1. Introduction

Concrete-filled steel tubes (CFST) are known as structural composite members, wherein the voids of steel tubes are filled with concrete to enhance stiffness and load-bearing capacity [

1]. The inter-boundary stresses of structural members are key to engineering advanced composites. Thus, the inherent engineering properties of such materials have earned them the global application as a state-of-the-art technique in the construction industry [

2,

3]. In such a design pattern, structural members are combined, such as the case in concrete-filled steel tubes, to provide unprecedented structural properties as solutions to a focused situation [

1]. Concrete-filled steel tubes have numerous benefits, several advantages over ordinary structural steel, and normal reinforced concrete applications. The infill of concrete is restrained by the steel tube, resulting in producing a tri-axial limit state of compression that upsurges, which causes a hike in the strain and strength capacities of the infill of concrete [

4]. The concrete restrains the steel tubes from both global and local buckling. Consequently, the distortion capacity of a CFST compares favorably with those of hollow tubes [

5]. Further, the composited strength of both the concrete and steel offers outstanding compressive axial load and stiffness capacity. This makes the composite highly suitable for compressive structural applications, such as in columns [

6]. Concrete-filled steel tubes is also permitted a fast construction since the steel tube abolishes the formwork and reinforcement related to concrete infill and reinforced concrete construction, which is quickly filled and formed [

1]. The constituents of HPC contribute most efficiently to different structural requirements including strength, toughness, energy absorption capacity, durability, corrosion resistance, and damage tolerance when subjected to large deformations in structural members [

7].

It is reported that, in cases of long-span structural members that require restriction in cross-sectional dimensions and that experience seismic forces, quivers, and vibrations, for such a situation, structural steel-filled concrete offers the best solution [

8]. It combines the advantages of the concrete and steel such as the optimized cross-sectional dimensions, high strength, stability, and toughness [

3,

9]. The flexural behaviors of these concrete-filled steel tube (CFST) composite beams have been increasingly researched by engineers in the last two decades to enable the common use of (CFST) in structural projects [

10]. Usually, aside from the fact that the beams, when compared to their hollow steel tube counterpart beams, display a high self-weight in return, they exhibit specific strengths, such as higher ductility, moment capacity, and stiffness. Concrete filled into the tube may significantly reduce or protect local buckling which happens mostly in the hollow tubes’ compressed zones [

11]. Strengthening is, however, needed in the CFST flexural members because of deterioration due to the natural and environmental factors and possible upgrade of a structural member to accommodate additional loads [

12]. Project funding, often times, are significantly raised as a result of the strengthening practices for the present steel and composite structural parts by replacement and addition of new steel elements, because these repair works are time and capital intensive [

13]. In recent years, engineers have made utilization of carbon fiber-reinforced polymer (CFRP) schemes for steel sections’ strengthening [

12,

13,

14]. These schemes are suitable for resisting harsh weathers and possess high strength and elasticity compared with its weight ratio higher than those of the steel [

15].

The use of CFRP in steel members has been investigated in previous studies. The adoption of different retrofitting techniques, application of loads, and behavioral cohesiveness across the CFRP and steel boundary of composited elements have equally been critically analyzed [

6]. Generally, the strengthening of CFST flexural members with CFRP sheets of one direction using the full strengthening sheet of their cross-section has been examined previously in various studies [

5]. Carbon fiber-reinforced polymer (CFRP) sheets that can effectively resist the high-tension stress are utilized to mainly upgrade the capacities of both the simply wrapped steel and concrete-steel I-beams when equally laid along their tension flange [

16]. In addition, it could be difficult to achieve an adequately strengthened cross-section by reducing the quantity of the CFRP in a partially retrofitted CFST beam. This is so because loads are applied on the top flanges of beams, typically, when used as girders for bridges [

17]. Employing the CFRP schemes could thus be considered as an appropriate solution when following the same strengthening concept of steel-beam as the simply supported CFST beams are strengthened from the bottom flanges [

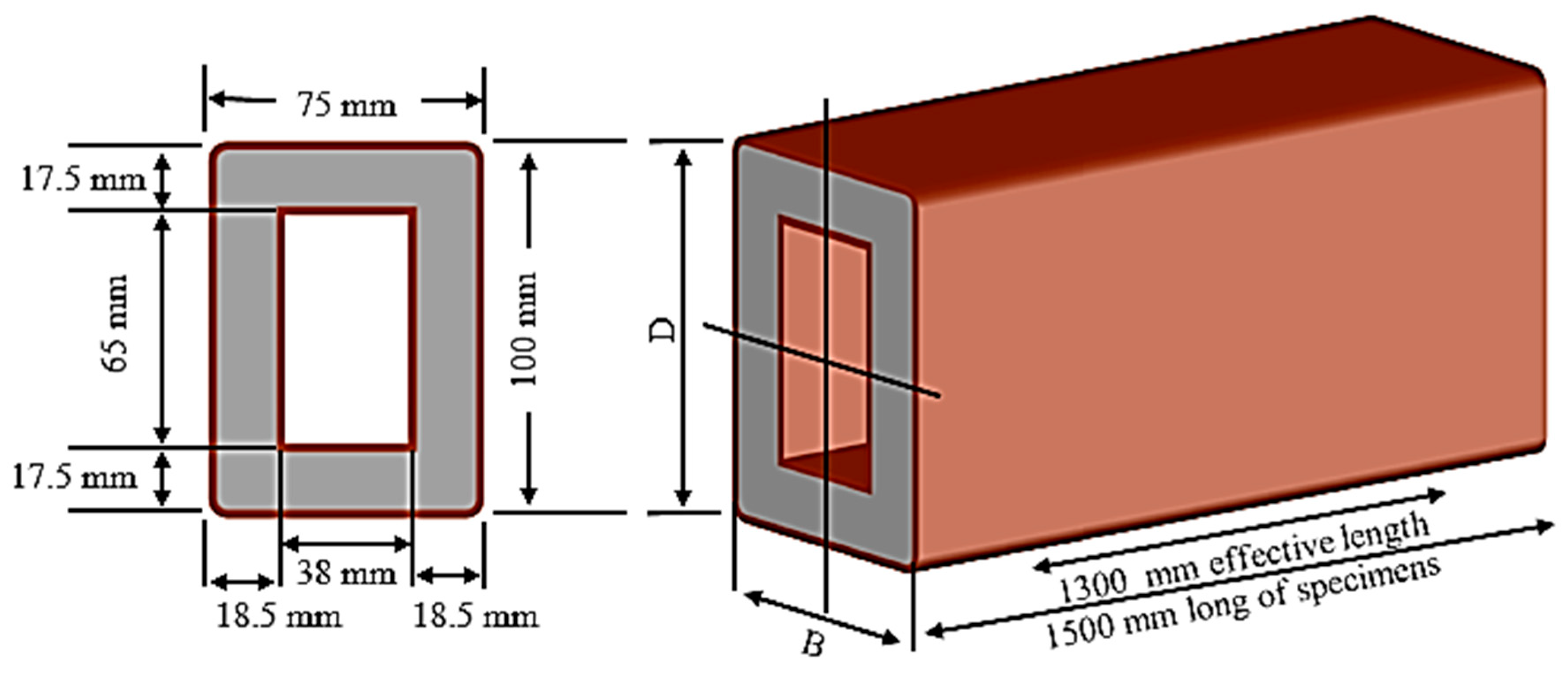

18]. Another composite construction innovation is known as the concrete-filled double-skin steel tubes (CFDST). Although the CFDST members display almost all the strengths of the traditional CFST members, they exhibit a lighter in weight, higher bending stiffness, and better cyclic performance [

19]. Two concentric steel tubes with concrete sandwiched within them are what embedded in this innovative composite construction. The steel tubes can be circular hollow sections (CHS), square hollow sections (SHS), or rectangular hollow sections (RHS) [

20] which eventually lead to several possible combinations as shown in

Figure 1.

Yu et al. [

21] have studied the flexural behavior of hybrid FRP concrete steel double-skin tubular beam (DSTB). The specimens exhibited high ductility performance and high shear resistance. The authors concluded that the flexural response of a DSTB, including the flexural stiffness, the ultimate load, and cracking can be substantially improved by shifting the inner steel tube toward the tension region or providing FRP bars as additional longitudinal reinforcement. Uenaka and Kitoh [

22] have investigated the mechanical behavior of a concrete-filled double skin circular (CFDST) hollow beam. The results presented that the failure mechanisms of the tested beams were governed by the parameter di/do (diameter of inner tube over a diameter of the outer tube) where the beams with highest di/do, experienced filled concrete crushing in the early stage of loading. Moreover, Idris and Ozbakkloglu [

23] have studied the effects of varying the inner diameter of steel tube and the use of mechanical connectors on the steel tube on the flexural behavior of hybrid circular double-skin tubular beams under static load. The results showed high inelastic deformation and minimal strength degradations. The higher inner diameter decreased the slip between the concrete and the steel tube of DSTB as well as the mechanical connectors. Therefore, the flexural capacity of the tested beams was improved significantly. Concrete-filled, double-skin steel tube (CFDST) beams using CFRP sheets and high-performance fiber-reinforced cementitious composite have never been investigated to date. This research, therefore, aims to study the effectiveness of employing the unidirectional CFRP sheets in the strengthening of the high-strength rectangular double-skin steel tube beams filled with high-performance reinforced fiber composite concrete under four-point bending. The effects of various parameters, such as configuration, multiple CFRP layers, and varied wrapping lengths of CFRP in high-performance fiber-reinforced cementitious filled-double skin steel tube (HPCFDST) beams, were investigated.

Previous laboratory works have been studied the bending performance of CFST [

16,

17,

18,

19,

20,

21,

22,

23,

24]. The major findings provided an overview of the CFST bending behavior; nevertheless, the investigational campaigns were limited, and, consequently, it is tough to examine the full-scale specimens to determine significant parameters of the design aspect [

17]. Further empirical studies and analytical finite element methods (FEM) would buffer and complement the previous findings. The analytical FEM would offer a great opportunity to investigate parameters such as sizes, geometry, and structural arrangements that are difficult to replicate in actual experimental exercises [

18]. Several studies have engaged macro-element and fiber-based models to analyze the CFST column and beam [

25]. The use of fiber-reinforced polymer (FRP) composites in the fabrication of novel high-performance composite elements, such as beams and columns, in the shape of CFFTs, has been widely become common and tested under flexural loads [

26,

27].

As proceedings from past studies on CFFTs, a novel composite design of steel tubes with embedded CFRP tubes filled with concrete has gained prominent research interest [

1]. The double-skin tubular columns and beams (i.e., DSTCs and DSTBs) depend on a similar CFRP tube confinement apparatus that is shown in CFFTs. In that case, the integration of the benefits of the three essential materials can be harnessed to display good structural performance. Several laboratory investigations have been considered on the composite components [

1,

18,

27,

28,

29,

30]. However, there are some gaps in the existing studies, which include the compatibility of infilled concrete with the skin section materials. In most cases, concrete was much weaker than the skin sections, therefore either the failure happened in concrete, whereas the skin sections were stressed at moderate to a low level, which would be an uneconomical solution. Therefore, this study used high-strength fiber-reinforced concrete to optimize the load-carrying capacity of the steel section and infilled concrete.

The main findings of these investigations were the the performance features provided by the CFFT composites subjected to different loading conditions. Whereas, the most significant role of such design systems is its efficacy in result verifications. For the DSTC and DSTB application, the composite behavioral features between concrete infill and double-skin steel tube filled with ultra-high cementitious materials integrated with CFRP sheets are yet to be studied. Thus, the aim of this study was to experimentally investigate the flexural behavior of a double-skin steel tube filled with high-performance concrete and strengthened with CFRP sheets and to compare the results with an analytical study using equations presented by four different codes.