An Integrated Approach of GRA Coupled with Principal Component Analysis for Multi-Optimization of Shielded Metal Arc Welding (SMAW) Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Work Piece Material

2.2. Parameters and Response Variables

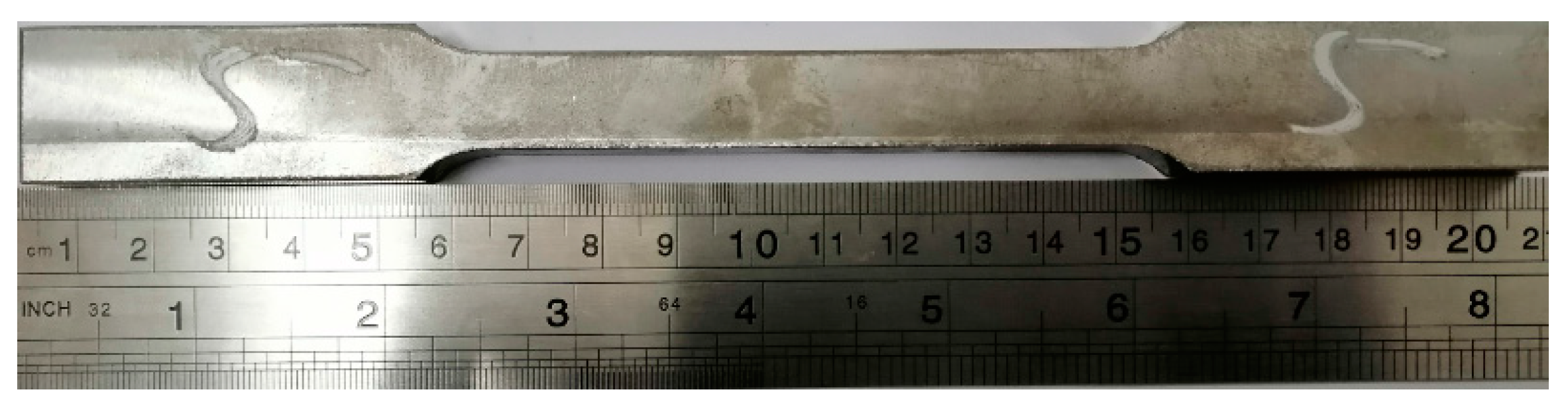

2.2.1. Tensile Strength

2.2.2. Impact Energy

2.2.3. Hardness

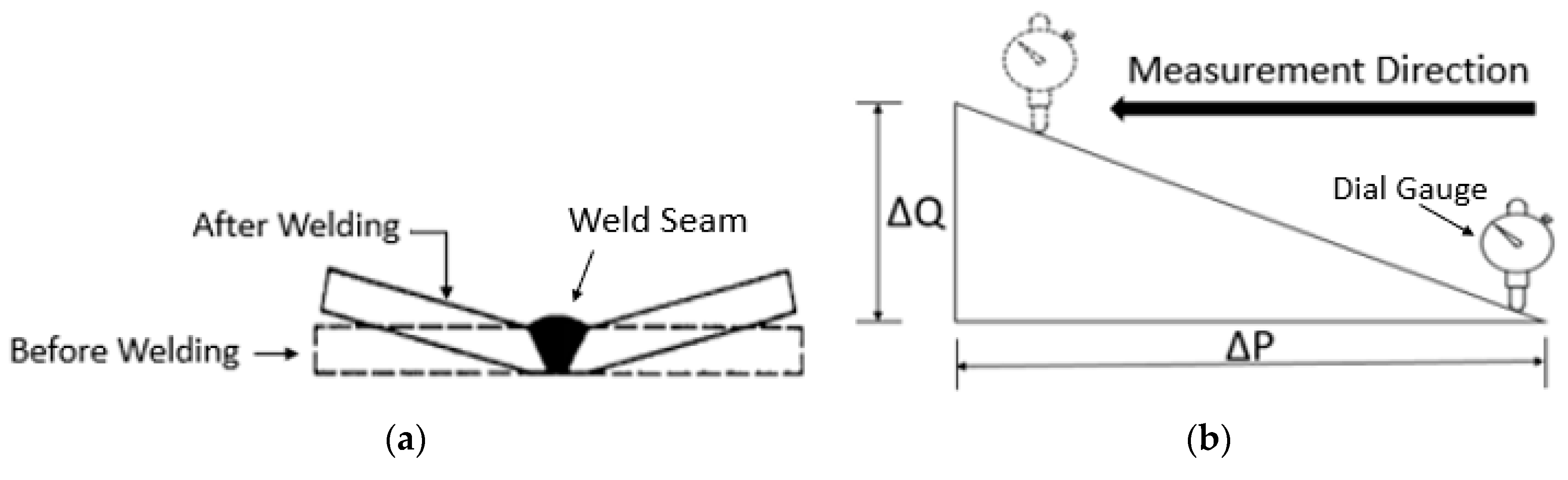

2.2.4. Angular Distortion (AD)

3. Experimental Design

3.1. Groove Angle

3.2. Preheating

3.3. Electrode Diameter

3.4. Root Gap

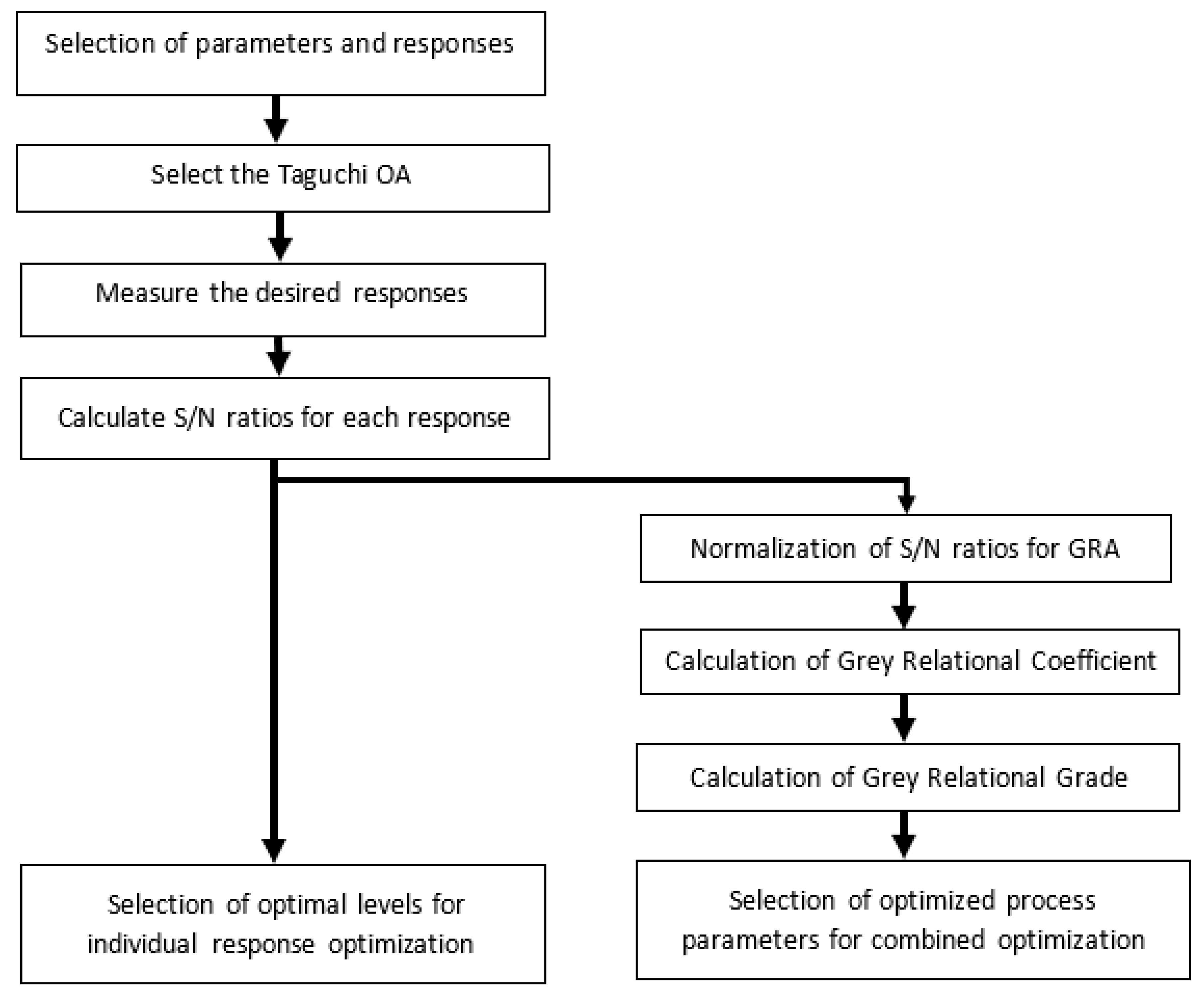

4. Optimization Methodology

Principal Component Analysis (PCA)

5. Results and Discussion

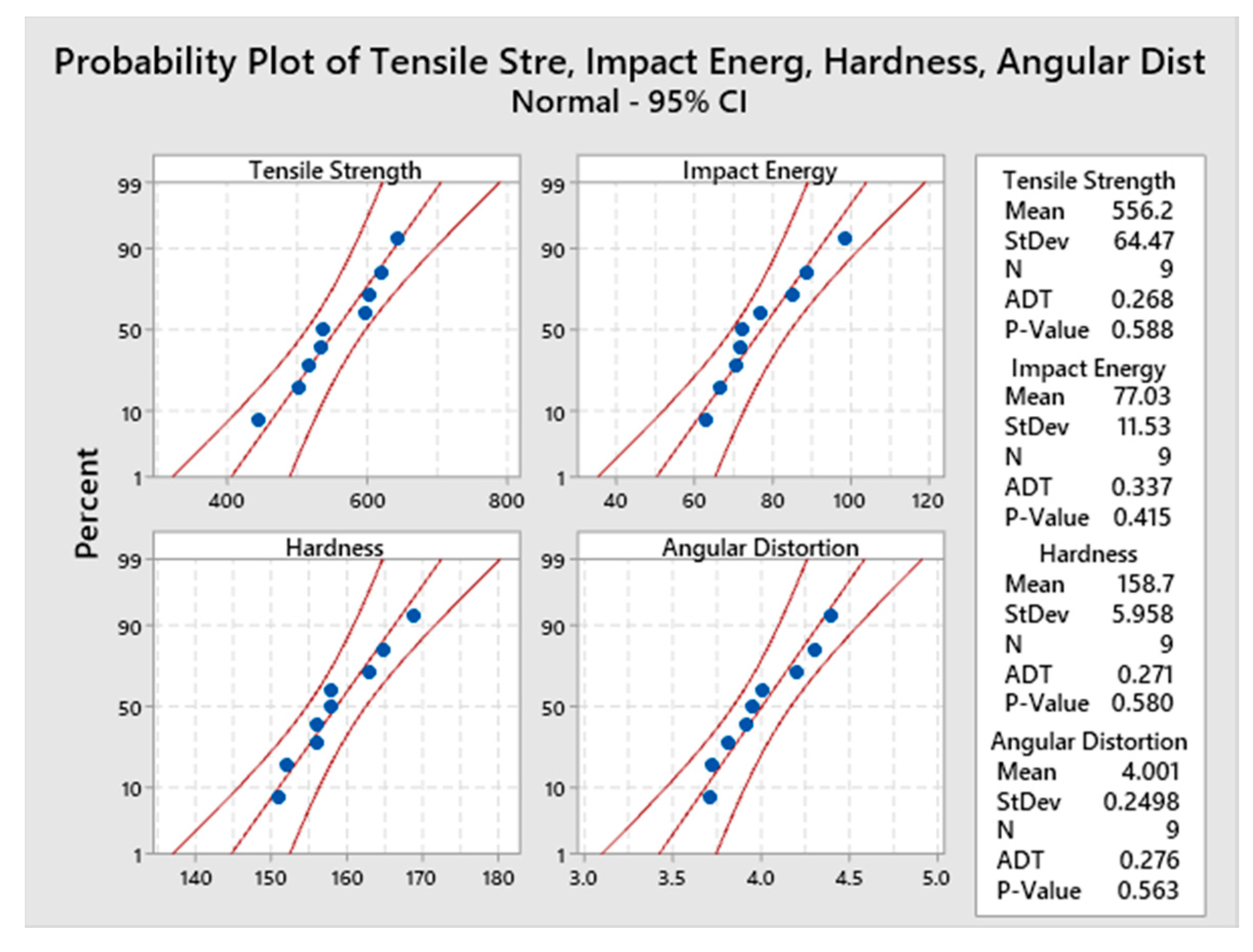

5.1. Probability Plots

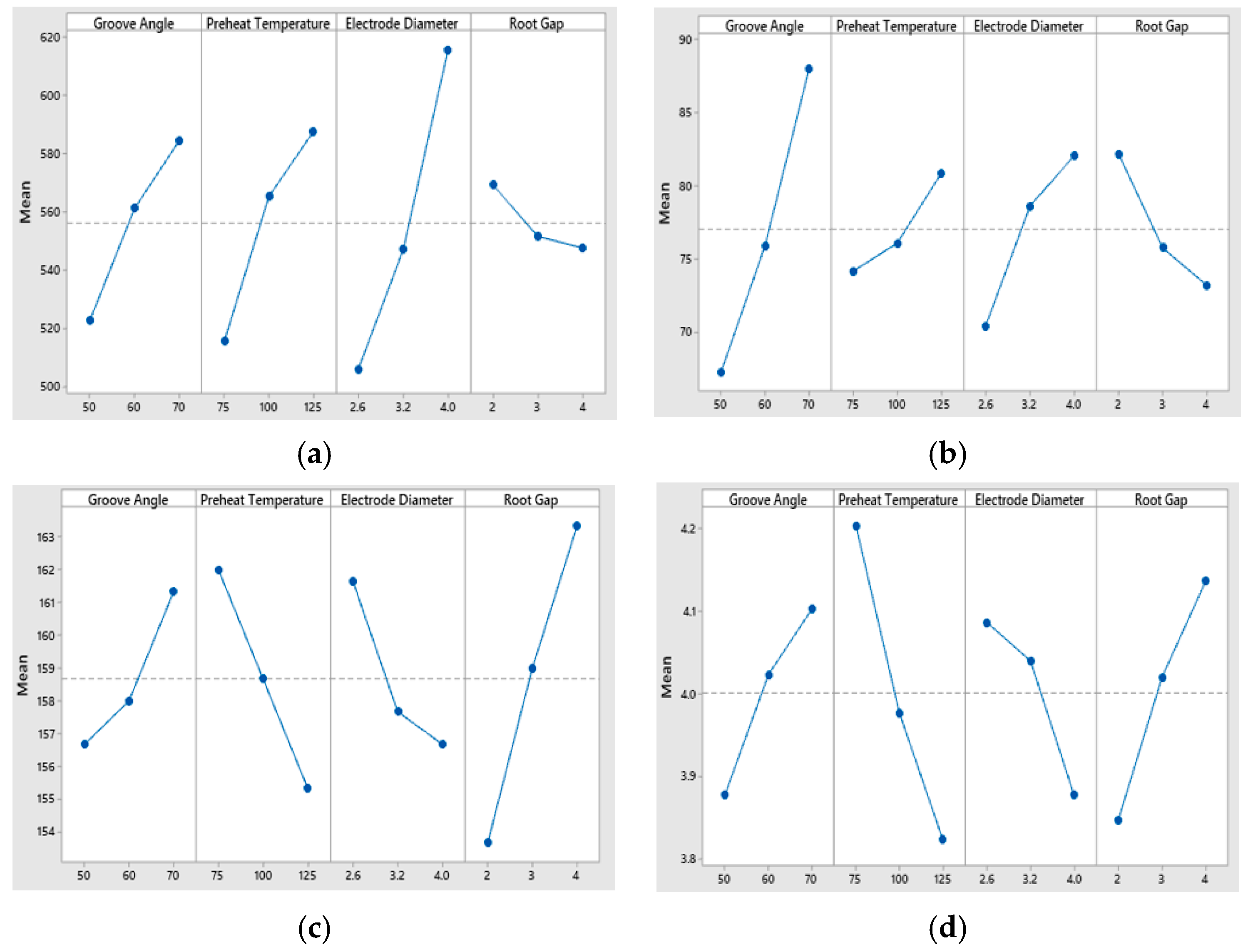

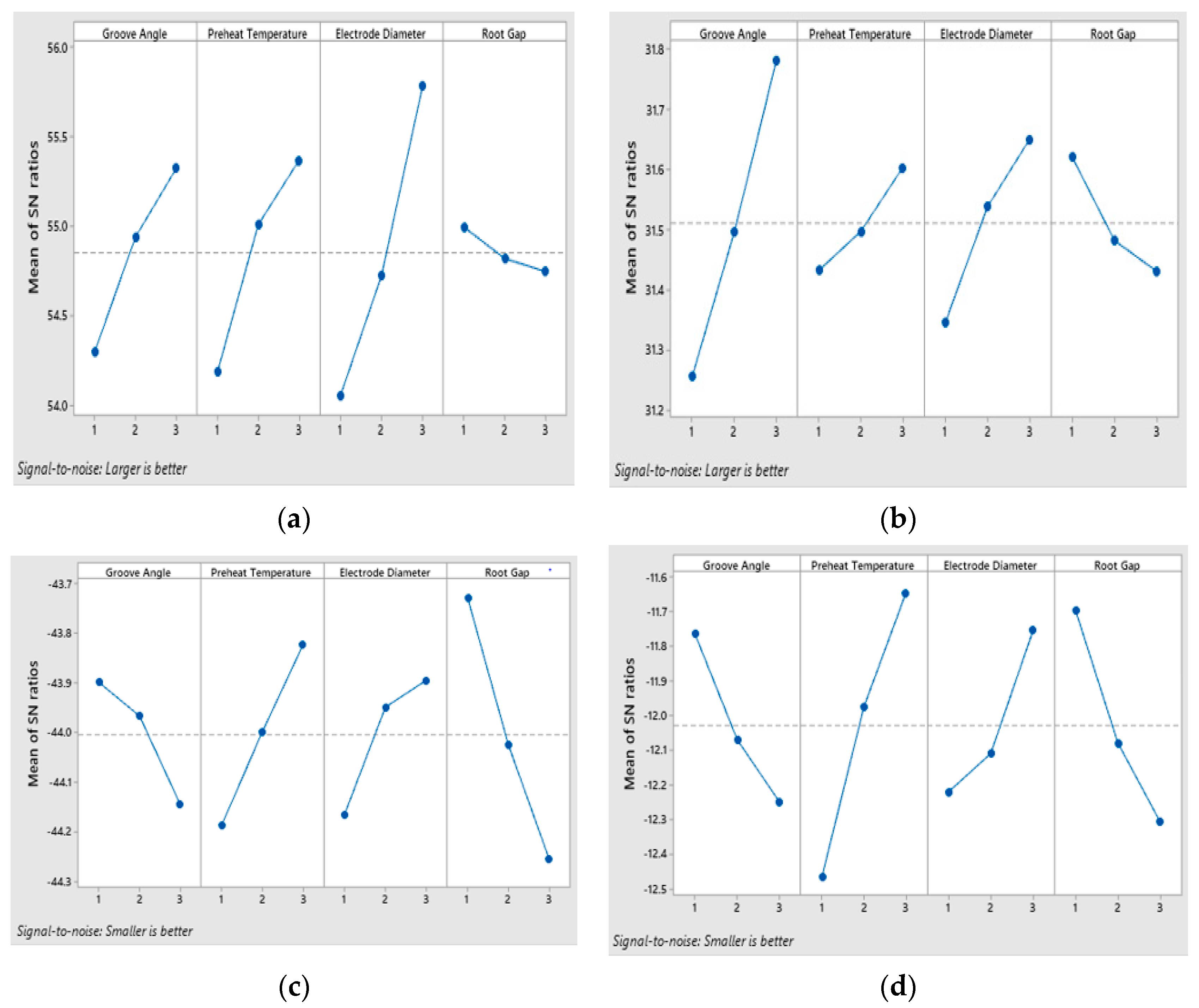

5.2. ANOVA and Main Effect Plots of Means for Individual Responses

5.2.1. Groove Angle

5.2.2. Preheating

5.2.3. Electrode Diameter

5.2.4. Root Gap

5.3. Single Objective Optimization

5.4. Multi Response Optimization based on GRA and PCA

6. Confirmation Experiment

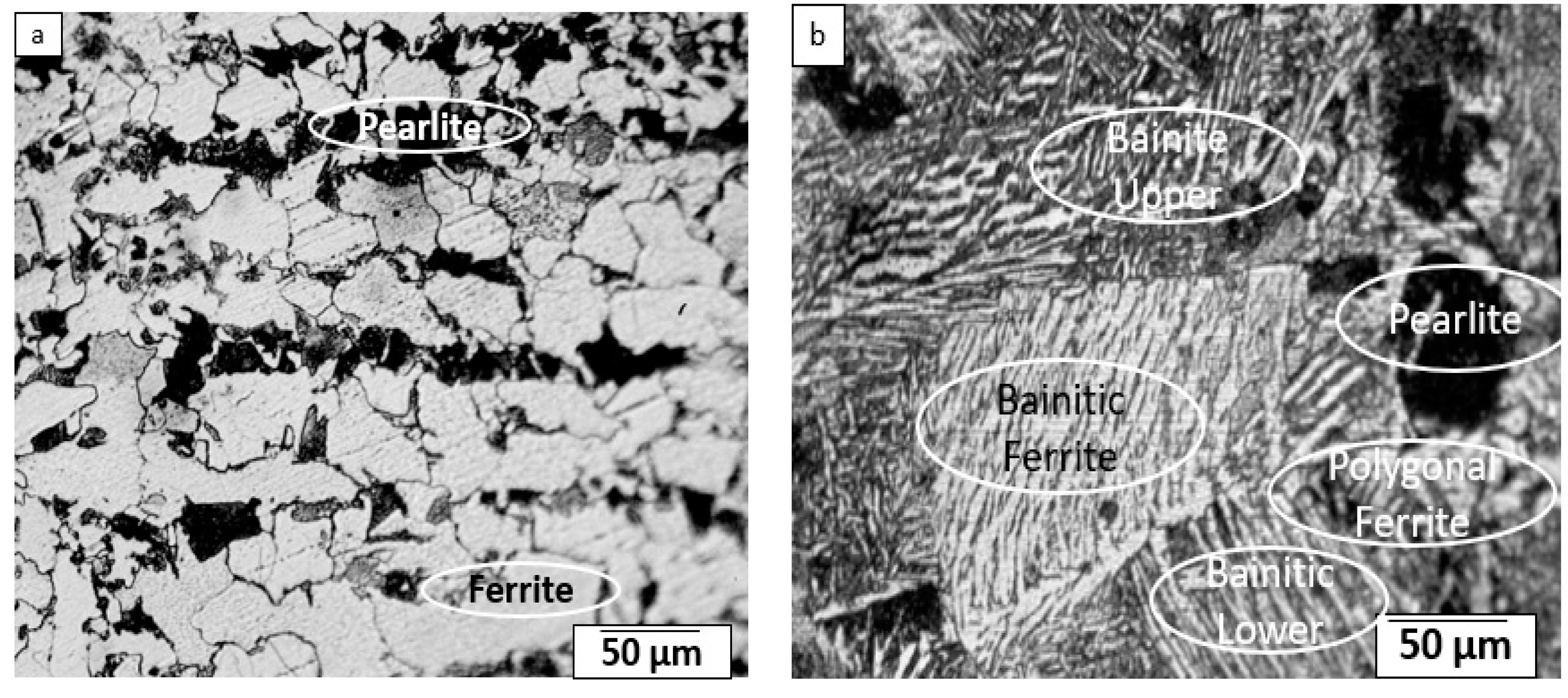

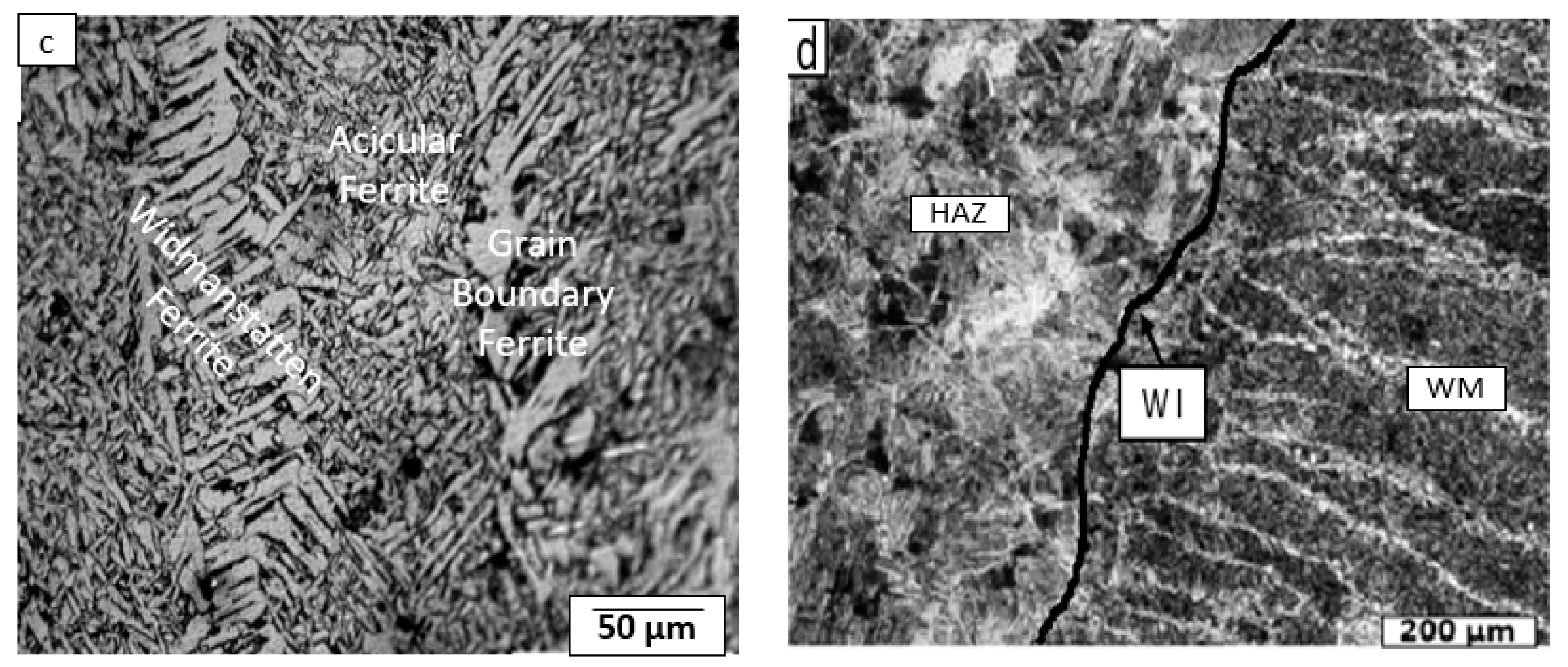

7. Microstructure

8. Conclusions

- To achieve multiple objective optimization of SMAW process for pressure vessel steel SA 516 grade 70, the optimal combination of parameters is GA3PHT1ED3RG3.

- The percentage contributions of each quality response for principal component in decreasing order are angular distortion (28.40%), tensile strength (27.79%), hardness (27.14%), and impact energy (16.72%) respectively.

- The analysis of the average of GRG revealed that groove angle has the maximum influence, followed by electrode diameter, root gap, and preheat temperature, respectively.

- The analysis of the average of W-GRG revealed that groove angle has maximum influence, followed by root gap, preheat temperature, and electrode diameter, respectively.

- GRA and W-GRG identified identical optimal combination of input parameters as: groove angle 70°; preheat temperature 75 °C; electrode diameter 4 mm; and root gap 4 mm.

- Significant improvement in GRG from initial condition to optimal setting is found as 0.2898 as is achieved by GRA approach.

- Finally, a confirmatory experiment on GRG/W-GRA based optimal settings showed an improvement of 23.80% in tensile strength, 64.38% in impact energy, 3.01% in hardness, and 7.14% in angular distortion.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mahajan, S.; Chhibber, R. Investigations on dissimilar welding of P91/SS304L using Nickel-based electrodes. Mater. Manuf. Process. 2020, 35, 1–14. [Google Scholar] [CrossRef]

- Khamari, B.K.; Dash, S.S.; Karak, S.K.; Biswal, B.B. Effect of welding parameters on mechanical and microstructural properties of GMAW and SMAW mild steel joints. Ironmak. Steelmak. 2019, 1–8. [Google Scholar] [CrossRef]

- Saxena, A.; Kumaraswamy, A.; Reddy, G.M.; Madhu, V. Influence of welding consumables on tensile and impact properties of multi-pass SMAW Armox 500T steel joints vis-a-vis base metal. Def. Technol. 2018, 14, 188–195. [Google Scholar] [CrossRef]

- Ahmed, S.R.; Agarwal, L.A.; Daniel, B. Effect of different post weld heat treatments on the mechanical properties of Cr-Mo boiler steel welded with SMAW process. Mater. Today Proc. 2015, 2, 1059–1066. [Google Scholar] [CrossRef]

- Chandel, R.; Seow, H.; Cheong, F. Effect of increasing deposition rate on the bead geometry of submerged arc welds. J. Mater. Process. Technol. 1997, 72, 124–128. [Google Scholar] [CrossRef]

- Sharma, A.; Arora, N.; Mishra, B.K. A practical approach towards mathematical modeling of deposition rate during twin-wire submerged arc welding. Int. J. Adv. Manuf. Technol. 2008, 36, 463–474. [Google Scholar] [CrossRef]

- Dong, Q.; Shen, L.; Cao, F.; Jia, Y.; Liao, K.; Wang, M. Effect of thermomechanical processing on the microstructure and properties of a Cu-Fe-P alloy. J. Mater. Eng. Perform. 2015, 24, 1531–1539. [Google Scholar] [CrossRef]

- Richardson, R.; Gutow, D.; Anderson, R.; Farson, D. Coaxial arc weld pool viewing for process monitoring and control. Weld. J. 1984, 63, 43–50. [Google Scholar]

- Ahire, P.; Patil, U.; Kadam, M. Genetic algorithm based optimization of the process parameters for manual metal arc welding of dissimilar metal joint. Proc. Manuf. 2018, 20, 106–112. [Google Scholar] [CrossRef]

- Ali, M.; Rao, C.; Rao, D. Study the effect of shielded metal arc welding process parameters, cryo-treatment and preheating on welding characteristics and modelling by an artificial neural network. Aust. J. Mech. Eng. 2014, 12, 195–207. [Google Scholar] [CrossRef]

- Bhaduri, A.; Gill, T.; Srinivasan, G.; Sujith, S. Optimised post-weld heat treatment procedures and heat input for welding 17–4PH stainless steel. Sci. Technol. Weld. Join. 1999, 4, 295–301. [Google Scholar] [CrossRef]

- Osayi, A.; Egbe, E.; Lawal, S. Optimization of process parameters of manual arc welding of mild steel using taguchi method. Am. J. Mech. Eng. 2015, 3, 93–97. [Google Scholar]

- Safeen, W.; Hussain, S.; Wasim, A.; Jahanzaib, M.; Aziz, H.; Abdalla, H. Predicting the tensile strength, impact toughness, and hardness of friction stir-welded AA6061-T6 using response surface methodology. Int. J. Adv. Manuf. Technol. 2016, 87, 1765–1781. [Google Scholar] [CrossRef]

- Seong, W.-J. Prediction and characteristics of angular distortion in multi-layer butt welding. Materials 2019, 12, 1435. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Armentani, E.; Esposito, R.; Sepe, R. The influence of thermal properties and preheating on residual stresses in welding. Int. J. Comput. Mater. Sci. Surf. Eng. 2007, 1, 146–162. [Google Scholar] [CrossRef]

- Ramasamy, N.; Jeyasimman, D.; Kathiravan, R.; Raju, N. Influence of Welding Sequence on Residual Stresses Induced in As-Welded Plug Weld of Low-Carbon Steel Plate. Trans. Indian Inst. Met. 2019, 72, 1361–1369. [Google Scholar] [CrossRef]

- Arifin, A.; Gunawan, A.M.; Yani, I.; Pratiwi, D.K.; Yanis, M.; Sani, K.A. Optimization of Angular Distortion on Weld Joints Using Taguchi Approach. J. Kejuruter. 2019, 31, 19–23. [Google Scholar]

- Kumar, P.N.; Rajadurai, A.; Muthuramalingam, T. Multi-response optimization on mechanical properties of silica fly ash filled polyester composites using taguchi-grey relational analysis. Silicon 2018, 10, 1723–1729. [Google Scholar] [CrossRef]

- Paul, T.; Saha, A.; Majumder, H.; Dey, V.; Dutta, P. Multi-objective optimization of some correlated process parameters in EDM of Inconel 800 using a hybrid approach. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 300. [Google Scholar] [CrossRef]

- Umair, M.; Shaker, K.; Ahmad, N.; Hussain, M.; Jabbar, M.; Nawab, Y. Simultaneous optimization of woven fabric properties using principal component analysis. J. Nat. Fibers 2017, 14, 846–857. [Google Scholar] [CrossRef]

- Saha, A.; Mondal, S.C. Multi-objective optimization of manual metal arc welding process parameters for nano-structured hardfacing material using hybrid approach. Measurement 2017, 102, 80–89. [Google Scholar] [CrossRef]

- Adalarasan, R.; Sundaram, A.S. Parameter design in friction welding of Al/SiC/Al 2 O 3 composite using grey theory based principal component analysis (GT-PCA). J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 1515–1528. [Google Scholar] [CrossRef]

- Salah, A.N.; Kaddami, M. Effect of Filler Metal Diameter on Weld Joint of Carbon Steel SA516 Gr 70 and Filler Metal SFA 5.17 in Submerged Arc Welding SAW. Int. J. Mater. Metall. Eng. 2019, 13, 114–117. [Google Scholar]

- ASTM A 526/516 M—90. Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate and Lower Temperature Services; ASTM International: West Conshohocken, PA, USA, 1996. [Google Scholar]

- ASTM A 370. Standard Test Methods and Definitions for Mechanical for Mechanical Testing of Steel Products; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Long, H.; Gery, D.; Carlier, A.; Maropoulos, P. Prediction of welding distortion in butt joint of thin plates. Mater. Des. 2009, 30, 4126–4135. [Google Scholar] [CrossRef]

- Huang, H.-Y. Effects of activating flux on the welded joint characteristics in gas metal arc welding. Mater. Des. (1980–2015) 2010, 31, 2488–2495. [Google Scholar] [CrossRef]

- Canel, T.; Zeren, M.; Sınmazçelik, T. Laser parameters optimization of surface treating of Al 6082-T6 with Taguchi method. Opt. Laser Technol. 2019, 120, 105714. [Google Scholar] [CrossRef]

- İpek, N.E.; Elaldi, F. Analysis of welding groove angle and geometry on strength of armor steel. Mater. Manuf. Process. 2012, 27, 1437–1441. [Google Scholar] [CrossRef]

- Ghosh, P.; Singh, U. Influence of pre-and post-weld heating on weldability of modified 9Cr–1Mo (V–Nb) steel pipe under shielded metal arc and tungsten inert gas welding processes. Sci. Technol. Weld. Join. 2004, 9, 229–236. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H.; Liang, W. Numerical simulation of welding distortion in large structures. Comp. Methods Appl. Mech. Eng. 2007, 196, 4613–4627. [Google Scholar] [CrossRef]

- AWS. Welding Handbook: Welding Processes; American Welding Society: Miami, FL, USA, 1992; Volume 2. [Google Scholar]

- Butt, M.T.Z.; Ahmed, S.; Rasool, S.; Ali, U.; Rehman, S. Effect of Welding Techniques (GTAW & SMAW) on the Microstructure & Mechanical Properties of Mild Steel SA 516 Gr. 70. Electr. Eng. 2009, 6, 35–40. [Google Scholar]

- Jorge, L.D.; Cândido, V.S.; da Silva, A.C.R.; Filho, F.D.G.; Pereira, A.C.; da Luz, F.S.; Monteiro, S.N. Mechanical properties and microstructure of SMAW welded and thermically treated HSLA-80 steel. J. Mater. Res. Technol. 2018, 7, 598–605. [Google Scholar] [CrossRef]

- Oyyaravelu, R.; Kuppan, P.; Arivazhagan, N. Metallurgical and mechanical properties of laser welded high strength low alloy steel. J. Adv. Res. 2016, 7, 463–472. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lan, L.; Kong, X.; Qiu, C.; Zhao, D. Influence of microstructural aspects on impact toughness of multi-pass submerged arc welded HSLA steel joints. Mater. Des. 2016, 90, 488–498. [Google Scholar] [CrossRef]

- Kurt, H.I.; Oduncuoglu, M.; Yilmaz, N.F.; Ergul, E.; Asmatulu, R. A comparative study on the effect of welding parameters of austenitic stainless steels using artificial neural network and Taguchi approaches with ANOVA analysis. Metals 2018, 8, 326. [Google Scholar] [CrossRef] [Green Version]

- Nandagopal, K.; Kailasanathan, C. Analysis of mechanical properties and optimization of gas tungsten Arc welding (GTAW) parameters on dissimilar metal titanium (6Al4V) and aluminium 7075 by Taguchi and ANOVA techniques. J. Alloys Compd. 2016, 682, 503–516. [Google Scholar] [CrossRef]

- Pandiarajan, S.; Kumaran, S.S.; Kumaraswamidhas, L.; Saravanan, R. Interfacial microstructure and optimization of friction welding by Taguchi and ANOVA method on SA 213 tube to SA 387 tube plate without backing block using an external tool. J. Alloys Compd. 2016, 654, 534–545. [Google Scholar] [CrossRef]

- Satheesh, M.; Dhas, J. Multi Objective Optimization of Weld Parameters of Boiler Steel Using Fuzzy Based Desirability Function. J. Eng. Sci. Technol. Rev. 2014, 7, 29–36. [Google Scholar] [CrossRef]

- Panda, S.; Mishra, D.; Biswal, B.B. Determination of optimum parameters with multi-performance characteristics in laser drilling—A grey relational analysis approach. Int. J. Adv. Manuf. Technol. 2011, 54, 957–967. [Google Scholar] [CrossRef]

- Kuo, C.-F.J.; Su, T.-L. Optimization of multiple quality characteristics for polyether ether ketone injection molding process. Fibers Polym. 2006, 7, 404–413. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Güllü, A. Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes 25. J. Clean. Prod. 2015, 91, 347–357. [Google Scholar] [CrossRef]

- Palanikumar, K.; Latha, B.; Senthilkumar, V.; Davim, J.P. Analysis on drilling of glass fiber–reinforced polymer (GFRP) composites using grey relational analysis. Mater. Manuf. Process. 2012, 27, 297–305. [Google Scholar] [CrossRef]

- Sonawane, S.A.; Kulkarni, M. Optimization of machining parameters of WEDM for Nimonic-75 alloy using principal component analysis integrated with Taguchi method. J. King Saud Univ. Eng. Sci. 2018, 30, 250–258. [Google Scholar] [CrossRef]

- Lee, W.J.; Mendis, G.P.; Triebe, M.J.; Sutherland, J.W. Monitoring of a machining process using kernel principal component analysis and kernel density estimation. J. Intell. Manuf. 2019, 31, 1–15. [Google Scholar] [CrossRef]

- Stephens, M.A. EDF statistics for goodness of fit and some comparisons. J. Am. Stat. Assoc. 1974, 69, 730–737. [Google Scholar] [CrossRef]

- Purwaningrum, Y.; Kusuma, P.L.T.; Darmawan, D. An Experimental Study on Effect of T-Joint’s Root Gap on Welding Properties. Appl. Mech. Mater. 2017, 863, 323–327. [Google Scholar] [CrossRef]

- Weerasekralage, L.S.K.; Karunarathne, M.; Pathirana, S. Optimization of Shielded Metal Arc Welding (SMAW) process for mild steel. IJSRST 2018, 4, 1536–1543. [Google Scholar]

- Kumar, S.; Singh, R. Investigation of tensile properties of shielded metal arc weldments of AISI 1018 mild steel with preheating process. Mater. Today Proc. 2019, 26, 209–222. [Google Scholar] [CrossRef]

- Lee, C.; Bhadeshia, H.; Lee, H.-C. Effect of plastic deformation on the formation of acicular ferrite. Mater. Sci. Eng. A 2003, 360, 249–257. [Google Scholar] [CrossRef]

- Bodude, M.; Momohjimoh, I. Studies on effects of welding parameters on the mechanical properties of welded low-carbon steel. J. Miner. Mater. Charact. Eng. 2015, 3, 142. [Google Scholar] [CrossRef] [Green Version]

- Talabi, S.; Owolabi, O.; Adebisi, J.; Yahaya, T. Effect of welding variables on mechanical properties of low carbon steel welded joint. Adv. Prod. Eng. Manag. 2014, 9, 181–186. [Google Scholar] [CrossRef] [Green Version]

- Saha, D.; Westerbaan, D.; Nayak, S.; Biro, E.; Gerlich, A.; Zhou, Y. Microstructure-properties correlation in fiber laser welding of dual-phase and HSLA steels. Mater. Sci. Eng. A 2014, 607, 445–453. [Google Scholar] [CrossRef]

- Akellaa, S.; Kumarb, B.R. Distortion control in TIG welding process with Taguchi approach. Adv. Mater. Manuf. Charact. 2013, 3, 99–206. [Google Scholar]

- Singh, T.; Singh, A.; Saini, S. Effect of Groove Design on the Mechanical Properties of Shielded Metal Arc Welded Joints. Indian J. Sci. Technol. 2019, 12, 1–9. [Google Scholar]

- Pathak, D.; Singh, R.P.; Gaur, S.; Balu, V. Influence of groove angle on hardness and reinforcement height of shielded metal arc welded joints for low carbon AISI 1016 steel plates. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Hu, L.; Huang, J.; Li, Z.; Wu, Y. Effects of preheating temperature on cold cracks, microstructures and properties of high power laser hybrid welded 10Ni3CrMoV steel. Mater. Des. 2011, 32, 1931–1939. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H. Prediction of welding residual stress in multi-pass butt-welded modified 9Cr–1Mo steel pipe considering phase transformation effects. Comput. Mater. Sci. 2006, 37, 209–219. [Google Scholar] [CrossRef]

- Schenk, T.; Richardson, I.; Kraska, M.; Ohnimus, S. A study on the influence of clamping on welding distortion. Comput. Mater. Sci. 2009, 45, 999–1005. [Google Scholar] [CrossRef]

- Qinglei, J.; Yajiang, L.; Juan, W.; Lei, Z. Characterization on strength and toughness of welded joint for Q550 steel. Bull. Mater. Sci. 2011, 34, 161–167. [Google Scholar] [CrossRef]

- Adamczuk, P.C.; Machado, I.G.; Mazzaferro, J.A.E. Methodology for predicting the angular distortion in multi-pass butt-joint welding. J. Mater. Process. Technol. 2017, 240, 305–313. [Google Scholar] [CrossRef]

- Hashemi, M.; Halvaee, A. Effect of GTAW Parameters on Structure and Mechanical Properties of C86300 Weld Joint. Trans. Indian Inst. Met. 2014, 67, 741–752. [Google Scholar] [CrossRef]

- Jang, G.; Kim, H.; Kang, S. The effects of root opening on mechanical properties, deformation and residual stress of weldments. Weld. Res. Suppl. 2001, 80, 80–89. [Google Scholar]

- Abid, M.; Siddique, M. Numerical simulation to study the effect of tack welds and root gap on welding deformations and residual stresses of a pipe-flange joint. Int. J. Press. Vessels Pip. 2005, 82, 860–871. [Google Scholar] [CrossRef]

- Biswas, P.; Mandal, N.; Vasu, P.; Padasalag, S.B. Analysis of welding distortion due to narrow-gap welding of upper port plug. Fusion Eng. Des. 2010, 85, 780–788. [Google Scholar] [CrossRef]

- Chate, G.R.; Patel, G.M.; Kulkarni, R.M.; Vernekar, P.; Deshpande, A.S.; Parappagoudar, M.B. Study of the effect of nano-silica particles on resin-bonded moulding sand properties and quality of casting. Silicon 2018, 10, 1921–1936. [Google Scholar] [CrossRef]

- Amanie, J.; Oguocha, I.; Yannacopoulos, S. Effect of submerged arc welding parameters on microstructure of SA516 steel weld metal. Can. Metall. Q. 2012, 51, 48–57. [Google Scholar] [CrossRef]

- Dorschu, K. Factors affecting weld metal properties in carbon and low alloy pressure vessel steels. Weld. Res. Counc. Bull. 1977, 231, 1–64. [Google Scholar]

- Prajapati, P.J.; Badheka, V.J. Investigation on three different weldments on performance of SA516 Gr70 steel material. Alex. Eng. J. 2019, 58, 637–646. [Google Scholar] [CrossRef]

| Element | C | Al | V | Cr | P | Mn | Si | Sn | N | As | S | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % by weight | 0.22 | 0.039 | 0.002 | 0.03 | 0.018 | 0.99 | 0.18 | 0.002 | 0.005 | 0.002 | 0.008 | 0.02 |

| Exp. No. | Coded Matrix | Un-Coded Matrix | Experimental Result | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | GA | PHT | ED | RG | TS (MPa) | IE (J) | H (HB) | AD (θ) | |

| 1 | 1 | 1 | 1 | 1 | 50 | 75 | 2.6 | 2 | 445 | 62.88 | 158 | 4.01 |

| 2 | 1 | 2 | 2 | 2 | 50 | 100 | 3.2 | 3 | 518 | 66.59 | 156 | 3.91 |

| 3 | 1 | 3 | 3 | 3 | 50 | 125 | 4.0 | 4 | 605 | 72.28 | 156 | 3.71 |

| 4 | 2 | 1 | 2 | 3 | 60 | 75 | 3.2 | 4 | 503 | 70.77 | 165 | 4.4 |

| 5 | 2 | 2 | 3 | 1 | 60 | 100 | 4.0 | 2 | 643 | 85.10 | 151 | 3.72 |

| 6 | 2 | 3 | 1 | 2 | 60 | 125 | 2.6 | 3 | 538 | 71.80 | 158 | 3.95 |

| 7 | 3 | 1 | 3 | 2 | 70 | 75 | 4.0 | 3 | 599 | 88.84 | 163 | 4.2 |

| 8 | 3 | 2 | 1 | 3 | 70 | 100 | 2.6 | 4 | 535 | 76.56 | 169 | 4.3 |

| 9 | 3 | 3 | 2 | 1 | 70 | 125 | 3.2 | 2 | 620 | 98.48 | 152 | 3.81 |

| Parameters | Symbol | Units | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| Groove Angle | A | Θ | 50 | 60 | 70 |

| Pre-Heat Temperature | B | °C | 75 | 100 | 125 |

| Electrode Diameter | C | mm | 2.6 | 3.2 | 4 |

| Root Gap | D | mm | 2 | 3 | 4 |

| Component | PC 1 | PC 2 | PC 3 | PC 4 |

|---|---|---|---|---|

| Eigen Value | 2.4549 | 1.1014 | 0.2804 | 0.1634 |

| Variation (%) | 0.614 | 0.275 | 0.070 | 0.041 |

| Cumulative (%) | 0.614 | 0.889 | 0.959 | 1.000 |

| Eigen Vector | −0.527 | 0.390 | −0.705 | −0.272 |

| −0.409 | 0.662 | 0.592 | 0.207 | |

| 0.521 | 0.461 | −0.371 | 0.615 | |

| 0.533 | 0.444 | 0.121 | −0.710 |

| Source | DoF | Adj SS | Adj MS | F-Value | p-Value | % Contribution | |

|---|---|---|---|---|---|---|---|

| Tensile strength | Groove angle | 1 | 5504.6 | 5504.6 | 23.98 | 0.008 | 16.55 |

| Preheat temperature | 1 | 7776 | 7776 | 33.88 | 0.004 | 23.38 | |

| Electrode diameter | 1 | 18351.4 | 18351.4 | 79.97 | 0.001 | 55.18 | |

| Root gap | 1 | 704.2 | 704.2 | 3.07 | 0.155 | 2.11 | |

| Error | 4 | 918 | 229.5 | 2.76 | |||

| Total | 8 | 33253.6 | 100 | ||||

| Impact energy | Groove angle | 1 | 648.99 | 648.99 | 80.68 | 0.001 | 61.03 |

| Preheat temperature | 1 | 67.13 | 67.13 | 8.35 | 0.045 | 6.31 | |

| Electrode diameter | 1 | 194.79 | 194.79 | 24.21 | 0.008 | 18.32 | |

| Root gap | 1 | 120.154 | 120.154 | 14.94 | 0.018 | 11.3 | |

| Error | 4 | 32.18 | 3.02 | ||||

| Total | 8 | 1063.24 | 100 | ||||

| Hardness | Groove angle | 1 | 34.105 | 34.105 | 17.24 | 0.014 | 12 |

| Preheat temperature | 1 | 66.667 | 66.667 | 33.7 | 0.004 | 23.47 | |

| Electrode diameter | 1 | 35.149 | 35.149 | 17.77 | 0.014 | 12.37 | |

| Root gap | 1 | 140.167 | 140.167 | 70.86 | 0.001 | 49.35 | |

| Error | 4 | 7.913 | 1.978 | 2.78 | |||

| Total | 8 | 284 | 100 | ||||

| Angular distortion | Groove angle | 1 | 0.0731 | 0.0731 | 20.57 | 0.011 | 14.64 |

| Preheat temperature | 1 | 0.2166 | 0.2166 | 60.95 | 0.001 | 43.38 | |

| Electrode diameter | 1 | 0.06923 | 0.06923 | 19.48 | 0.012 | 13.86 | |

| Root gap | 1 | 0.12615 | 0.12615 | 35.5 | 0.004 | 25.26 | |

| Error | 4 | 0.01421 | 0.00355 | 2.84 | |||

| Total | 8 | 0.49929 | 100 |

| Exp. No. | S/N Ratios of Responses | |||

|---|---|---|---|---|

| Tensile Strength | Impact Energy | Hardness | Angular Distortion | |

| 1 | 52.97 | 35.97 | −43.97 | −12.06 |

| 2 | 54.29 | 36.47 | −43.86 | −11.84 |

| 3 | 55.64 | 37.18 | −43.86 | −11.39 * |

| 4 | 54.03 | 37.00 | −44.35 | −12.87 |

| 5 | 56.16 * | 38.60 | −43.58 * | −11.41 |

| 6 | 54.62 | 37.12 | −43.97 | −11.93 |

| 7 | 55.55 | 38.97 | −44.24 | −12.46 |

| 8 | 54.57 | 37.68 | −44.56 | −12.67 |

| 9 | 55.85 | 39.87 * | −43.64 | −11.62 |

| Optimum | A2B2C3D1 | A3B3C2D1 | A2B2C3D1 | A1B3C3D3 |

| Exp No. | Normalization | Grey Relational Coefficient | GRG | Rank | W-GRG | Rank | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TS | IE | H | AD | TS | IE | H | AD | |||||

| 1 | 0.00 | 0.00 | 0.40 | 0.46 | 0.33 | 0.33 | 0.46 | 0.48 | 0.400 | 9 | 0.408 | 9 |

| 2 | 0.41 | 0.13 | 0.29 | 0.31 | 0.46 | 0.36 | 0.41 | 0.42 | 0.414 | 8 | 0.419 | 8 |

| 3 | 0.83 | 0.31 | 0.29 | 0.00 | 0.75 | 0.42 | 0.41 | 0.33 | 0.479 | 6 | 0.485 | 6 |

| 4 | 0.33 | 0.26 | 0.79 | 1.00 | 0.43 | 0.40 | 0.70 | 1.00 | 0.633 | 4 | 0.661 | 3 |

| 5 | 1.00 | 0.67 | 0.00 | 0.02 | 1.00 | 0.61 | 0.33 | 0.34 | 0.569 | 5 | 0.565 | 5 |

| 6 | 0.52 | 0.30 | 0.40 | 0.37 | 0.51 | 0.42 | 0.46 | 0.44 | 0.455 | 7 | 0.459 | 7 |

| 7 | 0.81 | 0.77 | 0.68 | 0.73 | 0.72 | 0.69 | 0.61 | 0.65 | 0.665 | 2 | 0.664 | 2 |

| 8 | 0.50 | 0.44 | 1.00 | 0.87 | 0.50 | 0.47 | 1.00 | 0.79 | 0.689 | 1 | 0.712 | 1 |

| 9 | 0.90 | 1.00 | 0.06 | 0.16 | 0.83 | 1.00 | 0.35 | 0.37 | 0.638 | 3 | 0.598 | 4 |

| Parameters | Average of GRG | Average of W-GRG | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Levels | Delta | Rank | Levels | Delta | Rank | |||||

| 1 | 2 | 3 | 1 | 2 | 3 | |||||

| GA | 0.431 | 0.552 | 0.664 * | 0.2334 | 1 | 0.437 | 0.561 | 0.658 * | 0.220 | 1 |

| PHT | 0.566 * | 0.557 | 0.524 | 0.0423 | 4 | 0.577 * | 0.566 | 0.514 | 0.063 | 3 |

| ED | 0.515 | 0.562 | 0.571 * | 0.0564 | 3 | 0.526 | 0.560 | 0.571 * | 0.063 | 4 |

| RG | 0.535 | 0.511 | 0.601 * | 0.0893 | 2 | 0.524 | 0.514 | 0.619 * | 0.105 | 2 |

| Response Variable | Contribution |

|---|---|

| Tensile Strength | 0.2777 |

| Impact Energy | 0.1672 |

| Hardness | 0.2714 |

| Angular Distortion | 0.2840 |

| Initial Condition A2B2C3D2 | Confirmatory Experiment Results | Improvement from Initial Condition (%) | |

|---|---|---|---|

| GRG/W-GRA | GRG/W-GRA | ||

| Tensile Strength (MPa) | 545.6 | 675.5 | 23.80 |

| Impact Energy (J) | 60.76 | 99.88 | 64.38 |

| Hardness (HB) | 166 | 161 | 3.01 |

| Angular Distortion (θ) | 4.2 | 3.9 | 7.14 |

| Optimal Condition | - | A3B1C3D3 | |

| Grey Relational Grade | 0.5417 | 0.7645 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qazi, M.I.; Akhtar, R.; Abas, M.; Khalid, Q.S.; Babar, A.R.; Pruncu, C.I. An Integrated Approach of GRA Coupled with Principal Component Analysis for Multi-Optimization of Shielded Metal Arc Welding (SMAW) Process. Materials 2020, 13, 3457. https://doi.org/10.3390/ma13163457

Qazi MI, Akhtar R, Abas M, Khalid QS, Babar AR, Pruncu CI. An Integrated Approach of GRA Coupled with Principal Component Analysis for Multi-Optimization of Shielded Metal Arc Welding (SMAW) Process. Materials. 2020; 13(16):3457. https://doi.org/10.3390/ma13163457

Chicago/Turabian StyleQazi, Mohsin Iqbal, Rehman Akhtar, Muhammad Abas, Qazi Salman Khalid, Abdur Rehman Babar, and Catalin Iulian Pruncu. 2020. "An Integrated Approach of GRA Coupled with Principal Component Analysis for Multi-Optimization of Shielded Metal Arc Welding (SMAW) Process" Materials 13, no. 16: 3457. https://doi.org/10.3390/ma13163457

APA StyleQazi, M. I., Akhtar, R., Abas, M., Khalid, Q. S., Babar, A. R., & Pruncu, C. I. (2020). An Integrated Approach of GRA Coupled with Principal Component Analysis for Multi-Optimization of Shielded Metal Arc Welding (SMAW) Process. Materials, 13(16), 3457. https://doi.org/10.3390/ma13163457