A Study on the Reduction in Hydration Heat and Thermal Strain of Concrete with Addition of Sugarcane Bagasse Fiber

Abstract

1. Introduction

2. Methodology

2.1. Preliminary Trials Applied to Sugarcane Bagasse Residues

2.2. Materials

2.3. Concrete Mixture

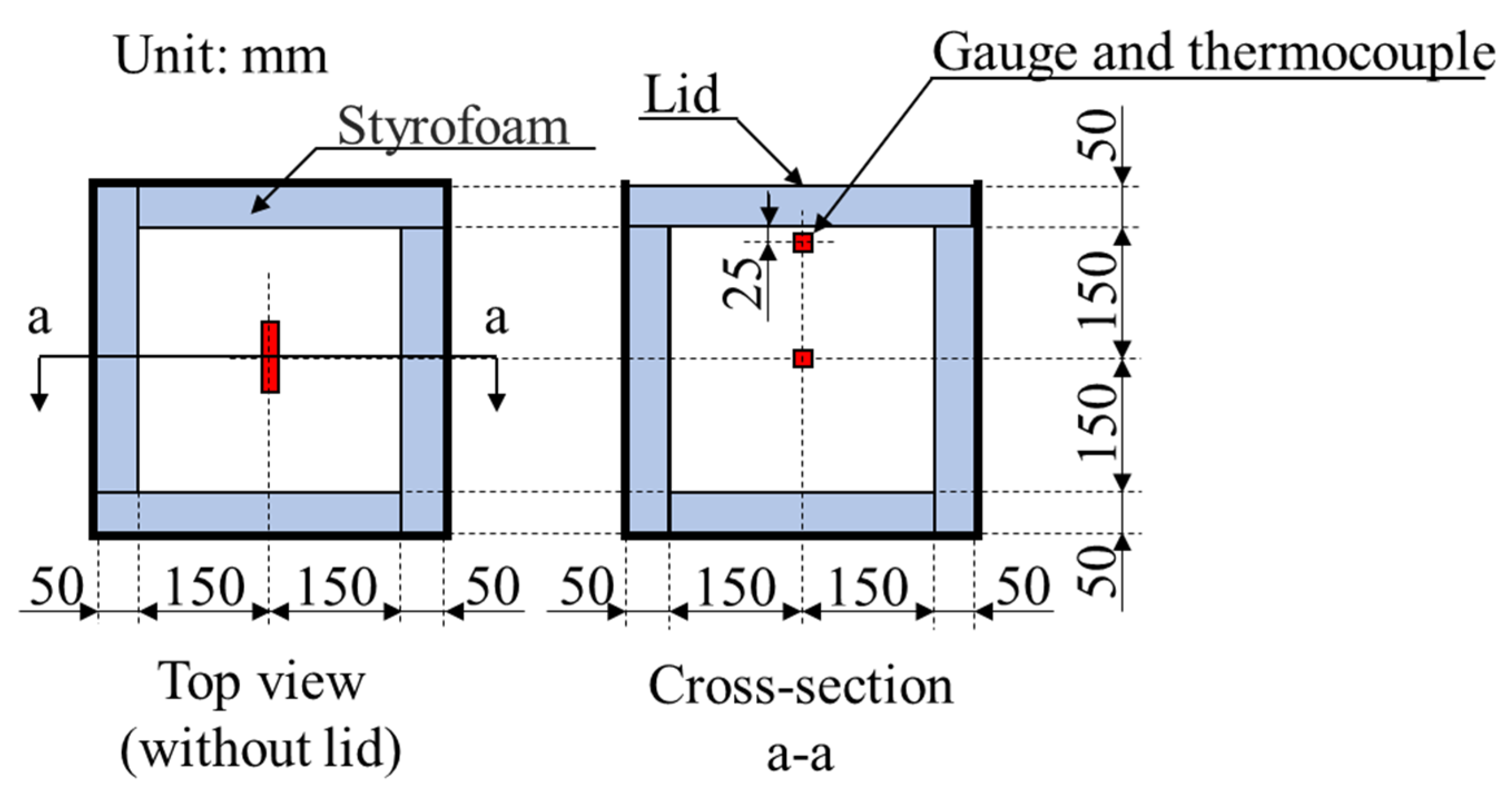

2.4. Preparation of Concrete Specimens and the Tests Applied

3. Results and Discussions

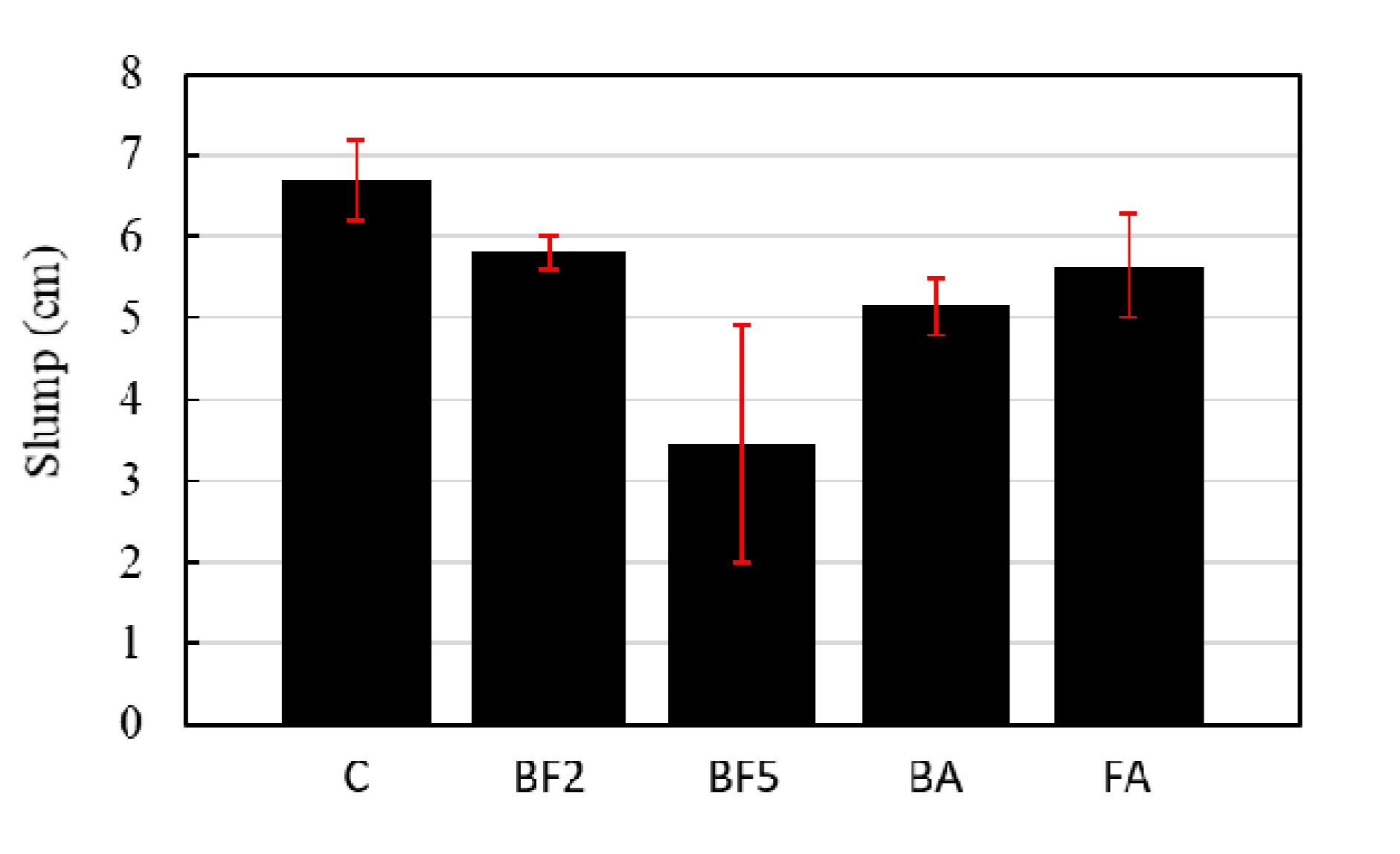

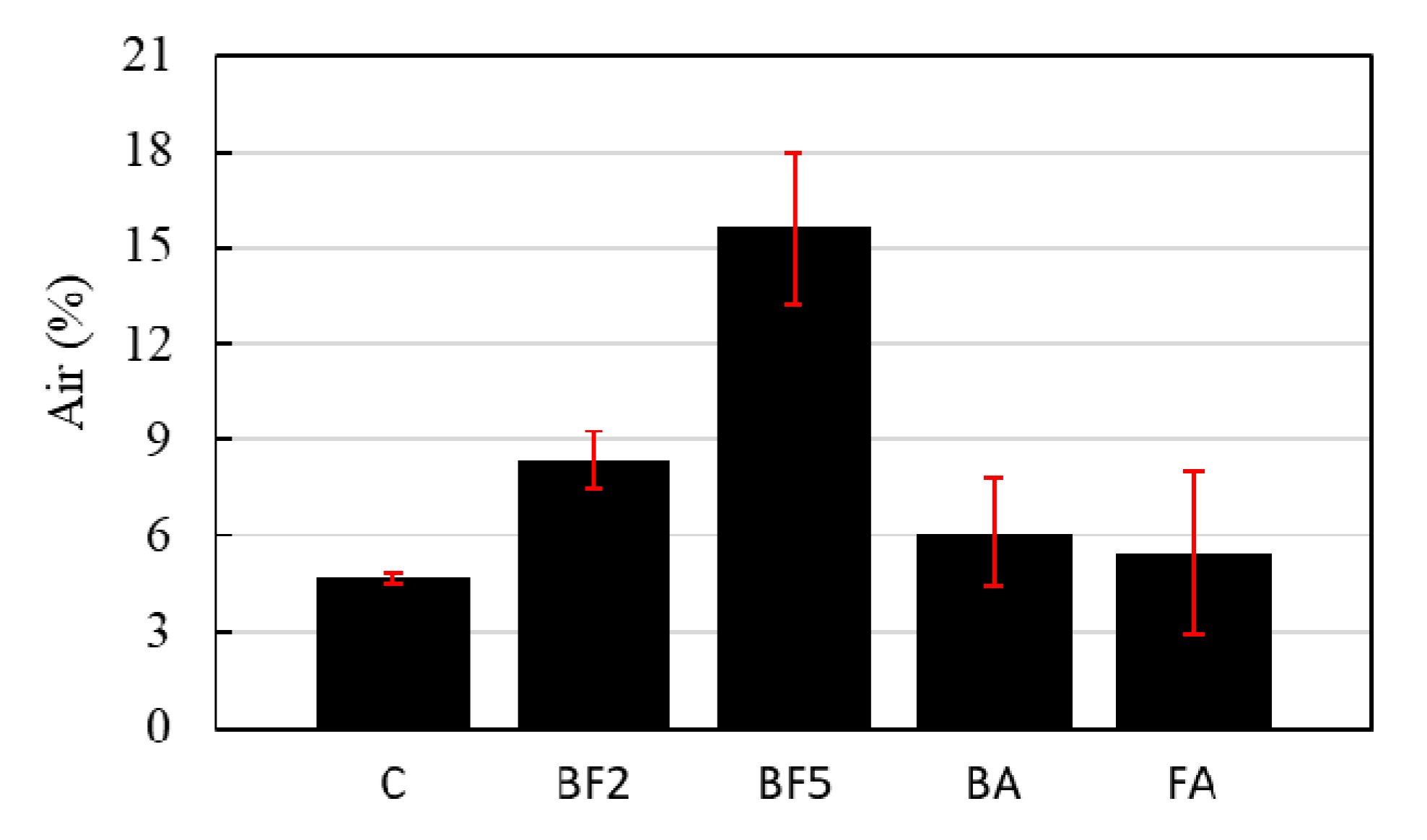

3.1. Fresh Concrete

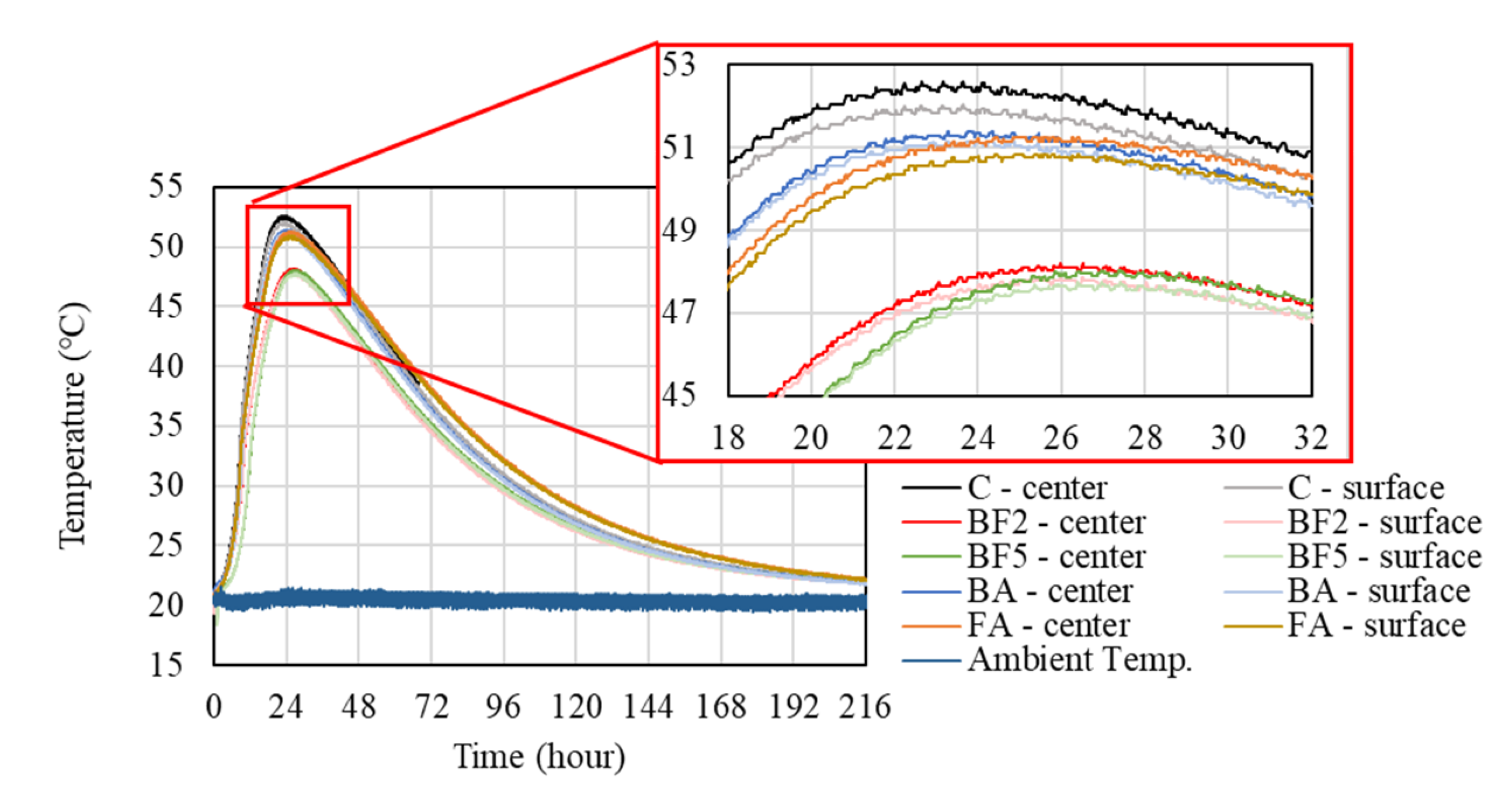

3.2. Heat of Hydration

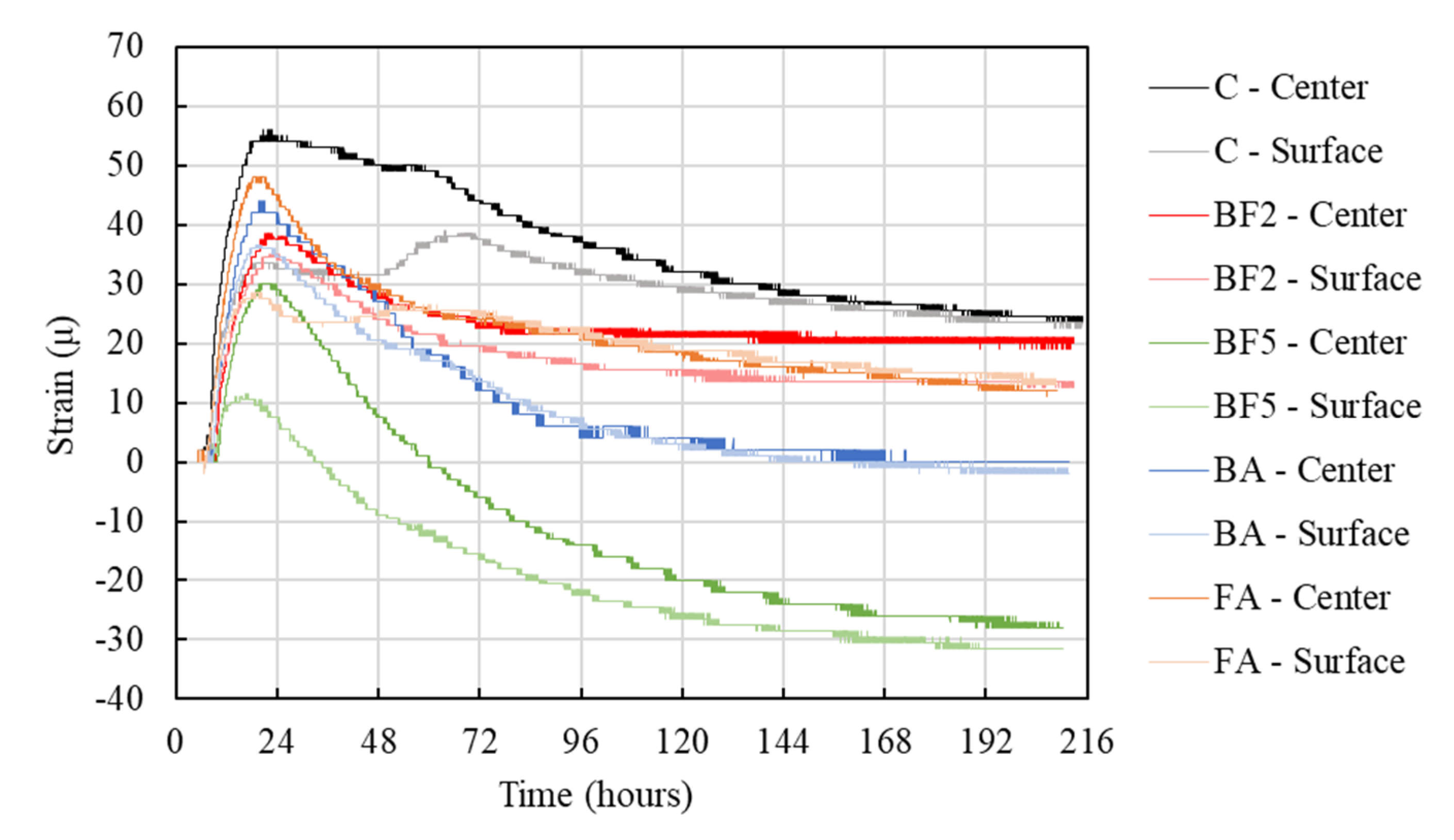

3.3. Relationship between the Heat of Hydration and Strain

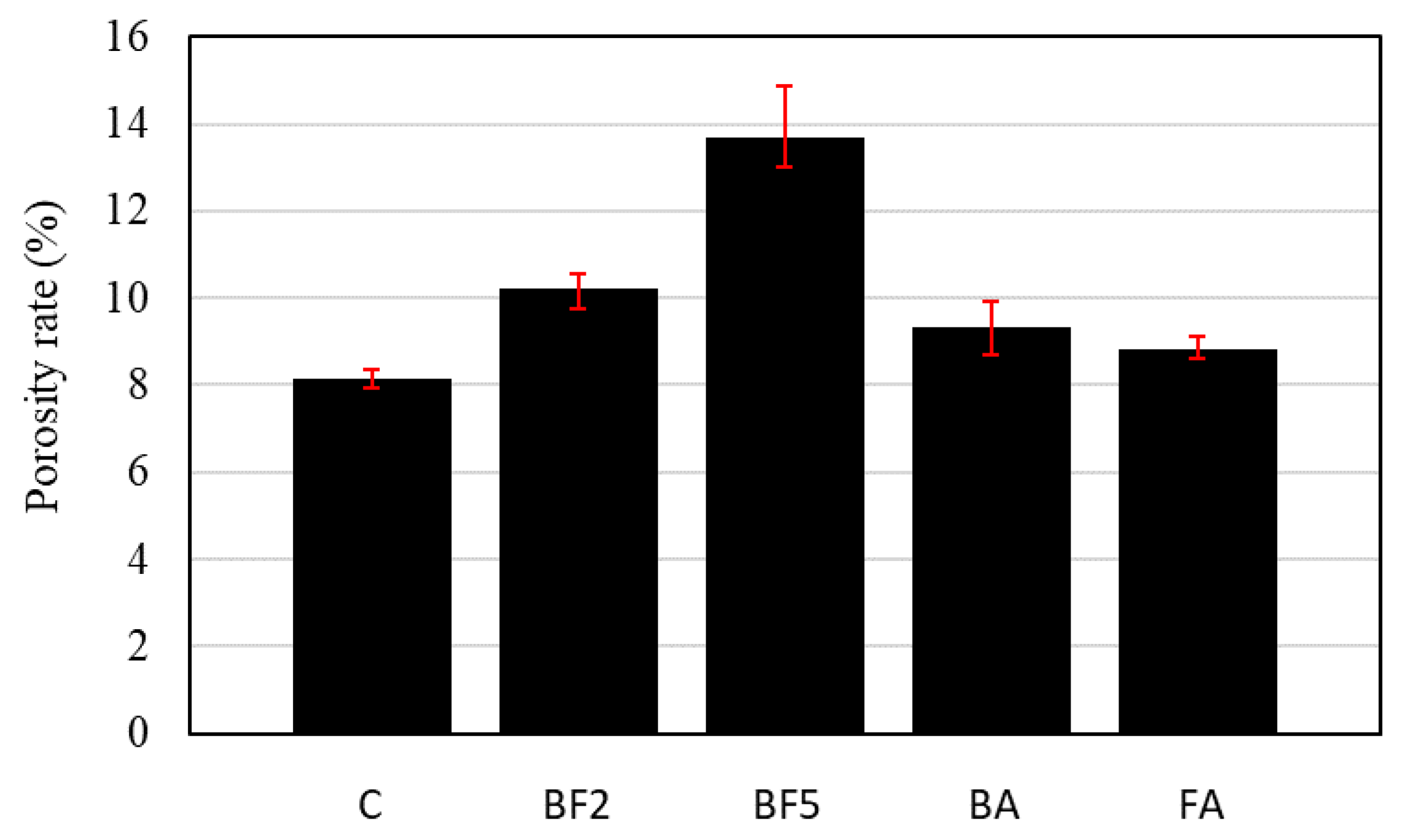

3.4. Porosity Rate and the Water Retention Rate

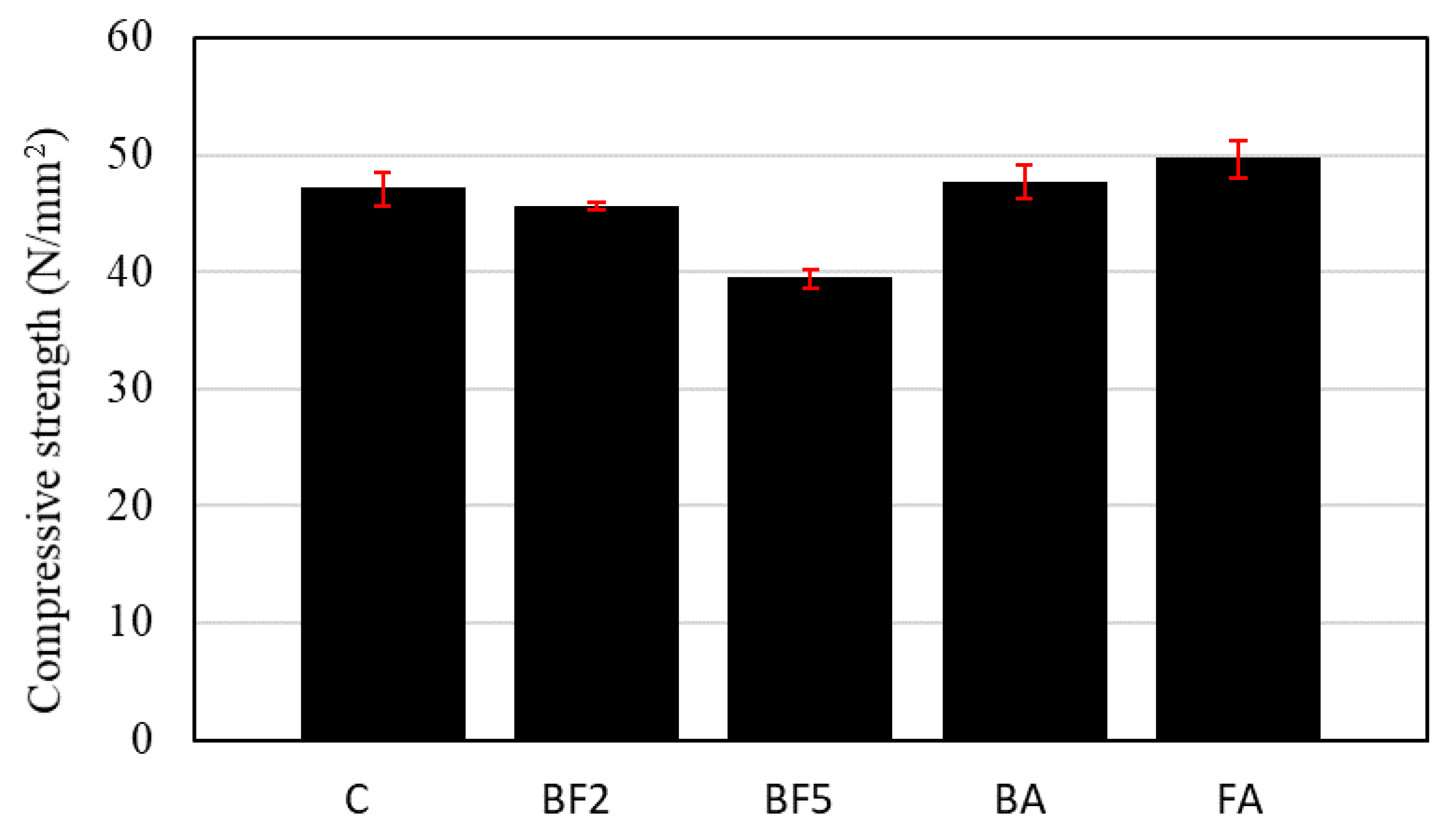

3.5. Compressive Strength

3.6. Modulus of Elasticity

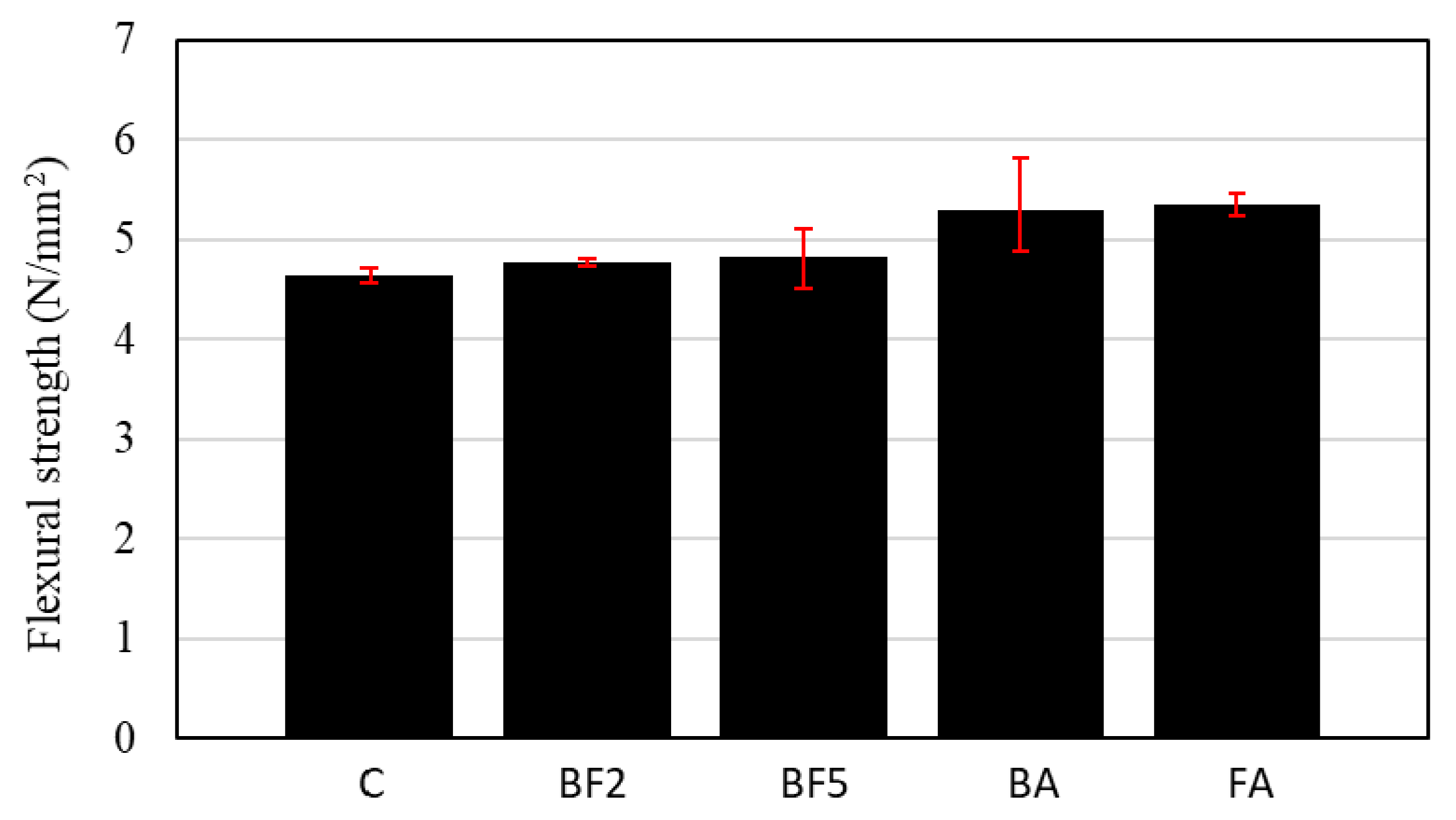

3.7. Flexural Strength

3.8. Split Tensile Strength

4. Conclusions

- The slump decreased with the addition of the fiber amount compared to the control mixture. However, the amount of air increased as the amount of mixed fibers increased.

- With the addition of the bagasse fiber, the heat of hydration of all mixtures was reduced. In the case when 5% of the bagasse fiber was added, the peak temperature neared 48 °C, approximately 4.5 °C lower than the control mixture.

- In the cases in which the bagasse fiber was added, the peak temperature was reached later than the control mixture. In the case when 2% of the bagasse fiber was added, the temperature peak was achieved 26 h after the concrete placement, while the control mixture temperature peak was achieved 4 h earlier.

- In the case of the control mixture, the strain rose to a value of approximately 55 μ, while, in the case of the mixture in which 5% of bagasse fiber was added, the strain value was 30 μ, a difference of about 25 μ.

- In the case where the bagasse fiber was added, the compressive strength decreased. However, the compressive strength increased when the ashes were added to the mixtures, thereby exceeding the control mixture.

- The flexural strength of all concrete specimens with added fiber exceeded the value of the control specimen.

- The split tensile strength increased when 2.0% of the fiber content was added to the mixture. On the other hand, with 5.0% of the fiber, the split tensile strength decreased.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nguyen, T.-C.; Bach, L. Reducing temperature difference in mass concrete by surface insulation. Mag. Civ. Eng. 2019, 88, 70–79. [Google Scholar]

- Abbas, Z.H.; Majdi, H.S. Study of heat of hydration of Portland cement used in Iraq. Case Stud. Constr. Mater. 2017, 7, 154–162. [Google Scholar] [CrossRef]

- Gorzelańczyk, T.; Hoła, J.; Sadowski, L.; Schabowicz, K. Non-destructive identification of cracks in unilaterally accessible massive concrete walls in hydroelectric power plant. Arch. Civ. Mech. Eng. 2016, 16, 413–421. [Google Scholar] [CrossRef]

- Gorzelańczyk, T.; Hoła, J.; Sadowski, Ł.; Schabowicz, K. Methodology of non-destructive identification of defective concrete zones in unilaterally accessible massive members. J. Civ. Eng. Manag. 2013, 19, 775–786. [Google Scholar] [CrossRef]

- Patil, A. Heat of Hydration in the Placement of Mass Concrete. Int. J. Eng. Adv. Technol. IJEAT 2015, 4, 1–4. [Google Scholar]

- Frıas, M.; Sánchez de Rojas, M.I.; Cabrera, J. The effect that the pozzolanic reaction of metakaolin has on the heat evolution in metakaolin-cement mortars. Cem. Concr. Res. 2000, 30, 209–216. [Google Scholar] [CrossRef]

- Sánchez de Rojas, M.I.; Luxan, M.P.; Frıas, M.; Garcıa, N. The influence of different additions on Portland cement hydration heat. Cem. Concr. Res. 1993, 23, 46–54. [Google Scholar] [CrossRef]

- Ganjigatti, M.; Kashinath, B.R.; Prakash, K.B. Effect of Replacement of Cement by Different Pozzolanic Materials on Heat of Hydration and Setting Time of Concrete. Int. J. Environ. Agric. Res. IJOEAR 2015, 1, 24–29. [Google Scholar]

- Nili, M.; Salehi, A. Assessing the effectiveness of pozzolans in massive high-strength concrete. Constr. Build. Mater. 2010, 24, 2108–2116. [Google Scholar] [CrossRef]

- Awal, A.S.M.A.; Hussin, M. Effect of Palm Oil Fuel Ash in Controlling Heat of Hydration of Concrete. Procedia Eng. 2011, 14, 2650–2657. [Google Scholar] [CrossRef]

- Japan Concrete Institute. Guidelines for Control of Cracking of Mass Concrete; Japan Concrete Institute: Tokyo, Japan, 2016. [Google Scholar]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Adhikari, B.; Majumder, S.B. Effect of Jute as Fiber Reinforcement Controlling the Hydration Characteristics of Cement Matrix. Ind. Eng. Chem. Res. 2013, 52, 1252–1260. [Google Scholar] [CrossRef]

- Sarabi, S.; Bakhshi, H.; Sarkardeh, H.; Nikoo, H.S. Thermal stress control using waste steel fibers in massive concretes. Eur. Phys. J. Plus 2017, 132, 1–8. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment—A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Kavitha, S.; Felix Kala, T. A review on natural fibres in the concrete. Int. J. Adv. Eng. Technol. 2017, 1, 1–4. [Google Scholar]

- Zakaria, N.Z.; Sulieman, M.Z.; Talib, R. Turning Natural Fiber Reinforced Cement Composite as Innovative Alternative Sustainable Construction Material A Review Paper. Int. J. Adv. Eng. Manag. Sci. IJAEMS 2015, 1, 24–31. [Google Scholar]

- Benaimeche, O.; Seghir, N.T.; Sadowski, L.; Mellas, M. The Utilization of Vegetable Fibers in Cementitious Materials. Ref. Module Mater. Sci. Mater. Eng. 2020, 2, 649–662. [Google Scholar]

- Ribeiro, B.; Yamashiki, Y.; Yamamoto, T. A study on mechanical properties of mortar with sugarcane bagasse fiber and bagasse ash. J. Mater. Cycles Waste Manag. 2020. [Google Scholar] [CrossRef]

- Ferreira, C.R.; Tavares, S.S.; Ferreira, B.H.M.; Fernandes, A.M.; Fonseca, S.J.G.; Oliveira, C.A.D.S.; Teixeira, R.L.P.; Gouveia, L.L.D.A. Comparative study about mechanical properties of strutural standard concrete and concrete with addition of vegetable fibers. Mater. Res. 2017, 20, 102–107. [Google Scholar] [CrossRef]

- Cabral, M.R.; Fiorelli, J.; Savastano, H., Jr.; Lagacé, R.; Godbout, S.; Palacios, J.H. Study of the potential use of the sugarcane bagasse in cement-panels. In Proceedings of the 10th International Conference on Composite Science and Technology, Lisboa, Portugal, 2–4 September 2015. [Google Scholar]

- Arsène, M.-A.; Okwo, A.; Bilba, K.; Soboyejo, A.B.O.; Soboyejo, W.O. Chemically and thermally treated vegetable fibers for reinforcement of cement-based composites. Mater. Manuf. Process. 2007, 22, 214–227. [Google Scholar] [CrossRef]

- Onésippe, C.; Passe-Coutrin, N.; Toro, F.; Delvasto, S.; Bilba, K.; Arsène, M.-A. Sugar cane bagasse fibres reinforced cement composites: Thermal considerations. Compos. Part A 2010, 41, 549–556. [Google Scholar] [CrossRef]

- Ibrahim, M.N.M.; Pearce, G.R. Effects of chemical pretreatments on the composition and In vitro digestibility of crop by-products. Agric. Wastes 1983, 5, 135–156. [Google Scholar] [CrossRef]

- Saraz, J.A.O.; Aristizabal, F.V.; Herrera Mejí, J.A. Mechanical behavior of the concrete reinforced with sugar cane bagasse fibers (in Spanish). Dyna Medellin Colombia 2007, 74, 69–79. [Google Scholar]

- Tian, H.; Zhang, Y.X. The influence of bagasse fibre and fly ash on the long-term properties of green cementitious composites. Constr. Build. Mater. 2016, 111, 237–250. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Bilba, K.; Arsene, M.-A.; Ouensanga, A. Sugar cane bagasse fibre reinforced cement composites. Part I. Influence of the botanical components of bagasse on the setting of bagasse/cement composite. Cem. Concr. Compos. 2003, 25, 91–96. [Google Scholar] [CrossRef]

- Jo, B.-W.; Chakraborty, S.; Yoon, K.W. A hypothetical model based on effectiveness of combined alkali and polymer latex modified jute fibre in controlling the setting and hydration behaviour of cement. Constr. Build. Mater. 2014, 68, 1–9. [Google Scholar] [CrossRef]

- Bishop, M.; Barron, A.R. Cement Hydration Inhibition with Sucrose, Tartaric Acid, and Lignosulfonate: Analytical and Spectroscopic Study. Ind. Eng. Chem. Res. 2006, 45, 7042–7049. [Google Scholar] [CrossRef]

- Chuc, N.T.; Thoan, P.V.; Kiet, B.A. The Effects of Insulation Thickness on Temperature Field and Evaluating Cracking in the Mass Concrete. Electr. J. Struct. Eng. 2018, 18, 128–132. [Google Scholar]

- Tahersima, M.; Ley, T.; Tikalsky, P. Hydration Heat in a Mass Concrete and a Thin Slab with Limestone Blended Cement. Int. J. Mater. Sci. Eng. 2017, 5, 79–86. [Google Scholar] [CrossRef]

- Bui, P.T.; Ogawa, Y.; Kawai, K. Long-term pozzolanic reaction of fly ash in hardened cement-based paste internally activated by natural injection of saturated Ca(OH)2 solution. Mater. Struct. 2018, 51, 144. [Google Scholar] [CrossRef]

- Kumar Mehta, P. High-performance, high-volume fly ash concrete for sustainable development. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; pp. 3–14. [Google Scholar]

- Lee, C.Y.; Lee, H.K.; Lee, K.M. Strength and microstructural characteristics of chemically activated fly ash–cement systems. Cem. Concr. Res. 2003, 33, 425–431. [Google Scholar] [CrossRef]

- Japan Society of Civil Engineers. Standard Specifications for Concrete Structures—2017, Design; Japan Society of Civil Engineers: Tokyo, Japan, 2017. [Google Scholar]

- Liu, B.; Xie, Y.; Li, J. Influence of steam curing on the compressive strength of concrete containing supplementary cementing materials. Cem. Concr. Res. 2005, 35, 994–998. [Google Scholar] [CrossRef]

| Properties | Materials | ||||

|---|---|---|---|---|---|

| Cement | S | G | BA | FA (II) | |

| Density (g/cm3) | 3.16 | 2.57 | 2.57 | 2.1 | 2.24 |

| Total alkali content (%) | 0.56 | ― | ― | ― | ― |

| Admixtures | Main Components | Color | Density | Total Alkali | Cl− |

|---|---|---|---|---|---|

| (20 °C, g/cm3) | Content (%) | Content (%) | |||

| WRA | Complexes of lignin | Dark | 1.23–1.27 | 1 | 0.03 |

| (No.70) | sulfonic acid compound | brown | |||

| and polyol | |||||

| AEA | Alkyl ether type | Light | 1.02–1.06 | 1.1 | 0.01 |

| (303A) | anionic surfactant | yellow |

| Properties | BF |

|---|---|

| Density (g/cm3) | 0.71 |

| Length (mm) | 17.9 (average) |

| Diameter (mm) | 0.56 (average) |

| Aspect Ratio | 32 |

| Tensile strength (N/mm2) | 132 |

| Composites | Fiber | W/B | Unit (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (Vol. %) | (%) | C | W | S | G | BA | FA | BF | WRA | AEA | |

| C | — | 45 | 389 | 175 | 876 | 950 | — | — | — | 1.17 | 0.0125 |

| BF2 | 2.0 | 824 | — | — | 14 | ||||||

| BF5 | 5.0 | 746 | — | — | 36 | ||||||

| BA | 2.0 | 43 | 780 | 22 | — | 14 | |||||

| FA | 2.0 | 41 | — | 39 | |||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribeiro, B.; Yamamoto, T.; Yamashiki, Y. A Study on the Reduction in Hydration Heat and Thermal Strain of Concrete with Addition of Sugarcane Bagasse Fiber. Materials 2020, 13, 3005. https://doi.org/10.3390/ma13133005

Ribeiro B, Yamamoto T, Yamashiki Y. A Study on the Reduction in Hydration Heat and Thermal Strain of Concrete with Addition of Sugarcane Bagasse Fiber. Materials. 2020; 13(13):3005. https://doi.org/10.3390/ma13133005

Chicago/Turabian StyleRibeiro, Bruno, Takashi Yamamoto, and Yosuke Yamashiki. 2020. "A Study on the Reduction in Hydration Heat and Thermal Strain of Concrete with Addition of Sugarcane Bagasse Fiber" Materials 13, no. 13: 3005. https://doi.org/10.3390/ma13133005

APA StyleRibeiro, B., Yamamoto, T., & Yamashiki, Y. (2020). A Study on the Reduction in Hydration Heat and Thermal Strain of Concrete with Addition of Sugarcane Bagasse Fiber. Materials, 13(13), 3005. https://doi.org/10.3390/ma13133005