Microstructure and Mechanical Properties of Al/Steel Butt Joint by Hybrid CMT Welding with External Axial Magnetic Field

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

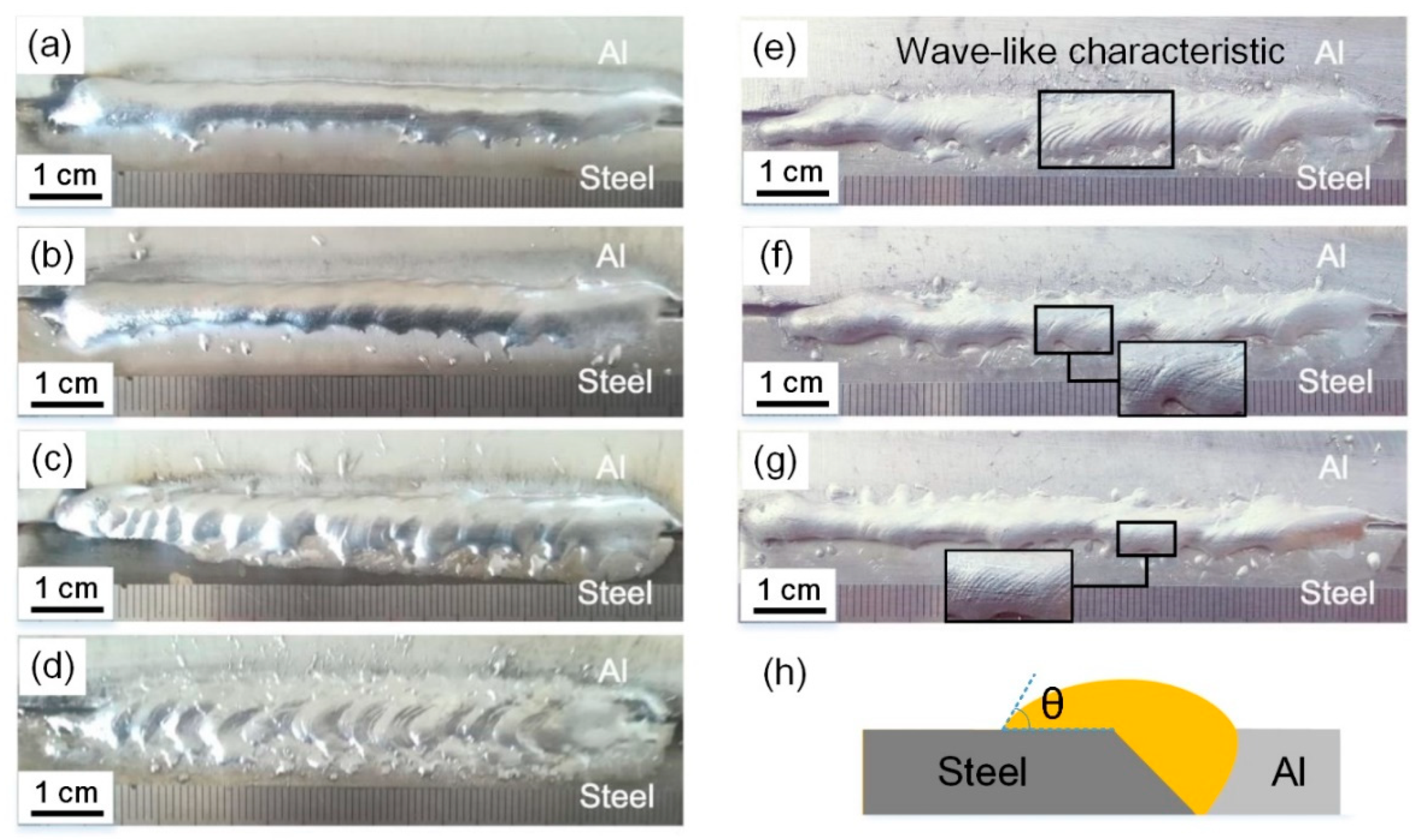

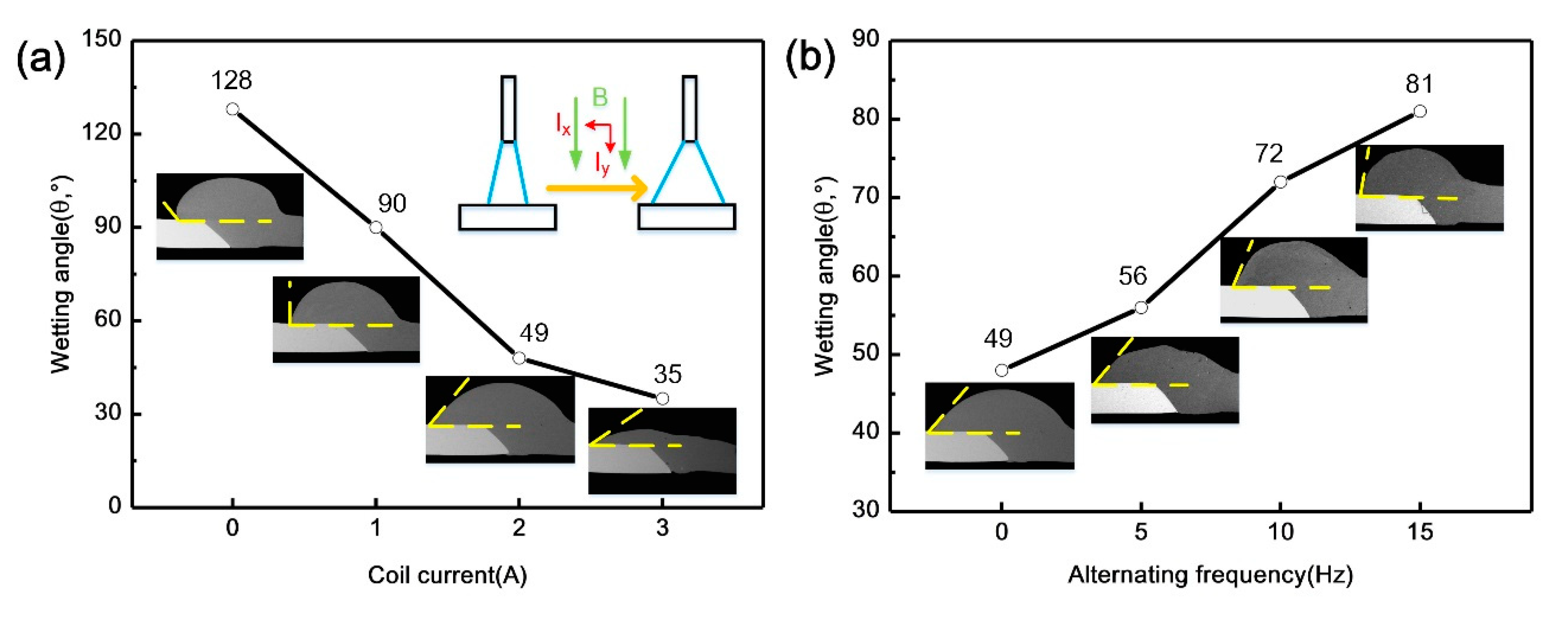

3.1. Weld Appearance

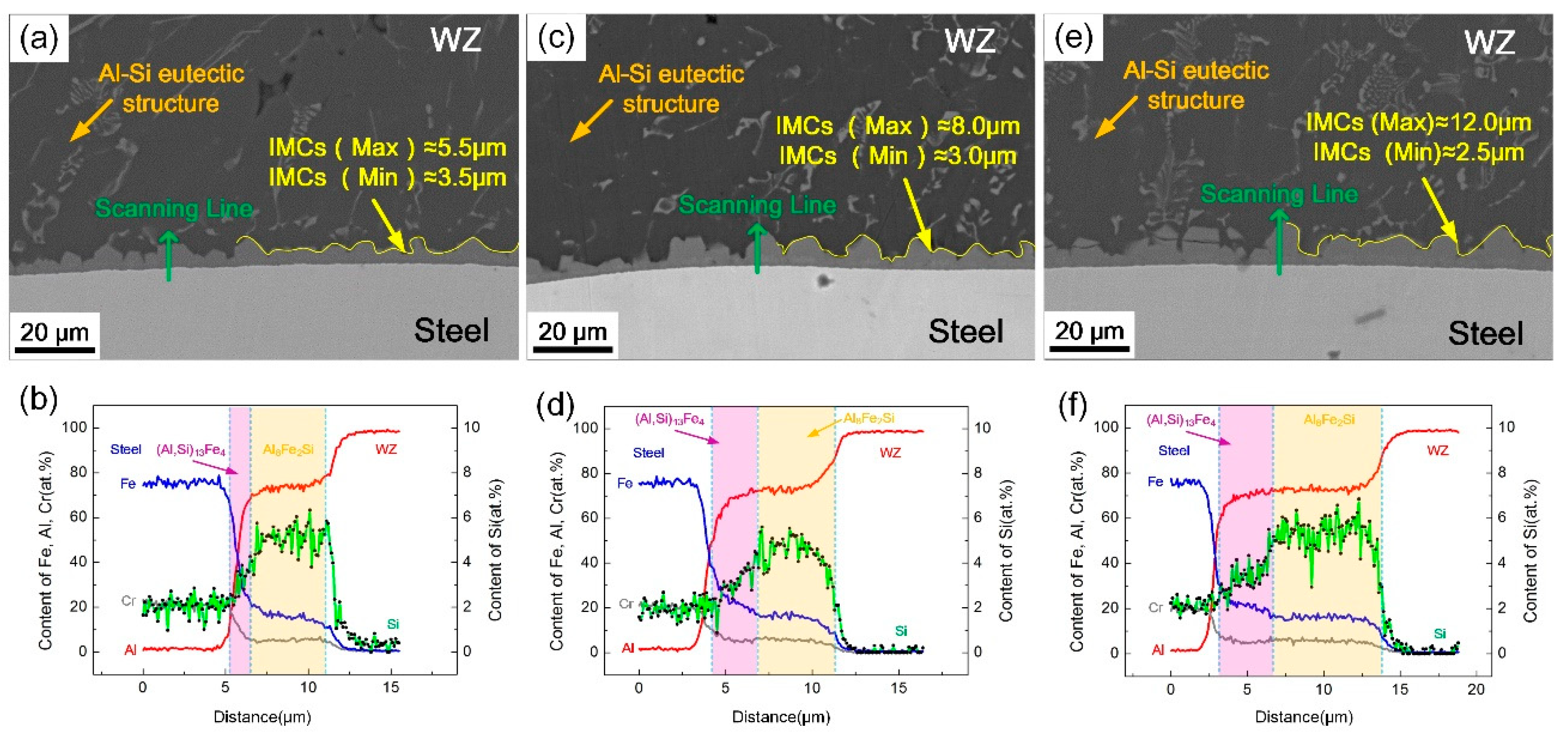

3.2. Interfacial Microstructure

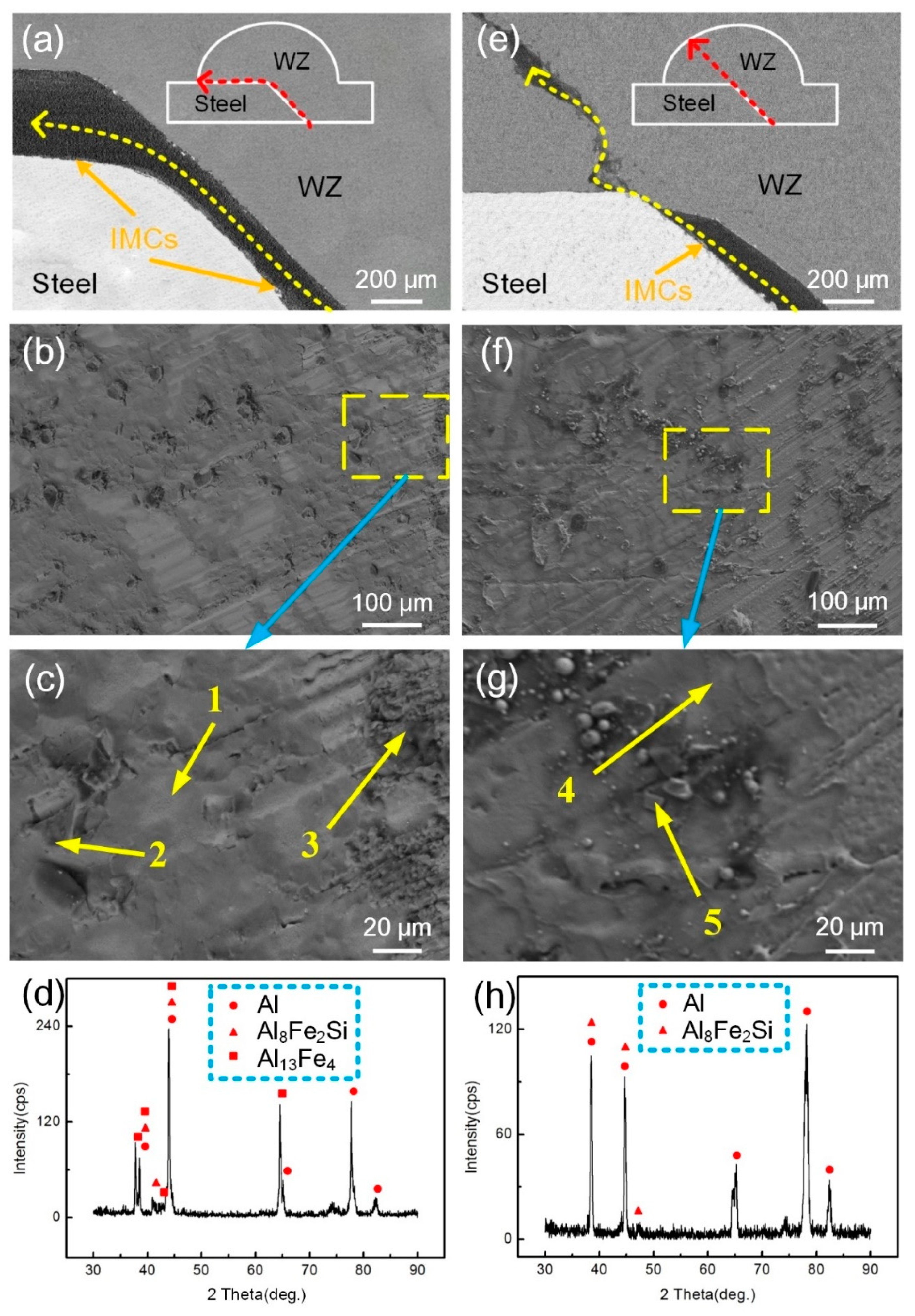

3.3. Tensile Strength and Failure Behavior

4. Conclusions

- (1)

- With the increase of coil current, the spreadability of the molten filler was improved and the wetting angle decreased from to 128° to 35°. The wetting facilitation effect on the molten pool was reduced with the increase of alternating frequency. The wave-like characteristic occurred on the weld surface after the solidification of the fiercely stirred molten pool.

- (2)

- With the assistance of the magnetic field, the growth of the IMC layer was inhibited and the transformation of the IMC layer from (Al, Si)13Fe4 to Al8Fe2Si phase was promoted, which was beneficial to the mechanical properties of Al/steel joints. However, excessive coil current and the increase of alternating frequency resulted in a thicker and uneven IMC layer.

- (3)

- The maximum tensile strength reached 130.2 MPa with the coil current and alternating frequency of 2 A and 0 Hz, increasing by a 61.6% contrast with the normal CMT welding process. The fracture path changed from the (Al, Si)13Fe4 layer to Al8Fe2Si layer-welding zone.

- (4)

- In future work, the effect of the magnetic field on the dynamic behavior of the molten pool will be investigated by numerical analysis combined with experimental observation.

Author Contributions

Funding

Conflicts of Interest

References

- Gullino, A.; Matteis, P.; D’Aiuto, F. Review of aluminum-to-steel welding technologies for car-body applications. Metals 2019, 9, 315. [Google Scholar] [CrossRef] [Green Version]

- Greenberg, B.A.; Ivanov, M.A.; Pushkin, M.S.; Inozemtsev, A.V.; Patselov, A.M.; Tankeyev, A.P.; Kuzmin, S.V.; Lysak, V.I. Formation of intermetallic compounds during explosive welding. Metall. Mater. Trans. A 2016, 47, 5461–5473. [Google Scholar] [CrossRef]

- Bataev, I.A.; Ivanov, I.V.; Malyutina, Y.N.; Émurlaev, K.I.; Émurlaeva, Y.Y. High plastic deformations and high cooling rates at the interface of explosion-welded materials. Met. Sci. Heat. Treat. 2019, 60, 674–679. [Google Scholar] [CrossRef]

- Chen, Y.C.; Komazaki, T.; Kim, Y.G.; Tsumura, T.; Nakata, K. Interface microstructure study of friction stir lap joint of AC4C cast aluminum alloy and zinc-coated steel. Mater. Chem. Phys. 2008, 111, 375–380. [Google Scholar] [CrossRef]

- Cao, R.; Yu, G.; Chen, J.H.; Wang, P.C. Cold metal transfer joining aluminum alloys-to-galvanized mild steel. J. Mater. Process. Technol. 2013, 213, 1753–1763. [Google Scholar] [CrossRef]

- Springer, H.; Szczepaniak, A.; Raabe, D. On the role of zinc on the formation and growth of intermetallic phases during interdiffusion between steel and aluminium alloys. Acta Mater. 2015, 96, 203–211. [Google Scholar] [CrossRef]

- Arghavani, M.R.; Movahedi, M.; Kokabi, A.H. Role of zinc layer in resistance spot welding of aluminium to steel. Mater. Des. 2016, 102, 106–114. [Google Scholar] [CrossRef]

- Su, J.H.; Yang, J.; Li, Y.L.; Yu, Z.S.; Chen, J.S.; Zhao, W.Q.; Liu, H.B.; Tan, C.W. Microstructure and mechanical properties of laser fusion welded Al/steel joints using a Zn-based filler wire. Opt. Laser Technol. 2020, 122, 105882. [Google Scholar] [CrossRef]

- He, H.; Lin, S.B.; Yang, C.L.; Fan, C.L.; Chen, Z. Combination effects of nocolok flux with Ni powder on properties and microstructures of aluminum-stainless steel TIG welding-brazing joint. J. Mater. Eng. Perform. 2013, 22, 3315–3323. [Google Scholar] [CrossRef]

- Song, J.L.; Lin, S.B.; Yang, C.L.; Fan, C.L. Effects of Si additions on intermetallic compound layer of aluminum-steel TIG welding-brazing joint. J. Alloy. Compd. 2009, 488, 217–222. [Google Scholar] [CrossRef]

- Song, J.L.; Lin, S.B.; Yang, C.L.; Fan, C.L.; Ma, G.C. Analysis of intermetallic layer in dissimilar TIG welding-brazing butt joint of aluminium alloy to stainless steel. Sci. Technol. Weld. Join. 2010, 15, 213–218. [Google Scholar] [CrossRef]

- Springer, H.; Kostka, A.; Payton, E.J.; Raabe, D.; Kaysser-Pyzalla, A.; Eggeler, G. On the formation and growth of intermetallic phases during interdiffusion between low-carbon steel and aluminum alloys. Acta Mater. 2011, 59, 1586–1600. [Google Scholar] [CrossRef]

- Yang, J.; Yu, Z.S.; Li, Y.L.; Zhang, H.; Guo, W.; Zhou, N. Influence of alloy elements on microstructure and mechanical properties of Al/steel dissimilar joint by laser welding/brazing. Weld. World 2018, 62, 427–433. [Google Scholar] [CrossRef]

- Xia, H.B.; Zhao, X.Y.; Tan, C.W.; Chen, B.; Song, X.G.; Li, L.Q. Effect of Si content on the interfacial reactions in laser welded-brazed Al/steel dissimilar butted joint. J. Mater. Process. Technol. 2018, 258, 9–21. [Google Scholar] [CrossRef]

- Wachowski, M.; Kosturek, R.; Śniezek, L.; Sebastian, M.; Stefanik, A.; Szota, P. The effect of post-weld hot-rolling on the properties of explosively welded Mg/Al/Ti multilayer composite. Materials 2020, 13, 1930. [Google Scholar] [CrossRef] [Green Version]

- Shiran, M.K.G.; Khalaj, G.; Pouraliakbar, H.; Jandaghi, M.R.; Dehnavi, A.S.; Bakhtiari, H. Multilayer Cu/Al/Cu explosive welded joints: Characterizing heat treatment effect on the interface microstructure and mechanical properties. J. Manuf. Process. 2018, 35, 657–663. [Google Scholar] [CrossRef]

- Shiran, M.K.G.; Khalaj, G.; Pouraliakbar, H.; Jandaghi, M.; Bakhtiari, H.; Shirazi, M. Effects of heat treatment on the intermetallic compounds and mechanical properties of the stainless steel 321-aluminum 1230 explosive-welding interface. Int. J. Miner. Met. Mater. 2017, 24, 1267–1277. [Google Scholar] [CrossRef]

- Li, L.Q.; Xia, H.B.; Tan, C.W.; Ma, N.S. Influence of laser power on interfacial microstructure and mechanical properties of laser welded-brazed Al/steel dissimilar butted joint. J. Manuf. Process. 2018, 32, 160–174. [Google Scholar] [CrossRef]

- Sun, J.H.; Yan, Q.; Gao, W.; Huang, J. Investigation of laser welding on butt joints of Al/steel dissimilar materials. Mater. Des. 2015, 83, 120–128. [Google Scholar] [CrossRef]

- Yuan, R.; Deng, S.J.; Cui, H.C.; Chen, Y.X.; Lu, F.G. Interface characterization and mechanical properties of dual beam laser welding-brazing Al/steel dissimilar metals. J. Manuf. Process. 2019, 40, 37–45. [Google Scholar] [CrossRef]

- Mathieu, A.; Rajashekar, S.; Deschamps, A.; Suery, M.; Matte, S.; Grevey, D.; Cicala, E. Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire). Opt. Laser Technol. 2007, 39, 652–661. [Google Scholar] [CrossRef]

- Sun, J.H.; Yan, Q.; Li, Z.G.; Huang, J. Effect of bevel angle on microstructure and mechanical property of Al/steel butt joint using laser welding-brazing method. Mater. Des. 2016, 90, 468–477. [Google Scholar] [CrossRef]

- Chen, R.; Jiang, P.; Shao, X.Y.; Mi, G.Y.; Wang, C.M. Effect of magnetic field on crystallographic orientation for stainless steel 316L laser-MIG hybrid welds and its strengthening mechanism on fatigue resistance. Int. J. Fatigue 2018, 112, 308–317. [Google Scholar] [CrossRef]

- Yan, F.; Wang, X.W.; Chai, F.; Ma, H.J.; Tian, L.L.; Du, X.Z.; Wang, C.M.; Wang, W. Improvement of microstructure and performance for steel/Al welds produced by magnetic field assisted laser welding. Opt. Laser Technol. 2019, 113, 164–170. [Google Scholar] [CrossRef]

- Sun, Q.J.; Li, J.Z.; Liu, Y.B.; Jiang, Y.L.; Kang, K.X.; Feng, J.C. Arc characteristics and droplet transfer process in CMT welding with a magnetic field. J. Manuf. Process. 2018, 32, 48–56. [Google Scholar] [CrossRef]

- Jin, P.; Liu, Y.B.; Sun, Q.J.; Li, J.Z.; Chen, K.; Hou, S.J.; Yang, H.; Zhou, Y.H.; Feng, J.C. Wetting mechanism and microstructure evolution of TC4/304 stainless steel joined by CMT with an assisted hybrid magnetic field. J. Alloy. Compd. 2020, 819, 152951. [Google Scholar] [CrossRef]

- Wang, L.W.; Suo, Y.C.; Wu, C.F.; Wang, D.L.; Liang, Z.M. Effect of pulse frequency on microstructure and mechanical properties of 2198 Al-Li alloy joints obtained by ultrahigh-frequency pulse AC CMT welding. Materials 2019, 12, 79. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q.J.; Li, J.Z.; Liu, Y.B.; Li, B.P.; Xu, P.W.; Feng, J.C. Microstructural characterization and mechanical properties of Al/Ti joint welded by CMT method—Assisted hybrid magnetic field. Mater. Des. 2017, 116, 316–324. [Google Scholar] [CrossRef]

- Gupta, S.P. Intermetallic compound formation in Fe-Al-Si ternary system: Part I. Mater. Charact. 2003, 46, 269–291. [Google Scholar] [CrossRef]

| Materials | Al | Fe | Si | Cr | Mn | Ni | Mg | Cu | Ti | C |

|---|---|---|---|---|---|---|---|---|---|---|

| 6061-T6 | Bal. | 0.7 | 0.4–0.8 | - | 0.15 | - | 08–1.2 | 0.15–0.4 | - | 1.0 |

| SS304 | - | Bal. | 1.0 | 18-20 | 2.0 | 8.0–11 | - | - | 0.08 | 0.08 |

| ER4043 | Bal. | 0.8 | 4.5–6.0 | - | 0.3 | - | 0.05 | 0.3 | 0.2 | - |

| Wire Feeding Speed (M/Min) | Welding Current (A) | Welding Speed (mm/s) | Coil Current (A) | Magnetic Intensity (mT) | Alternating Frequency (Hz) |

|---|---|---|---|---|---|

| 4.1 | 73 | 6 | 0 | 0 | 0 |

| 4.1 | 73 | 6 | 1 | 6.4 | 0 |

| 4.1 | 73 | 6 | 2 | 13.3 | 0 |

| 4.1 | 73 | 6 | 3 | 19.5 | 0 |

| 4.1 | 73 | 6 | 2 | 13.3 | 5 |

| 4.1 | 73 | 6 | 2 | 13.3 | 10 |

| 4.1 | 73 | 6 | 2 | 13.3 | 15 |

| Location | Al (at.%) | Si (at.%) | Fe (at.%) | Possible Phase |

|---|---|---|---|---|

| 1 | 75.5 | 6.1 | 18.4 | Al8Fe2Si |

| 2 | 69.8 | 5.9 | 24.3 | (Al, Si)13Fe4 |

| 3 | 72.6 | 8.3 | 19.1 | Al8Fe2Si |

| Location | Al (at.%) | Si (at.%) | Fe (at.%) | Possible Phase |

|---|---|---|---|---|

| 1 | 69.7 | 5.8 | 24.5 | (Al, Si)13Fe4 |

| 2 | 98.1 | 1.9 | - | α-Al solid |

| 3 | 72.6 | 8.3 | 19.1 | Al8Fe2Si |

| 4 | 74.2 | 8.0 | 17.8 | Al8Fe2Si |

| 5 | 92.8 | 7.2 | - | α-Al solid |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, K.; Liu, Y.; Li, J.; Liu, C.; Zhen, Z.; Wang, Y.; Sun, Q. Microstructure and Mechanical Properties of Al/Steel Butt Joint by Hybrid CMT Welding with External Axial Magnetic Field. Materials 2020, 13, 3601. https://doi.org/10.3390/ma13163601

Kang K, Liu Y, Li J, Liu C, Zhen Z, Wang Y, Sun Q. Microstructure and Mechanical Properties of Al/Steel Butt Joint by Hybrid CMT Welding with External Axial Magnetic Field. Materials. 2020; 13(16):3601. https://doi.org/10.3390/ma13163601

Chicago/Turabian StyleKang, Kexin, Yibo Liu, Junzhao Li, Chao Liu, Zuyang Zhen, Yaxin Wang, and Qingjie Sun. 2020. "Microstructure and Mechanical Properties of Al/Steel Butt Joint by Hybrid CMT Welding with External Axial Magnetic Field" Materials 13, no. 16: 3601. https://doi.org/10.3390/ma13163601