Study on the Influence of Surface Temperature Field of Aluminum Alloy Etched by Laser Water Jet Composite Machining

Abstract

:1. Introduction

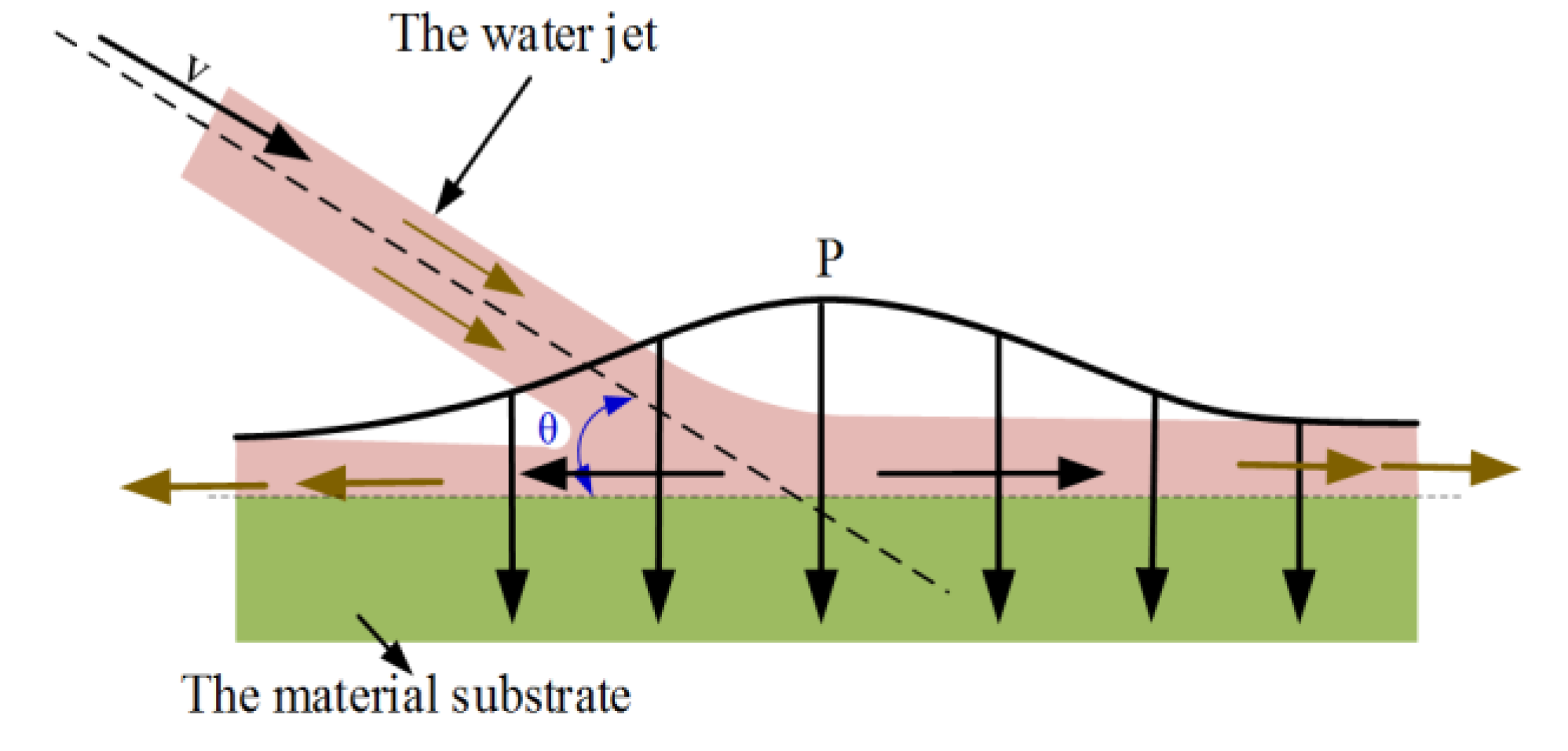

2. Theoretical Analysis of Water Jet Action

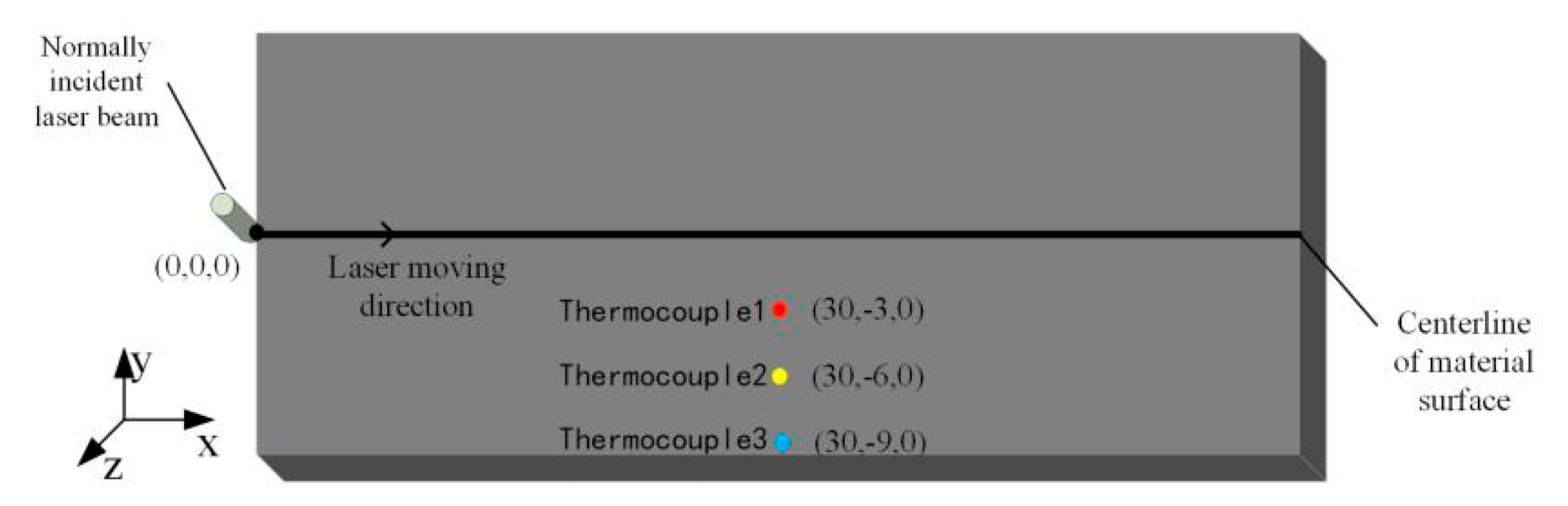

3. Simulation of the Temperature Field of 7075 Aluminum Alloy Surface by Water Jet Assisted Laser Etching

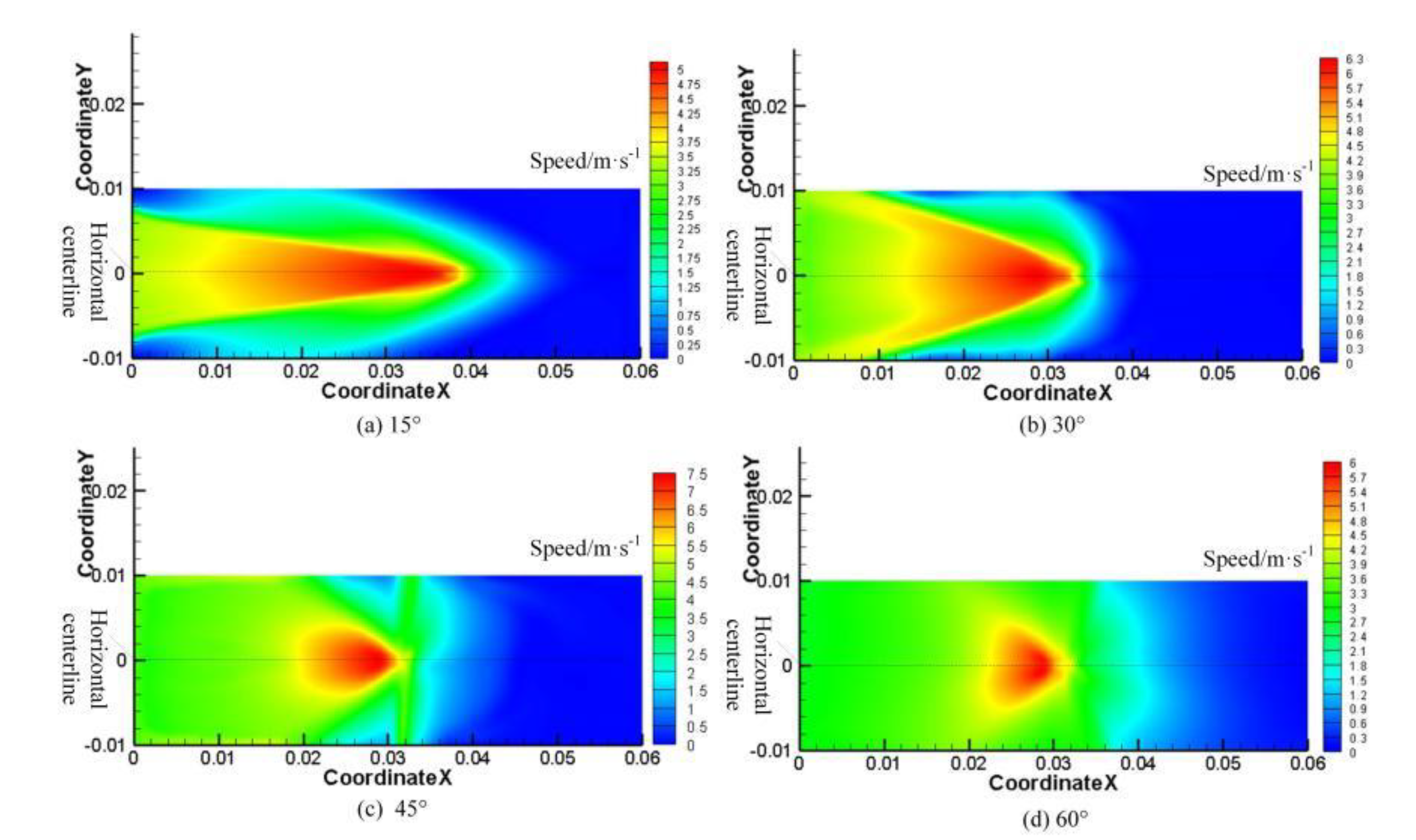

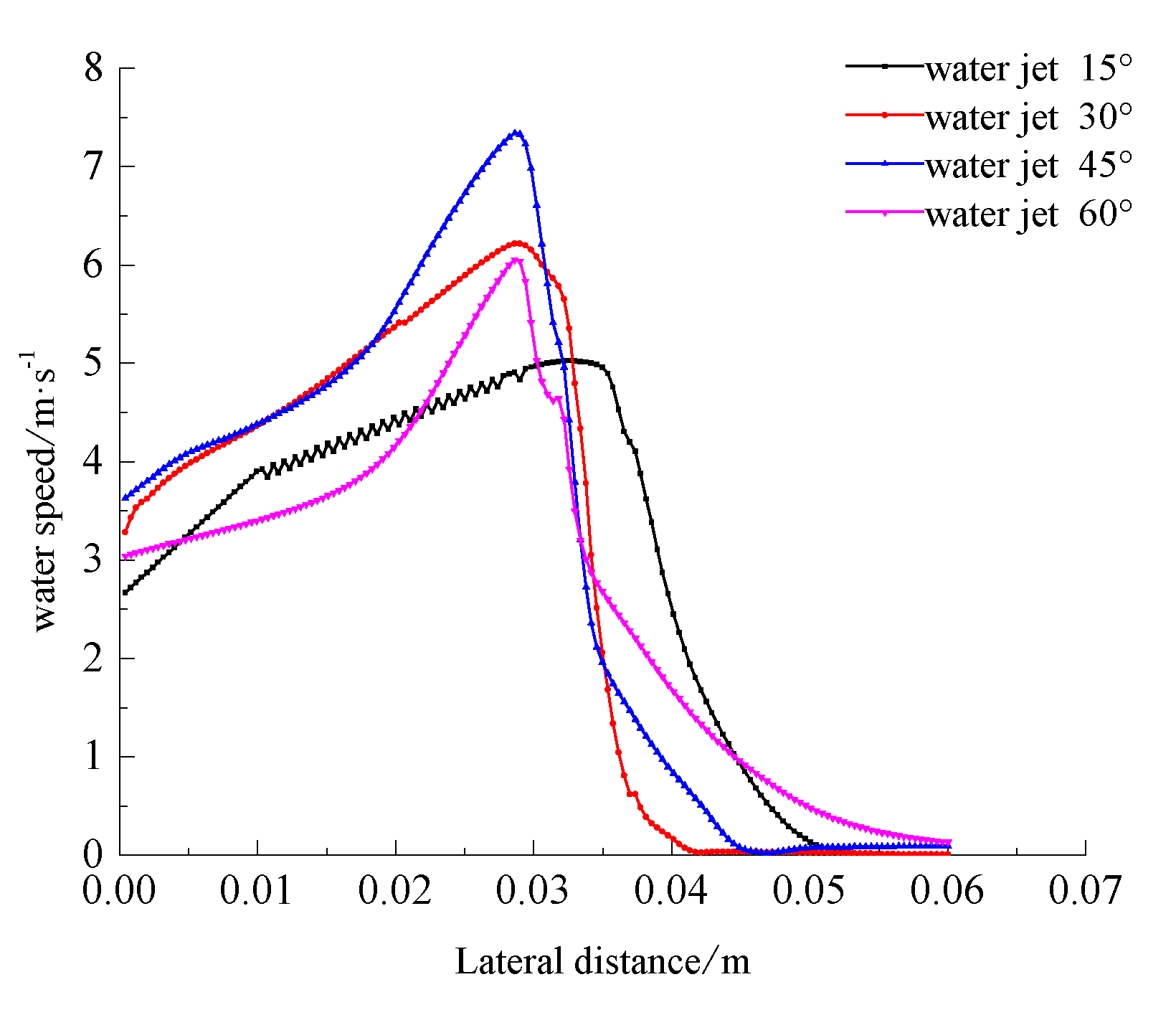

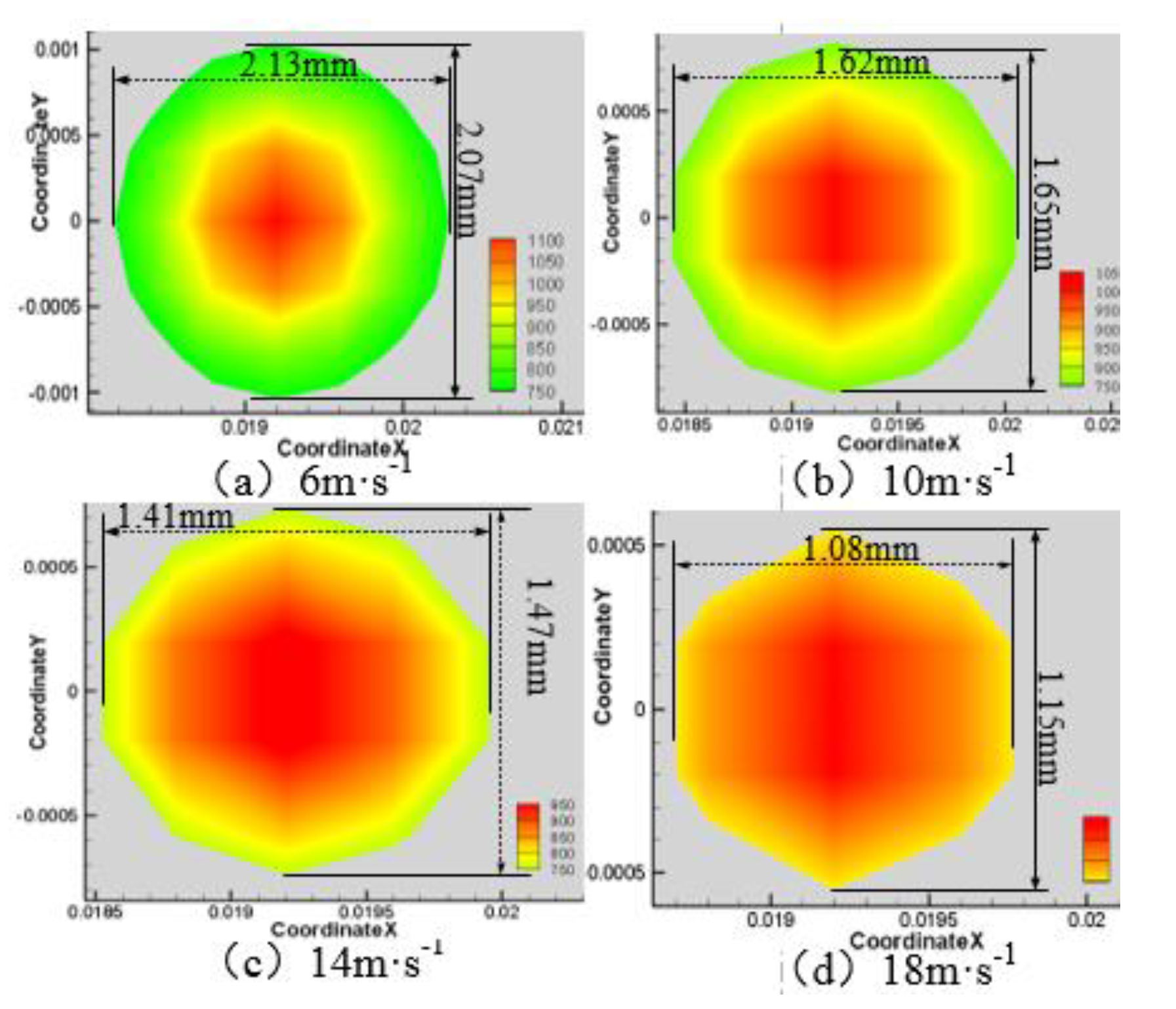

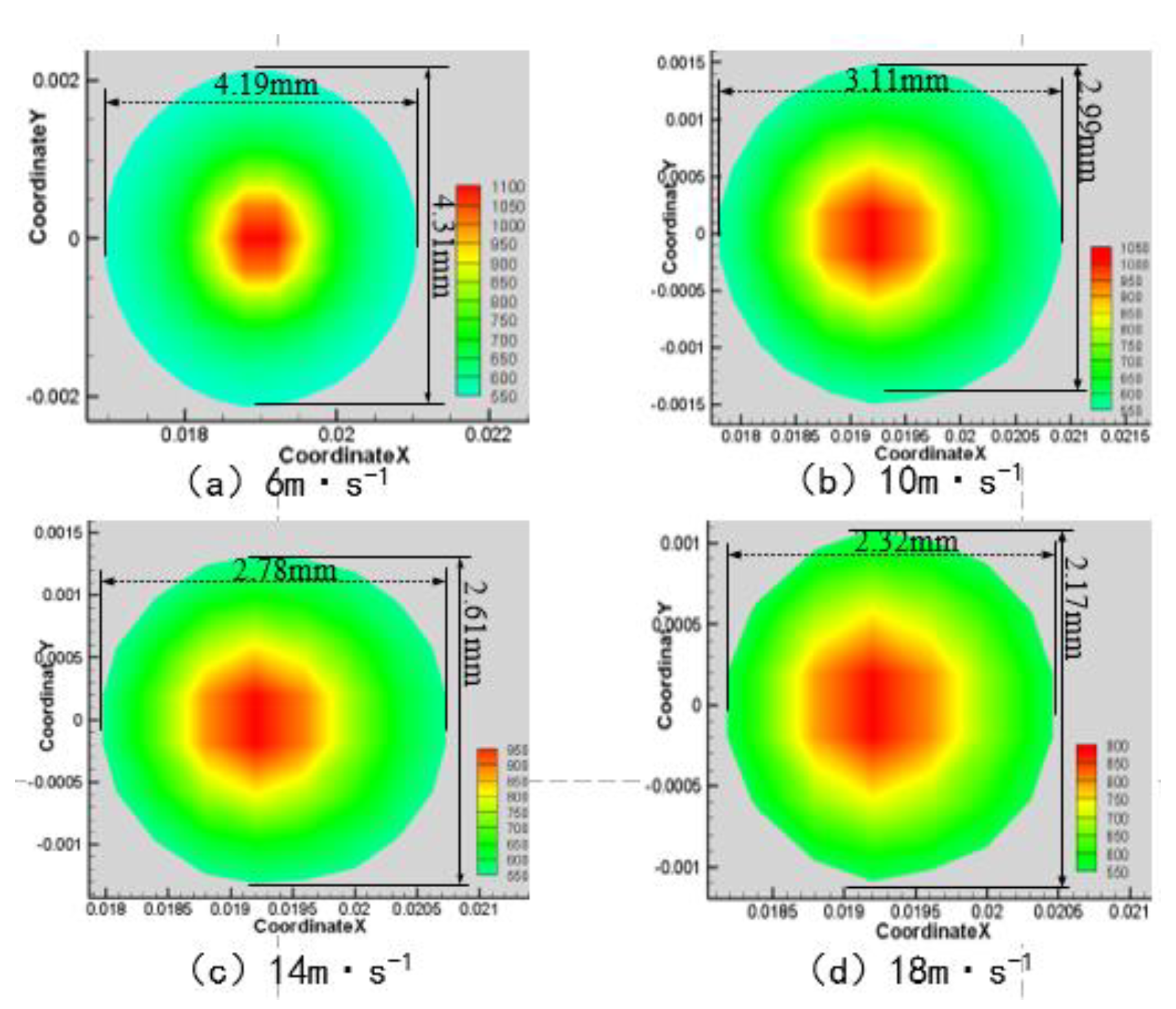

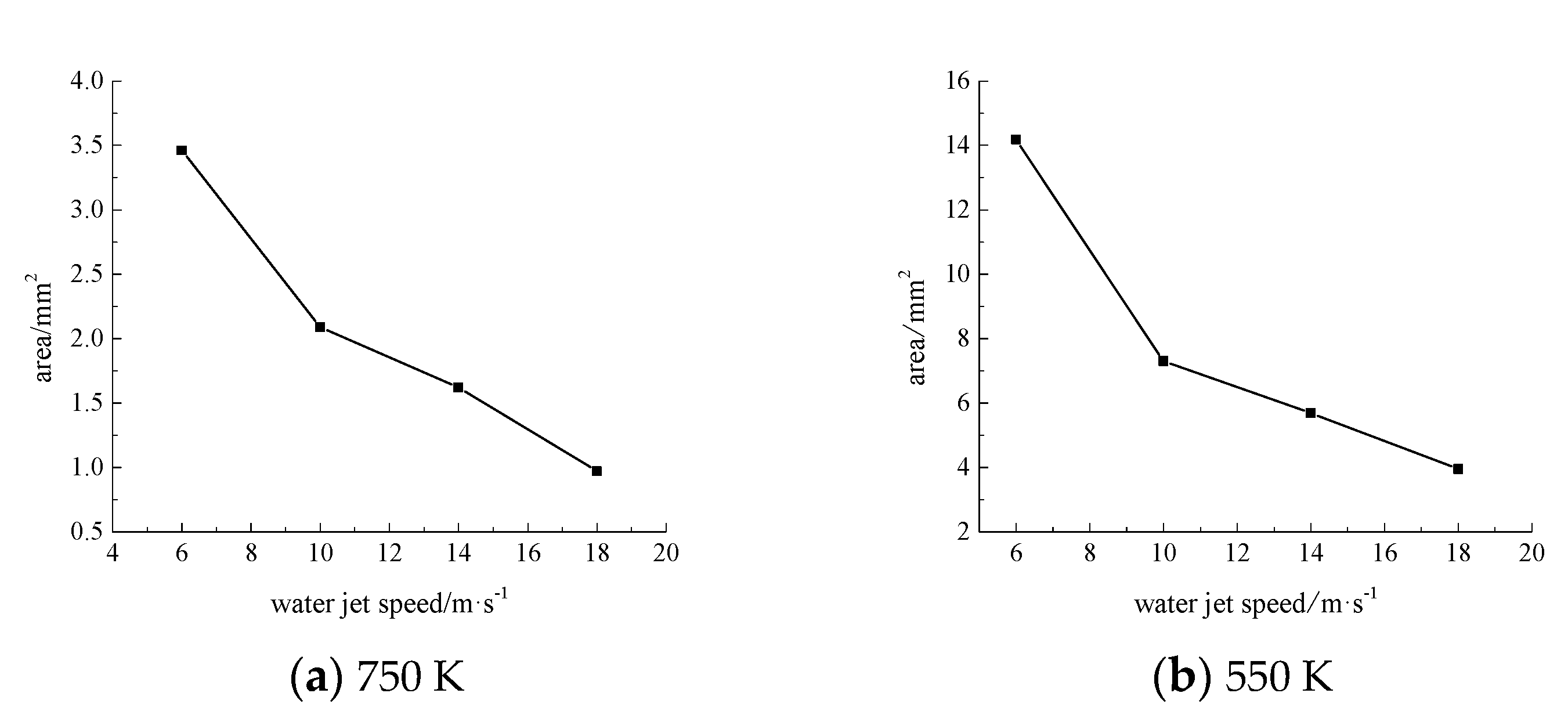

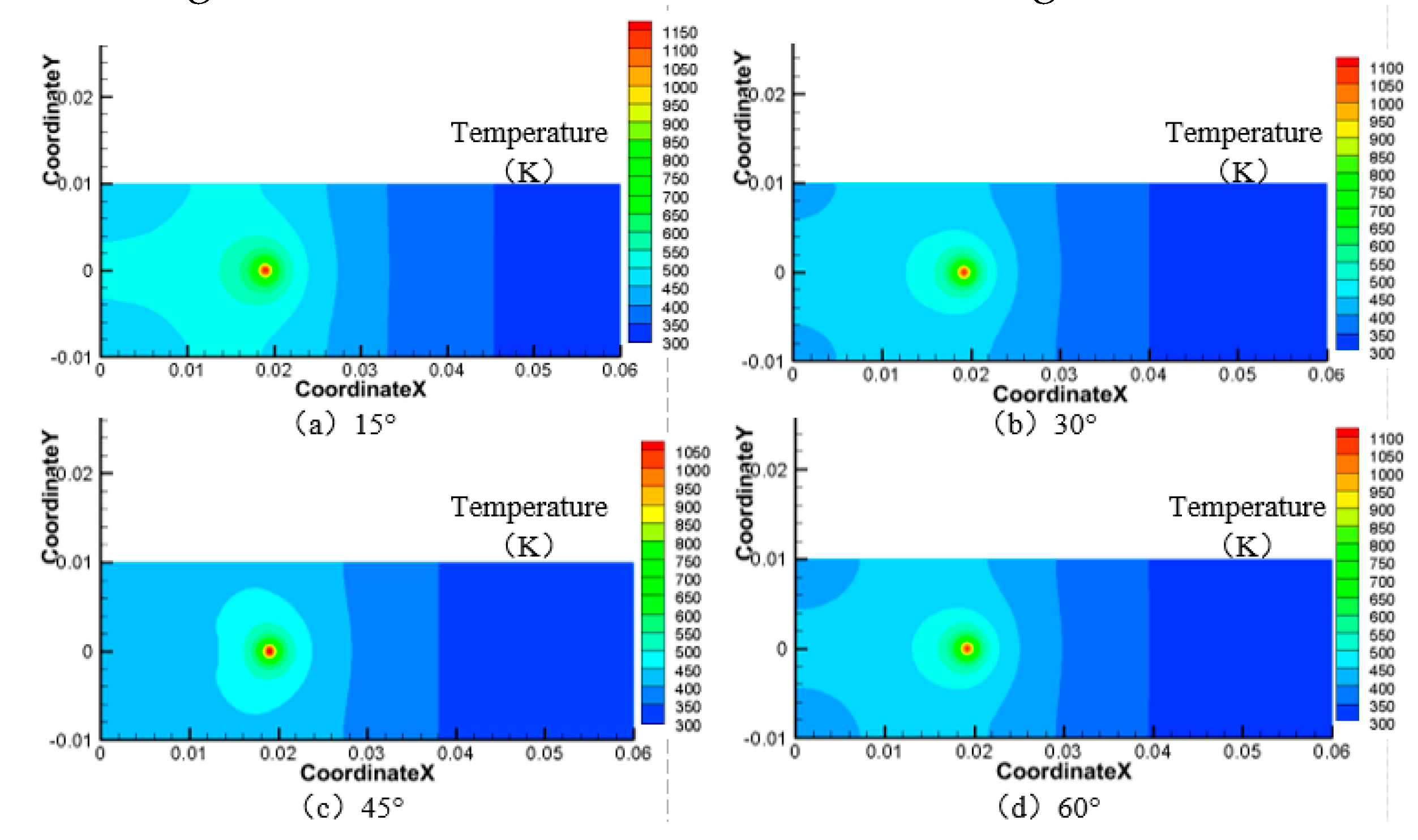

3.1. Water Jet Impact Simulation

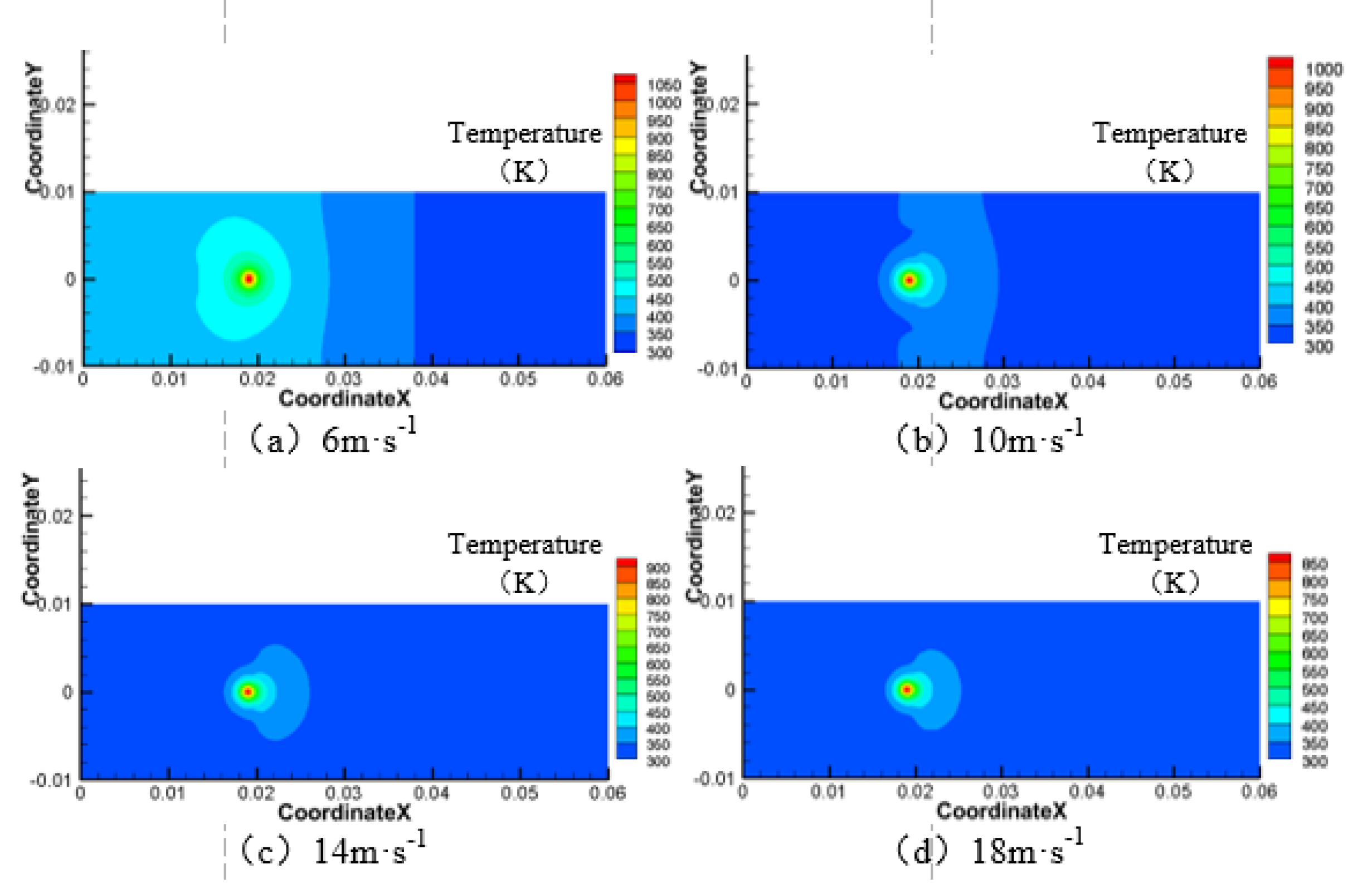

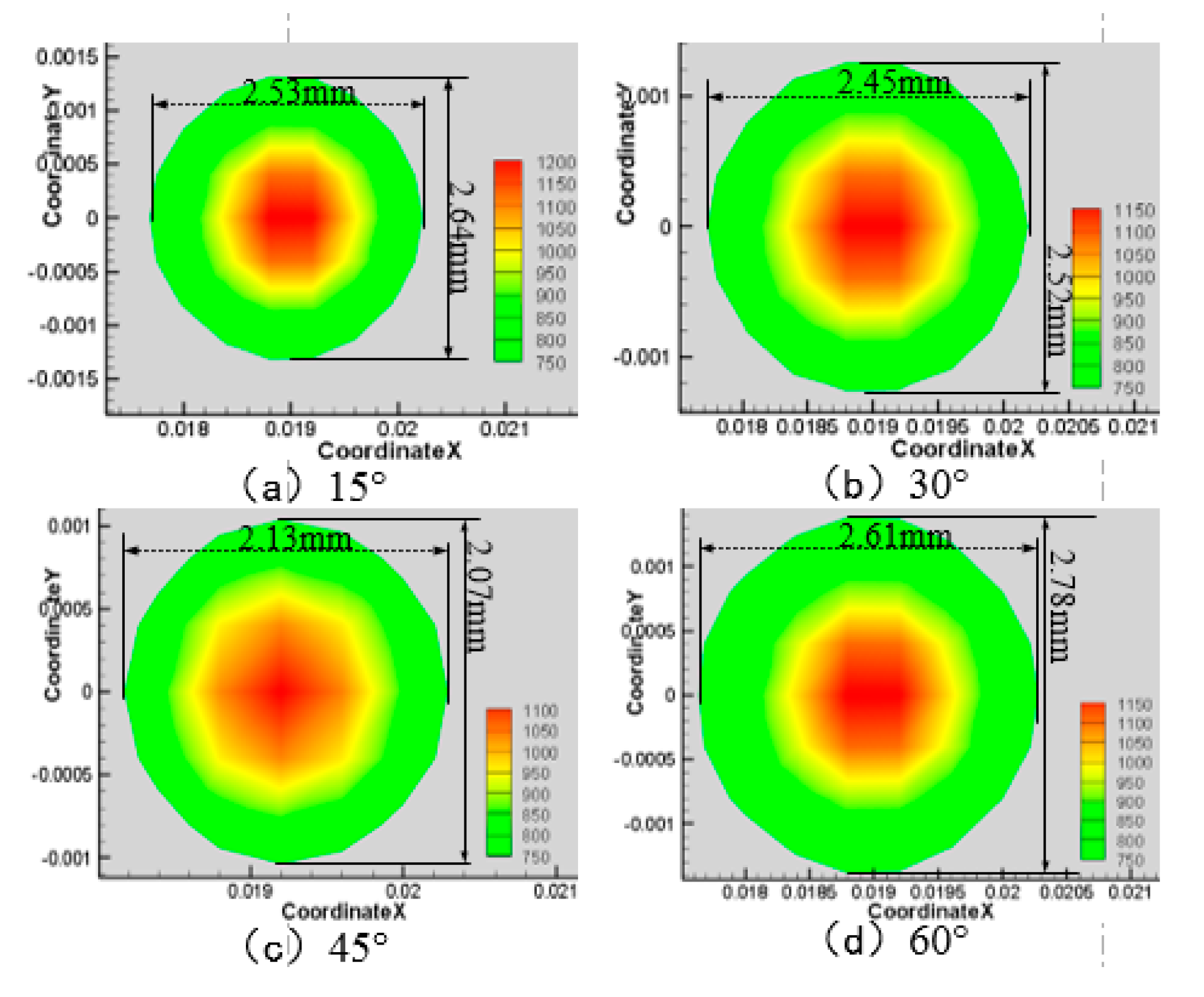

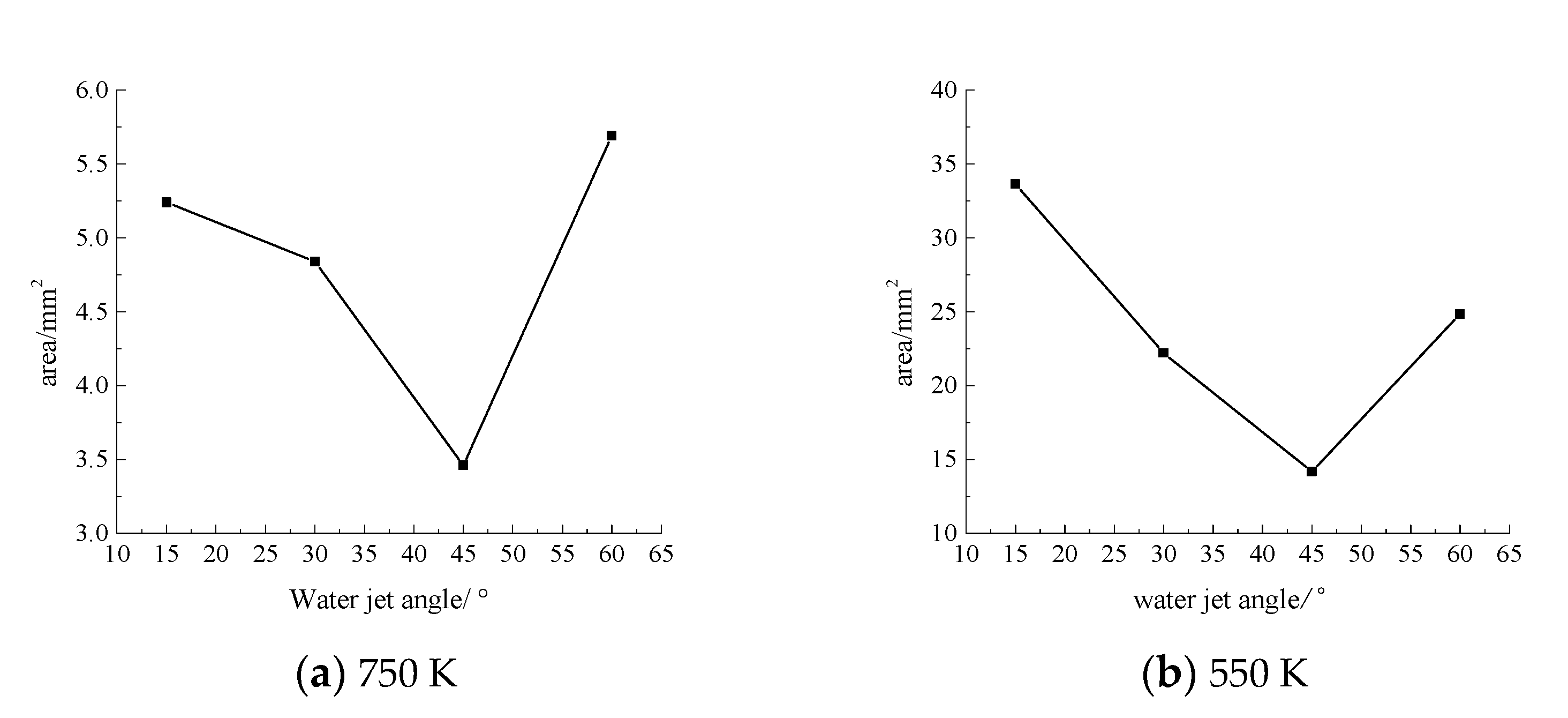

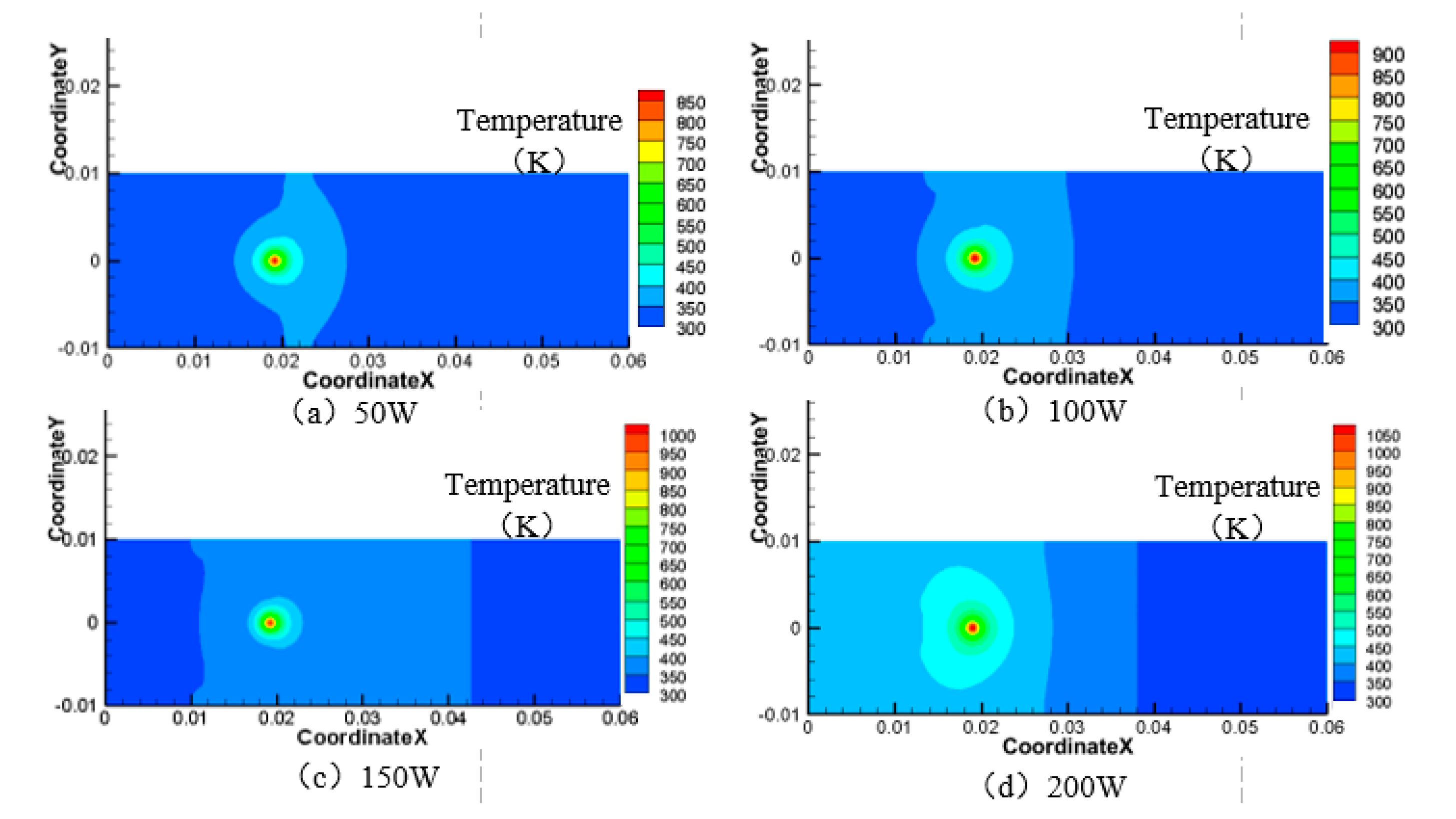

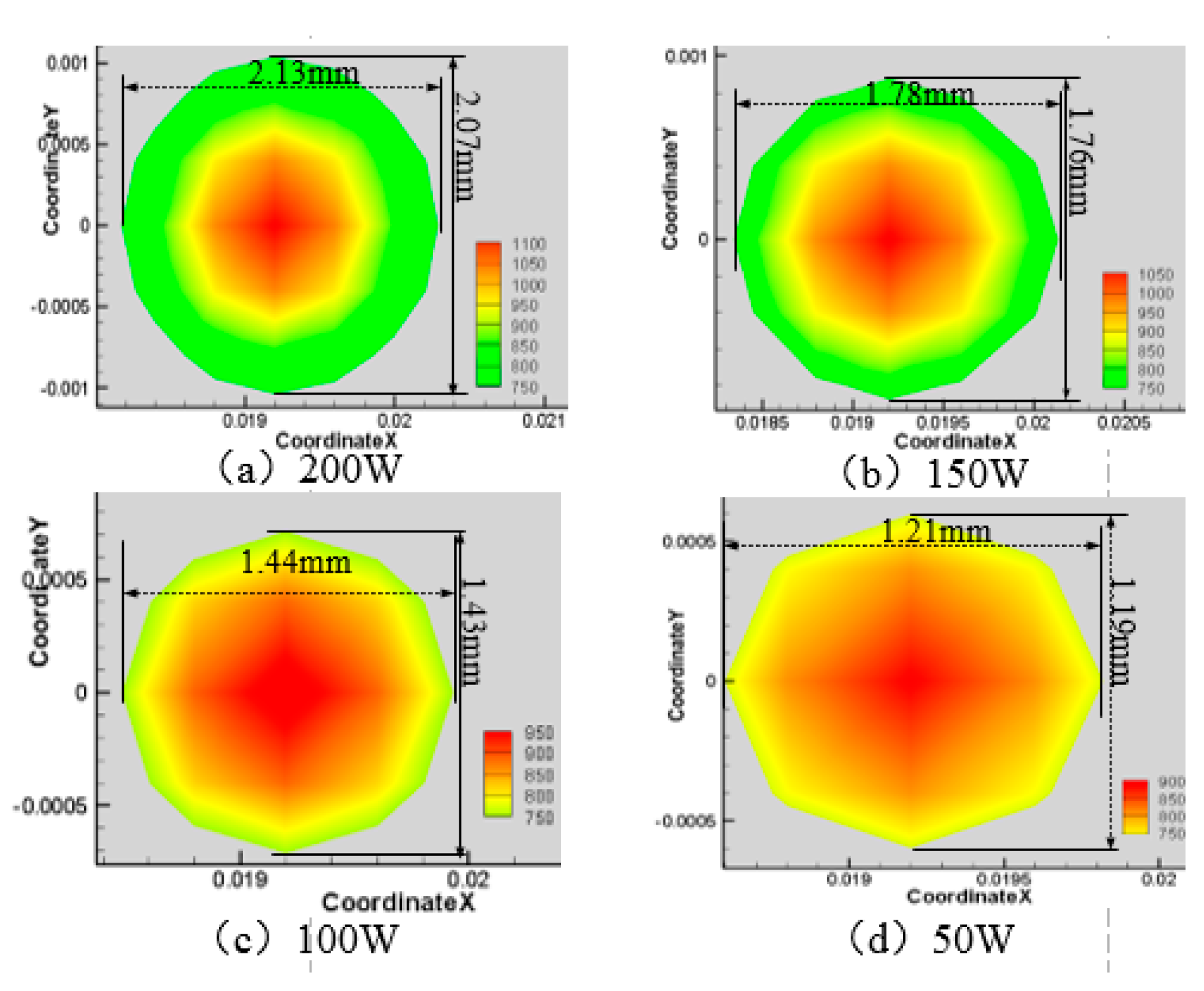

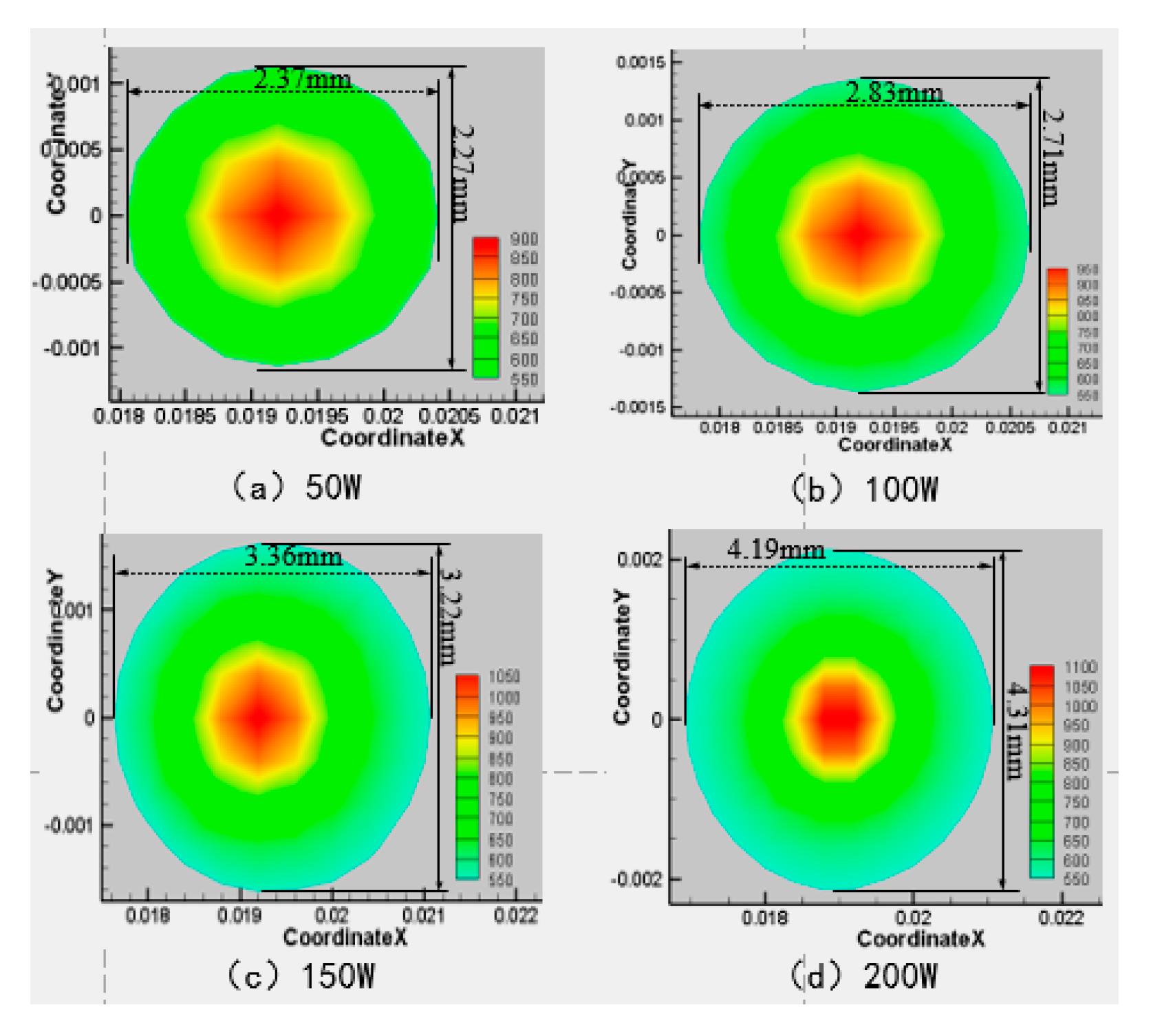

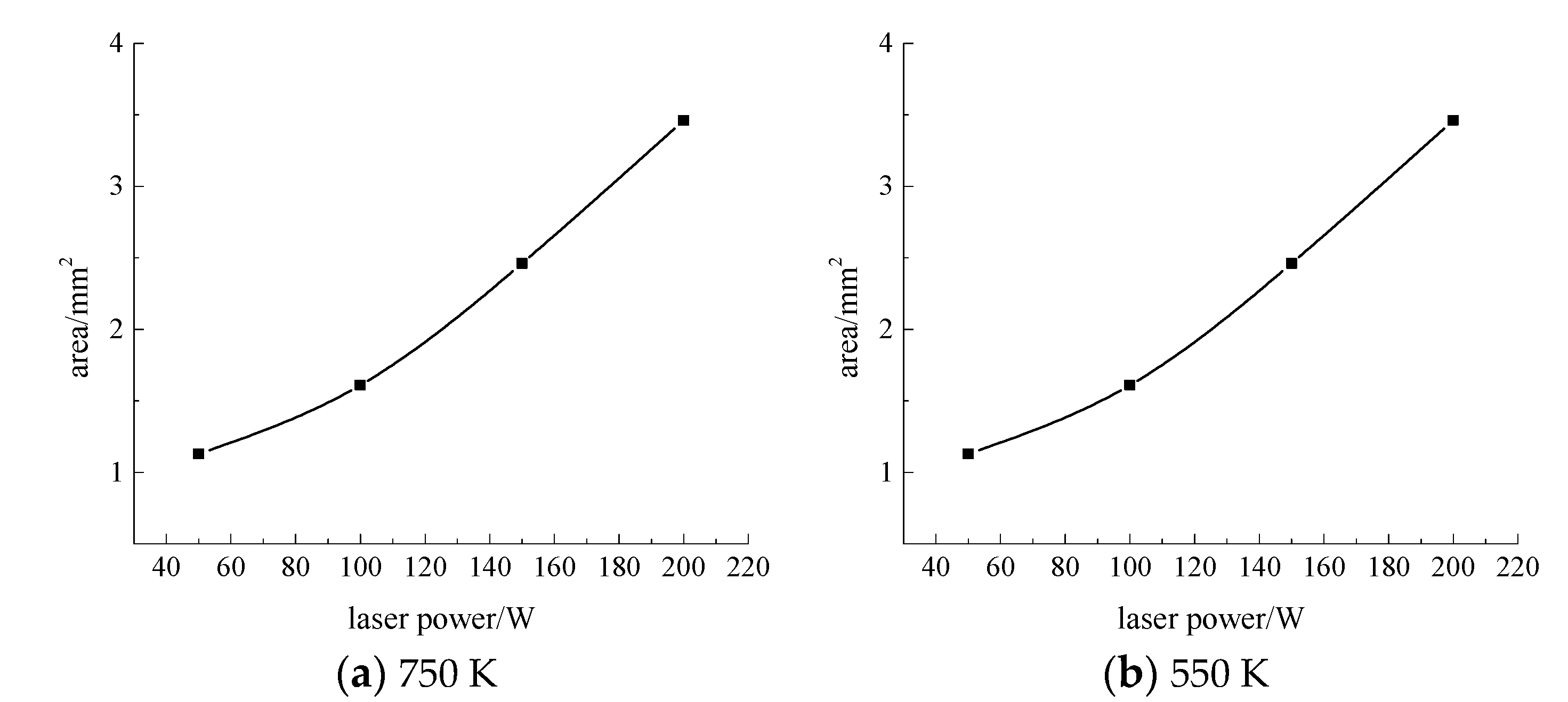

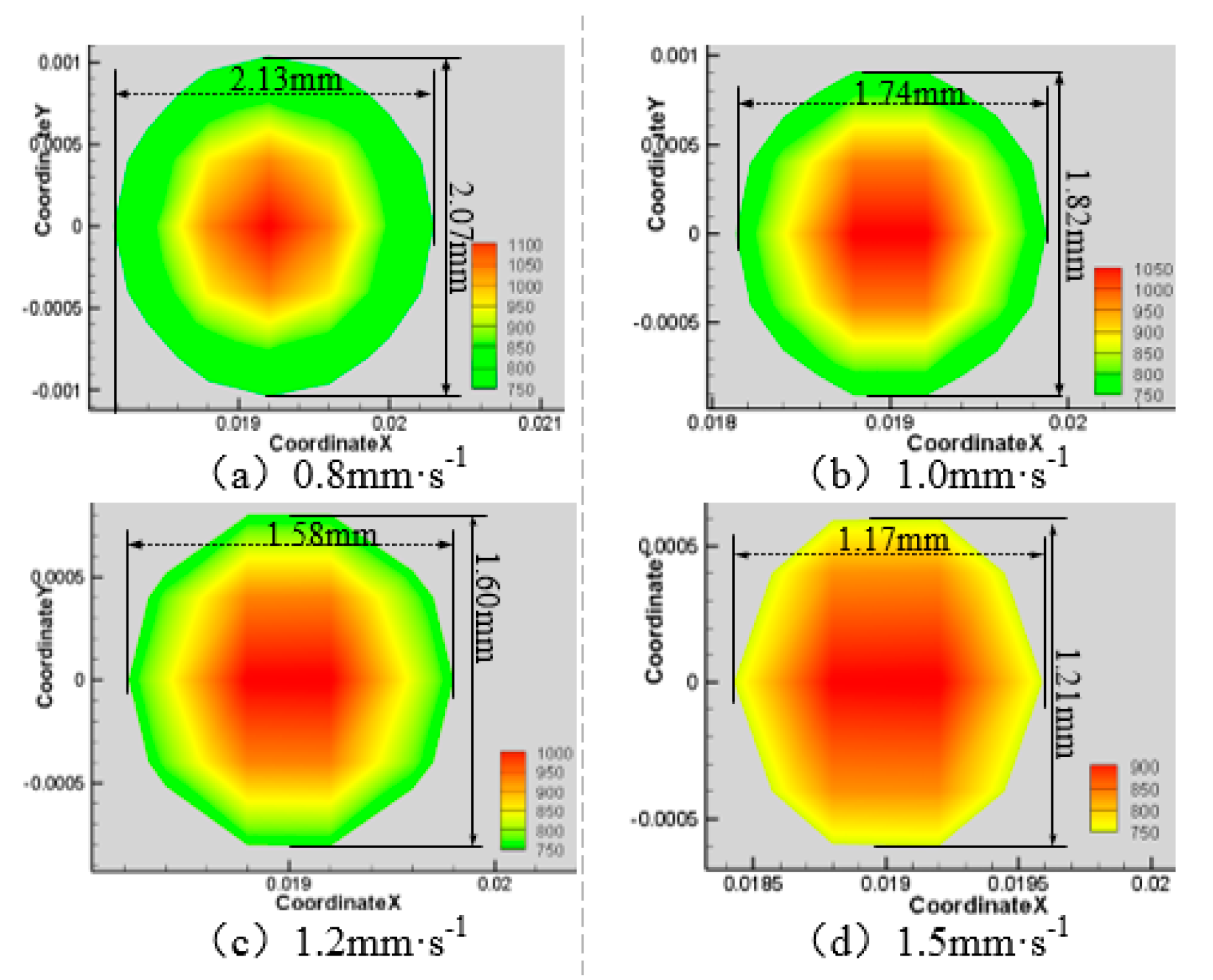

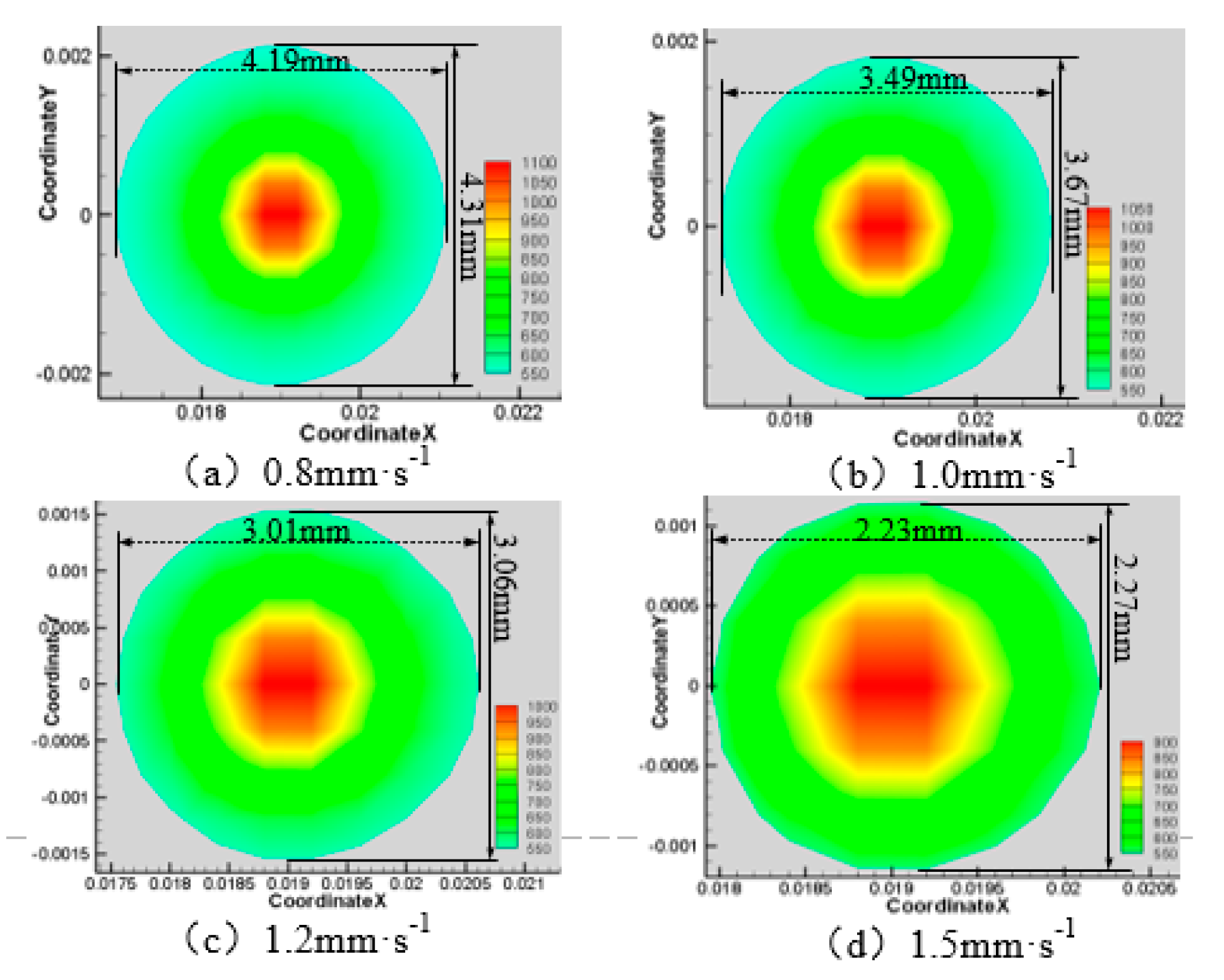

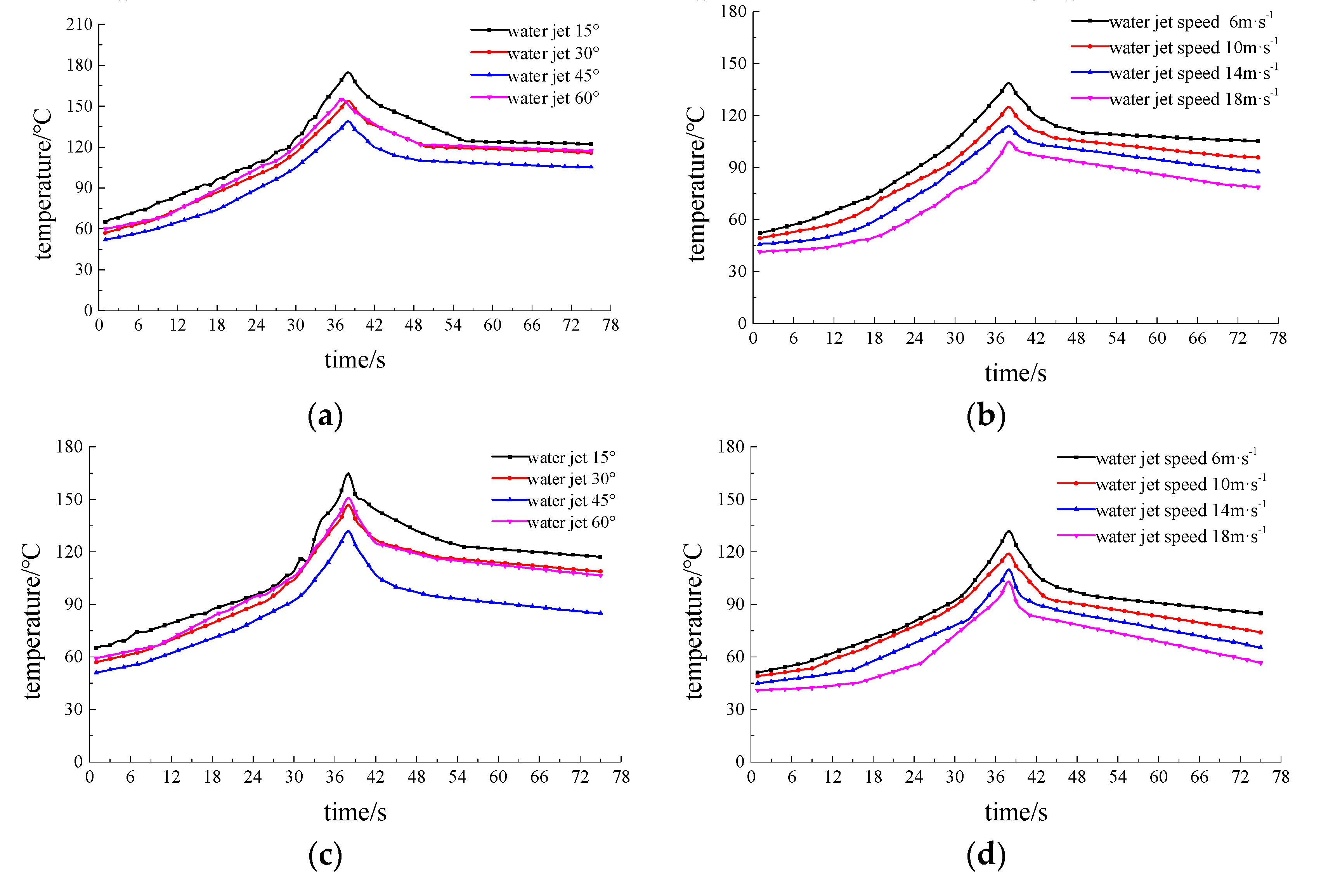

3.2. Water Jet Assisted Laser Etching of the 7075 Aluminum Alloy Surface Temperature Field Analysis

4. Experimental Detection and Processing Results

4.1. Experimental Processing System

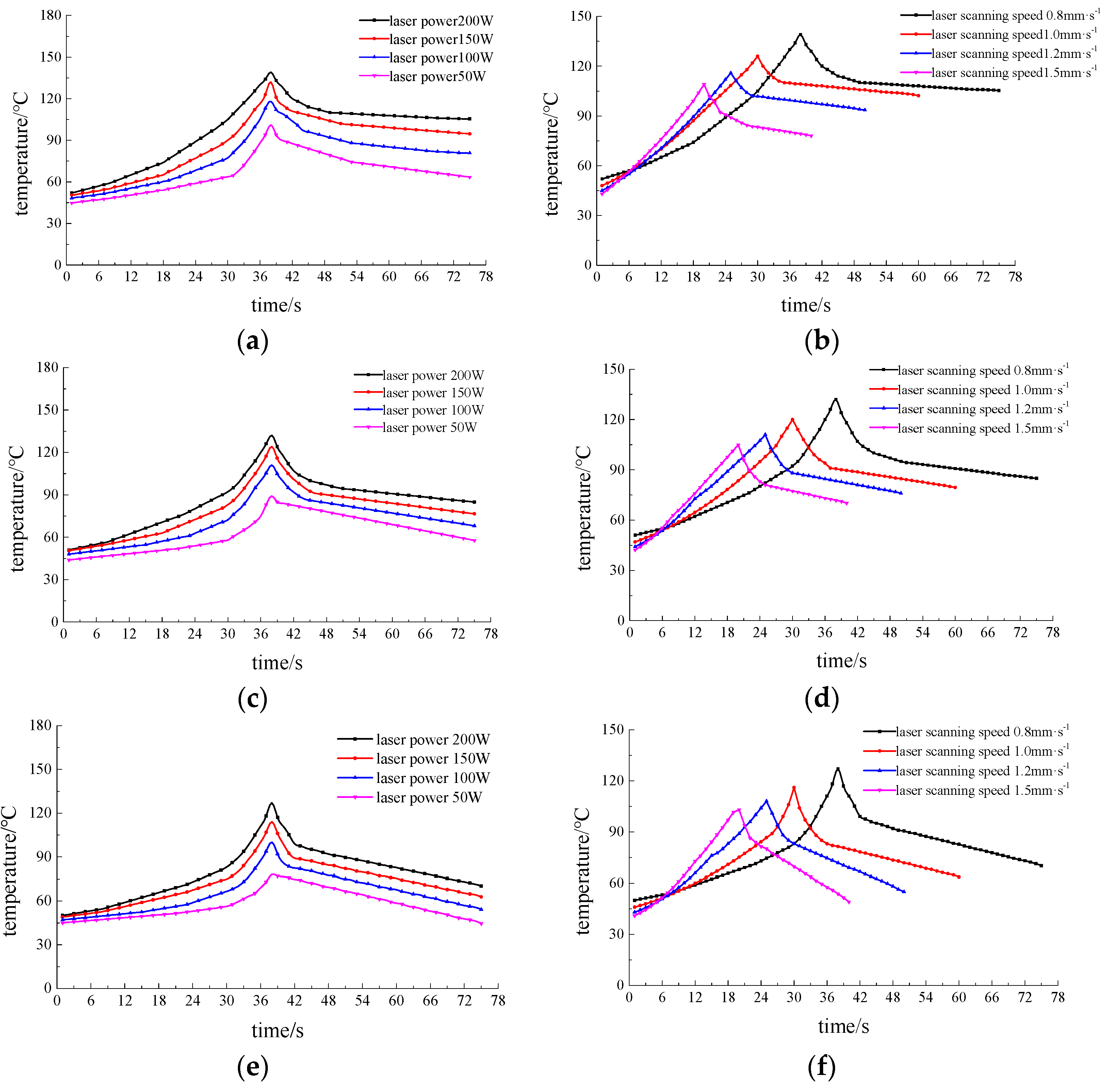

4.2. Water Jet Assisted Laser Etching of the 7075 Aluminum Alloy Surface Temperature Field Result Analysis

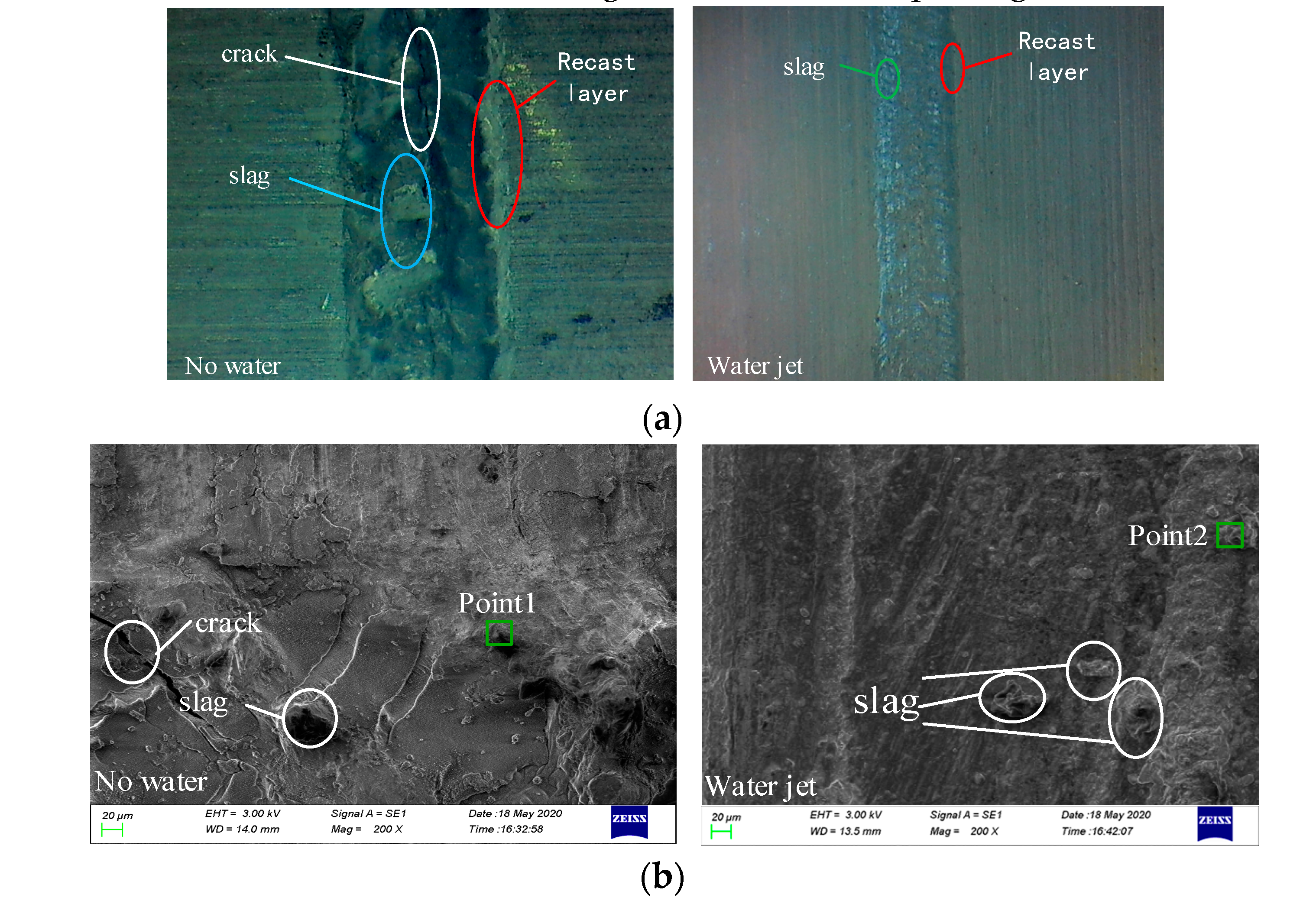

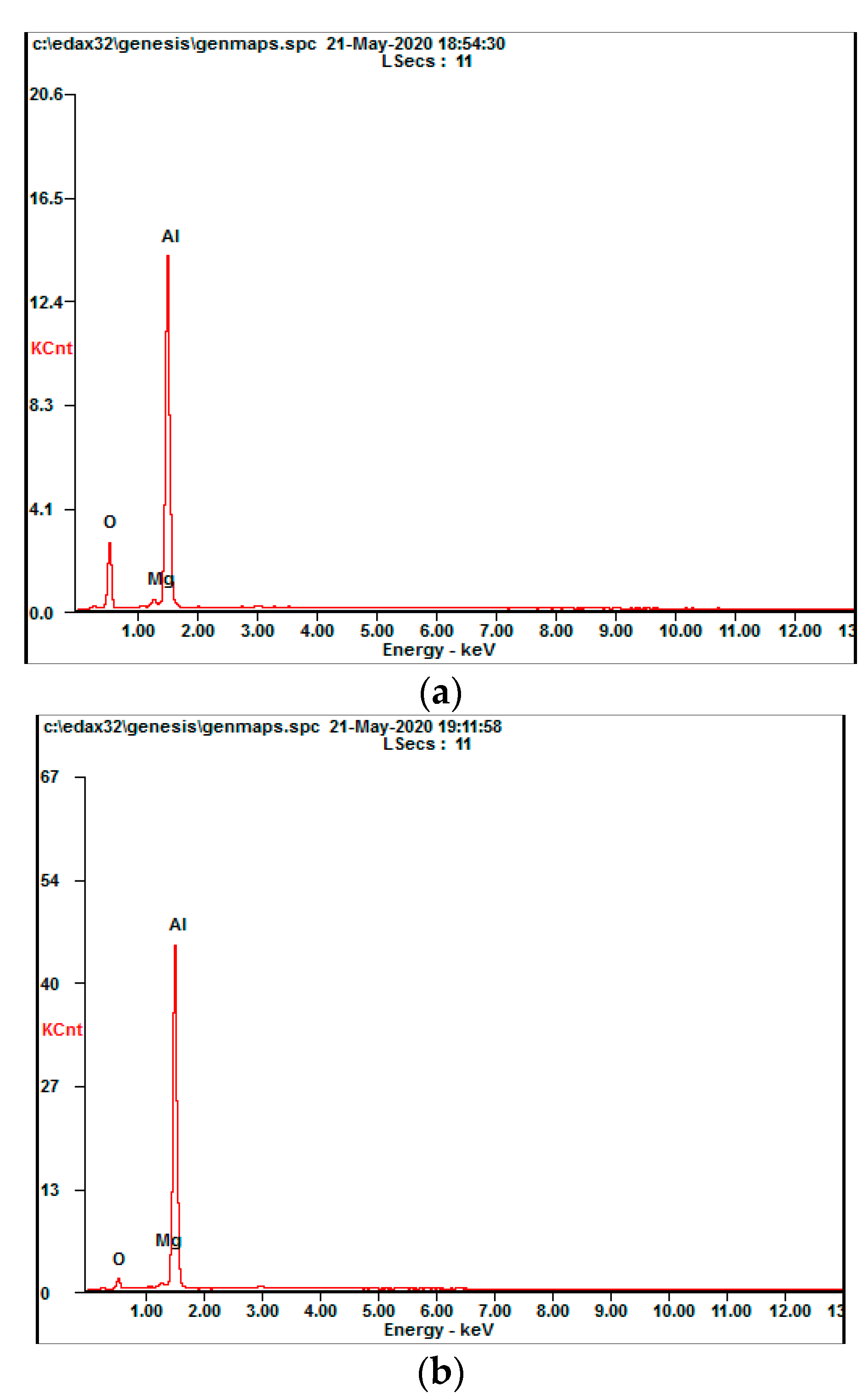

4.3. Processing Quality and Energy Spectrum Analysis

5. Conclusions

- (1)

- When the incident angle of the water jet is 45°, the speed of the water jet is 14 m·s−1, the laser power is 100 W, and the laser scanning speed is 1.2 mm·s−1, the quality of the processing groove is relatively good; there are no cracks at the bottom of the tank, and there is less slag accumulation.

- (2)

- In the process of water-jet-assisted laser machining, the temperature of the middle monitoring point on the material surface increases at first and then declines with the laser processing time. The highest temperature is located in the intermediate time of laser scanning, and the maximum temperature increases with the increase of laser power and decreases with the increase of laser scanning speed. The velocity and incident angle of the water jet plays an important role in the cooling of the material surface. With the increase of the water jet velocity, the cooling effect on the material surface increases gradually, and with the increase of the water jet angle, the cooling effect on the material surface increases at first and then decreases. When the incident angle is 45°, the cooling effect on the temperature field of the material surface is better.

- (3)

- In anhydrous laser machining, there are more recasting layers on both sides of the groove, and at the same time, more slag is produced at the bottom of the groove than in the water-jet-assisted laser machining, and there are cracks at the bottom of the groove. Water-jet-assisted laser machining greatly reduces the recasting layer on both sides of the groove, and the slag particles produced at the bottom of the groove are smaller than those of anhydrous assisted laser etching, and the width and depth of the groove are reduced. The quality of water-jet-assisted laser etching is better than that of anhydrous-assisted laser etching.

- (4)

- In the process of water-jet-assisted laser machining, the main composition of the slag deposited at the bottom of the tank has does not changed. Due to the continuous erosion of water, the aluminum alloy material reacts with water at a high temperature, the content of the oxygen element increases significantly, the content of the aluminum element decreases relatively, while the content of the magnesium element remains almost unchanged.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wan, Y.; Cheng, K.; Fu, X.L.; Liu, Z.Q. An experiment-based investigation on surface corrosion resistance behaviors of aluminum alloy 7050-T7451 after end milling. Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol. 2013, 227, 1297–1305. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, J.; Panicker, S.S.; Jin, H.-K.; Panda, S.; Lee, M.-G. Mechanical properties, springback, and formability of W-temper and peak aged 7075 aluminum alloy sheets: Experiments and modeling. Int. J. Mech. Sci. 2020, 26. [Google Scholar] [CrossRef]

- Lu, J.; Song, Y.; Hua, L.; Zhou, P.; Xie, G. Effect of temperature on friction and galling behavior of 7075 aluminum alloy sheet based on ball-on-plate sliding test. Tribol. Int. 2019, 140, 105872. [Google Scholar] [CrossRef]

- Li, S.; Hou, B. Material Behavior Modeling in Machining Simulation of 7075-T651 Aluminum Alloy. J. Eng. Mater. Techno. 2014, 136, 011001. [Google Scholar] [CrossRef]

- Saito, S.; Kato, S.; Suzuki, S.; Hasunuma, S.; Ogawa, T.; Mano, S.; Miyagawa, K. Crack Growth Characteristics of Aluminum Alloys Dominated by the Mechanisms of Fatigue Crack Growth or Stress Corrosion Cracking. Mater. Trans. 2017, 60, 2346–2352. [Google Scholar]

- Qiong, W.; Li, D.; Zhang, Y. Detecting Milling Deformation in 7075 Aluminum Alloy Aeronautical Monolithic Components Using the Quasi-Symmetric Machining Method. Metals 2016, 6, 80. [Google Scholar]

- Shi, S.; Sun, M.; Hao, Y.; Zhang, Y.; Pang, X.; Zhang, Y.N.; Liu, Z. Effect of surface treatment process on the ability of aluminum alloy to resist laser damage. China Laser 2016, 43, 51–58. [Google Scholar]

- Masurtschak, S.; Friel, R.J.; Gillner, A.; Ryll, J.; Harris, R. Laser-machined microchannel effect on microstructure and oxide formation of an ultrasonically processed aluminum alloy. J. Eng. Mater. Techno. 2015, 137, 011006.1–011006.11. [Google Scholar] [CrossRef]

- Mandal, K.K.; Kuar, A.S.; Mitra, S. Experimental investigation on laser micro-machining of Al 7075 Al. Opt. Laser Technol. 2018, 107, 260–267. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.Z.; Zhu, H.T. An investigation of hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2012, 56, 39–49. [Google Scholar] [CrossRef]

- Kruusing, A. Underwater and Water-assisted Laser Processing: Part1—General Features, Steam Cleaning and Shock Processing. Opt. Lasers Eng. 2004, 41, 307–327. [Google Scholar] [CrossRef]

- Kruusing, A. Underwaterand Water-assisted Laser Processing: Part2-Etching, Cutting and rarely used Methods. Opt. Lasers Eng. 2004, 41, 329–332. [Google Scholar] [CrossRef]

- Jyri, A.; Yijő, A. Cutting thin Sheet Metal with a Water Jet guided Laser using Various Cutting Distances, Feed Speeds and Angles of Incidence. J. Adv. Manuf. Technol. 2007, 33, 961–967. [Google Scholar]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.Z.; Zhu, H.T. Heating and material removal process in hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2014, 79, 1–16. [Google Scholar] [CrossRef]

- Chen, X.; Yuan, G.; Zheng, W. Experimental research on water jet assisted laser etching Al2O3 ceramics. Appl. Laser 2013, 24, 278–284. [Google Scholar]

- Mullick, S.; Madhukar, Y., Dr.; Roy, S.; Nath, A. An investigation of energy loss mechanisms in water-jet assisted underwater laser cutting process using an analytical model. Int. J. Mach. Tools Manuf. 2015, 91, 62–75. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, J.; Li, W. Microgrooving of Germanium Wafers Using Laser and Hybrid Laser-Waterjet Technologies. Adv. Mater. Res. 2014, 1017, 193–198. [Google Scholar] [CrossRef] [Green Version]

- Eddie, Y.K. The stability of 305μm-diameter water jet for jet-guided laser machining. Int. J. Adv. Manuf. Technol. 2015, 7, 939–946. [Google Scholar]

- Madhukar, Y.K.; Mutlick, S.; Nath, A.K. An investigation on co-axial water-jet assisted fiber laser cutting ofmetal sheets. Opt. Lasers Eng. 2016, 77, 203–218. [Google Scholar] [CrossRef]

- Wang, L.; Huang, C.; Wang, J.; Zhu, H.; Liang, S. An experimental investigation on laser assisted waterjet micro-milling of silicon nitride ceramics. Ceram. Int. 2017, 44, 5636–5645. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Song, W.; Chao, W.; Yao, Z. Effects of a low-pressure water jet assisting the laser etching of polycrystalline silicon. Appl. Phys. 2018, 124, 556.1–556.14. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Wu, C.; Ma, Y.; Zhang, Y.; Huang, L.; Liu, W. Optimization of Processing Parameters for Water-Jet-Assisted Laser Etching of Polycrystalline Silicon. Appl. Phys. 2019, 9, 1882. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Theofanous, T.G. Film boiling on spheres in single and two-phase flows. part i. experimental studies. In Proceedings of the ANS National Heat Transfer Conference, Portland, OR, USA, 5–9 August 1995. [Google Scholar]

- Liu, X.; Lienhard, J.; Lombara, J. Convective heat transfer by impingement of circular liquid. ASME J. Heat Transf. 1991, 113, 571–582. [Google Scholar] [CrossRef]

- Cui, X.; Sun, J. High Pressure Water Jet Technology; Coal Industry Press: Beijing, China, 1993. [Google Scholar]

- Starik, A.M.; Kuleshov, P.S.; Sharipov, A.S.; Nataliya, S.T.; Chuen-Jinn, T. Numerical analysis of nanoaluminum combustion in steam. Combust. Flame 2014, 161, 1659–1667. [Google Scholar] [CrossRef]

- Zhang, T. High-temperature kinetics and exothermic characteristics of hydrogen production of aluminum-based metal fuels with water. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2017. [Google Scholar]

| Density (g·cm−3) | 2.8 |

| Solidus melting point (°C) Liquidus melting point (°C) | 477 635 |

| Boiling point (°C) | 2065 |

| Antioxidant | good |

| Poisson’s ratio | 0.33 |

| Serial Number | Water Speed (m∙s−1) | Impact Angle (°) | Laser Power (W) | Laser Scanning Speed (mm∙s−1) |

|---|---|---|---|---|

| 1 | 6/10/14/18 | 45° | 200 | 0.8 |

| 2 | 6 | 15°/30°/45°/60° | 200 | 0.8 |

| 3 | 6 | 45° | 50/100/150/200 | 0.8/1/1.0/1.5 |

| 4 | 6 | 45° | 200 | 0.8 |

| Position | Element | at.% | wt.% | Position | Element | at.% | wt.% |

|---|---|---|---|---|---|---|---|

| 1 | O | 17.74 | 11.36 | 2 | O | 48.69 | 36.07 |

| Mg | 1.56 | 1.52 | Mg | 1.56 | 1.75 | ||

| Al | 80.7 | 87.12 | Al | 49.75 | 62.18 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Xu, X.; Liu, W.; Huang, L.; Li, H.; Wu, C.; Mu, W.; Li, X. Study on the Influence of Surface Temperature Field of Aluminum Alloy Etched by Laser Water Jet Composite Machining. Materials 2020, 13, 3206. https://doi.org/10.3390/ma13143206

Chen X, Xu X, Liu W, Huang L, Li H, Wu C, Mu W, Li X. Study on the Influence of Surface Temperature Field of Aluminum Alloy Etched by Laser Water Jet Composite Machining. Materials. 2020; 13(14):3206. https://doi.org/10.3390/ma13143206

Chicago/Turabian StyleChen, Xuehui, Xin Xu, Wei Liu, Lei Huang, Hao Li, Chao Wu, Weihao Mu, and Xiang Li. 2020. "Study on the Influence of Surface Temperature Field of Aluminum Alloy Etched by Laser Water Jet Composite Machining" Materials 13, no. 14: 3206. https://doi.org/10.3390/ma13143206