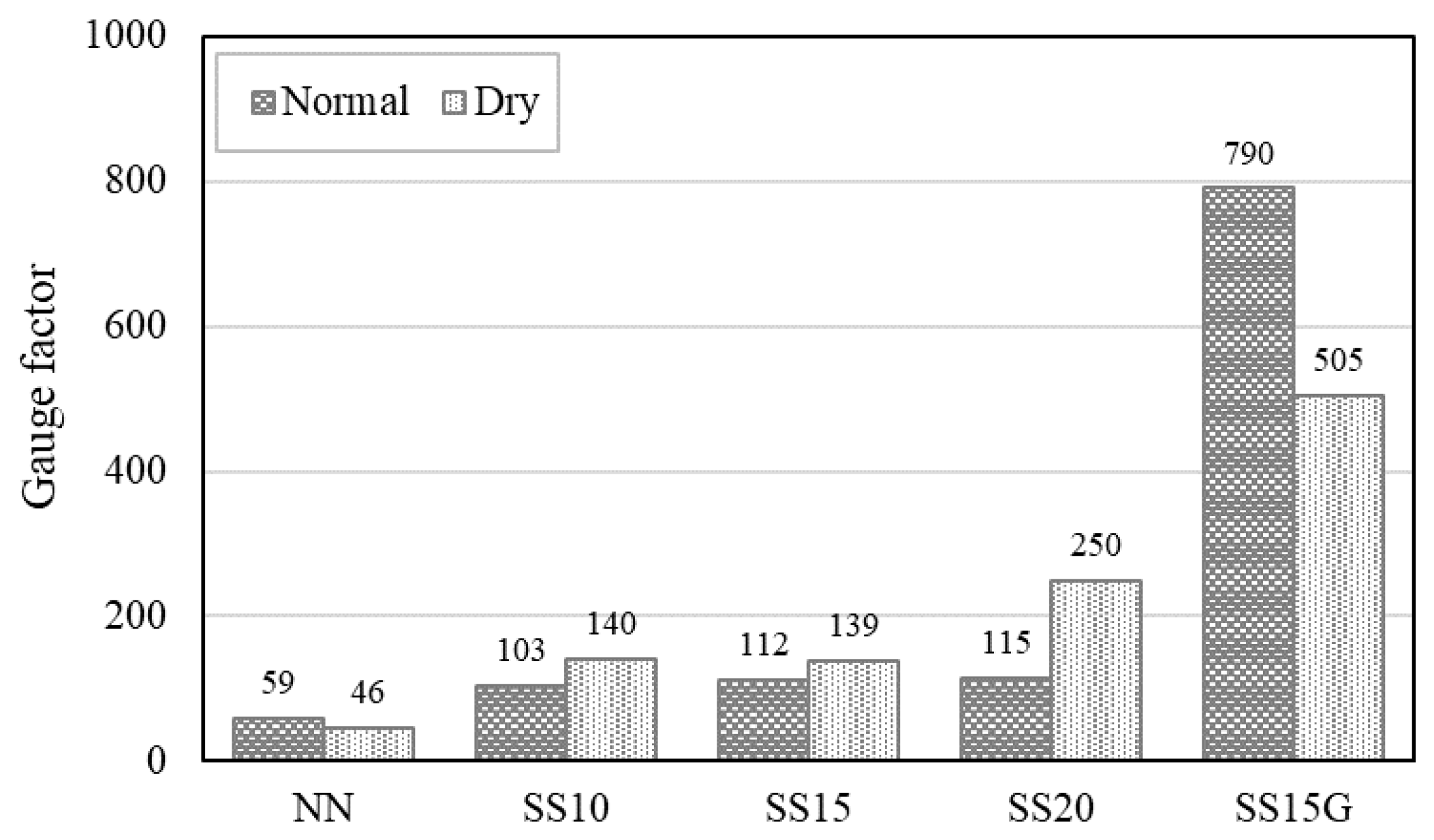

3.2.3. Electrical Sensitivity

4. Conclusions

- Steelmaking slag delayed hydration process, and, when steelmaking slag was incorporated, the strength decreased. However, it was confirmed that the reduction of the strength of the concrete containing steelmaking slag could be improved through the incorporation of gypsum.

- The electrical conductivity of steelmaking slag is included in the range of semi-conductors, and the electrical resistivity decreased as the replacement ratio of steelmaking slag increased. In addition, the incorporation of gypsum improved the conductivity of the concrete. On the other hand, the electrical resistivity is dependent on the moisture in the concrete, and, when the concrete specimen was dried, the electrical resistivity increased about two times or more.

- The iron oxide in the steelmaking slag formed a conductive path in the concrete, and the reduction of the potential barrier due to the increase in the cyclic compressive load increased the FCR. The dry series showed higher FCR values than the normal series, and, when the specimen was dried, the maximum FCRs of SS15, SS20, and SS15G increased by 40.10%, 129.68%, and 23.70%, respectively. Through this, it could be seen that the electrical piezoresistivity of concrete was affected by moisture.

- The GF improved as the replacement ratio of the steelmaking slag increased. In general, when the moisture in concrete decreases, the GF decreases; however, the mixes incorporating only steelmaking slag showed the opposite trend. This was because moisture in concrete came into contact with free CaO and caused cracks, which affected the conductive path in concrete. When the specimens were dried, the GF of SS10, SS15, and SS20 increased by 37, 27, and 135, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Demircilioglu, E.; Teomete, E.; Ozbulut, O.E. Strain sensitivity of steel-fiber-reinforced industrial smart concrete. J. Intell. Mater. Syst. Struct. 2020, 31, 127–136. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic self-sensing concrete and structures: A review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Tian, Z.; Li, Y.; Zheng, J.; Wang, S. A state-of-the-art on self-sensing concrete: Materials, fabrication and properties. Compos. B Eng. 2019, 177, 107437. [Google Scholar] [CrossRef]

- Choi, E.; Yuan, T.; Lee, J.; Yoon, Y. Self-sensing Properties of Concrete with Electric Arc Furnace Slag and Steel Fiber. J. Korean Soc. Hazard Mitig. 2019, 19, 265–274. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Han, B.; Wan, B.; Cai, G.; Li, Z. Strain monitoring of concrete components using embedded carbon nanofibers/epoxy sensors. Constr. Build. Mater. 2018, 186, 367–378. [Google Scholar] [CrossRef]

- Chung, D.D.L. Carbon materials for structural self-sensing, electromagnetic shielding and thermal interfacing. Carbon 2012, 50, 3342–3353. [Google Scholar] [CrossRef]

- Chung, D.D.L. Electrically conductive cement-based materials. Adv. Cem. Res. 2004, 16, 167–176. [Google Scholar] [CrossRef]

- Lee, S.-J.; You, I.; Zi, G.; Yoo, D.-Y. Experimental investigation of the piezoresistive properties of cement composites with hybrid carbon fibers and nanotubes. Sensors 2017, 17, 2516. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Lee, S.-J. Electrical properties of cement-based composites with carbon nanotubes, graphene, and graphite nanofibers. Sensors 2017, 17, 1064. [Google Scholar] [CrossRef]

- Monteiro, A.O.; Cachim, P.B.; Costa, P.M.F.J. Self-sensing piezoresistive cement composite loaded with carbon black particles. Cem. Concr. Compos. 2017, 81, 59–65. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Ou, J. Nickel particle-based self-sensing pavement for vehicle detection. Measurement 2011, 44, 1645–1650. [Google Scholar] [CrossRef]

- Hong, S.; Yuan, T.; Choi, J.; Yoon, Y. Evaluating Microstructure and Self-Sensing Properties of High-Strength Concrete with Electric-Arc-Furnace Oxidizing Slag. J. Korean Soc. Hazard Mitig. 2019, 19, 189–197. [Google Scholar] [CrossRef]

- Baeza, F.J.; Galao, O.; Vegas, I.J.; Cano, M.; Garcés, P. Influence of recycled slag aggregates on the conductivity and strain sensing capacity of carbon fiber reinforced cement mortars. Constr. Build. Mater. 2018, 184, 311–319. [Google Scholar] [CrossRef]

- Lee, S.Y.; Le, H.V.; Kim, D.J. Self-stress sensing smart concrete containing fine steel slag aggregates and steel fibers under high compressive stress. Constr. Build. Mater. 2019, 220, 149–160. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Choi, J.-S.; Yuan, T.-F.; Yoon, Y.-S.; Mitchell, D. Comparing properties of concrete containing electric arc furnace slag and granulated blast furnace slag. Materials 2019, 12, 1371. [Google Scholar] [CrossRef]

- Hekal, E.E.; Abo-El-Enein, S.A.; El-Korashy, S.A.; Megahed, G.M.; El-Sayed, T.M. Hydration characteristics of Portland cement—Electric arc furnace slag blends. HBRC J. 2013, 9, 118–124. [Google Scholar] [CrossRef]

- ASTM C136: Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C33: Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2018.

- Roslan, N.H.; Ismail, M.; Abdul-Majid, Z.; Ghoreishiamiri, S.; Muhammad, B. Performance of steel slag and steel sludge in concrete. Constr. Build. Mater. 2016, 104, 16–24. [Google Scholar] [CrossRef]

- ASTM C39: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C192: Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C403: Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C496: Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017.

- Chiarello, M.; Zinno, R. Electrical conductivity of self-monitoring CFRC. Cem. Concr. Compos. 2005, 27, 463–469. [Google Scholar] [CrossRef]

- Han, B.; Guan, X.; Ou, J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors. Sens. Actuators A Phys. 2007, 135, 360–369. [Google Scholar] [CrossRef]

- Chen, B.; Wu, K.; Yao, W. Conductivity of carbon fiber reinforced cement-based composites. Cem. Concr. Compos. 2004, 26, 291–297. [Google Scholar] [CrossRef]

- You, I.; Yoo, D.-Y.; Kim, S.; Kim, M.-J.; Zi, G. Electrical and self-sensing properties of ultra-high-performance fiber-reinforced concrete with carbon nanotubes. Sensors 2017, 17, 2481. [Google Scholar] [CrossRef] [PubMed]

- Banthia, N.; Djeridane, S.; Pigeon, M. Electrical resistivity of carbon and steel micro-fiber reinforced cements. Cem. Concr. Res. 1992, 22, 804–814. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Youn, H.; Lee, S.-J. Electrical and piezoresistive properties of cement composites with carbon nanomaterials. J. Comp. Mater. 2018, 52, 3325–3340. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; You, I.; Lee, S.-J. Electrical and piezoresistive sensing capacities of cement paste with multi-walled carbon nanotubes. Arch. Civ. Mech. Eng. 2018, 18, 371–384. [Google Scholar] [CrossRef]

- Lee, K.-H.; Kim, G.-Y.; Lee, B.-K.; Shin, K.-S.; Nam, J.-S. Setting Time, Compressive Strength and Drying Shrinkage of Mortar with Alpha-Calcium Sulfate Hemihydrate. J. Korea Inst. Struct. Maint. Inspect. 2017, 21, 117–124. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Souza, J.D.; Campos, S.C.; Fernandes, L.F.; Camarini, G. Pressured recycled gypsum plaster and wastes: Characteristics of eco-friendly building components. Constr. Build. Mater. 2018, 191, 136–144. [Google Scholar] [CrossRef]

- Blaney, L. Magnetite (Fe3O4): Properties, synthesis, and applications. Lehigh Rev. 2007, 15, 33–81. [Google Scholar]

- Pundir, A.; Garg, M.; Singh, R. Evaluation of properties of gypsum plaster-superplasticizer blends of improved performance. J. Build. Eng. 2015, 4, 223–230. [Google Scholar] [CrossRef]

- Hong, Y.; Li, Z.; Qiao, G.; Ou, J.; Cheng, W. Pressure sensitivity of multiscale carbon-admixtures–enhanced cement-based composites. Nanomater. Nanotechnol. 2018, 8, 1847980418793529. [Google Scholar] [CrossRef]

- Lee, N.-K.; Park, G.-J.; Park, J.-J.; Kim, S.-W. A Study on the Electrical Conductivity and Electromagnetic Shielding of High Performance Fiber Reinforced Cementitious Composites (HPFRCC). J. Korea Inst. Struct. Maint. Inspect. 2019, 23, 37–43. [Google Scholar] [CrossRef]

- Demircilioğlu, E.; Teomete, E.; Schlangen, E.; Baeza, F.J. Temperature and moisture effects on electrical resistance and strain sensitivity of smart concrete. Constr. Build. Mater. 2019, 224, 420–427. [Google Scholar] [CrossRef]

- Song, C.; Choi, S. Moisture-dependent piezoresistive responses of CNT-embedded cementitious composites. Compos. Struct. 2017, 170, 103–110. [Google Scholar] [CrossRef]

| Mix | W/B * | By Cement Weight Ratio | SS ** (%) | G *** (%) | SP **** (%) | |||

|---|---|---|---|---|---|---|---|---|

| Water | Cement | Fine Aggregate | Coarse Aggregate | |||||

| NN | 0.325 | 0.32 | 1.00 | 1.25 | 1.86 | - | - | 0.19 |

| SS10 | 0.325 | 0.36 | 1.00 | 1.39 | 2.06 | 10 | - | 0.19 |

| SS15 | 0.325 | 0.38 | 1.00 | 1.48 | 2.18 | 15 | - | 0.19 |

| SS20 | 0.325 | 0.41 | 1.00 | 1.57 | 2.32 | 20 | - | 0.19 |

| SS15G | 0.325 | 0.38 | 1.00 | 1.48 | 2.18 | 15 | 2 | 0.19 |

| Composition % (Mass) | Cement | SS |

|---|---|---|

| SiO2 | 23.0 | 14.2 |

| CaO | 63.0 | 22.1 |

| Al2O3 | 6.5 | 11.1 |

| T-Fe * | 3.0 | 39.9 |

| MgO | 2.0 | 3.33 |

| SO3 | 1.9 | 0.02 |

| MnO | - | 5.59 |

| TiO2 | - | 0.69 |

| Density (g/cm3) | 3.15 | 3.96 |

| Blaine (cm2/g) | 3413 | 4893 |

| Mix | Initial Set (h) | Final Set (h) | a | b | R2 |

|---|---|---|---|---|---|

| NN | 4.54 | 8.79 | −1.524 | 3.147 | 0.956 |

| SS10 | 5.59 | 9.03 | −2.697 | 4.336 | 0.989 |

| SS15 | 5.67 | 9.33 | −2.609 | 4.182 | 0.988 |

| SS20 | 5.82 | 9.88 | −2.464 | 3.932 | 0.993 |

| SS15G | 5.23 | 9.40 | −2.001 | 3.544 | 0.911 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, S.-H.; Yuan, T.-F.; Choi, J.-S.; Yoon, Y.-S. Effects of Steelmaking Slag and Moisture on Electrical Properties of Concrete. Materials 2020, 13, 2675. https://doi.org/10.3390/ma13122675

Hong S-H, Yuan T-F, Choi J-S, Yoon Y-S. Effects of Steelmaking Slag and Moisture on Electrical Properties of Concrete. Materials. 2020; 13(12):2675. https://doi.org/10.3390/ma13122675

Chicago/Turabian StyleHong, Se-Hee, Tian-Feng Yuan, Jin-Seok Choi, and Young-Soo Yoon. 2020. "Effects of Steelmaking Slag and Moisture on Electrical Properties of Concrete" Materials 13, no. 12: 2675. https://doi.org/10.3390/ma13122675

APA StyleHong, S.-H., Yuan, T.-F., Choi, J.-S., & Yoon, Y.-S. (2020). Effects of Steelmaking Slag and Moisture on Electrical Properties of Concrete. Materials, 13(12), 2675. https://doi.org/10.3390/ma13122675