Microstructure and Mechanical Properties of 4Al Alumina-Forming Austenitic Steel after Cold-Rolling Deformation and Annealing

Abstract

1. Introduction

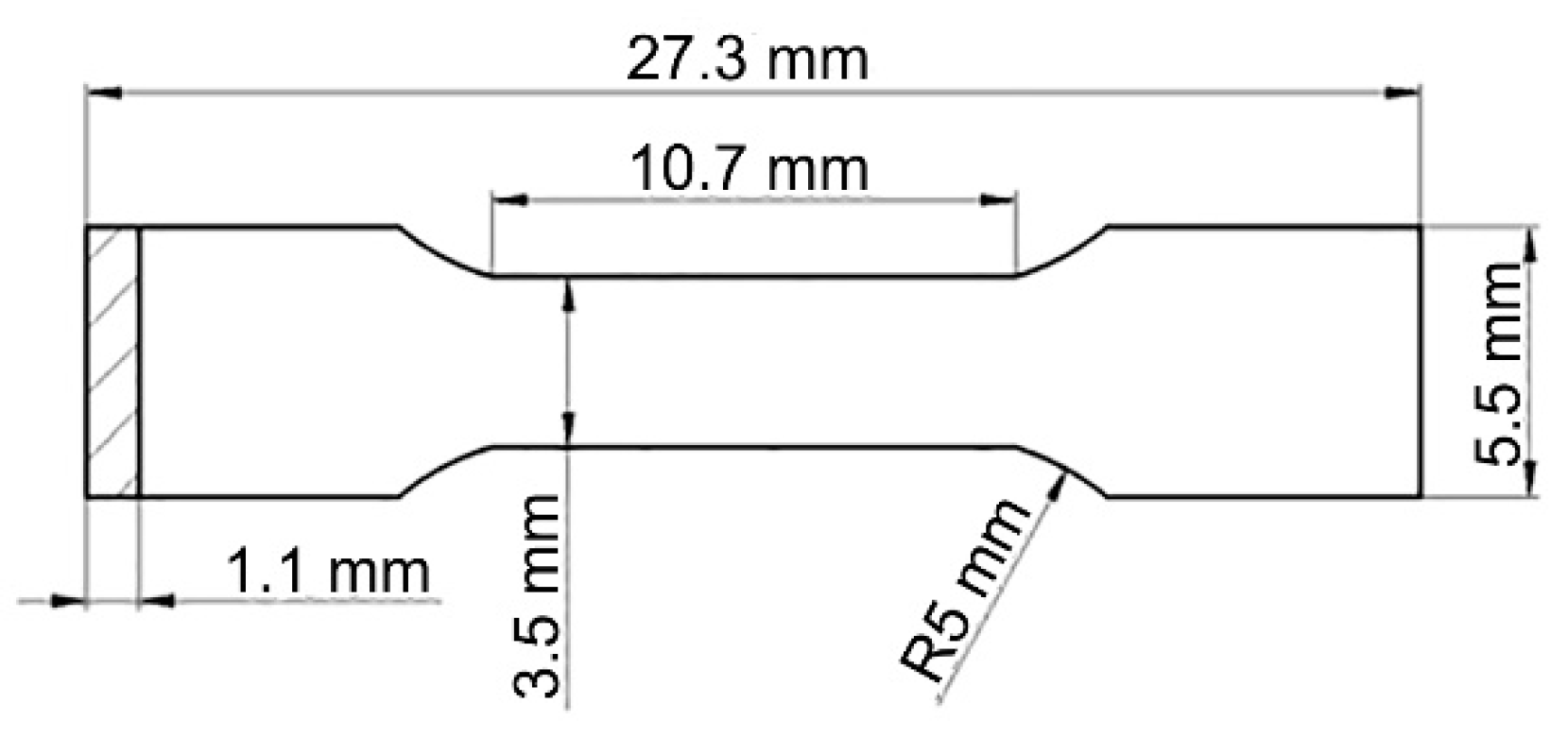

2. Experimental Procedures

3. Results

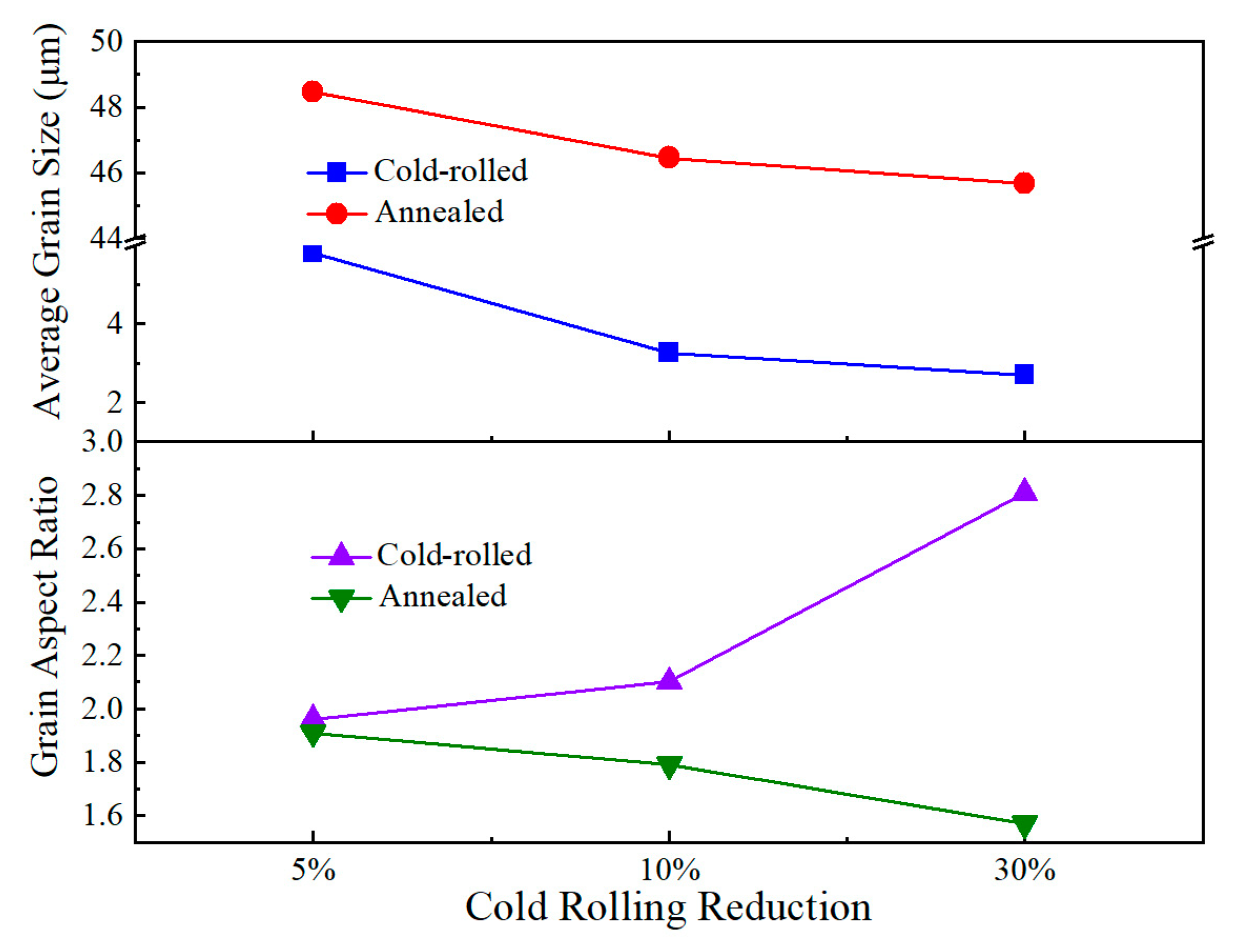

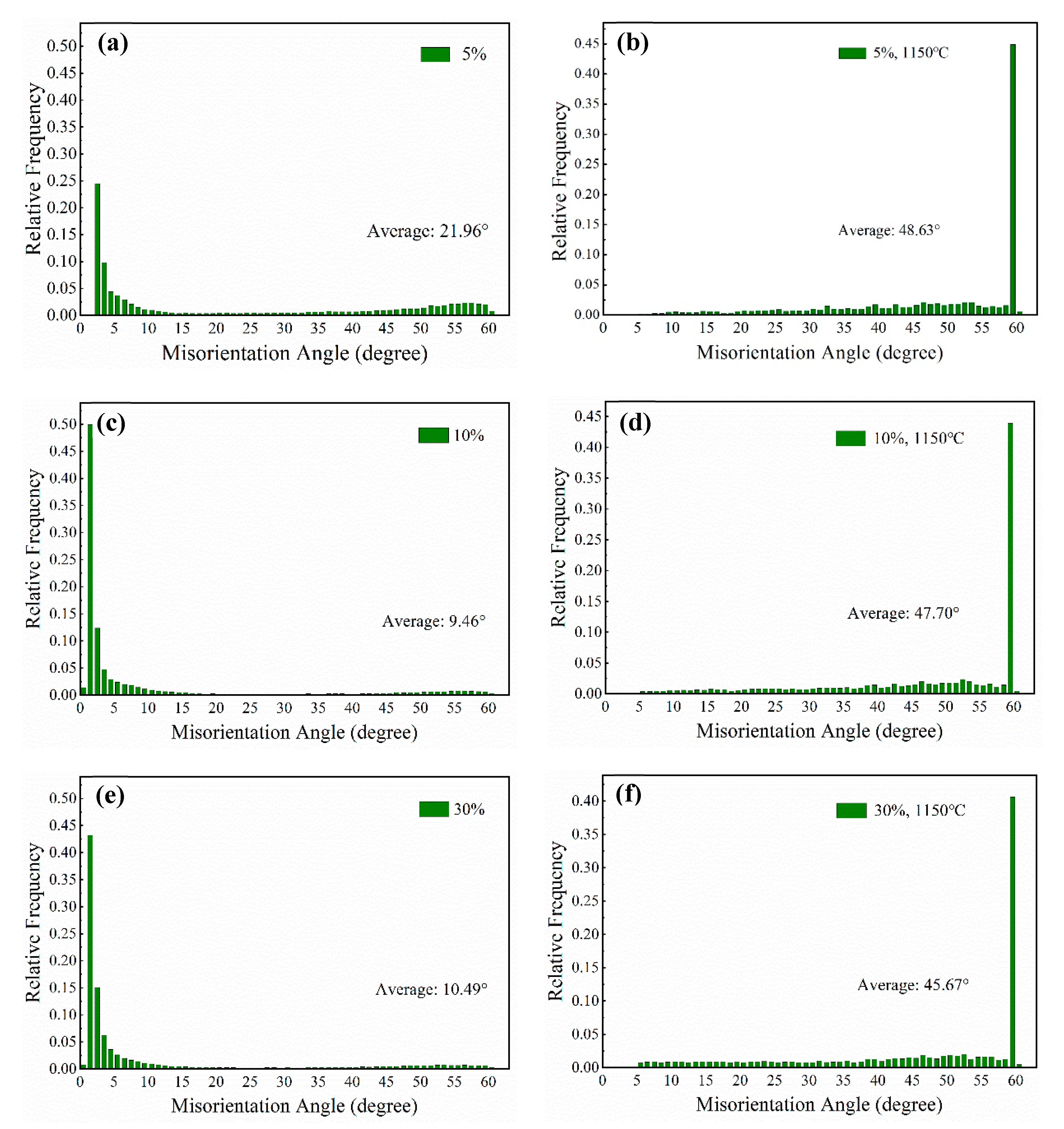

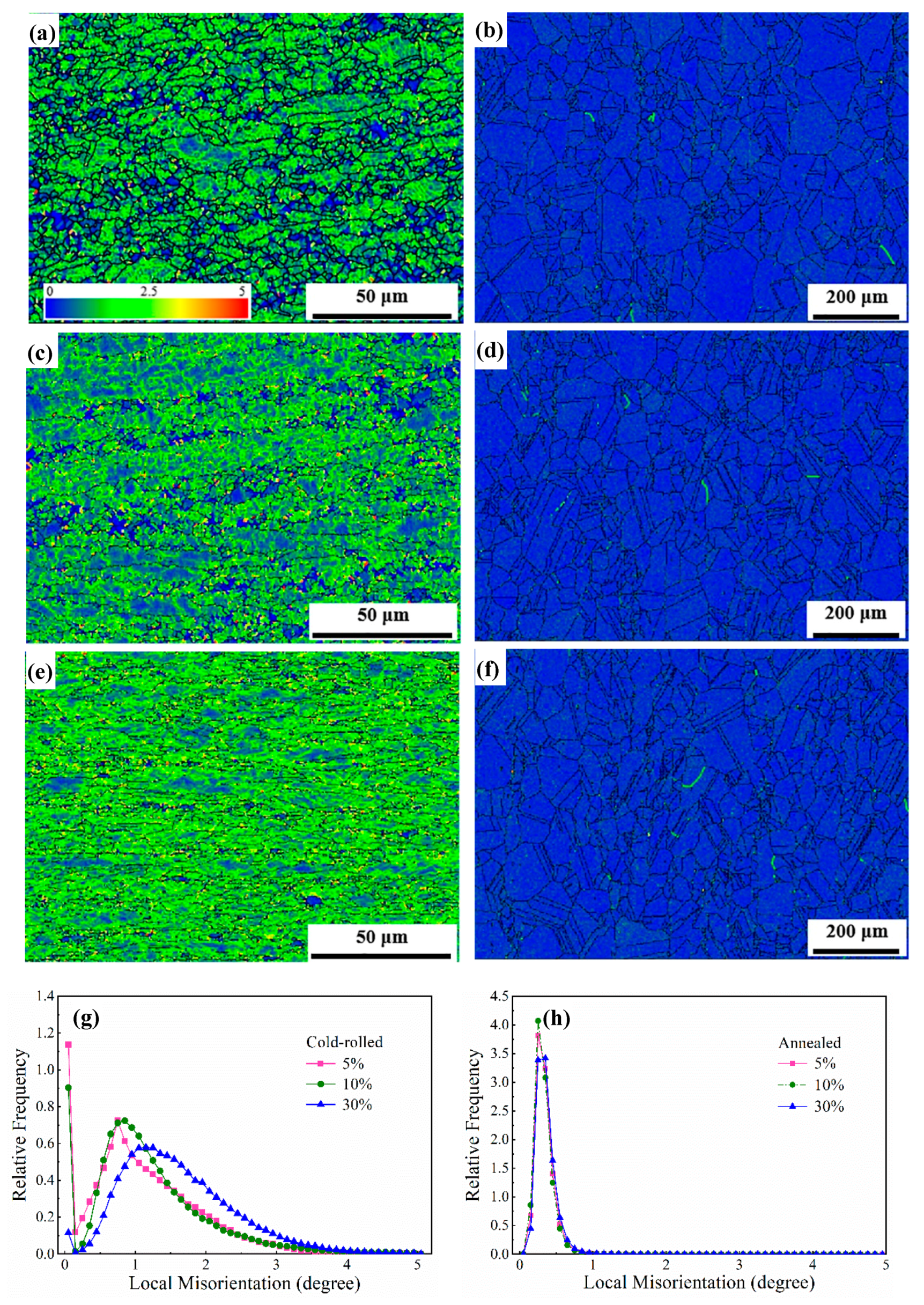

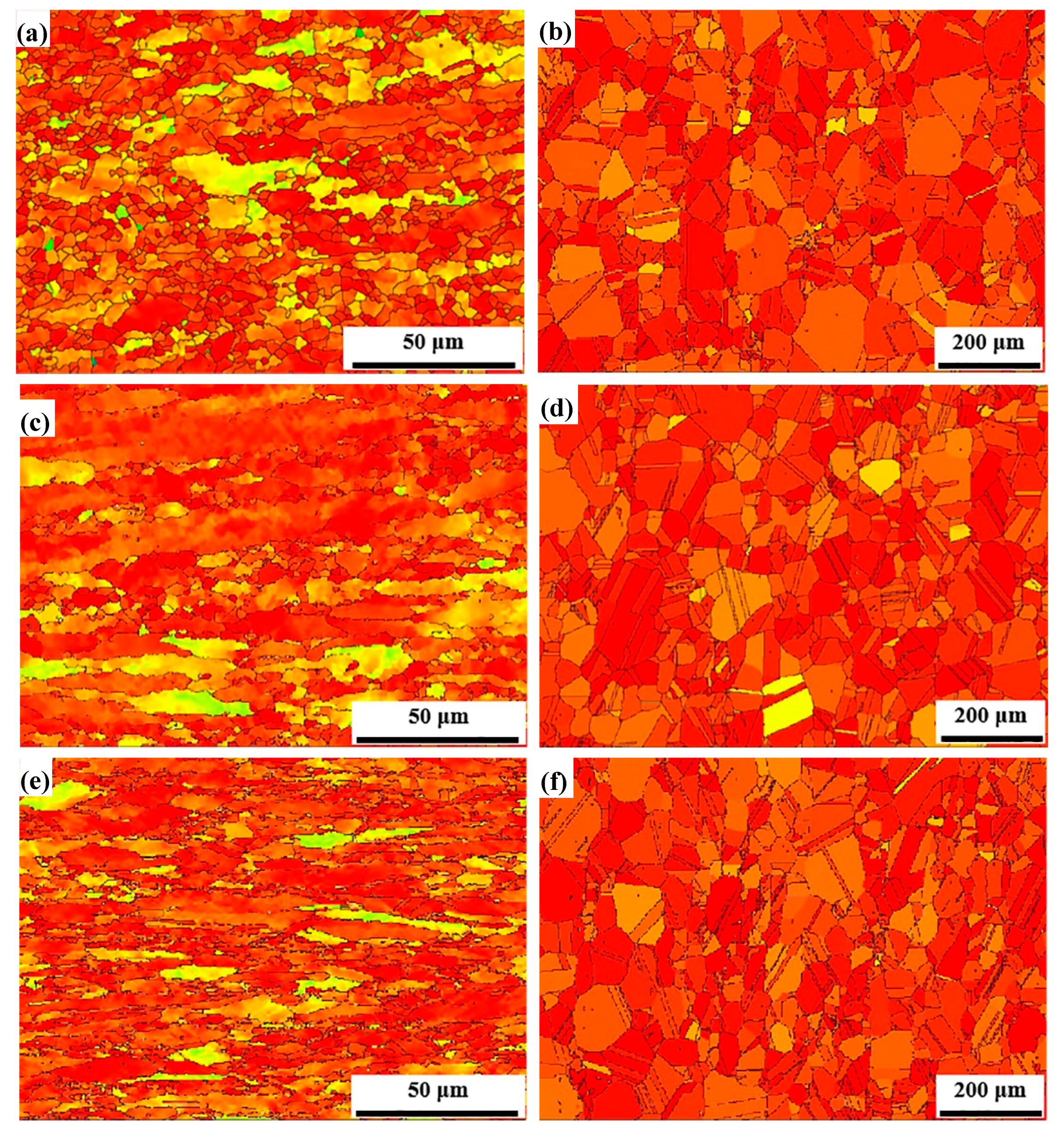

3.1. Microstructural Evolution

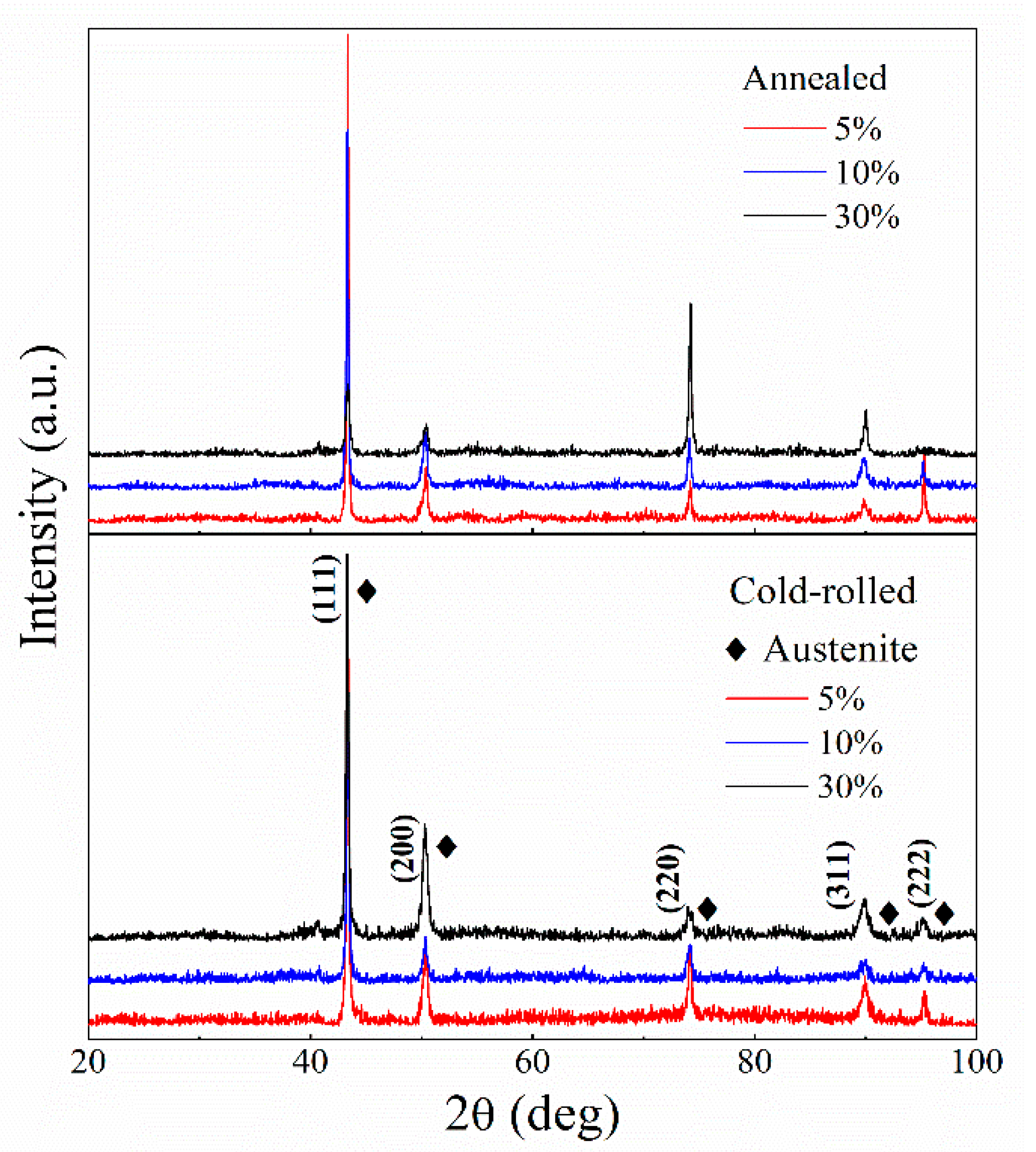

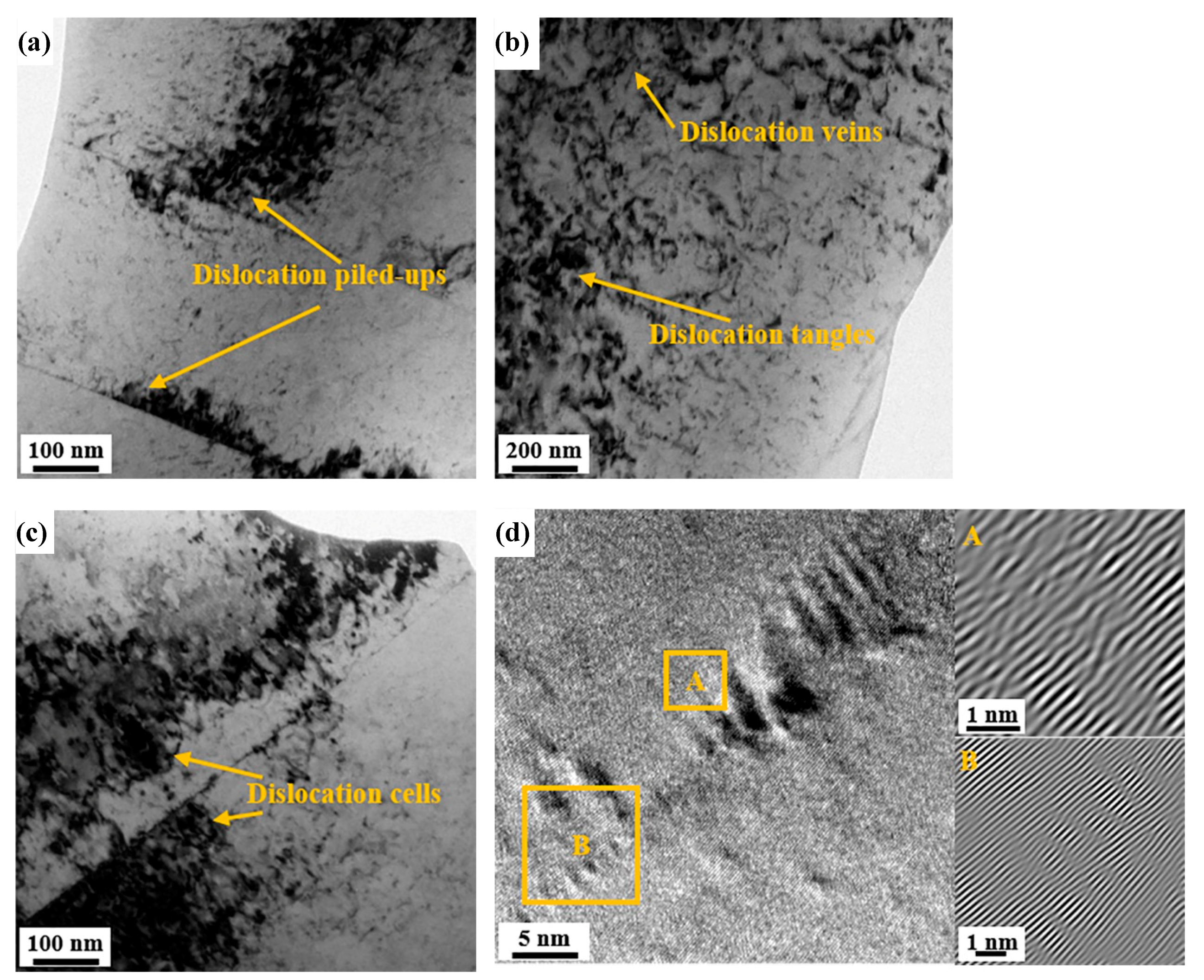

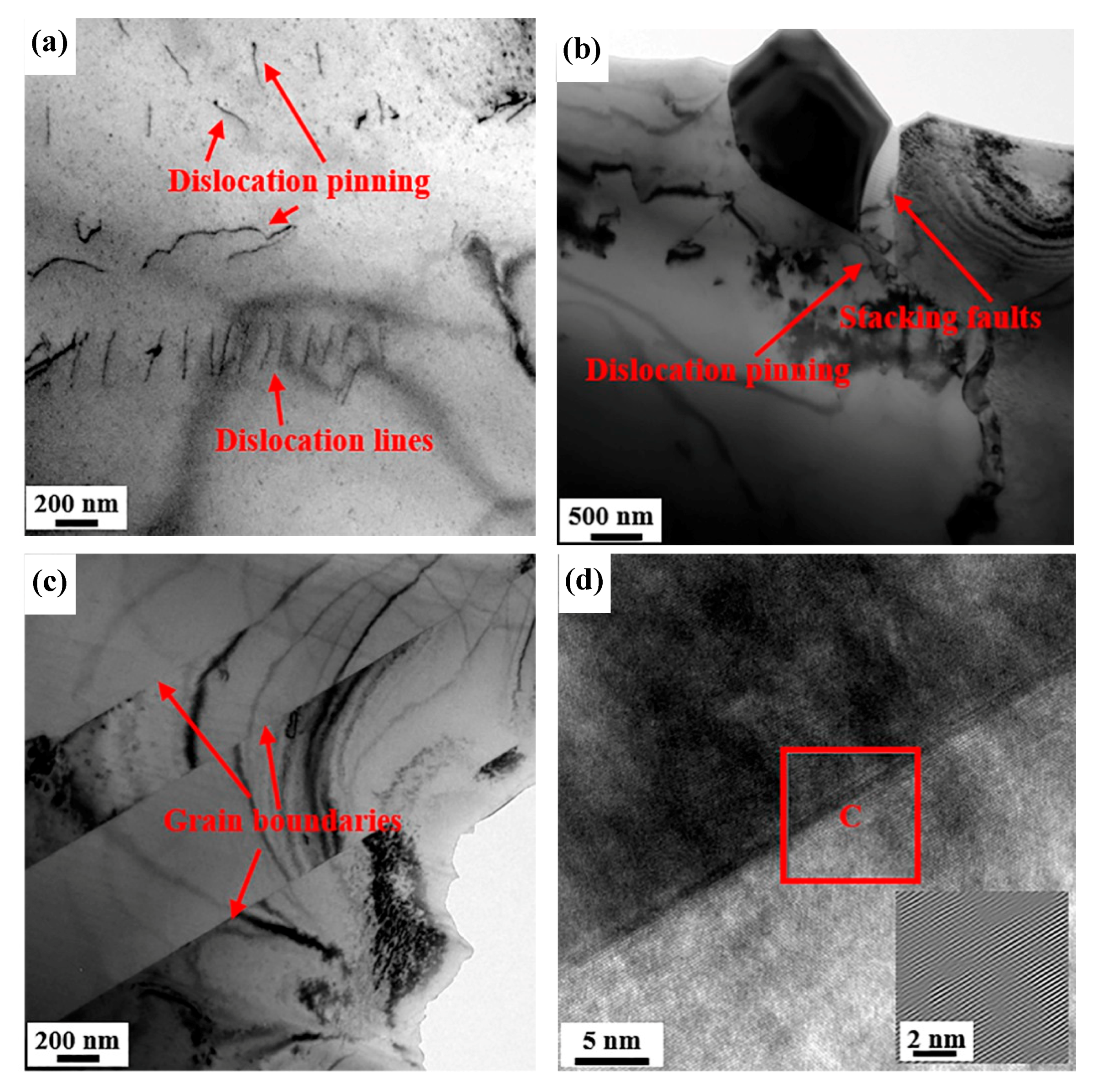

3.2. Dislocation Density and Characterization

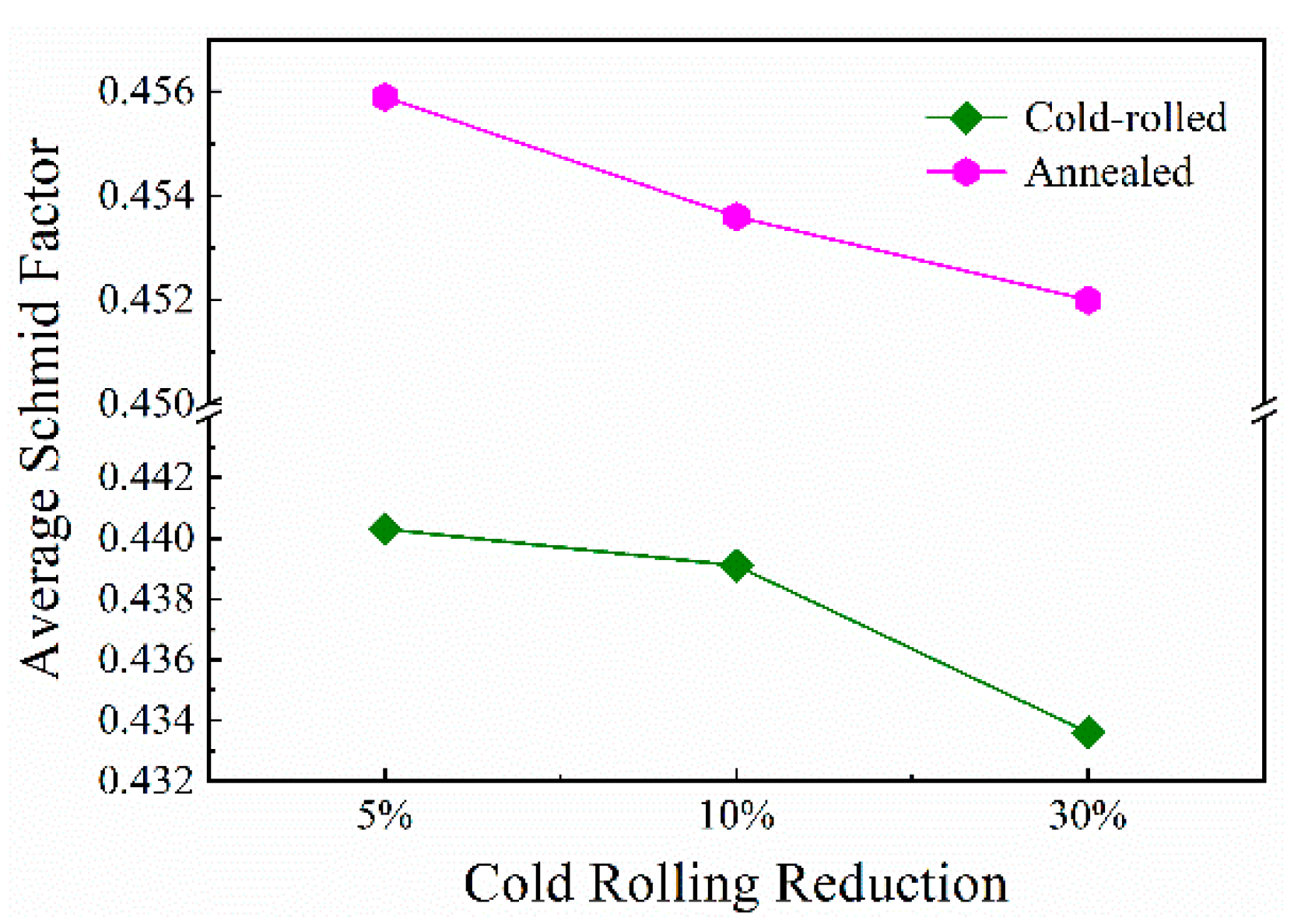

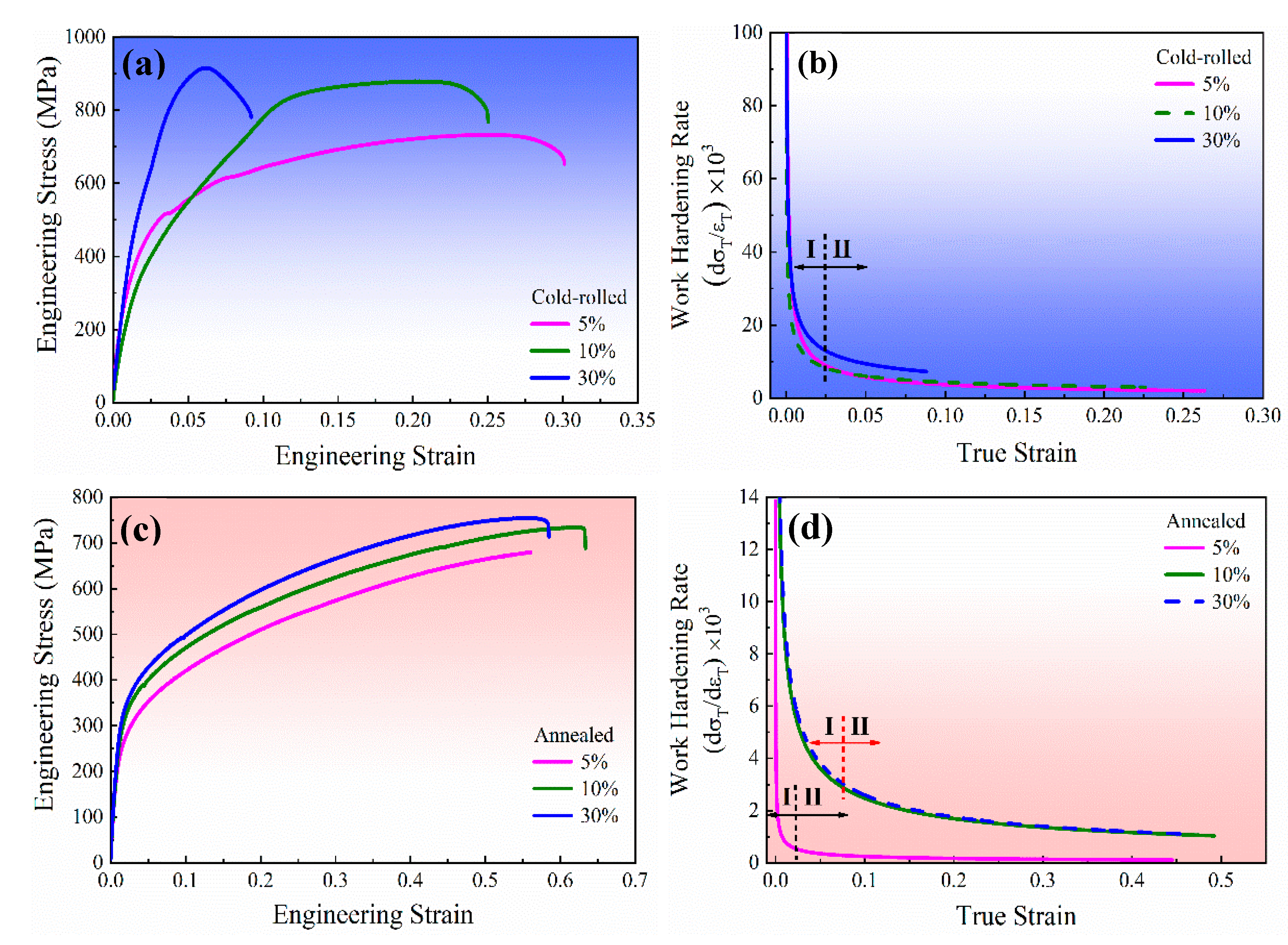

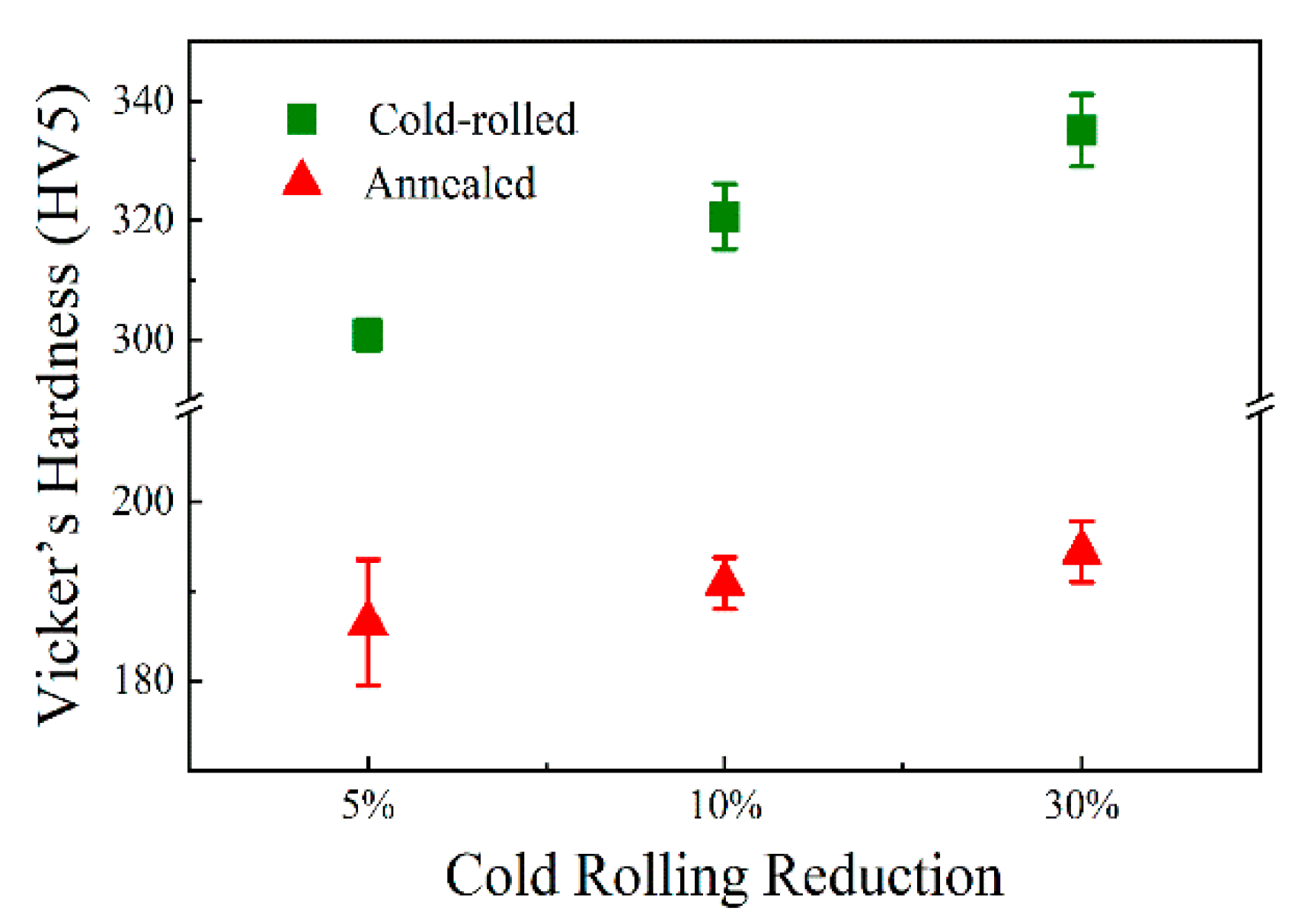

3.3. Schmid Factor and Mechanical Properties

4. Discussion

4.1. The Effect of Cold Rolling on Microstructural Evolution

4.2. Grain Boundary Strengthening and Dislocation Strengthening

5. Conclusions

- (1)

- The microstructure of AFA steel was significantly affected by the cold rolling. With the increase in cold-rolling reduction, the average grain size decreased. After annealing treatment, the grain aspect ratio declined, grains were gradually equiaxed and lots of twin boundaries formed.

- (2)

- Most grain boundaries were LAGBs which distributed below 15° after cold rolling, and the HAGBs were dominant and appeared as peaks around 59° after annealing treatment.

- (3)

- The dislocation density increased from 3.2 × 1014 m−2 to 8.02 × 1018 m−2 by increasing the reduction from 5% to 30%. The dislocations tangled, piled up and even formed cellular substructures. After annealing treatment, some stored dislocations decomposed and annihilated, and the dislocation density integrally decreased. However, the dislocation density was highest in the sample with 30% reduction.

- (4)

- Grain boundaries and dislocation strengthening mechanisms are dominant for the cold-deformed AFA steel. With the increase in cold-rolled deformation, the strength and hardness presented an increased trend in cold-rolled and annealed samples. The highest yield strength and hardness were 909 MPa and 335 HV of 30% cold-rolled samples, respectively. The strength properties decreased after annealing. The contribution of dislocations on strength was more than 60% in all samples.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Z.; Gao, Q.; Zhang, H.; Luo, S.-H.; Zhang, X.; Li, W.; Jiang, Y.; Li, H. EBSD analysis and mechanical properties of alumina-forming austenitic steel during hot deformation and annealing. Mater. Sci. Eng. A 2019, 755, 106–115. [Google Scholar] [CrossRef]

- Maziasz, P.J. Development of creep-resistant and oxidation-resistant austenitic stainless steels for high temperature applications. JOM 2017, 70, 66–75. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Brady, M.; Lu, Z.P.; Maziasz, P.J.; Liu, C.; Pint, B.A.; More, K.L.; Meyer, H.M.; Payzant, E.A. Creep-resistant, Al2O3-forming austenitic stainless steels. Science 2007, 316, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Wen, D.; Li, Z.; Jiang, B.; Wang, Q.; Chen, G.; Tang, R.; Zhang, R.; Dong, C.; Liaw, P. Effects of Nb/Ti/V/Ta on phase precipitation and oxidation resistance at 1073 K in alumina-forming austenitic stainless steels. Mater. Charact. 2018, 144, 86–98. [Google Scholar] [CrossRef]

- Wang, C.; Gao, Q.; Yuan, Y.; Zhang, H.; Zhang, J.; Wang, Q.; Qu, F. Microstructure evolutions of Ni-Ti-Nb-Al alloys with different Al addition. J. Alloy. Compd. 2017, 695, 2923–2929. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Muralidharan, G.; Brady, M. Development of L12-ordered Ni3(Al,Ti)-strengthened alumina-forming austenitic stainless steel alloys. Scr. Mater. 2013, 69, 816–819. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Takeyama, M.; Lu, Z.; Liu, C.; Evans, N.; Maziasz, P.J.; Brady, M. Alloying effects on creep and oxidation resistance of austenitic stainless steel alloys employing intermetallic precipitates. Intermetallics 2008, 16, 453–462. [Google Scholar] [CrossRef]

- Zhao, W.; Zhou, D.; Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Wang, X.; Lu, Z. Ultrahigh stability and strong precipitation strengthening of nanosized NbC in alumina-forming austenitic stainless steels subjecting to long-term high-temperature exposure. Mater. Sci. Eng. A 2018, 738, 295–307. [Google Scholar] [CrossRef]

- Trotter, G.; Rayner, G.; Baker, I.; Munroe, P. Accelerated precipitation in the AFA stainless steel Fe–20Cr–30Ni–2Nb–5Al via cold working. Intermetallics 2014, 53, 120–128. [Google Scholar] [CrossRef]

- Gao, Q.; Jiang, Y.; Liu, Z.; Zhang, H.; Jiang, C.; Zhang, X.; Li, H. Effects of alloying elements on microstructure and mechanical properties of Co–Ni–Al–Ti superalloy. Mater. Sci. Eng. A 2020, 779, 139139. [Google Scholar] [CrossRef]

- Kacher, J.; Eftink, B.; Cui, B.; Robertson, I. Dislocation interactions with grain boundaries. Curr. Opin. Solid State Mater. Sci. 2014, 18, 227–243. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Liu, Y.; Wu, Y.; Guo, Q.; Li, H.; Wang, H. Effect of annealing treatment on microstructure evolution and creep behavior of a multiphase Ni3Al-based superalloy. Mater. Sci. Eng. A 2019, 743, 623–635. [Google Scholar] [CrossRef]

- Golański, G.; Zieliński, A.; Sroka, M.; Słania, J. The effect of service on microstructure and mechanical properties of HR3C heat-resistant austenitic stainless steel. Materials 2020, 13, 1297. [Google Scholar] [CrossRef] [PubMed]

- Meyers, M.A.; Mishra, A.; Benson, D. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Xu, D.; Li, G.; Wan, X.; Misra, R.; Yu, J.; Zhang, Y.; Xu, G. The significant impact of cold deformation on structure-property relationship in phase reversion-induced stainless steels. Mater. Charact. 2018, 145, 157–171. [Google Scholar] [CrossRef]

- Hughes, D.; Hansen, N. Microstructure and strength of nickel at large strains. Acta Mater. 2000, 48, 2985–3004. [Google Scholar] [CrossRef]

- Wang, H.; Jing, H.; Zhao, L.; Han, Y.; Lv, X.; Xu, L. Dislocation structure evolution in 304L stainless steel and weld joint during cyclic plastic deformation. Mater. Sci. Eng. A 2017, 690, 16–31. [Google Scholar] [CrossRef]

- Dini, G.; Ueji, R.; Najafizadeh, A.; Monir-Vaghefi, S. Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 2010, 527, 2759–2763. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, H.; Li, H.; Zhang, X.; Qu, F.; Jiang, Y.; Liu, Z.; Jiang, C. Hot deformation of alumina-forming austenitic steel: EBSD study and flow behavior. J. Mater. Sci. 2019, 54, 8760–8777. [Google Scholar] [CrossRef]

- Gao, Q.; Qu, F.; Zhang, H.; Huo, Q. Austenite grain growth in alumina-forming austenitic steel. J. Mater. Res. 2016, 31, 1732–1740. [Google Scholar] [CrossRef]

- Ma, X.; Huang, C.; Moering, J.; Ruppert, M.; Höppel, H.-W.; Göken, M.; Narayan, J.; Zhu, Y. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Jedrychowski, M.; Tarasiuk, J.; Bacroix, B.; Wroński, S. Electron backscatter diffraction investigation of local misorientations and orientation gradients in connection with evolution of grain boundary structures in deformed and annealed zirconium. A new approach in grain boundary analysis. J. Appl. Crystallogr. 2013, 46, 483–492. [Google Scholar] [CrossRef]

- Kamaya, M. Measurement of local plastic strain distribution of stainless steel by electron backscatter diffraction. Mater. Charact. 2009, 60, 125–132. [Google Scholar] [CrossRef]

- Ashrafi, H.; Shamanian, M.; Emadi, R.; Ghassemali, E. Void formation and plastic deformation mechanism of a cold-rolled dual-phase steel during tension. Acta Met. Sin. Engl. Lett. 2019, 33, 299–306. [Google Scholar] [CrossRef]

- Takebayashi, S.; Kunieda, T.; Yoshinaga, N.; Ushioda, K.; Ogata, S. Comparison of the dislocation density in martensitic steels evaluated by some x-ray diffraction methods. ISIJ Int. 2010, 50, 875–882. [Google Scholar] [CrossRef]

- Pešička, J.; Kuzel, R.; Dronhofer, A.; Eggeler, G. The evolution of dislocation density during heat treatment and creep of tempered martensite ferritic steels. Acta Mater. 2003, 51, 4847–4862. [Google Scholar] [CrossRef]

- Renzetti, R.; Sandim, H.; Bolmaro, R.E.; Suzuki, P.A.; Möslang, A. X-ray evaluation of dislocation density in ODS-Eurofer steel. Mater. Sci. Eng. A 2012, 534, 142–146. [Google Scholar] [CrossRef]

- Stukowski, A.; Albe, K.; Farkas, D. Nanotwinned fcc metals: Strengthening versus softening mechanisms. Phys. Rev. B 2010, 82, 82. [Google Scholar] [CrossRef]

- Stoller, R.; Zinkle, S.J. On the relationship between uniaxial yield strength and resolved shear stress in polycrystalline materials. J. Nucl. Mater. 2000, 283, 349–352. [Google Scholar] [CrossRef]

- Ng, K.; Ngan, A. Breakdown of Schmid’s law in micropillars. Scr. Mater. 2008, 59, 796–799. [Google Scholar] [CrossRef]

- Graca, S.; Colaço, R.; Carvalho, P.R.; Vilar, R. Determination of dislocation density from hardness measurements in metals. Mater. Lett. 2008, 62, 3812–3814. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Lee, T.-H.; Shin, E.; Oh, C.-S.; Ha, H.-Y.; Kim, S.-J. Correlation between stacking fault energy and deformation microstructure in high-interstitial-alloyed austenitic steels. Acta Mater. 2010, 58, 3173–3186. [Google Scholar] [CrossRef]

- Wei, Y.; Qiao, S.; Lu, F.; Liu, W. Failure transition mechanism in creep rupture of modified casting 9Cr-1.5Mo-1Co welded joint. Mater. Des. 2016, 97, 268–278. [Google Scholar] [CrossRef]

- Kim, J.; De Cooman, B.C. Stacking fault energy and deformation mechanisms in Fe-xMn-0.6C-yAl TWIP steel. Mater. Sci. Eng. A 2016, 676, 216–231. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X.; Pantleon, W.; Winther, G. Grain orientation and dislocation patterns. Philos. Mag. 2006, 86, 3981–3994. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Y.; Li, C.; Xia, X.; Wu, J.; Li, H. Coarsening behavior of γ′ precipitates in the γ’+γ area of a Ni3Al-based alloy. J. Alloy. Compd. 2019, 771, 526–533. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, M.-C.; Unenbayar, T.; Zhao, Y.-C.; Xie, B.; Tian, Y.; Shan, Y.-Y.; Yang, K. Hot deformation behavior of a new nuclear use reduced activation ferritic/martensitic steel. Acta Met. Sin. Engl. Lett. 2018, 32, 825–834. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X.; Ueji, R.; Tsuji, N. Structure and strength after large strain deformation. Mater. Sci. Eng. A 2004, 387, 191–194. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D.; Hansen, N. Geometrically necessary, incidental and subgrain boundaries. Scr. Met. Mater. 1991, 25, 1557–1562. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.; Ma, Z. Enhanced strength and ductility of friction stir processed Cu–Al alloys with abundant twin boundaries. Scr. Mater. 2013, 68, 751–754. [Google Scholar] [CrossRef]

- Jang, M.-H.; Kang, J.-Y.; Jang, J.H.; Lee, T.-H.; Lee, C. Microstructure control to improve creep strength of alumina-forming austenitic heat-resistant steel by pre-strain. Mater. Charact. 2018, 137, 1–8. [Google Scholar] [CrossRef]

- Zhang, X.; Hansen, N.; Gao, Y.; Huang, X. Hall–Petch and dislocation strengthening in graded nanostructured steel. Acta Mater. 2012, 60, 5933–5943. [Google Scholar] [CrossRef]

- Seok, M.-Y.; Choi, I.-C.; Moon, J.; Kim, S.; Ramamurty, U.; Jang, J.-I. Estimation of the Hall–Petch strengthening coefficient of steels through nanoindentation. Scr. Mater. 2014, 87, 49–52. [Google Scholar] [CrossRef]

- Astafurov, S.; Maier, G.G.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Astafurova, E.G. The strain-rate dependence of the Hall-Petch effect in two austenitic stainless steels with different stacking fault energies. Mater. Sci. Eng. A 2019, 756, 365–372. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Grain size effect on strain hardening in twinning-induced plasticity steels. Scr. Mater. 2012, 66, 992–996. [Google Scholar] [CrossRef]

- Olmsted, D.L.; Foiles, S.M.; Holm, E. Survey of computed grain boundary properties in face-centered cubic metals: I. Grain boundary energy. Acta Mater. 2009, 57, 3694–3703. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Brady, M.; Santella, M.; Bei, H.; Maziasz, P.J.; Pint, B.A. Overview of strategies for high-temperature creep and oxidation resistance of alumina-forming austenitic stainless steels. Met. Mater. Trans. A 2010, 42, 922–931. [Google Scholar] [CrossRef]

- Zhao, B.; Fan, J.; Chen, Z.; Dong, X.; Sun, F.; Zhang, L. Evolution of precipitates in a Cu-containing alumina-forming austenitic steel after short-term mechanical tests. Mater. Charact. 2017, 125, 37–45. [Google Scholar] [CrossRef]

| Element | Fe | Cr | Ni | Al | Si | Mo | Nb | C | Mn | W | Cu | Ti | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | Bal | 11.16 | 20.54 | 3.96 | 0.14 | 2.25 | 2.02 | 0.06 | 2.06 | 0.05 | 0.05 | 0.013 | 0.04 |

| Sample | Cold-Rolled | Annealed | ||||

|---|---|---|---|---|---|---|

| 5% | 10% | 30% | 5% | 10% | 30% | |

| Recrystallized | 3.2 | 1.13 | 1.75 | 96.80 | 97.21 | 97.56 |

| Substructured | 23.15 | 8.91 | 1.98 | 2.98 | 2.59 | 2.28 |

| Deformed | 73.65 | 89.96 | 96.26 | 0.22 | 0.20 | 0.16 |

| Sample | Cold-rolled | Annealed | ||||

|---|---|---|---|---|---|---|

| 5% | 10% | 30% | 5% | 10% | 30% | |

| ε (%) | 0.12 | 0.13 | 0.19 | 0.062 | 0.07 | 0.129 |

| ρ (1014 m−2) | 3.2 | 3.76 | 8.02 | 0.854 | 1.08 | 1.25 |

| Sample | Cold-Rolled | Annealed | ||||

|---|---|---|---|---|---|---|

| 5% | 10% | 30% | 5% | 10% | 30% | |

| Yield strength (MPa) | 636 | 703 | 909 | 321.6 | 374 | 396 |

| Tensile strength (MPa) | 803 | 879.5 | 916.2 | 680.15 | 734.6 | 755 |

| Elongation (%) | 30 | 25.3 | 10.3 | 63.6 | 58.9 | 56 |

| Sample | Cold-Rolled | Annealed | ||||

|---|---|---|---|---|---|---|

| 5% | 10% | 30% | 5% | 10% | 30% | |

| σGB (MPa) | 164.16 | 218.77 | 240.39 | 56.74 | 57.95 | 58.45 |

| PσGB (%) | 25.81 | 31.12 | 26.45 | 17.64 | 15.49 | 14.76 |

| σd (MPa) | 393.55 | 426.6 | 623.12 | 203.31 | 229.69 | 249.29 |

| Pσd (%) | 61.87 | 60.68 | 68.55 | 63.22 | 61.41 | 62.95 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Gao, Q.; Zhang, H.; Liu, Z.; Li, H. Microstructure and Mechanical Properties of 4Al Alumina-Forming Austenitic Steel after Cold-Rolling Deformation and Annealing. Materials 2020, 13, 2767. https://doi.org/10.3390/ma13122767

Jiang C, Gao Q, Zhang H, Liu Z, Li H. Microstructure and Mechanical Properties of 4Al Alumina-Forming Austenitic Steel after Cold-Rolling Deformation and Annealing. Materials. 2020; 13(12):2767. https://doi.org/10.3390/ma13122767

Chicago/Turabian StyleJiang, Chenchen, Qiuzhi Gao, Hailian Zhang, Ziyun Liu, and Huijun Li. 2020. "Microstructure and Mechanical Properties of 4Al Alumina-Forming Austenitic Steel after Cold-Rolling Deformation and Annealing" Materials 13, no. 12: 2767. https://doi.org/10.3390/ma13122767

APA StyleJiang, C., Gao, Q., Zhang, H., Liu, Z., & Li, H. (2020). Microstructure and Mechanical Properties of 4Al Alumina-Forming Austenitic Steel after Cold-Rolling Deformation and Annealing. Materials, 13(12), 2767. https://doi.org/10.3390/ma13122767