Mechanical Properties of Carbon-Fabric-Reinforced High-Strength Matrices

Abstract

:1. Introduction

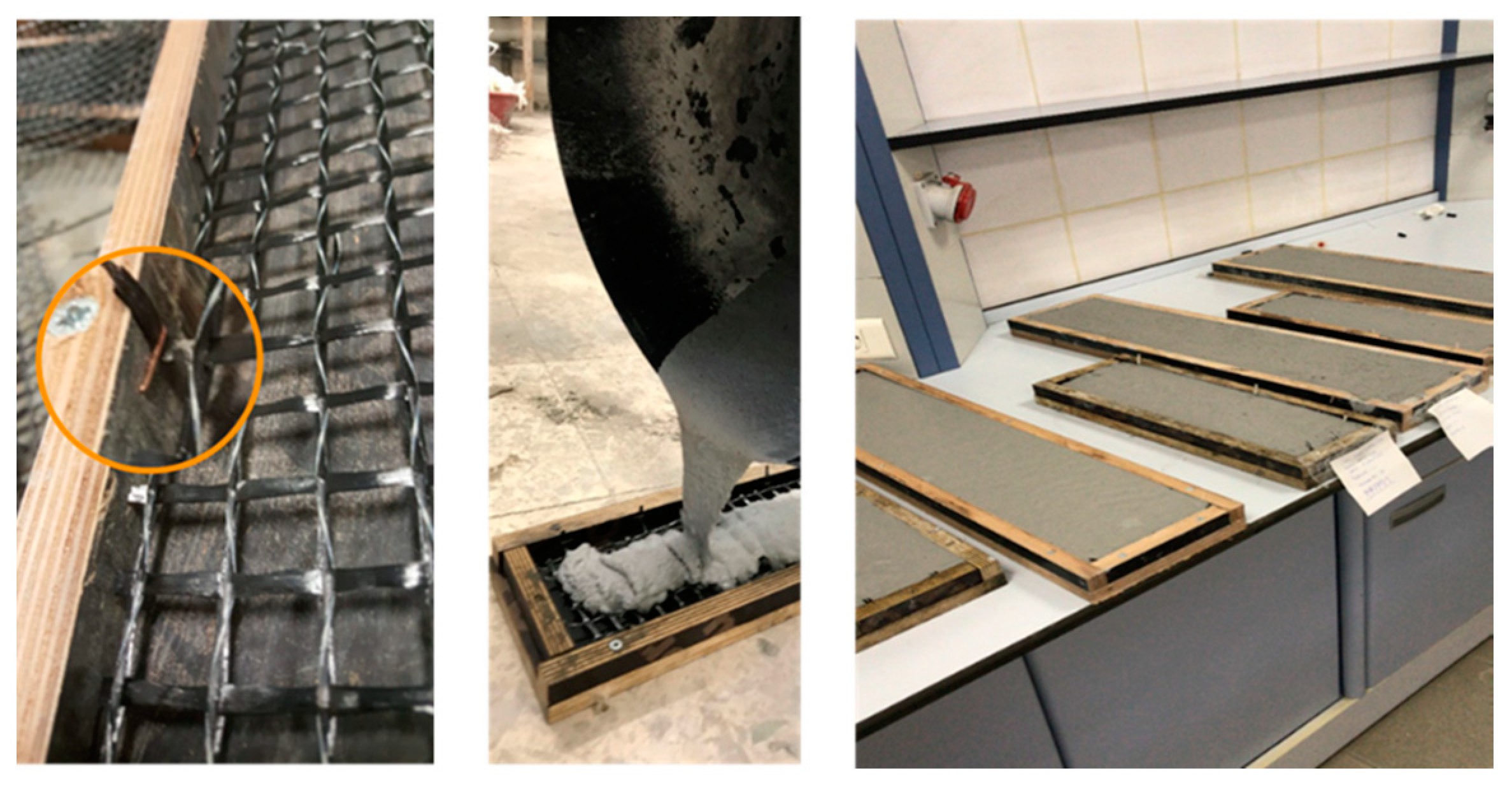

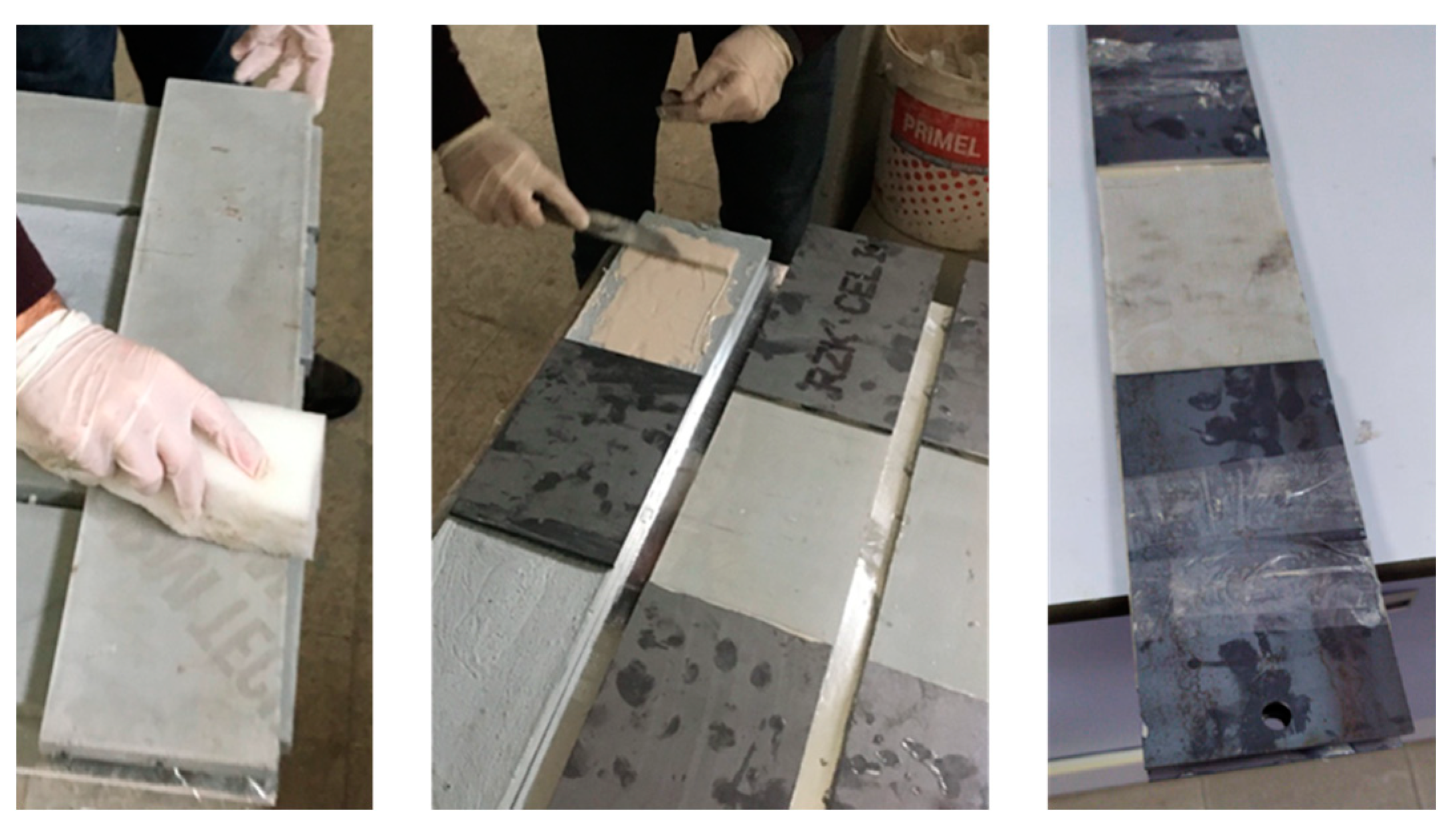

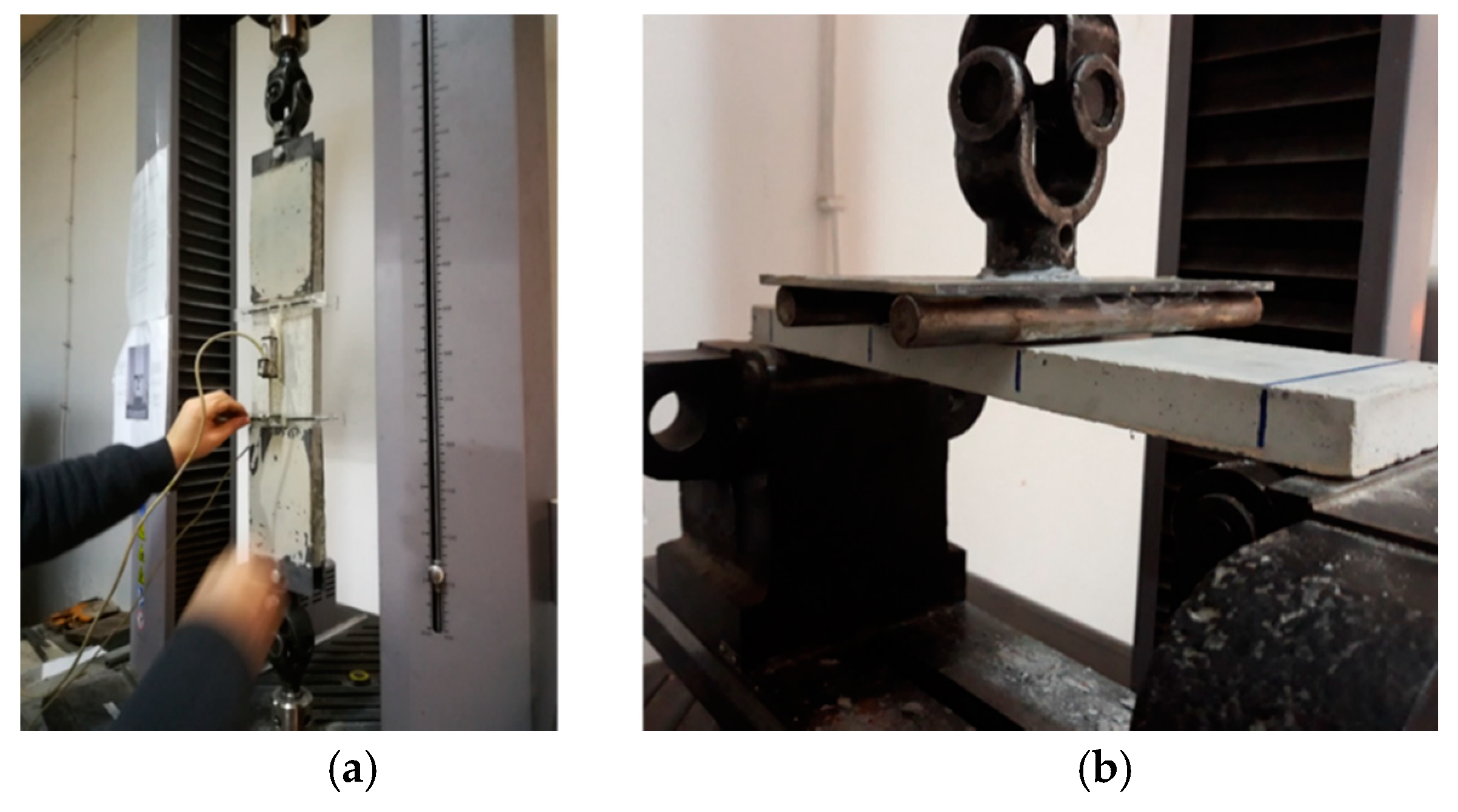

2. Materials and Test Methods

3. Test Results and Discussion

3.1. Compressive Strength Tests for the Mortars

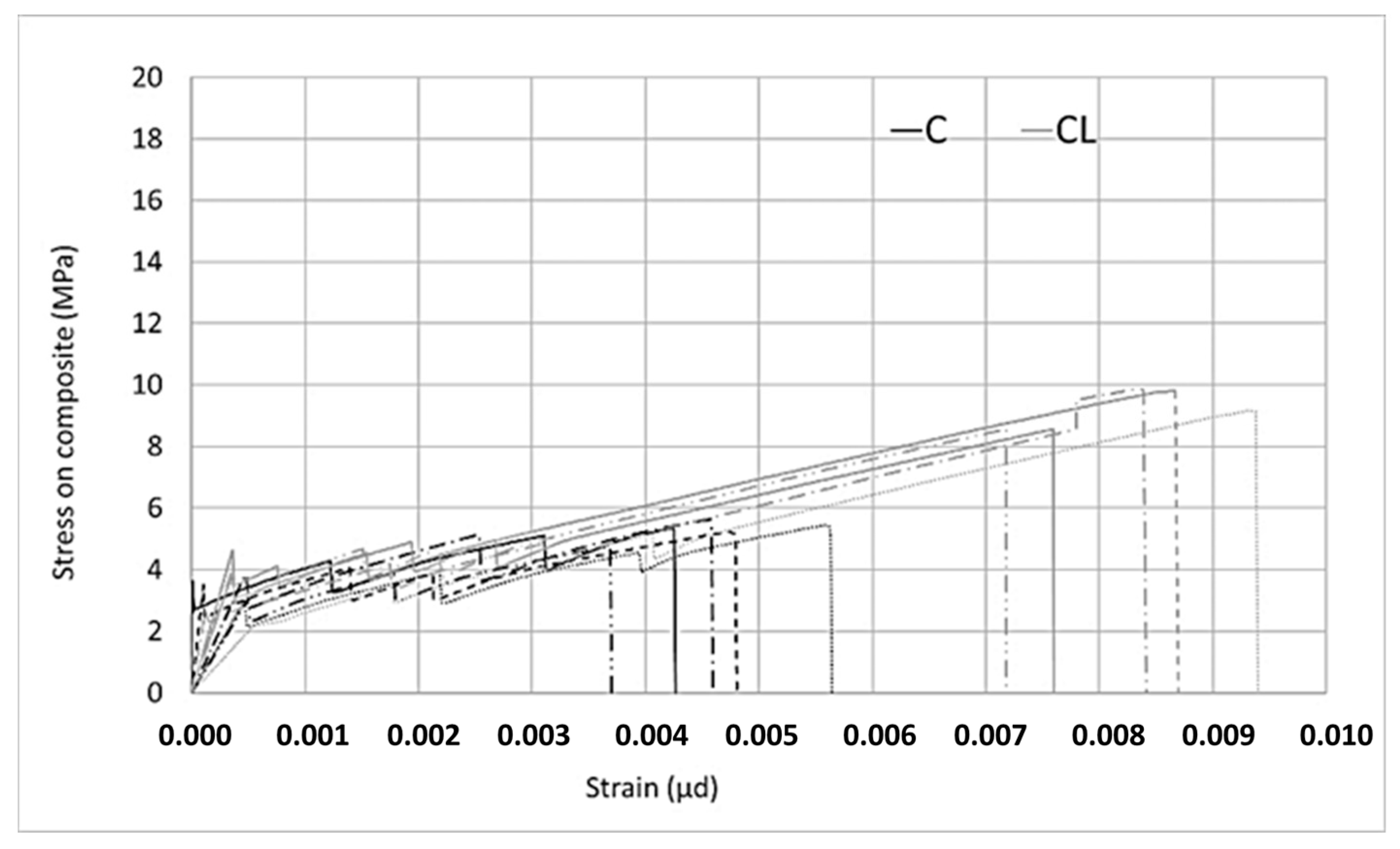

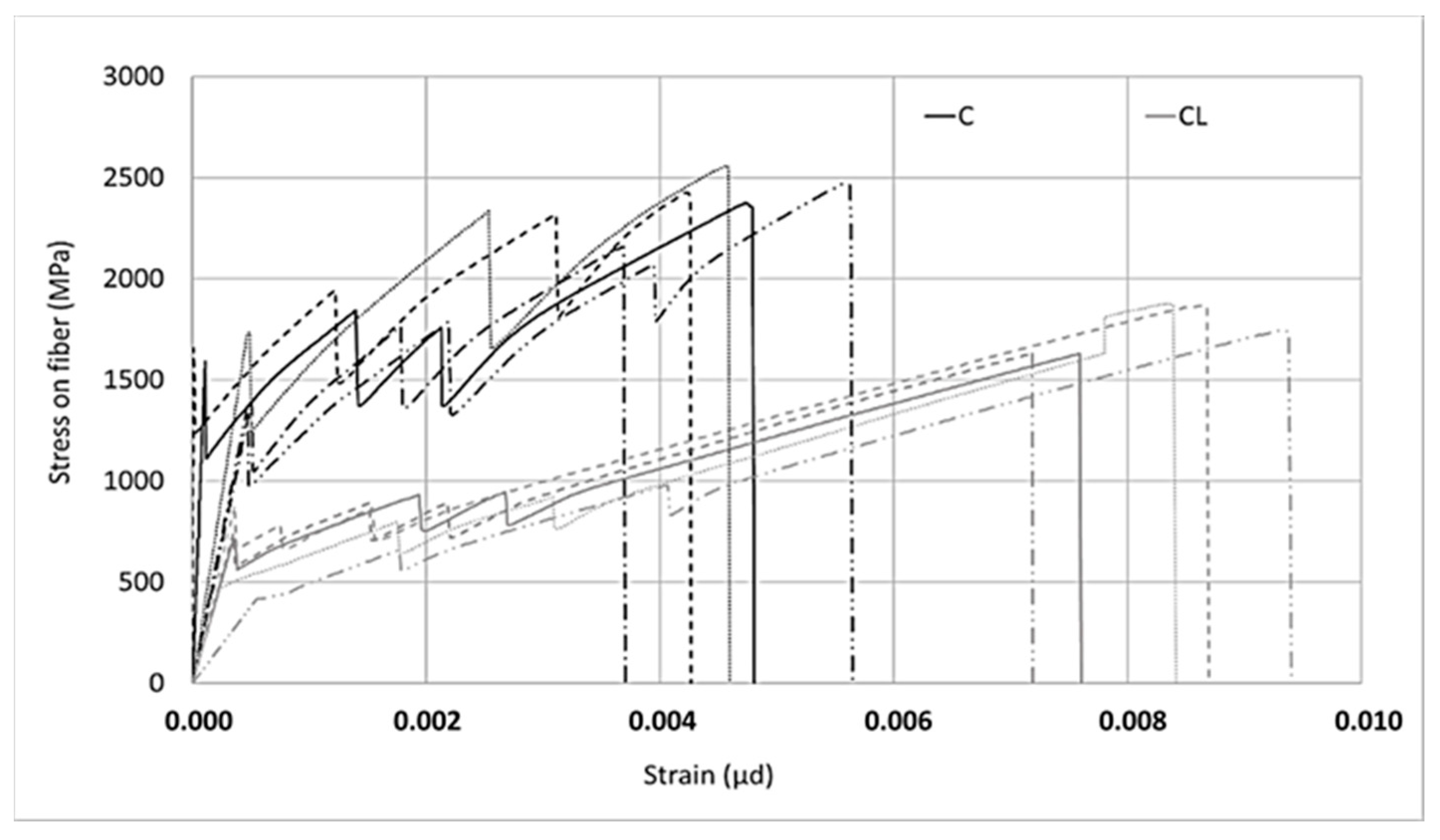

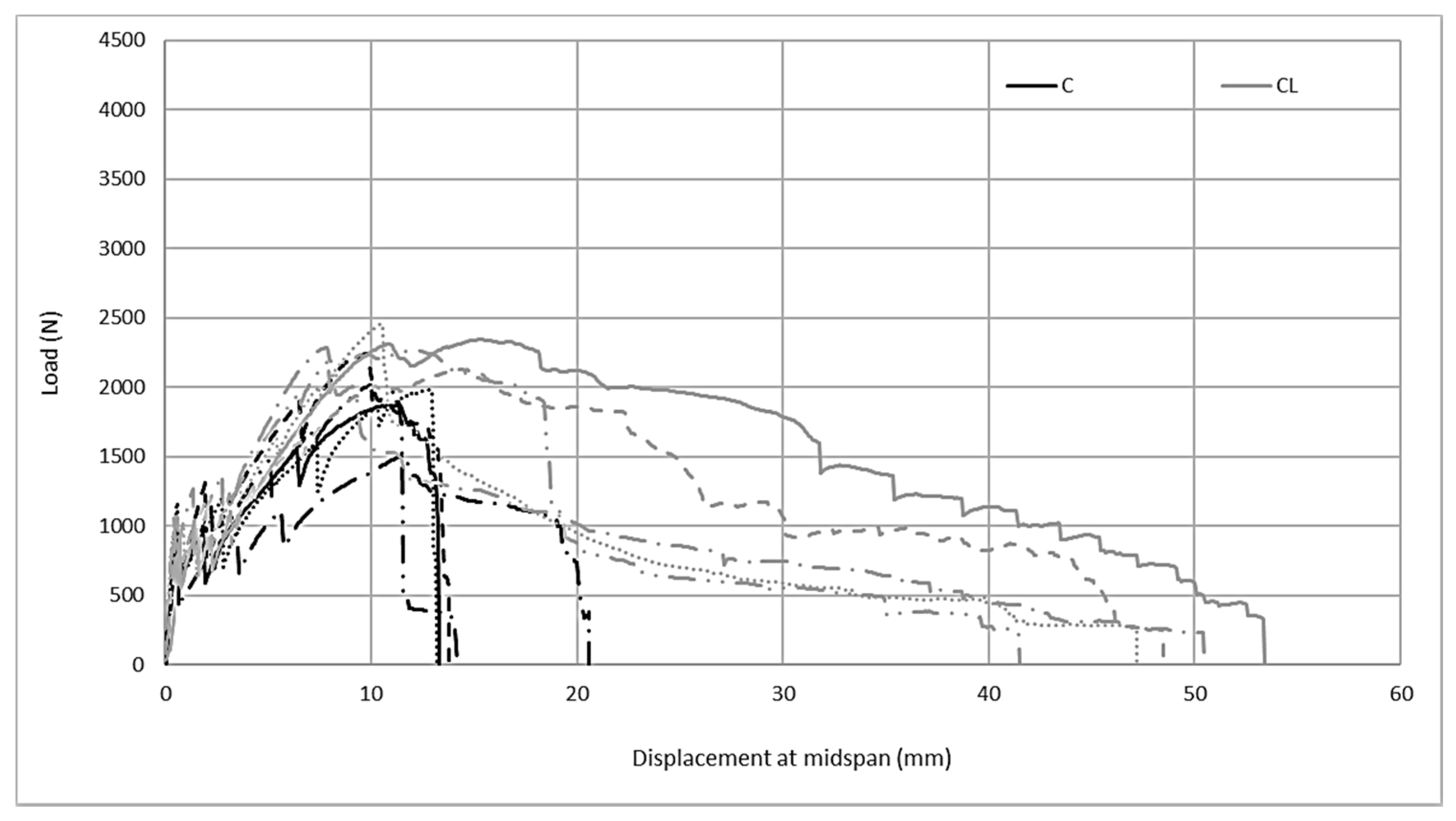

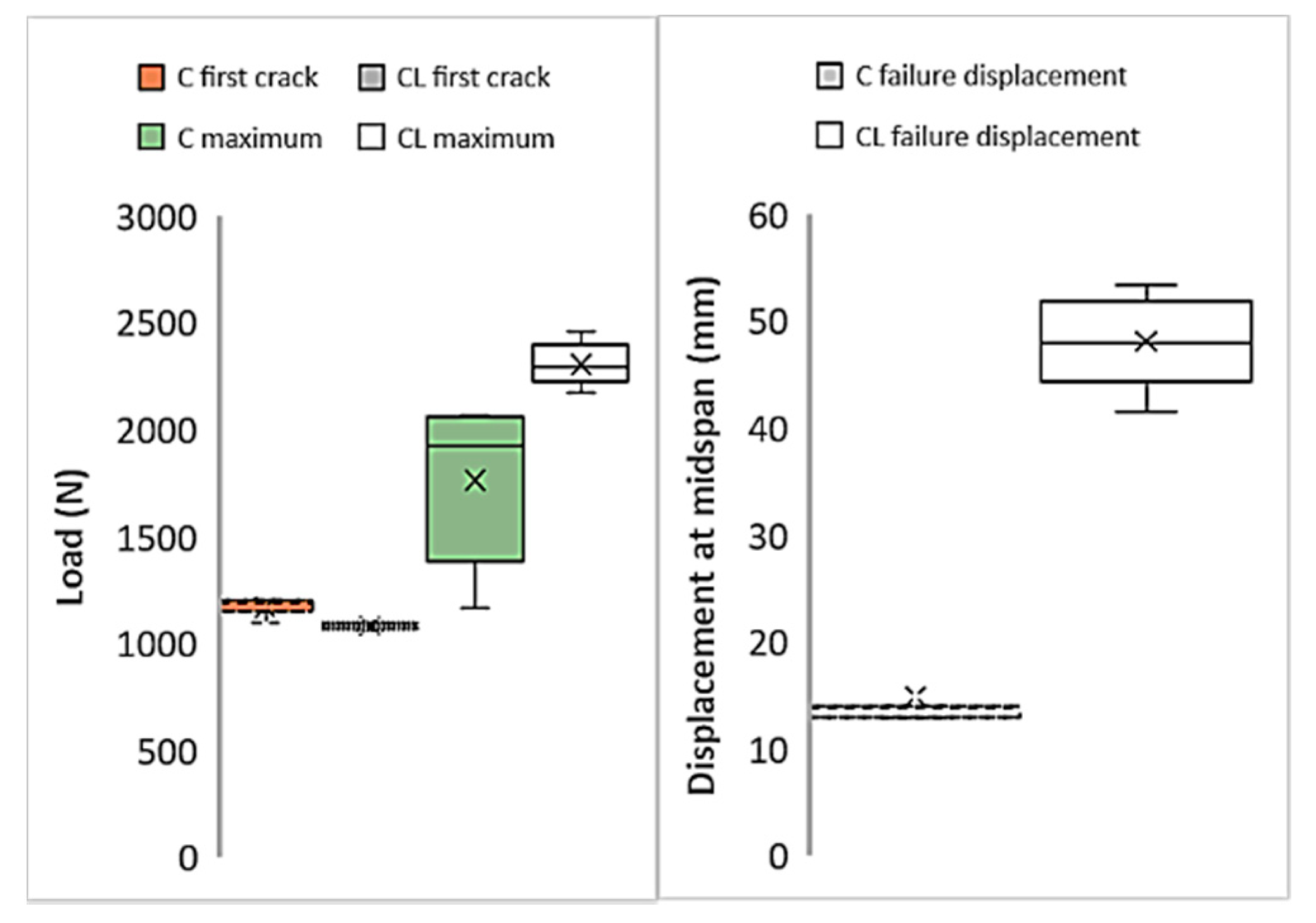

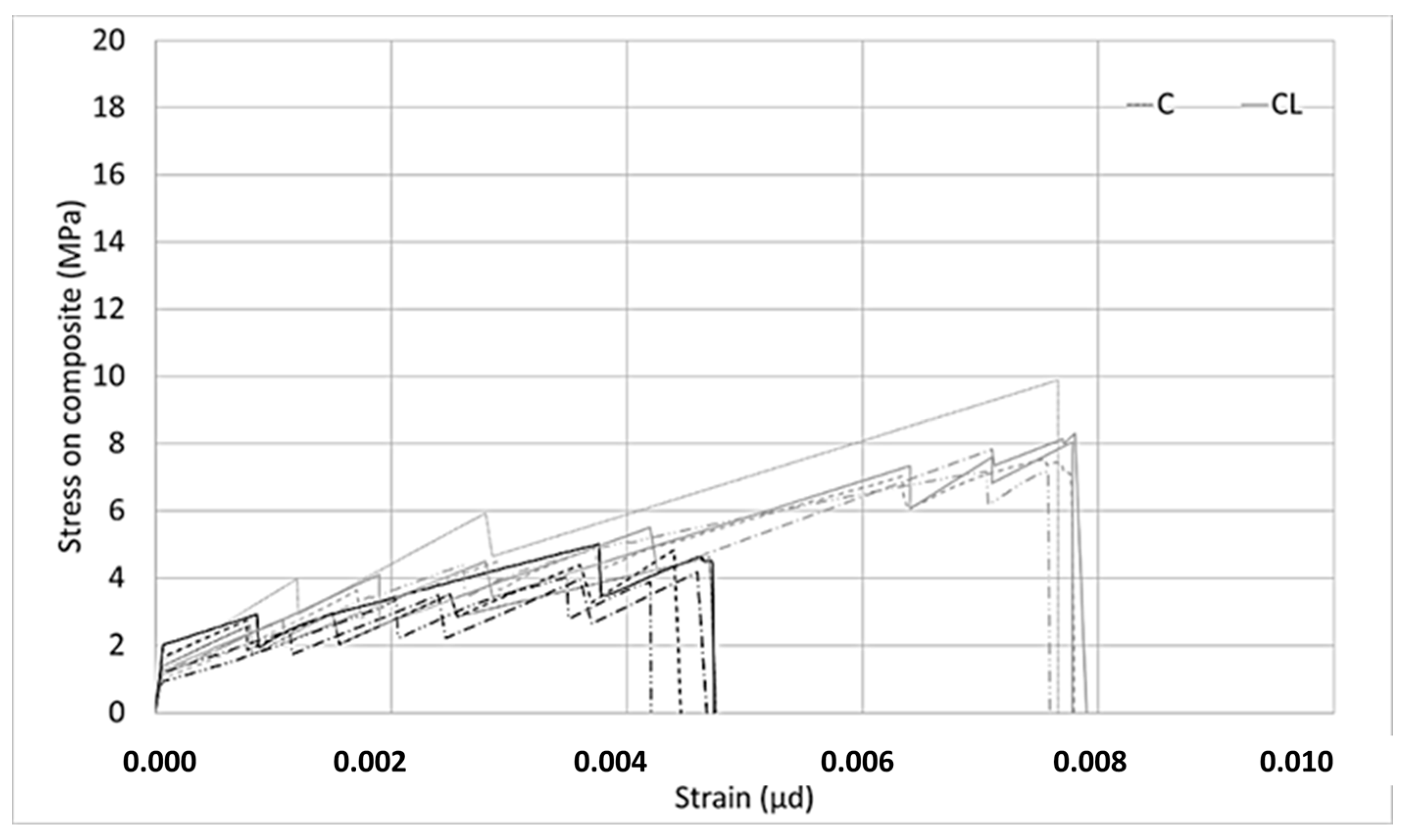

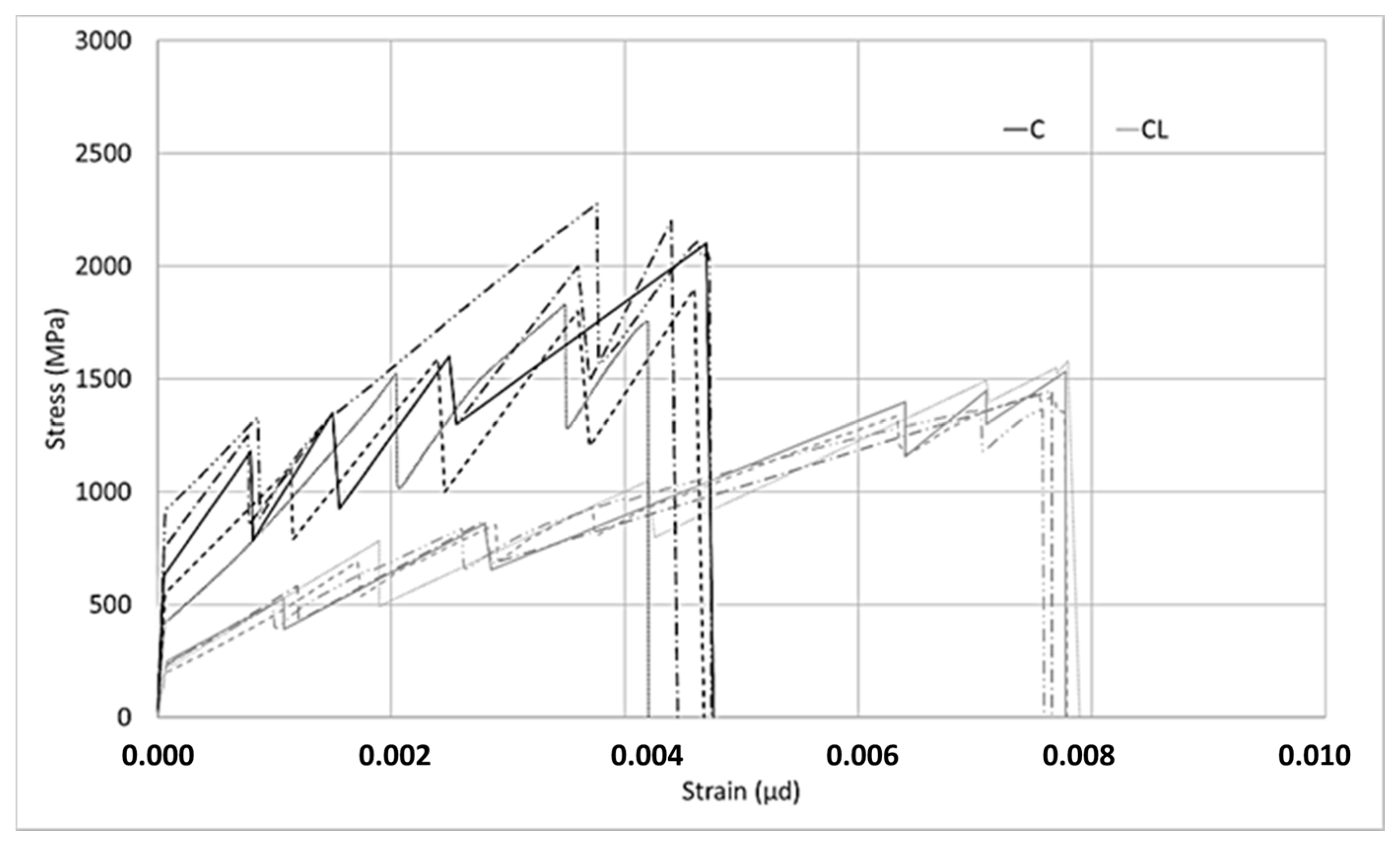

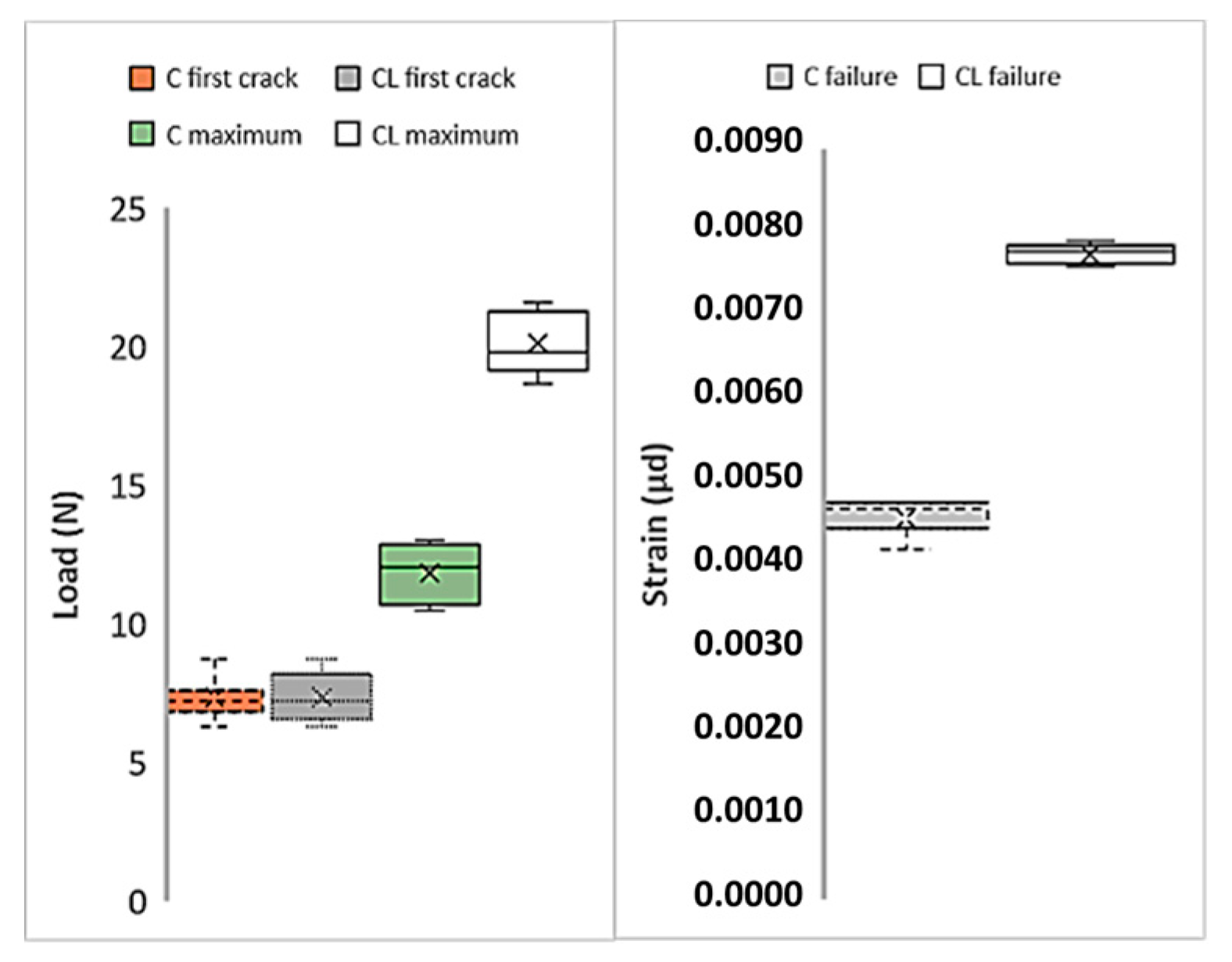

3.2. Tensile and Flexural Test Results of Composites Produced with M60 Matrix

3.3. Tensile and Flexural Test Results for Composites Produced with the M120 Matrix

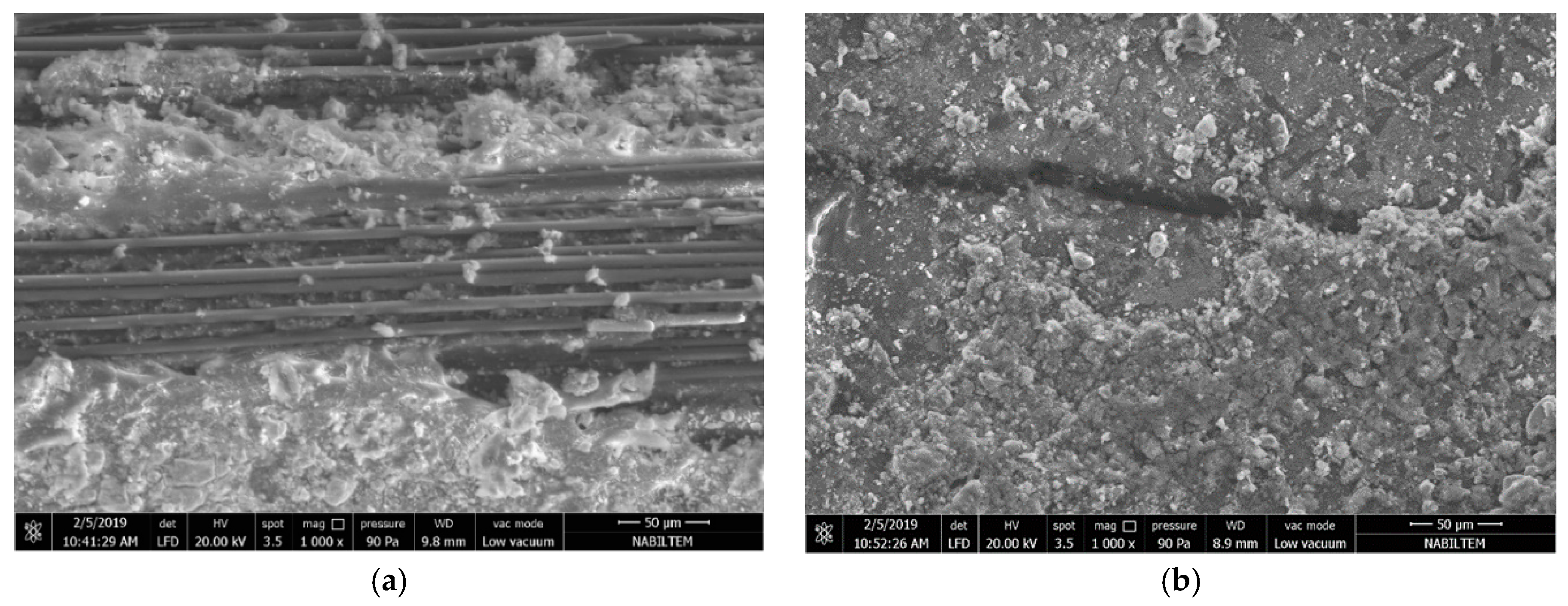

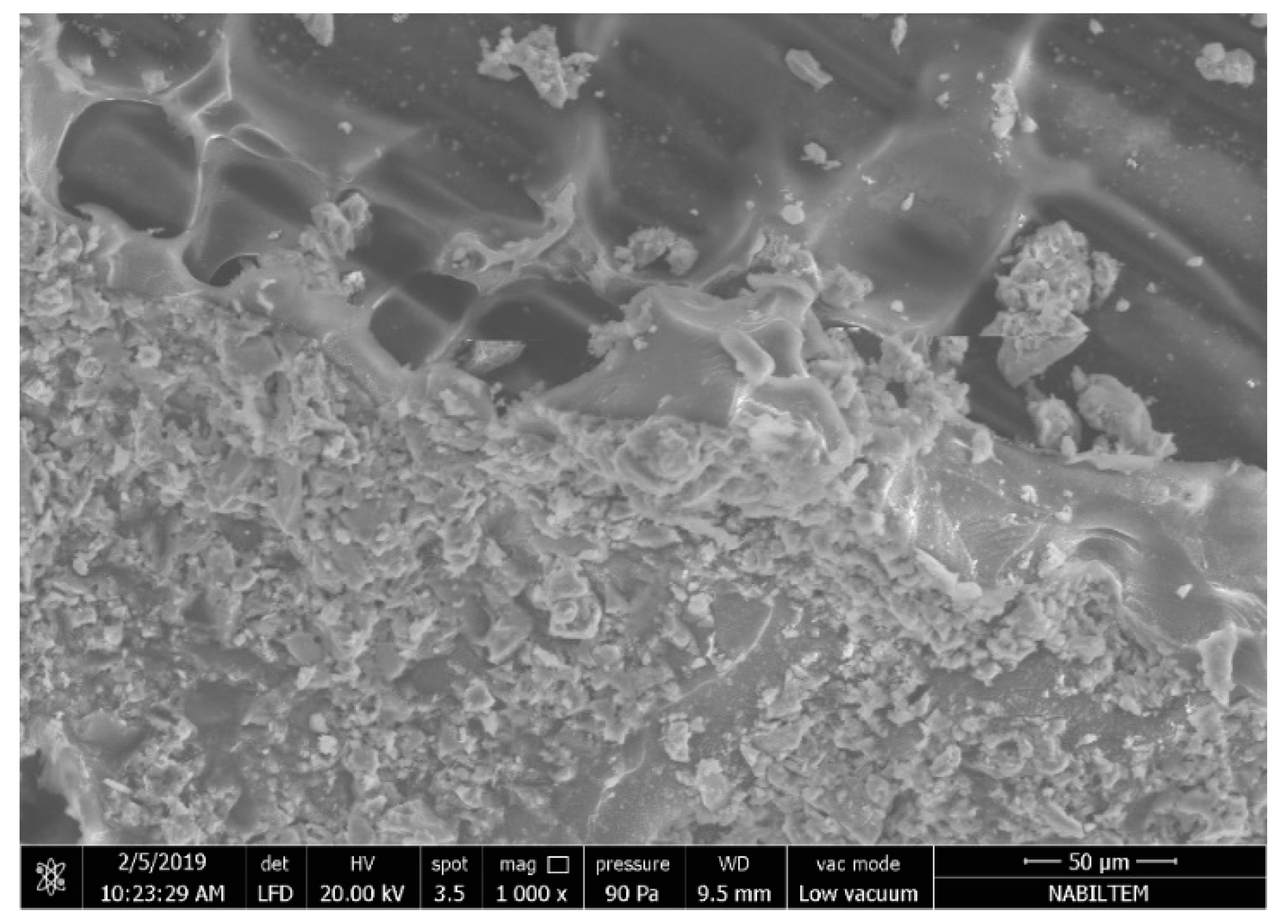

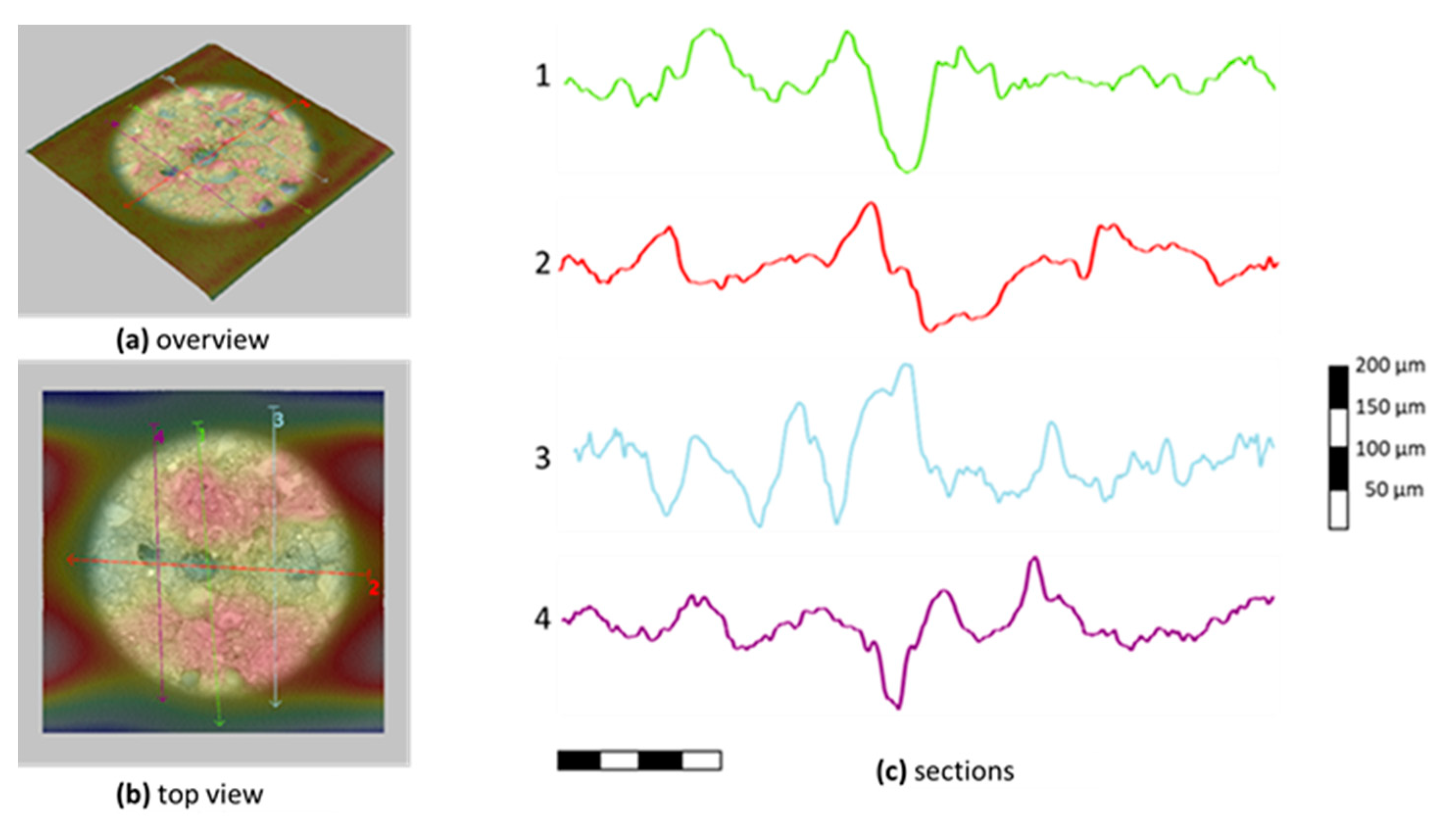

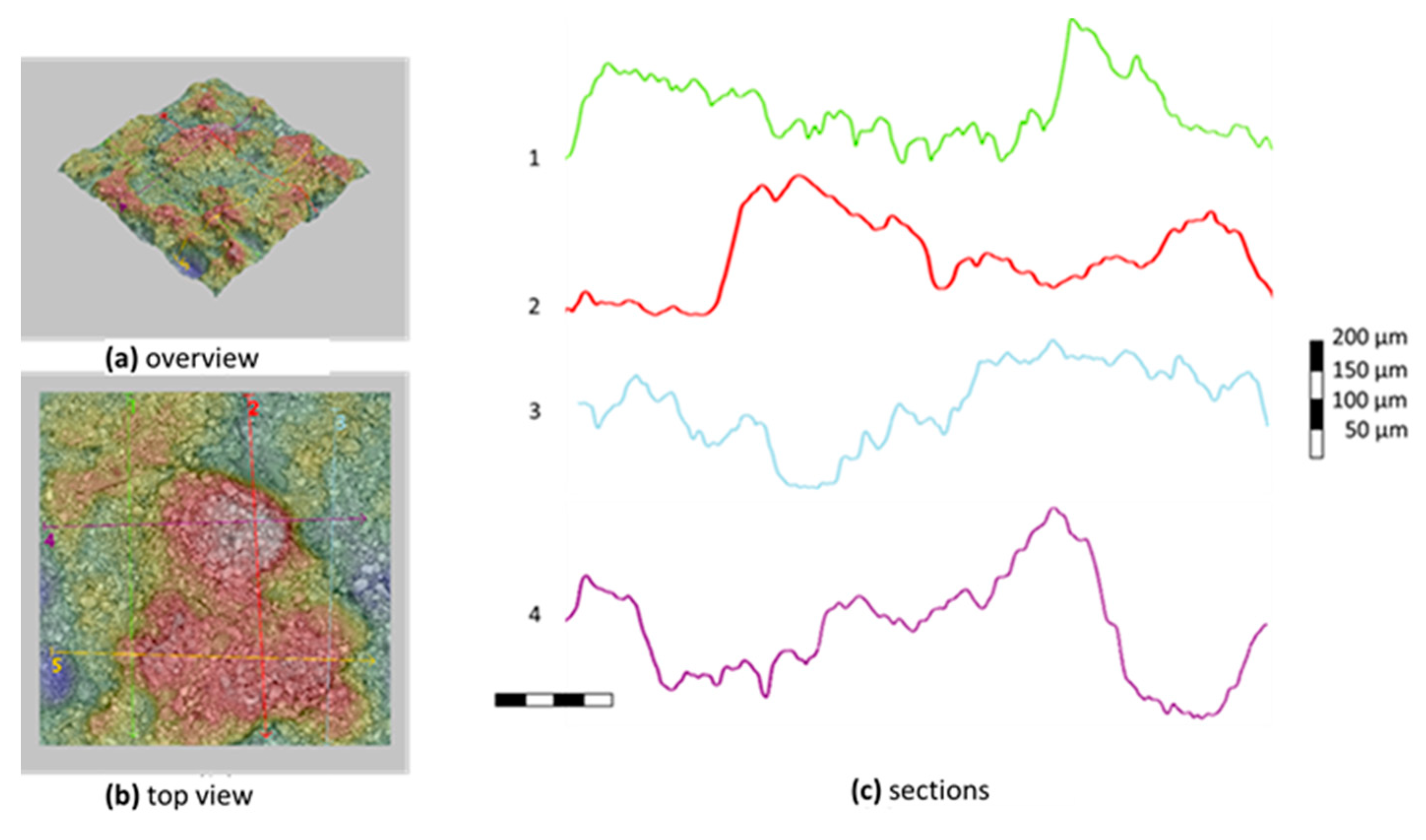

3.4. Microstructural Investigation

4. Conclusions

- In the experiments on the composite, regardless of the amount of fiber in the direction of loading, the parts of the graphs until the first crack occurs depend on the matrix properties and are managed by the matrix. After the first cracks had occurred, the multiple cracking mechanism was activated in all samples in tensile and flexural tests and strain hardening behavior was observed. In tensile tests, the load suddenly dropped to zero after the maximum load was reached in all of the samples, and then failure occurred. In flexural tests, while samples produced with the CL fabric and M60 composites showed strain softening behavior, composites produced with M120 mortar showed similar strain softening behavior when using the C fabric. The strain softening behavior affects the ductility of the sample in flexural tests. If carbon fibers are used in a beneficial direction, the mechanical energy absorbed in the stage after the maximum load is reached is higher;

- The first crack loads were not significantly different when different fabrics were used for flexure and tensile tests. The maximum loads increased when CL fabric was used. With the increase of fiber area in the direction of the load, the load order carried along this direction increases. However, this increase does not have to be proportional to the fiber area used in the direction of the load. Improvement of the matrix properties over 60 MPa has no significant effect on composite mechanical properties;

- Regarding the performance of high-strength cementitious mortar and carbon fiber composites, the interface of the coatings with the carbon fiber or cementitious matrix affects the performance. The fibers, fiber–matrix interface, coating material, and matrix properties should be optimized to give best performance for the composite. Optimization can be done by modeling the peel-off strengths of the coating on the fibers. It should be noted that the defects in the interface and elements that disrupt the homogeneity significantly affect composite performance;

- When the residual amounts of high-strength cementitious matrix on the SBR-coated carbon fiber fabric were examined, it was clear that the SBR coating provided sufficient adherence for the cementitious matrix. In the microtopography studies, it was found that the high-strength matrix had better adhesion to the coating. However, factors such as the coating type and coating thickness should be taken into consideration regarding the composite performance;

- The thickness of the coating takes advantage of the performance of the fibers and transfers the loads on the coating to the fibers. The parts with low coating thickness were peeled off over the carbon fibers;

- By reducing the amount of carbon fiber along the load-carrying direction, the amount of coating corresponding to the unit area of the carbon fiber is increased. The carbon fibers can be used more efficiently and the loads in the matrix can be transferred to the carbon fibers through the coating–matrix interface, allowing the carbon fibers to carry more loads. Thus, carbon fibers can be used more efficiently by carrying closer loads. It has been demonstrated that the increase in the ratio of the carbon fiber to the cement matrix interface per unit area of carbon fiber is effective in increasing the load transferred to carbon fibers. Using more carbon fibers in one direction increases the load-bearing capacity of the composite in terms of tensile strength and bending. However, using a higher yarn numbers with thinner yarn will further increase the tensile stresses on the fiber and the overall load-carrying capacity;

- Further studies could investigate which coatings might be optimized by performing experimental studies on different coating types, as well as which carbon fiber thicknesses should be used.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; Elsevier Applied Science: London, UK, 1990. [Google Scholar]

- Balaguru, P.N.; Shah, S.P. Fiber-Reinforced Cement Composites; McGraw-Hill: New York, NY, USA, 1992; ISBN 978-0-07-056400-8. [Google Scholar]

- Peled, A.; Bentur, A. Fabric Structure and Its Reinforcing Efficiency in Textile Reinforced Cement Composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 107–118. [Google Scholar] [CrossRef]

- Wang, Y. Utilization of Recycled Carpet Waste Fibers for Reinforcement of Concrete and Soil. Polym. Plast. Technol. Eng. 1999, 38, 533–546. [Google Scholar] [CrossRef]

- Kurt, G. Lif İçeriği Ve Su/çimento Oranının Fibrobetonun Mekanik Davranışına Etkileri. Master’s Thesis, Istanbul Technical University, Istanbul, Turkey, 2006. [Google Scholar]

- Horikoshi, T.; Ogawa, A.; Saito, T.; Hoshiro, H. Properties of Polyvinylalcohol Fiber as Reinforcing Materials for Cementitious Composites. In International RILEM Workshop on High Performance Fiber Reinforced Cementitious; RILEM Publications SARL: Paris, France, 2006; pp. 145–153. [Google Scholar]

- Mobasher, B.; Peled, A.; Pahilajani, J. Distributed Cracking and Stiffness Degradation in Fabric-Cement Composites. Mater. Struct. 2007, 39, 317–331. [Google Scholar] [CrossRef]

- Peled, A. Pre-Tensioning of Fabrics in Cement-Based Composites. Cem. Concr. Res. 2007, 37, 805–813. [Google Scholar] [CrossRef]

- Peled, A.; Sueki, S.; Mobasher, B. Bonding in Fabric–Cement Systems: Effects of Fabrication Methods. Cem. Concr. Res. 2006, 36, 1661–1671. [Google Scholar] [CrossRef]

- Hegger, J.; Voss, S. Investigations on the Bearing Behaviour and Application Potential of Textile Reinforced Concrete. Eng. Struct. 2008, 30, 2050–2056. [Google Scholar] [CrossRef]

- Trapko, T. Confined Concrete Elements with PBO-FRCM Composites. Constr. Build. Mater. 2014, 73, 332–338. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Triantafillou, T.C.; Bournas, D.A. On the Design of Shear-Strengthened RC Members Through the Use of Textile Reinforced Mortar Overlays. Compos. Part B Eng. 2018, 147, 178–196. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Experimental Analysis on Bond Between PBO-FRCM Strengthening Materials and Concrete. Compos. Part B Eng. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Lignola, G.P.; Caggegi, C.; Ceroni, F.; De Santis, S.; Krajewski, P.; Lourenço, P.B.; Morganti, M.; Papanicolaou, C.; Pellegrino, C.; Prota, A. Performance Assessment of Basalt FRCM for Retrofit Applications on Masonry. Compos. Part B Eng. 2017, 128, 1–18. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical Properties of FRCM Using Carbon Fabrics with Different Coating Treatments. Compos. Part B Eng. 2016, 88, 220–228. [Google Scholar] [CrossRef]

- Cevallos, O.A.; Olivito, R.S. Effects of Fabric Parameters on the Tensile Behaviour of Sustainable Cementitious Composites. Compos. Part B Eng. 2015, 69, 256–266. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U. A Study on the Bond Behavior of Different FRCM systems. MATEC Web Conf. 2018, 199, 09003. [Google Scholar] [CrossRef]

- Scheffler, C.; Gao, S.L.; Plonka, R.; Mäder, E.; Hempel, S.; Butler, M.; Mechtcherine, V. Interphase Modification of Alkali-Resistant Glass Fibres and Carbon Fibres for Textile Reinforced Concrete I: Fibre Properties and Durability. Compos. Sci. Technol. 2009, 69, 531–538. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Jamshidi, M.; Latifi, M. Performance of Fibers Embedded in a Cementitious Matrix. J. Appl. Polym. Sci. 2009. [Google Scholar] [CrossRef]

- Tuncel, E.Y.; Polat Pekmezci, I.; Pekmezci, B.Y. Behavior of Textile Reinforced Lime Composites Under Flexural Loads. In Proceedings of the 9th International Conference on Structural Analysis of Historical Constructions (SAHC2014), Mexico City, Mexico, 14–17 October 2014. [Google Scholar]

- Tuncel, E.Y.; Polat Pekmezci, I.; Pekmezci, B.Y.; Karagüzel Kayaoğlu, B. Properties of Lime Based Textile Reinforced Composites. In Proceedings of the 5th International Istanbul Textile Congress, Istanbul, Turkey, 11–12 September 2015. [Google Scholar]

- Peled, A.; Cohen, Z.; Pasder, Y.; Roye, A.; Gries, T. Influences of Textile Characteristics on the Tensile Properties of Warp Knitted Cement Based Composites. Cem. Concr. Compos. 2008, 30, 174–183. [Google Scholar] [CrossRef]

- Peled, A.; Bentur, A.; Yankelevsky, D. Effects of Woven Fabric Geometry on the Bonding Performance of Cementitious Composites. Adv. Cem. Base Mater. 1998, 7, 20–27. [Google Scholar] [CrossRef]

- Peled, A.; Bentur, A. Geometrical Characteristics and Efficiency of Textile Fabrics for Reinforcing Cement Composites. Cem. Concr. Res. 2000, 30, 781–790. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Textile-Reinforced Mortar (TRM) versus Fibre-Reinforced Polymers (FRP) in Flexural Strengthening of RC Beams. Constr. Build. Mater. 2017, 151, 279–291. [Google Scholar] [CrossRef]

- De, A.; Silva, F.; Butler, M.; Hempel, S.; Toledo Filho, R.D.; Mechtcherine, V. Effects of Elevated Temperatures on the Interface Properties of Carbon Textile-Reinforced Concrete. Cem. Concr. Compos. 2014, 48, 26–34. [Google Scholar] [CrossRef]

- Hegger, J.; Molter, M.; Schneider, H.N.; Schatzke, C. Fassaden aus Textilbewehrtem Beton. Betonw. Fert. Tech. 2001, 67, 68–72. [Google Scholar]

- Hegger, J.; Will, N.; Voss, S.; Schneider, H.N. Extrem Dünne Fassadenelemente aus Textilbewehrtem Beton. Betonw. Fert. Tech. 2005, 71, 56–57. [Google Scholar]

- Azam, R.; Soudki, K. FRCM Strengthening of Shear-Critical RC Beams. J. Compos. Constr. 2014, 18, 04014012. [Google Scholar] [CrossRef]

- Hempel, R.; Helbig, U.; Lieboldt, M.; Engler, T. Innovative Composite Pipes of Plastic and Textile Reinforced Concrete. Betonw. Fert. Tech. 2006, 72, 86. [Google Scholar]

- Novotná, M.; Kostelecká, M.; Hodková, J.; Vokáč, M. Use of Textile Reinforced Concrete—Especially for Facade Panels. AMR 2014, 923, 142–145. [Google Scholar] [CrossRef]

- Williams Portal, N.; Flansbjer, M.; Zandi, K.; Wlasak, L.; Malaga, K. Bending Behaviour of Novel Textile Reinforced Concrete-Foamed Concrete (TRC-FC) Sandwich Elements. Compos. Struct. 2017, 177, 104–118. [Google Scholar] [CrossRef]

- Dey, V.; Zani, G.; Colombo, M.; Di Prisco, M.; Mobasher, B. Flexural Impact Response of Textile-Reinforced Aerated Concrete Sandwich Panels. Mater. Des. 2015, 86, 187–197. [Google Scholar] [CrossRef]

- Shams, A.; Hegger, J.; Horstmann, M. An Analytical Model for Sandwich Panels Made of Textile-Reinforced Concrete. Constr. Build. Mater. 2014, 64, 451–459. [Google Scholar] [CrossRef]

- Colombo, I.G.; Colombo, M.; di Prisco, M. Bending Behaviour of Textile Reinforced Concrete Sandwich Beams. Constr. Build. Mater. 2015, 95, 675–685. [Google Scholar] [CrossRef]

- Koutas, L.N.; Bournas, D.A. Flexural Strengthening of Two-Way RC Slabs with Textile-Reinforced Mortar: Experimental Investigation and Design Equations. J. Compos. Constr. 2017, 21, 04016065. [Google Scholar] [CrossRef]

- Koutas, L.N.; Bournas, D.A. Out-of-Plane Strengthening of Masonry-Infilled RC Frames with Textile-Reinforced Mortar Jackets. J. Compos. Constr. 2019, 23, 04018079. [Google Scholar] [CrossRef]

- Shabdin, M.; Zargaran, M.; Attari, N.K.A. Experimental Diagonal Tension (Shear) Test of Un-Reinforced Masonry (URM) Walls Strengthened with Textile Reinforced Mortar (TRM). Constr. Build. Mater. 2018, 164, 704–715. [Google Scholar] [CrossRef]

- Kariou, F.A.; Triantafyllou, S.P.; Bournas, D.A.; Koutas, L.N. Out-of-plane Response of Masonry Walls Strengthened Using Textile-Mortar System. Constr. Build. Mater. 2018, 165, 769–781. [Google Scholar] [CrossRef] [Green Version]

- Babaeidarabad, S.; Arboleda, D.; Loreto, G.; Nanni, A. Shear Strengthening of Un-Reinforced Concrete Masonry Walls with Fabric-Reinforced-Cementitious-Matrix. Constr. Build. Mater. 2014, 65, 243–253. [Google Scholar] [CrossRef]

- Donnini, J.; Spagnuolo, S.; Corinaldesi, V. A Comparison Between the Use of FRP, FRCM and HPM for Concrete Confinement. Compos. Part B Eng. 2019, 160, 586–594. [Google Scholar] [CrossRef]

- Voit, K.; Kirnbauer, J. Tensile Characteristics and Fracture Energy of Fiber Reinforced and Non-Reinforced Ultra High Performance Concrete (UHPC). Int. J. Fract. 2014, 188, 147–157. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S. Factors Affecting Bond Development Between Ultra High Performance Concrete (UHPC) and Steel Bar Reinforcement. Constr. Build. Mater. 2017, 144, 412–422. [Google Scholar] [CrossRef]

- Azizinamini, A.; Stark, M.; Roller, J.J.; Ghosh, S.K. Bond Performance of Reinforcing Bars Embedded in High-Strength Concrete. ACI Struct. J. 1993, 90. [Google Scholar] [CrossRef]

- Chao, S.-H.; Naaman, A.E.; Parra-Montesinos, G.J. Bond Behavior of Reinforcing Bars in Tensile Strain-Hardening Fiber-Reinforced Cement Composites. ACI Struct. J. 2009, 106, 897. [Google Scholar]

- Preinstorfer, P.; Kromoser, B.; Kollegger, J. Flexural Behaviour of Filigree Slab Elements Made of Carbon Reinforced UHPC. Constr. Build. Mater. 2019, 199, 416–423. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 239-R18: Ultra-High-Performance Concrete: An Emerging Technology Report; American Concrete Institute: Farmington Hills, MI, USA, 2018. [Google Scholar]

- Arora, A.; Aguayo, M.; Hansen, H.; Castro, C.; Federspiel, E.; Mobasher, B.; Neithalath, N. Microstructural Packing- and Rheology-Based Binder Selection and Characterization for Ultra-High Performance Concrete (UHPC). Cem. Concr. Res. 2018, 103, 179–190. [Google Scholar] [CrossRef]

- Arora, A.; Almujaddidi, A.; Kianmofrad, F.; Mobasher, B.; Neithalath, N. Material Design of Economical Ultra-High Performance Concrete (UHPC) and Evaluation of Their Properties. Cem. Concr. Res. 2019, 104, 103346. [Google Scholar] [CrossRef]

- Ford, E.; Arora, A.; Mobasher, B.; Hoover, C.G.; Neithalath, N. Elucidating the Nano-Mechanical Behavior of Multi-Component Binders for Ultra-High Performance Concrete. Constr. Build. Mater. 2020, 243, 118214. [Google Scholar] [CrossRef]

- RILEM Technical Committee. 232-TDT: Test Methods and Design of Textile Reinforced Concrete; RILEM: Paris, France, 2014. [Google Scholar]

- ICC-Evaluation Service. AC434: Acceptance Criteria for Masonry and Concrete Strengthening Using Fiber-Reinforced Cementitious Matrix (FRCM) Composite Systems; ICC-Evaluation Service: Whittier, CA, USA, 2013. [Google Scholar]

- American Concrete Institute. ACI 549.4-R20: Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix and Steel-Reinforced Grout Systems for Repair and Strengthening of Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2020. [Google Scholar]

- De Santis, S.; de Felice, G. Tensile Behaviour of Mortar-Based Composites for Externally Bonded Reinforcement Systems. Compos. Part B Eng. 2015, 68, 401–413. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pekmezci, B.Y.; Çopuroğlu, A. Mechanical Properties of Carbon-Fabric-Reinforced High-Strength Matrices. Materials 2020, 13, 3508. https://doi.org/10.3390/ma13163508

Pekmezci BY, Çopuroğlu A. Mechanical Properties of Carbon-Fabric-Reinforced High-Strength Matrices. Materials. 2020; 13(16):3508. https://doi.org/10.3390/ma13163508

Chicago/Turabian StylePekmezci, Bekir Yılmaz, and Ali Çopuroğlu. 2020. "Mechanical Properties of Carbon-Fabric-Reinforced High-Strength Matrices" Materials 13, no. 16: 3508. https://doi.org/10.3390/ma13163508

APA StylePekmezci, B. Y., & Çopuroğlu, A. (2020). Mechanical Properties of Carbon-Fabric-Reinforced High-Strength Matrices. Materials, 13(16), 3508. https://doi.org/10.3390/ma13163508