The Effect of Poly(Vinyl Chloride) Powder Addition on the Thermomechanical Properties of Epoxy Composites Reinforced with Basalt Fiber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Methods

3. Results

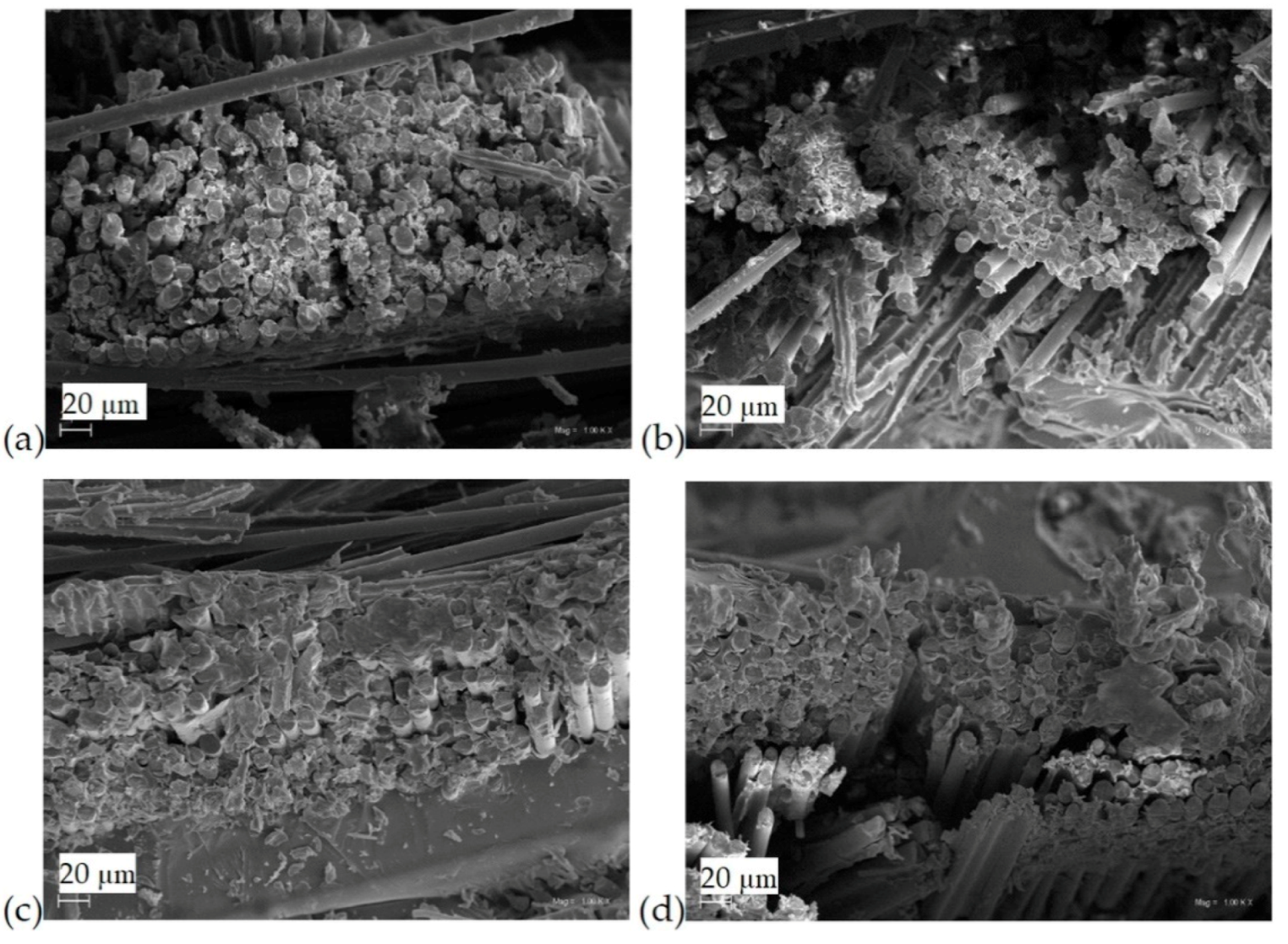

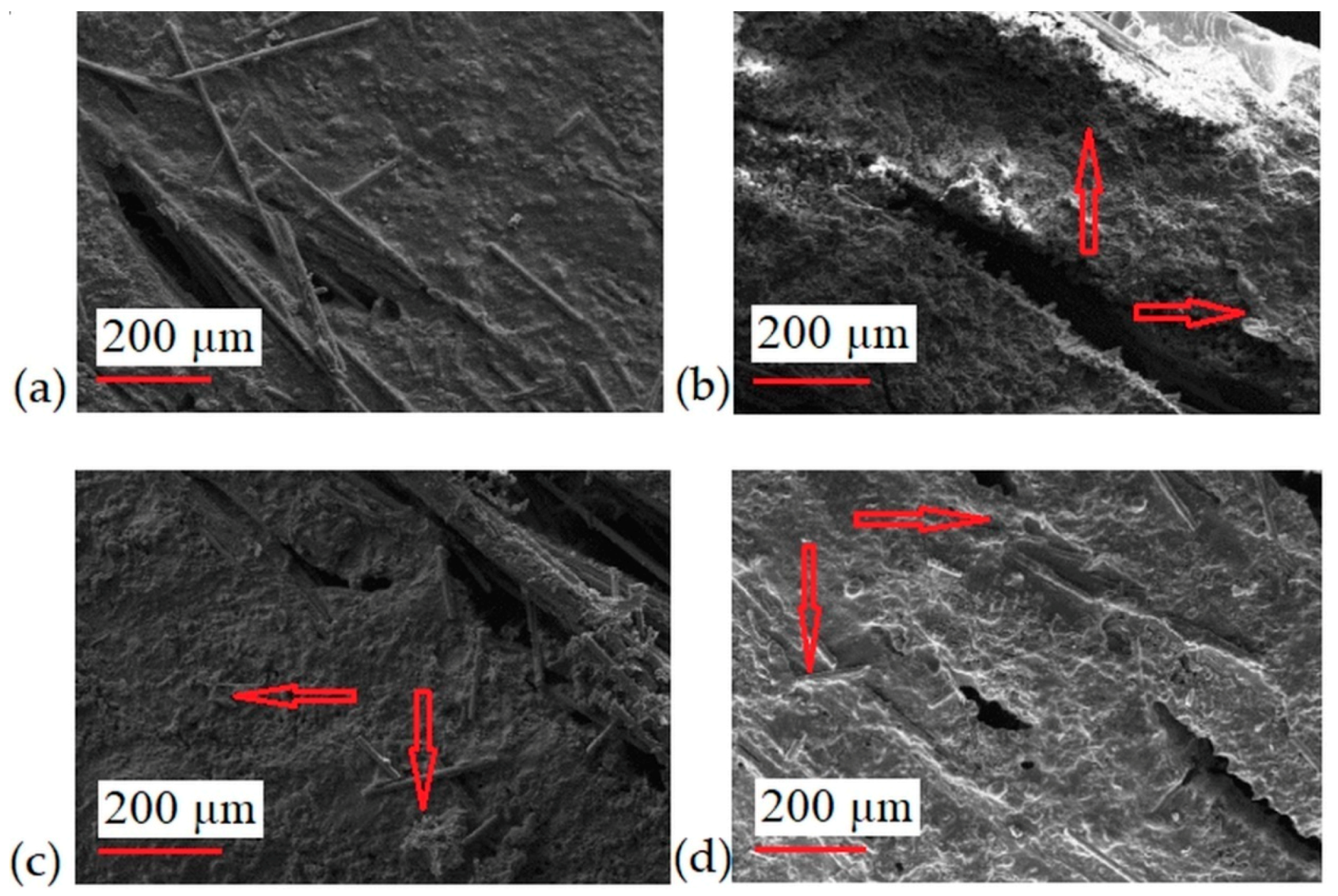

3.1. Composites Structure

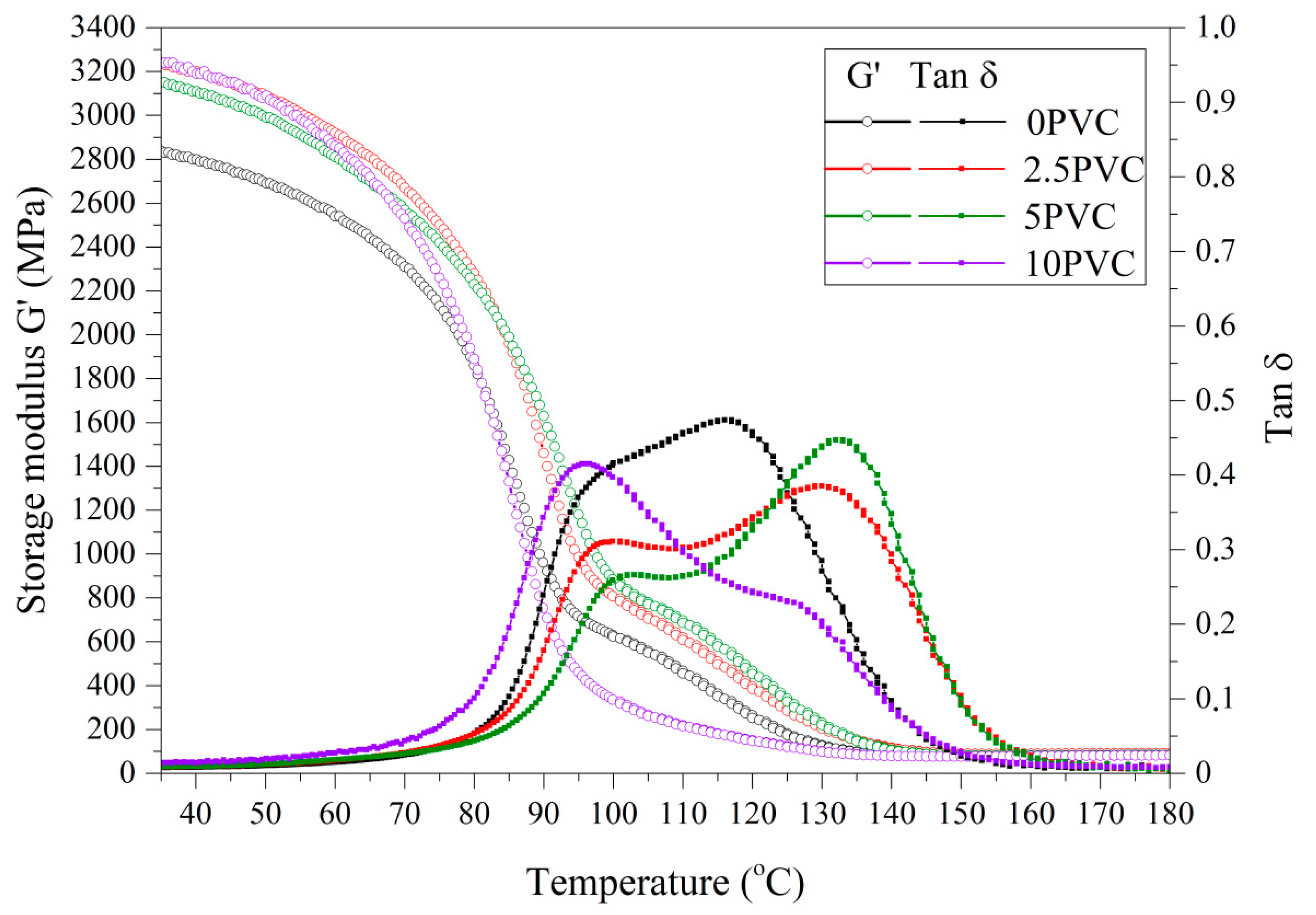

3.2. Thermomechanical Properties

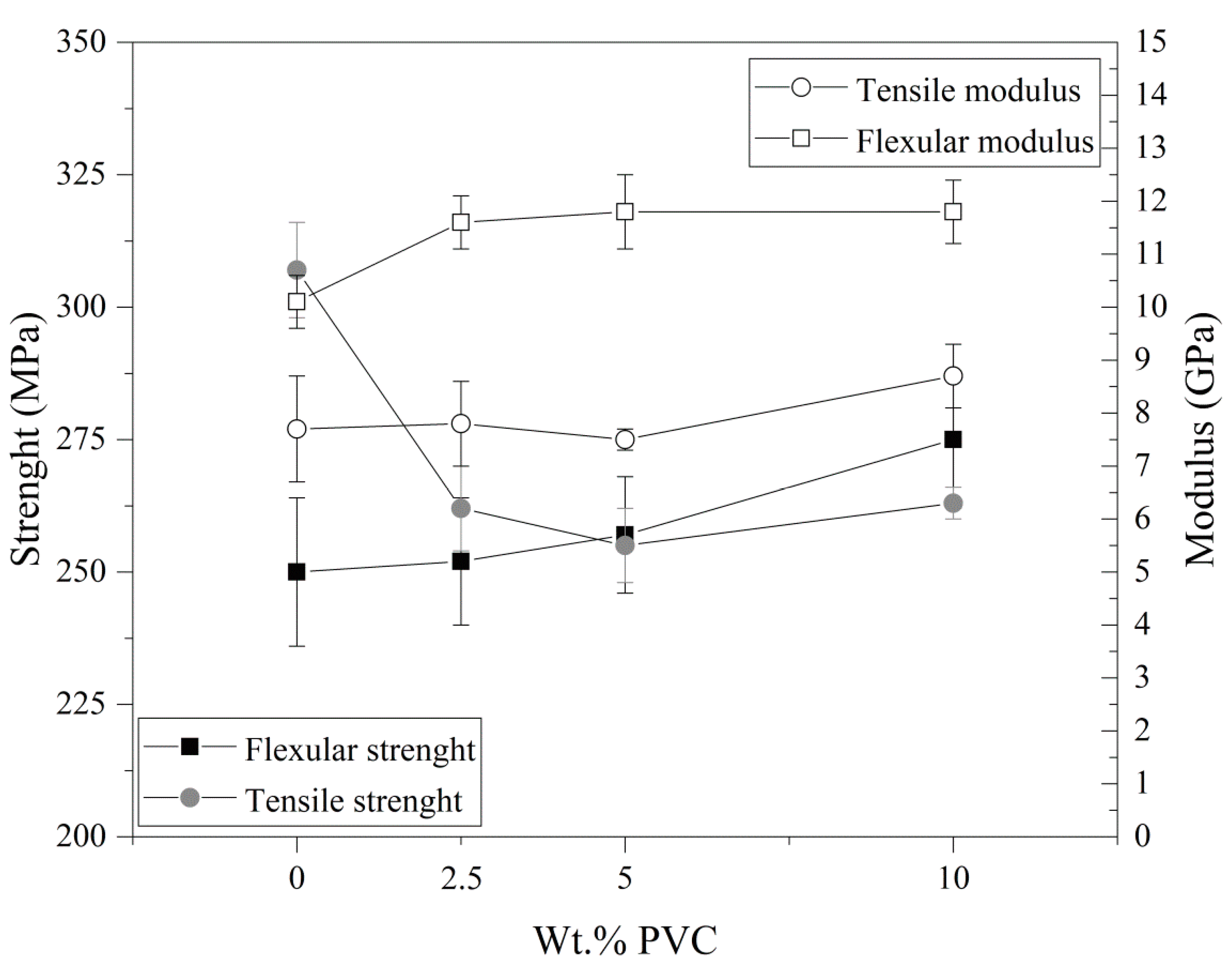

3.3. Flexural Behaviors

3.4. Tensile Behaviors

3.5. Interlaminar Shear Strength

3.6. Hardness

3.7. Thermal Stability

3.8. Fire Behavior

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ferreira, F.; Pinheiro, I.; de Souza, S.; Mei, L.; Lona, L. Polymer Composites Reinforced with Natural Fibers and Nanocellulose in the Automotive Industry: A Short Review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Ravishankar, B.; Nayak, S.K.; Kader, M.A. Hybrid composites for automotive applications—A review. J. Reinf. Plast. Compos. 2019, 38, 835–845. [Google Scholar] [CrossRef]

- Brunner, A.J. Fracture mechanics of polymer composites in aerospace applications. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2020; pp. 195–252. [Google Scholar]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 2020, 190, 122164. [Google Scholar] [CrossRef]

- Hejna, A.; Sulyman, M.; Przybysz, M.; Saeb, M.R.; Klein, M.; Formela, K. On the Correlation of Lignocellulosic Filler Composition with the Performance Properties of Poly(ε-Caprolactone) Based Biocomposites. Waste Biomass Valorization 2020, 11, 1467–1479. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Sterzynski, T. Effect of Polyhedral Oligomeric Silsesquioxane on the Melting, Structure, and Mechanical Behavior of Polyoxymethylene. Polymers 2018, 10, 203. [Google Scholar] [CrossRef] [PubMed]

- Czarnecka-Komorowska, D.; Sterzynski, T.; Dutkiewicz, M. Polyoxymethylene/Polyhedral Oligomeric Silsesquioxane Composites: Processing, Crystallization, Morphology and Thermo-Mechanical Behavior. Int. Polym. Process. 2016, 31, 598–606. [Google Scholar] [CrossRef]

- Matykiewicz, D. Hybrid Epoxy Composites with Both Powder and Fiber Filler: A Review of Mechanical and Thermomechanical Properties. Materials 2020, 13, 1802. [Google Scholar] [CrossRef]

- Mahesh Babu, S.; Venkateswara Rao, M. Experimental Studies on the Effect of Basalt Powder Inclusion on Mechanical Properties of Hybrid Epoxy and Polyester Composites Reinforced with Glass Fiber. In Advances in Manufacturing Technology; Springer: Singapore, 2019; pp. 25–31. [Google Scholar]

- Matykiewicz, D. Biochar as an Effective Filler of Carbon Fiber Reinforced Bio-Epoxy Composites. Processes 2020, 8, 724. [Google Scholar] [CrossRef]

- Oliwa, R.; Bulanda, K.; Oleksy, M.; Ostynska, P.; Budzik, G.; Plocinska, M.; Krauze, S. Fire resistance and mechanical properties of powder-epoxy composites reinforced with recycled glass fiber laminate. Polimery 2020, 65, 280–288. [Google Scholar] [CrossRef]

- Barra, G.; Guadagno, L.; Vertuccio, L.; Simonet, B.; Santos, B.; Zarrelli, M.; Arena, M.; Viscardi, M. Different Methods of Dispersing Carbon Nanotubes in Epoxy Resin and Initial Evaluation of the Obtained Nanocomposite as a Matrix of Carbon Fiber Reinforced Laminate in Terms of Vibroacoustic Performance and Flammability. Materials 2019, 12, 2998. [Google Scholar] [CrossRef]

- Scalici, T.; Pitarresi, G.; Badagliacco, D.; Fiore, V.; Valenza, A. Mechanical properties of basalt fiber reinforced composites manufactured with different vacuum assisted impregnation techniques. Compos. Part B Eng. 2016, 104, 35–43. [Google Scholar] [CrossRef]

- Petrucci, R.; Santulli, C.; Puglia, D.; Nisini, E.; Sarasini, F.; Tirillò, J.; Torre, L.; Minak, G.; Kenny, J.M. Impact and post-impact damage characterisation of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Compos. Part B Eng. 2015, 69, 507–515. [Google Scholar] [CrossRef]

- Raajeshkrishna, C.R.; Chandramohan, P. Effect of reinforcements and processing method on mechanical properties of glass and basalt epoxy composites. SN Appl. Sci. 2020, 2, 959. [Google Scholar] [CrossRef]

- Nautiyal, M.; Shrinet, A.; Ramachandran, M. Mechanical, Thermal and Morphological Characterization of Basalt Fibre Composite—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 810, 012043. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Valente, M.; Ferrante, L.; Cioffi, S.; Iannace, S.; Sorrentino, L. Hybrid composites based on aramid and basalt woven fabrics: Impact damage modes and residual flexural properties. Mater. Des. 2013, 49, 290–302. [Google Scholar] [CrossRef]

- Wang, X.; Wu, G.; Wu, Z.; Dong, Z.; Xie, Q. Evaluation of prestressed basalt fiber and hybrid fiber reinforced polymer tendons under marine environment. Mater. Des. 2014, 64, 721–728. [Google Scholar] [CrossRef]

- Tirillò, J.; Ferrante, L.; Sarasini, F.; Lampani, L.; Barbero, E.; Sánchez-Sáez, S.; Valente, T.; Gaudenzi, P. High velocity impact behaviour of hybrid basalt-carbon/epoxy composites. Compos. Struct. 2017, 168, 305–312. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Su, X.; Wang, Z. Synergistic reinforcement of epoxy/basalt fiber composites with dimensionally different nanoparticles. Polym. Eng. Sci. 2019, 59, 730–735. [Google Scholar] [CrossRef]

- Ary Subagia, I.D.G.; Tijing, L.D.; Kim, Y.; Kim, C.S.; Vista IV, F.P.; Shon, H.K. Mechanical performance of multiscale basalt fiber–epoxy laminates containing tourmaline micro/nano particles. Compos. Part B Eng. 2014, 58, 611–617. [Google Scholar] [CrossRef]

- Bulut, M. Mechanical characterization of Basalt/epoxy composite laminates containing graphene nanopellets. Compos. Part B Eng. 2017, 122, 71–78. [Google Scholar] [CrossRef]

- Kim, S.H.; Heo, Y.-J.; Park, M.; Min, B.-G.; Rhee, K.Y.; Park, S.-J. Effect of hydrophilic graphite flake on thermal conductivity and fracture toughness of basalt fibers/epoxy composites. Compos. Part B Eng. 2018, 153, 9–16. [Google Scholar] [CrossRef]

- Khosravi, H.; Eslami-Farsani, R. On the mechanical characterizations of unidirectional basalt fiber/epoxy laminated composites with 3-glycidoxypropyltrimethoxysilane functionalized multi-walled carbon nanotubes–enhanced matrix. J. Reinf. Plast. Compos. 2016, 35, 421–434. [Google Scholar] [CrossRef]

- Kim, M.; Lee, T.-W.; Park, S.-M.; Jeong, Y.G. Structures, electrical and mechanical properties of epoxy composites reinforced with MWCNT-coated basalt fibers. Compos. Part A Appl. Sci. Manuf. 2019, 123, 123–131. [Google Scholar] [CrossRef]

- Abdi, A.; Eslami-Farsani, R.; Khosravi, H. Evaluating the Mechanical Behavior of Basalt Fibers/Epoxy Composites Containing Surface-modified CaCO3 Nanoparticles. Fibers Polym. 2018, 19, 635–640. [Google Scholar] [CrossRef]

- Surana, I.; Pandya, D.J.; Padmaraj, N.H.; Hegde, S.; Chethan, K.N. Influence of filler material on mechanical and vibration properties of basalt/epoxy composites. Mater. Res. Express 2019, 6, 085342. [Google Scholar] [CrossRef]

- Barczewski, M.; Matykiewicz, D.; Sałasińska, K.; Kozicki, D.; Piasecki, A.; Skórczewska, K.; Lewandowski, K. Poly(vinyl chloride) powder as a low-cost flame retardant modifier for epoxy composites. Int. J. Polym. Anal. Charact. 2019, 24, 447–456. [Google Scholar] [CrossRef]

- Raajeshkrishna, C.R.; Chandramohan, P.; Saravanan, V.S. Thermomechanical characterization and morphological analysis of nano basalt reinforced epoxy nanocomposites. Int. J. Polym. Anal. Charact. 2020, 1–11. [Google Scholar] [CrossRef]

- Gupta, M.K.; Srivastava, R.K. Properties of sisal fibre reinforced epoxy composite. Indian J. Fibre Text. Res. 2016, 41, 235–241. [Google Scholar]

- Jouyandeh, M.; Ganjali, M.R.; Hadavand, B.S.; Aghazadeh, M.; Akbari, V.; Shammiry, F.; Saeb, M.R. Curing epoxy with polyvinyl chloride (PVC) surface-functionalized CoxFe3-xO4 nanoparticles. Prog. Org. Coatings 2019, 137, 105364. [Google Scholar] [CrossRef]

- Ilangovan, S.; Kumaran, S.S.; Vasudevan, A.; Naresh, K. Effect of silica nanoparticles on mechanical and thermal properties of neat epoxy and filament wounded E-glass/epoxy and basalt/epoxy composite tubes. Mater. Res. Express 2019, 6, 0850e2. [Google Scholar] [CrossRef]

- Naidu, P.P.; Raghavendra, G.; Ojha, S.; Paplal, B. Effect of g-C 3 N 4 nanofiller as filler on mechanical properties of multidirectional glass fiber epoxy hybrid composites. J. Appl. Polym. Sci. 2020, 137, 48413. [Google Scholar] [CrossRef]

- Subbaya, K.M.; Suresha, B.; Rajendra, N.; Varadarajan, Y.S. Grey-based Taguchi approach for wear assessment of SiC filled carbon–epoxy composites. Mater. Des. 2012, 41, 124–130. [Google Scholar] [CrossRef]

- Anays, M.M.; Tutikian, B.F.; Ortolan, V.; Oliveira, M.L.S.; Sampaio, C.H.; Gómez, P.L.; Silva, O.L.F. Fire resistance performance of concrete-PVC panels with polyvinyl chloride (PVC) stay in place (SIP) formwork. J. Mater. Res. Technol. 2019, 8, 4094–4107. [Google Scholar] [CrossRef]

| Name | G’(MPa) at 30 °C | G’(MPa) at 130 °C | TgI peak (°C) | TgII peak (°C) |

|---|---|---|---|---|

| 0PVC | 2870 | 128 | 116 | − |

| 2.5PVC | 3250 | 225 | 97 | 130 |

| 5PVC | 3180 | 221 | 100 | 132 |

| 10PVC | 3260 | 100 | 96 | 127 |

| Name | Flexural Strength (MPa) | Flexural Modulus (GPa) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| 0PVC | 250 ± 14 | 10.1 ± 0.5 | 307 ± 9 | 7.7 ± 1.2 | 4.7 ± 0.2 |

| 2.5PVC | 252 ± 12 | 11.6 ± 0.5 | 262 ± 8 | 7.8 ± 0.8 | 4.4 ± 0.2 |

| 5PVC | 257 ± 11 | 11.8 ± 0.7 | 255 ± 7 | 7.5 ± 0.2 | 4.1 ± 0.2 |

| 10PVC | 275 ± 13 | 11.8 ± 0.6 | 263 ± 3 | 8.7 ± 0.6 | 4.4 ± 0.1 |

| wt.% of Fillers and Name | Flexural Strength (MPa) | Flexural Modulus (GPa) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Ref. |

|---|---|---|---|---|---|

| 0 GNPs | 210 | 4.8 | 212 | 13.1 | [18] |

| 0.1 GNPs | 273 | 8.1 | 240 | 15.9 | |

| 0.2 GNPs | 232 | 7.8 | 224 | 14.2 | |

| 0.3 GNPs | 220 | 5.7 | 223 | 13.3 | |

| 0 SiO2 | 108 | 9 | − | − | |

| 0.5 SiO2 | 109 | 9.1 | − | − | [26] |

| 1 SiO2 | 132 | 9.6 | − | − | |

| 1.5 SiO2 | 137 | 10.9 | − | − | |

| 0 | − | − | 194 | 7.2 | |

| 2 sawdust | − | − | 252 | 7.5 | [22] |

| 4 sawdust | − | − | 205 | 7.0 | |

| 6 sawdust | − | − | 177 | 6.5 |

| Name | ILSS (MPa) | Max. Load, P (N) |

|---|---|---|

| 0PVC | 22.6 ± 0.6 | 756 ± 45 |

| 2.5PVC | 23.9 ± 0.3 | 960 ± 25 |

| 5PVC | 26.7 ± 0.4 | 1100 ± 22 |

| 10PVC | 23.8 ± 0.8 | 806 ± 60 |

| Name | T10% (°C) | Residual Mass (%) | DTG Peak Temperature (°C) | Max Degradation Rate (%/min) |

|---|---|---|---|---|

| PVC | 271.0 | 1.05 | 287.8 | 17.74 |

| 0PVC | 350.4 | 51.5 | 331.6 | 5.78 |

| 2.5PVC | 337.6 | 50.9 | 352.5 | 5.24 |

| 5PVC | 330.7 | 47.9 | 347.2 | 5.64 |

| 10PVC | 317.5 | 45.4 | 351.2 | 5.70 |

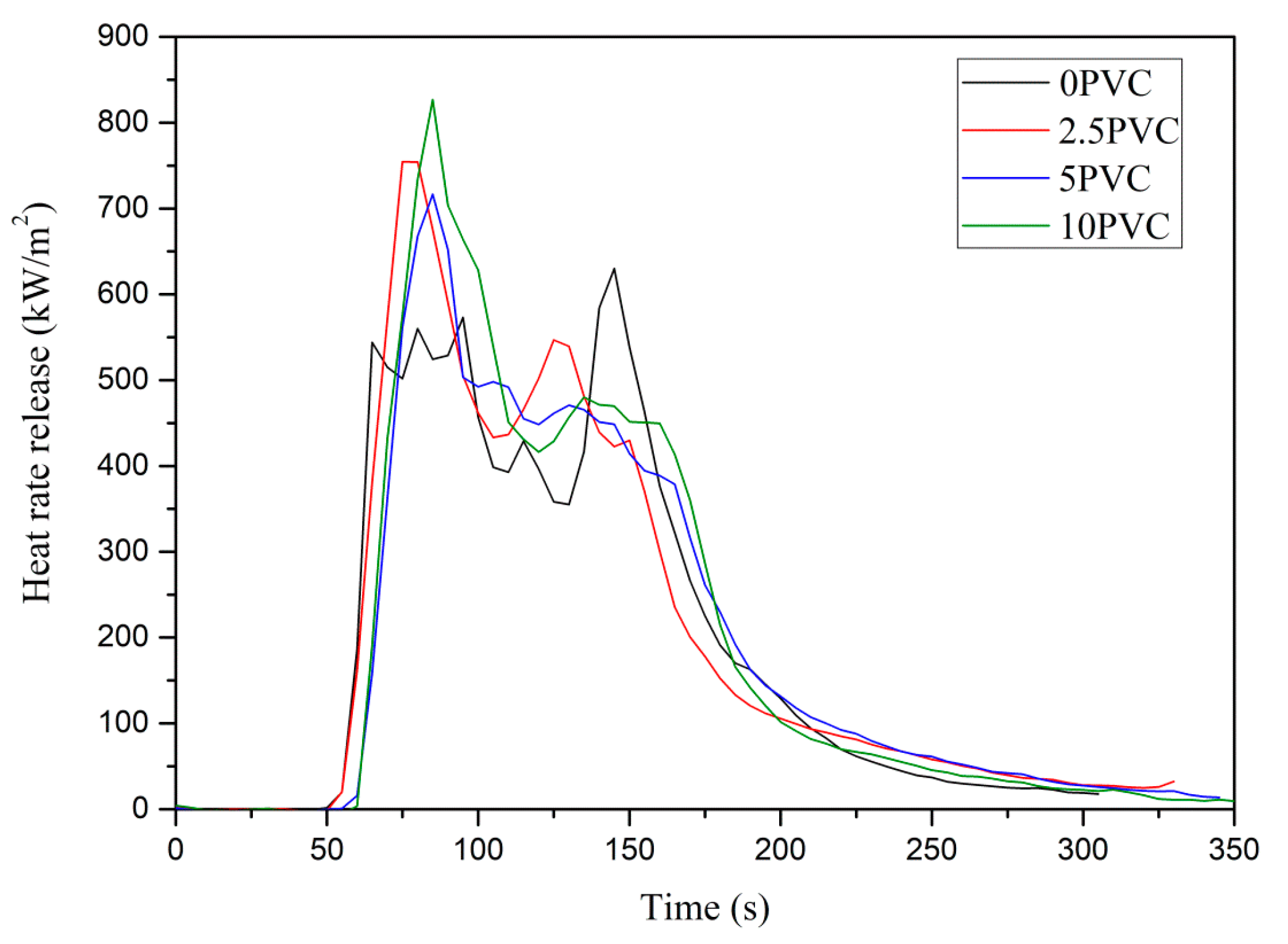

| Sample | TTI (s) | TTF (s) | av-HRR (kW/m2) | MARHE (kW/m2) | THR (MJ/m2) | Fire Residue (%) | SEA (m2/kg) |

|---|---|---|---|---|---|---|---|

| 0PVC | 63 (11 a) | 321 (32) | 239.0 (8) | 292.2 (10) | 63.0 (2) | 51.1 (3) | 865.2 (32) |

| 2.5PVC | 61 (10) | 333 (13) | 242.0 (13) | 318.1 (2) | 66.2 (6) | 50.5 (2) | 848.3 (42) |

| 5PVC | 54 (12) | 303 (25) | 245.4 (34) | 316.3 (18) | 52.9 (20) | 50.5 (1) | 898.2 (28) |

| 10PVC | 63 (5) | 375 (27) | 215.1 (23) | 315.2 (16) | 68.1 (8) | 47.5 (2) | 923.7 (54) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matykiewicz, D.; Sałasińska, K.; Barczewski, M. The Effect of Poly(Vinyl Chloride) Powder Addition on the Thermomechanical Properties of Epoxy Composites Reinforced with Basalt Fiber. Materials 2020, 13, 3611. https://doi.org/10.3390/ma13163611

Matykiewicz D, Sałasińska K, Barczewski M. The Effect of Poly(Vinyl Chloride) Powder Addition on the Thermomechanical Properties of Epoxy Composites Reinforced with Basalt Fiber. Materials. 2020; 13(16):3611. https://doi.org/10.3390/ma13163611

Chicago/Turabian StyleMatykiewicz, Danuta, Kamila Sałasińska, and Mateusz Barczewski. 2020. "The Effect of Poly(Vinyl Chloride) Powder Addition on the Thermomechanical Properties of Epoxy Composites Reinforced with Basalt Fiber" Materials 13, no. 16: 3611. https://doi.org/10.3390/ma13163611

APA StyleMatykiewicz, D., Sałasińska, K., & Barczewski, M. (2020). The Effect of Poly(Vinyl Chloride) Powder Addition on the Thermomechanical Properties of Epoxy Composites Reinforced with Basalt Fiber. Materials, 13(16), 3611. https://doi.org/10.3390/ma13163611