Rheological Behavior of Polymer/Carbon Nanotube Composites: An Overview

Abstract

:1. Introduction

2. Rheological Behavior of Polymer/CNT Nanocomposites

2.1. Polycarbonate-Based Nanocomposites

2.2. Polyethylene-Based Nanocomposites

2.3. Polypropylene-Based Nanocomposites

2.4. Polystyrene-Based Nanocomposites

2.5. Polyamide-Based Nanocomposites

2.6. Biopolymer-Based Nanocomposites

3. Rheological Behavior of Polymer Blends Filled with CNTs

4. Conclusions

- Higher values of viscosity and dynamic modulus are obtained in the resulting nanocomposites, as compared to those in the unfilled matrices, and, with an increase in the filler loading, the formation of an interconnected network structure is reached at a critical filler content known as the rheological percolation threshold, which strongly depends on the structural characteristics of the nanotubes.

- The formed interconnected network structure of anisometric fillers leads to an apparent yield stress, which is recognizable in a non-terminal behavior resulting in the appearance of a plateau in the modulus curves at low frequencies.

- Usually, CNTs have a modest effect on the high-frequency response and a significant influence on the low-frequency response, indicating that the embedded nanotubes are able to influence the polymer’s relaxation dynamics at length scales longer than the entanglement distance. This finding implies a minimal impact of the embedded nanofiller on the polymer processability.

- CNTs affect the non-linear viscoelastic responses of the polymer matrices, causing an anticipation of the transition toward the non-linear viscoelastic region.

- When CNTs are incorporated in a polymer blend, a different rheological behavior can be observed, mainly depending on the preferential localization of the embedded nanofiller.

Funding

Conflicts of Interest

References

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharya, M. Polymer Nanocomposites—A Comparison between Carbon Nanotubes, Graphene, and Clay as Nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Coiai, S.; Passaglia, E.; Pucci, A.; Ruggeri, G. Nanocomposites Based on Thermoplastic Polymers and Functional Nanofiller for Sensor Applications. Materials 2015, 8, 3377–3427. [Google Scholar] [CrossRef] [Green Version]

- Jones, W.E., Jr.; Chiguma, J.; Johnson, E.; Pachamuthu, A.; Santos, D. Electrically and Thermally Conducting Nanocomposites for Electronic Applications. Materials 2010, 3, 1478–1496. [Google Scholar] [CrossRef]

- Rodenas, T.; Luz, I.; Prieto, G.; Seoane, B.; Miro, H.; Corma, A.; Kapteijn, F.; Llabrés i Xamena, F.X.; Gascon, J. Metal–organic framework nanosheets in polymer composite materials for gas separation. Nat. Mater. 2015, 14, 48–55. [Google Scholar] [CrossRef]

- Arrigo, R.; Ronchetti, S.; Montanaro, L.; Malucelli, G. Effects of the nanofiller size and aspect ratio on the thermal and rheological behavior of PEG nanocomposites containing boehmites or hydrotalcites. J. Therm. Anal. Calorim. 2018, 134, 1167–1180. [Google Scholar] [CrossRef]

- Thomassin, J.M.; Jérôme, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mat. Sci. Eng. R. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, M. Polymer/layered silicate nanocomposites: A review from preparation to processing. Progr. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Lazzara, G.; Cavallaro, G.; Panchal, A.; Fakhrullin, R.; Stavitskaya, A.; Vinokurov, V.; Lvov, Y. An assembly of organic-inorganic composites using halloysite clay nanotubes. Curr. Opin. Colloid Interface Sci. 2018, 35, 42–50. [Google Scholar] [CrossRef]

- Karatrantos, A.; Clarke, N.; Composto, R.J.; Winey, K.I. Polymer conformations in polymer nanocomposites containing spherical nanoparticles. Soft Matter 2015, 11, 382–388. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moniruzzaman, M.; Winey, K.I. Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Arrigo, R.; Carroccio, S.; Curcuruto, G.; Guenzi, M.; Gambarotti, C.; Filippone, G. Multi-functional Polyhedral Oligomeric Silsesquioxane-functionalized Carbon Nanotubes for photo-oxidative stable Ultra-High Molecular Weight Polyethylene-based Nanocomposites. Europ. Polym. J. 2016, 75, 525–537. [Google Scholar] [CrossRef]

- Ruoff, R.S.; Lorents, D.C. Mechanical and thermal properties of carbon nanotubes. Carbon 1995, 33, 925–930. [Google Scholar] [CrossRef]

- Song, K.; Zhang, Y.; Meng, J.; Green, E.C.; Tajaddod, N.; Li, H.; Minus, M.L. Structural Polymer-Based Carbon Nanotube Composite Fibers: Understanding the Processing–Structure–Performance Relationship. Materials 2013, 6, 2543–2577. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Belin, T.; Epron, F. Characterization methods of carbon nanotubes: A review. Mater. Sci. Eng. B Adv. 2005, 119, 105–118. [Google Scholar] [CrossRef]

- Szabó, A.; Perri, C.; Csató, A.; Giordano, G.; Vuono, D.; Nagy, J.B. Synthesis Methods of Carbon Nanotubes and Related Materials. Materials 2010, 3, 3092–3140. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Janas, D. Towards monochiral carbon nanotubes: A review of progress in the sorting of single-walled carbon nanotubes. Mater. Chem. Front. 2018, 2, 36–63. [Google Scholar] [CrossRef]

- Green, M.J.; Behabtu, N.; Pasquali, M.; Adams, W.W. Nanotubes as polymers. Polymer 2009, 50, 4979–4997. [Google Scholar] [CrossRef] [Green Version]

- Thostenson, E.K.; Ren, Z.; Chou, T.W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef] [Green Version]

- Bikiaris, D. Microstructure and Properties of Polypropylene/Carbon Nanotube Nanocomposites. Materials 2010, 3, 2884–2946. [Google Scholar] [CrossRef]

- Banerjee, J.; Dutta, K. Melt-mixed carbon nanotubes/polymer nanocomposites. Polym. Compos. 2019, 40, 4473–4488. [Google Scholar] [CrossRef]

- Olek, M.; Ostrander, J.; Jurga, S.; Möhwald, H.; Kotov, N.; Kempa, K.; Giersig, M. Layer-by-Layer Assembled Composites from Multiwall Carbon Nanotubes with Different Morphologies. Nano Lett. 2004, 4, 1889–1895. [Google Scholar] [CrossRef]

- Brzeziński, M.; Biela, T. Polylactide nanocomposites with functionalized carbon nanotubes and their stereocomplexes: A focused review. Mater. Lett. 2014, 121, 244–250. [Google Scholar] [CrossRef]

- Basheer, B.V.; George, J.J.; Siengchin, S.; Parameswaranpillai, J. Polymer grafted carbon nanotubes—Synthesis, properties, and applications: A review. Nano Struct. Nano Objects 2020, 22, 100429. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Progr. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Wang, P.H.; Gulgunje, P.; Ghoshal, S.; Verghese, N.; Kumar, S. Rheological behavior of polypropylene nanocomposites with tailored polymer/multiwall carbon nanotubes interface. Polym. Compos. 2019, 59, 1763–1777. [Google Scholar] [CrossRef]

- Du, F.; Scogna, R.C.; Zhou, W.; Brand, S.; Fischer, J.E.; Winey, K.I. Nanotube Networks in Polymer Nanocomposites: Rheology and Electrical Conductivity. Macromolecules 2004, 37, 9048–9055. [Google Scholar] [CrossRef]

- Hu, G.; Zhao, C.; Zhang, S.; Yang, M.; Wang, Z. Low percolation thresholds of electrical conductivity and rheology in poly (ethylene terephthalate) through the networks of multi-walled carbon nanotubes. Polymer 2006, 47, 480–488. [Google Scholar] [CrossRef]

- Isayev, A.I.; Kumar, R.; Lewis, T.M. Ultrasound assisted twin screw extrusion of polymer–nanocomposites containing carbon nanotubes. Polymer 2009, 50, 250–260. [Google Scholar] [CrossRef]

- Hassanabadi, H.M.; Wilhelm, M.; Rodrigue, D. A rheological criterion to determine the percolation threshold in polymer nano-composites. Rheol Acta 2014, 53, 869–882. [Google Scholar] [CrossRef]

- Jyoti, J.; Singh, B.P.; Rajput, S.; Singh, V.N.; Dhakate, S.R. Detailed dynamic rheological studies of multiwall carbon nanotube-reinforced acrylonitrile butadiene styrene composite. J. Mater. Sci. 2016, 51, 2643–2652. [Google Scholar] [CrossRef]

- Ke, K.; Wanga, Y.; Liu, X.Q.; Cao, J.; Luo, Y.; Yang, W.; Xie, B.H.; Yang, M.B. A comparison of melt and solution mixing on the dispersion of carbon nanotubes in a poly (vinylidene fluoride) matrix. Compos. Part B Eng. 2012, 43, 1425–1432. [Google Scholar] [CrossRef]

- Wu, D.; Wu, L.; Zhou, W.; Sun, Y.; Zhang, M. Relations between the aspect ratio of carbon nanotubes and the formation of percolation networks in biodegradable polylactide/carbon nanotube composites. J. Polym. Sci. Polym. Phys. 2010, 48, 479–489. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, W.; Zeng, X.; Guo, X.; Zhang, Y.; Liu, P.; Ma, Y.; Zhang, Y. Effects of the filler size on the electrical percolation threshold of carbon black–carbon nanotube–polymer composites. J. Appl. Polym. Sci. 2018, 135, 46517. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Pan, F.; Zhang, J. A Numerical Study on Electrical Percolation of Polymer-Matrix Composites with Hybrid Fillers of Carbon Nanotubes and Carbon Black. J. Nanomater. 2014, 2014, 614797. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Ma, P.C.; Chow, W.S.; To, C.K.; Tang, B.Z.; Kim, J.K. Correlations between Percolation Threshold, Dispersion State, and Aspect Ratio of Carbon Nanotubes. Adv. Funct. Mater. 2007, 17, 3207–3215. [Google Scholar] [CrossRef]

- Ke, K.; Wang, Y.; Luo, Y.; Yang, W.; Xie, B.H.; Yang, M.B. Evolution of agglomerate structure of carbon nanotubes in multi-walled carbon nanotubes/polymer composite melt: A rheo-electrical study. Compos. Part B Eng. 2012, 43, 3281–3287. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Ahir, S.V.; Terentjev, E.M. Dispersion rheology of carbon nanotubes in a polymer matrix. Phys. Rev. B Condens. Matter 2006, 73, 125422. [Google Scholar] [CrossRef] [Green Version]

- Salzano de Luna, M.; Pellegrino, L.; Daghetta, M.; Mazzocchia, C.V.; Acierno, D.; Filippone, G. Importance of the morphology and structure of the primary aggregates for the dispersibility of carbon nanotubes in polymer melts. Compos. Sci. Technol. 2013, 85, 17–22. [Google Scholar] [CrossRef] [Green Version]

- Dintcheva, N.T.; Arrigo, R.; Nasillo, G.; Caponetti, E.; La Mantia, F.P. Effect of the Nanotube Aspect Ratio and Surface Functionalization on the Morphology and Properties of Multiwalled Carbon Nanotube Polyamide-Based Fibers. J. Appl. Polym. Sci. 2013, 129, 2479–2489. [Google Scholar] [CrossRef]

- Zhang, H.; Quan, L.; Shi, F.; Li, C.; Liu, H.; Xu, L. Rheological Behavior of Amino-Functionalized Multi-Walled Carbon Nanotube/Polyacrylonitrile Concentrated Solutions and Crystal Structure of Composite Fibers. Polymers 2018, 10, 186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chatterjee, T.; Krishnamoorti, R. Rheology of Polymer Carbon Nanotubes Composites. Soft Matter 2013, 9, 9515–9529. [Google Scholar] [CrossRef] [PubMed]

- Pötschke, P.; Bhattacharyya, A.R.; Janke, A.; Goering, H. Melt mixing of polycarbonate /multi-wall carbon nanotube composites. Compos. Interfaces 2003, 10, 389–404. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, J.; He, J.; Hu, G. Gelation in carbon nanotube/polymer composites. Polymer 2003, 44, 7529–7532. [Google Scholar] [CrossRef]

- Abdel-Goad, M.; Pötschke, P. Rheological characterization of melt processed polycarbonate multiwalled carbon nanotube composites. J. Non Newto. Fluid Mech. 2005, 128, 2–6. [Google Scholar] [CrossRef]

- Pötschke, P.; Fornes, T.D.; Paul, D.R. Rheological behavior of multiwalled carbon nanotube/polycarbonate composites. Polymer 2002, 43, 3247–3255. [Google Scholar] [CrossRef]

- Pötschke, P.; Abdel-Goad, M.; Alig, I.; Dudkin, S.; Lellinger, D. Rheological and dielectrical characterization of melt mixed polycarbonate-multiwalled carbon nanotube composites. Polymer 2004, 45, 8863–8870. [Google Scholar] [CrossRef]

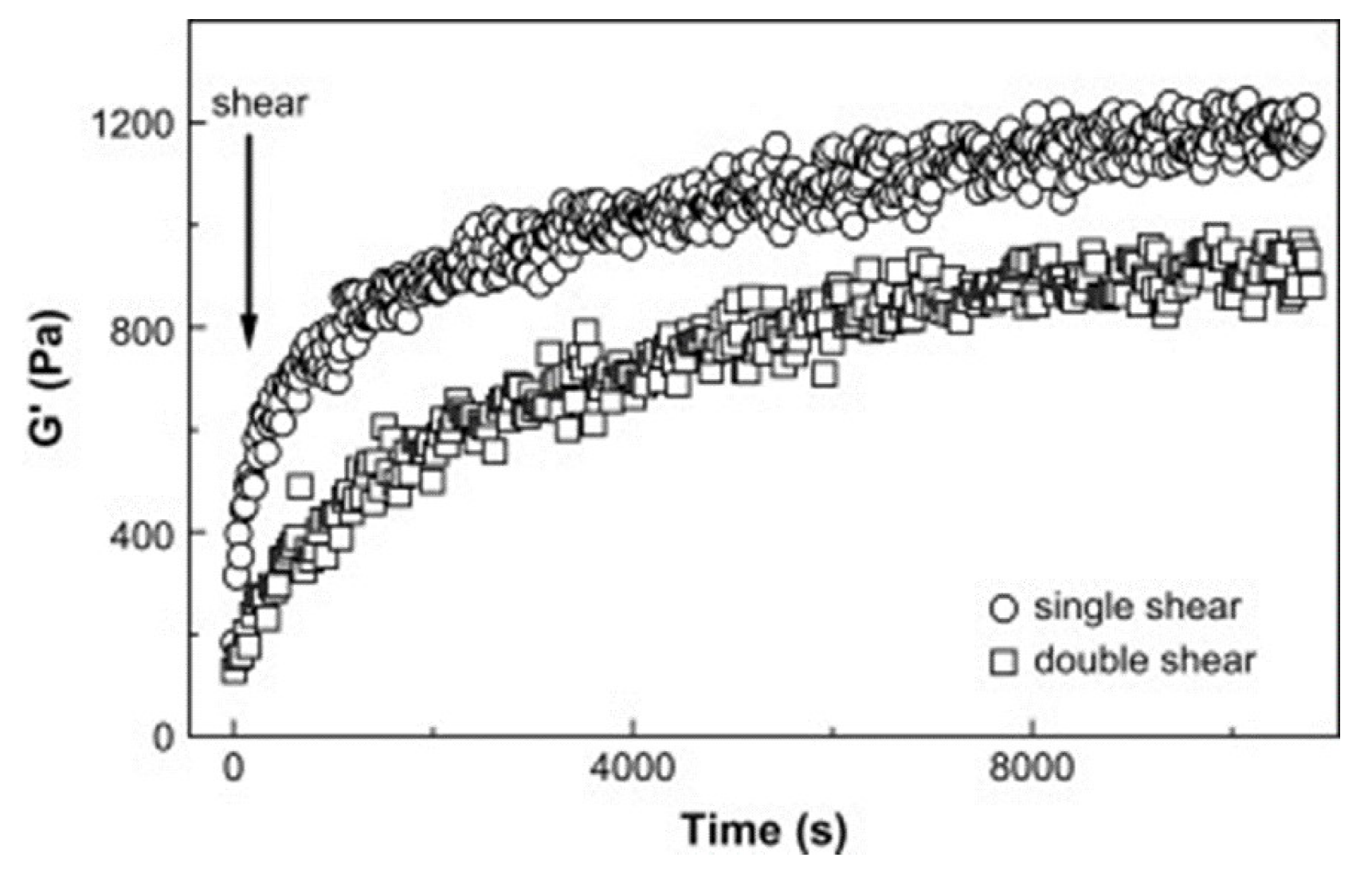

- Alig, I.; Skipa, T.; Lellinger, D.; Pötschke, P. Destruction and formation of a carbon nanotube network in polymer melts: Rheology and conductivity spectroscopy. Polymer 2008, 49, 3524–3532. [Google Scholar] [CrossRef]

- Alig, I.; Skipa, T.; Engel, M.; Lellinger, D.; Pegel, S.; Pötschke, P. Electrical conductivity recovery in carbon nanotube–polymer composites after transient shear. Phys. Status Solid B 2007, 244, 4223–4226. [Google Scholar] [CrossRef]

- Alig, I.; Skipa, T.; Lellinger, D.; Bierdel, M.; Meyer, H. Dynamic percolation of carbon nanotube agglomerates in a polymer matrix: Comparison of different model approaches. Phys. Status Solid B 2008, 245, 2264–2267. [Google Scholar] [CrossRef]

- Abbasi, S.; Carreau, P.J.; Derdouri, A.; Moan, M. Rheological properties and percolation in suspensions of multiwalled carbon nanotubes in polycarbonate. Rheol. Acta 2009, 48, 943–959. [Google Scholar] [CrossRef]

- Abbasi, S.; Carreau, P.J.; Derdouri, A. Flow induced orientation of multiwalled carbon nanotubes in polycarbonate nanocomposites: Rheology, conductivity and mechanical properties. Polymer 2010, 51, 922–935. [Google Scholar] [CrossRef] [Green Version]

- Zeiler, R.; Handge, U.A.; Dijkstra, D.J.; Meyer, H.; Altstädt, V. Influence of molar mass and temperature on the dynamics of network formation in polycarbonate/carbon nanotubes composites in oscillatory shear flows. Polymer 2011, 52, 430–442. [Google Scholar] [CrossRef]

- Mun, S.C.; Kim, M.; Prakashan, K.; Jung, H.J.; Son, Y.; Park, O.O. A new approach to determine rheological percolation of carbon nanotubes in microstructured polymer matrices. Carbon 2014, 67, 64–71. [Google Scholar] [CrossRef]

- Zhang, Q.; Rastogi, S.; Chen, D.; Lippits, D.; Lemstra, P.J. Low percolation threshold in single-walled carbon nanotube/high density polyethylene composites prepared by melt processing technique. Carbon 2006, 44, 778–785. [Google Scholar] [CrossRef]

- Zhang, Q.; Lippits, D.R.; Rastogi, S. Dispersion and Rheological Aspects of SWNTs in Ultrahigh Molecular Weight Polyethylene. Macromolecules 2006, 39, 658–666. [Google Scholar] [CrossRef]

- Vega, J.F.; Martínez-Salazar, J.; Trujillo, M.; Arnal, M.L.; Müller, A.J.; Bredeau, S.; Dubois, P. Rheology, Processing, Tensile Properties, and Crystallization of Polyethylene/Carbon Nanotube Nanocomposites. Macromolecules 2009, 42, 4719–4727. [Google Scholar] [CrossRef]

- Patil, N.; Balzano, L.; Portale, G.; Rastogi, S. Influence of Nanoparticles on the Rheological Behaviour and Initial Stages of Crystal Growth in Linear Polyethylene. Macromol. Chem. Phys. 2009, 210, 2174–2187. [Google Scholar] [CrossRef]

- Xiao, K.Q.; Zhang, L.C.; Zarudi, I. Mechanical and Rheological Properties of Carbon Nanotube-Reinforced Polyethylene composites. Compos. Sci. Technol. 2007, 67, 177–182. [Google Scholar] [CrossRef]

- Vega, J.F.; Da Silva, J.; Vicente-Alique, E.; Núñez-Ramírez, R.; Trujillo, M.; Arnal, M.L.; Müller, A.J.; Dubois, P.; Martínez-Salazar, J. Influence of Chain Branching and Molecular Weight on Melt Rheology and Crystallization of Polyethylene/Carbon Nanotube Nanocomposites. Macromolecules 2014, 47, 5668–5681. [Google Scholar] [CrossRef]

- Nobile, M.R.; Simon, G.P.; Valentino, O.; Morcom, M. Rheological and Structure Investigation of Melt Mixed Multi-Walled Carbon Nanotube/PE Composites. Macromol. Symp. 2007, 47, 78–87. [Google Scholar] [CrossRef]

- Nobile, M.R.; Valentino, O.; Morcom, M.; Simon, G.P.; Landi, G.; Neitzert, H.C. The Effect of the Nanotube Oxidation on the Rheological and Electrical Properties of CNT/HDPE Nanocomposites. Polym. Eng. Sci. 2017, 57, 665–673. [Google Scholar] [CrossRef]

- Arrigo, R.; Teresi, R.; Gambarotti, C.; Parisi, F.; Lazzara, G.; Dintcheva, N. Sonication-Induced Modification of Carbon Nanotubes: Effect on the Rheological and Thermo-Oxidative Behaviour of Polymer-Based Nanocomposites. Materials 2018, 11, 383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, B.; Jiang, Y.; Zhu, A. A novel modification of carbon nanotubes for improving the electrical and mechanical properties of polyethylene composites. Polym. Test 2019, 74, 72–76. [Google Scholar] [CrossRef]

- Song, Y.; Guan, A.; Zeng, L.; Zheng, Q. Time-concentration superpositioning principle accounting for the reinforcement and dissipation of high-density polyethylene composites melts. Compos. Sci. Technol. 2017, 151, 104–108. [Google Scholar] [CrossRef]

- Wang, Y.; Lv, F.; Song, Y.; Yang, Y.; Cao, Y.; Wang, J.; Li, C.; Wang, W. A facile rheological approach for the evaluation of “super toughness point” of compatibilized HDPE / MWCNT nanocomposites. Polym. Test 2020, 81, 106280. [Google Scholar] [CrossRef]

- Wu, P.; Luo, X.; Zhang, T.; Yang, Q. Contribution of oriented structure and rigid nanofillers to mechanical enhancement of die-drawn PP/MWCNT composites. Polym. Test 2020, 81, 106165. [Google Scholar] [CrossRef]

- Zhong, J.; Isayev, A.I. Ultrasonically assisted compounding of CNT with polypropylenes of different molecular weights. Polymer 2016, 107, 130–146. [Google Scholar] [CrossRef]

- Menzer, K.; Krause, B.; Boldt, R.; Kretzschmar, B.; Weidisch, R.; Pötschke, P. Percolation behaviour of multiwalled carbon nanotubes of altered length and primary agglomerate morphology in melt mixed isotactic polypropylene-based composites. Compos. Sci. Technol. 2011, 71, 1936–1943. [Google Scholar] [CrossRef]

- Gentile, G.; Ambrogi, V.; Cerruti, P.; Di Maio, R.; Nasti, G.; Carfagna, C. Pros and cons of melt annealing on the properties of MWCNT/polypropylene composites. Polym. Degrad. Stab. 2014, 110, 56–64. [Google Scholar] [CrossRef]

- Fernandez, M.; Huegun, A.; Santamaria, A. Relevance of Rheology on the Properties of PP/MWCNT Nanocomposites Elaborated with Different Irradiation/Mixing Protocols. Fluids 2019, 4, 7. [Google Scholar] [CrossRef] [Green Version]

- Teng, C.C.; Maa, C.C.M.; Huang, Y.W.; Yuen, S.M.; Wenga, C.C.; Chen, C.H.; Su, S.F. Effect of MWCNT content on rheological and dynamic mechanical properties of multiwalled carbon nanotube/polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1869–1875. [Google Scholar] [CrossRef]

- Thiébaud, F.; Gelin, J.C. Characterization of rheological behaviors of polypropylene/carbon nanotubes composites and modeling their flow in a twin-screw mixer. Compos. Sci. Technol. 2010, 70, 647–656. [Google Scholar] [CrossRef] [Green Version]

- Gupta, J.; Wan, C.; Haddleton, D.M.; McNally, T. Plasticisation and compatibilisation of poly(propylene) with poly (lauryl acrylate) surface modified MWCNTs. Polymer 2017, 133, 89–101. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Gu, S.Y.; Zhang, Y.H.; Ren, J. Effect of Dispersion on Rheological and Mechanical Properties of Polypropylene/Carbon Nanotubes Nanocomposites. Polym. Eng. Sci. 2012, 52, 1485–1494. [Google Scholar] [CrossRef]

- Pan, Y.; Li, L. Percolation and gel-like behavior of multiwalled carbon nanotube/polypropylene composites influenced by nanotube aspect ratio. Polymer 2014, 54, 1218–1226. [Google Scholar] [CrossRef]

- Wang, P.H.; Sarkar, S.; Gulgunje, P.; Verghese, N. Structure and rheological behavior of polypropylene interphase at high carbon nanotube concentration. Polymer 2018, 150, 10–25. [Google Scholar] [CrossRef]

- Kota, A.K.; Cipriano, B.H.; Duesterberg, M.K.; Gershon, A.L.; Powell, D.; Raghavan, S.R.; Bruck, H.A. Electrical and Rheological Percolation in Polystyrene/MWCNT. Nanocomposites. Macromolecules 2007, 40, 7400–7406. [Google Scholar] [CrossRef]

- Cipiriano, B.H.; Kashiwagi, T.; Raghavan, S.R.; Yang, Y.; Grulke, E.A.; Yamamoto, K.; Shields, J.R.; Douglas, J.F. Effects of aspect ratio of MWNT on the flammability properties of polymer nanocomposites. Polymer 2007, 48, 6086–6096. [Google Scholar] [CrossRef]

- Zhang, Q.; Fang, F.; Zhao, X.; Li, Y.; Zhu, M.; Chen, D. Use of Dynamic Rheological Behavior to Estimate the Dispersion of Carbon Nanotubes in Carbon Nanotube/Polymer Composites. J. Phys. Chem. B 2008, 112, 12606–12611. [Google Scholar] [CrossRef]

- Huang, C.L.; Wang, C. Rheological and conductive percolation laws for syndiotactic polystyrene composites filled with carbon nanocapsules and carbon nanotubes. Carbon 2011, 49, 2334–2344. [Google Scholar] [CrossRef]

- Arrigo, R.; Morici, E.; Cammarata, M.; Dintcheva, N. Rheological percolation threshold in high viscosity polymer/CNTs nanocomposites. J. Eng. Mech. 2017, 143, D4016006. [Google Scholar] [CrossRef]

- Amr, I.T.; Al-Amer, A.; Thomas, S.; Al-Harthi, M.; Girei, S.A.; Sougrat, R.; Atieh, M.A. Effect of acid treated carbon nanotubes on mechanical, rheological and thermal properties of polystyrene nanocomposites. Compos. Part B Eng. 2011, 42, 1554–1561. [Google Scholar] [CrossRef]

- Mitchell, C.A.; Bahr, J.L.; Arepalli, S.; Tour, J.M.; Krishnamoorti, R. Dispersion of Functionalized Carbon Nanotubes in Polystyrene. Macomolecules 2002, 35, 8825–8830. [Google Scholar] [CrossRef]

- Kota, A.K.; Cipriano, B.H.; Powell, D.; Raghavan, S.R.; Bruck, H.A. Quantitative characterization of the formation of an interpenetrating phase composite in polystyrene from the percolation of multiwalled carbon nanotubes. Nanotechnology 2007, 18, 505705. [Google Scholar] [CrossRef] [Green Version]

- McClory, C.; Pötschke, P.; McNally, T. Influence of Screw Speed on Electrical and Rheological Percolation of Melt-Mixed High-Impact Polystyrene/MWCNT Nanocomposites. Macromol. Mater. Eng. 2011, 296, 59–69. [Google Scholar] [CrossRef]

- Faraguna, F.; Pötschke, P.; Pionteck, J. Preparation of polystyrene nanocomposites with functionalized carbon nanotubes by melt and solution mixing: Investigation of dispersion, melt rheology, electrical and thermal properties. Polymer 2017, 132, 325–341. [Google Scholar] [CrossRef]

- Kamkar, M.; Sultana, S.M.N.; Pawar, S.P.; Eshraghian, A.; Erfanian, E.; Sundararaj, E. The key role of processing in tuning nonlinear viscoelastic properties and microwave absorption in CNT-based polymer nanocomposites. Mater. Today Commun. 2020, 24, 101010. [Google Scholar] [CrossRef]

- Marcourt, M.; Cassagnau, P.; Fulchiron, R.; Rousseaux, D.; Lhost, O.; Karam, S. High Impact Polystyrene/CNT nanocomposites: Application of volume segregation strategy and behavior under extensional deformation. Polymer 2018, 157, 156–165. [Google Scholar] [CrossRef]

- Wang, B.; Sun, G.; He, X.; Liu, J. The Effect of Multiwall Carbon Nanotube on the Crystallization, Morphology, and Rheological Properties of Nylon1010 Nanocomposites. Polym. Eng. Sci. 2007, 47, 1610–1620. [Google Scholar] [CrossRef]

- Wang, M.; Wang, W.; Liu, T.; Zhang, W.D. Melt rheological properties of nylon 6/multi-walled carbon nanotube composites. Compos. Sci. Technol. 2008, 68, 2498–2502. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; Van den Eynde, M.; Kruth, J.P.; Goderis, B.; Van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Verkinderen, O.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.P. Effect of PA12 powder reuse on coalescence behaviour and microstructure of SLS parts. Eur. Polym. J. 2017, 92, 250–262. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.M.; Song, M. Improving the mechanical properties of saler-sintered polyamide 12 through incorporation of carbon nanotubes. Polym. Eng. Sci. 2003, 53, 1937–1946. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.M.; Song, M.; Okamoto, M. Influence of carbon nanotubes on the rheology and dynamic mechanical properties of polyamide-12 for laser sintering. Polym. Test 2014, 36, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H.; Lee, S.G.; Kim, S.H. Isothermal crystallization behavior and mechanical properties of polylactide/carbon nanotube nanocomposites. Compos. Part A Appl. Sci. Manuf. 2013, 46, 11–18. [Google Scholar] [CrossRef]

- Xu, Z.; Niu, Y.; Yang, L.; Xie, W.; Li, H.; Gan, Z.; Wang, Z. Morphology, rheology and crystallization behavior of polylactide composites prepared through addition of five-armed star polylactide grafted multiwalled carbon nanotubes. Polymer 2010, 51, 730–737. [Google Scholar] [CrossRef]

- Wu, D.; Wu, L.; Zhang, M.; Zhao, Y. Viscoelasticity and thermal stability of polylactide composites with various functionalized carbon nanotubes. Polym. Degrad. Stab. 2008, 93, 1577–1589. [Google Scholar] [CrossRef]

- Pötschke, P.; Villmow, T.; Krause, B. Melt mixed PCL/MWCNT composites prepared at different rotation speeds: Characterization of rheological, thermal, and electrical properties, molecular weight, MWCNT macrodispersion, and MWCNT length distribution. Polymer 2013, 54, 3071–3078. [Google Scholar] [CrossRef]

- Vega, J.F.; Fernandez-Alcazar, J.; Lopez, J.V.; Michell, R.M.; Perez-Camargo, R.A.; Ruelle, B.; Martınez-Salazar, J.; Arnal, M.L.; Dubois, P.; Muller, A.J. Competition Between Supernucleation and Plasticization in the Crystallization and Rheological Behavior of PCL/CNT-Based Nanocomposites and Nanohybrids. J. Polym. Sci. Polym. Phys. 2017, 55, 1310–1325. [Google Scholar] [CrossRef] [Green Version]

- Salzano de Luna, M.; Filippone, G. Effects of nanoparticles on the morphology of immiscible polymer blends–Challenges and opportunities. Eur. Polym. J. 2016, 79, 198–218. [Google Scholar] [CrossRef]

- Altobelli, R.; Salzano de Luna, M.; Filippone, G. Interfacial crowding of nanoplatelets in co-continuous polymer blends: Assembly, elasticity and structure of the interfacial nanoparticle network. Soft Matter 2017, 13, 6465–6473. [Google Scholar] [CrossRef] [PubMed]

- Fenouillot, F.; Cassagnau, P.; Majestè, J.C. Uneven distribution of nanoparticles in immiscible fluids: Morphology development in polymer blends. Polymer 2009, 50, 1333–1350. [Google Scholar] [CrossRef] [Green Version]

- Otero-Navas, I.; Arjmand, M.; Sundararaj, U. Carbon nanotube induced double percolation in polymer blends: Morphology, rheology and broadband dielectric properties. Polymer 2017, 114, 122–134. [Google Scholar] [CrossRef]

- Göldel, A.; Kasaliwal, G.R.; Pötschke, P.; Heinrich, G. The kinetics of CNT transfer between immiscible blend phases during melt mixing. Polymer 2012, 53, 411–421. [Google Scholar] [CrossRef]

- Azizi, S.; Azizi, M.; Sabetzadeh, M. The Role of Multiwalled Carbon Nanotubes in the Mechanical, Thermal, Rheological, and Electrical Properties of PP/PLA/MWCNTs Nanocomposites. J. Compos. Sci. 2019, 3, 64. [Google Scholar] [CrossRef] [Green Version]

- Poothanari, M.A.; Xavier, P.; Bose, S.; Kalarikkal, N.; Komalan, C.; Thomas, S. Compatibilising action of multiwalled carbon nanotubes in polycarbonate/polypropylene (PC/PP) blends: Phase morphology, viscoelastic phase separation, rheology and percolation. J. Polym. Res. 2019, 26, 178. [Google Scholar] [CrossRef]

- Lopes Pereira, E.C.; Soares, B.G.; Silva, A.A.; Farias da Silva, J.M.; Barra, G.M.O.; Livi, S. Conductive heterogeneous blend composites of PP/PA12 filled with ionic liquids treated-CNT. Polym. Test 2019, 74, 187–195. [Google Scholar] [CrossRef]

- Nasti, G.; Gentile, G.; Cerruti, P.; Carfagna, C.; Ambrogi, V. Double percolation of multiwalled carbon nanotubes in polystyrene/polylactic acid blends. Polymer 2016, 99, 193–203. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Modeling of viscosity and complex modulus for poly (lactic acid)/poly (ethylene oxide)/carbon nanotubes nanocomposites assuming yield stress and network breaking time. Compos. Part B Eng. 2019, 156, 100–107. [Google Scholar] [CrossRef]

- Behera, K.; Chang, Y.H.; Yadav, M.; Chiu, F.C. Enhanced thermal stability, toughness, and electrical conductivity of carbon nanotube-reinforced biodegradable poly (lactic acid)/poly (ethylene oxide) blend-based nanocomposites. Polymer 2020, 186, 122002. [Google Scholar] [CrossRef]

- Ko, S.W.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J. Rheology and Physical Characteristics of Synthetic Biodegradable Aliphatic Polymer Blends Dispersed with MWNTs. Macromol. Mater. Eng. 2010, 295, 320–328. [Google Scholar] [CrossRef]

- Zheng, L.J.; Li, Y.D.; Weng, Y.X.; Zhu, J.; Zeng, J.B. Localization control of carbon nanotubes in immiscible polymer blends through dynamic vulcanization. Compos. Part B Eng. 2019, 167, 683–689. [Google Scholar] [CrossRef]

- Du, B.; Handge, U.A.; Majeed, S.; Abetz, V. Localization of functionalized MWCNT in SAN/PPE blends and their influence on rheological properties. Polymer 2012, 53, 5491–5501. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Liu, X.; Liu, H.; Wang, Y.; Guo, Z.; Liu, C. Multi-walled carbon nanotube in a miscible PEO/PMMA blend: Thermal and rheological behavior. Polym. Test 2019, 75, 367–372. [Google Scholar] [CrossRef]

- Darshan, T.G.; Veluri, S.; Kartik, B.; Yen-Hsiang, C.; Fang-Chyou, C. Poly(butylene succinate)/high density polyethylene blend-based nanocomposites with enhanced physical properties—Selectively localized carbon nanotube in pseudo-double percolated structure. Polym. Degrad. Stab. 2019, 163, 185–194. [Google Scholar] [CrossRef]

- Bose, S.; Bhattacharyya, A.R.; Kodgire, P.V.; Misra, A.; Potschke, P. Rheology, Morphology, and Crystallization Behavior of Melt-Mixed Blends of Polyamide 6 and Acrylonitrile-Butadiene-Styrene: Influence of Reactive Compatibilizer Premixed with Multiwall Carbon Nanotubes. J. Appl. Polym. Sci. 2007, 106, 3394–3408. [Google Scholar] [CrossRef]

- Zare, Y.; Garmabi, H.; Rhee, K.Y. Structural and phase separation characterization of poly(lactic acid)/poly(ethylene oxide)/carbon nanotube nanocomposites by rheological examinations. Compos. Part B Eng. 2018, 144, 1–10. [Google Scholar] [CrossRef]

- Hwang, T.Y.; Yoo, Y.; Lee, J.W. Electrical conductivity, phase behavior, and rheology of polypropylene/polystyrene blends with multi-walled carbon nanotube. Rheol. Acta 2012, 51, 623–636. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Q.; Huang, Y.; Liao, X.; Niu, Y. Influence of phase coarsening and filler agglomeration on electrical and rheological properties of MWNTs-filled PP/PMMA composites under annealing. Polymer 2015, 79, 159–170. [Google Scholar] [CrossRef]

- Salehiyan, R.; Nofar, M.; Sinha Ray, S.; Ojijo, V. Kinetically Controlled Localization of Carbon Nanotubes in Polylactide/Poly(vinylidene fluoride) Blend Nanocomposites and Their Influence on Electromagnetic Interference Shielding, Electrical Conductivity, and Rheological Properties. J. Phys. Chem. C 2019, 123, 19195–19207. [Google Scholar] [CrossRef]

| Blend Constituents | CNT Amount (wt.%) | Processing Method | Rheological Behavior | Ref. |

|---|---|---|---|---|

| Polypropylene/Polylactide | 0.5–2 | Melt-mixing | Solid-like behavior induced by nanofiller network | [108] |

| Polycarbonate/Polypropylene | 1–10 | Melt-mixing | Non-terminal rheological response at low frequencies | [109] |

| Polypropylene/Polyamide12 | 0.94–3.67 | Melt-mixing and injection molding | Pseudo-plastic behavior | [110] |

| Polystyrene/Polylactide | 2 | Dilution of a masterbatch by melt-mixing | Mixed viscoelastic/solid-like due to the incomplete formation of the nanotube network | [111] |

| Polylactide/Polyethylene Oxide | 1–2 | Solution casting | A viscosity model was proposed, predicting complex modulus as a function of zero viscosity, yield stress, relaxation time and network breaking time | [112] |

| Polylactide/Polyethylene Oxide | 0.29–2.91 | Melt-mixing | Formation of a (pseudo-)network structure | [113] |

| Polylactide/Polybutylene Adipate Terephthalate | 0.25–4 | Melt-mixing | Appearance of a distinct shear-thinning behavior | [114] |

| Polylactide/Crosslinked Polyurethane | 0.1–1 | Melt-mixing | Transition from liquid-like to solid-like response | [115] |

| Styrene Acrylonitrile/Polyphenylene Ether | 1 | Solution casting and melt-mixing | Migration of functionalized CNTs into the Polyphentlene phase, leading to a decrease in both dynamic modulus and complex viscosity. | [116] |

| Polyethylene Oxide/Poly(methyl methacrylate) | 0.5–4 | Melt-mixing | Absence of zero-shear viscosity for CNT contents exceeding 4 wt.% | [117] |

| Polybutylene Succinate/High Density Polyethylene | 0.29-2.91 | Melt-mixing | Formation of a pseudo-network structure leading to enhanced complex viscosity and storage modulus | [118] |

| Polyamide6/Acrylonitrile Butadiene Styrene | 0.05–0.25 | Melt-mixing | Increased viscosity and storage modulus due to a reinforcing effect of the interface by the presence of MWNT | [119] |

| Polylactide/Polyethylene Oxide | 1–2 | Solution-mixing | Different values of the low frequency modulus were obtained depending on the prevailing effect between relaxation of Polyethylene oxide droplets and formation of CNT network | [120] |

| Type of Matrix | Highlights |

|---|---|

| PC | |

| PE |

|

| PP |

|

| PS |

|

| PA |

|

| Biopolymers |

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arrigo, R.; Malucelli, G. Rheological Behavior of Polymer/Carbon Nanotube Composites: An Overview. Materials 2020, 13, 2771. https://doi.org/10.3390/ma13122771

Arrigo R, Malucelli G. Rheological Behavior of Polymer/Carbon Nanotube Composites: An Overview. Materials. 2020; 13(12):2771. https://doi.org/10.3390/ma13122771

Chicago/Turabian StyleArrigo, Rossella, and Giulio Malucelli. 2020. "Rheological Behavior of Polymer/Carbon Nanotube Composites: An Overview" Materials 13, no. 12: 2771. https://doi.org/10.3390/ma13122771