Effect of Chemical Aggressive Media on the Flexural Properties of Cured-In-Place Pipes Supported by Microstructure Observation and Acoustic Emission

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composition of CIPP Sample

2.2. Monitoring of Chemical Resistance

2.3. Determination of Flexural Properties

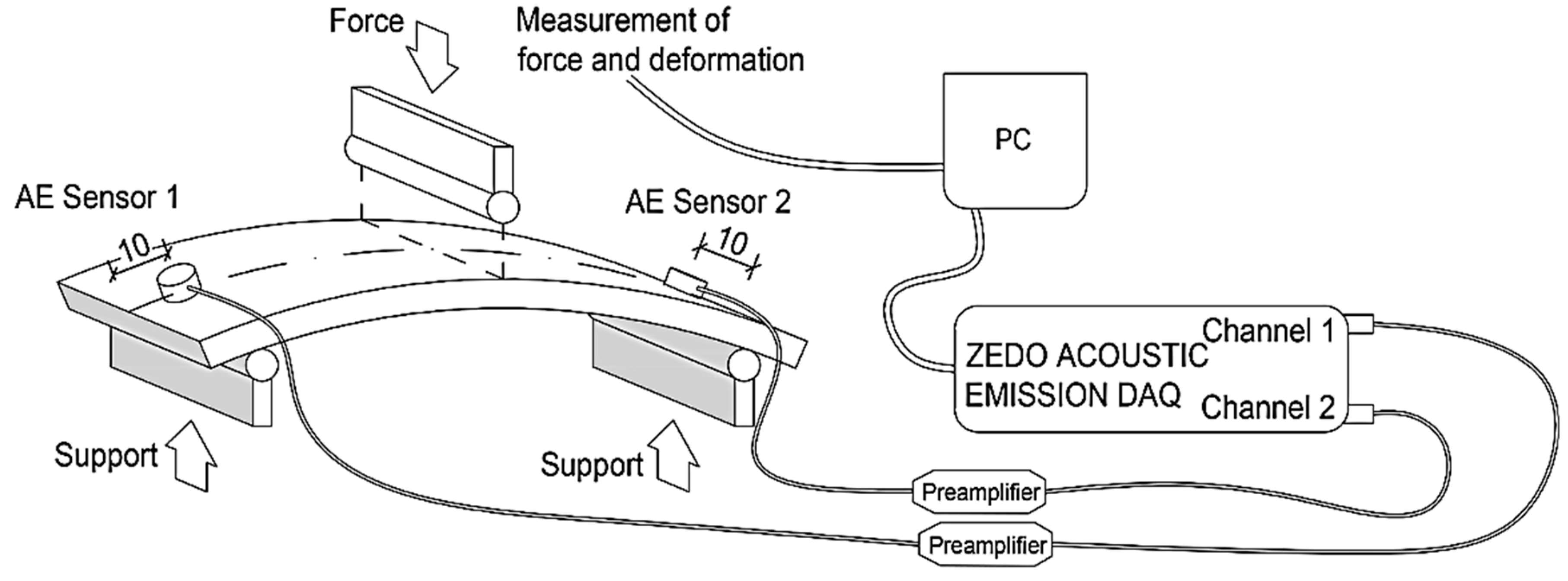

2.4. Acoustic Emission

Description of the Experiment—Set for Measurement of Activity of AE

2.5. Microstucture Observation

3. Results and Discussion

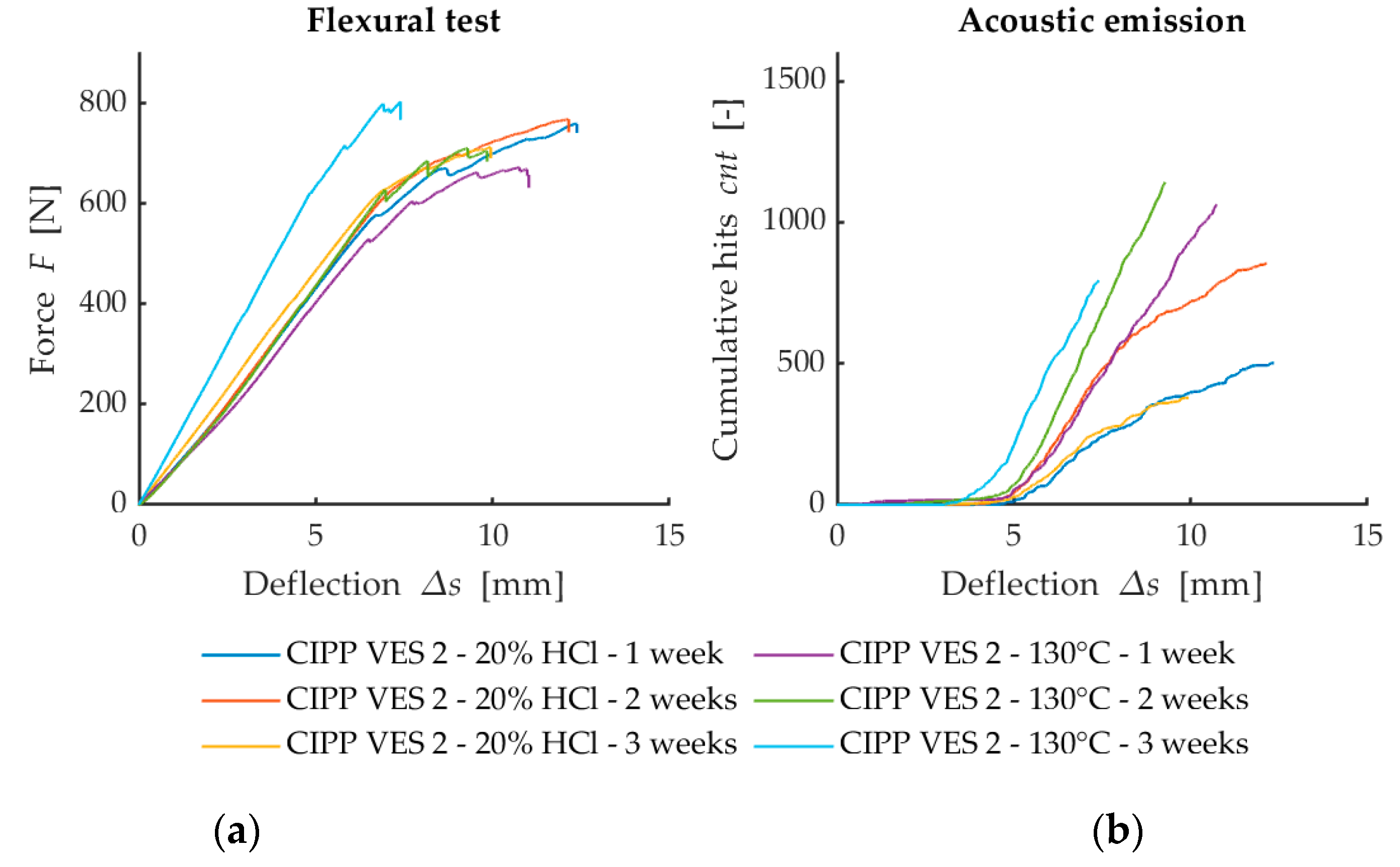

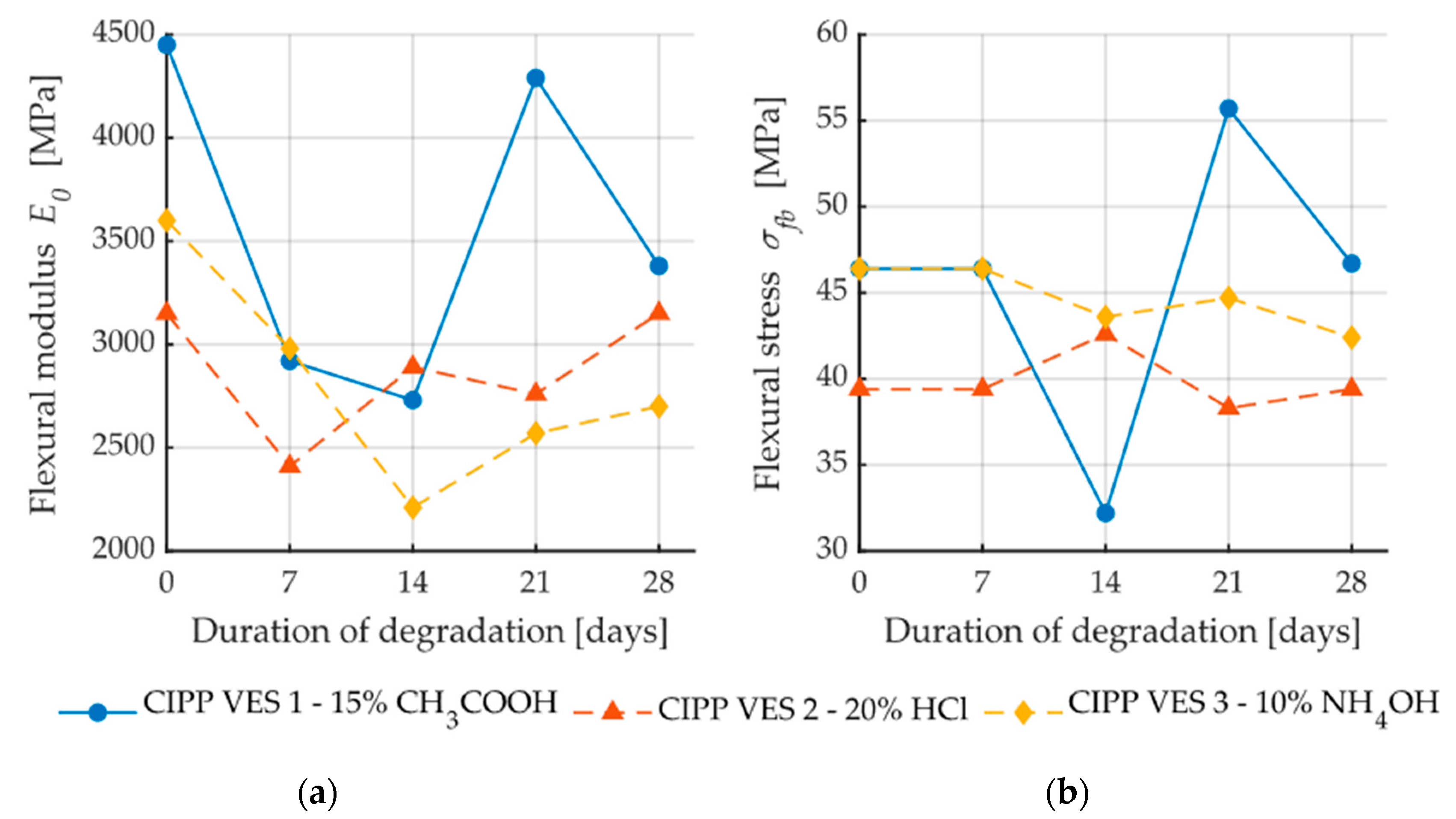

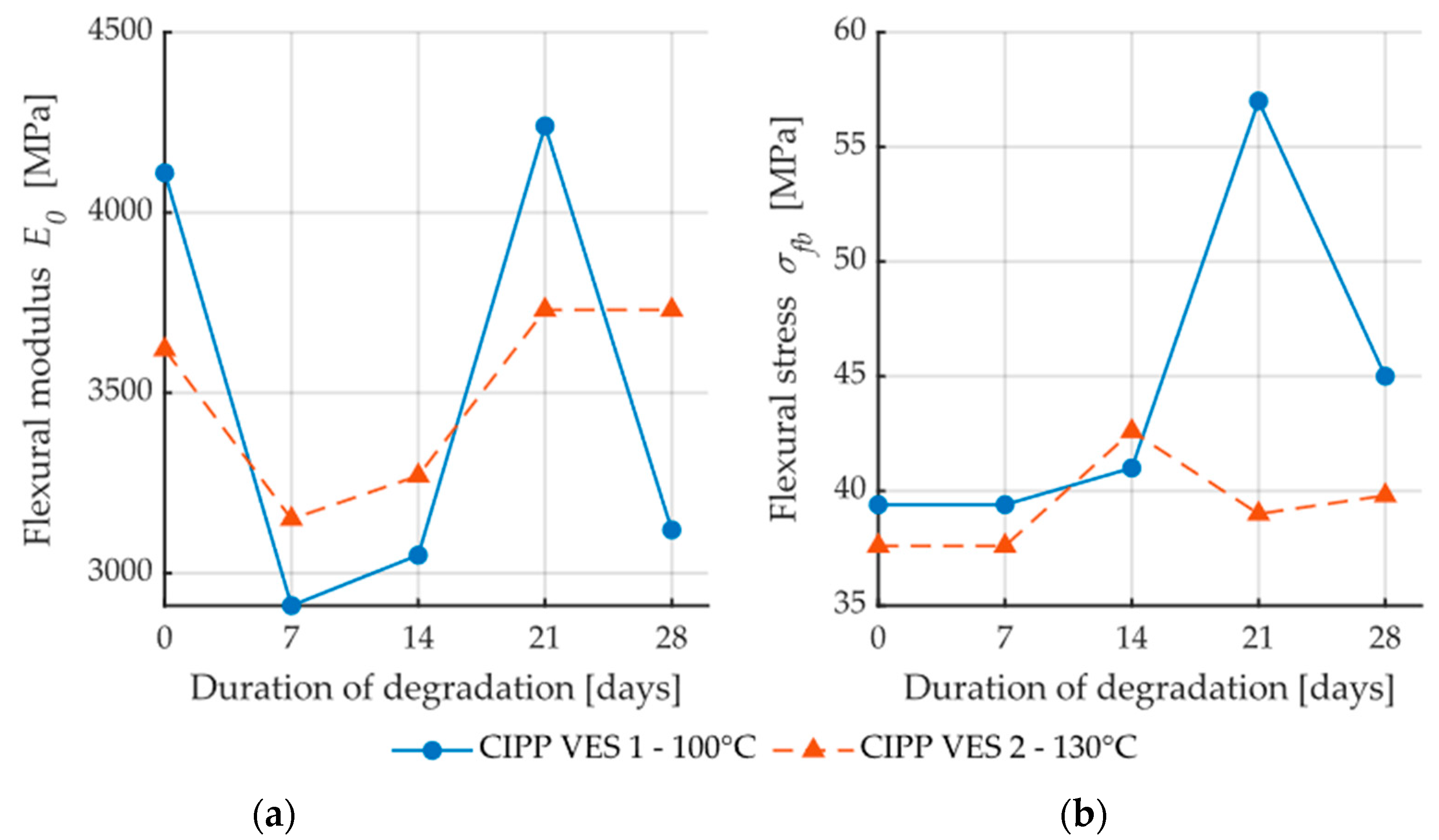

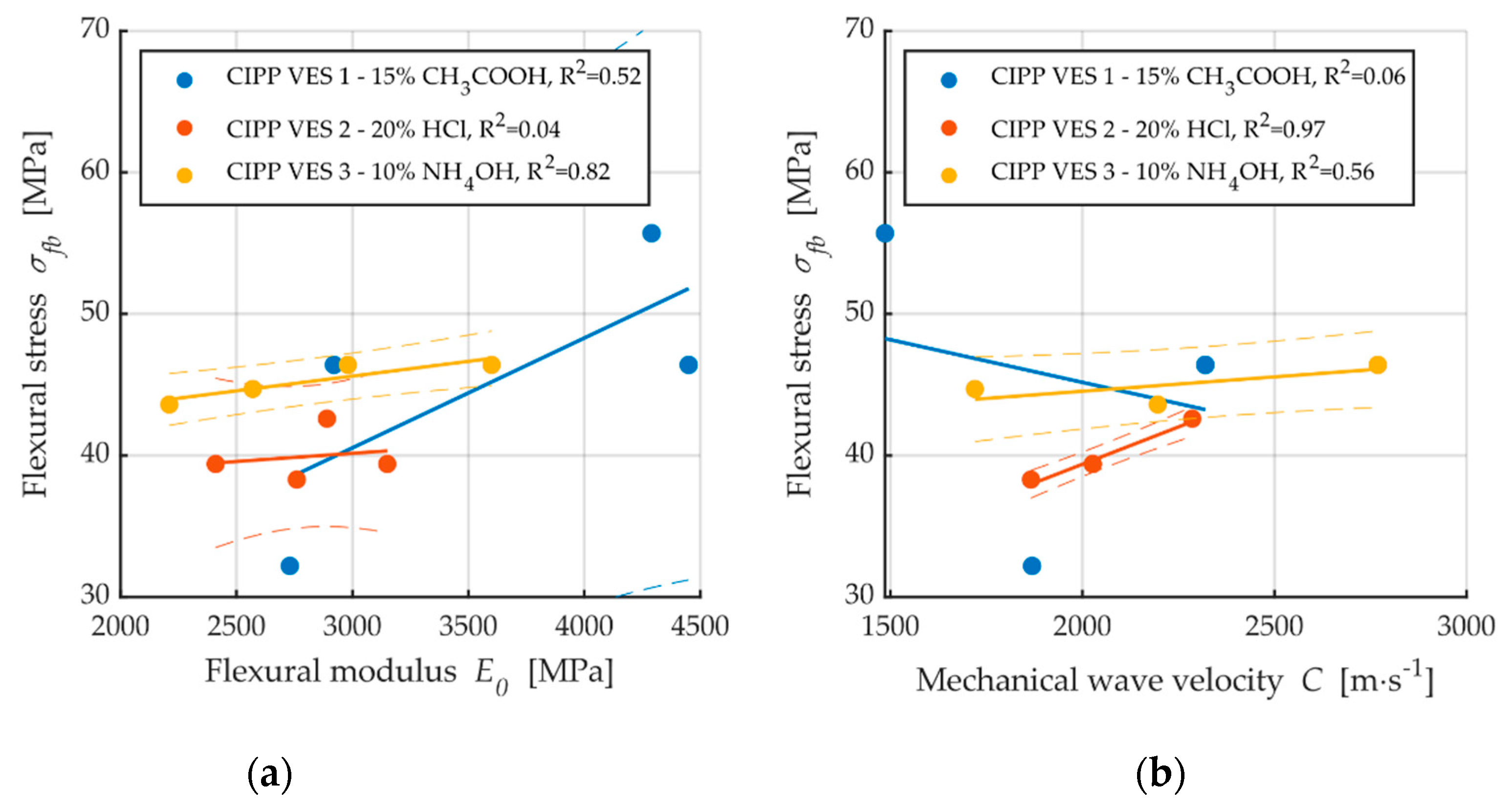

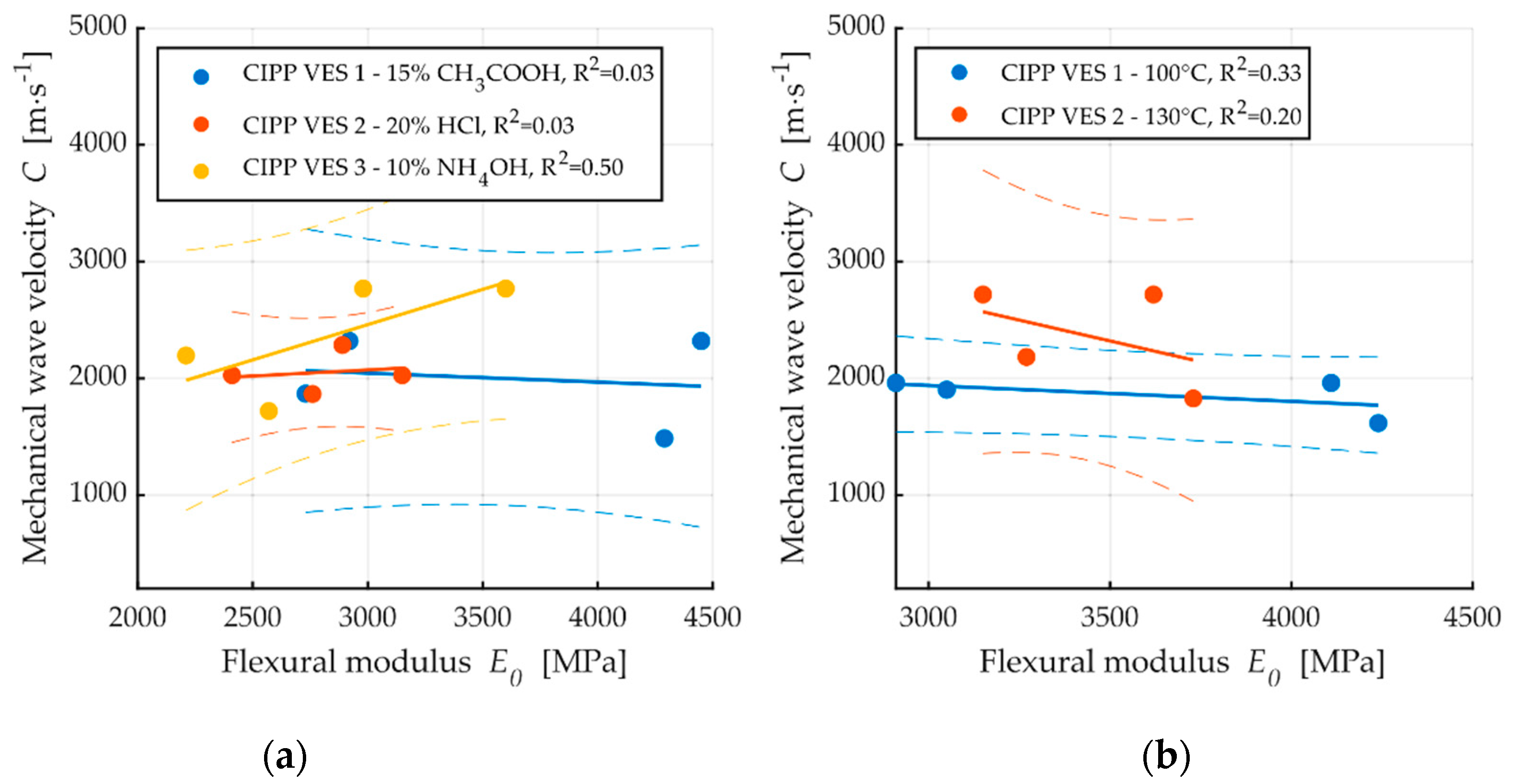

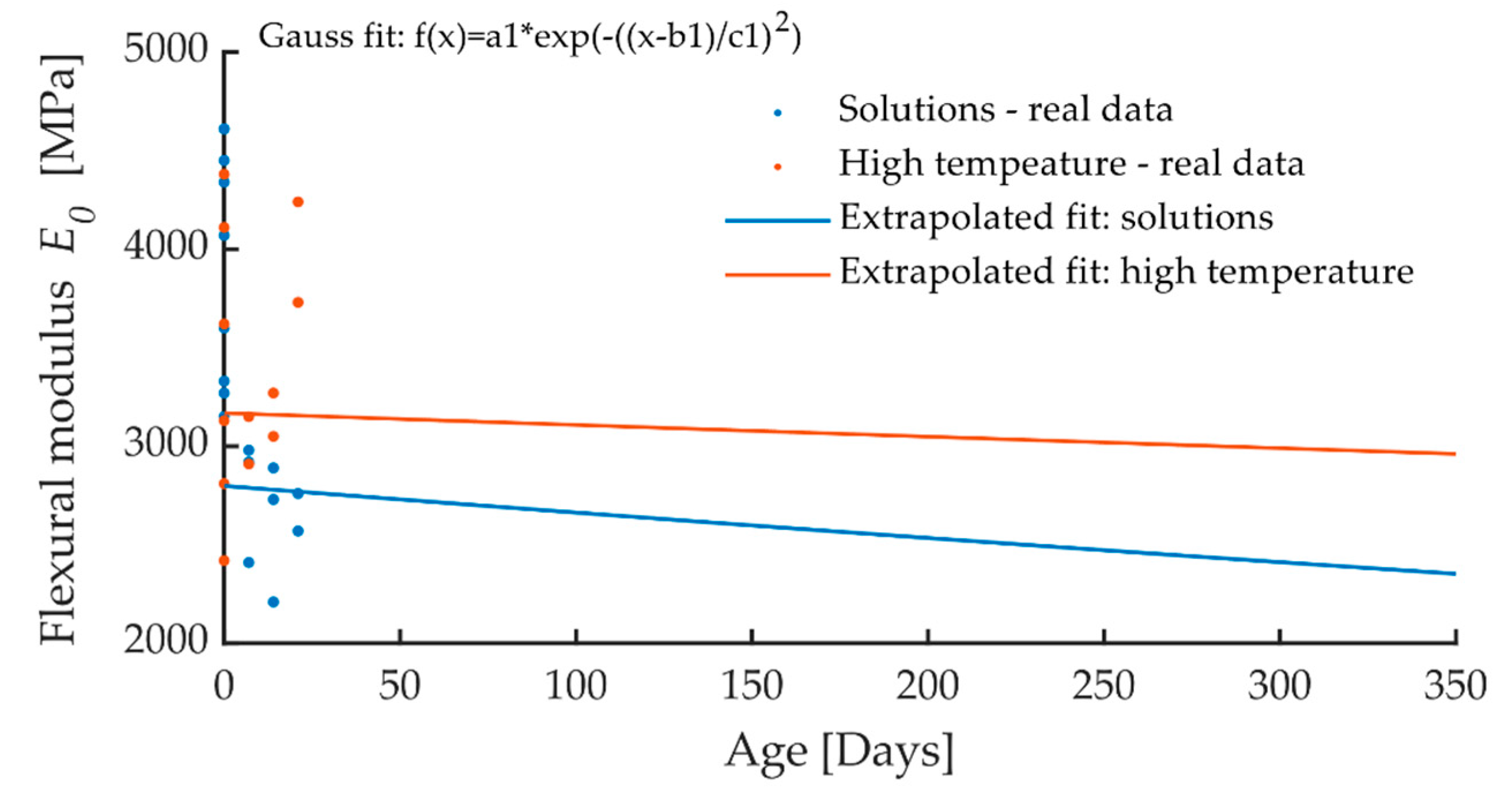

3.1. How Flexural Properties and AE Are Affected by an Aggressive Environment

3.1.1. Comparison of Flexural Properties and Cumulative Hits

3.1.2. Velocity of Propagation of Acoustic Wave in Material

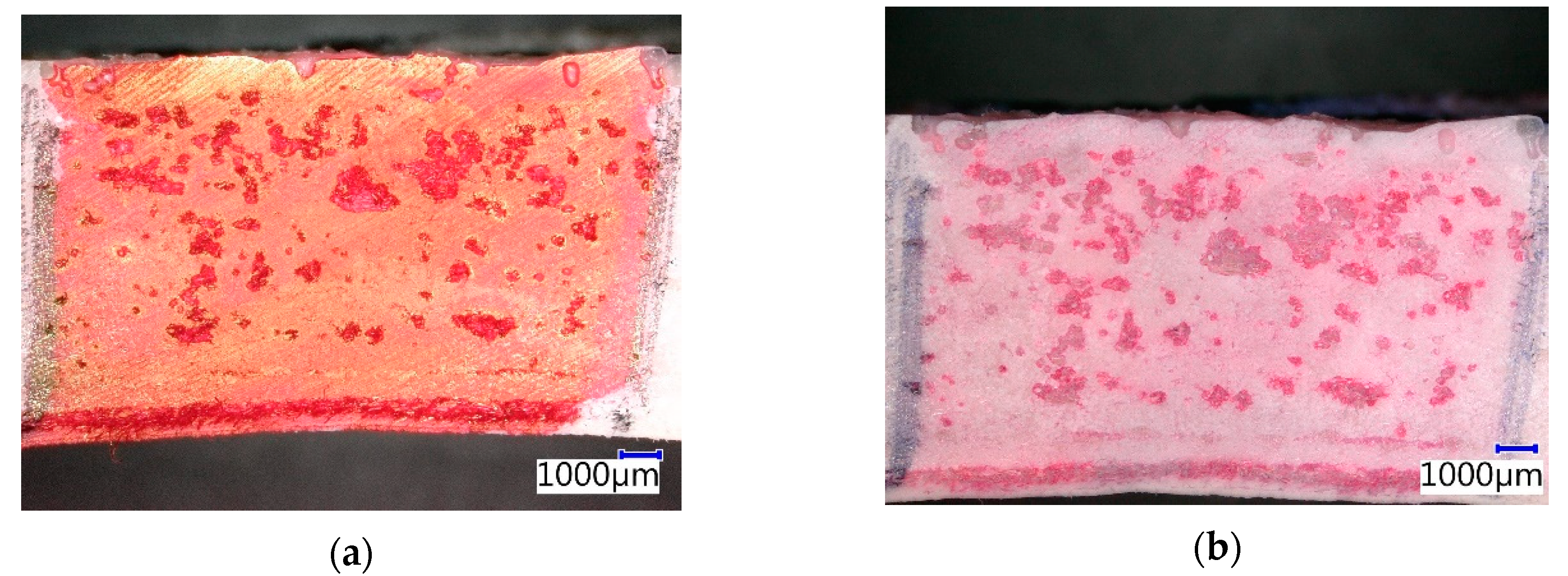

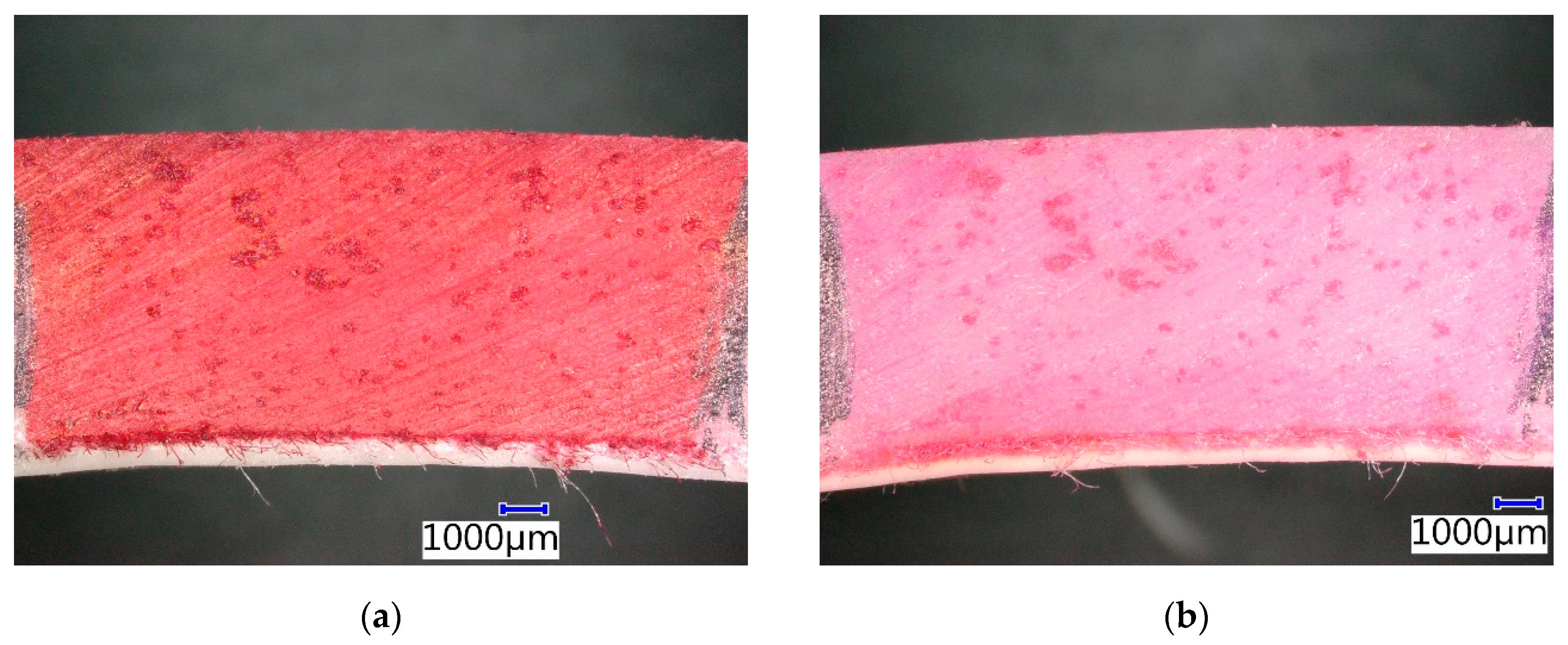

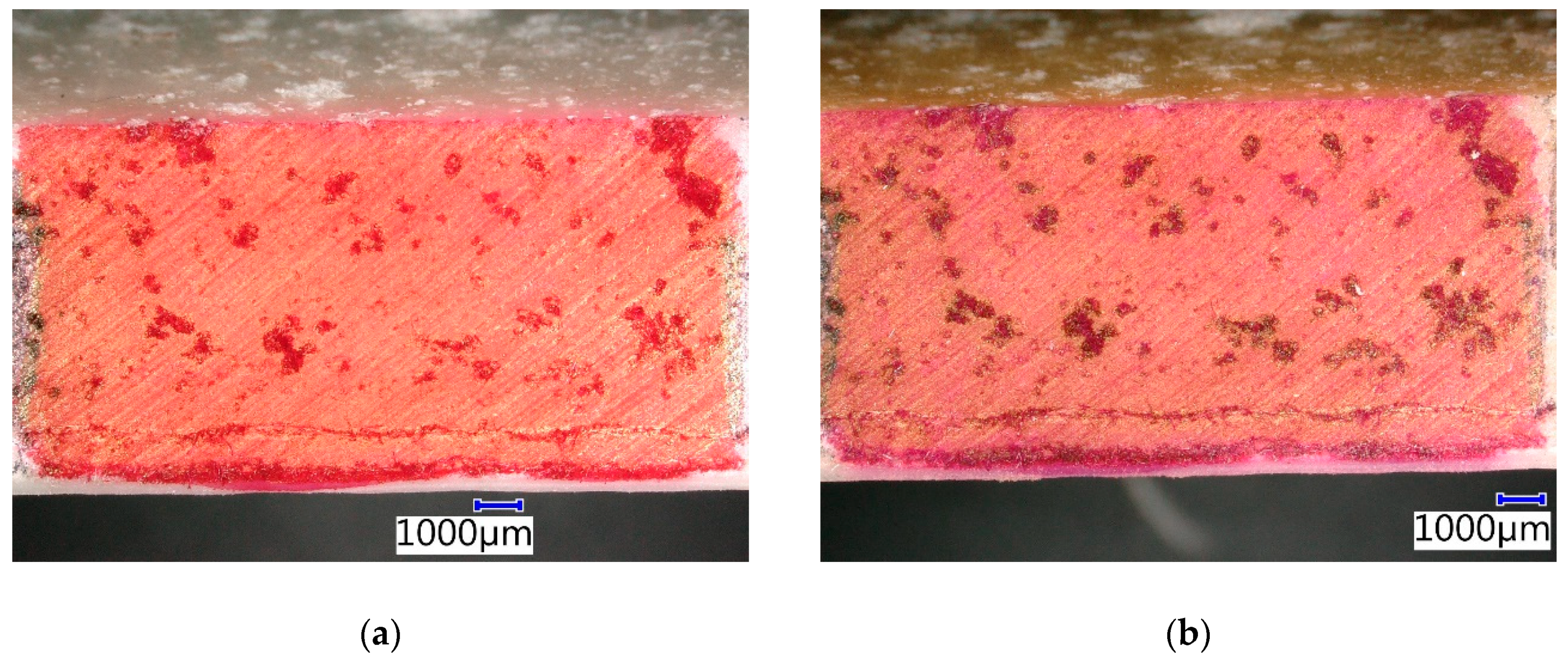

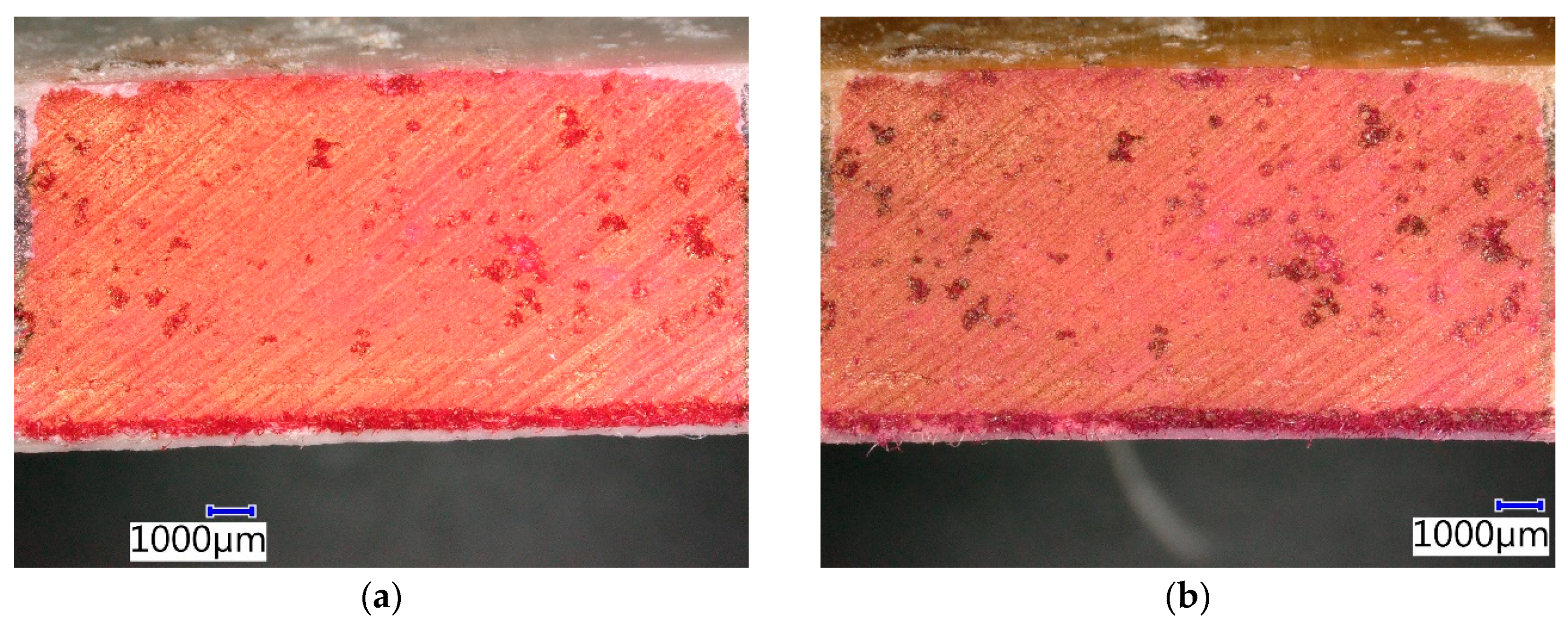

3.2. Microstructure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Seongkyum, K.; Kwanho, L. Field Performance of Recycled Plastic Foundation for Pipeline. Materials 2015, 8, 2673–2687. [Google Scholar]

- Wood, E. Method of Lining a Pipe. United States Patent US4009063, 22 February 1977. [Google Scholar]

- Wood, E. Formation of a Lining in Pipelines. United States Patent US4439469, 27 March 1984. [Google Scholar]

- Allouche, E.; Alam, S.; Simicevic, J.; Condit, W.; Headington, B.; Matthews, J.; Kampbell, E.; Sangster, T.; Downey, D. 2.0: CIPP Technology Development. In A Retrospective Evaluation of Cured-in-Place-Pipe (CIPP) Used in Municipal Gravity Sewers; U.S. Environmental Protection Agency: Edison, NJ, USA, 2011; pp. 4–14. [Google Scholar]

- Allouche, E.; Alam, S.; Simicevic, J.; Sterling, R.; Condit, W.; Matthews, J.; Selvakumar, A. A pilot study for retrospective evaluation of cured-in-place pipe (CIPP) rehabilitation of municipal gravity sewers. Tunn. Undergr. Space Technol. 2014, 39, 82–93. [Google Scholar] [CrossRef]

- Lonardo, P.M. Sviluppi e Prospettive Delle Tecnologie con Limitato Ricorso a Scavo Nella Gestione Delle Reti di Servizio Sotterranee; Atti della Giornata di Studio ATIG: Verona, Italy, 1996. [Google Scholar]

- LANZO Lining Services. Engineering Design Guide for Rehabilitation with Cured-in-Place-pipe. Available online: https://www.lanzo.net/pdf/lanzo-lining-guide-2410.pdf (accessed on 29 April 2020).

- Donaldson, B.M. Environmental Implications of Cured-in-Place Pipe Rehabilitation Technology. Trans. Res. Rec. J. Trans. Res. Board 2009, 2123, 172–179. [Google Scholar] [CrossRef] [Green Version]

- Lonardo, P.M. Trenchless Technology: The Italian Way. No-Dig Int. 1998, 9, 1–3. [Google Scholar]

- Yang, H.; Lee, J. Comparison of unsaturated polyester and vinylester resins in low temperature polymerization. J. Appl. Polym. Sci. 2001, 79, 1230–1242. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Tavares, C.M.L.; Ferreira, J.M. Chemical resistance of polyester polymer concrete to acids and salts. J. Polym. Eng. 2002, 22, 27–44. [Google Scholar] [CrossRef]

- Gu, H. Dynamic mechanical analysis of the seawater treated glass/polyester composite. Mater. Des. 2009, 30, 2774–2777. [Google Scholar] [CrossRef]

- Visco, A.M.; Campo, N.; Cianciafara, P. Comparison of seawater absorption properties of thermoset resins based composites. Compos. Part A 2011, 42, 123–130. [Google Scholar] [CrossRef]

- Kleweno, D. Physical Properties and Chemical Resistance of Selected Resins for Cured-in-Place Pipe Rehabilitation. In Buried Plastic Pipe Technology, 2nd ed.; Eckstein, D., Ed.; ASTM International: West Conshohocken, PA, USA, 1994; Volume 2, pp. 79–96. [Google Scholar]

- Benmokrane, B.; Ali, A.H.; Mohamed, H.M.; ElSafty, A.; Manalo, A. Laboratory assessment and durability performance of vinyl-ester, polyester, and epoxy glass-FRP bars for concrete structures. Compos. Part B 2017, 114, 163–174. [Google Scholar] [CrossRef] [Green Version]

- Bruzzone, A.A.G.; Lonardo, P.M.; Diverio, G. Experimental Characterization of Cured In Place Pipes (CIPP); DIPTEM, University of Genoa: Genoa, Italy, 2015. [Google Scholar]

- Suzuky, H.; Takemoto, M.; Ono, K. A study of fracture dynamics in a model composite by acoustic emission signal processing. J. Acoust. Emiss. 1993, 11, 117–128. [Google Scholar]

- Farhidzadeh, A.; Dehghan-Niri, E.; Zhong, Z.; Salamone, S.; Aref, A.; Filiatrault, A. Post-earthquake evaluation of pipelines rehabilitated with cured in place lining technology using acoustic emission. Constr. Build. Mater. 2014, 54, 326–338. [Google Scholar] [CrossRef]

- Farhidzadeh, A.; Dehghan-Niri, E.; Salamone, S. Structural Health monitoring of pipelines rehabilitated with lining technology. In Proceedings of the SPIE, San Diego, CA, USA, 9–13 March 2014; Farhidzadeh, A., Dehghan-Niri, E., Salamone, S., Eds.; SPIE: Bellingham, WA, USA, 2014; Volume 9064. [Google Scholar]

- Grosse, C.U.; Linzer, L.M. Signal-Based AE Analysis. In Acoustic Emission Testing; Grosse, C.U., Ohtsu, M., Eds.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; pp. 53–59. [Google Scholar]

- Nakamura, H. Roles and Safety/Health of Technicians Involved in Non-destructive Testing. In Practical Acoustic Emission Testing; Inaba, H., Nakamura, H., Enoki, M., Eds.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2016; pp. 1–4. [Google Scholar]

- Lacidogna, G.; Manuello, A.; Niccolini, G.; Accornero, F.; Carpinteri, A. Acoustic Emission Wireless Monitoring of Structures. In Acoustic Emission (AE) and Related Non-destructive Evaluation (NDE) Techniques in the Fracture Mechanics of Concrete; Ohtsu, M., Ed.; Woodhead Publishing: Sawston, Cambridge, UK, 2015; pp. 15–40. [Google Scholar]

- Shahri, M.N.; Yousefi, J.; Fotouhi, M.; Najfabadi, M.A. Damage evaluation of composite materials using acoustic emission features and Hilbert transform. J. Compos. Mater. 2015, 50, 1897–1907. [Google Scholar] [CrossRef]

- Sagasta, F.; Zitto, M.E.; Piotrkowski, R.; Benavent-Climent, A.; Suarez, E.; Gallego, A. Acoustic emission energy b-value for local damage evaluation in reinforced concrete structures subjected to seismic loadings. Mech. Syst. Signal Process. 2018, 102, 262–277. [Google Scholar] [CrossRef]

- Civera, M.; Ferraris, M.; Ceravolo, R.; Surace, C.; Betti, R. The Teager-Kaiser energy cepstral coefficients as an effective structural health monitoring tool. Appl. Sci. 2019, 9, 5064. [Google Scholar] [CrossRef] [Green Version]

- Ferraris, M.; Civera, M.; Ceravalo, R.; Surace, C.; Betti, R. Using Enhanced cepstral analysis for structural health monitoring. In Proceedings of the 13th International Conference on Damage Assessment of Structures, Porto, Portugal, 9–10 July 2019; Wahab, B., Ed.; Springer: Singapore, 2019; pp. 150–165. [Google Scholar]

- Sokołowska, J.J. Long-Term Compressive Strength of Polymer Concrete-like Composites with Various Fillers. Materials 2020, 13, 1207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marihart, H.; Lackner, G.; Schauritsch, G. Structural health monitoring using acoustic emission on metallic components in industrial plants. In Proceedings of the 33nd European Conference on Acoustic Emission, Senlis, France, 12–14 September 2018. [Google Scholar]

- Ono, K. Review on structural health evaluation with acoustic emission. Appl. Sci. 2018, 8, 958. [Google Scholar] [CrossRef] [Green Version]

- Madarshasian, R.; Soltangharaei, V.; Anay, R.; Caicedo, J.; Ziehl, P. Hsu-Nielsen source acoustic emission data on a concrete block. Data Brief 2019, 23, 103813. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimkhanlou, A.; Salamone, S. Single-sensor acoustic emission source localization in plate-like structures: A deep learning approach. In Proceedings of the SPIE Conference, Denver, CO, USA, 5–8 March 2018. [Google Scholar]

- Boczar, T.; Lorenc, M. Time-frequency analysis of the calibrating signals generated in the Hsu-Nielsen system. Phys. Chem. Solid State 2006, 7, 585–588. [Google Scholar]

- Gregory, N.M.; Han, Z. Damage determination in ceramic composites subject to tensile fatigue using acoustic emission. Materials 2018, 11, 2477. [Google Scholar]

| Sample | Aggressive Environment | Duration | Width [mm] | Thickness 1 [mm] | Length [mm] | Radius of Curvature R2 [mm] |

|---|---|---|---|---|---|---|

| CIPP VES1 | 15% CH3COOH | 1 week | 49.94 | 7.71 | 148.15 | 146.14 |

| 2 weeks | 49.99 | 7.62 | 148.19 | 146.18 | ||

| 3 weeks | 49.96 | 7.83 | 148.21 | 146.12 | ||

| 4 weeks | 49.98 | 7.74 | 148.17 | 146.15 | ||

| CIPP VES2 | 20% HCl | 1 week | 49.97 | 8.81 | 158.14 | 145.58 |

| 2 weeks | 49.95 | 9.02 | 158.03 | 145.48 | ||

| 3 weeks | 49.96 | 9.08 | 157.98 | 145.43 | ||

| 4 weeks | 49.95 | 9.05 | 158.02 | 145.69 | ||

| CIPP VES3 | 10% NH4OH | 1 week | 50.03 | 8.60 | 153.80 | 145.69 |

| 2 weeks | 50.07 | 9.02 | 154.04 | 145.52 | ||

| 3 weeks | 49.96 | 9.13 | 153.87 | 145.42 | ||

| 4 weeks | 50.00 | 9.11 | 154.14 | 145.61 | ||

| CIPP VES1 | 100 °C | 1 week | 49.97 | 7.72 | 7.70 | 146.13 |

| 2 weeks | 49.98 | 7.62 | 7.63 | 146.15 | ||

| 3 weeks | 49.98 | 7.92 | 7.84 | 146.18 | ||

| 4 weeks | 49.96 | 7.78 | 7.75 | 146.05 | ||

| CIPP VES2 | 130 °C | 1 week | 49.95 | 8.61 | 8.61 | 145.69 |

| 2 weeks | 49.98 | 8.92 | 8.83 | 145.57 | ||

| 3 weeks | 49.91 | 9.14 | 8.91 | 145.40 | ||

| 4 weeks | 49.93 | 9.17 | 8.85 | 145.53 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hodul, J.; Majerová, J.; Drochytka, R.; Dvořák, R.; Topolář, L.; Pazdera, L. Effect of Chemical Aggressive Media on the Flexural Properties of Cured-In-Place Pipes Supported by Microstructure Observation and Acoustic Emission. Materials 2020, 13, 3051. https://doi.org/10.3390/ma13143051

Hodul J, Majerová J, Drochytka R, Dvořák R, Topolář L, Pazdera L. Effect of Chemical Aggressive Media on the Flexural Properties of Cured-In-Place Pipes Supported by Microstructure Observation and Acoustic Emission. Materials. 2020; 13(14):3051. https://doi.org/10.3390/ma13143051

Chicago/Turabian StyleHodul, Jakub, Jana Majerová, Rostislav Drochytka, Richard Dvořák, Libor Topolář, and Luboš Pazdera. 2020. "Effect of Chemical Aggressive Media on the Flexural Properties of Cured-In-Place Pipes Supported by Microstructure Observation and Acoustic Emission" Materials 13, no. 14: 3051. https://doi.org/10.3390/ma13143051

APA StyleHodul, J., Majerová, J., Drochytka, R., Dvořák, R., Topolář, L., & Pazdera, L. (2020). Effect of Chemical Aggressive Media on the Flexural Properties of Cured-In-Place Pipes Supported by Microstructure Observation and Acoustic Emission. Materials, 13(14), 3051. https://doi.org/10.3390/ma13143051