Experimental Study of Drilling Temperature, Geometrical Errors and Thermal Expansion of Drill on Hole Accuracy When Drilling CFRP/Ti Alloy Stacks

Abstract

1. Introduction

2. Materials and Methods

2.1. Workpiece Material and Cutting Tool

2.2. Numerical Setup

2.2.1. Drill Geometry and Boundary Conditions

2.2.2. Numerical Results

2.3. Experimental Setup

3. Experimental Results and Discussion

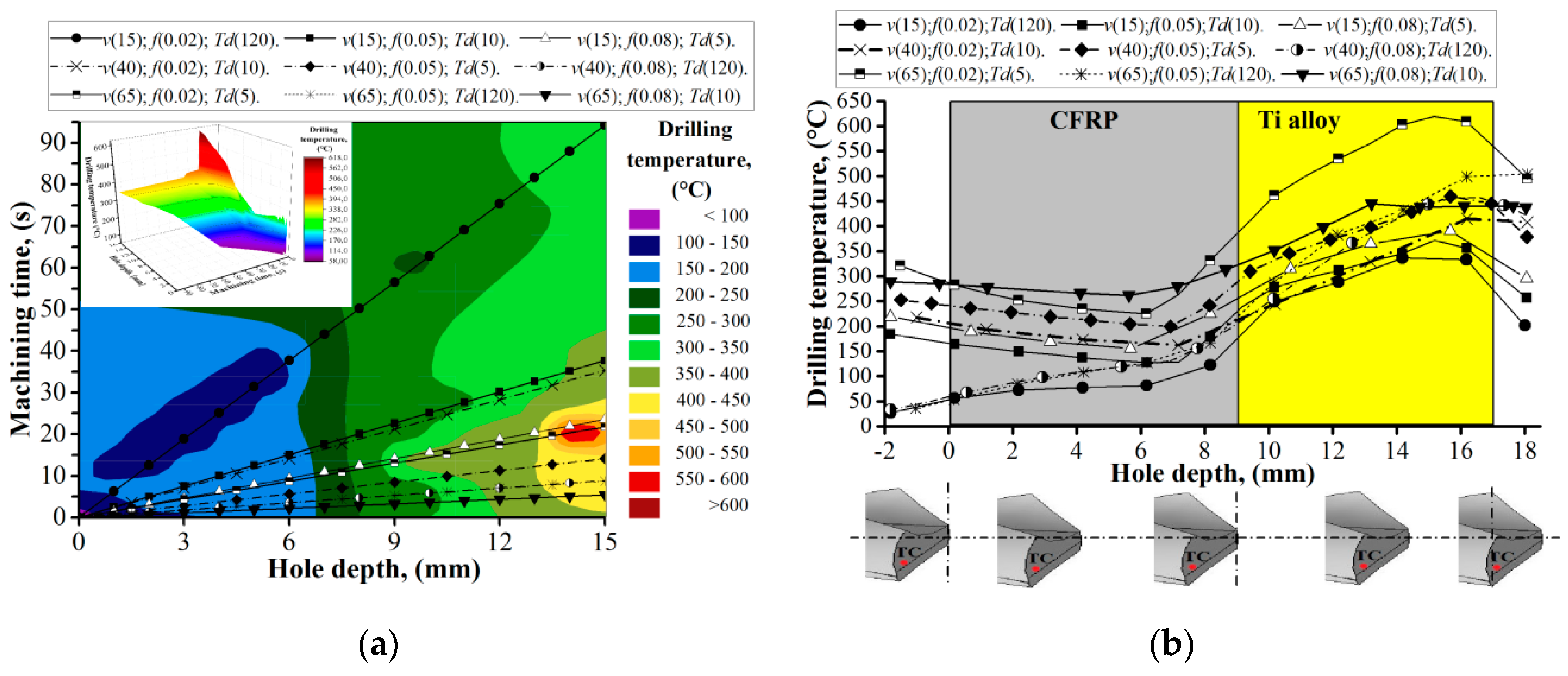

3.1. Drilling Temperature

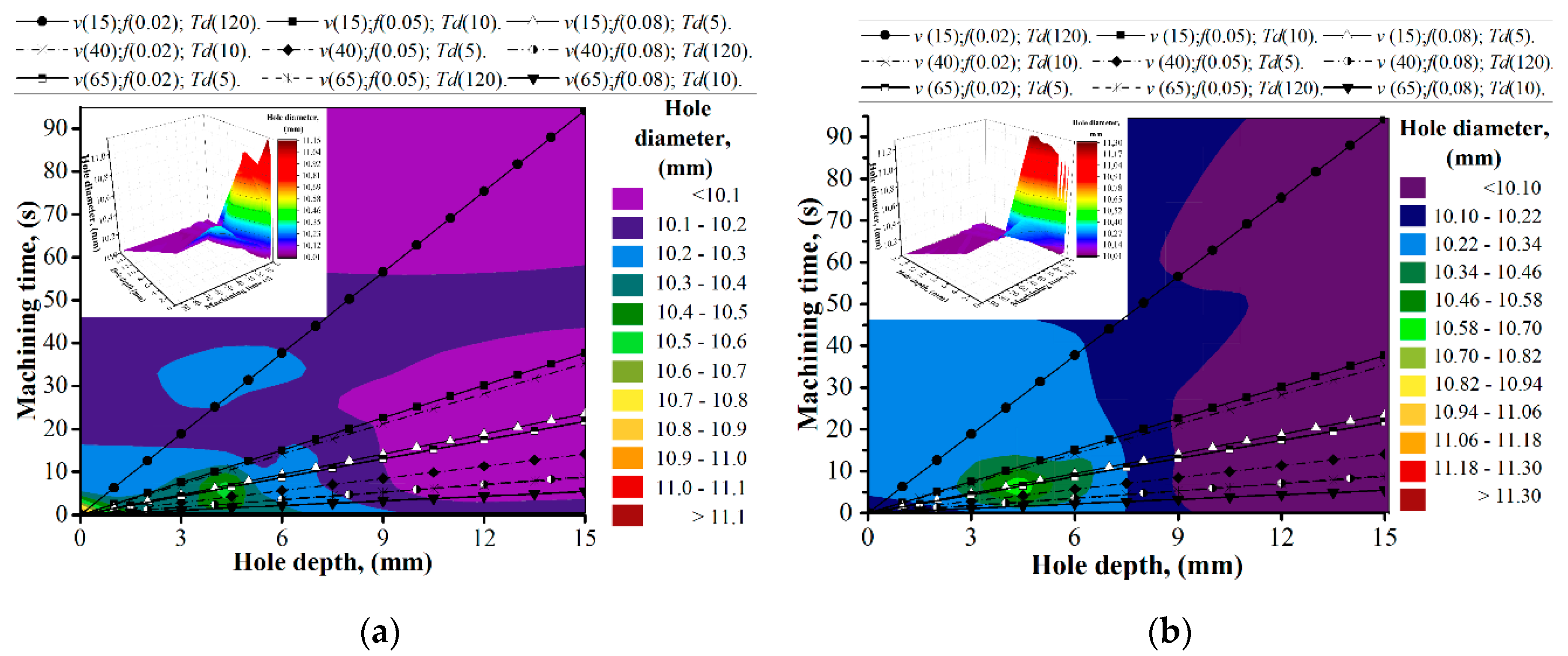

3.2. Hole Diameter and Roundness

4. Conclusions

- The experimental study shows that the time delay factor has a significant influence on drilling temperature, which increased from 49% to 62% in CFRP and 14% to 29% in Ti alloy with respect to cutting parameters. At the same time, in trails that were run without the effect of time delay under “cold drill machining” conditions, the drilling temperature increased from 13% to 32% in CFRP and 10% to 27% in Ti alloy.

- During the measurement of drilling temperature when drilling the CFRP/Ti alloy stack under 5 s and 10 s time delay, the heat dissipation effect in CFRP was noticed, which was characterized by decreasing drilling temperatures.

- Heat dissipation in CFRP reduced the thermal-dependent properties of CFRP, which resulted in hole roundness increases in the range of 75 µm to 120 µm corresponding to cutting conditions and machining time.

- It was found that the hole taper in CFRP is influenced by the combination of the Ti alloy chip sliding effect and the thermal expansion of the tool. At the same time, in Ti alloy, the hole taper is influenced by the combination of the radial run out of the drill and thermal expansion of the tool. Based on the measurement of hole diameter with the CNC coordinate measuring machine combined with the results of drilling temperature values, it was determined that increasing drilling temperatures up to ≈ 600 °C leads to the rising of the hole diameter deviation in Ti alloy up to 56 µm. In other trails, where drilling temperature was in the range of (350–500 °C), the deviation of hole diameter varied from 8 µm to 22 µm.

- The maximal thermal expansion of the drill varied from 11 µm to 27 µm and impacted from 12% to 37% of the total deviation of the hole diameter in Ti alloy corresponding to cutting conditions.

- Wireless measurement of the drilling temperature used in the current study suggested the possibility of real-time temperature monitoring to study the wear rate of the drill, the drill geometry’s effect on hole diameter, and roundness when drilling. The phenomenon of thermal expansion reported in the present study can be used as an input for future studies for the optimization of cutting conditions when drilling CFRP/Ti alloy stacks.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, D.; Ramuh, M. Stuidy on the Drilling of Titanium/Graphite Hybrid Composites. J. Eng. Mater. Technol. 2007, 129, 390–396. [Google Scholar] [CrossRef]

- Isbilir, O.; Ghassemieh, E. Comparative Study of Tool Life and Hole Quality in Drilling of CFRP/Titanium Stack Using Coated Carbide Drill. Int. J. Mach. Sci. Technol. 2013, 17, 380–409. [Google Scholar] [CrossRef]

- Shyha, I.; Soo, S.L.; Aspinwall, D.K.; Bradley, S.; Dawson, S.; Pretorius, C.J. Drilling of Titanium/CFRP/Aluminium Stacks. Key Eng. Mater. 2010, 447–448, 624–633. [Google Scholar] [CrossRef]

- Chen, W.-C. Some experimental investigations in drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int. J. Mach. Tools Manuf. 1997, 37, 1097–1108. [Google Scholar] [CrossRef]

- Davim, P.; Rubio, C.; Abrao, A.M. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos. Sci. Technol. 2007, 67, 1939–1945. [Google Scholar] [CrossRef]

- Voß, R.; Henerichs, M.; Rupp, S.; Kuster, F.; Wegener, K. Evaluation of bore exit quality for fiber reinforced plastics includeing delamination and uncut fiber. CIRP J. Manuf. Sci. Technol. 2016, 12, 56–66. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S. Evaluation of Worpliece Temperature during Drilling of GLARE Fiber Metal Laminates Using Drilling of GLARE Fiber Metal Laminates Using Fiber Orientation and Spray Mist Application. Materials 2016, 622, 1–17. [Google Scholar]

- Wang, C.Y.; Chen, Y.H.; An, Q.L.; Cai, X.J.; Ming, W.W.; Chen, M. Drilling Temperature and Hole Quality in Drilling of CFRP/Aluminium Stacks Using Diamond Coated Drill. Int. J. Precis. Eng. Manuf. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Ghafarizadeh, S.; Lebrun, G.; Chatelain, J.F. Experimental Investigation of the Cutting Temperature and Surface Quality during Milling of Unidirectional Carbon Fiber Reinforced Plastic. J. Compos. Mater. 2016, 50, 1059–1071. [Google Scholar] [CrossRef]

- Moghaddas, M.A.; Graff, K.F. Temperature Measurement in Ultrasonic-aasisted Drilling Process. Int. J. Adv. Manuf. Technol. 2019, 103, 187–199. [Google Scholar] [CrossRef]

- Park, J.-M.; Kwon, D.-J.; Wang, Z.-J.; Gu, G.-Y.; DeVries, K.L. A New Strategy of Carbon Fiber Reinforced Plastic Drilling Evaluation Using Thermal Measurement. J. Compos. Mater. 2013, 47, 2005–2011. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. An Embedded Multi-sensor System on the Rotating Dynamometer fo Real-time Condition Monitoring in Milling. Int. J. Adv. Manuf. Technol. 2017, 95, 811–823. [Google Scholar] [CrossRef]

- Yashiro, T.; Ogawa, T.; Sasahara, H. Temperature Measurement of Cutting Tool and Machined Surface Layer in Milling of CFRP. Int. J. Mach. Tools Manuf. 2013, 70, 63–69. [Google Scholar] [CrossRef]

- Wei, Y.; An, Q.L.; Ming, W.; Chen, M. Effect of Drilling Parameters and Tool Geometry on Drilling Performance in Drilling Carbon Fiber—Reinforced Plastic/Titanium Alloy Stacks. Adv. Mech. Eng. 2016, 8, 1–16. [Google Scholar] [CrossRef]

- Celik, Y.H. Investigating the Effects of Cutting Parameters on the Hole Quality in Drilling the Ti-6Al-4V alloy. Mater. Technol. 2014, 48, 653–659. [Google Scholar]

- Basmaci, G.; Said Yoruk, A.; Koklu, U.; Morkavuk, S. Impact of Cryogenic Condition and Drill Diameter on Drilling Performance of CFRP. Appl. Sci. 2017, 7, 667. [Google Scholar] [CrossRef]

- Janos, L.; Janos, K. Tool Wear Cutting Temperature at Machining of Composites. Adv. Mater. Res. 2011, 325, 381–386. [Google Scholar]

- Eynian, M.; Das, K.; Wretland, A. Effect of tool wear on quality in drilling of titanium alloy Ti6Al4V, Part I: Cutting Forces, Burr Formation, Surface Quality and Defects. High Speed Mach. 2017, 3, 1–10. [Google Scholar] [CrossRef]

- Sauer, K.; Dix, M.; Putz, M. Process Forces Analysis and a New Feed Control Strategy for Drilling of Unidirectional Carbon Fiber Reinforced Plastics (UD-CFRP). J. Manuf. Mater. Process. 2018, 2, 46. [Google Scholar] [CrossRef]

- Benezech, L.; Landon, Y.; Rubio, W. Study of Manufacturing Defects and Tool Geometry Optimisation for Multi-Material Stack Drilling. Adv. Mater. Res. 2012, 423, 1–11. [Google Scholar] [CrossRef]

- Hassan, M.H.; Mahmud, A.S.; Abdulah, J. Effects of Twist Drill Geometry and Drilling Parameters on CFRP-Aluminum Stack Up in Single Shot Drilling. SciFed Mater. Res. Lett. 2018, 2, 1–14. [Google Scholar]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M.H. Low-frequency Vibration-Assisted Drilling of Hybrid CFRP/Ti6Al4V stacked Material. Int. J. Adv. Manuf. Technol. 2018, 98, 2801–2817. [Google Scholar] [CrossRef]

- Onawumi, P.Y.; Roy, A.; Silberschmidt, V.V.; Merson, E. Ultrasonically assisted drilling of aerospace CFRP/Ti stack. Procedia CIRP 2018, 77, 383–386. [Google Scholar] [CrossRef]

- Senthilkumar, M.; Probukarthi, A.; Krishnaraj, V. Machining of CFRP/Ti6Al4V stack under minimal quantity lubricating condition. J. Mech. Sci. Technol. 2018, 32, 3787–3796. [Google Scholar] [CrossRef]

- Caggiano, A.; Angelone, R.; Teti, R. Image Analysis for CFRP Drilling Hole Quality Assessment. Procedia CIRP 2017, 62, 440–445. [Google Scholar] [CrossRef]

- Zitoune, R.; Krishnaraj, V.; Collombet, F.; Le Roux, S. Experimental and numerical analysis on drilling of carbon fibre reinforced plastic and aluminium stacks. Compos. Struct. 2016, 146, 148–158. [Google Scholar] [CrossRef]

- Xu, J.; Mansori, M. Experimental study on drilling mechanisms and strategies of hybrid CFRP/Ti stacks. Compos. Struct. 2016, 157, 461–482. [Google Scholar] [CrossRef]

- Abdelhafeez, A.M.; Soo, S.L.; Aspinwall, D.K.; Dowson, A.; Arnold, D. Burr formation and hole quality when drilling titanium and aluminium alloy. Procedia CIRP 2015, 37, 230–235. [Google Scholar] [CrossRef]

- Kim, D.; Beal, A.; Kang, K.; Kim, S.-Y. Hole quality assessment of drilled CFRP and CFRP-Ti stacks holes using polycrystalline diamond (PCD) tools. Carbon Lett. 2017, 23, 1–8. [Google Scholar]

- Giasin, K.; Ayvar-Soberanis, S. Microstructural investigation of drilling induced damage in fibre metal laminates constituents. Composites 2017, 97, 166–178. [Google Scholar] [CrossRef]

- Kumar, D.; Gururaja, S. Experimental Investigation of CFRP/Ti Stack Drilling Under Cryogenic Condition. In Proceedings of the International Conference on Composite Materials and Structures ICCMS, Hyterabad, India, 27–29 December 2017. [Google Scholar]

- Kuo, C.-L.; Aspinwall, D.; Thomas, W.; Carr, C.; Pearson, D.; M’Saoubi, R.; Leahy, W. Performance of multi-margin coated tools in oneshot shot drilling of metallic-composite stack materials under varying feed rate and pecking conditions. In Proceedings of the 38th International Matador Conference, Yunlin, Taiwan, 28–30 March 2015; pp. 231–238. [Google Scholar]

- Merzouki, J.; Poulachon, G.; Rossi, F.; Ayed, Y.; Abrivard, G. Method of Hole Shrinkage Radial Forces Measurement in Ti6Al4V Drilling. In Proceedings of the 16th CIRP Conference on Modelling of Machining Operations, Burgundy, France, 15–16 June 2017; pp. 629–634. [Google Scholar]

- Xu, J.; Mkaddem, A.; Mansori, M. Recent advances in drilling hybrid FRP/Ti composite: A state-of-the-art review. Compos. Struct. 2016, 135, 316–338. [Google Scholar] [CrossRef]

- Zhu, Z.; Sui, S.; Sun, J.; Li, J.; Liu, K. Invistigation on drilling performance of titanium alloy Ti6Al4V based on response surface method. In Proceedings of the 12th International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017; pp. 1–8. [Google Scholar]

- Zhou, L.; Dong, H.; Chen, Z.; Gao, K. Hole diameter variation and roundness in dry orbital drilling of CFRP/Ti stacks. Int. J. Adv. Manuf. Technol. 2016, 87, 811–824. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Almaskari, F.; Hafeez, F. Thermal Aspects in Machining CFRPs: Effect of Cutter Type and Cutting Parameters. Int. J. Adv. Manuf. Technol. 2019, 100, 2569–2582. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Duan, Y. Effect of Drilling Area Temperature on Drilling of Carbon Fiber Reinforced Plymer Composites due to Temperature-Dependent Properties. Int. J. Adv. Manuf. Technol. 2018, 96, 2943–2951. [Google Scholar] [CrossRef]

- Kolesnyk, V.; Kryvoruchko, D.; Hatala, M.; Mital, D.; Hutyrova, Z.; Duplak, J.; Alowa, M. The effect of cutting temperature on carbide drilling life in the process of CFRP/steel stacks drilling. Manuf. Technol. 2015, 15, 357–362. [Google Scholar] [CrossRef]

- Gulpak, M.; Sölter, J. Development and validation of a hybrid model for the prediction of shape deviations in dry machining processes. Procedia CIRP 2015, 31, 346–351. [Google Scholar] [CrossRef]

- Miguélez, M.; Zaera, R.; Molinari, A.; Cheriguene, R.; Rusinek, A. Residual Stresses in Orthogonal Cutting of Metals: The Effect of Thermomechanical Coupling Parameters and of Friction. J. Therm. Stresses 2009, 32, 269–289. [Google Scholar] [CrossRef][Green Version]

- Bollig, P.; Michna, J.; Faltin, C.; Schneider, J.; Zanger, F.; Schießl, R.; Schulze, V. Experimental and Simulative Modeling of Drilling Processes for the Compensation of Thermal Effects. In Thermal Effects in Complex Machining Processes; Biermann, D., Hollmann, F., Eds.; Lecture Notes in Production Engineering; Springer: Berlin, Germany, 2018; pp. 145–180. [Google Scholar] [CrossRef]

- Aerospace Material Specifications. Titanium Alloy, Bars, Wire, and Rings, Titanium 6-2-4-2, Solution and Precipitation Heat Treated (SAE AMS 4975:2017); SAE International: Pittsburgh, PA, USA, 2017. [Google Scholar]

- Kurlov, A.S.; Gusev, A.I. Hardmetals WC—Co Based on Nanocrystalline Powders of Tungsten Carbide WC. In Tungsten Carbides: Structure, Properties and Application in Hardmetals; Kurlov, A.S., Gusev, A.I., Eds.; Springer: Berlin, Germany, 2013; pp. 191–213. [Google Scholar] [CrossRef]

- Voss, R.; Henerichs, M.; Kuster, F. Comparison of Conventional Drilling and Orbital Drilling in Machining Carbon Fibre Reinforced Plastics (CFRP). CIRP Ann. Manuf. Technol. 2016, 65, 137–140. [Google Scholar] [CrossRef]

- Prasanth, R.; Senthilkumar, M.; Prabu, K.; Krishnaraj, V. Identification of Drill Position in CFRP/Titanium alloy Stacks using Acoustic Emission Signals. In Proceedings of the International Conference on Advances in Materials, Manufacturing and Applications, Tamil Nadu, India, 9–11 April 2015; pp. 1174–1181. [Google Scholar]

- Wertheim, R.; Hanan, U.B.; Ihlenfeldt, S.; Stoll, A.; Treppe, F. Acoustic Emission for Controlling Drill Position in Fiber-reinforced Plastic and Metal Stack. CIRP Ann. Manuf. Technol. 2012, 61, 75–78. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; El Mansori, M.; Ren, F. A Study on Drilling High-Strength CFRP Laminates: Frictional Heat and Cutting Temperature. Materials 2018, 11, 2366. [Google Scholar] [CrossRef]

- Banks, L.; Ellis, B. The glass transition temperatures of highly crosslinked networks: Cured epoxy resins. Polymer 1982, 23, 1466–1472. [Google Scholar] [CrossRef]

- Bussu, G.; Lazzeri, A. On the use of dynamic mechanical thermal analysis (DMTA) for measuring glass transition temperature of polymer matrix fibre reinforced composites. J. Mater. Sci. 2006, 41, 6072–6076. [Google Scholar] [CrossRef]

- Merino-Perez, J.L.; Royer, R.; Ayvar-Soberanis, S.; Merson, E.; Hodzic, A. On the temperatures developed in CFRP drilling using uncoated WC-Co tools Part I: Workpiece constituents, cutting speed and heat dissipation. Compos. Struct. 2015, 123, 161–168. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Totten, E.G. Self-Organization During Friction Advanved Surface-Engineered Materials and Systems Design; CRC Press: Boca Raton, FL, USA, 2019; p. 459. ISBN 9780367390365. [Google Scholar]

- Fox-Rabinovich, G.S.; Gershman, I.S.; Yamamoto, K.; Biksa, A.; Veldhuis, S.C.; Beake, B.D.; Kovalev, A.I. Self-Organization during Friction in Complex Surface Engineered Tribosystems. Entropy 2010, 12, 275–288. [Google Scholar] [CrossRef]

- Prisco, U.; Impero, F.; Rubino, F. Peck drilling of CFRP/titanium stacks: Effect of tool wear on hole dimensional and geometrical accuracy. Prod. Eng. 2019, 13, 529–553. [Google Scholar] [CrossRef]

- Jurko, J.; Dzupon, M.; Panda, A.; Zajac, J. Study influence of plastic deformation a new extra low carbon stainless steels XCr17Ni7MoTiN under the surface finish when drilling. Adv. Mater. Res. 2012, 538–541, 1312–1315. [Google Scholar] [CrossRef]

- Skoric, S.; Udiljak, T.; Ciglar, D. Study of the suitability of the machining of rotating surfaces. J. Trans. Famena 2008, 32, 69–83. [Google Scholar]

- Sentyakov, K.; Peterka, J.; Smirnov, V.; Bozek, P.; Sviatskii, V. Modeling of Boring Mandrel Working Process with Vibration Damper. Materials 2020, 13, 1931. [Google Scholar] [CrossRef]

- Jurko, J.; Panda, A.; Behun, M. Prediction of a new form of the cutting tool according to achieve the desired surface quality. Appl. Mech. Mater. 2012, 268–270, 473–476. [Google Scholar] [CrossRef]

- Kliac, M.; Staroveski, T.; Udiljak, T. Tool Wear Classification using Decision Treesin Stone Drilling Applications: A Preliminary Study. Procedia Eng. 2014, 69, 1326–1335. [Google Scholar] [CrossRef]

| Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Density (kg/m3) | Elongation (%) | Thermal Conductivity (W/m K) | Hardness (HV) |

|---|---|---|---|---|---|

| 735 | 115 | 4550 | 10 | 9.63 | 178 |

| Geometric Parameters | Drill Number in Respect to Trail Number | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| D (mm) | 10.008 | 10.003 | 10.003 | 10.003 | 10.000 | 10.000 | 10.000 | 10.000 | 10.000 |

| Radial runout (mm) | 0.010 | 0.012 | 0.016 | 0.008 | 0.008 | 0.008 | 0.008 | 0.008 | 0.008 |

| Density (kg/m3) | Coefficient of Thermal Expansion (°C−1) | Zero-Thermal Expansion (°C) | Young’s Modulus (GPa) | Poisson’s Ration | Bulk Modulus (GPa) | Shear Modulus (GPa) |

| 15700 | 4.8 | 22 | 615 | 0.24 | 643 | 274 |

| Compressive Yield Strength (MPa) | Tensile Ultimate Strength (MPa) | Isotropic Thermal Conductivity (W/mm·°C) | Specific Heat (J/kg·°C) | - | ||

| 177 °C | 427 °C | 876 °C | ||||

| 4780 | 350 | 0.38 | 0.44 | 0.52 | 434 | - |

| Drilling Performance | Levels of Factors | Coding DOE in According to Taguchi L9 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Trail Number | |||||||||||||

| 1 | 2 | 3 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| A | Cutting speed v (m/min) | 15 | 40 | 65 | 1A | 1A | 1A | 2A | 2A | 2A | 3A | 3A | 3A |

| B | Feed, f (mm) | 0.02 | 0.05 | 0.08 | 1B | 2B | 3B | 1B | 2B | 3B | 1B | 2B | 3B |

| C | Time delay Td (s) | CDM (120) | 10 | HDM (5) | 1C | 2C | 3C | 2C | 3C | 1C | 3C | 1C | 2C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolesnyk, V.; Peterka, J.; Kuruc, M.; Šimna, V.; Moravčíková, J.; Vopát, T.; Lisovenko, D. Experimental Study of Drilling Temperature, Geometrical Errors and Thermal Expansion of Drill on Hole Accuracy When Drilling CFRP/Ti Alloy Stacks. Materials 2020, 13, 3232. https://doi.org/10.3390/ma13143232

Kolesnyk V, Peterka J, Kuruc M, Šimna V, Moravčíková J, Vopát T, Lisovenko D. Experimental Study of Drilling Temperature, Geometrical Errors and Thermal Expansion of Drill on Hole Accuracy When Drilling CFRP/Ti Alloy Stacks. Materials. 2020; 13(14):3232. https://doi.org/10.3390/ma13143232

Chicago/Turabian StyleKolesnyk, Vitalii, Jozef Peterka, Marcel Kuruc, Vladimír Šimna, Jana Moravčíková, Tomáš Vopát, and Dmytro Lisovenko. 2020. "Experimental Study of Drilling Temperature, Geometrical Errors and Thermal Expansion of Drill on Hole Accuracy When Drilling CFRP/Ti Alloy Stacks" Materials 13, no. 14: 3232. https://doi.org/10.3390/ma13143232

APA StyleKolesnyk, V., Peterka, J., Kuruc, M., Šimna, V., Moravčíková, J., Vopát, T., & Lisovenko, D. (2020). Experimental Study of Drilling Temperature, Geometrical Errors and Thermal Expansion of Drill on Hole Accuracy When Drilling CFRP/Ti Alloy Stacks. Materials, 13(14), 3232. https://doi.org/10.3390/ma13143232