Pseudo-Ductility, Morphology and Fractography Resulting from the Synergistic Effect of CaCO3 and Bentonite in HDPE Polymer Nano Composite

Abstract

:1. Introduction

1.1. Polymer/Fillers Interfacial Interaction

2. Materials and Methods

2.1. Materials

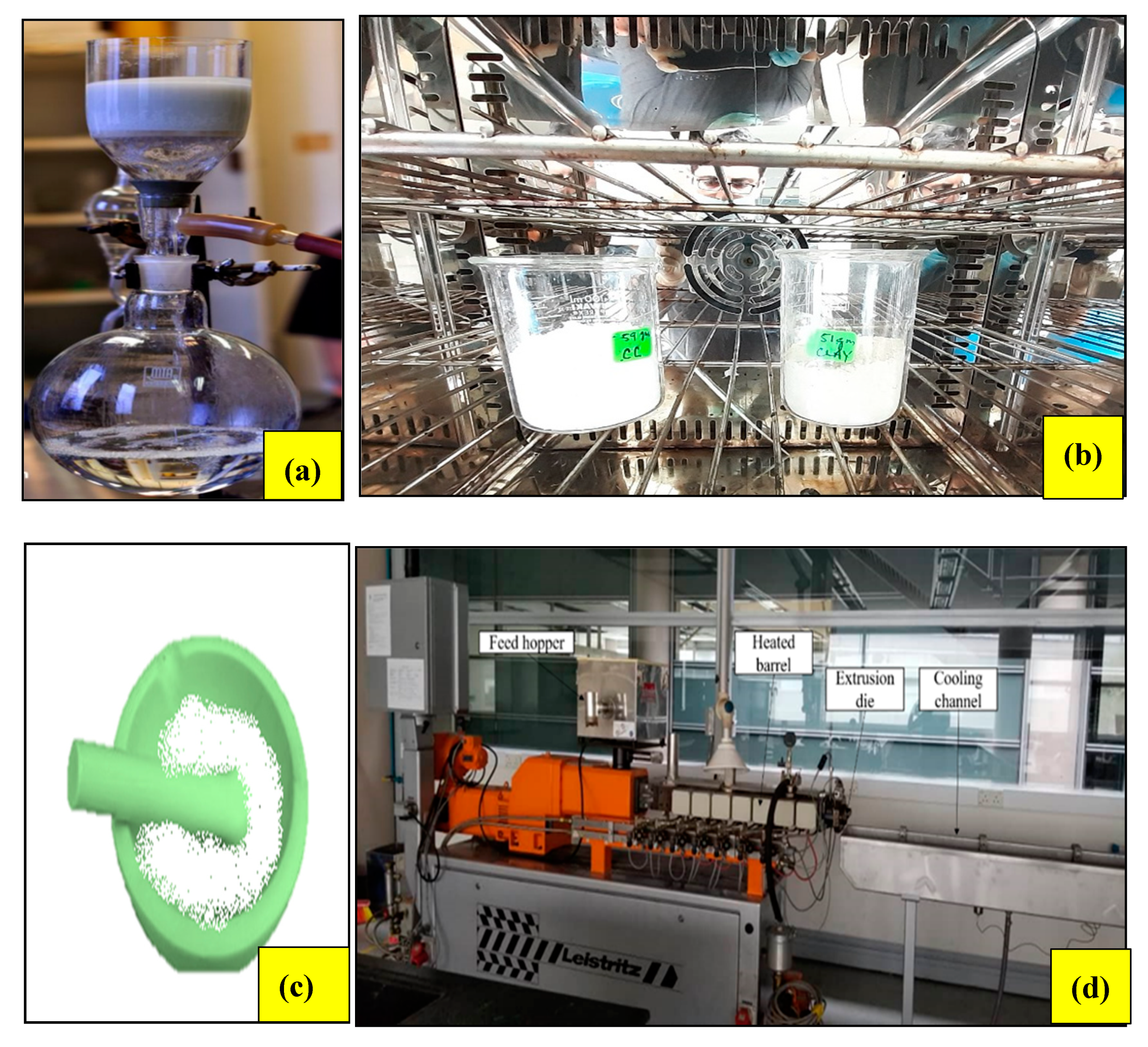

2.2. Composite/Sample Fabrication

2.3. Methodology

3. Results

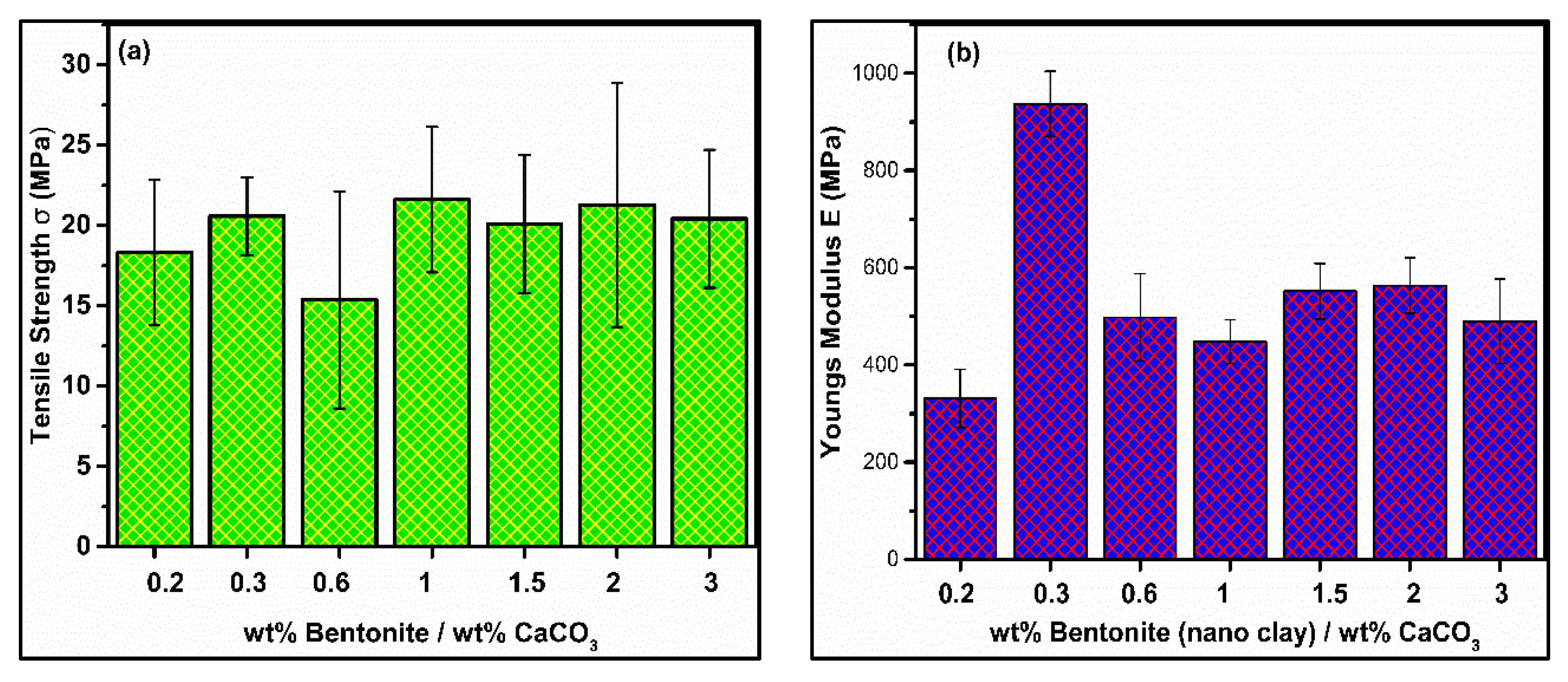

3.1. Tensile Strength (σ)

3.2. Young’s Modulus (E)

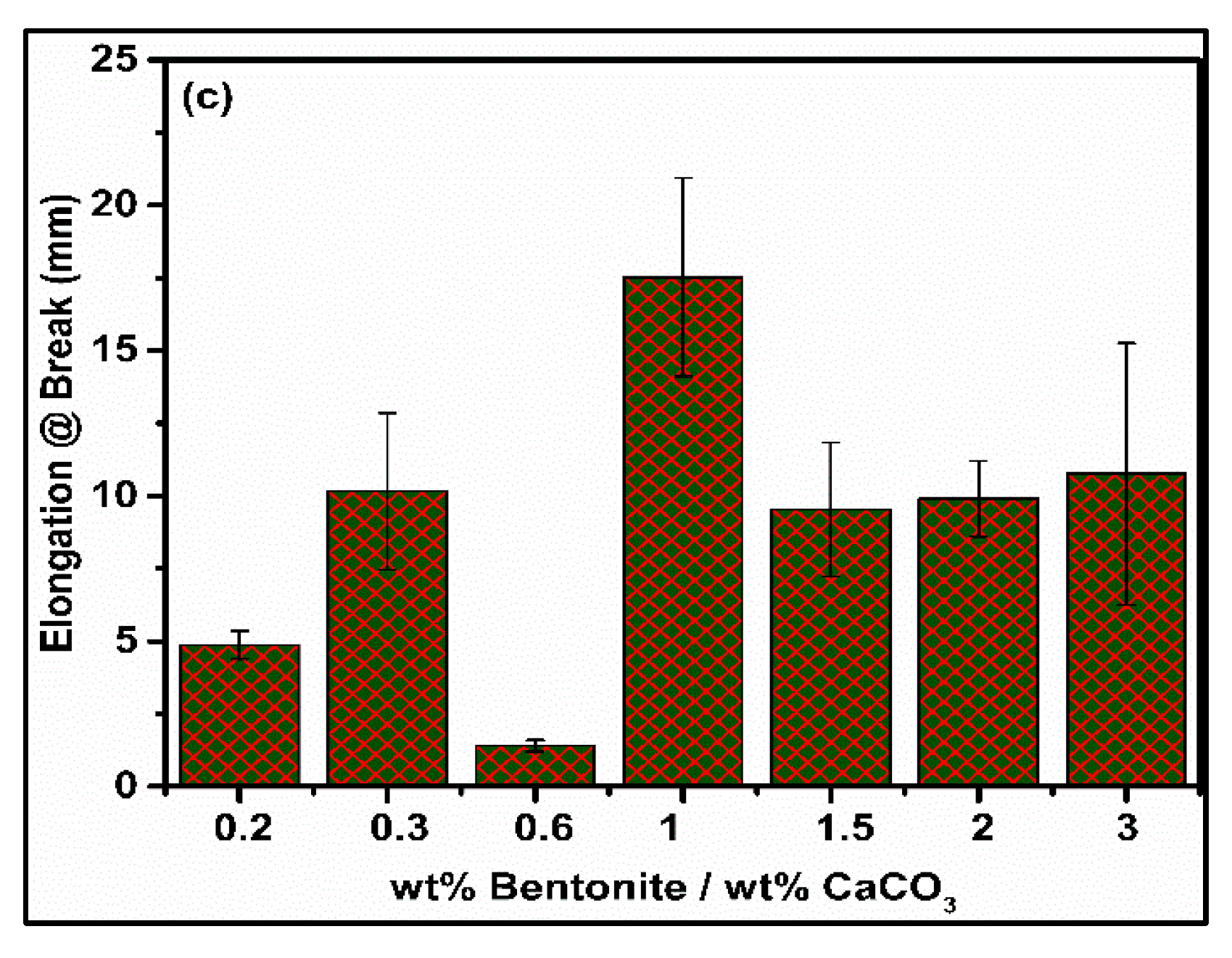

3.3. Elongation at Break

- Case 1: Micro-void generated in the matrix during fabrication.

- Case 2: A crack fusing with another crack already generated (by a micro defect or by case 1).

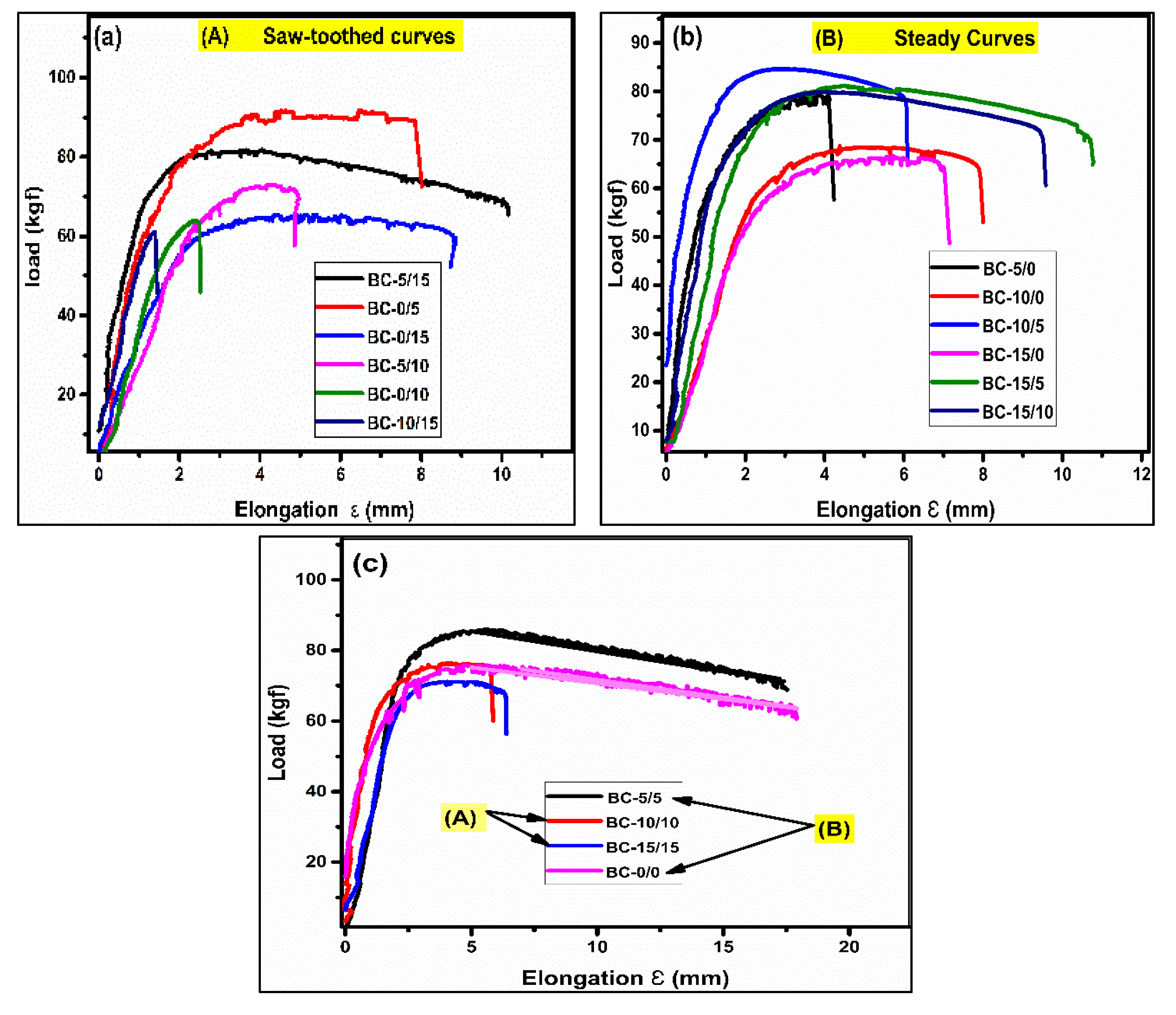

3.4. Load–Extension Curve

3.5. Morphological Analysis

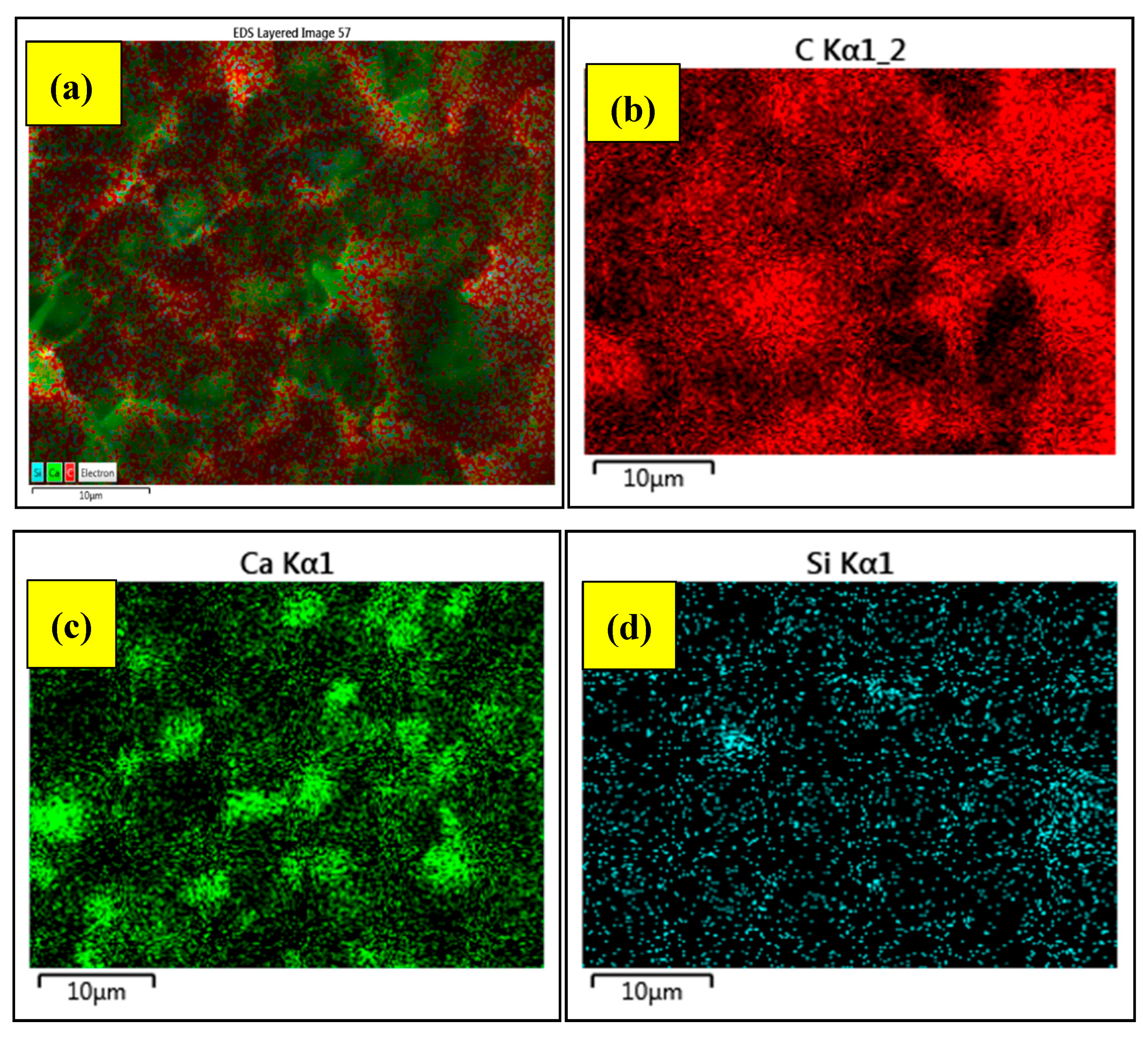

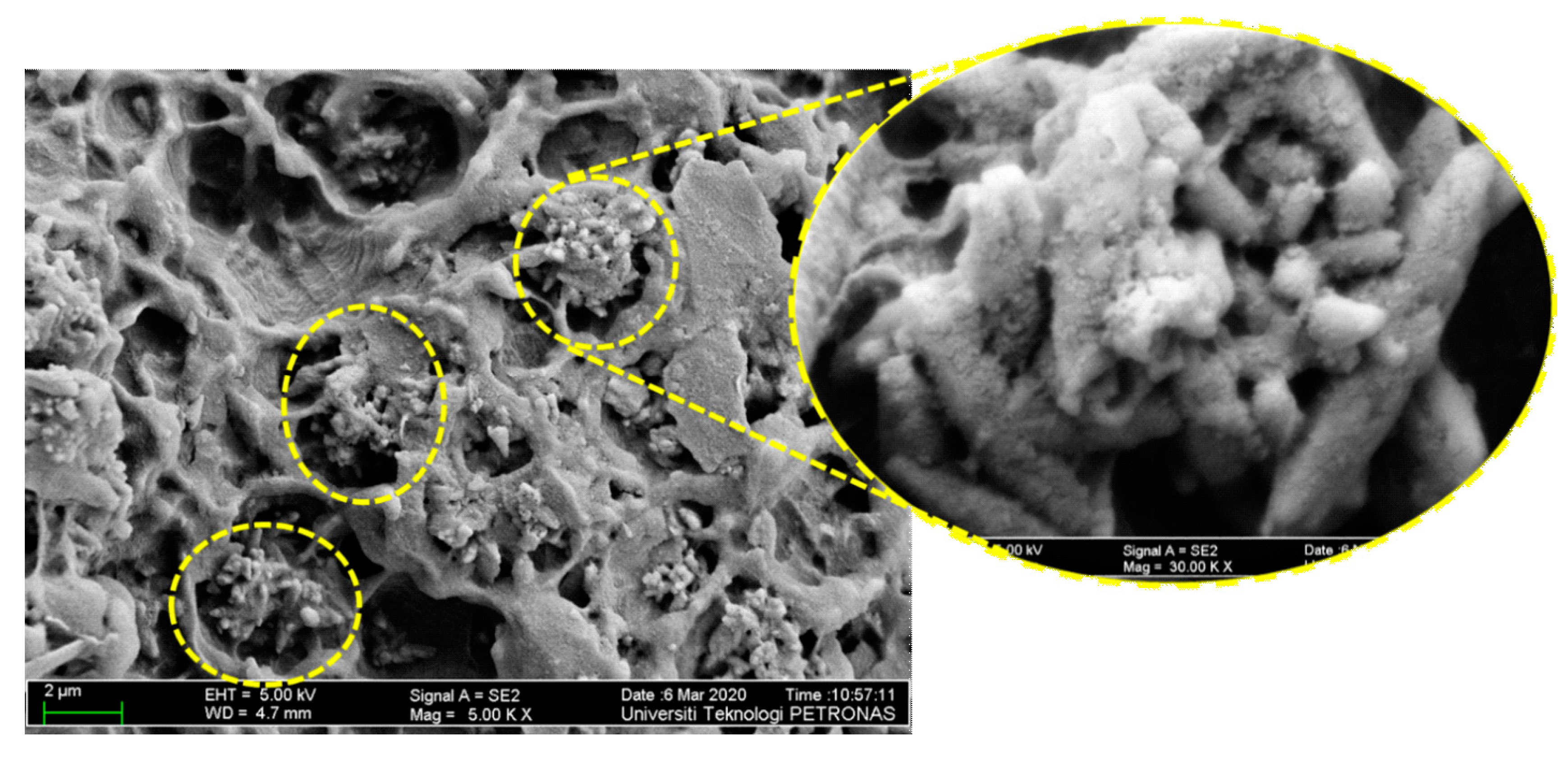

3.5.1. Dispersions Analysis

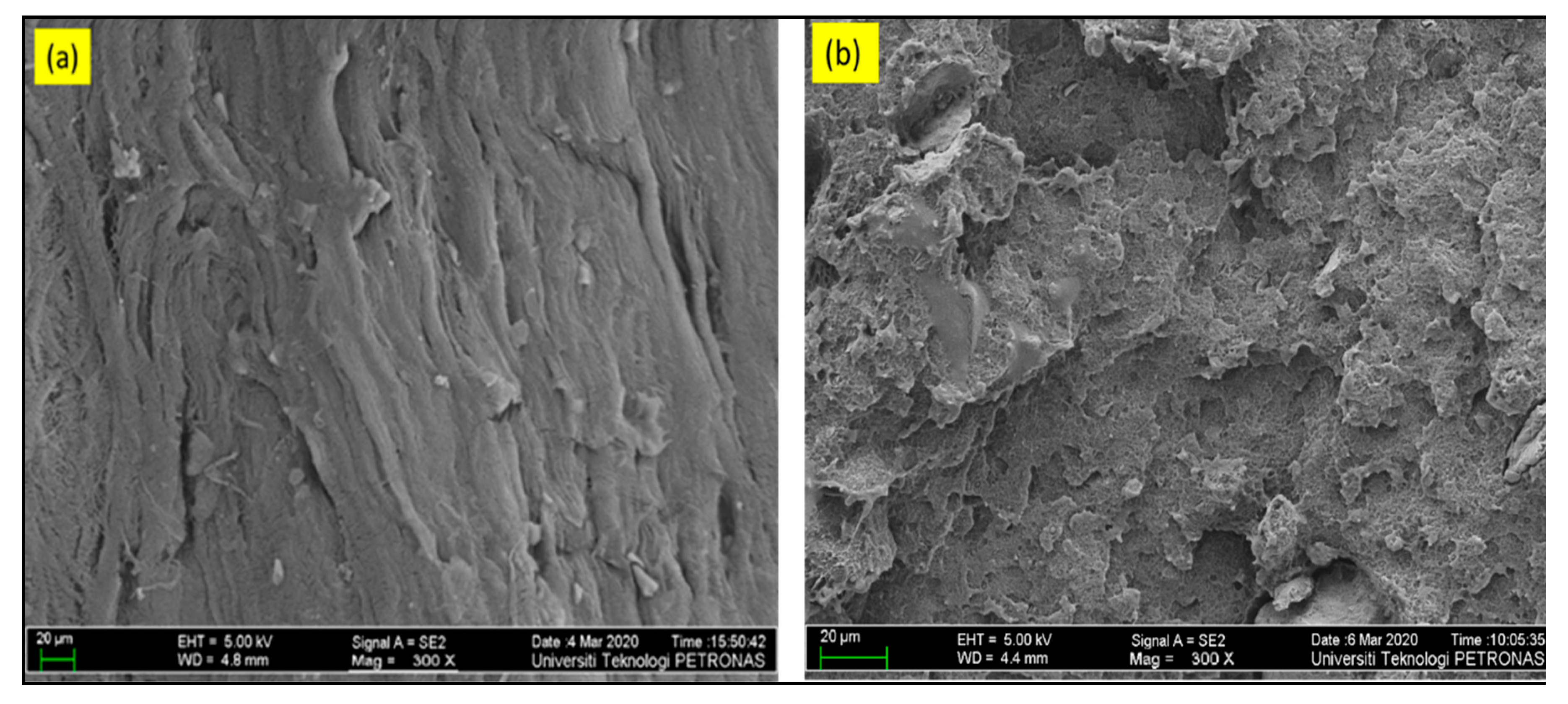

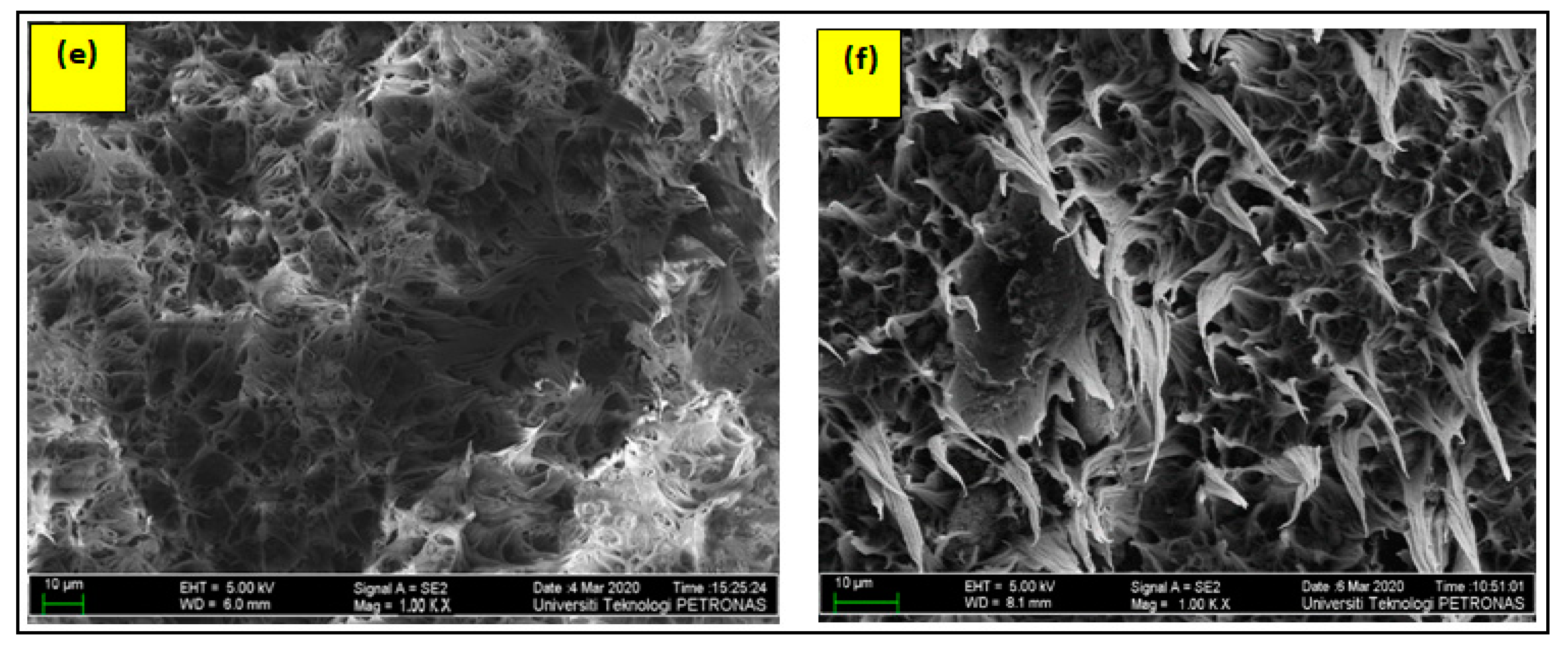

3.5.2. Fractographic Analysis

4. Conclusions

- Sufficient strength transfer between HDPE-bentonite and CaCO3 can be achieved without the application of surfactants.

- The values of elongation of the samples undergoing stress softening are higher while Young’s modulus is compromised in case of stress softening.

- Stress-softened samples are identified with more toughness, having higher values of elongation, and rougher patterns were noted in fractography thus more ductility.

- It is evident from EDS mapping and elemental characterization that inhomogeneity was reduced by the compatibilization effect of bentonite nano clay, but this is limited to the case when the content of bentonite exceeded that of CaCO3 or in some cases when an equal amount of bentonite and CaCO3 was used.

- Similarly, CaCO3 nano particles were encapsulated when the bentonite nano clay dominated the samples. In other cases, there was not enough bentonite to perform this encapsulation and properties were not enhanced.

Author Contributions

Funding

Conflicts of Interest

References

- Prato, A.; Longana, M.L.; Hussain, A.; Wisnom, M.R. Post-impact behaviour of pseudo-ductile thin-ply angle-ply hybrid composites. Materials 2019, 12, 579. [Google Scholar] [CrossRef] [Green Version]

- Renner, K.; Yang, M.S.; Móczó, J.; Choi, H.J.; Pukánszky, B. Analysis of the debonding process in polypropylene model composites. Eur. Polym. J. 2005, 41, 2520–2529. [Google Scholar] [CrossRef]

- Wood, W.; Kumar, S.; Zhong, W.H. Synthesis of Organosilane-Modified Carbon Nanofibers and Influence of Silane Coating Thickness on the Performance of Polyethylene Nanocomposites. Macromol. Mater. Eng. 2010, 295, 1125–1135. [Google Scholar] [CrossRef]

- Lazzeri, A.; Zebarjad, S.M.; Pracella, M.; Cavalier, K.; Rosa, R. Filler toughening of plastics. Part 1—The effect of surface interactions on physico-mechanical properties and rheological behaviour of ultrafine CaCO3/HDPE nanocomposites. Polymer 2005, 46, 827–844. [Google Scholar] [CrossRef]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef] [Green Version]

- Zuiderduin, W.; Westzaan, C.; Huetink, J.; Gaymans, R. Toughening of polypropylene with calcium carbonate particles. Polymer 2003, 44, 261–275. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Laura, D.; Keskkula, H.; Barlow, J.; Paul, D. Effect of rubber particle size and rubber type on the mechanical properties of glass fiber reinforced, rubber-toughened nylon 6. Polymer 2003, 44, 3347–3361. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, H.; Chan, C.-M.; Wu, J. The toughening mechanism of polypropylene/calcium carbonate nanocomposites. Polymer 2010, 51, 3277–3284. [Google Scholar] [CrossRef]

- Sahin, M.; Schlögl, S.; Kalinka, G.; Wang, J.; Kaynak, B.; Mühlbacher, I.; Ziegler, W.; Kern, W.; Grützmacher, H. Tailoring the interfaces in glass fiber-reinforced photopolymer composites. Polymer 2018, 141, 221–231. [Google Scholar] [CrossRef]

- D’Anna, A.; Arrigo, R.; Frache, A. PLA/PHB Blends: Biocompatibilizer Effects. Polymers 2019, 11, 1416. [Google Scholar]

- Zhang, X.; Simon, L.C. In situ polymerization of hybrid polyethylene-alumina nanocomposites. Macromol. Mater. Eng. 2005, 290, 573–583. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Y.; Eyler, A.; Zhong, W.-H. Synergistic effects of hybrid graphitic nanofillers on simultaneously enhanced wear and mechanical properties of polymer nanocomposites. Eur. Polym. J. 2014, 55, 210–221. [Google Scholar] [CrossRef]

- Moghbelli, E.; Sue, H.-J.; Jain, S. Stabilization and control of phase morphology of PA/SAN blends via incorporation of exfoliated clay. Polymer 2010, 51, 4231–4237. [Google Scholar] [CrossRef]

- Tiwari, R.R.; Paul, D.R. Effect of organoclay on the morphology, phase stability and mechanical properties of polypropylene/polystyrene blends. Polymer 2011, 52, 1141–1154. [Google Scholar] [CrossRef]

- Wang, J.; Jin, X.; Li, C.; Wang, W.; Wu, H.; Guo, S. Graphene and graphene derivatives toughening polymers: Toward high toughness and strength. Chem. Eng. J. 2019, 370, 831–854. [Google Scholar] [CrossRef]

- Wang, K.; Chen, L.; Wu, J.; Toh, M.L.; He, C.; Yee, A.F. Epoxy nanocomposites with highly exfoliated clay: Mechanical properties and fracture mechanisms. Macromolecules 2005, 38, 788–800. [Google Scholar] [CrossRef]

- Wang, H.-X.; Fang, X.; Feng, B.; Gao, Z.-R.; Wu, S.-Z.; Li, Y.-C. Influence of Temperature on the Mechanical Properties and Reactive Behavior of Al-PTFE under Quasi-Static Compression. Polymers 2018, 10, 56. [Google Scholar] [CrossRef] [Green Version]

- Thio, Y.S.; Argon, A.S.; Cohen, R.E.; Weinberg, M. Toughening of isotactic polypropylene with CaCO3 particles. Polymer 2002, 43, 3661–3674. [Google Scholar] [CrossRef]

- Eiras, D.; Pessan, L.A. Mechanical properties of polypropylene/calcium carbonate nanocomposites. Mater. Res. 2009, 12, 517–522. [Google Scholar] [CrossRef] [Green Version]

- Ning, N.; Fu, S.; Zhang, W.; Chen, F.; Wang, K.; Deng, H.; Zhang, Q.; Fu, Q. Realizing the enhancement of interfacial interaction in semicrystalline polymer/filler composites via interfacial crystallization. Prog. Polym. Sci. 2012, 37, 1425–1455. [Google Scholar] [CrossRef]

- Gunning, M.; Istrate, O.; Geever, L.; Lyons, J.; Blackie, P.; Chen, B.; Higginbotham, C. The effect of maleic anhydride grafting efficiency on the flexural properties of polyethylene composites. J. Appl. Polym. Sci. 2012, 124, 4799–4808. [Google Scholar] [CrossRef]

- Ruamcharoen, J.; Ratana, T.; Ruamcharoen, P. Bentonite as a reinforcing and compatibilizing filler for natural rubber and polystyrene blends in latex stage. Polym. Eng. Sci. 2014, 54, 1436–1443. [Google Scholar] [CrossRef]

- Zhu, Y.; Ma, H.-Y.; Tong, L.-F.; Fang, Z.-P. “Cutting effect” of organoclay platelets in compatibilizing immiscible polypropylene/polystyrene blends. J. Zhejiang Univ. Sci. A 2008, 9, 1614–1620. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Bai, J. Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos. Sci. Technol. 2013, 74, 221–227. [Google Scholar] [CrossRef]

- Bartczak, Z.; Argon, A.; Cohen, R.; Weinberg, M. Toughness mechanism in semi-crystalline polymer blends: II. High-density polyethylene toughened with calcium carbonate filler particles. Polymer 1999, 40, 2347–2365. [Google Scholar] [CrossRef]

- Palabiyik, M.; Bahadur, S. Mechanical and tribological properties of polyamide 6 and high density polyethylene polyblends with and without compatibilizer. Wear 2000, 246, 149–158. [Google Scholar] [CrossRef]

- Irez, A.B.; Bayraktar, E.; Miskioglu, I. Fracture Toughness Analysis of Epoxy-Recycled Rubber-Based Composite Reinforced with Graphene Nanoplatelets for Structural Applications in Automotive and Aeronautics. Polymers 2020, 12, 448. [Google Scholar] [CrossRef] [Green Version]

- Fei, Y.; Fang, W.; Zhong, M.; Jin, J.; Fan, P.; Yang, J.; Fei, Z.; Chen, F.; Kuang, T. Morphological structure, rheological behavior, mechanical properties and sound insulation performance of thermoplastic rubber composites reinforced by different inorganic fillers. Polymers 2018, 10, 276. [Google Scholar] [CrossRef] [Green Version]

- Kinloch, A.; Maxwell, D.; Young, R. The fracture of hybrid-particulate composites. J. Mater. Sci. 1985, 20, 4169–4184. [Google Scholar] [CrossRef]

- Meddad, A.; Fisa, B. Stress-strain behavior and tensile dilatometry of glass bead-filled polypropylene and polyamide 6. J. Appl. Polym. Sci. 1997, 64, 653–665. [Google Scholar] [CrossRef]

- Chen, L.; Wong, S.C.; Liu, T.; Lu, X.; He, C. Deformation mechanisms of nanoclay-reinforced maleic anhydride-modified polypropylene. J. Polym. Sci. B Polym. Phys. 2004, 42, 2759–2768. [Google Scholar] [CrossRef]

- Drozdov, A.D.; Dorfmann, A. The stress–strain response and ultimate strength of filled elastomers. Comput. Mater. Sci. 2001, 21, 395–417. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Q.; Fu, Q. Compatibilization of immiscible poly (propylene)/polystyrene blends using clay. Macromol. Rapid Commun. 2003, 24, 231–235. [Google Scholar] [CrossRef]

- Gahleitner, M.; Kretzschmar, B.; Pospiech, D.; Ingolic, E.; Reichelt, N.; Bernreitner, K. Morphology and mechanical properties of polypropylene/polyamide 6 nanocomposites prepared by a two-step melt-compounding process. J. Appl. Polym. Sci. 2006, 100, 283–291. [Google Scholar] [CrossRef]

- Chow, W.; Ishak, Z.M.; Ishiaku, U.; Karger-Kocsis, J.; Apostolov, A. The effect of organoclay on the mechanical properties and morphology of injection-molded polyamide 6/polypropylene nanocomposites. J. Appl. Polym. Sci. 2004, 91, 175–189. [Google Scholar] [CrossRef]

- Lin, L.; Luo, Y.; Li, X. Synthesis of diblock polyampholyte PAMPS-b-PMAPTAC and its adsorption on bentonite. Polymers 2019, 11, 49. [Google Scholar] [CrossRef] [Green Version]

- Salam, H.; Dong, Y.; Davies, I.; Pramanik, A. The effects of material formulation and manufacturing process on mechanical and thermal properties of epoxy/clay nanocomposites. Int. J. Adv. Manuf. Technol. 2016, 87, 1999–2012. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Yee, A. Inorganic particle toughening I: Micro-mechanical deformations in the fracture of glass bead filled epoxies. Polymer 2001, 42, 577–588. [Google Scholar] [CrossRef]

| Sample | Tensile Strength (MPa) | Elastic Limit (MPa) | E (MPa) | Elongation at Break (mm) |

|---|---|---|---|---|

| BC-0/0 | 19.06 ± 0.48 | 10.65 ± 2.31 | 596 ± 58.43 | 17.91 ± 0.48 |

| BC-0/5 | 23.06 ± 4.50 | 13.24 ± 5.60 | 788 ± 60.70 | 7.85 ± 5.6 |

| BC-0/10 | 16.06 ± 3.60 | 12.669 ± 3.50 | 515 ± 80.90 | 2.51 ± 1.5 |

| BC-0/15 | 16.46 ± 6.40 | 11.65 ± 4.70 | 331 ± 70.39 | 8.73 ± 3.80 |

| BC-5/10 | 18.31 ± 3.80 | 15.99 ± 5.90 | 372 ± 30.51 | 6.40 ±4.87 |

| BC-5/15 | 20.37 ± 7.50 | 12.63 ± 2.31 | 937 ± 42.39 | 10.16 ± 4.50 |

| BC-10/15 | 15.36 ± 6.30 | 15.35 ± 3.50 | 498 ± 56.51 | 4.50 ± 1.40 |

| Sample | Tensile Strength (MPa) | Elastic Limit (MPa) | E (MPa) | Elongation at Break (mm) |

|---|---|---|---|---|

| BC-0/0 | 19.06 ± 0.48 | 10.65 ± 2.31 | 596 ± 58.43 | 17.91 ± 0.48 |

| BC-5/0 | 20 ± 1.44 | 12.97 ± 5.91 | 772 ± 59.58 | 4.11 ± 7.9 |

| BC-10/0 | 17.28 ± 8.31 | 14.88 ± 3.21 | 308 ± 64.59 | 7.95 ± 6.5 |

| BC-10/5 | 21.28 ± 5.40 | 12.53 ± 4.57 | 563 ± 80.90 | 9.9 ± 4.50 |

| BC-15/0 | 16.75 ± 8.39 | 12.44 ± 6.51 | 363 ± 60.21 | 7.02 ± 6.50 |

| BC-15/5 | 20.41± 7.49 | 16.10 ± 8.48 | 490 ± 30.32 | 10.76 ± 8.90 |

| BC-15/10 | 20.09 ± 6.50 | 15.73 ± 7.77 | 552 ± 40.51 | 9.53 ± 3.80 |

| Sample | Tensile Strength (MPa) | Elastic Limit (MPa) | E (MPa) | Elongation at Break (mm) |

|---|---|---|---|---|

| BC-0/0 | 19.06 ± 0.48 | 10.65 ± 2.31 | 596 ± 58.43 | 17.91 ± 0.48 |

| BC-5/5 | 21.61 ± 1.85 | 18.69 ± 5.60 | 448 ± 63.66 | 17.53 ± 8.9 |

| BC-10/10 | 19.22 ± 7.86 | 12.58 ± 6.70 | 619 ± 75.78 | 5.77 ± 5.6 |

| BC-15/15 | 17.89 ± 3.41 | 16.29 ± 8.90 | 345 ± 89.67 | 6.37 ± 4.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, T.; Ya, H.H.; Khan, R.; Hidayat Syah Lubis, A.M.; Mahadzir, S. Pseudo-Ductility, Morphology and Fractography Resulting from the Synergistic Effect of CaCO3 and Bentonite in HDPE Polymer Nano Composite. Materials 2020, 13, 3333. https://doi.org/10.3390/ma13153333

Ahmed T, Ya HH, Khan R, Hidayat Syah Lubis AM, Mahadzir S. Pseudo-Ductility, Morphology and Fractography Resulting from the Synergistic Effect of CaCO3 and Bentonite in HDPE Polymer Nano Composite. Materials. 2020; 13(15):3333. https://doi.org/10.3390/ma13153333

Chicago/Turabian StyleAhmed, Tauseef, Hamdan H. Ya, Rehan Khan, Abdul Munir Hidayat Syah Lubis, and Shuhaimi Mahadzir. 2020. "Pseudo-Ductility, Morphology and Fractography Resulting from the Synergistic Effect of CaCO3 and Bentonite in HDPE Polymer Nano Composite" Materials 13, no. 15: 3333. https://doi.org/10.3390/ma13153333

APA StyleAhmed, T., Ya, H. H., Khan, R., Hidayat Syah Lubis, A. M., & Mahadzir, S. (2020). Pseudo-Ductility, Morphology and Fractography Resulting from the Synergistic Effect of CaCO3 and Bentonite in HDPE Polymer Nano Composite. Materials, 13(15), 3333. https://doi.org/10.3390/ma13153333