Retentive Characteristics of a New Attachment System for Hybrid Dentures

Abstract

1. Introduction

2. Materials and Methods

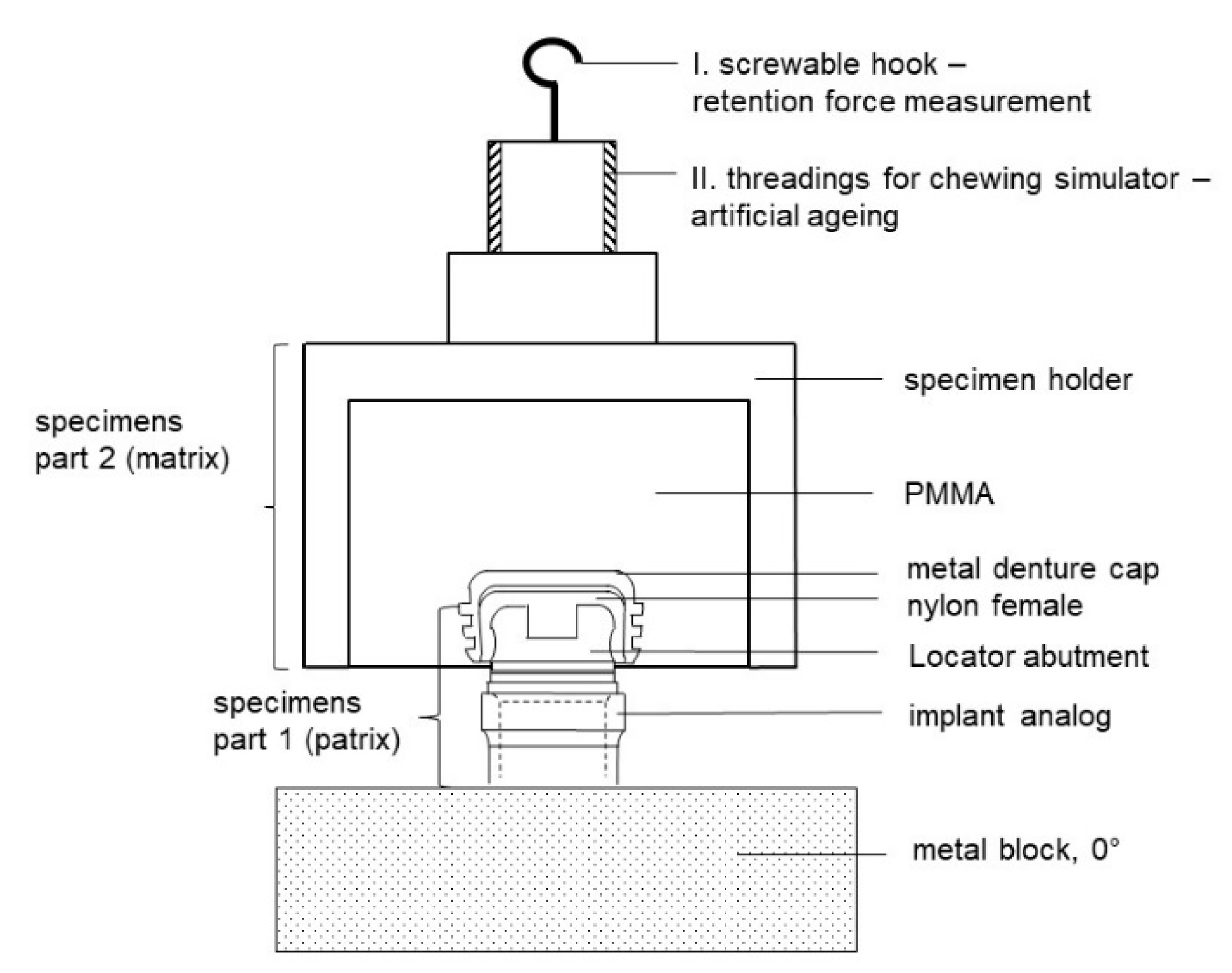

2.1. Specimen Fabrication

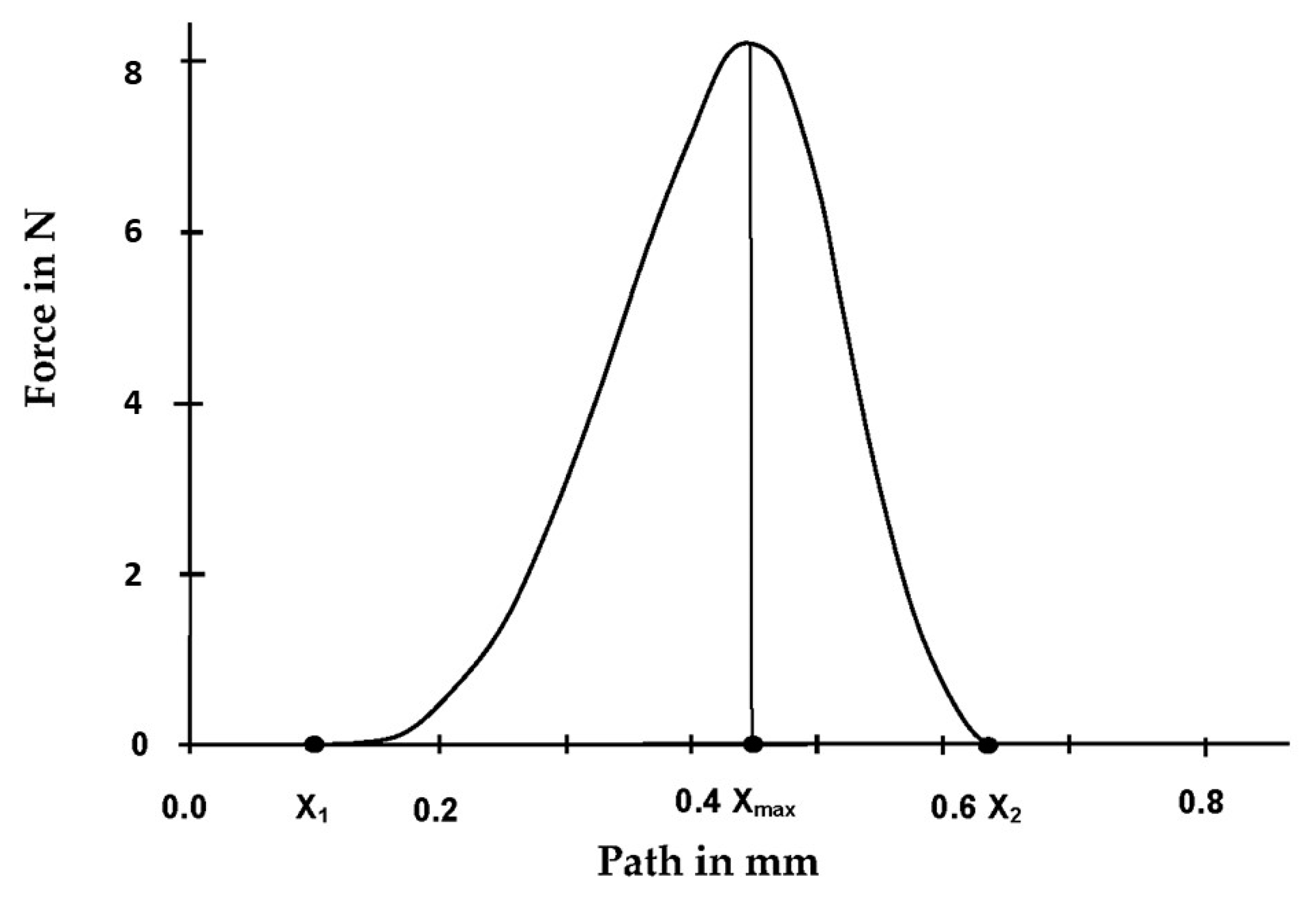

2.2. Retention Force Measurement

2.3. Artificial Ageing

2.4. Release Period

2.5. Microscopic Measurement

2.6. Statistical Analyses

2.6.1. Comparison of the Mean Value of the Initially Measured Retention Forces with the Manufacturer’s Specifications, Independent of the Implant Angulation

2.6.2. Comparison of Mean Values of the Initially Measured Retention Forces with the Retention Forces after the Ageing Simulations, Independent of the Implant Angulation

2.6.3. Comparison of the Mean Values of the Retention Forces of the Different Attachment Systems Measured Initially and after Ageing, Independent of the Implant Angulation

2.6.4. Differentiation—Individual Test Series

2.6.5. Influence of Implant Angulation on the Attachment Systems

2.6.6. Comparison of Release Periods During Retention Force Measurements

3. Results

3.1. Mean Value Comparison of the Initially Measured Retention Forces in Comparison to the Manufacturer’s Specifications, Independent of the Implant Angulation

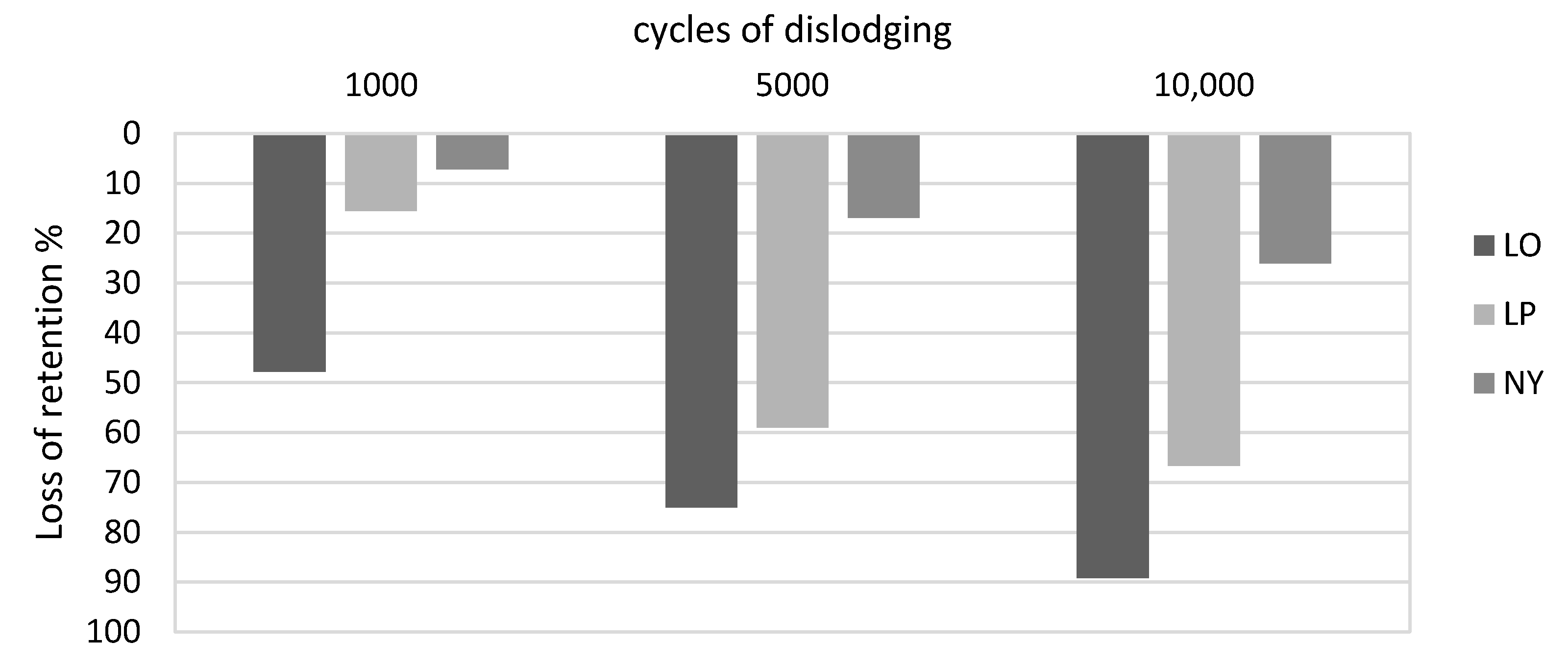

3.2. Mean Value Comparison of the Initially Measured Retention Forces Compared to the Retention Forces after The Ageing Simulations, Independent of the Implant Angulation

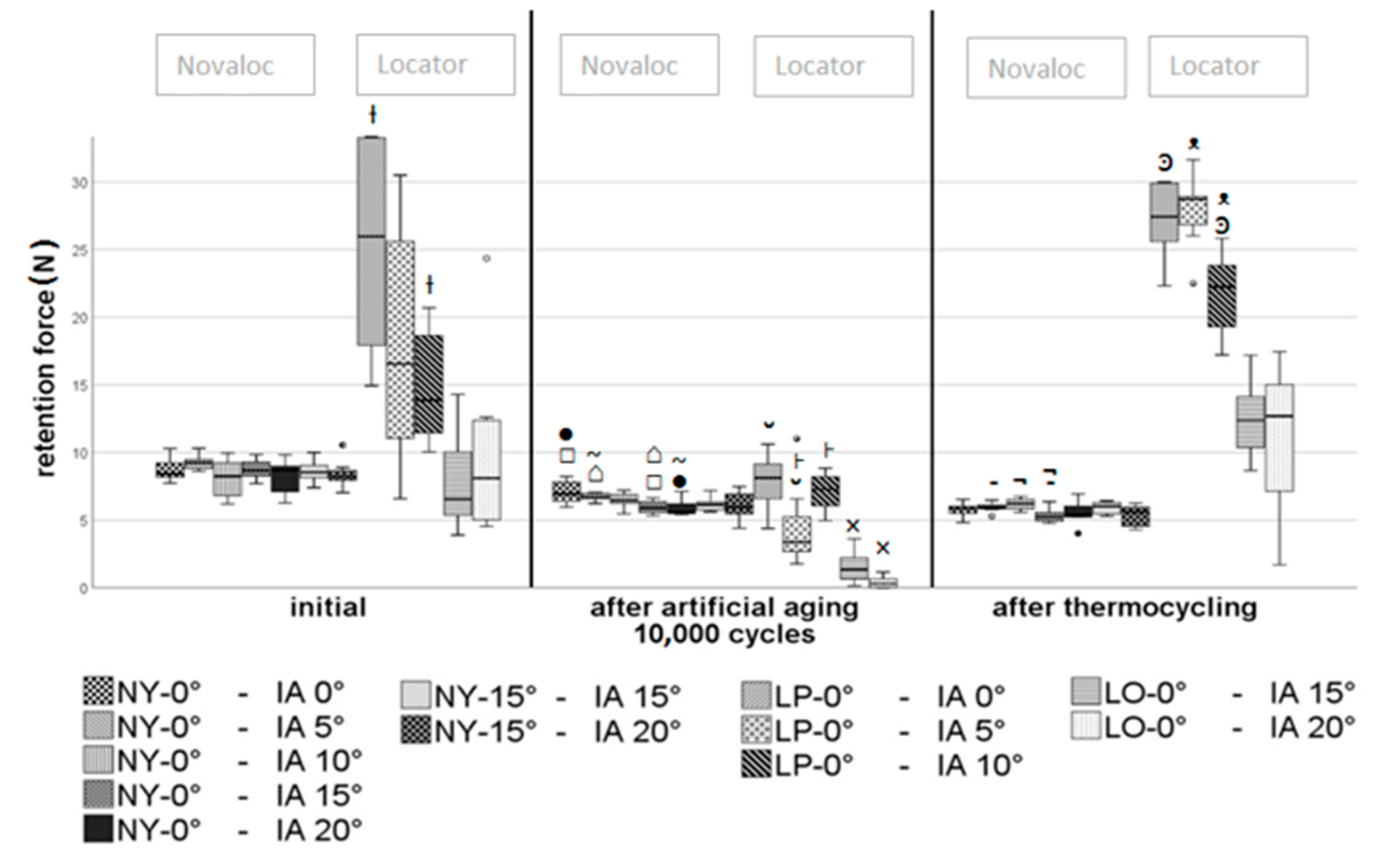

3.3. Mean Value Comparison of the Retention Forces of the Different Attachment Systems Measured Initially and after Ageing, Independent of the Implant Angulation

3.4. Differentiation—Individual Test Series

3.4.1. Influence of Artificial Ageing According to Matrix Color Coding and Implant Angulation

3.4.2. Influence of Implant Angulation on the Attachment Systems

3.5. Comparison of Release Periods During Retention Force Measurements

3.6. Dimensional Behavior of the Matrices

4. Discussion

4.1. Mean Value Comparison of the Initially Measured Retention Forces Compared to the Manufacturer’s Specifications Independent of Implant Angulation—Null Hypothesis 1

4.2. Mean Value Comparison of the Initially Measured Retention Forces Compared to the Retention Forces after the Ageing Simulations Independent of Implant Angulation—Null Hypothesis 2

4.2.1. Ageing: Insertions and Removals

4.2.2. Ageing by Thermocycling

4.3. Influence of Implant Angulation on the Attachment Systems—In Combination—Null Hypothesis 3

4.3.1. Novaloc

4.3.2. Locator

4.4. Microscopic Measurement

4.5. Comparison of Release Periods During Retention Force Measurements

5. Conclusions

- The retention force specifications of the manufacturers are guide values and can vary considerably depending on the test parameters.

- During the simulated wearing period of >9 years, all tested attachment systems showed wear reactions. With a retention force loss of 26.14%, the Novaloc attachment system showed a comparatively continuous curve. In contrast, the total retention force loss of the Locator attachment system of ~77.5% was in the clinically relevant range.

- In the current study, implant angulation had no clinically relevant influence on the retention forces of the Novaloc system. With to the angled 15°—Novaloc abutment, divergences could be compensated, and identical retention forces could be determined in relation to the pull-off direction and abutment axis. Similarly, with the orange Locator inserts, no difference could be verified at varying implant angulations.

- Future in vivo studies have to be conducted to verify the tendencies found in the current investigation. The angulation of implant abutments seems to be promising in terms of constant retention forces. Thus, it might be interesting to compare the clinical longevity of angulated attachment systems (e.g., Novaloc system) with currently introduced attachment systems that consist of matrices with a tilting mechanism (e.g., OT Equator system).

Author Contributions

Funding

Conflicts of Interest

References

- Davis, D.M. Implant-stabilized overdentures. Dent. Update 1997, 24, 106–109. [Google Scholar]

- Feine, J.S.; Carlsson, G.E.; Awad, M.A.; Chehade, A.; Duncan, W.J.; Gizani, S.; Head, T.; Heydecke, G.; Lund, J.P.; Macentee, M.I.; et al. The McGill consensus statement on overdentures. Mandibular two-implant overdentures as the first choice standard of care for edentulous patients. Gerodontology 2002, 19, 3–4. [Google Scholar]

- Thomason, J.M.; Kelly, S.A.M.; Bendkowski, A.; Ellis, J.S. Two implant retained overdentures-a review of the literature supporting the McGill and York consensus statements. J. Dent. 2012, 40, 22–34. [Google Scholar] [CrossRef]

- Hoeksema, A.R.; Visser, A.; Raghoebar, G.M.; Vissink, A.; Meijer, H.J. Influence of age on clinical performance of mandibular two-implant overdentures: A 10-year prospective comparative study. Clin. Implants Dent. Relat. Res. 2016, 18, 745–751. [Google Scholar] [CrossRef]

- Cune, M.S.; de Putter, C.; Hoogstraten, J. Treatment outcome with implant-retained overdentures: Part II—Patient satisfaction and predictability of subjective treatment outcome. J. Prosthet. Dent. 1994, 72, 152–158. [Google Scholar] [CrossRef]

- Emami, E.; Heydecke, G.; Romprè, P.H.; de Grandmont, P.; Feine, J.S. Impact of implant support for mandibular dentures on satisfaction, oral and general health-related quality of life: A meta-analysis of randomized-controlled trials. Clin. Oral Implants Res. 2009, 20, 533–544. [Google Scholar] [CrossRef] [PubMed]

- Boeckler, A.F.; Zschiegner, F.; Voigt, D.; Setz, J.M. Implantatprothetische Verbindungselemente zur Verankerung von herausnehmbarem Zahnersatz—Eine Übersicht. Implantologie 2009, 17, 241–267. [Google Scholar]

- Vercruyssen, M.; Quirynen, M. Long-term, retrospective evaluation (implant and patient-centred outcome) of the two-implant-supported overdenture in the mandible. Part 2: Marginal bone loss. Clin. Oral Implants Res. 2010, 21, 466–472. [Google Scholar] [CrossRef] [PubMed]

- Doundoulakis, J.H.; Eckert, S.E.; Lindquist, C.C.; Jeffcoat, M.K. The implant-supported overdenture as an alternative to the complete mandibular denture. J. Am. Dent. Assoc. 2003, 134, 1455–1458. [Google Scholar] [CrossRef] [PubMed]

- Petropoulos, V.C.; Smith, W.; Kousvelari, E. Comparison of retention and release periods for implant overdenture attachments. Int. J. Oral Maxillofac. Implants 1997, 12, 176–185. [Google Scholar]

- Chung, K.H.; Chung, C.Y.; Cagna, D.R.; Cronin Jr, R.J. Retention characteristics of attachment systems for implant overdentures. J. Prosthodont. 2004, 13, 221–226. [Google Scholar] [CrossRef] [PubMed]

- Boeckler, A.; Morton, D.; Ehring, C.; Setz, J.M. Mechanical properties of magnetic attachments for removable prostheses on teeth and implants. J. Prosthodont. 2008, 17, 608–615. [Google Scholar] [CrossRef] [PubMed]

- Türk, P.E.; Geckili, O.; Türk, Y.; Günay, V.; Bilgin, T. In vitro comparison of the retentive properties of ball and locator attachments for implant overdentures. Int. J. Oral Maxillofac. Implants 2014, 29, 1106–1113. [Google Scholar] [CrossRef] [PubMed]

- Walton, J.N.; Huizinga, S.C.; Peck, C.C. Implant angulation: A measurement technique, implant overdenture maintenance, and the influence of surgical experience. Int. J. Prosthodont. 2001, 14, 523–530. [Google Scholar] [PubMed]

- Jabbour, Z.; Fromentin, O.; Lassauzay, C.; Abi Nader, S.; Correa, J.A.; Feine, J.; de Albuquerque Junior, R.F. Effect of implant angulation on attachment retention in mandibular two-implant overdentures: A clinical study. Clin. Implants Dent. Relat. Res. 2014, 16, 565–571. [Google Scholar] [CrossRef]

- Yang, T.C.; Maeda, Y.; Gonda, T.; Kotecha, S. Attachment systems for implant overdenture: Influence of implant inclination on retentive and lateral forces. Clin. Oral Implants Res. 2011, 22, 1315–1319. [Google Scholar] [CrossRef] [PubMed]

- Stephens, G.J.; di Vitale, N.; O’Sullivan, E.; McDonald, A. The influence of interimplant divergence on the retention characteristics of locator attachments, a laboratory study. J. Prosthodont. 2014, 23, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Schweyen, R.; Beuer, F.; Arnold, C.; Hey, J. Retentive characteristics of a vinylpolysiloxane overdenture attachment system. Clin. Oral Investig. 2015, 19, 947–953. [Google Scholar] [CrossRef]

- Gehrke, P.; Johannson, D.; Fischer, C.; Stawarczyk, B.; Beuer, F. In vitro fatigue and fracture resistance of one- and two-piece CAD/CAM zirconia implant abutments. Int. J. Oral Maxillofac. Implants 2015, 30, 546–554. [Google Scholar] [CrossRef]

- Visser, A.; Raghoebar, G.M.; Meijer, H.J.; Batenburg, R.H.; Vissink, A. Mandibular overdentures supported by two or four endosseous implants. A 5-year prospective study. Clin. Oral Implants Res. 2005, 16, 19–25. [Google Scholar] [CrossRef]

- Hargraves, A.; Foster, M. Hydrocryl: An aid to retention? J. Dent. 1976, 4, 33–41. [Google Scholar] [CrossRef]

- Frank, R.P.; Nicholls, J.I. A study of the flexibility of wrought wire clasps. J. Prosthet. Dent. 1981, 45, 259–267. [Google Scholar] [CrossRef]

- Stewart, B.L.; Edwards, R.O. Retention and wear of precision-type attachments. J. Prosthet. Dent. 1983, 49, 28–34. [Google Scholar] [CrossRef]

- Rangert, B.; Jemt, T.; Jörneus, L. Forces and moments on Branemark implants. Int. J. Oral Maxillofac. Implants 1989, 4, 241–247. [Google Scholar]

- Trakas, T.; Michalakis, K.; Kang, K.; Hirayama, H. Attachment systems for implant retained overdentures: A litearture review. Implant Dent. 2006, 15, 24–34. [Google Scholar] [CrossRef]

- Arnold, C.; Hey, J.; Setz, J.M.; Boeckler, A.F.; Schweyen, R. Retention force of removable partial dentures with different double crowns. Clin. Oral Investig. 2018, 22, 1641–1649. [Google Scholar] [CrossRef]

- Mínguez-Tomás, N.; Alonso-Pérez-Barquero, J.; Fernández-Estevan, L.; Vicente-Escuder, Á.; Selva-Otaolaurruchi, E.J. In vitro retention capacity of two overdenture attachment systems: Locator® and Equator®. J. Clin. Exp. Dent. 2018, 10, 681–686. [Google Scholar] [CrossRef]

- Elsyad, M.A.; Emera, R.M.; Ashmawy, T.M. Effect of Distal Implant Inclination on Dislodging Forces of Different Locator Attachments Used for Mandibular Overdentures: An In Vitro Study. J. Prosthodont. 2019, 28, 666–674. [Google Scholar] [CrossRef]

- Dunlap, W.P.; Cortina, J.M.; Vaslow, J.B.; Burke, M.J. Meta-analysis of experiments with matched groups or repeated measures designs. Psychol. Methods 1996, 1, 170–177. [Google Scholar] [CrossRef]

- Anusavice, K.J. Philipps’ Science of Dental Materials; WB Saunders: Philadelphia, PA, USA, 1996. [Google Scholar]

- Alsabeeha, N.H.M.; Payne, A.G.T.; Swain, M.V. Attachment systems for mandibular two-implant overdentures: A review of in vitro investigations on retention and wear features. Int. J. Prosthodont. 2009, 22, 429–440. [Google Scholar]

- Rutkanas, V.; Mizutani, H. Retentive and stabilizing properties of stud and magnetic attachments retaining manibular overdenture. Stomatologija 2004, 6, 85–90. [Google Scholar]

- Chung, K.H.; Whiting, D.; Kronstrom, M.; Chan, D.; Wataha, J. Retentive characteristics of overdenture attachments during repeated dislodging and cyclic loading. Int. J. Prosthodont. 2011, 24, 127–129. [Google Scholar] [PubMed]

- Sarnat, A.E. The efficiency of cobalt samarium (Co5Sm) magnets as retention units for overdentures. J. Dent. 1983, 11, 324–333. [Google Scholar] [CrossRef]

- Besimo, C.E.; Guarneri, A. In vitro retention force changes of prefabricated attachments for overdentures. J. Oral Rehabil. 2003, 30, 671–678. [Google Scholar] [CrossRef]

- Abi Nader, S.; De Souza, R.F.; Fortin, D.; De Koninck, L.; Fromentin, O.; Albuquerque Junior, R.F. Effect of simulated masticatory loading on the retention of stud attachments for implant overdentures. J. Oral Rehabil. 2011, 38, 157–164. [Google Scholar] [CrossRef]

- Evtimovska, E.; Masri, R.; Driscoll, C.F.; Romberg, E. The change in retentive values of locator attachments and hader clips over time. J. Prosthodont. 2009, 18, 479–483. [Google Scholar] [CrossRef]

- Rutkunas, V.; Mizutani, H.; Takahashi, H.; Iwasaki, N. Wear simulation effects on overdenture stud attachments. Dent. Mater. J. 2011, 30, 845–853. [Google Scholar] [CrossRef]

- Bayer, S.; Keilig, L.; Kraus, D.; Grüner, M.; Stark, H.; Mues, S.; Enkling, N. Influence of the lubricant and the alloy on the wear behaviour of attachments. Gerodontology 2011, 28, 221–226. [Google Scholar] [CrossRef]

- Srinivasan, M.; Schimmel, M.; Badoud, I.; Ammann, P.; Herrmann, F.R.; Müller, F. Influence of implant angulation and cyclic dislodging on the retentive force of two different overdenture attachments—An in vitro study. Clin. Oral Implants Res. 2016, 27, 604–611. [Google Scholar] [CrossRef]

- Engelhardt, F.; Zeman, F.; Behr, M.; Hahmel, S. Prosthetic complications and maintenance requirements in locator-attached implant-supported overdentures: A retrospective study. Eur. J. Prosthodont. Restor. Dent. 2016, 24, 31–35. [Google Scholar]

- Yue, Q.; Yilmaz, B.; Abou-Ayash, S.; Zimmermann, P.; Brägger, U.; Schimmel, M. Use of an attachment system with angulated abutments and polyetheretherketone inserts to retain a maxillary overdenture: A clinical report. J. Prosthet. Dent. 2019. [Google Scholar] [CrossRef]

- Cervino, G.; Montanari, M.; Santonocito, D.; Nicita, F.; Baldari, R.; De Angelis, C.; Storni, G.; Fiorillo, L. Comparison of Two Low-Profile Prosthetic Retention System Interfaces: Preliminary Data of an In Vitro Study. Prosthesis 2019, 1, 54–60. [Google Scholar] [CrossRef]

- Scrascia, R.; Fiorillo, L.; Gaita, V.; Secondo, L.; Nicita, F.; Cervino, G. Implant-Supported Prosthesis for Edentulous Patient Rehabilitation. From Temporary Prosthesis to Definitive with a New Protocol: A Single Case Report. Prosthesis 2020, 2, 10–24. [Google Scholar] [CrossRef]

- Arnold, C.; Hey, J.; Schweyen, R.; Setz, J.M. Accuracy of CAD-CAM-fabricated removable partial dentures. J. Prosthet. Dent. 2017, 119, 586–592. [Google Scholar] [CrossRef]

| Attachment System (Manufacturer) | Description | Material | Labeling | Test Series–IA 1 |

|---|---|---|---|---|

| Novaloc Retentive System (Institut Straumann AG, Basel, Switzerland) | RN Novaloc Abutment; 0° Gingiva height: 3 mm | Titanium grade 5 Amorphous Diamond-Like Carbon (ADLC) | N-0° | NY-0° IA 0° NY-0° IA 5° NY-0° IA 10° NY-0° IA 15° NY-0° IA 20° |

| RN Novaloc Abutment; 15° Gingiva height: 3 mm | Titanium grade 5 Amorphous Diamond -Like Carbon (ADLC) | N-15° | NY-15° IA 15° NY-15° IA 20° | |

| Novaloc 2 retention Inserts yellow | Polyether ether ketone (PEEK) | Y | ||

| Locator Attachment System (Zest Dental Solutions, Carlsbad, CA, USA) | RN Locator Abutment 0°-straight; Gingiva height: 3 mm | Titanium-aluminum-vanadium alloy (TAV) | L-0° | |

| Locator 3 Replacement Male pink; light retention; angulation: 0°–10°; height: 1.7 mm | Nylon | P | LP-0° IA 0° LP-0° IA 5° LP-0° IA 10° | |

| Locator 3 Replacement Male orange; light retention; extended range; angulation: 10°–20°; height: 1.7 mm | Nylon | O | LO-0° IA 15° LO-0° IA 20° |

| Matrix, Retention Inserts | Manufacturer Specifications | Retention Force Measurements | |||||

|---|---|---|---|---|---|---|---|

| Initial | After Artificial Ageing (10,000 Cycles) | After Thermocycling | |||||

| (LP) Locator pink | 3 Ibs (13.34 N) 1360 g | Mean 19.39 N ± 8.10 N | Median 17.8 N | Mean 6.46 N ± 2.62 N | Median 6.99 N | Mean 26.08 N ± 4.96 N | Median 25.92 N |

| (LO) Locator orange | 2 Ibs (8.90 N) 910 g | Mean 8.8 N ± 5.28 N | Median 6.57 N | Mean 0.96 N ± 1.03 N | Median 0.66 N | Mean 11.77 N ± 4.16 N | Median 12.39 N |

| (NY) Novaloc yellow | 2.7 Ibs (12.00 N) ca. 1200 g | Mean 8.57 N ± 0.99 | Median 8.62 N | Mean 6.33 N ± 0.74 N | Median 6.34 N | Mean 5.72 N ± 0.63 N | Median 5.78 N |

| Series | A: Initial | B: 100 Cycles | C: 200 Cycles | D: 500 Cycles | E: 1000 Cycles | F: 5000 Cycles | G: 10,000 Cycles |

|---|---|---|---|---|---|---|---|

| p-value from | a) to | b) to | c) to | d) to | e) to | f) to | g) to |

| Retention NY-0° IA-0° | 8.71 N f) 0.026 g) 0.025 | 7.95 N | 7.88 N | 7.95 N | 7.79 N | 7.17 N a) 0.026 | 7.06 N a) 0.025 |

| Retention NY-0° IA-5° | 9.25 N b, d, e) <0.001 c, f, g) 0.001 | 8.46 N a) <0.001 f) 0.016 g) 0.012 | 8.50 N a) 0.001 f) 0.010 g) 0.004 | 8.32 N a) <0.001 f) 0.015 g) 0.007 | 8.16 N a) <0.001 g) 0.015 | 7.39 N a) 0.001 b) 0.016 c) 0.010 d) 0.015 e) 0.015 | 6.73 N a) 0.001 b) 0.012 c) 0.004 d) 0.007 |

| Retention NY-0° IA-10° 1 | 8.10 N | 7.80 N | 7.43 N | 7.59 N g) 0.038 | 7.62 N g) 0.021 | 6.90 N | 6.48 N d) 0.038 e) 0.021 |

| Retention NY-0° IA-15° | 8.75 N e) 0.006 f) 0.003 g) <0.001 | 8.65 N f) 0.001 g) <0.001 | 8.27 N g) <0.001 | 8.24 N g) <0.001 | 8.14 N a) 0.006 g) <0.001 | 6.92 N a) 0.003 b) 0.001 | 5.95 N a–e) <0.001 |

| Retention NY-0° IA-20° | 8.21 N f) 0.004 g) 0.015 | 7.72 N f) 0.005 | 7.67 N f) 0.011 g) 0.045 | 7.86 N f) 0.020 g) 0.022 | 7.94 N f) <0.001 g) 0.004 | 6.59 N a) 0.004 b) 0.005 c) 0.011 d) 0.020 e) <0.001 | 5.89 N a) 0.015 d) 0.022 e) 0.004 |

| Retention NY-15° IA-15° | 8.60 N b) 0.002 c) 0.044 f) 0.017 g) <0.001 | 8.00 N a) 0.002 g) 0.003 | 8.05 N a) 0.044 g) 0.001 | 8.19 N g) 0.001 | 8.35 N f) 0.017 g) 0.001 | 7.22 N a,e) 0.017 g) 0.008 | 6.15 N a) <0.001 b) 0.003 c–e) 0.001 f) 0.008 |

| Retention NY-15° IA-20° | 8.34 N g) 0.003 | 8.21 N g) 0.001 | 8.07 N g) 0.004 | 8.08 N e) 0.029 g) 0.001 | 7.68 N d) 0.029 g) 0.002 | 7.70 N g) 0.013 | 6.07 N a) 0.003 b, d) 0.001 c) 0.004 e) 0.002 f) 0.013 |

| Retention LP-0° IA-0° 1 | 25.41 N f) 0.005 g) 0.006 | 29.33 N f) 0.019 g) 0.021 | 29.26 N e) 0.004 f, g) <0.001 | 26.42 N e) 0.002 f, g) <0.001 | 15.78 N c) 0.004 d) 0.002 f) 0.006 g) 0.005 | 7.71 N a) 0.005 b) 0.019 c, d) <0.001 e) 0.006 | 7.83 N a) 0.006 b) 0.021 c, d) <0.001 e) 0.005 |

| Retention LP-0° IA-5° 1 | 17.94 N g) 0.04 | 14.43 N g) 0.039 | 10.46 N d) 0.002 | 22.30 N c) 0.002 e) 0.003 f, g) <0.001 | 12.74 N d) 0.003 f) 0.024 g) 0.002 | 6.71 N d) <0.001 e) 0.024 | 4.42 N a) 0.049 b) 0.039 d) <0.001 e) 0.002 |

| Retention LP-0° IA-10° 1 | 14.81 N g) 0.014 | 13.17 N e) 0.010 g) 0.002 | 10.51 N d) 0.049 e) 0.001 g) 0.011 | 22.06 N c) 0.049 f) 0.027 g) 0.010 | 20.62 N b) 0.010 c) 0.001 f, g) <0.001 | 9.41 N d) 0.027 e) <0.001 | 7.11 N a) 0.014 b) 0.002 c) 0.011 d) 0.010 e) <0.001 |

| Retention LO-0° IA-15° 1 | 7.76 N f) 0.045 g) 0.021 | 4.63 N f) 0.006 g) 0.001 | 4.87 N f) 0.003 g) 0.001 | 8.59 N f) 0.004 g) 0.002 | 4.93 N f) 0.009 g) 0.001 | 2.29 N a) 0.045 b) 0.006 c) 0.003 d) 0.004 | 1.52 N a) 0.021 b, c, e) 0.001 d) 0.002 |

| Retention LO-0° IA-20° 1 | 9.98 N | 7.31 N | 4.73 N f) 0.043 g) 0.001 | 4.91 N f) 0.045 g) 0.001 | 4.32 N f) 0.041 g) <0.001 | 2.15 N c) 0.043 d) 0.045 e) 0.041 | 0.39 N c, d) 0.001 e) <0.001 |

| Series 1 | Release Period (min) |

|---|---|

| NY-0°–IA-0° | 0.00314 |

| NY-0°–IA-20° | 0.00318 |

| NY-0°–IA-15° | 0.00355 |

| NY-0°–IA-10° | 0.00367 |

| LO-0°–IA-15° | 0.00368 |

| LO-0°–IA-20° | 0.00369 |

| NY-15°–IA-20° | 0.00377 |

| NY-0°–IA-5 ° | 0.00413 |

| NY-15°–IA-15° | 0.00417 |

| LP-0°–IA-5° | 0.00459 |

| LP-0°–IA-10° | 0.00490 |

| LP-0°–IA-0° | 0.00492 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arnold, C.; Stampa, C.; Schweyen, R.; Hey, J.; Boeckler, A. Retentive Characteristics of a New Attachment System for Hybrid Dentures. Materials 2020, 13, 3434. https://doi.org/10.3390/ma13153434

Arnold C, Stampa C, Schweyen R, Hey J, Boeckler A. Retentive Characteristics of a New Attachment System for Hybrid Dentures. Materials. 2020; 13(15):3434. https://doi.org/10.3390/ma13153434

Chicago/Turabian StyleArnold, Christin, Charlotte Stampa, Ramona Schweyen, Jeremias Hey, and Arne Boeckler. 2020. "Retentive Characteristics of a New Attachment System for Hybrid Dentures" Materials 13, no. 15: 3434. https://doi.org/10.3390/ma13153434

APA StyleArnold, C., Stampa, C., Schweyen, R., Hey, J., & Boeckler, A. (2020). Retentive Characteristics of a New Attachment System for Hybrid Dentures. Materials, 13(15), 3434. https://doi.org/10.3390/ma13153434