Wire-Based Additive Manufacturing of Ti-6Al-4V Using Electron Beam Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Setup

2.3. Heat Treatment

2.4. Metallographic Characterization

2.5. Mechanical Characterization

2.6. Residual Stress Measurements in Single Wall

3. Results

3.1. Single Layer Experiments

3.1.1. Dimension of Single Beads

3.1.2. Dilution of Single Bead

3.1.3. Overlapping Distance for Multi Track

3.2. Building AM Block

3.3. Chemical Composition AM Block

3.4. Metallography

3.5. Residual Stresses by High Energy Dispersive X-ray Diffraction

3.6. Mechanical Properties

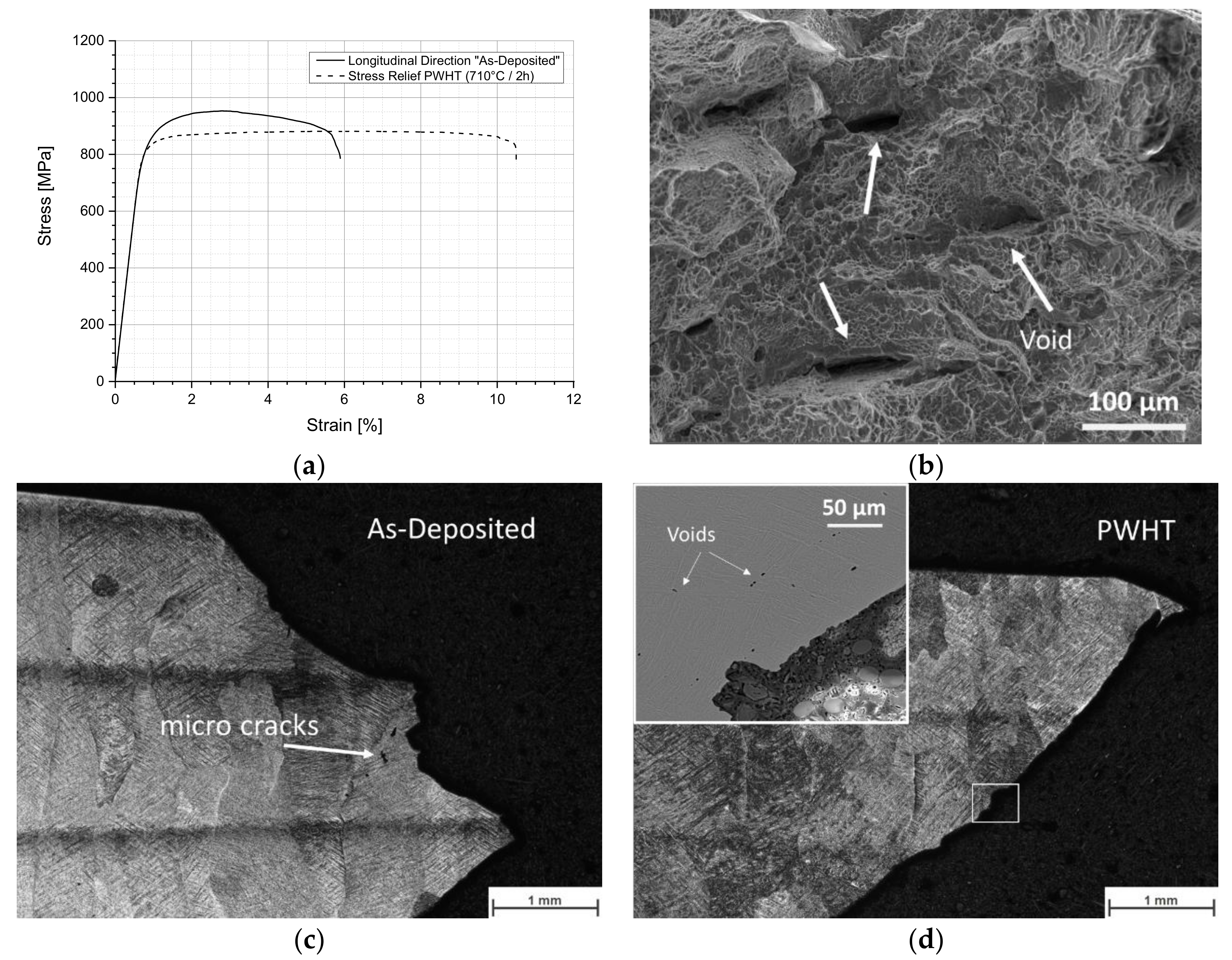

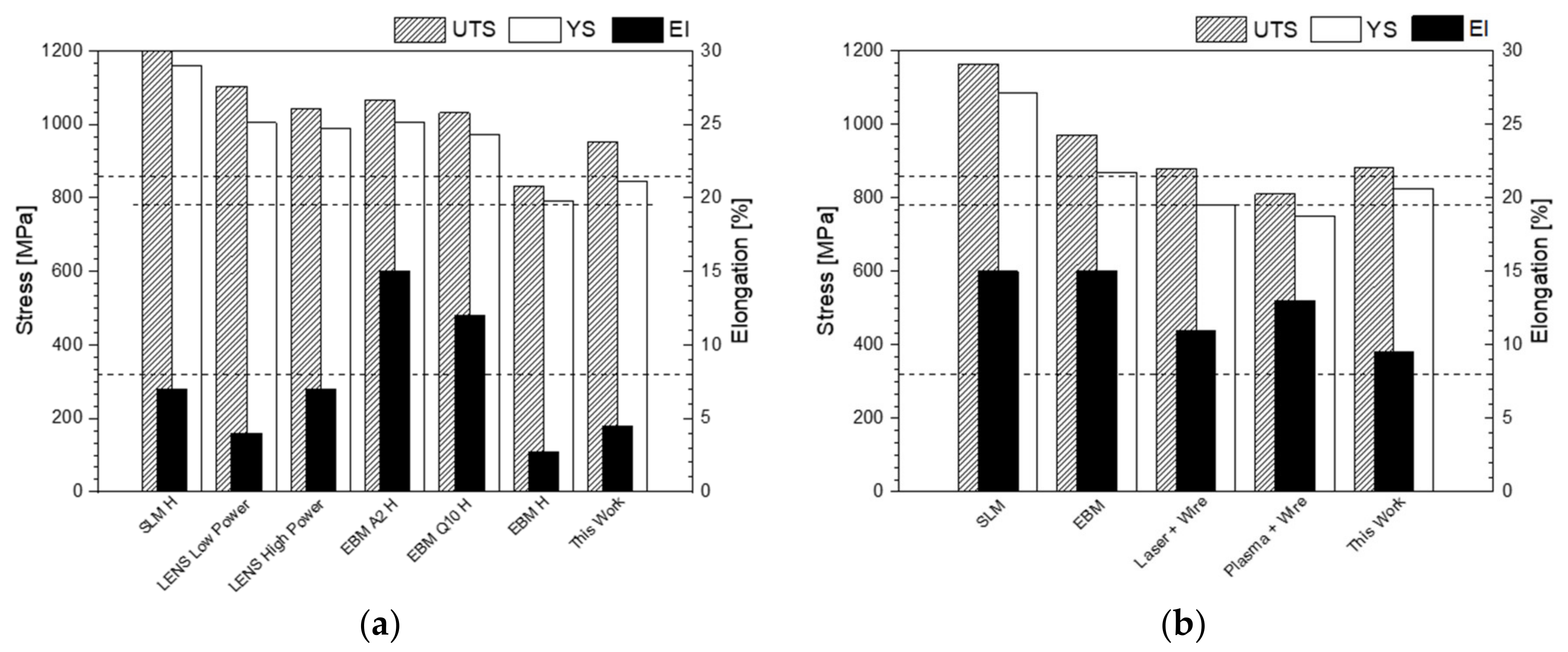

3.6.1. Tensile Test

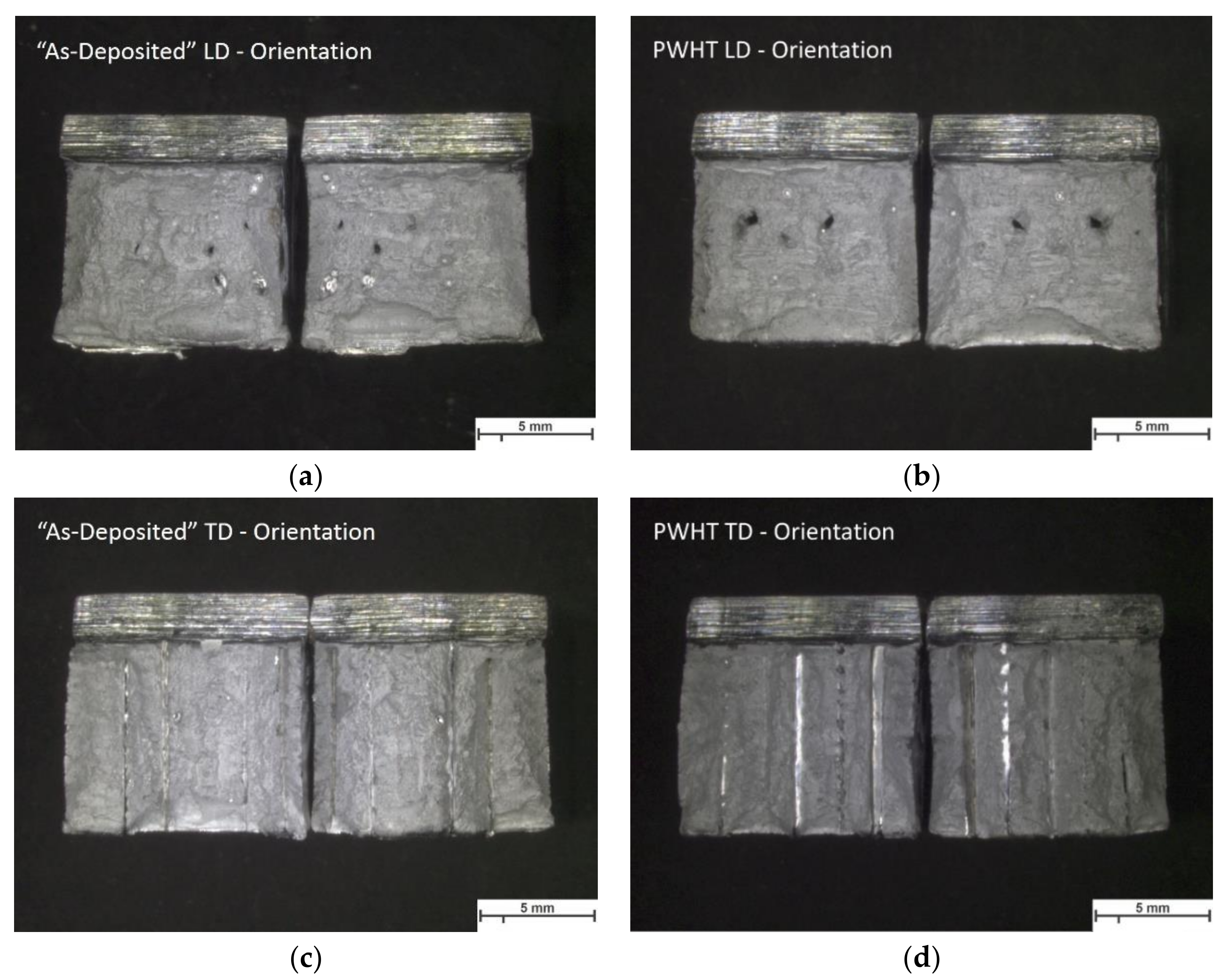

3.6.2. Charpy V-Notch Impact Tests

3.6.3. Hardness Testing

4. Discussion

4.1. Electron Beam Processing

4.1.1. Dimension of Single Beads

4.1.2. Dilution of Single Bead

4.1.3. Overlapping Distance for Multi Track

4.1.4. Building AM Block

4.2. Effect of the Microstructure on the Mechanical Properties

5. Conclusions

- During the building of the wall, the bead shape is mainly affected by the beam current, the weld-velocity, and the feeding rate of the wire.

- A fast build-up process with minimum energy input guaranteed a dilution of 28%, which facilitate an optimal overlapping distance to reduce the wave-like surface.

- The use of a symmetric welding sequence with an overlapping distance of 70–75% of the bead-width permits a flat surface and a linear growth rate of the block.

- The chemical composition of the AM material shows only evaporation losses of aluminum in the range of approx. 1 wt %.

- As-deposited condition showed a mixture of finer α and martensitic structure within the coarser columnar prior β grains, providing a low tensile strength compared to similar additive manufacturing processes.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ISO 17296-2:2015. Additive Manufacturing—General Principles—Part 2: Overview of Process Categories and Feedstock; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Taminger, K.; Hafley, R. Electron beam freeform fabrication: A rapid metal deposition process. In Proceedings of the 3rd Annual Automotive Composites Conference, Troy, MI, USA, 9–10 September 2003. [Google Scholar]

- Wanjara, P.; Watanabe, K.; De Formanoir, C.; Yang, Q.; Bescond, C.; Godet, S.; Brochu, M.; Nezaki, K.; Gholipour, J.; Patnaik, P. Titanium alloy repair with wire-feed electron beam additive manufacturing technology. Adv. Mater. Sci. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Zhu, J.; Fan, J.; Zhou, Q.; Peng, Y.; Guo, S. Microstructure and mechanical properties of Ti-6Al-4V alloy fabricated using electron beam freeform fabrication. Vacuum 2019, 167, 364–373. [Google Scholar] [CrossRef]

- Savchenko, N.L. Structure and phase composition of Ti-6Al-4V alloy made by additive manufacturing technology. AIP Conf. Proc. 2019, 2167, 020310. [Google Scholar] [CrossRef]

- Taminger, K.; Hafley, R. Electron beam freeform fabrication for cost effective near-net shape manufacturing. In Proceedings of the NATO AVT-139 Specialists’ Meeting—Cost Effective Manufacture via Net Shape Processing, Amsterdam, The Netherlands, 15 May 2006. [Google Scholar]

- Schultz, H. Electron Beam Welding, 1st ed.; Elsevier Science & Technology: Cambridge, UK, 1994. [Google Scholar]

- Sciaky Inc. Electron Beam Additive Manufacturing. Available online: http://www.sciaky.com/additive-manufacturing/electron-beam-additive-manufacturing-technology (accessed on 12 January 2020).

- Wallace, T.; Bey, K.; Taminger, K.; Hafley, R. A design of experiments approach defining the relationships between processing and microstructure for Ti-6Al-4V. In Proceedings of the 15th Solid Freeform Fabrication Symposium, Austin, TX, USA, 2–4 August 2004. [Google Scholar]

- Fuchs, J.; Schneider, C.; Enzinger, N. Wire-based additive manufacturing using an electron beam as heat source. Weld. World 2018, 62, 267–275. [Google Scholar] [CrossRef] [Green Version]

- Gockel, J.; Beuth, J.; Taminger, K. Integrated control of solidification microstructure and melt pool dimensions in electron beam wire feed additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2014, 1, 119–126. [Google Scholar] [CrossRef]

- Gockel, J.; Fox, J.; Beuth, J.; Hafley, R. Integrated melt pool and microstructure control for Ti-6Al-4V thin wall additive manufacturing. Mater. Sci. Technol. 2015, 31, 912–916. [Google Scholar] [CrossRef]

- Tang, Q.; Pang, S.; Chen, B.; Suo, H.; Zhou, J. A three dimensional transient model for heat transfer and fluid flow of weld pool during electron beam freeform fabrication of Ti-6-Al-4-V alloy. Int. J. Heat Mass Transf. 2014, 78, 203–215. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; van Duin, S.; Larkin, N. Bead modelling and implementation of adaptive MAT path in wire and arc additive manufacturing. Robot. Comput. Integr. Manuf. 2016, 39, 32–42. [Google Scholar] [CrossRef]

- Greitemeier, D. Untersuchung der Einflussparameter Auf die Mechanischen Eigenschaften von Additiv Gefertigtem TiAl6V4; Springer Vieweg: Wiesbaden, Germany, 2016. [Google Scholar] [CrossRef]

- Fadida, R.; Rittel, D.; Shirizly, A. Dynamic mechanical behavior of additively manufactured Ti6Al4V with controlled voids. J. Appl. Mech. Trans. 2015, 82. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 10, 160–170. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Mileweski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.; Wallbrink, C. A review of the as-built SLM Ti-6Al-4V mechanical properties towards achieving fatigue resistant designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef] [Green Version]

- Tiferet, E.; Ganor, M.; Zolotaryov, D.; Garkun, A.; Hadjadj, A.; Chonin, M.; Ganor, Y.; Noiman, D.; Halevy, I.; Tevet, O.; et al. Mapping the tray of electron beam melting of Ti-6Al-4V: Properties and microstructure. Materials 2019, 12, 1470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCG Verlag GmbH & CoKGaA: Weinheim, Germany, 2003. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J. Titanium; Springer: Berlin, Germany, 2007. [Google Scholar] [CrossRef]

- Zhang, L.C.; Liu, Y.; Li, S.; Hao, Y. Additive manufacturing of titanium alloys by electron beam melting: A review. Adv. Eng. Mater. 2017, 20, 1700842. [Google Scholar] [CrossRef]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D.J. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Murr, L.E.; Esquivel, E.V.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Martinez, E.Y.; Medina, F.; Hernandez, D.H.; Martinez, E.; Stafford, S.W.; et al. Microstructure and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V. Mater. Charact. 2008, 60, 96–105. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Zhai, Y.; Galarraga, H.; Lados, D.A. Microstructure, static properties, and fatigue crack growth mechanisms in Ti-6Al-4V fabricated by additive manufacturing: LENS and EBM. Eng. Fail. Anal. 2016, 69, 3–14. [Google Scholar] [CrossRef]

- Fachinotti, V.D.; Cardona, A.; Baufeld, B.; Van der Biest, O. Finite-element modelling of heat transfer in shaped metal deposition and experimental validation. Acta Mater. 2012, 60, 6621–6630. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Baufeld, B.; Brandl, E.; Van der Biest, O. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Wang, J.; Lin, X.; Li, J.; Hu, Y.; Zhou, Y.; Wang, C.; Li, Q.; Huang, W. Effects of deposition strategies on macro/microstructure and mechanical properties of wire and arc additive manufactured Ti–6Al–4V. Mater. Sci. Eng. A 2019, 754, 735–749. [Google Scholar] [CrossRef]

- Wang, J.; Lin, X.; Wang, J.; Yang, H.; Zhou, Y.; Wang, C.; Li, Q.; Huang, W. Grain morphology evolution and texture characterization of wire and arc additive manufactured Ti-6Al-4V. J. Alloys Compd. 2018, 768, 97–113. [Google Scholar] [CrossRef]

- DVS 2713:2016-04. Schweißen von Titanwerkstoffen Werkstoffe—Prozesse—Fertigung—Prüfung und Bewertung von Schweißverbindungen; DVS-Verlag GmbH: Düsseldorf, Germany, 2016. [Google Scholar]

- DIN 65084:1990-04. Luft-und Raumfahrt Wärmebehandlung von Titan und Titan-Knetlegierungen; CEN: Brussels, Belgium, 1990. [Google Scholar]

- DIN EN ISO 6892-1:2017-02. Metallische Werkstoffe—Zugversuch—Teil 1: Prüfverfahren bei Raumtemperatur; CEN: Brussels, Belgium, 2017. [Google Scholar]

- DIN EN ISO 148-1:2017-05. Metallische Werkstoffe—Kerbschlagbiegeversuch nach Charpy—Teil 1: Prüfverfahren; CEN: Brussels, Belgium, 2017. [Google Scholar]

- DIN EN ISO 6507-1:2016-08. Metallische Werkstoffe—Härteprüfung nach Vickers—Teil 1: Prüfverfahren; CEN: Brussels, Belgium, 2016. [Google Scholar]

- Larson, A.C.; von Dreele, R.B. General Structure Analysis System (GSAS); LANL Report No. LAUR 86-748; Los Alamos National Laboratory: Los Alamos, NM, USA, 2000. Available online: http://www.ncnr.nist.gov/xtal/software/gsas.html (accessed on 6 June 2020).

- Fahrenwaldt, H.J.; Schuler, V. Praxiswissen Schweißtechnik; Vieweg+Teubner: Wiesbaden, Germany, 2006. [Google Scholar]

- Suryakumar, S.; Karunakaran, K.P.; Bernard, A.; Chandrasekhar, U.; Raghavender, N.; Sharma, D. Weld bead modeling and process optimization in Hybrid Layered Manufacturing. CAD Comput. Aided Des. 2011, 43, 331–344. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput. Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef] [Green Version]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Larkin, N. Adaptive path planning for wire-feed additive manufacturing using medial axis transformation. J. Clean. Prod. 2016, 133, 942–952. [Google Scholar] [CrossRef]

- Jin, Y.; He, Y.; Fu, J.; Gan, W.; Lin, Z. Optimization of tool-path generation for material extrusion-based additive manufacturing technology. Addit. Manuf. 2014, 1, 32–47. [Google Scholar] [CrossRef]

- Jin, Y.; He, Y.; Fu, J.; Zhang, A.; Du, J. A non-retraction path planning approach for extrusion-based additive manufacturing. Robot. Comput. Integr. Manuf. 2017, 48, 132–144. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot. Comput. Integr. Manuf. 2015, 34, 8–19. [Google Scholar] [CrossRef] [Green Version]

- Ding, D.; Shen, C.; Pan, Z.; Cuiuri, D.; Li, H.; Larkin, N.; van Duin, S. Towards an automated robotic arc-welding-based additive manufacturing system from CAD to finished part. Comput. Des. 2016, 73, 66–75. [Google Scholar] [CrossRef] [Green Version]

- Stockinger, J.; Wiednig, C.A.; Enzinger, N.; Sommitsch, C.; Huber, D.; Stockinger, M. Additive Manufacturing via Cold Metal Transfer. In Proceedings of the Metal Additive Manufacturing Conference, Linz, Austria, 24–25 November 2016. [Google Scholar]

- Plangger, J.; Schabhüttl, P.; Vuherer, T.; Enzinger, N. CMT additive manufacturing of a high strength steel alloy for application in crane construction. Metals 2019, 9, 650. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Pang, S.; Tang, Q.; Suo, H.; Gong, S. Evaporation Ripped Metallurgical Pore in Electron Beam Freeform Fabrication of Ti-6-Al-4-V. Mater. Manuf. Process. 2016, 31, 1995–2000. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Ivanchenko, V.G.; Akhonin, S.V.; Ivasishin, O.M. Diffusion models for evaporation losses during electron-beam melting of alpha/beta-titanium alloys. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2004, 35, 235–245. [Google Scholar] [CrossRef]

- Juechter, V.; Scharowsky, T.; Singer, R.F.; Körner, C. Processing window and evaporation phenomena for Ti-6Al-4V produced by selective electron beam melting. Acta Mater. 2014, 76, 252–258. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Chen, J.; Zheng, M.; Yan, Z.; Lu, X.; Lin, X.; Huang, W. Element vaporization of Ti-6AL-4V alloy during selective laser melting. Metals 2020, 10, 435. [Google Scholar] [CrossRef] [Green Version]

- Sequeira Almeida, P.M.; Williams, S. Innovative process model of Ti-6Al-4V additive layer manufacturing using cold metal transfer (CMT). In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010. [Google Scholar]

- Bermingham, M.J.; StJohn, D.H.; Krynen, J.; Tedman-Jones, S.; Dargusch, M.S. Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing. Acta Mater. 2019, 168, 261–274. [Google Scholar] [CrossRef]

- Åkerfeldt, P.; Antti, M.-L.; Pederson, R. Influence of microstructure on mechanical properties of laser metal wire-deposited Ti-6Al-4V. Mater. Sci. Eng. A 2016, 674, 428–437. [Google Scholar] [CrossRef]

- Ho, A.; Zhao, H.; Fellowes, J.W.; Martina, F.; Davis, A.E.; Prangnell, P.B. On the origin of microstructural banding in Ti-6Al4V wire-arc based high deposition rate additive manufacturing. Acta Mater. 2019, 166, 306–323. [Google Scholar] [CrossRef]

- Haubrich, J.; Gussone, J.; Barriobero-Vila, P.; Kürnsteiner, P.; Jägle, E.A.; Raabe, D.; Schell, N.; Requena, G. The role of lattice defects, element partitioning and intrinsic heat effects on the microstructure in selective laser melted Ti-6Al-4V. Acta Mater. 2019, 167, 136–148. [Google Scholar] [CrossRef]

- Daymond, M.R.; Bourke, M.A.M.; von Dreele, R.B. Use of Rietveld refinement to fit a hexagonal crystal structure in the presence of elastic and plastic anisotropy. J. Appl. Phys. 1999, 85, 739–747. [Google Scholar] [CrossRef]

- Lundbäck, A.; Pederson, R.; Colliander, M.H.; Brice, C.; Steuwer, A.; Heralic, A.; Buslaps, T.; Lindgren, L.-E. Modeling and experimental measurement with synchrotron radiation of residual stresses in laser metal deposited Ti-6Al-4V. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef] [Green Version]

- ASTM F136-13. Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401); ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Grell, W.A.; Solis-Ramos, E.; Clark, E.; Lucon, E.; Garboczi, E.J.; Predecki, P.K.; Loftus, Z.; Kumosa, M. Effect of powder oxidation on the impact toughness of electron beam melting Ti-6Al-4V. Addit. Manuf. 2017, 17, 123–134. [Google Scholar] [CrossRef]

- Yasa, E.; Deckers, J.; Kruth, J.-P.; Rombouts, M.; Luyten, J. Charpy impact testing of metallic selective laser melting parts. Virtual Phys. Prototyp. 2010, 5, 89–98. [Google Scholar] [CrossRef]

- Wu, M.W.; Lai, P.H. The positive effect of hot isostatic pressing on improving the anisotropies of bending and impact properties in selective laser melted Ti-6Al-4V alloy. Mater. Sci. Eng. A 2016, 658, 429–438. [Google Scholar] [CrossRef]

- Sliva, A.P.; Dragunov, V.K.; Terentyev, E.V.; Goncharov, A.L. EBW of aluminium alloys with application of electron beam oscillation. Proc. J. Phys. Conf. Ser. 2018, 1089, 012005. [Google Scholar] [CrossRef] [Green Version]

- Gudenko, A.V.; Sliva, A.P. Influence of electron beam oscillation parameters on the formation of details by electron beam metal wire deposition method. Proc. J. Phys. Conf. Ser. 2018, 1109, 012037. [Google Scholar] [CrossRef]

- Dragunov, V.K.; Goryachkina, M.V.; Gudenko, A.V.; Sliva, A.P.; Shcherbakov, A.V. Investigation of the optimal modes of electron-beam wire deposition. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tomsk, Russia, 3–7 September 2019. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, B.; Li, X.; Li, R. Effects of metal-vapor jet force on the physical behavior of melting wire transfer in electron beam additive manufacturing. J. Mater. Process. Technol. 2015, 220, 243–250. [Google Scholar] [CrossRef]

- Hu, R.; Luo, M.; Liu, T.; Liang, L.; Huang, A.; Trushnikov, D.; Karunakaran, K.P.; Pang, S. Thermal fluid dynamics of liquid bridge transfer in laser wire deposition 3D printing. Sci. Technol. Weld. Join. 2018, 24, 401–411. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Gao, H.; Wu, L. Modeling of bead section profile and overlapping beads with experimental validation for robotic GMAW-based rapid manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 417–423. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of hatch spacing on melt pool and as-built quality during selective laser melting of stainless steel: Modeling and experimental approaches. Materials 2019, 12, 50. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Nai, M.L.S.; Sin, W.J.; Lu, S.; Zhang, B.; Bai, J.; Song, J.; Wei, J. Effect of overlap distance on the microstructure and mechanical properties of in situ welded parts built by electron beam melting process. J. Alloys Compd. 2019, 772, 247–255. [Google Scholar] [CrossRef]

- Cao, Y.; Zhu, S.; Liang, X.; Wang, W. Overlapping model of beads and curve fitting of bead section for rapid manufacturing by robotic MAG welding process. Robot. Comput. Integr. Manuf. 2011, 27, 641–645. [Google Scholar] [CrossRef]

- Li, Y.; Han, Q.; Zhang, G.; Horváth, I. A layers-overlapping strategy for robotic wire and arc additive manufacturing of multi-layer multi-bead components with homogeneous layers. Int. J. Adv. Manuf. Technol. 2018, 96, 3331–3344. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, L.; Buhl, J.; Bambach, M. Multi-bead overlapping models for tool path generation in wire-arc additive manufacturing processes. Procedia Manuf. 2020, 47, 1123–1128. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Han, Q.; Zhang, G.; Horváth, I. Enhanced beads overlapping model for wire and arc additive manufacturing of multi-layer multi-bead metallic parts. J. Mater. Process. Technol. 2018, 252, 838–848. [Google Scholar] [CrossRef]

- Aiyiti, W.; Zhao, W.; Lu, B.; Tang, Y. Investigation of the overlapping parameters of MPAW-based rapid prototyping. Rapid Prototyp. J. 2006, 12, 165–172. [Google Scholar] [CrossRef]

- Nikam, S.H.; Jain, N.K. Finite element simulation of pre-heating effect on melt pool size during micro-plasma transferred arc deposition process. IOP Conf. Ser. Mater. Sci. Eng. 2018, 389, 012006. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Edwards, P.; O’Conner, A.; Ramulu, M. Electron beam additive manufacturing of titanium components: Properties and performance. J. Manuf. Sci. Eng. 2013, 135. [Google Scholar] [CrossRef]

- Chong, Y.; Bhattacharjee, T.; Yi, J.; Shibata, A.; Tsuji, N. Mechanical properties of fully martensite microstructure in Ti-6Al-4V alloy transformed from refined beta grains obtained by rapid heat treatment (RHT). Scr. Mater. 2017, 138, 66–70. [Google Scholar] [CrossRef]

| Material | Al (wt. %) | V (wt. %) | Fe (wt. %) | Ti (wt. %) | C (wt. %) | N (wt. %) | O (wt. %) |

|---|---|---|---|---|---|---|---|

| Solid Wire | 6.36 | 3.48 | 0.11 | bal. | 0.018 | <0.005 | n.m. |

| Attribute | Abbreviation | Unit | Values |

|---|---|---|---|

| Acceleration voltage | Uacc | kV | 90 |

| Beam current | Ibeam | mA | 17.5–46.7 |

| Welding speed | vweld | mm/s | 9.0–11.0 |

| Wire feed rate | Vwire | m/min | 2.7–3.9 |

| Feed angle | αfeed | - | 55 |

| Focal point | fp | - | Substrate Surface |

| Beam figure (bop) | - | - | Concentric Circles |

| Frequency (bop) | f | Hz | 1000 |

| Amplitude of deflection (bop) | x,y | mm | Ø 4 |

| Factor | Unit | Heat Input | ||||

|---|---|---|---|---|---|---|

| Moderate | High | |||||

| Low | High | Low | High | |||

| Beam current | Ibeam | mA | 17.5 | 21.4 | 31.1 | 46.7 |

| Welding speed | vweld | mm/s | 9.0 | 11.0 | 9.0 | 11.0 |

| Wire feed rate | Vwire | m/min | 2.7 | 3.3 | 3.3 | 3.9 |

| Figure 3 | Beam Current | Welding Speed | Wire Feed Rate | Material Input per Length | Dilution |

|---|---|---|---|---|---|

| (mA) | (mm/s) | (m/min) | (-) | (%) | |

| (a) | 17.5 | 11 | 2.7 | 4.1 | 45 |

| (b) | 21.4 | 11 | 3.3 | 5.0 | 45 |

| (c) | 21.4 | 9 | 2.7 | 5.0 | 52 |

| (d) | 17.5 | 9 | 3.3 | 6.1 | 28 |

| Material | Al (wt. %) | V (wt. %) | Fe (wt. %) | Ti (wt. %) | C (wt. %) | N (wt. %) | O (wt. %) |

|---|---|---|---|---|---|---|---|

| AM block no. 1 | 5.47 | 3.39 | 0.11 | bal. | 0.017 | <0.005 | 0.11 |

| AM block no. 2 | 5.49 | 3.46 | 0.10 | bal. | 0.019 | <0.005 | 0.11 |

| Sample Orientation | As-Deposited | PWHT | ||

|---|---|---|---|---|

| Impact Energy (J) | Lateral Expansion (mm) | Impact Energy (J) | Lateral Expansion (mm) | |

| LD | 54 | 0.6 | 45 | 0.4 |

| TD | 40 | 0.3 | 34 | 0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pixner, F.; Warchomicka, F.; Peter, P.; Steuwer, A.; Colliander, M.H.; Pederson, R.; Enzinger, N. Wire-Based Additive Manufacturing of Ti-6Al-4V Using Electron Beam Technique. Materials 2020, 13, 3310. https://doi.org/10.3390/ma13153310

Pixner F, Warchomicka F, Peter P, Steuwer A, Colliander MH, Pederson R, Enzinger N. Wire-Based Additive Manufacturing of Ti-6Al-4V Using Electron Beam Technique. Materials. 2020; 13(15):3310. https://doi.org/10.3390/ma13153310

Chicago/Turabian StylePixner, Florian, Fernando Warchomicka, Patrick Peter, Axel Steuwer, Magnus Hörnqvist Colliander, Robert Pederson, and Norbert Enzinger. 2020. "Wire-Based Additive Manufacturing of Ti-6Al-4V Using Electron Beam Technique" Materials 13, no. 15: 3310. https://doi.org/10.3390/ma13153310

APA StylePixner, F., Warchomicka, F., Peter, P., Steuwer, A., Colliander, M. H., Pederson, R., & Enzinger, N. (2020). Wire-Based Additive Manufacturing of Ti-6Al-4V Using Electron Beam Technique. Materials, 13(15), 3310. https://doi.org/10.3390/ma13153310